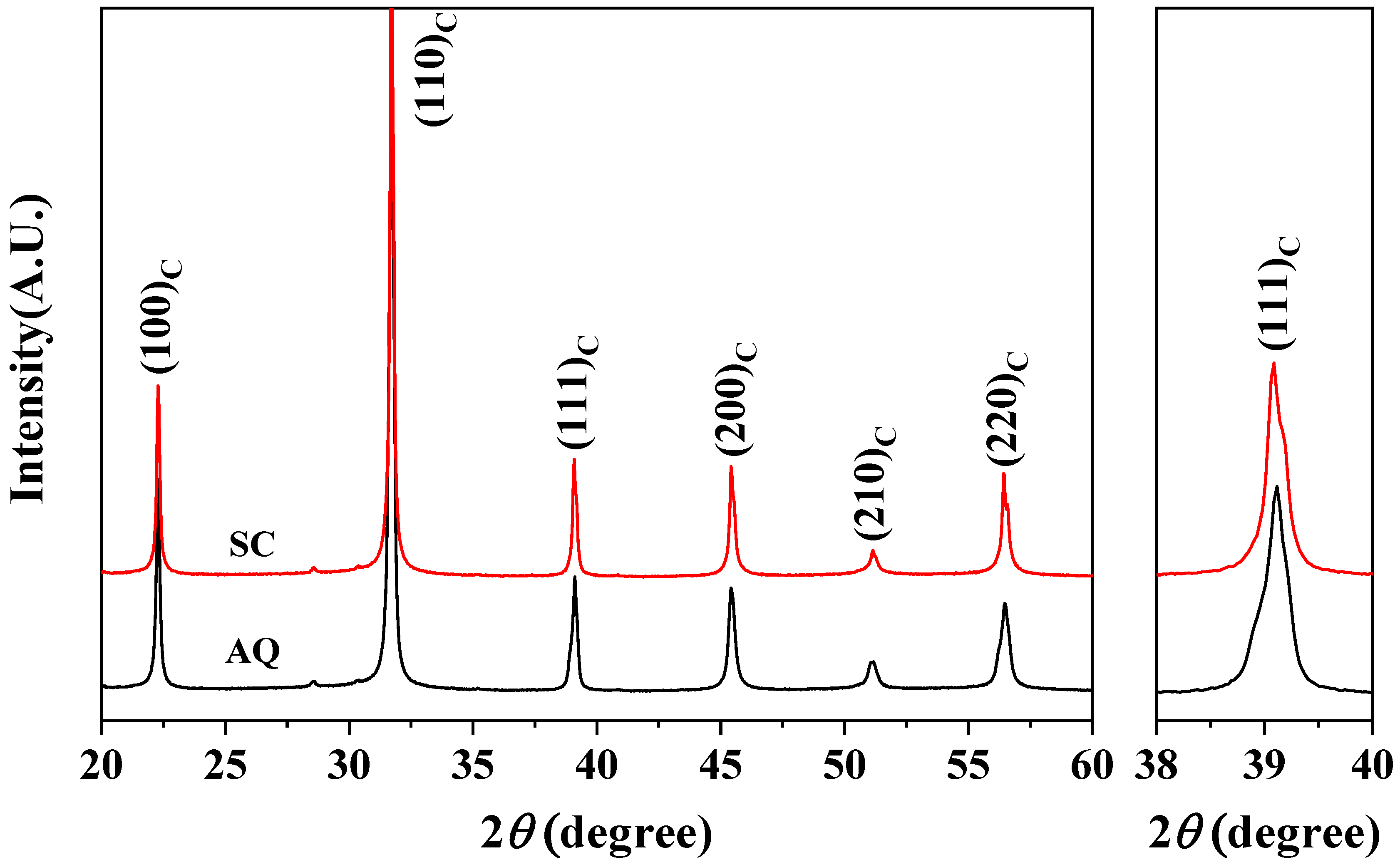

Crystal Structures and Piezoelectric Properties of Quenched and Slowly-Cooled BiFeO3-BaTiO3 Ceramics

Abstract

1. Introduction

2. Experimental

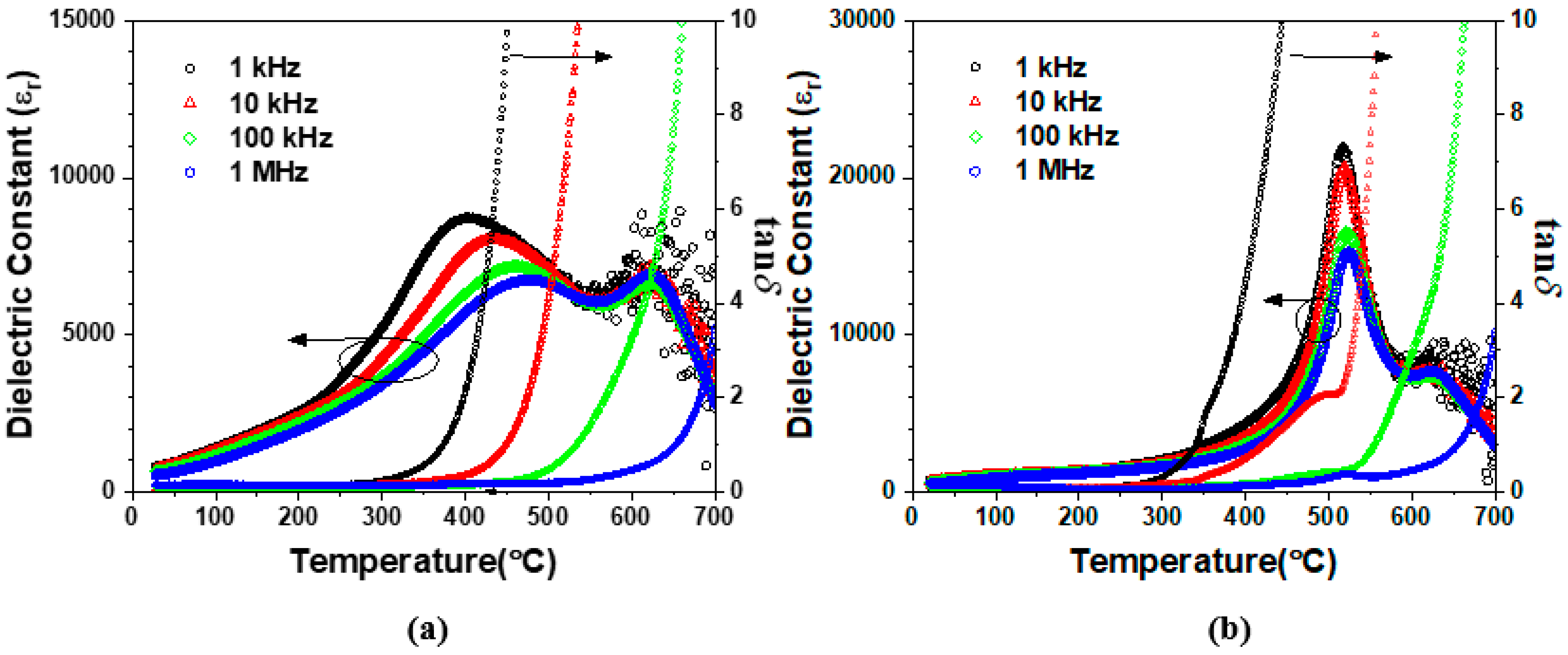

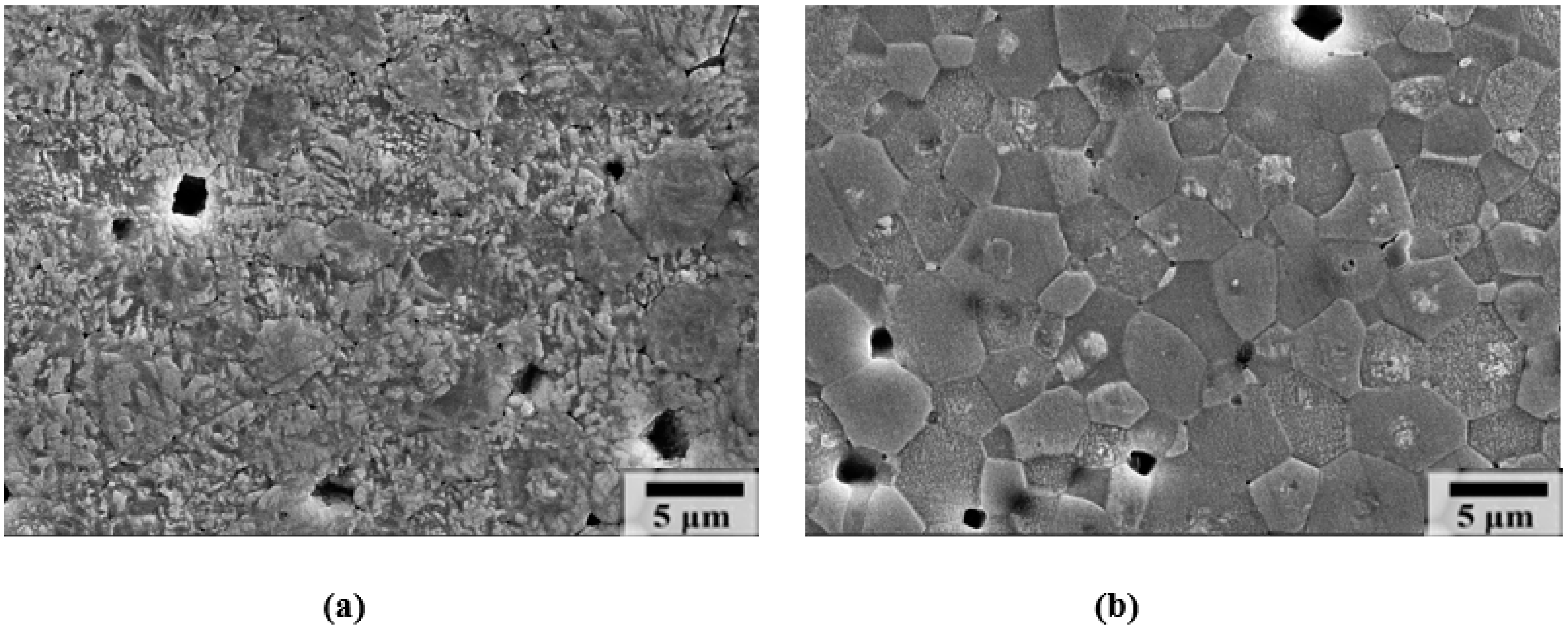

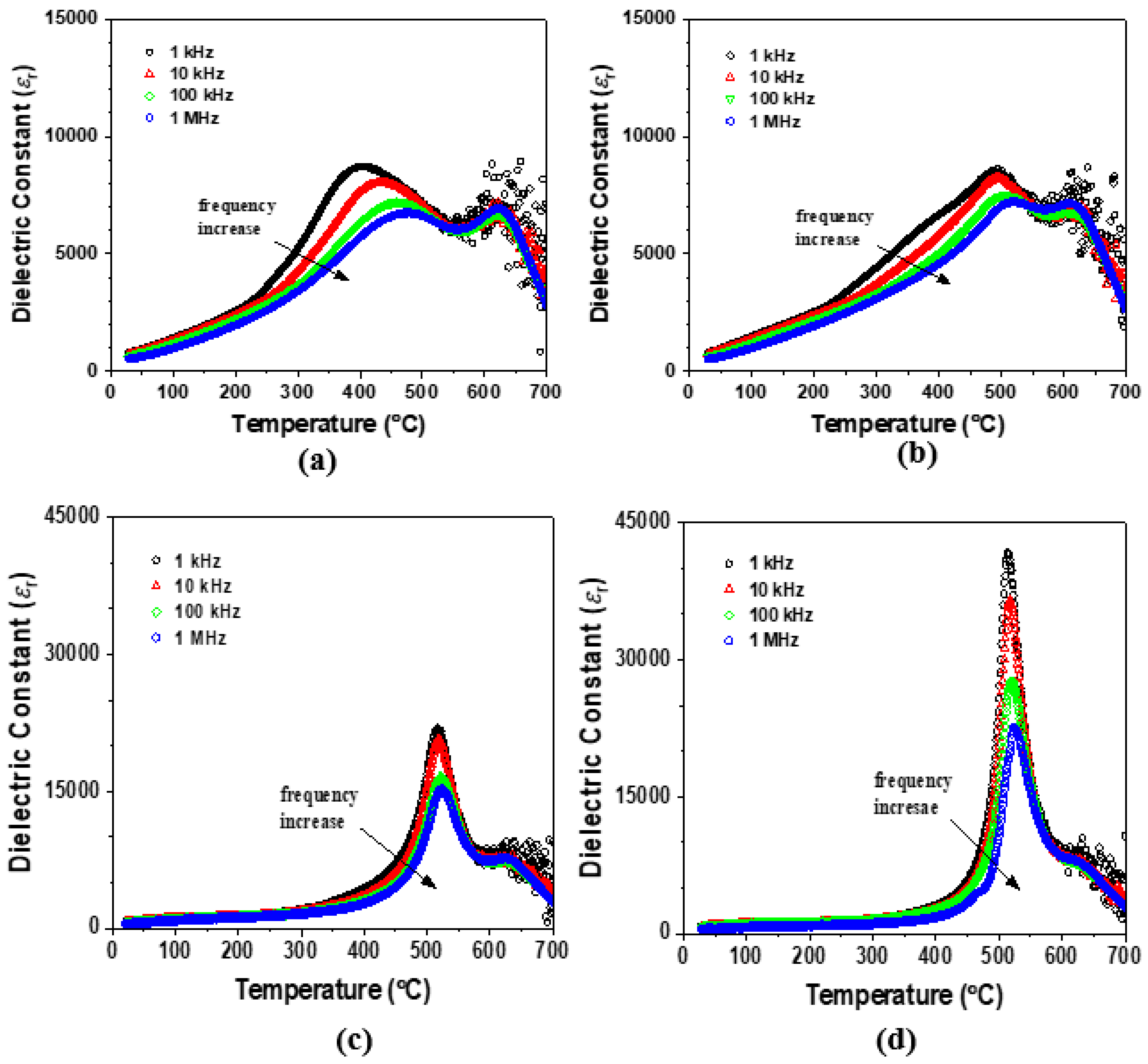

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rödel, J.; Webber, K.G.; Dittmer, R.; Jo, W.; Kimura, M.; Damjanovic, D. Transferring Lead-Free Piezoelectric Ceramics into Application. J. Eur. Ceram. Soc. 2015, 35, 1659–1681. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, Y.; Wu, J.; Wang, J.; Pennycook, S.J. Microstructural Origins of High Piezoelectric Performance: A Pathway to Practical Lead-Free Materials. Adv. Funct. Mater. 2019, 29, 1902911. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Y.; Gao, J.; Zhou, Z.; Wang, H.; Wang, K. High-Performance Lead-Free Piezoelectrics with Local Structural Heterogeneity. Energy Environ. Sci. 2018, 11, 3531. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K,Na)NbO3-Based Lead-Free Piezoceramics: Fundamental Aspects, Processing Technologies, and Remaining Challenges. J. Am. Ceram. Soc. 2013, 96, 3677. [Google Scholar] [CrossRef]

- Wang, D.; Wang, G.; Murakami, S.; Fan, Z.; Feteira, A.; Zhou, D.; Sun, S.; Zhao, Q.; Reaney, I.M. BiFeO3-BaTiO3: A New Generation of Lead-Free Electroceramics. J. Adv. Dielectr. 2018, 8, 1830004. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, D.J.; Park, J.S.; Kim, S.W.; Song, T.K.; Kim, M.H.; Kim, W.J.; Do, D.; Jeong, I.K. High-Performance Lead-Free Piezoceramics with High Curie Temperatures. Adv. Mater. 2015, 27, 6976. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, J.; Guo, J.; Cheng, Z.; Wang, J.; Liu, H.; Zhang, S. Excellent Thermal Stability and Aging Behaviors in BiFeO3-BaTiO3 Piezoelectric Ceramics with Rhombohedral Phase. J. Am. Ceram. Soc. 2020, 103, 374–381. [Google Scholar] [CrossRef]

- Li, Q.; Wei, J.; Tu, T.; Cheng, J.; Chen, J. Remarkable Piezoelectricity and Stable High-Temperature Dielectric Properties of Quenched BiFeO3–BaTiO3 Ceramics. J. Am. Ceram. Soc. 2017, 100, 5573–5583. [Google Scholar] [CrossRef]

- Murakami, S.; Ahmed, N.T.A.F.; Wang, D.; Feteira, A.; Sinclair, D.C.; Reaney, I.M. Optimising Dopants and Properties in BiMeO3 (Me = Al, Ga, Sc, Y, Mg2/3Nb1/3, Zn2/3Nb1/3, Zn1/2Ti1/2) Lead-Free BaTiO3-BiFeO3 Based Ceramics for Actuator Applications. J. Eur. Ceram. Soc. 2018, 38, 4220–4231. [Google Scholar] [CrossRef]

- Kumar, M.M.; Srinivas, A.; Suryanarayana, S.V. Structure Property Relations in BiFeO3/BaTiO3 Solid Solutions. J. Appl. Phys. 2000, 87, 855–862. [Google Scholar] [CrossRef]

- Leontsev, S.O.; Eitel, R.E. Dielectric and Piezoelectric Properties in Mn-Modified (1−x)BiFeO3–xBaTiO3 Ceramics. J. Am. Ceram. Soc. 2009, 92, 2957–2961. [Google Scholar] [CrossRef]

- Kim, S.; Khanal, G.P.; Nam, H.-W.; Fujii, I.; Ueno, S.; Moriyoshi, C.; Kuroiwa, Y.; Wada, S. Structural and Electrical Characteristics of Potential Candidate Lead-Free BiFeO3-BaTiO3 Piezoelectric Ceramics. J. Appl. Phys. 2017, 122, 164105. [Google Scholar] [CrossRef]

- Karpinsky, D.V.; Silibin, M.V.; Trukhanov, S.V.; Trukhanov, A.V.; Zhaludkevich, A.L.; Latushka, S.I.; Zhaludkevich, D.V.; Khomchenko, V.A.; Alikin, D.O.; Abramov, A.S.; et al. Peculiarities of the Crystal Structure Evolution of BiFeO3–BaTiO3 Ceramics across Structural Phase Transitions. Nanomaterials 2020, 10, 801. [Google Scholar] [CrossRef] [PubMed]

- Karpinsky, D.V.; Silibin, M.V.; Trukhanov, A.V.; Zhaludkevich, A.L.; Latushka, S.I.; Zhaludkevich, D.V.; Sikolenko, V.A.; Khomchenko, V.A. Evolution of Crystal Structure of Ba and Ti Co-Doped BiFeO3 Ceramics at the Morphotropic Phase Boundary. J. Alloys Compd. 2019, 803, 1136–1140. [Google Scholar] [CrossRef]

- Kang, F.; Zhang, L.; Huang, B.; Mao, P.; Wang, Z.; Sun, Q.; Wang, J.; Hu, D. Enhanced Electromechanical Properties of SrTiO3-BiFeO3-BaTiO3 Ceramics via Relaxor Behavior and Phase Boundary Design. J. Eur. Ceram. Soc. 2020, 40, 1198–1204. [Google Scholar] [CrossRef]

- Calisir, I.; Hall, D.A. Chemical Heterogeneity and Approaches to Its Control in BiFeO3–BaTiO3 Lead-Free Ferroelectrics. J. Mater. Chem. C 2018, 6, 134–136. [Google Scholar] [CrossRef]

- Calisir, I.; Kleppe, A.K.; Feteira, A.; Hall, D.A. Quenching-Assisted Actuation Mechanisms in Core–Shell Structured BiFeO3–BaTiO3 Piezoceramics. J. Mater. Chem. C 2019, 7, 10218–10230. [Google Scholar] [CrossRef]

- Wang, G.; Fan, Z.; Murakami, S.; Lu, Z.; Hall, D.; Sinclair, D.; Feteira, A.; Tan, X.; Jones, J.; Kleppe, A.K.; et al. Origin of the Large Electrostrain in BiFeO3-BaTiO3 Based Lead-Free Ceramics. J. Mater. Chem. A 2019, 7, 21254. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J. Quenched Bismuth Ferrite-Barium Titanate Lead-Free Piezoelectric Ceramics. J. Alloys Compd. 2016, 676, 505–512. [Google Scholar] [CrossRef]

- Go, S.-H.; Kim, K.S.; Kim, J.S.; Cheon, C.I. Effects of Attrition Milling on the Microstructure and Piezoelectric Properties of BiFeO3-BaTiO3 Ceramics. J. Korean Ceram. Soc. 2023, 60, 669–678. [Google Scholar] [CrossRef]

- Kim, K.S.; Choi, Y.R.; Chae, K.W.; Kim, J.S.; Cheon, C.I. Low Temperature Sintering and Enhanced Piezoelectric Properties of BiFeO3-BaTiO3 Ceramics by Homogeneous Calcination. Ceram. Int. 2024, 50, 32447–32456. [Google Scholar] [CrossRef]

- Gotardo, R.A.M.; Viana, D.S.F.; Olzon-Dionysio, M.; Souza, S.D.; Garcia, D.; Eiras, J.A.; Alves, M.F.S.; Cótica, L.F.; Santos, I.A.; Coelho, A.A. Ferroic States and Phase Coexistence in BiFeO3-BaTiO3 Solid Solutions. J. Appl. Phys. 2012, 112, 104112. [Google Scholar] [CrossRef]

- Zhu, L.-F.; Lei, X.-W.; Zhao, L.; Hussain, M.I.; Zhao, G.-Z.; Zhang, B.-P. Phase Structure and Energy Storage Performance for BiFeO3–BaTiO3 Based Lead-Free Ferroelectric Ceramics. Ceram. Int. 2019, 45, 20266–20275. [Google Scholar] [CrossRef]

- Fujii, I.; Mitsui, R.; Nakashima, K.; Kumada, N.; Shimada, M.; Watanabe, T.; Hayashi, J.; Yabuta, H.; Kubota, M.; Fukui, T.; et al. Structural, Dielectric, and Piezoelectric Properties of Mn-Doped BaTiO3–Bi(Mg1/2Ti1/2)O3–BiFeO3 Ceramics. Jpn. J. Appl. Phys. 2011, 50, 09ND07. [Google Scholar] [CrossRef]

- Kim, D.S.; Cheon, C.I.; Lee, S.S.; Kim, J.S. Effect of Cooling Rate on Phase Transitions and Ferroelectric Properties in 0.75BiFeO3-0.25BaTiO3 Ceramics. Appl. Phys. Lett. 2016, 109, 202902. [Google Scholar] [CrossRef]

- Malik, R.A.; Hussain, A.; Song, T.K.; Kim, W.-J.; Ahmed, R.; Sung, Y.S.; Kim, M.-H. Enhanced Electromechanical Properties of (1-x)BiFeO3–BaTiO3–xLiNbO3 Ceramics by Quenching Process. Ceram. Int. 2017, 43, S198–S203. [Google Scholar] [CrossRef]

- Kim, S.; Khanal, G.P.; Ueno, S.; Moriyoshi, C.; Kuroiwa, Y.; Wada, S. Revealing the Role of Heat Treatment in Enhancement of Electrical Properties of Lead-Free Piezoelectric Ceramics. J. Appl. Phys. 2017, 122, 014103. [Google Scholar] [CrossRef]

- Maqbool, A.; Malik, R.A.; Hussain, A.; Akram, F.; Rafiq, M.A.; Saleem, M.; Khalid, F.A.; Song, T.-K.; Kim, W.-J.; Kim, M.-H. Evolution of Ferroelectric and Piezoelectric Response by Heat Treatment in Pseudocubic BiFeO3–BaTiO3 Ceramics. J. Electroceram. 2018, 41, 99–104. [Google Scholar] [CrossRef]

- Wang, D.; Fan, Z.; Li, W.; Zhou, D.; Feteira, A.; Wang, G.; Murakami, S.; Sun, S.; Zhao, Q.; Tan, X.; et al. High Energy Storage Density and Large Strain in Bi(Zn2/3Nb1/3)O3-Doped BiFeO3–BaTiO3 Ceramics. ACS Appl. Energy Mater. 2018, 1, 4403–4412. [Google Scholar] [CrossRef]

- Murakami, S.; Wang, D.; Mostaed, A.; Khesro, A.; Feteira, A.; Sinclair, D.C.; Fan, Z.; Tan, X.; Reaney, I.M. High Strain (0.4%) Bi(Mg2/3Nb1/3)O3-BaTiO3-BiFeO3 Lead-Free Piezoelectric Ceramics and Multilayers. J. Am. Ceram. Soc. 2018, 101, 5428–5442. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, J.; Xiong, P.; Huang, W.; Song, J.; Yin, L.; Tong, P.; Zhu, X.; Sun, Y. The Effects of Quenching on Electrical Properties, and Leakage Behaviors of 0.67BiFeO3–0.33BaTiO3 Solid Solutions. J. Mater. Sci. Mater. Electron. 2018, 29, 7311–7317. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, D.J.; Choi, H.I.; Kim, M.-H.; Song, T.K.; Kim, W.-J.; Do, D. Thermal Quenching Effects on the Ferroelectric and Piezoelectric Properties of BiFeO3–BaTiO3 Ceramics. ACS Appl. Electron. Mater. 2019, 1, 1772–1780. [Google Scholar] [CrossRef]

- Calisir, I.; Amirov, A.A.; Kleppe, A.K.; Hall, D. Optimisation of Functional Properties in Lead-Free BiFeO3–BaTiO3 Ceramics through La3+ Substitution Strategy. J. Mater. Chem. A 2018, 6, 5378–5397. [Google Scholar] [CrossRef]

- Wang, B.; Fu, C.; Liu, X.; Xie, B.; Hall, D.A. Microchemical Homogeneity and Quenching-Induced Property Enhancement in BiFeO3–BaTiO3 Ceramics. Open Ceram. 2023, 13, 100322. [Google Scholar] [CrossRef]

- Bai, H.; Li, J.; Hong, Y.; Zhou, Z. Enhanced Ferroelectricity and Magnetism of Quenched (1-x)BiFeO3-xBaTiO3 Ceramics. J. Adv. Ceram. 2020, 9, 7–12. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, L.; Zhang, B.-P.; Wang, K.-K. Lead-Free 0.7BiFeO3-0.3BaTiO3 High-Temperature Piezoelectric Ceramics: Nano-BaTiO3 Raw Powder Leading to a Distinct Reaction Path and Enhanced Electrical Properties. Ceram. Int. 2019, 45, 10438–10447. [Google Scholar] [CrossRef]

- Kim, S.; Nam, H.; Calisir, I. Lead-Free BiFeO3-Based Piezoelectrics: A Review of Controversial Issues and Current Research State. Materials 2022, 15, 4388. [Google Scholar] [CrossRef]

- Catalan, G.; Scott, J.F. Physics and Applications of Bismuth Ferrite. Adv. Mater. 2009, 21, 2463–2485. [Google Scholar] [CrossRef]

- Lee, J.-H.; Oak, M.-A.; Choi, H.J.; Son, J.Y.; Jang, H.M. Rhombohedral–Orthorhombic Morphotropic Phase Boundary in BiFeO3-Based Multiferroics: First-Principles Prediction. J. Mater. Chem. 2012, 22, 1667. [Google Scholar] [CrossRef]

- Dolgos, M.R.; Adem, U.; Manjon-Sanz, A.; Wan, X.; Comyn, T.P.; Stevenson, T.; Bennett, J.; Bell, A.J.; Tran, T.T.; Halasyamani, P.S.; et al. Perovskite B-Site Compositional Control of [110]p Polar Displacement Coupling in an Ambient-Pressure-Stable Bismuth-Based Ferroelectric. Angew. Chem. Int. Ed. 2012, 51, 10770–10775. [Google Scholar] [CrossRef]

- Khesro, A.; Boston, R.; Sterianou, I.; Sinclair, D.C.; Reaney, I.M. Phase Transitions, Domain Structure, and Pseudosymmetry in La- and Ti-doped BiFeO3. J. Appl. Phys. 2016, 119, 054101. [Google Scholar] [CrossRef]

- Karimi, S.; Reaney, I.M.; Han, Y.; Pokorny, J.; Sterianou, I. Crystal Chemistry and Domain Structure of Rare-Earth Doped BiFeO3 Ceramics. J. Mater. Sci. 2009, 44, 5102–5112. [Google Scholar] [CrossRef]

- Troyanchuk, I.O.; Bushinsky, M.V.; Karpinsky, D.V.; Mantytskaya, O.S.; Fedotova, V.V.; Prochnenko, O.I. Structural Transformations and Magnetic Properties of Bi1–xLnxFeO3 (Ln = La, Nd, Eu) Multiferroics. Phys. Status Solidi B 2009, 246, 1901–1907. [Google Scholar] [CrossRef]

- Song, A.; Tang, Y.-C.; Li, H.; Wang, N.; Zhao, L.; Pei, J.; Zhang, B.-P. Enhanced Piezoelectricity in 0.7BiFeO3-0.3BaTiO3 Lead-Free Ceramics: Distinct Effect of Poling Engineering. J. Mater. 2023, 9, 971–979. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, W.; Zhang, S. Flexoelectric Nano-Generator: Materials, Structures and Devices. Nano Energy 2013, 2, 1079–1092. [Google Scholar] [CrossRef]

- Yasui, K.; Itasaka, H.; Mimura, K.; Kato, K. Coexistence of Flexo- and Ferro-Electric Effects in an Ordered Assembly of BaTiO3 Nanocubes. Nanomaterials 2022, 12, 188. [Google Scholar] [CrossRef]

- Catalan, G.; Sinnamon, L.J.; Gregg, J.M. The Effect of Flexoelectricity on the Dielectric Properties of Inhomogeneously Strained Ferroelectric Thin Films. J. Phys. Condens. Matter 2004, 16, 2253–2264. [Google Scholar] [CrossRef]

- Ma, W.; Cross, L.E. Flexoelectric Effect in Ceramic Lead Zirconate Titanate. Appl. Phys. Lett. 2005, 86, 072905. [Google Scholar] [CrossRef]

- Ma, W.; Cross, L.E. Strain-Gradient-Induced Electric Polarization in Lead Zirconate Titanate Ceramics. Appl. Phys. Lett. 2003, 82, 3293–3295. [Google Scholar] [CrossRef]

- Wang, L.; Liang, R.; Zhou, Z.; Li, M.; Gu, M.; Wang, P.; Dong, X. Electrical Conduction Mechanisms and Effect of Atmosphere Annealing on the Electrical Properties of BiFeO3-BaTiO3 Ceramics. J. Eur. Ceram. Soc. 2019, 39, 4727–4734. [Google Scholar] [CrossRef]

| Phase | Fraction | Lattice Parameters | R Factors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (SG) | a (Å) | b (Å) | c (Å) | Rp | Rwp | Rexp | Rb | Rf | |

| R3c | 0.41 | 5.6111 (15) | 5.6111 (15) | 13.7452 (53) | 8.53 | 11.22 | 2.54 | 5.81 | 4.95 |

| Pmm | 0.59 | 3.9624 (5) | 3.9624 (5) | 3.9624 (5) | 5.85 | 4.12 | |||

| R3m | 0.36 | 5.6027 (27) | 5.6027 (27) | 6.8579 (20) | 7.55 | 9.64 | 2.54 | 5.90 | 4.93 |

| Pmm | 0.64 | 3.9605 (4) | 3.9605 (4) | 3.9605 (4) | 5.38 | 3.74 | |||

| R3c | 0.37 | 5.6006 (18) | 5.6006 (18) | 13.7248 (98) | 7.51 | 9.77 | 2.54 | 6.98 | 6.35 |

| P4mm | 0.63 | 3.9603 (3) | 3.9603 (3) | 3.9603 (3) | 6.91 | 5.52 | |||

| R3m | 0.34 | 5.6222 (10) | 5.6222 (10) | 6.8569 (11) | 8.16 | 10.66 | 2.54 | 5.60 | 4.94 |

| P4mm | 0.66 | 3.9576 (6) | 3.9576 (6) | 3.9617 (5) | 5.26 | 4.10 | |||

| R3c | 0.20 | 5.6020 (11) | 5.6020 (11) | 13.7495 (51) | 5.77 | 7.45 | 2.54 | 5.17 | 3.35 |

| Pmc21 | 0.80 | 7.9193 (5) | 5.5981 (4) | 5.6049 (6) | 5.00 | 3.58 | |||

| R3m | 0.35 | 5.6009 (7) | 5.6009 (7) | 6.8717 (30) | 5.51 | 7.25 | 2.53 | 4.43 | 3.51 |

| Pmc21 | 0.65 | 7.9190 (5) | 5.5968 (4) | 5.6029 (14) | 4.25 | 3.75 | |||

| R3c | 0.23 | 5.6024 (9) | 5.6024 (9) | 13.7442 (77) | 5.78 | 7.44 | 2.54 | 5.15 | 3.63 |

| Pbnm | 0.77 | 5.5983 (4) | 7.9202 (5) | 5.6051 (10) | 5.13 | 3.57 | |||

| R3m | 0.41 | 5.6018 (5) | 5.6018 (5) | 6.8743 (23) | 5.47 | 7.23 | 2.54 | 3.77 | 3.38 |

| Pbnm | 0.59 | 5.5988 (4) | 7.9210 (5) | 5.6028 (14) | 3.87 | 3.52 | |||

| Phase | Fraction | Lattice Parameters | R Factors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (SG) | a (Å) | b (Å) | c (Å) | Rp | Rwp | Rexp | Rb | Rf | |

| R3c | 0.42 | 5.5978 (20) | 5.5978 (20) | 13.7985 (35) | 5.47 | 7.09 | 2.40 | 3.60 | 2.16 |

| Pm3m | 0.58 | 3.9630 (4) | 3.9630 (4) | 3.9630 (4) | 2.81 | 1.96 | |||

| R3m | 0.37 | 5.6029 (19) | 5.6029 (19) | 6.8879 (15) | 5.56 | 7.24 | 2.41 | 2.85 | 2.34 |

| Pmm | 0.63 | 3.9599 (3) | 3.9599 (3) | 3.9599 (3) | 2.79 | 1.91 | |||

| R3c | 0.31 | 5.5966 (27) | 5.5966 (27) | 13.7839 (35) | 5.47 | 7.09 | 2.40 | 2.58 | 2.16 |

| P4mm | 0.69 | 3.9597 (6) | 3.9597 (6) | 3.9641 (12) | 2.81 | 1.96 | |||

| R3m | 0.35 | 5.6012 (15) | 5.6012 (15) | 6.8887 (13) | 5.46 | 7.27 | 2.40 | 3.01 | 2.91 |

| P4mm | 0.65 | 3.9597 (19) | 3.9597 (19) | 3.9596 (40) | 3.06 | 2.63 | |||

| R3c | 0.21 | 5.6104 (11) | 5.6104 (11) | 13.7321 (122) | 4.55 | 6.05 | 2.40 | 2.99 | 2.38 |

| Pmc21 | 0.79 | 7.9190 (7) | 5.5915 (5) | 5.6150 (15) | 3.01 | 2.28 | |||

| R3m | 0.29 | 5.6079 (9) | 5.6079 (9) | 6.8795 (35) | 4.54 | 5.99 | 2.40 | 2.55 | 2.20 |

| Pmc21 | 0.71 | 7.9205 (8) | 5.5908 (6) | 5.6105 (15) | 2.62 | 2.17 | |||

| R3c | 0.20 | 5.6109 (12) | 5.6109 (12) | 13.7635 (42) | 4.41 | 5.91 | 2.40 | 2.44 | 2.37 |

| Pbnm | 0.80 | 5.5920 (6) | 7.9206 (7) | 5.61008 (9) | 2.37 | 2.28 | |||

| R3m | 0.21 | 5.6089 (12) | 5.6089 (12) | 6.8811 (21) | 4.29 | 5.83 | 2.40 | 2.61 | 2.01 |

| Pbnm | 0.79 | 5.5921 (5) | 7.9206 (7) | 5.6116 (8) | 2.41 | 1.90 | |||

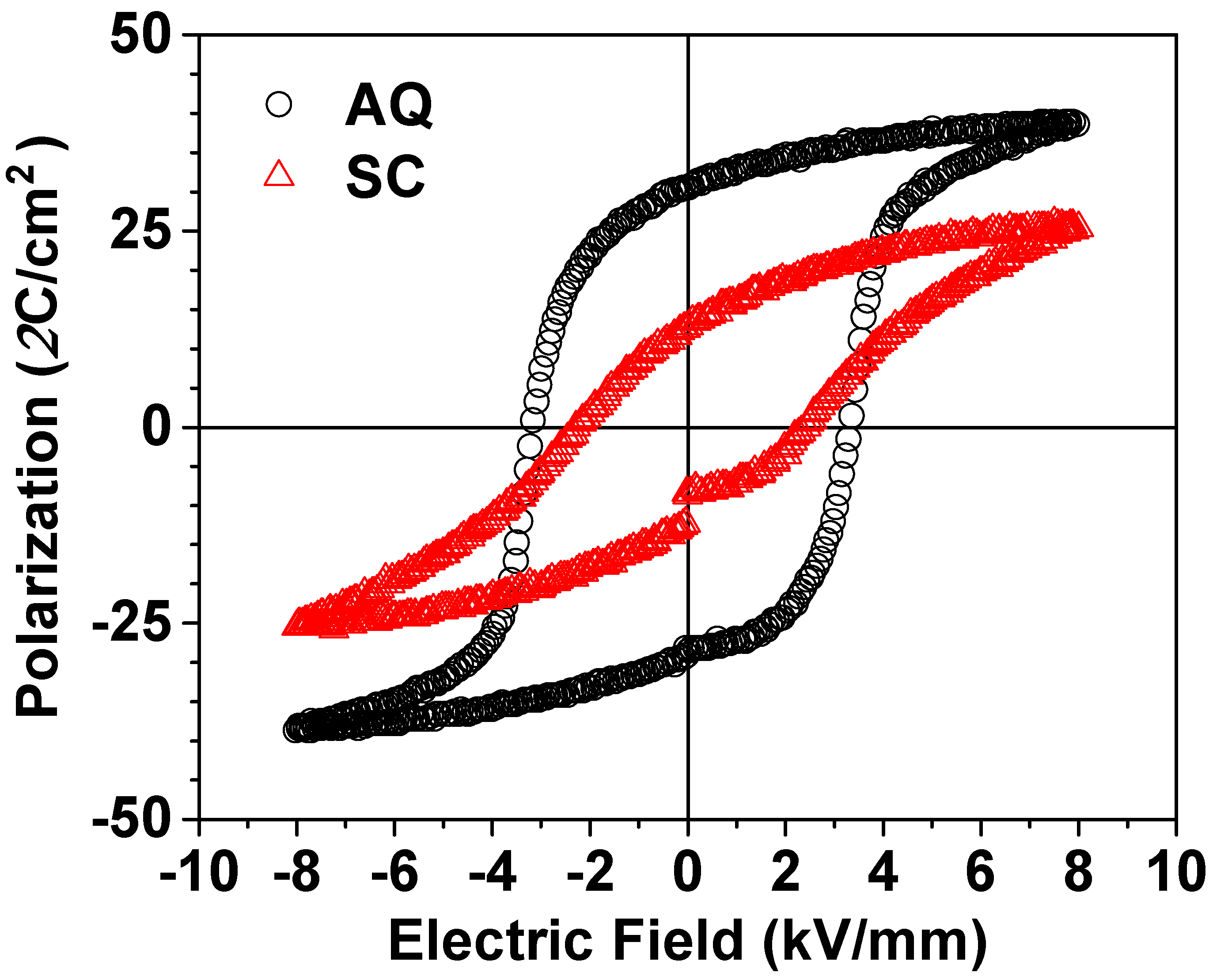

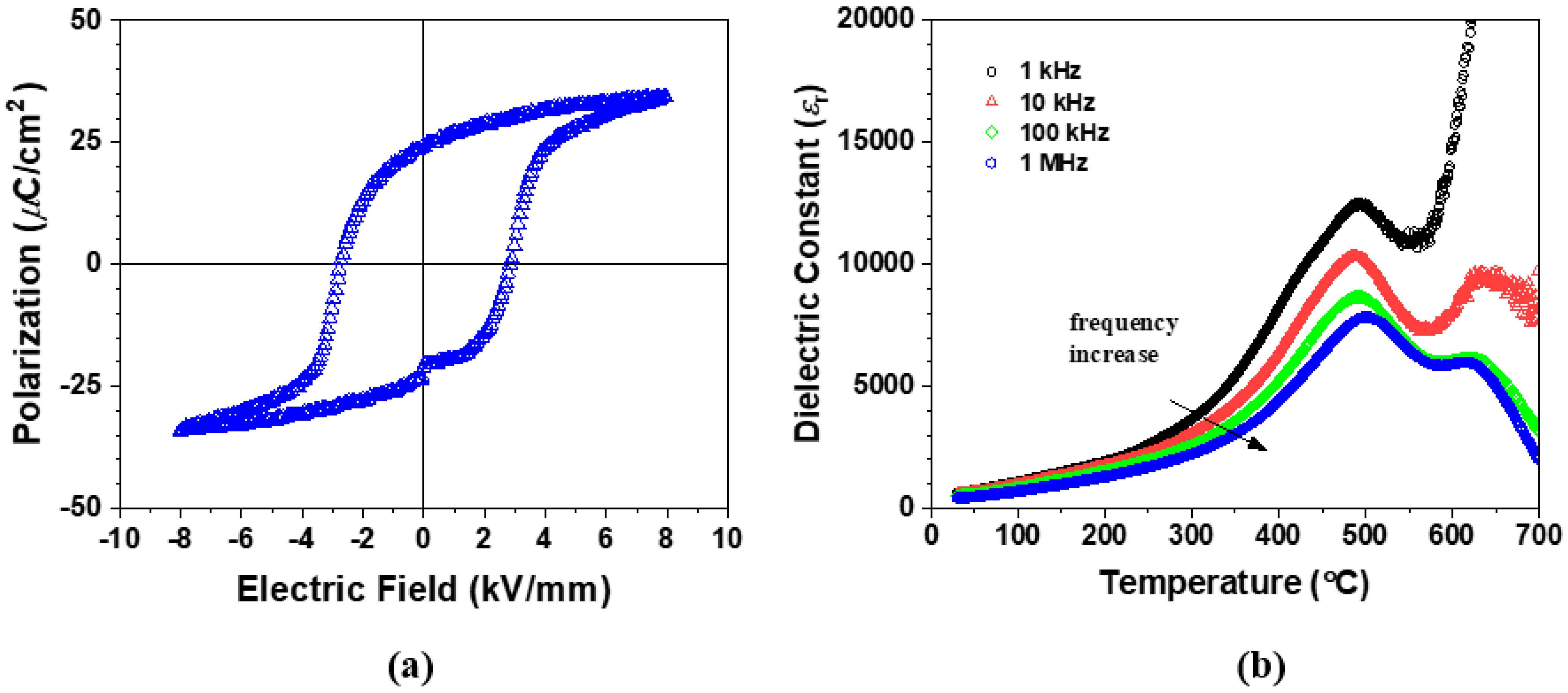

| Sample | εr | tan δ | d33 (pC/N) | kp | θmax (°) |

|---|---|---|---|---|---|

| AQ | 780 | 0.053 | 191 | 0.365 | 57.2 |

| SC | 759 | 0.057 | 65 | 0.204 | −43.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Go, S.H.; Kim, K.S.; Choi, Y.R.; Kim, J.-S.; Cheon, C.I. Crystal Structures and Piezoelectric Properties of Quenched and Slowly-Cooled BiFeO3-BaTiO3 Ceramics. Materials 2024, 17, 4492. https://doi.org/10.3390/ma17184492

Go SH, Kim KS, Choi YR, Kim J-S, Cheon CI. Crystal Structures and Piezoelectric Properties of Quenched and Slowly-Cooled BiFeO3-BaTiO3 Ceramics. Materials. 2024; 17(18):4492. https://doi.org/10.3390/ma17184492

Chicago/Turabian StyleGo, Su Hwan, Kang San Kim, Ye Rok Choi, Jeong-Seog Kim, and Chae Il Cheon. 2024. "Crystal Structures and Piezoelectric Properties of Quenched and Slowly-Cooled BiFeO3-BaTiO3 Ceramics" Materials 17, no. 18: 4492. https://doi.org/10.3390/ma17184492

APA StyleGo, S. H., Kim, K. S., Choi, Y. R., Kim, J.-S., & Cheon, C. I. (2024). Crystal Structures and Piezoelectric Properties of Quenched and Slowly-Cooled BiFeO3-BaTiO3 Ceramics. Materials, 17(18), 4492. https://doi.org/10.3390/ma17184492