High Purity, Crystallinity and Electromechanical Sensitivity of Lead-Free (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 Synthesized Using an EDTA/glycerol Modified Pechini Method

Abstract

1. Introduction

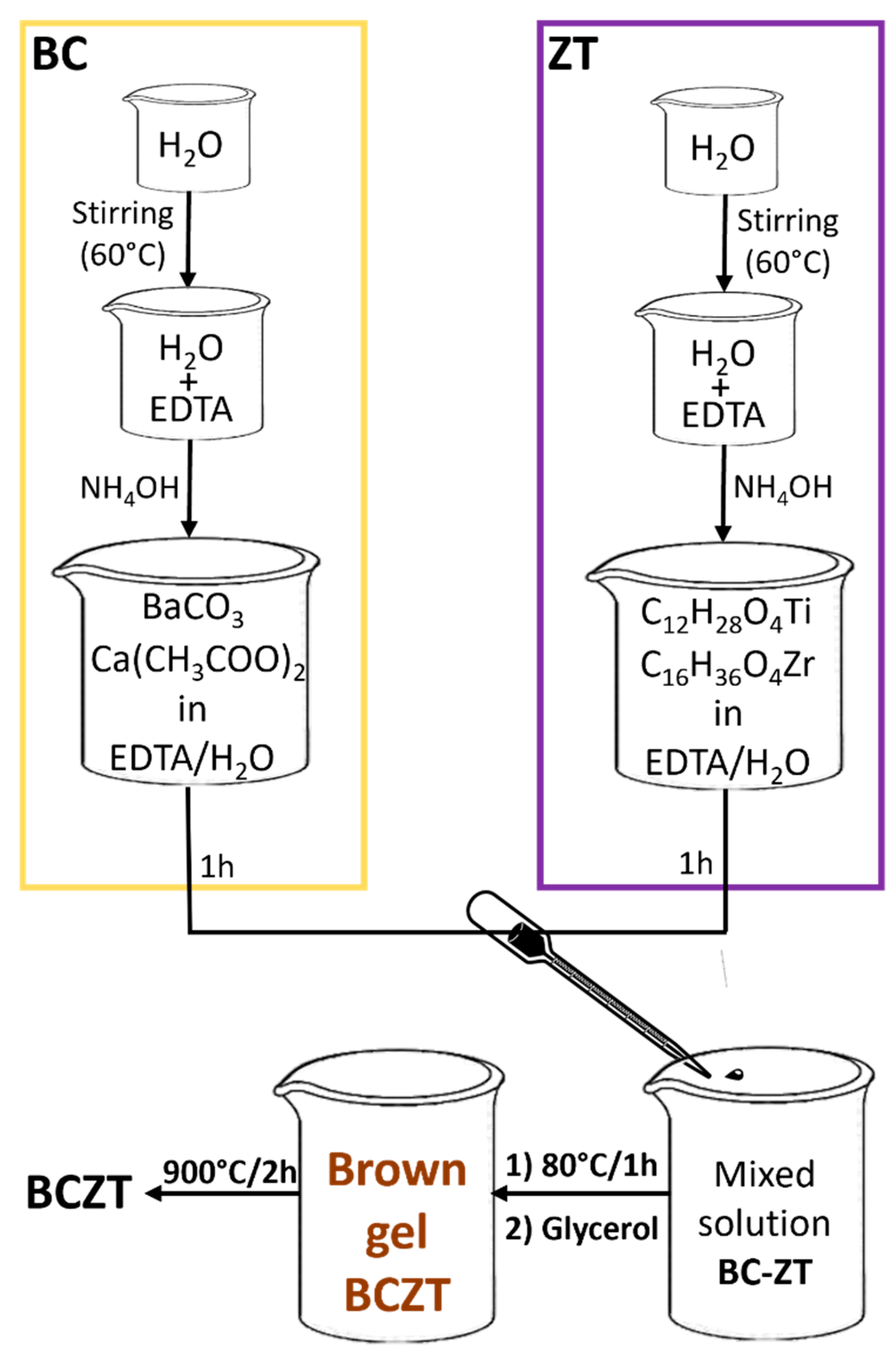

2. Materials and Methods

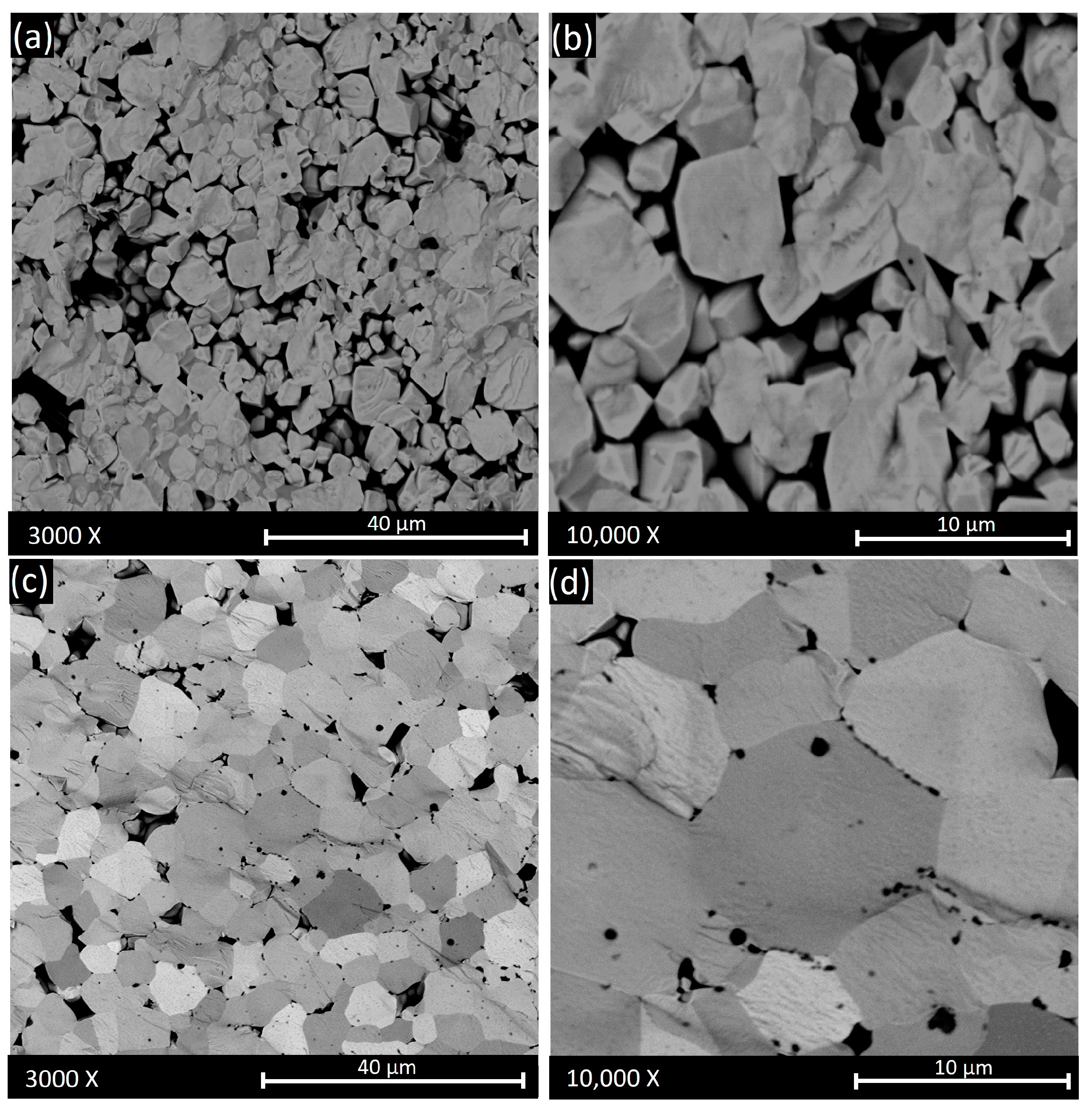

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sekhar, M.C.; Veena, E.; Kumar, N.S.; Naidu, K.C.B.; Mallikarjuna, A.; Basha, D.B. A Review on Piezoelectric Materials and Their Applications. Cryst. Res. Technol. 2023, 58, 2200130. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large Piezoelectric Effect in Pb-Free Ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef] [PubMed]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.A.; Rödel, J. BaTiO3-Based Piezoelectrics: Fundamentals, Current Status, and Perspectives. Appl. Phys. Rev. 2017, 4, 41305. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Liu, W.; Zhou, C.; Ren, X. Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications. Actuators 2017, 6, 24. [Google Scholar] [CrossRef]

- Buatip, N.; Dhanunjaya, M.; Amonpattaratkit, P.; Pomyai, P.; Sonklin, T.; Reichmann, K.; Janphaung, P.; Pojprapai, S. Comparison of Conventional and Reactive Sintering Techniques for Lead–Free BCZT Ferroelectric Ceramics. Radiat. Phys. Chem. 2020, 172, 108770. [Google Scholar] [CrossRef]

- Shi, S.; Hashimoto, H.; Sekino, T. Optimizing the Piezoelectric Properties of Ba0.85Ca0.15Zr0.10Ti0.90O3·lead-Free Ceramics via Two-Step Sintering. Ceram. Int. 2023, 49, 12293–12300. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Harumoto, T.; Zhang, S.; Tu, R.; Shen, Q.; Shi, J. Structure and Electrical Properties of BCZT Ceramics Derived from Microwave-Assisted Sol–Gel-Hydrothermal Synthesized Powders. Sci. Rep. 2020, 10, 20352. [Google Scholar] [CrossRef]

- Ji, X.; Peng, Q.; Wang, C.; Shi, J. Structure and Sintering Characteristics of Rapid Synthesizing BCZT Powders by Microwave Assisted Sol–Gel-Hydrothermal Method at Low Temperature. J. Mater. Sci. Mater. Electron. 2023, 34, 28. [Google Scholar] [CrossRef]

- Danks, A.E.; Hall, S.R.; Schnepp, Z. The Evolution of “sol-Gel” Chemistry as a Technique for Materials Synthesis. Mater. Horiz. 2016, 3, 91–112. [Google Scholar] [CrossRef]

- Navas, D.; Fuentes, S.; Castro-Alvarez, A.; Chavez-Angel, E. Review on Sol-Gel Synthesis of Perovskite and Oxide Nanomaterials. Gels 2021, 7, 275. [Google Scholar] [CrossRef]

- Kumar, A.S.; Lekha, C.S.C.; Vivek, S.; Anantharaman, M.R.; Saravanan, K.V.; Nair, S.S. Giant Voltage Generating Microcantilevers Based on Ba0.85Ca0.15Zr0.1Ti0.9O3 and Co76Fe14Ni4Si5B for next-Generation Energy Harvesters. Scr. Mater. 2020, 180, 11–15. [Google Scholar] [CrossRef]

- Kurajica, S. A Brief Review on the Use of Chelation Agents in Sol-Gel Synthesis with Emphasis on β-Diketones and β-Ketoesters. Chem. Biochem. Eng. Q. 2019, 33, 295–301. [Google Scholar] [CrossRef]

- Motta, M.; Deimling, C.V.; Saeki, M.J.; Lisboa-Filho, P.N. Chelating Agent Effects in the Synthesis of Mesoscopic-Size Superconducting Particles. J. Sol-Gel Sci. Technol. 2008, 46, 201–207. [Google Scholar] [CrossRef]

- Ianculescu, A.; Berger, D.; Matei, C.; Budrugeac, P.; Mitoseriu, L.; Vasile, E. Synthesis of BaTiO3 by Soft Chemistry Routes. J. Electroceram. 2010, 24, 46–50. [Google Scholar] [CrossRef]

- Leth, P.M.; Gregersen, M. Ethylene Glycol Poisoning. Forensic Sci. Int. 2005, 155, 179–184. [Google Scholar] [CrossRef]

- Gu, Y.; Jérôme, F. Glycerol as a Sustainable Solvent for Green Chemistry. Green Chem. 2010, 12, 1127–1138. [Google Scholar] [CrossRef]

- Henderson, R.K.; Jiménez-González, C.; Constable, D.J.C.; Alston, S.R.; Inglis, G.G.A.; Fisher, G.; Sherwood, J.; Binks, S.P.; Curzons, A.D. Expanding GSK’s Solvent Selection Guide–Embedding Sustainability into Solvent Selection Starting at Medicinal Chemistry. Green Chem. 2011, 13, 854–862. [Google Scholar] [CrossRef]

- Aziguli, H.; Zhang, T.; Yu, P. Effect of Additive Glycerol on Piezoelectric Properties of Modified Sol-Gel (Ba0.85ca0.15)(Ti0.9zr0.1)O3 Ceramics. Mater. Sci. Forum 2020, 993, 791–798. [Google Scholar] [CrossRef]

- Meeke, T.R. Publication and Proposed Revision of ANSI/IEEE Standard 176-1987 “ANSI/IEEE Standard on Piezoelectricity”. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1996, 43, 717–718. [Google Scholar] [CrossRef]

- Pardo, L.; García, Á.; Schubert, F.; Kynast, A.; Scholehwar, T.; Jacas, A.; Bartolomé, J.F. Determination of the Pic700 Ceramic’s Complex Piezo-Dielectric and Elastic Matrices from Manageable Aspect Ratio Resonators. Materials 2021, 14, 4076. [Google Scholar] [CrossRef]

- Lutterotti, L. Total Pattern Fitting for the Combined Size-Strain-Stress-Texture Determination in Thin Film Diffraction. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 334–340. [Google Scholar] [CrossRef]

- Graulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Le Bail, A. Crystallography Open Database—An Open-Access Collection of Crystal Structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef] [PubMed]

- Baraskar, B.G.; Kolekar, Y.D.; Thombare, B.R.; James, A.R.; Kambale, R.C.; Ramana, C.V. Enhanced Piezoelectric, Ferroelectric, and Electrostrictive Properties of Lead-Free (1-x)BCZT-(x)BCST Electroceramics with Energy Harvesting Capability. Small 2023, 19, 2300549. [Google Scholar] [CrossRef] [PubMed]

- Jaimeewong, P.; Promsawat, M.; Watcharapasorn, A.; Jiansirisomboon, S. Comparative Study of Properties of BCZT Ceramics Prepared from Conventional and Sol-Gel Auto Combustion Powders. Integr. Ferroelectr. 2016, 175, 25–32. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Chao, X.; Wei, L.; Yang, B.; Wang, D.; Yang, Z. Synthesis, Structure, Dielectric, Piezoelectric, and Energy Storage Performance of (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 Ceramics Prepared by Different Methods. J. Mater. Sci. Mater. Electron. 2016, 27, 5047–5058. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Wang, Y.H.; Zhang, M.; Zhao, N.; Gong, S.; Chen, Q. First-Principles Calculations of the Structural, Electronic and Optical Properties of BaZrxTi1-XO3 (x = 0, 0.25, 0.5, 0.75). Chin. Phys. Lett. 2011, 28, 67101. [Google Scholar] [CrossRef]

- Premkumar, S.; Radhakrishnan, S.; Mathe, V.L. Understanding A and B-Site Engineered Lead-Free Ba(1-X)CaxZryTi(1-y)O3 piezoceramics: A Perspective from DFT. J. Mater. Chem. C 2021, 9, 4248–4259. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA 3 for Three-Dimensional Visualization of Crystal, Volumetric and Morphology Data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Luo, W.; Chen, G.; Zhang, S.; Tu, R.; Shen, Q.; Shi, J.; Zhang, L. Effect of Solution Concentration on Low-Temperature Synthesis of BCZT Powders by Sol–Gel-Hydrothermal Method. J. Sol-Gel Sci. Technol. 2020, 94, 205–212. [Google Scholar] [CrossRef]

- Praveen, J.P.; Kumar, K.; James, A.R.; Karthik, T.; Asthana, S.; Das, D. Large Piezoelectric Strain Observed in Sol-Gel Derived BZT-BCT Ceramics. Curr. Appl. Phys. 2014, 14, 396–402. [Google Scholar] [CrossRef]

- Mureddu, M.; Bartolomé, J.F.; Lopez-Esteban, S.; Dore, M.; Enzo, S.; García, Á.; Garroni, S.; Pardo, L. Solid State Processing of BCZT Piezoceramics Using Ultra Low Synthesis and Sintering Temperatures. Materials 2023, 16, 945. [Google Scholar] [CrossRef] [PubMed]

- Amorín, H.; Venet, M.; García, J.E.; Ochoa, D.A.; Ramos, P.; López-Sánchez, J.; Rubio-Zuazo, J.; Castro, A.; Algueró, M. Insights into the Early Size Effects of Lead-Free Piezoelectric Ba0.85Ca0.15Zr0.1Ti0.9O3. Adv. Electron. Mater. 2023, 2300556, 1–12. [Google Scholar] [CrossRef]

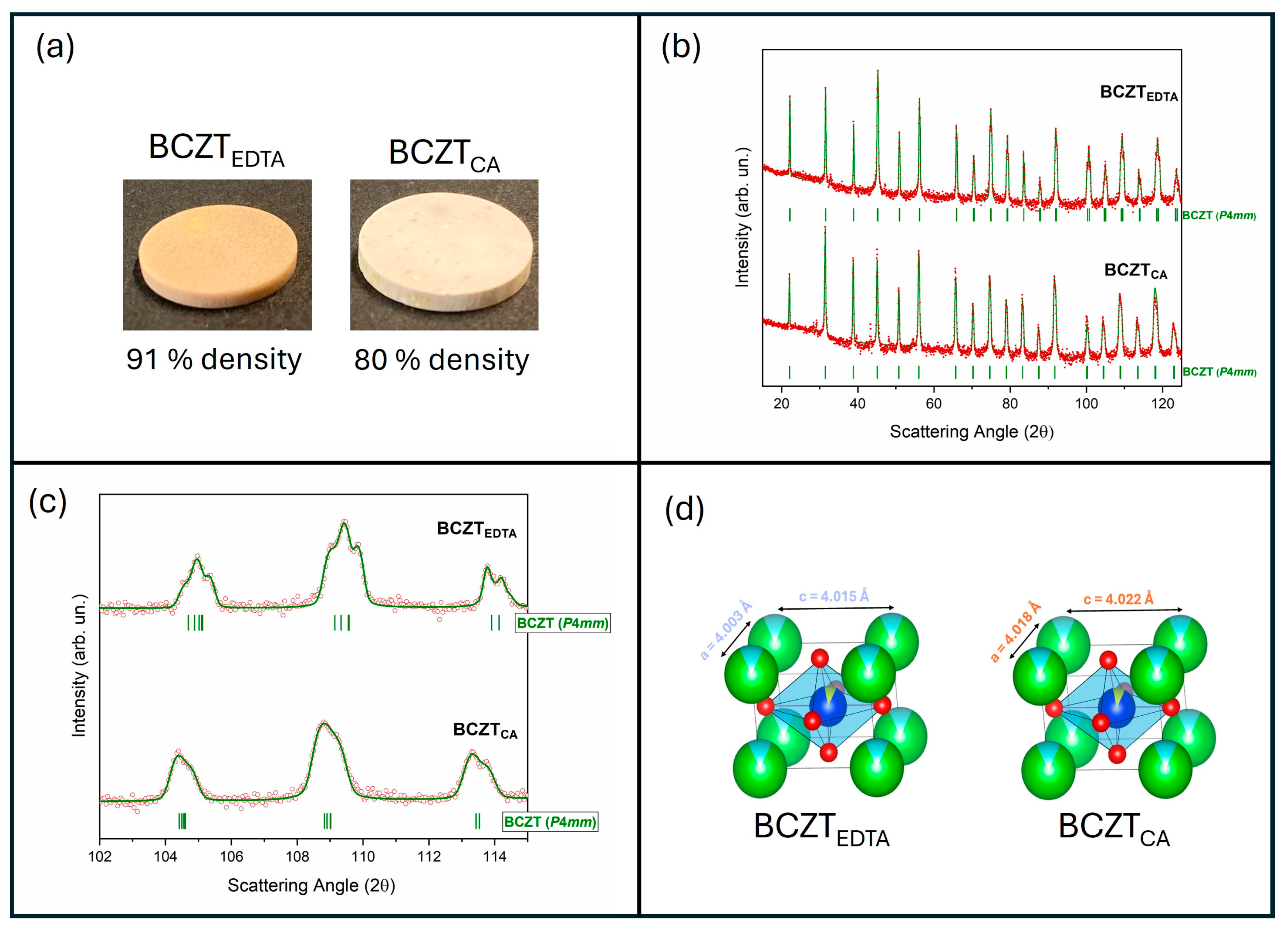

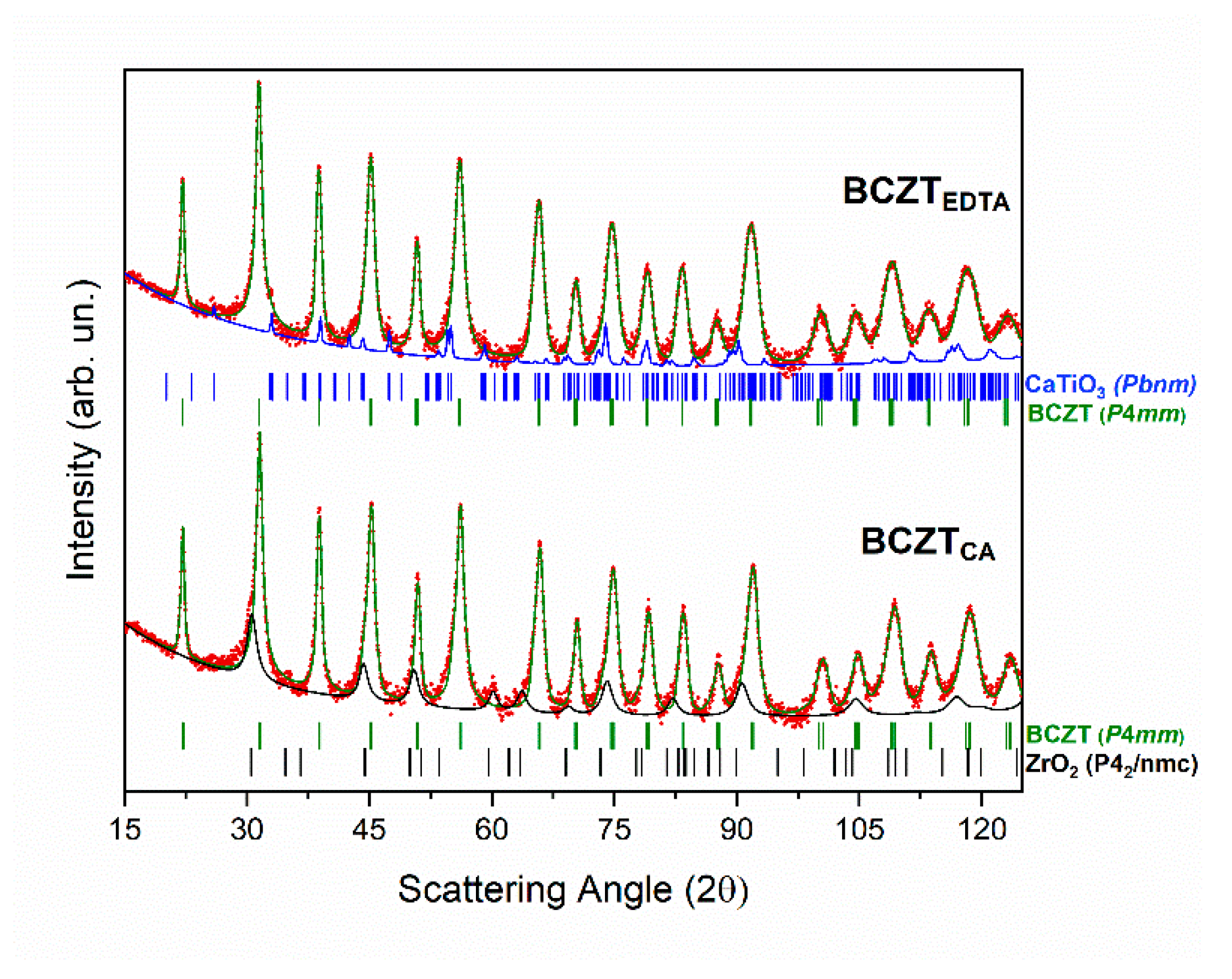

| BCZTEDTA | Composition (wt.%) | a (Å) | b (Å) | c (Å) | Cryst.Size (Å) | rms |

|---|---|---|---|---|---|---|

| BCZT (S.G.: P4mm) | 98 | 4.015 | 4.015 | 4.027 | 980 | 4.0 × 10−4 |

| CaTiO3 (S.G.: Pbnm) | 2 | 5.400 | 5.457 | 7.654 | 990 | 8.9 × 10−4 |

| BCZTCA | Composition (wt.%) | a (Å) | b (Å) | c (Å) | Cryst.Size (Å) | rms |

| BCZT (S.G.: P4mm) | 77 | 4.008 | 4.008 | 4.024 | 820 | 3.7 × 10−4 |

| ZrO2 (S.G.: P42/nmc) | 23 | 3.621 | 3.621 | 5.001 | 440 | 2.0 × 10−3 |

| BCZTEDTA | Composition (wt.%) | a (Å) | b (Å) | c (Å) | Cryst.Size (Å) | rms |

|---|---|---|---|---|---|---|

| BCZT (S.G.: P4mm) | 100 | 4.003 | 4.003 | 4.015 | >2000 | 6.9 × 10−4 |

| BCZTCA | Composition (wt.%) | a (Å) | b (Å) | c (Å) | Cryst.Size (Å) | rms |

| BCZT (S.G.: P4mm) | 100 | 4.017 | 4.017 | 4.022 | >2000 | 9.4 × 10−4 |

| Properties | |

|---|---|

| Density (g/cm3) | 5.26 |

| d33(pC/N) | 451 (440 after 2 h) |

| ℜ2 | 0.9986 |

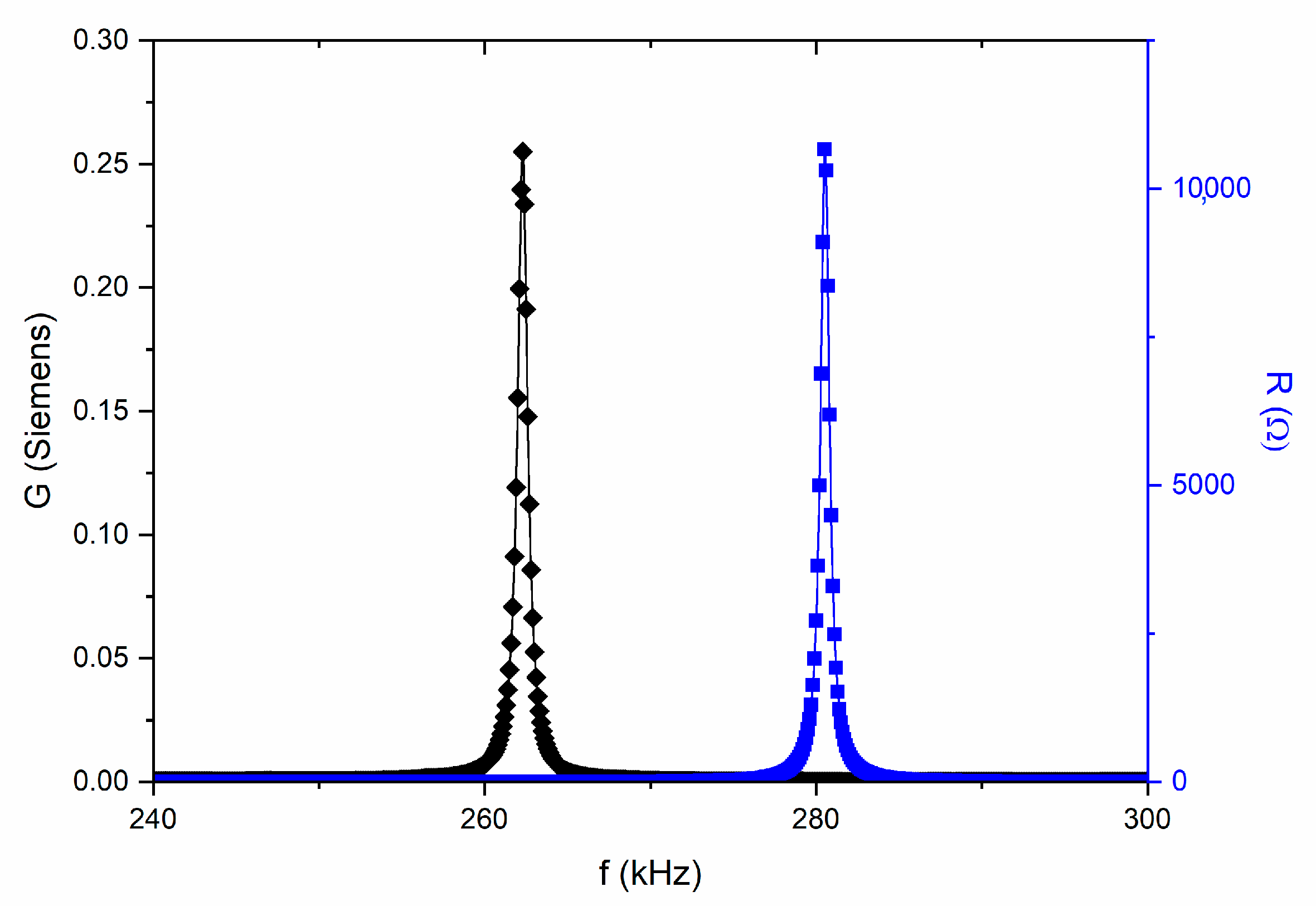

| kp (%) | 40.35 |

| Np(kHz·mm) | 2898 |

| d′31 (pC/N) | −160 |

| Qp(d31) | 113 |

| (1010N m−2) | 9.8 |

| Qm | 343 |

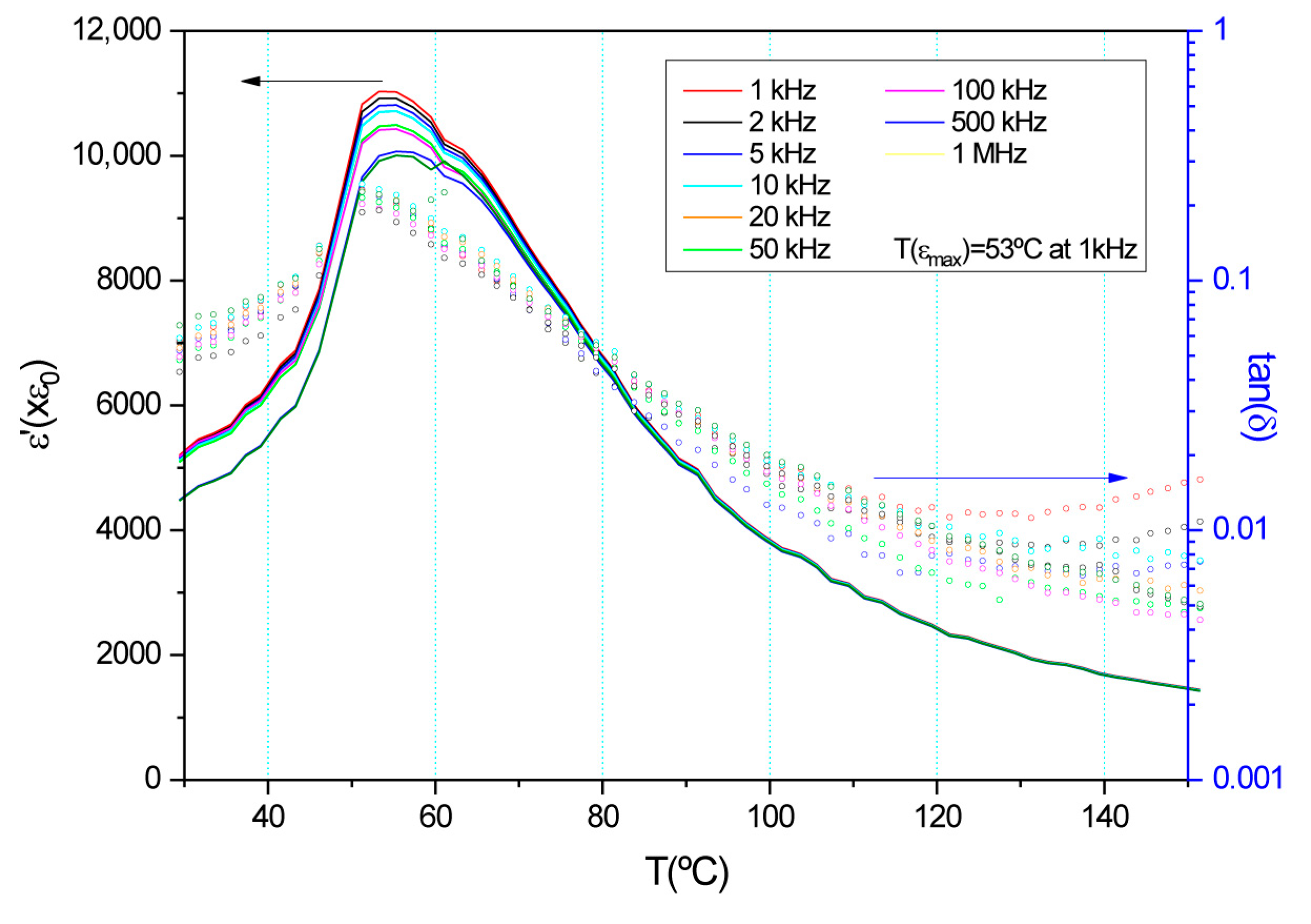

| 4790 | |

| tan δ | 0.007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caggiu, L.; Cau, C.; Mureddu, M.; Enzo, S.; Murgia, F.; Pardo, L.; Lopez-Esteban, S.; Bartolomé, J.F.; Mulas, G.; Orrù, R.; et al. High Purity, Crystallinity and Electromechanical Sensitivity of Lead-Free (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 Synthesized Using an EDTA/glycerol Modified Pechini Method. Materials 2025, 18, 1180. https://doi.org/10.3390/ma18051180

Caggiu L, Cau C, Mureddu M, Enzo S, Murgia F, Pardo L, Lopez-Esteban S, Bartolomé JF, Mulas G, Orrù R, et al. High Purity, Crystallinity and Electromechanical Sensitivity of Lead-Free (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 Synthesized Using an EDTA/glycerol Modified Pechini Method. Materials. 2025; 18(5):1180. https://doi.org/10.3390/ma18051180

Chicago/Turabian StyleCaggiu, Laura, Costantino Cau, Marzia Mureddu, Stefano Enzo, Fabrizio Murgia, Lorena Pardo, Sonia Lopez-Esteban, Jose F. Bartolomé, Gabriele Mulas, Roberto Orrù, and et al. 2025. "High Purity, Crystallinity and Electromechanical Sensitivity of Lead-Free (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 Synthesized Using an EDTA/glycerol Modified Pechini Method" Materials 18, no. 5: 1180. https://doi.org/10.3390/ma18051180

APA StyleCaggiu, L., Cau, C., Mureddu, M., Enzo, S., Murgia, F., Pardo, L., Lopez-Esteban, S., Bartolomé, J. F., Mulas, G., Orrù, R., & Garroni, S. (2025). High Purity, Crystallinity and Electromechanical Sensitivity of Lead-Free (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 Synthesized Using an EDTA/glycerol Modified Pechini Method. Materials, 18(5), 1180. https://doi.org/10.3390/ma18051180