Effect of High-Pressure Torsion Temperatures on the Precipitation and Properties of Cu-Cr Alloy

Abstract

1. Introduction

2. Experimental Section

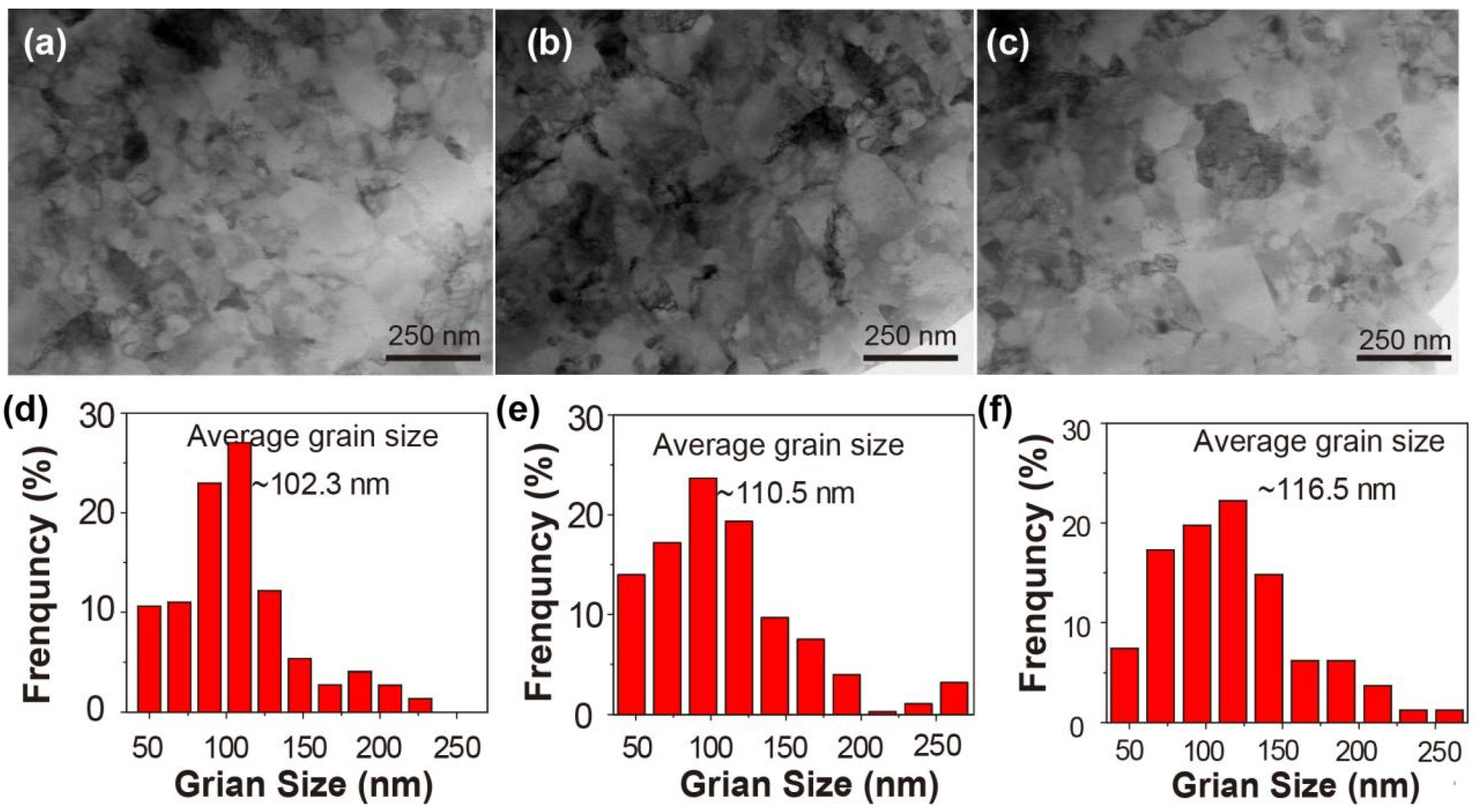

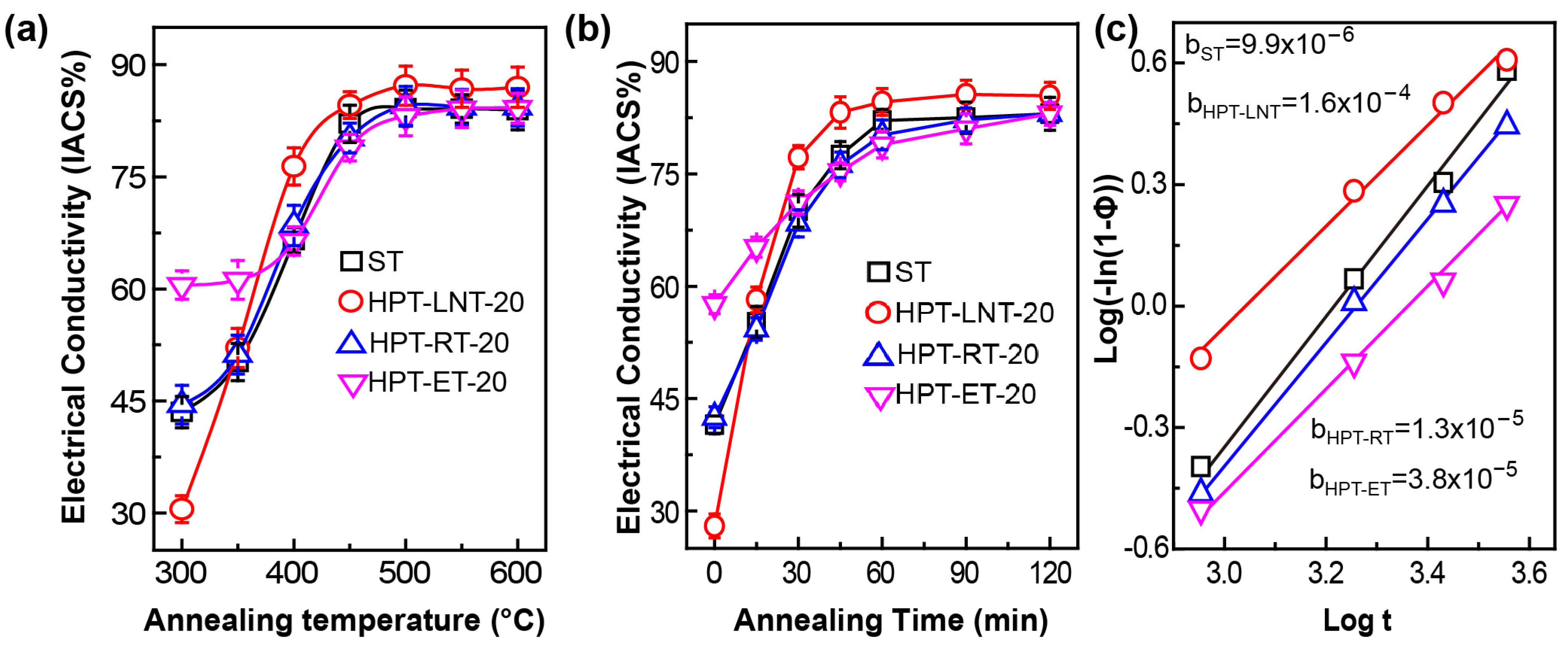

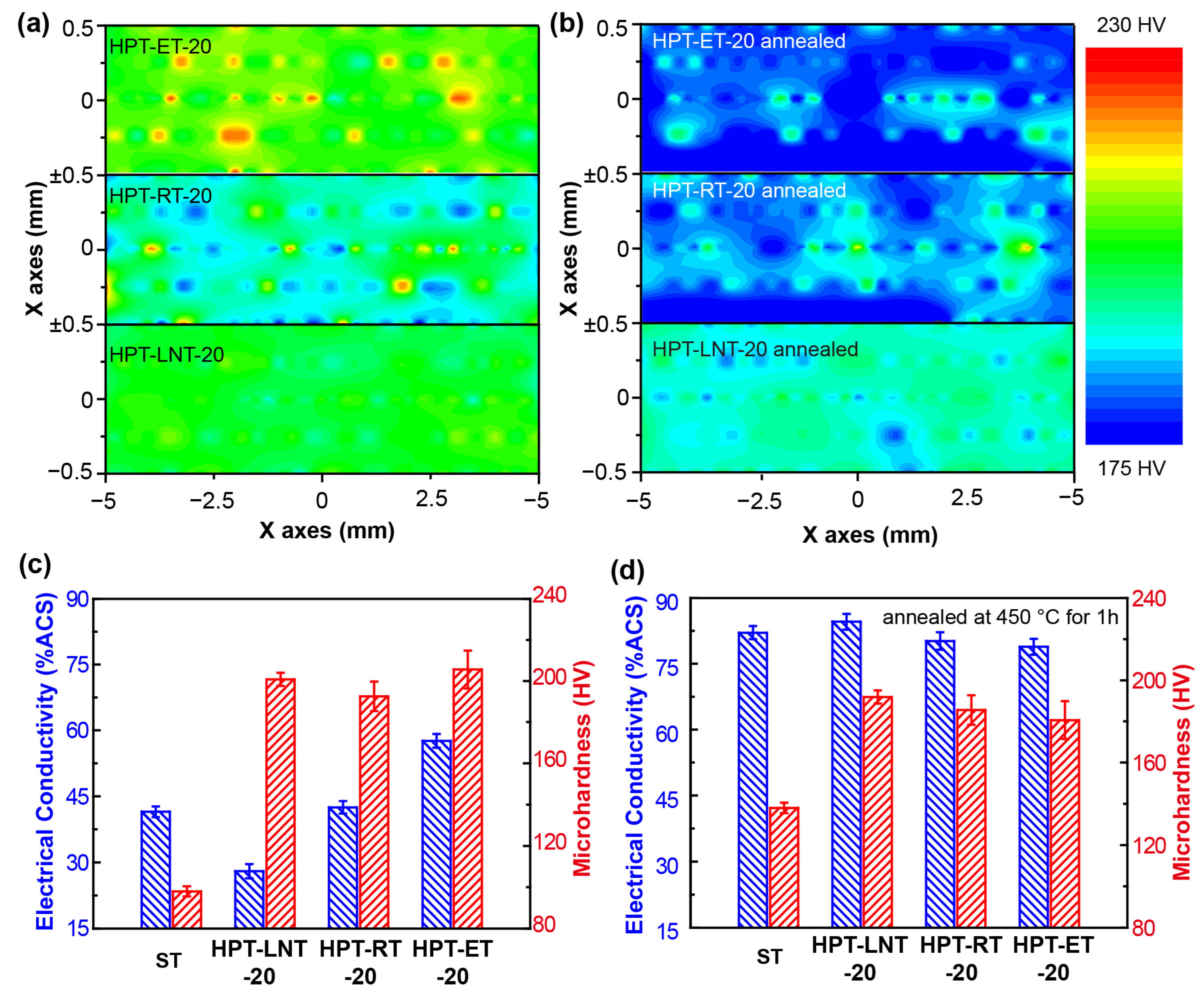

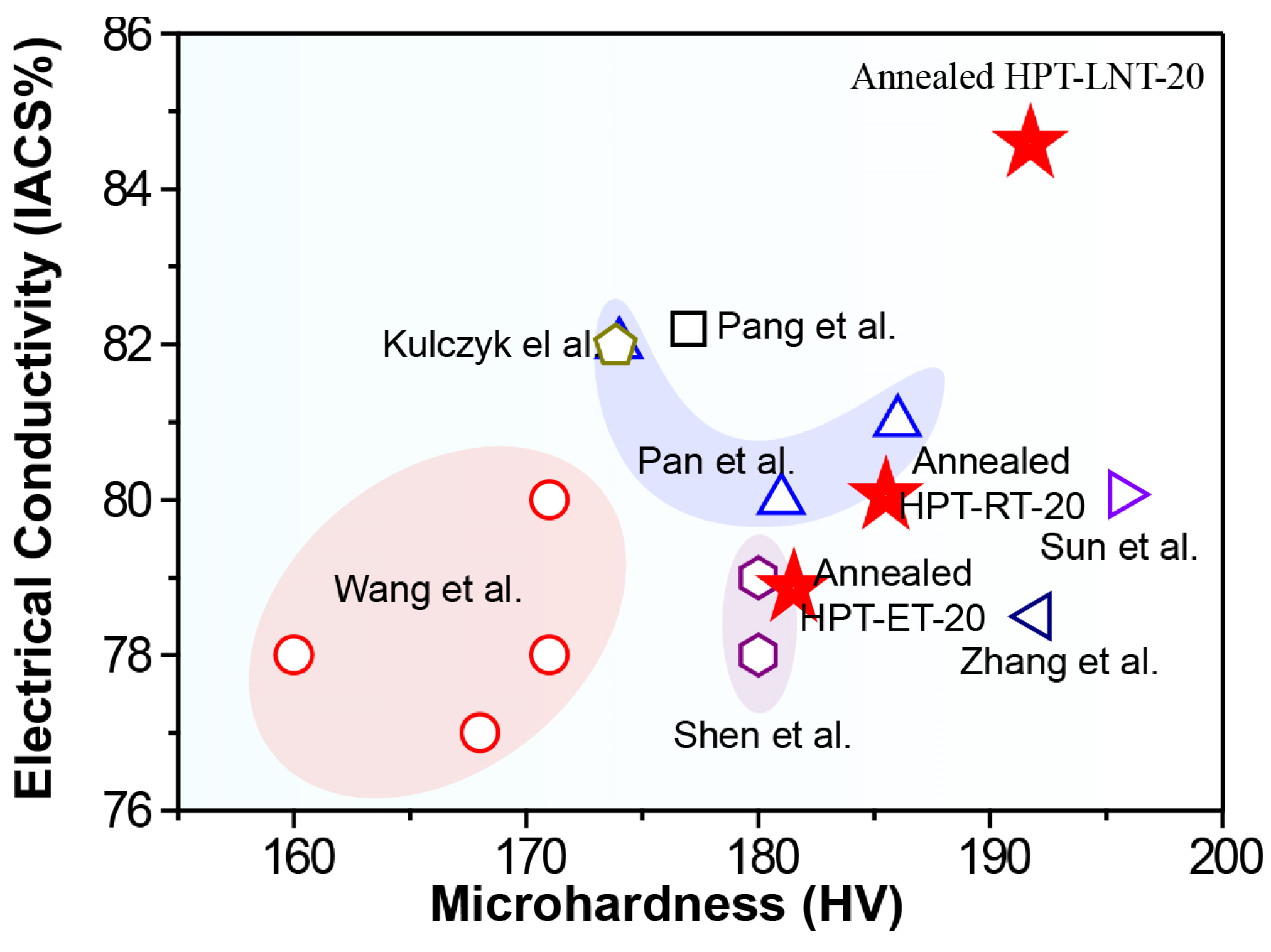

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, K.; Wang, Y.; Guo, M.; Wang, H.; Mo, Y.; Dong, X.; Lou, H. Recent development of advanced precipitation-strengthened Cu alloys with high strength and conductivity: A review. Prog. Mater. Sci. 2023, 138, 101141. [Google Scholar] [CrossRef]

- Ma, W.; Cao, F.; Gao, L.; Jiang, Y.; Chen, Z.; Shi, H.; Wang, Y.; Liang, S. Strength-ductility synergy in a hierarchical Cu-Cr-Zr alloy processed via laser powder bed fusion. J. Mater. Sci. Technol. 2024, 191, 122–133. [Google Scholar] [CrossRef]

- Yang, H.; Ma, Z.; Lei, C.; Meng, L.; Fang, Y.; Liu, J.; Wang, H. High strength and high conductivity Cu alloys: A review. Sci. China Technol. Sci. 2020, 63, 2505–2517. [Google Scholar] [CrossRef]

- Terentyev, D.; Rieth, M.; Pintsuk, G.; Von Müller, A.; Antusch, S.; Zinovev, A.; Bakaev, A.; Poleshchuk, K.; Aiello, G. Effect of neutron irradiation on tensile properties of advanced Cu-based alloys and composites developed for fusion applications. J. Nucl. Mater. 2023, 584, 154587. [Google Scholar] [CrossRef]

- Shen, Z.; Lin, Z.; Shi, P.; Zhu, J.; Zheng, T.; Ding, B.; Guo, Y.; Zhong, Y. Enhanced electrical, mechanical and tribological properties of Cu-Cr-Zr alloys by continuous extrusion forming and subsequent aging treatment. J. Mater. Sci. Technol. 2022, 110, 187–197. [Google Scholar] [CrossRef]

- Chbihi, A.; Sauvage, X.; Blavette, D. Atomic scale investigation of Cr precipitation in copper. Acta Mater. 2012, 60, 4575–4585. [Google Scholar] [CrossRef]

- Peng, L.; Xie, H.; Huang, G.; Xu, G.; Yin, X.; Feng, X.; Mi, X.; Yang, Z. The phase transformation and strengthening of a Cu-0.71 wt% Cr alloy. J. Alloy Compd. 2017, 708, 1096–1102. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Shen, B.; Yu, F.X. Precipitation in a Cu–Cr–Zr–Mg alloy during aging. Mater. Charact. 2013, 81, 68–75. [Google Scholar] [CrossRef]

- Yang, H.Y.; Li, K.Q.; Bu, Y.Q.; Wu, J.M.; Fang, Y.T.; Meng, L.; Liu, J.B.; Wang, H.T. Nanoprecipitates induced dislocation pinning and multiplication strategy for designing high strength, plasticity and conductivity Cu alloys. Scripta Mater. 2021, 195, 113741. [Google Scholar] [CrossRef]

- Shan, L.; Yang, L.; Wang, Y. Improving the high temperature mechanical performance of Cu–Cr alloy induced by residual nano-sized Cr precipitates. Mater. Sci. Eng. A 2022, 845, 143250. [Google Scholar] [CrossRef]

- Liu, J.; Hou, M.; Yang, H.; Xie, H.; Yang, C.; Zhang, J.; Feng, Q.; Wang, L.; Meng, L.; Wang, H. In-situ TEM study of the dynamic interactions between dislocations and precipitates in a Cu-Cr-Zr alloy. J. Alloy Compd. 2018, 765, 560–568. [Google Scholar] [CrossRef]

- Wang, L.; Martin, D.; Chen, W.-Y.; Baldo, P.M.; Li, M.; Wirth, B.D.; Zinkle, S.J. Effect of sink strength on coherency loss of precipitates in dilute Cu-base alloys during in situ ion irradiation. Acta Mater. 2021, 210, 116812. [Google Scholar] [CrossRef]

- Szajewski, B.A.; Crone, J.C.; Knap, J. Dislocation precipitate bypass through elastically mismatched precipitates. Model. Simul. Mat. Sci. Eng. 2021, 29, 025005. [Google Scholar] [CrossRef]

- León, K.V.; Muñoz-Morris, M.A.; Morris, D.G. Optimisation of strength and ductility of Cu–Cr–Zr by combining severe plastic deformation and precipitation. Mater. Sci. Eng. A 2012, 536, 181–189. [Google Scholar] [CrossRef]

- Chu, Z.; Pan, X.; Wei, W.; Wei, K.; Alexandrov, I.V.; An, X.; Wang, D.; Liu, X. High strength and electrical conductivity of nanostructured Cu–1Cr–0.1Zr alloy processed by multi–stage deformation and aging. J. Mater. Res. Technol. 2024, 29, 2051–2060. [Google Scholar] [CrossRef]

- Fu, H.; Xu, S.; Li, W.; Xie, J.; Zhao, H.; Pan, Z. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2017, 700, 107–115. [Google Scholar] [CrossRef]

- Caldatto Dalan, F.; de Lima Andreani, G.F.; Travessa, D.N.; Faizov, I.A.; Faizova, S.; Cardoso, K.R. Effect of ECAP processing on distribution of second phase particles, hardness and electrical conductivity of Cu−0.81Cr−0.07Zr alloy. T. Nonferr. Metal Soc. 2022, 32, 217–232. [Google Scholar] [CrossRef]

- Li, R.; Guo, E.; Chen, Z.; Kang, H.; Wang, W.; Zou, C.; Li, T.; Wang, T. Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging. J. Alloy Compd. 2019, 771, 1044–1051. [Google Scholar] [CrossRef]

- Guo, T.; Qian, D.; Huang, D.; Li, K.; Gao, Y.; Ding, Y. Deformation microstructure and properties control of Cu-0.6Cr alloy in cryo-equal channel angular pressing. J. Cent. South Univ. 2023, 30, 2094–2106. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Gunderov, D.; Asfandiyarov, R.; Astanin, V.; Sharafutdinov, A. Slippage during High-Pressure Torsion: Accumulative High-Pressure Torsion—Overview of the Latest Results. Metals 2023, 13, 1340. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Lutterotti, L.; Gialanella, S. X-ray diffraction characterization of heavily deformed metallic specimens. Acta Mater. 1998, 46, 101–110. [Google Scholar] [CrossRef]

- Vinogradov, A.; Suzuki, Y.; Ishida, T.; Kitagawa, K.; Kopylov, V.I. Effect of Chemical Composition on Structure and Properties of Ultrafine Grained Cu-Cr-Zr Alloys Produced by Equal-Channel Angular Pressing. Mater. Trans. 2004, 45, 2187–2191. [Google Scholar] [CrossRef]

- Purcek, G.; Yanar, H.; Demirtas, M.; Alemdag, Y.; Shangina, D.V.; Dobatkin, S.V. Optimization of strength, ductility and electrical conductivity of Cu–Cr–Zr alloy by combining multi-route ECAP and aging. Mater. Sci. Eng. A 2016, 649, 114–122. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, X.; Yang, W.; Gao, W.; Li, Q.; He, J. Microstructural evolution and properties of a Cu-Fe-Mn-P alloys with high strength and high conductivity. Mater. Today Commun. 2024, 39, 108611. [Google Scholar] [CrossRef]

- Qu, S.; An, X.H.; Yang, H.J.; Huang, C.X.; Yang, G.; Zang, Q.S.; Wang, Z.G.; Wu, S.D.; Zhang, Z.F. Microstructural evolution and mechanical properties of Cu–Al alloys subjected to equal channel angular pressing. Acta Mater. 2009, 57, 1586–1601. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Z.G.; Li, W. Effects of Thermo-mechanical Treatment on Microstructure and Properties of Cu-Cr-Zr Alloys. Phys. Procedia 2013, 50, 55–60. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, F.; Liu, W.; Xie, G.; Liu, X. Enhanced combination of mechanical and electrical properties of a Cu-Cr-Zr alloy by optimized two-step thermomechanical treatment. Mater. Today Commun. 2024, 39, 108876. [Google Scholar] [CrossRef]

- Shen, D.P.; Xu, N.; Gong, M.Y.; Li, P.; Zhou, H.B.; Tong, W.P.; Wilde, G. Improved tensile strength and electrical conductivity in Cu–Cr–Zr alloys by controlling the precipitation behavior through severe warm rolling. J. Mater. Sci. 2020, 55, 12499–12512. [Google Scholar] [CrossRef]

- Deschamps, A.; Hutchinson, C.R. Precipitation kinetics in metallic alloys: Experiments and modeling. Acta Mater. 2021, 220, 117338. [Google Scholar] [CrossRef]

- Kiana, S.; Christopher, V. A critical review on applications of the Avrami equation beyond materials science. J. R. Soc. Interface. 2023, 20, 20230242. [Google Scholar]

- Janssens, K.G.F.; Raabe, D.; Kozeschnik, E.; Miodownik, M.A.; Nestler, B. Computational Materials Engineering—An Introduction to Microstructure Evolution; Elsevier B.V: London, UK, 2007. [Google Scholar]

- Tian, J.; Wang, W.; Li, H.; Shahzad, M.B.; Shan, Y.; Jiang, Z.; Yang, K. Effect of deformation on precipitation hardening behavior of a maraging steel in the aging process. Mater. Charact. 2019, 155, 109827. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y.; Lu, J.; Tan, S.; Jiang, F.; Sun, J. Effects of pre-deformation on precipitation behaviors and properties in Cu-Ni-Si-Cr alloy. Mater. Sci. Eng. A 2019, 742, 501–507. [Google Scholar] [CrossRef]

- Feng, M.; Wu, Q.; Xue, J.; Luo, Z.; Wang, Z.; An, X.; Liao, X.; Li, J.; Jin, S.; Sha, G. High-pressure-torsion-induced segregation, precipitation and grain refinement of Al-(Si, Mg and Cu) binary alloys. J. Mater. Sci. Technol. 2024, 199, 102–113. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, X.; Cai, P.; Li, P.; Cao, F.; Gao, F.; Liang, S. Precipitation behavior and microstructural evolution during thermo-mechanical processing of precipitation hardened Cu-Hf based alloys. Acta Mater. 2023, 245, 118659. [Google Scholar] [CrossRef]

- Pang, Y.; Xia, C.; Wang, M.; Li, Z.; Xiao, Z.; Wei, H.; Sheng, X.; Jia, Y.; Chen, C. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu–Cr alloy. J. Alloy Compd. 2014, 582, 786–792. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, J.; Qin, N.; Zhang, Y.; Li, S.; Xiao, Z.; Lei, Q.; Li, Z. Effects of minor rare earths on the microstructure and properties of Cu-Cr-Zr alloy. J. Alloy Compd. 2020, 847, 155762. [Google Scholar] [CrossRef]

- Pan, Z.Y.; Chen, J.B.; Li, J.F. Microstructure and properties of rare earth-containing Cu–Cr–Zr alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1206–1214. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, Q.; Andani, M.T.; Liu, X.; Zhang, H.; Wang, W.; Li, Y.; Yang, Y. Effects of build orientation and heat treatment on microstructure and properties of Cu–Cr–Zr alloy manufactured by laser powder bed fusion. Mater. Chem. Phys. 2023, 298, 127477. [Google Scholar] [CrossRef]

- Sun, L.X.; Tao, N.R.; Lu, K. A high strength and high electrical conductivity bulk CuCrZr alloy with nanotwins. Scripta Mater. 2015, 99, 73–76. [Google Scholar] [CrossRef]

- Kulczyk, M.; Pachla, W.; Godek, J.; Smalc-Koziorowska, J.; Skiba, J.; Przybysz, S.; Wróblewska, M.; Przybysz, M. Improved compromise between the electrical conductivity and hardness of the thermo-mechanically treated CuCrZr alloy. Mater. Sci. Eng. A 2018, 724, 45–52. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Shen, D.; Liu, G.; Tang, B. Effect of High-Pressure Torsion Temperatures on the Precipitation and Properties of Cu-Cr Alloy. Materials 2024, 17, 4429. https://doi.org/10.3390/ma17174429

Zhang Y, Shen D, Liu G, Tang B. Effect of High-Pressure Torsion Temperatures on the Precipitation and Properties of Cu-Cr Alloy. Materials. 2024; 17(17):4429. https://doi.org/10.3390/ma17174429

Chicago/Turabian StyleZhang, Yu, Depeng Shen, Guoqiang Liu, and Bingtao Tang. 2024. "Effect of High-Pressure Torsion Temperatures on the Precipitation and Properties of Cu-Cr Alloy" Materials 17, no. 17: 4429. https://doi.org/10.3390/ma17174429

APA StyleZhang, Y., Shen, D., Liu, G., & Tang, B. (2024). Effect of High-Pressure Torsion Temperatures on the Precipitation and Properties of Cu-Cr Alloy. Materials, 17(17), 4429. https://doi.org/10.3390/ma17174429