Texture of Hot-Compressed Metastable β-Titanium Alloy Ti5321 Studied by Neutron Diffraction

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

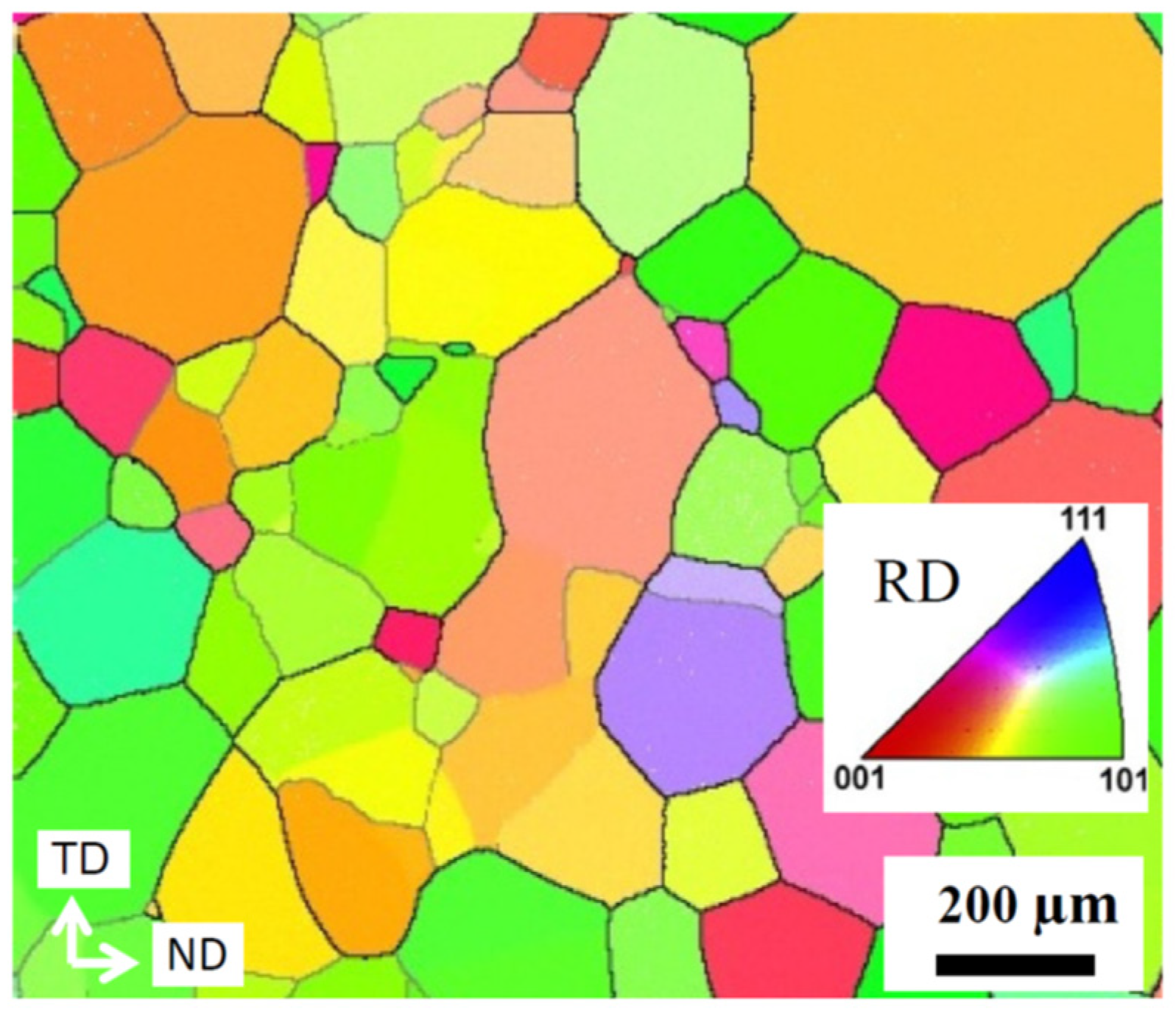

3.1. Microstructure and Texture of the β-Phase after Solution Treatment of the Hot-Rolled Bar

3.2. Texture of the β-Phase after Hot Compression

3.3. Texture of the α-Phase after Hot Compression and Effect of Phase Transformation on Texture Formation in the β-Phase

4. Conclusions

- After solution treatment of the hot-rolled alloy, in the β-phase there is still a weak cube component present as well as weaker αbcc-fiber components. The intensity of the cube component is much lower than that of the hot-rolled bar.

- Under the deformation conditions used during hot compression, a <100> fiber texture of the β-phase forms. With increasing deformation temperature, the intensity of the <100> fiber increases. The formation of a weak <100> fiber of the β-phase is associated with a certain level of α-participation.

- After hot compression, the texture of the α-phase shows an obvious fiber texture with <11-20> aligned parallel to the CA. The Burgers orientation relationship between the β- and α-phases is not maintained. Instead of the hcp α-phase, the orthorhombic martensitic α″-phase was observed in the sample, which was compressed near the β-transus temperature (probably just above it because of adiabatic heating). It is assumed that this phase nucleated heterogeneously during quenching from the deformed β-phase.

- The strong flow softening is due to both the dynamic globularization process based on stress-induced diffusion and the formation of fine GDRX β-grains.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, J.K.; Zhang, Z.X.; Gao, P.Y.; Yang, R.M.; Li, H.; Tang, B.; Kou, H.C.; Zhang, Y.D.; Esling, C.; Li, J.S. On the nature of a peculiar initial yield behavior in metastable β titanium alloy Ti-5Al-5Mo-5V-3Cr-0.5Fe with different initial microstructures. J. Mater. Sci. Technol. 2020, 38, 135–147. [Google Scholar] [CrossRef]

- Huang, C.W.; Zhao, Y.Q.; Xin, S.W.; Tan, C.S.; Zhou, W.; Li, Q.; Zeng, W.D. Effect of microstructure on high cycle fatigue behavior of Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy. Int. J. Fatigue 2017, 94, 30–40. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A review of metastable β titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, C.W.; Xu, Z.L.; Yang, J.; Long, S.L.; Tan, C.S.; Wan, M.P.; Liu, D.; Ji, S.L.; Zeng, W.D. Influence of notch root radius on high cycle fatigue properties and fatigue crack initiation behavior of Ti-55531 alloy with a multilevel lamellar microstructure. J. Mater. Res. Technol. 2023, 24, 6293–6311. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Premkumar, M.; Himabindu, V.S.; Banumathy, S.; Bhattacharjee, A.; Singh, A.K. Effect of mode of deformation by rolling on texture evolution and yield locus anisotropy in a multifunctional β titanium alloy. Mater. Sci. Eng. A 2012, 552, 15–23. [Google Scholar] [CrossRef]

- Banumathy, S.; Mandal, R.K.; Singh, A.K. Texture and anisotropy of a hot rolled Ti–16Nb alloy. J. Alloys Compd. 2010, 500, L26–L30. [Google Scholar] [CrossRef]

- Jones, N.G.; Dashwood, R.J.; Dye, D.; Jackson, M. Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr. Mater. Sci. Eng. A 2008, 490, 369–377. [Google Scholar] [CrossRef]

- Gu, B.; Chekhonin, P.; Schaarschuch, R.; Oertel, C.-G.; Xin, S.W.; Ma, C.L.; Zhou, L.; Gan, W.M.; Skrotzki, W. Microstructure, texture and hardness of a metastable β-titanium alloy after bar-rolling and annealing. J. Alloys Compd. 2020, 825, 154082. [Google Scholar] [CrossRef]

- Kou, H.C.; Chen, Y.; Tang, B.; Cui, Y.W.; Sun, F.; Li, J.S.; Xue, X.Y. An experimental study on the mechanism of texture evolution during hot-rolling process in a β titanium alloy. J. Alloys Compd. 2014, 603, 23–27. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.S.; Tang, B.; Kou, H.C.; Xue, X.Y.; Cui, Y.W. Texture evolution and dynamic recrystallization in a β titanium alloy during hot-rolling process. J. Alloys Compd. 2015, 618, 146–152. [Google Scholar] [CrossRef]

- Gurao, N.P.; Ashkar, A.A.; Suwas, S. Study of texture evolution in metastable β-Ti alloy as a function of strain path and its effect on α transformation texture. Mater. Sci. Eng. A 2009, 504, 24–35. [Google Scholar] [CrossRef]

- Engler, O.; Randle, V. Introduction to Texture Analysis: Macrotexture, Microtexture, and Orientation Mapping, 2nd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- Sander, B.; Raabe, D. Texture inhomogeneity in a Ti-Nb-based β-titanium alloy after warm rolling and recrystallization. Mater. Sci. Eng. A 2008, 479, 236–247. [Google Scholar] [CrossRef]

- Gu, B.; Chekhonin, P.; Xin, S.W.; Liu, G.Q.; Ma, C.L.; Zhou, L.; Skrotzki, W. Effect of temperature and strain rate on the deformation behavior of Ti5321 during hot-compression. J. Alloys Compd. 2021, 876, 159938. [Google Scholar] [CrossRef]

- Gu, B.; Chekhonin, P.; Xin, S.W.; Liu, G.Q.; Ma, C.L.; Skrotzki, W. Microstructure and texture development during hot-compression of Ti5321. Mater. Charact. 2021, 179, 111297. [Google Scholar] [CrossRef]

- Samajdar, I.; Verlinden, B.; Van Houtte, P.; Vanderschueren, D. γ -fibre recrystallization texture in IF-steel: An investigation on the recrystallization mechanisms. Mater. Sci. Eng. A 1997, 238, 343–350. [Google Scholar] [CrossRef]

- Rajmohan, N.; Hayakawa, Y.; Szpunar, J.A.; Root, J.R. Neutron diffraction method for stored energy measurement in interstitial free steel. Acta Mater. 1997, 45, 2485–2494. [Google Scholar] [CrossRef]

- Li, K.; Yang, P. The formation of strong {100} texture by dynamic strain-induced boundary migration in hot compressed Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Metals 2017, 7, 412. [Google Scholar] [CrossRef]

- McQueen, H.J. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Jackson, M.; Jones, N.G.; Dye, D.; Dashwood, R.J. Effect of initial microstructure on plastic flow behaviour during isothermal forging of Ti–10V–2Fe–3Al. Mater. Sci. Eng. A 2009, 501, 248–254. [Google Scholar] [CrossRef]

- Matsumoto, H.; Kitamura, M.; Li, Y.P.; Koizumi, Y.; Chiba, A. Hot forging characteristic of Ti–5Al–5V–5Mo–3Cr alloy with single metastable β microstructure. Mater. Sci. Eng. A 2014, 611, 337–344. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Ma, C.L.; Chang, H.; Xin, S.W.; Zhou, L. New high strength and high toughness titanium alloy with 1200 MPa. Mater. China 2016, 35, 914–918. (In Chinese) [Google Scholar]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The high energy materials science beamline (HEMS) at PETRA III. Mater. Sci. Forum 2014, 772, 57–61. [Google Scholar] [CrossRef]

- Chulist, R.; Wójcik, A.; Sozinov, A.; Tokarski, T.; Faryna, M.; Schell, N.; Skrotzki, W.; Li, B.; Sehitoglu, H.; Li, X.; et al. Adaptive phase or variant formation at the austenite/twinned martensite interface in modulated Ni–Mn–Ga martensite. Adv. Funct. Mater. 2024, 34, 2307322. [Google Scholar] [CrossRef]

- Wójcik, A.; Chulist, R.; Czaja, P.; Kowalczyk, M.; Zackiewicz, P.; Schell, N.; Maziarz, W. Evolution of microstructure and crystallographic texture of Ni-Mn-Ga melt-spun ribbons exhibiting 1.15% magnetic field-induced strain. Acta Mater. 2021, 219, 117237. [Google Scholar] [CrossRef]

- Brokmeier, H.-G.; Gan, W.M.; Randau, C.; Voeller, M.; Rebelo-Kornmeier, J.; Hofmann, M. Texture analysis at neutron diffractometer STRESS-SPEC. Nucl. Instrum. Methods Phys. Res. A 2011, 642, 87–92. [Google Scholar] [CrossRef]

- Randau, C.; Brokmeier, H.G.; Gan, W.M.; Hofmann, M.; Voeller, M.; Tekouo, W.; Al-hamdany, N.; Seidl, G.; Schreyer, A. Improved sample manipulation at the STRESS-SPEC neutron diffractometer using an industrial 6-axis robot for texture and strain analyses. Nucl. Instrum. Methods Phys. Res. A 2015, 794, 67–74. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ikehara, Y.; Kim, J.I.; Hosoda, H.; Miyazaki, S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater. 2006, 54, 2419–2429. [Google Scholar] [CrossRef]

- Hayama, A.O.F.; Lopes, J.F.S.C.; Gomes, M.J.; Abreu, H.F.G.; Caram, R. Crystallographic texture evolution in Ti–35Nb alloy deformed by cold rolling. Mater. Des. 2014, 60, 653–660. [Google Scholar] [CrossRef]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. β-Texture evolution during α precipitation in the two-step forging process of a near-β titanium alloy. Metall. Mater. Trans. A 2020, 51A, 5112–5122. [Google Scholar] [CrossRef]

- Germain, L.; Gey, N.; Humbert, M.; Vo, P.; Jahazi, M.; Bocher, P. Texture heterogeneities induced by subtransus processing of near α titanium alloys. Acta Mater. 2008, 56, 4298–4308. [Google Scholar] [CrossRef]

- Zheng, G.; Mao, X.; Tang, B.; Zhang, Y. Evolution of microstructure and texture of a near β titanium alloy during forging bar into disk. J. Alloys Compd. 2020, 831, 154750. [Google Scholar] [CrossRef]

- Wang, D.; Fan, Q.; Yang, L.; Gong, H.; Yuan, J.; Chen, K.; Zhu, X.; Cheng, X.; Zhou, Z. Effects of rolling reduction on Burgers orientation relationship and slip behavior of a Ti-5.5Mo-7.2Al-4.5Zr-2.6Sn-2.1Cr alloy. Mater. Res. Technol. 2021, 15, 3099–3109. [Google Scholar] [CrossRef]

- Zhao, J.; Zhong, J.; Yan, F.; Chai, F.; Dargusch, M. Deformation behaviour and mechanisms during hot compression at supertransus temperatures in Ti-10V-2Fe-3Al. J. Alloys Compd. 2017, 710, 616–627. [Google Scholar] [CrossRef]

- Sun, T.; Sun, L.; Teng, H.H.; Liu, W.H.; Wang, R.Q.; Zhao, X.J.; Zhou, J. Constitutive model and microstructure evolution of Ti65 titanium alloy. Materials 2024, 17, 2409. [Google Scholar] [CrossRef]

- Warchomicka, F.; Poletti, C.; Stockinger, M. Study of the hot deformation behaviour in Ti–5Al–5Mo–5V–3Cr–1Zr. Mater. Sci. Eng. A 2011, 528, 8277–8285. [Google Scholar] [CrossRef]

- Fan, J.K.; Kou, H.C.; Lai, M.J.; Tang, B.; Chang, H.; Li, J.S. Hot deformation mechanism and microstructure evolution of a new near β titanium alloy. Mater. Sci. Eng. A 2013, 584, 121–132. [Google Scholar] [CrossRef]

- Li, L.; Luo, J.; Yan, J.J.; Li, M.Q. Dynamic globularization and restoration mechanism of Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy during isothermal compression. J. Alloys Compd. 2015, 622, 174–183. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, B.; Chekhonin, P.; Chulist, R.; Gan, W.; Skrotzki, W. Texture of Hot-Compressed Metastable β-Titanium Alloy Ti5321 Studied by Neutron Diffraction. Materials 2024, 17, 4418. https://doi.org/10.3390/ma17174418

Gu B, Chekhonin P, Chulist R, Gan W, Skrotzki W. Texture of Hot-Compressed Metastable β-Titanium Alloy Ti5321 Studied by Neutron Diffraction. Materials. 2024; 17(17):4418. https://doi.org/10.3390/ma17174418

Chicago/Turabian StyleGu, Bin, Paul Chekhonin, Robert Chulist, Weimin Gan, and Werner Skrotzki. 2024. "Texture of Hot-Compressed Metastable β-Titanium Alloy Ti5321 Studied by Neutron Diffraction" Materials 17, no. 17: 4418. https://doi.org/10.3390/ma17174418

APA StyleGu, B., Chekhonin, P., Chulist, R., Gan, W., & Skrotzki, W. (2024). Texture of Hot-Compressed Metastable β-Titanium Alloy Ti5321 Studied by Neutron Diffraction. Materials, 17(17), 4418. https://doi.org/10.3390/ma17174418