Improvement in Mechanical Properties of Completely Decomposed Granite Soil Concrete Fabricated with Pre-Setting Pressurization

Abstract

:1. Introduction

2. Materials and Methods

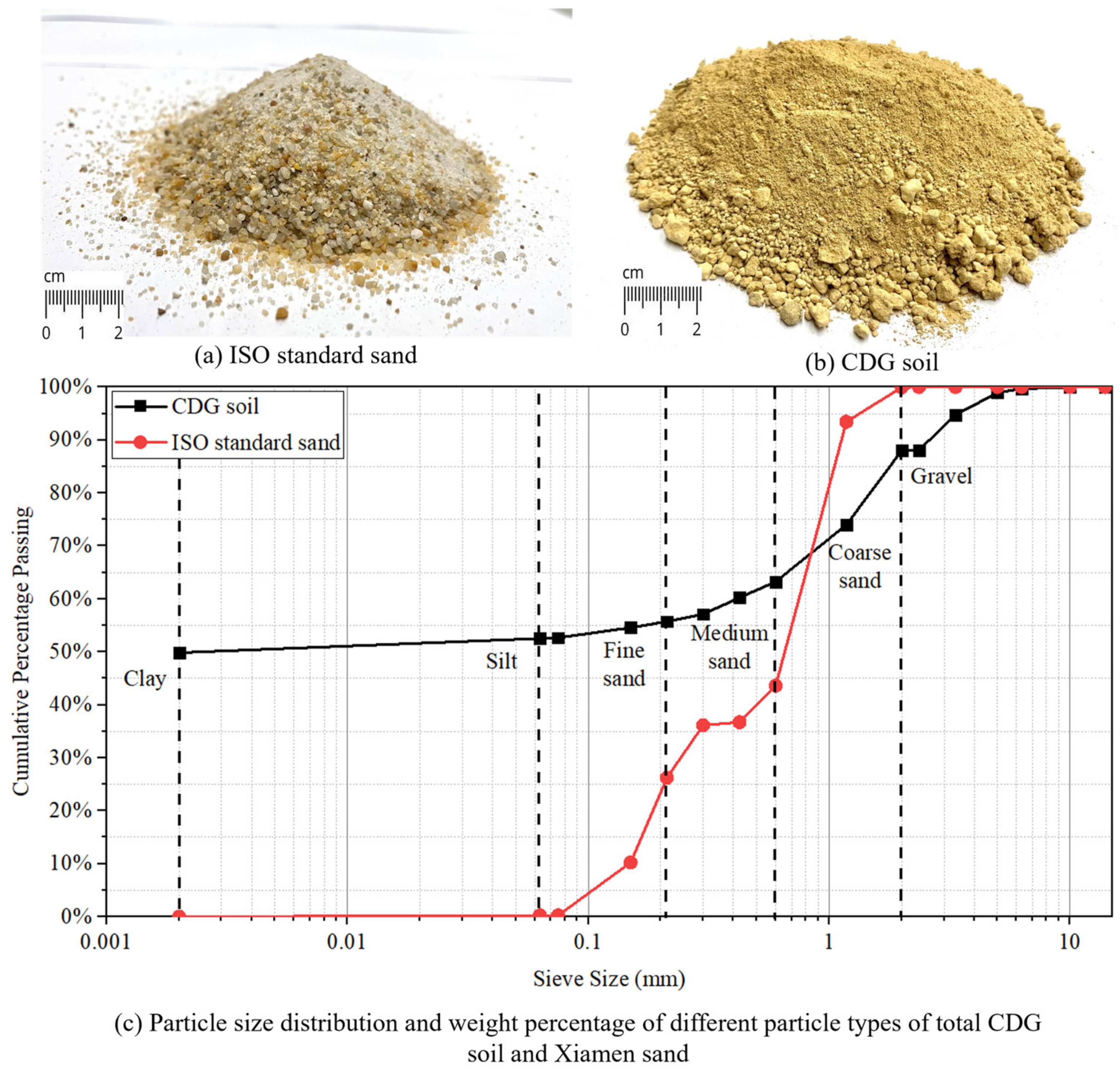

2.1. Materials

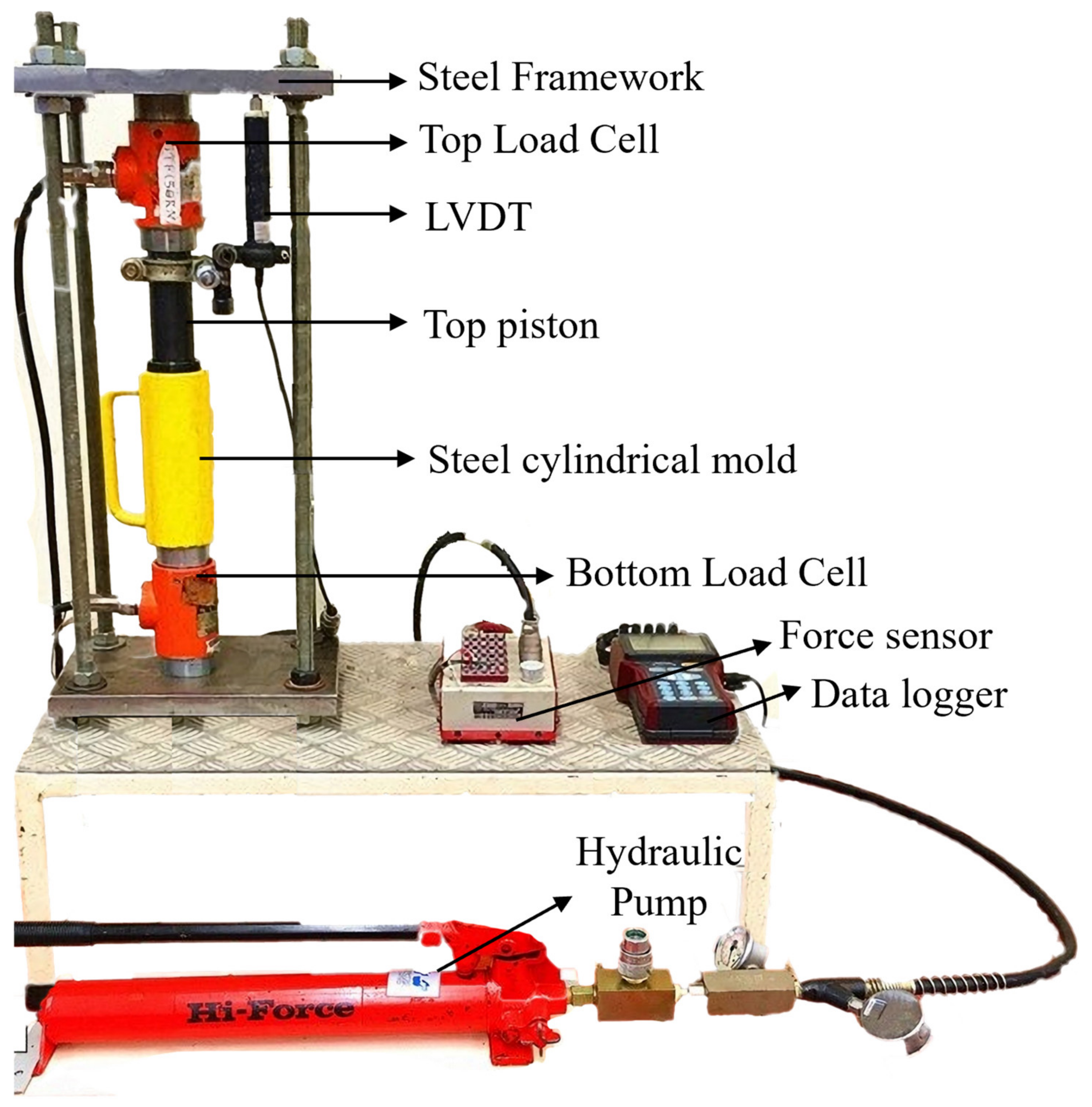

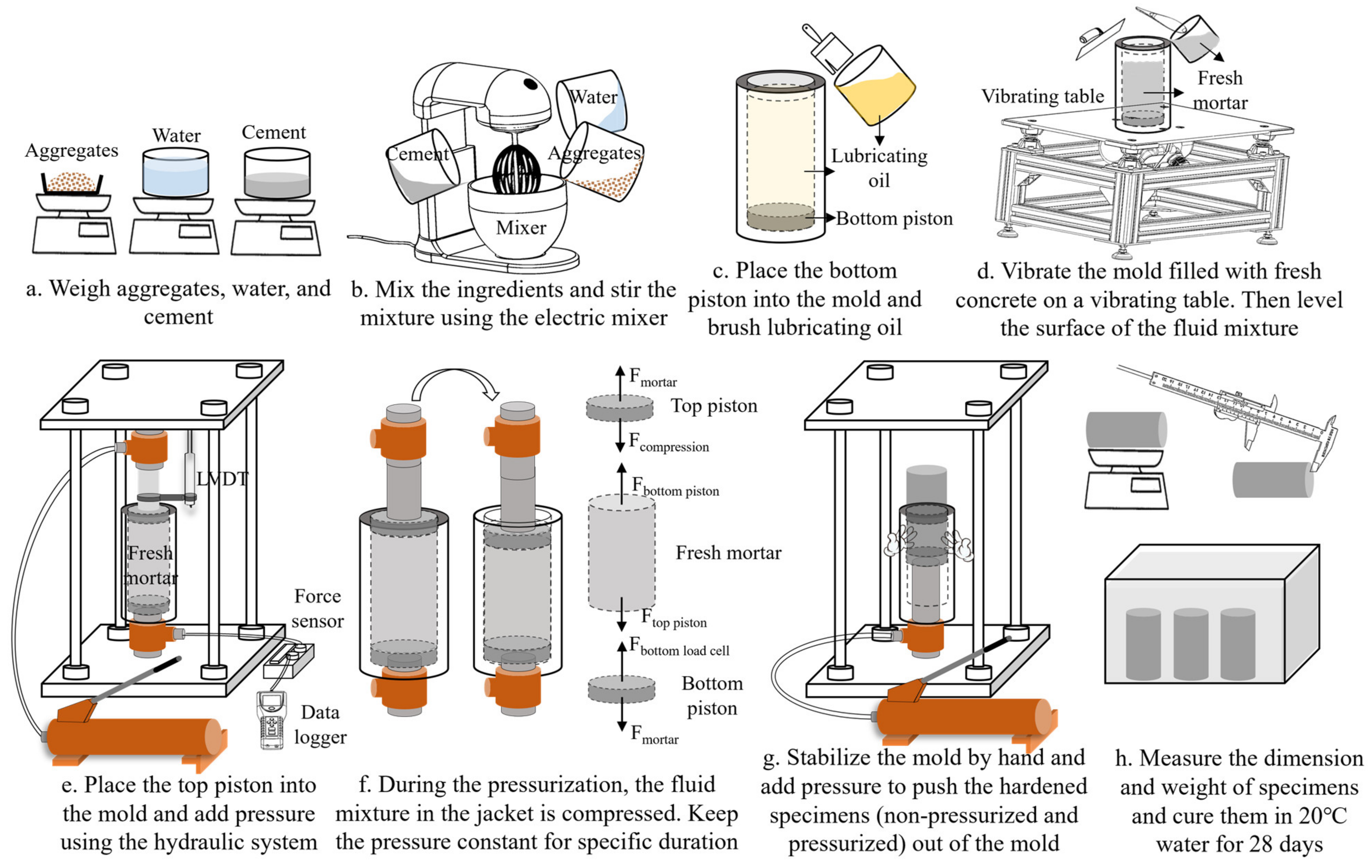

2.2. Experimental Apparatus and Procedure

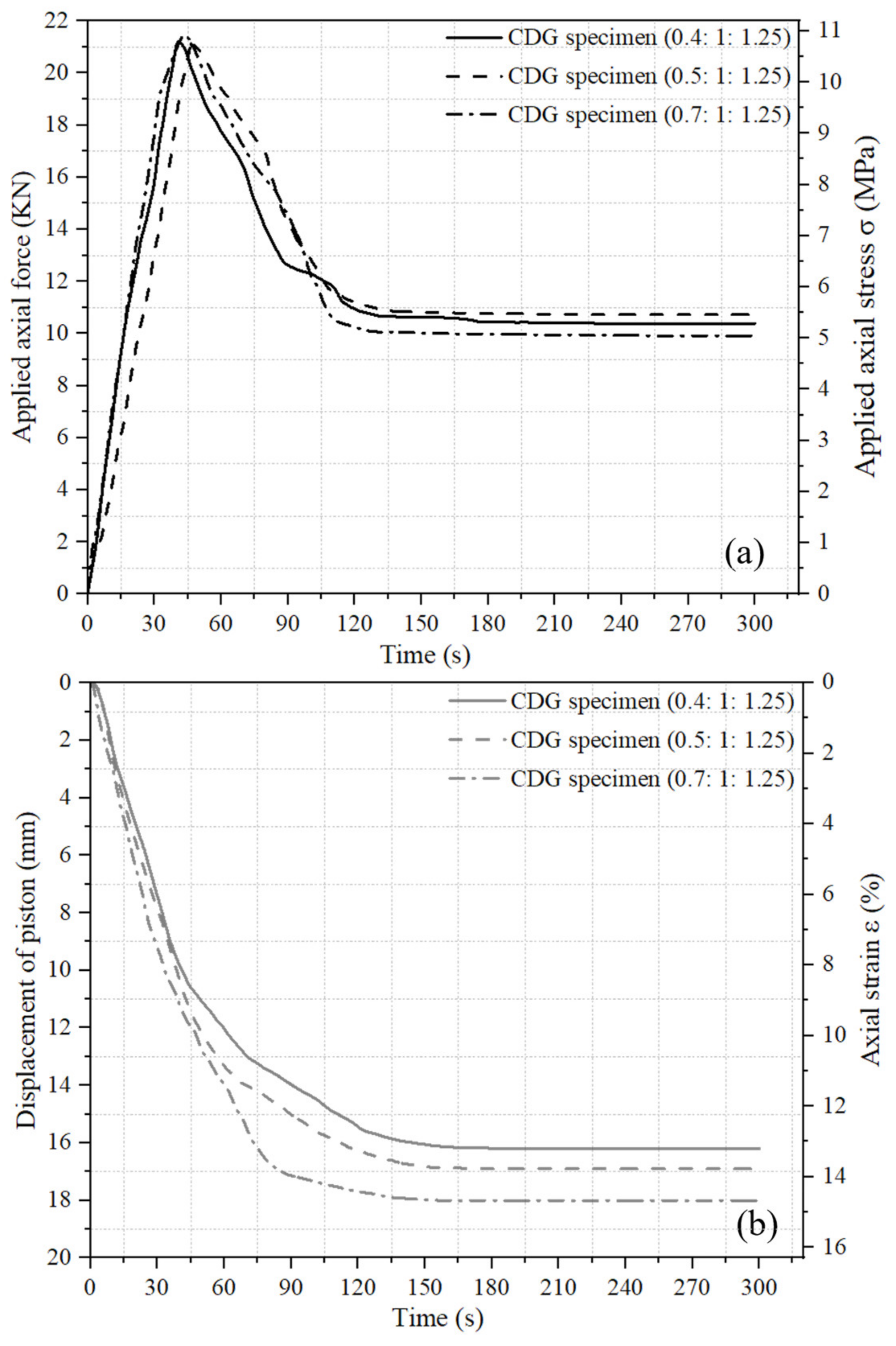

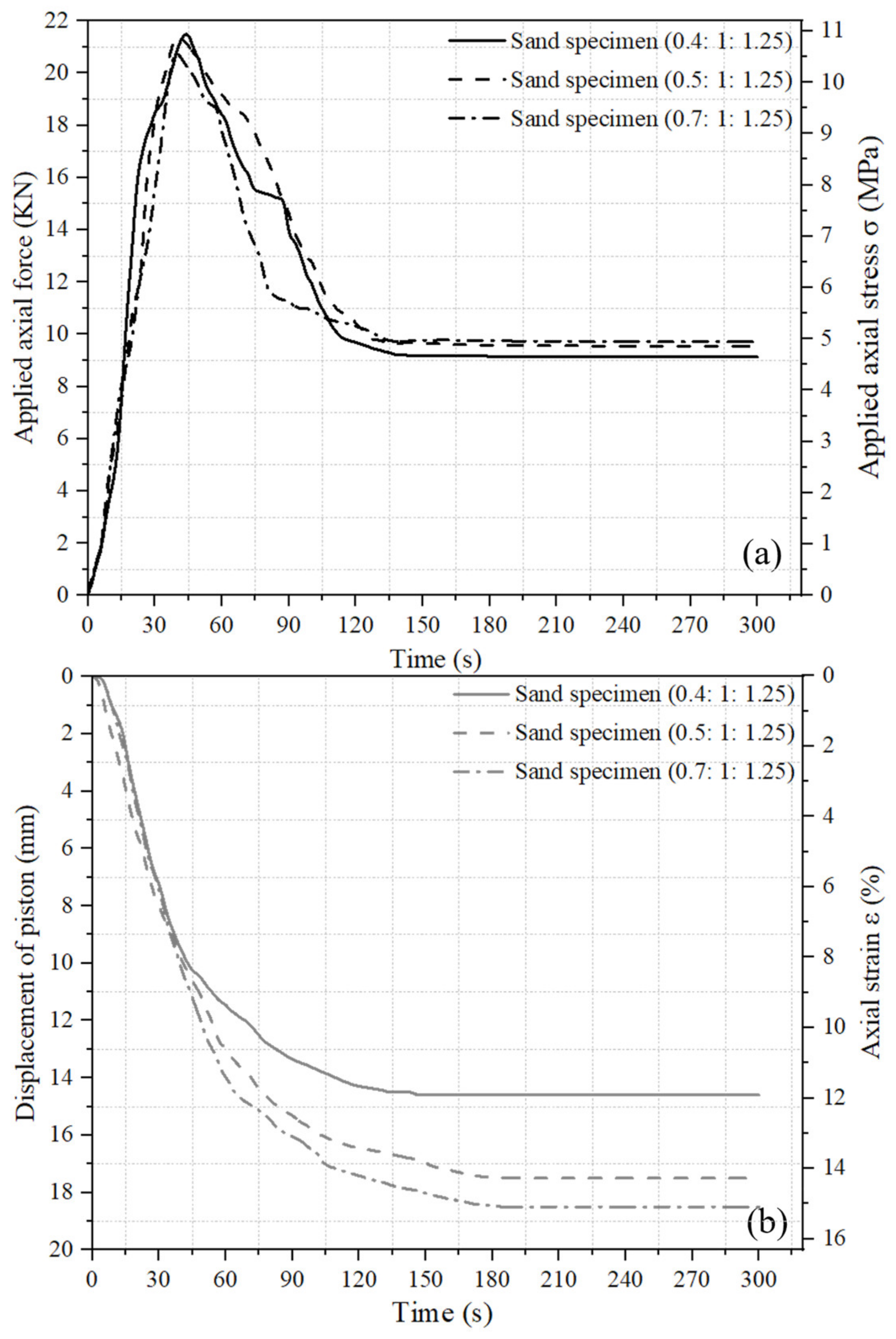

2.3. Variation in Axial Force and Displacement with Time during Pre-Setting Pressurization

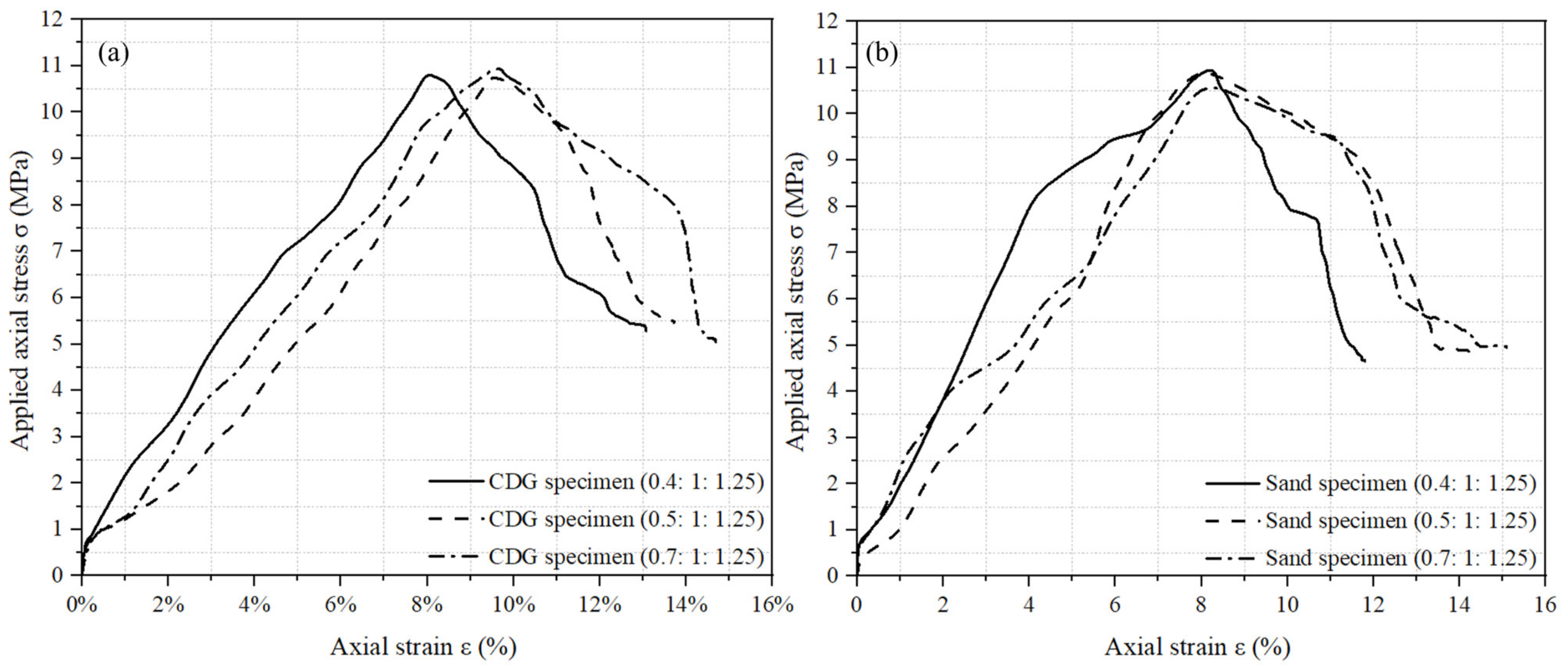

2.4. Variation in Axial Strain Versus the Applied Axial Stress during Pre-Setting Pressurization

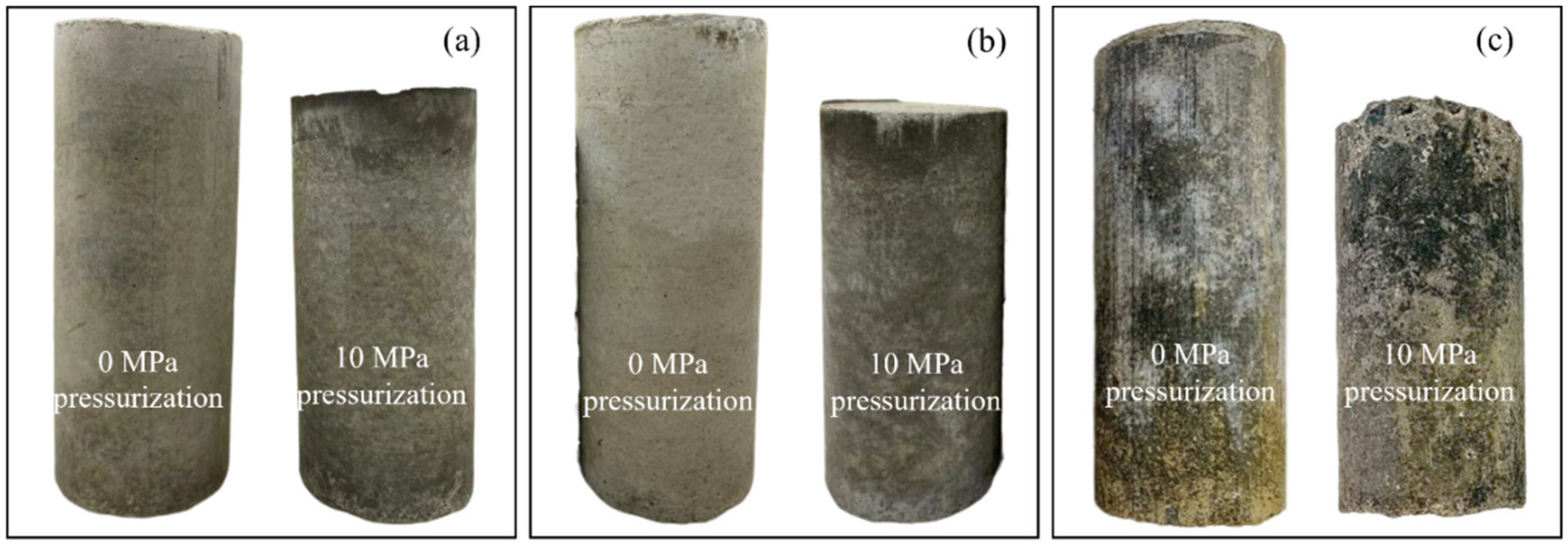

2.5. Prepared Specimens

3. Enhanced Properties of Hardened Concrete Specimens

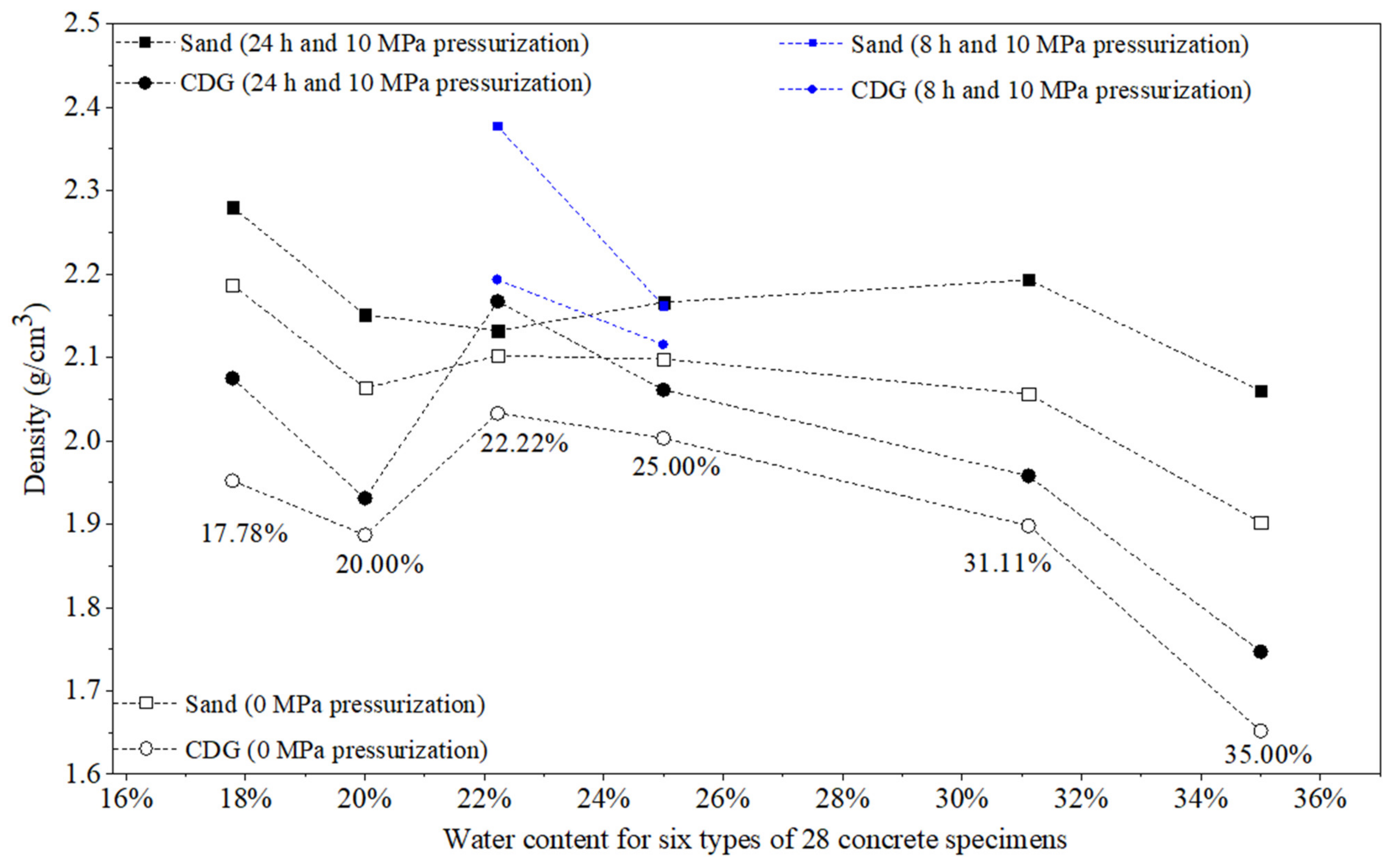

3.1. Results of Density

3.1.1. Effect of Water–Cement–Aggregate Ratio

3.1.2. Effect of the Pre-Setting Pressurization

3.1.3. Comparison between CDG and Sand

3.1.4. Key Findings

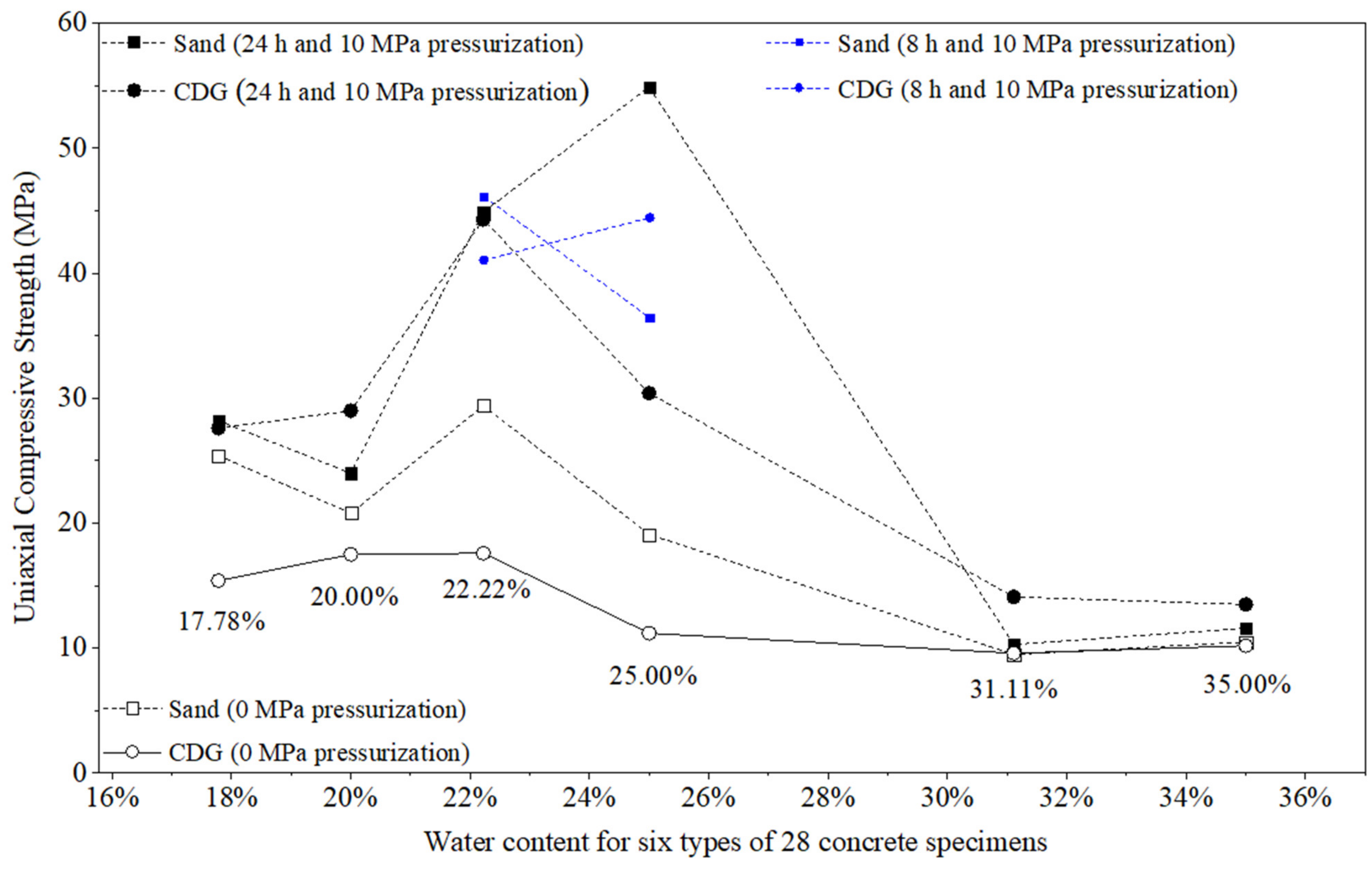

3.2. Results of UCS

3.2.1. Effect of Water–Cement–Aggregate Ratio

3.2.2. Effect of the Pre-Setting Pressurization

3.2.3. Comparisons between CDG and Sand

3.2.4. Key Findings

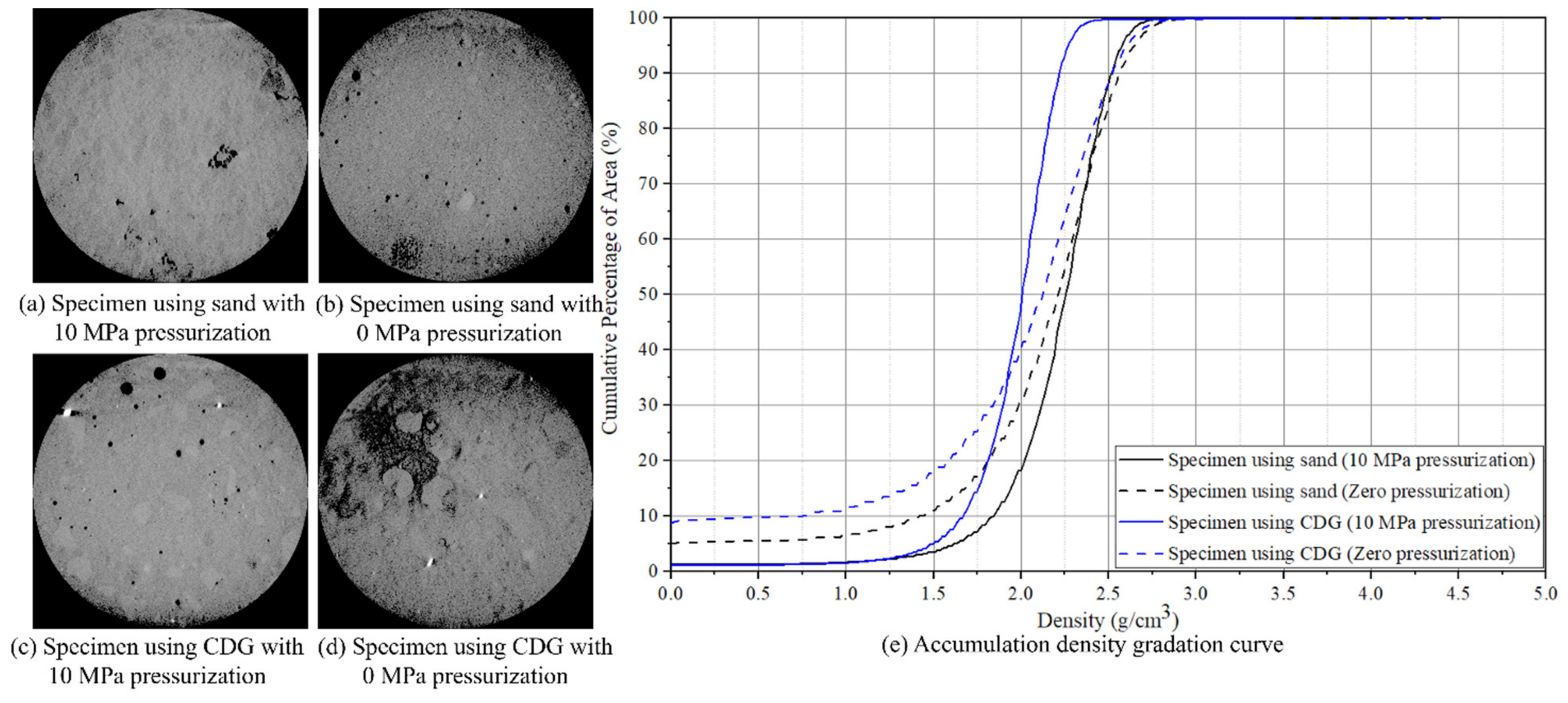

3.3. CT Observations

4. Summary and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aïtcin, P.-C.; Flatt, R.J. Science and Technology of Concrete Admixtures, 1st ed.; Elsevier Science: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and Concrete as an Engineering Material: An Historic Appraisal and Case Study Analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman: Harlow, UK, 1995. [Google Scholar]

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Concrete. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- EL Afandi, M.; Yehia, S.; Landolsi, T.; Qaddoumi, N.; Elchalakani, M. Concrete-to-Concrete Bond Strength: A Review. Constr. Build. Mater. 2023, 363, 129820. [Google Scholar] [CrossRef]

- Shen, J.; Xu, Q. Effect of Moisture Content and Porosity on Compressive Strength of Concrete during Drying at 105 °C. Constr. Build. Mater. 2019, 195, 19–27. [Google Scholar] [CrossRef]

- Roy, D.; Gouda, G.; Bobrowsky, A. Very high strength cement pastes prepared by hot pressing and other high pressure techniques. Cem. Concr. Res. 1972, 2, 349–366. [Google Scholar] [CrossRef]

- Bajza, A. Structure of compacted cement pastes. Cem. Concr. Res. 1983, 13, 239–245. [Google Scholar] [CrossRef]

- Justs, J.; Bajare, D.; Korjakins, A.; Mezinskis, G.; Locs, J.; Bumanis, G. Microstructural investigations of ultra-high performance concrete obtained by pressure application within the first 24 hours of hardening. Rigas Teh. Univ. Zinat. Raksti 2013, 14, 50–57. [Google Scholar] [CrossRef]

- Ipek, M.; Yilmaz, K.; Sümer, M.; Saribiyik, M. Effect of Pre-Setting Pressure Applied to Mechanical Behaviours of Reactive Powder Concrete during Setting Phase. Constr. Build. Mater. 2010, 25, 61–68. [Google Scholar] [CrossRef]

- İpek, M.; Yilmaz, K.; Uysal, M. The Effect of Pre-Setting Pressure Applied Flexural Strength and Fracture Toughness of Reactive Powder Concrete during the Setting Phase. Constr. Build. Mater. 2011, 26, 459–465. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Naghipour, M. Compressing fresh concrete technique and the effect of excess water content on physical–mechanical properties of compressed concrete. Mater. Des. 2012, 37, 256–267. [Google Scholar] [CrossRef]

- Nemati, M.; Nematzadeh, M.; Rahimi, S. Effect of Fresh Concrete Compression Technique on Pre- and Post-Heating Compressive Behavior of Steel Fiber-Reinforced Concrete: Experiments and RSM-Based Optimization. Constr. Build. Mater. 2023, 400, 132786. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Kazmi, S.M.S.; Wu, Y.-F. Development of New Layered Compression Casting Approach for Concrete. Cem. Concr. Compos. 2022, 134, 104738. [Google Scholar] [CrossRef]

- Wang, X.; Munir, M.J.; Wu, Y.-F. Effect of Mix Design Parameters on the Behavior of Compression Cast Concrete. J. Build. Eng. 2023, 76, 107399. [Google Scholar] [CrossRef]

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is Running out for Sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Chow, R.K.; Yip, S.W.; Kwan, A.K. Processing crushed rock fine to produce manufactured sand for improving overall performance of concrete. HKIE Trans. 2013, 20, 240–249. [Google Scholar] [CrossRef]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of Fine Recycled Aggregates in Concrete with Fly Ash and Steel Slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Santhosh, K.G.; Subhani, S.M.; Bahurudeen, A. Cleaner Production of Concrete by Using Industrial By-Products as Fine Aggregate: A Sustainable Solution to Excessive River Sand Mining. J. Build. Eng. 2021, 42, 102415. [Google Scholar] [CrossRef]

- Sing, C.; Love, P.; Tam, C. Review and exploration of river sand substitutes for concrete production in Asian countries. In Advances in Civil Engineering and Building Materials; CRC Press: Boca Raton, FL, USA, 2012; pp. 115–117. [Google Scholar] [CrossRef]

- Lumb, P. The Residual Soils of Hong Kong. Geotechnique 1965, 15, 180–194. [Google Scholar] [CrossRef]

- Shaw, R. Variations in Sub-Tropical Deep Weathering Profiles over the Kowloon Granite, Hong Kong. J. Geol. Soc. 1997, 154, 1077–1085. [Google Scholar] [CrossRef]

- Ma, S.; Song, Y.; Liu, J.; Kang, X.; Yue, Z.Q. Extended Wet Sieving Method for Determination of Complete Particle Size Distribution of General Soils. J. Rock Mech. Geotech. Eng. 2024, 16, 242–257. [Google Scholar] [CrossRef]

- Lin, H.; Zheng, S.; Lourenço, S.D.; Jaquin, P. Characterization of Coarse Soils Derived from Igneous Rocks for Rammed Earth. Eng. Geol. 2017, 228, 137–145. [Google Scholar] [CrossRef]

- Song, Y.; Ma, S.; Liu, J.; Yue, Z.Q. Laboratory Investigation of CDG Soil as Source of Fine Aggregates for Portland Cement Concrete. Constr. Build. Mater. 2023, 367, 130226. [Google Scholar] [CrossRef]

- Yue, Z.; Shang, Y.; Hu, R.; Tu, X. Five Test Methods for Porosity of Completely Decomposed Granite in Hong Kong. Int. J. Rock Mech. Min. Sci. 2004, 41, 201–208. [Google Scholar] [CrossRef]

- Dassekpo, J.-B.M.; Zha, X.; Zhan, J. Compressive Strength Performance of Geopolymer Paste Derived from Completely Decomposed Granite (CDG) and Partial Fly Ash Replacement. Constr. Build. Mater. 2017, 138, 195–203. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Z.; Chen, R.; Zhu, S.; Lin, J.; Tai, P. Compressive Strength of Fly Ash Based Geopolymer Utilizing Waste Completely Decomposed Granite. Case Stud. Constr. Mater. 2023, 19, e02667. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre Reinforced Cement-Based (FRC) Composites after over 40 Years of Development in Building and Civil Engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Habel, K.; Viviani, M.; Denarié, E.; Brühwiler, E. Development of the Mechanical Properties of an Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2006, 36, 1362–1370. [Google Scholar] [CrossRef]

- Moser, K.; Bergamini, A.; Christen, R.; Czaderski, C. Feasibility of Concrete Prestressed by Shape Memory Alloy Short Fibers. Mater. Struct. 2005, 38, 593–600. [Google Scholar] [CrossRef]

- Yu, K.; Wang, Y.; Yu, J.; Xu, S. A Strain-Hardening Cementitious Composites with the Tensile Capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- BSI, BS 5328-1; Concrete. Guide to Specifying Concrete. British Standard Institute: London, UK, 1997. [CrossRef]

- BSI, BS 12620; Aggregates for Concrete. British Standard Institute: London, UK, 2013. [CrossRef]

| Particle Type | Particle Sizes (mm) | Cumulative Passing Percentage (%) | |

|---|---|---|---|

| ISO Sand | CDG Soil | ||

| Gravel | 10 | 100 | 100 |

| 6.3 | 100 | 99.70 | |

| 5 | 100 | 98.95 | |

| 3.35 | 100 | 94.76 | |

| Coarse sand | 2.36 | 100 | 88.10 |

| 2 | 99.93 | 87.96 | |

| 1.18 | 93.43 | 73.99 | |

| Medium sand | 0.6 | 43.60 | 63.26 |

| 0.425 | 36.75 | 60.25 | |

| 0.3 | 36.13 | 57.12 | |

| Fine sand | 0.212 | 26.23 | 55.74 |

| 0.15 | 10.24 | 54.57 | |

| 0.075 | 0.23 | 52.66 | |

| Silt | 0.063 | 0.21 | 52.52 |

| Clay | 0.002 | 0 | 49.83 |

| Duration of Initial Pressurization (h) | Type of Aggregate | Water/Cement/ Aggregate Ratio | Water Content (%) | Density (g/cm3) | UCS (MPa) | ||

|---|---|---|---|---|---|---|---|

| 10 MPa Pressurization | 0 MPa Pressurization | 10 MPa Pressurization | 0 MPa Pressurization | ||||

| 24 | Sand | 0.4:1:1.25 | 17.78 | 2.280 | 2.187 | 28.2 | 25.4 |

| 0.4:1:1 | 20.00 | 2.151 | 2.063 | 24.0 | 20.8 | ||

| CDG | 0.4:1:1.25 | 17.78 | 2.075 | 1.952 | 27.6 | 15.4 | |

| 0.4:1:1 | 20.00 | 1.931 | 1.887 | 29.0 | 17.5 | ||

| 24 | Sand | 0.5:1:1.25 | 22.22 | 2.132 | 2.102 | 44.9 | 29.4 |

| 0.5:1:1 | 25.00 | 2.166 | 2.098 | 54.9 | 19.1 | ||

| CDG | 0.5:1:1.25 | 22.22 | 2.167 | 2.033 | 44.3 | 17.6 | |

| 0.5:1:1 | 25.00 | 2.061 | 2.003 | 30.4 | 11.2 | ||

| 8 | Sand | 0.5:1:1.25 | 22.22 | 2.377 | - | 46.1 | - |

| 0.5:1:1 | 25.00 | 2.162 | - | 36.4 | - | ||

| CDG | 0.5:1:1.25 | 22.22 | 2.193 | - | 41.0 | - | |

| 0.5:1:1 | 25.00 | 2.115 | - | 44.4 | - | ||

| 24 | Sand | 0.7:1:1.25 | 31.11 | 2.193 | 2.056 | 10.3 | 9.5 |

| 0.7:1:1 | 35.00 | 2.060 | 1.902 | 11.6 | 10.5 | ||

| CDG | 0.7:1:1.25 | 31.11 | 1.958 | 1.898 | 14.1 | 9.6 | |

| 0.7:1:1 | 35.00 | 1.747 | 1.652 | 13.5 | 10.2 | ||

| Type of Aggregates | Water/Cement/Aggregate Ratio | Increase in Density (g/cm3) | Increase in UCS (MPa) |

|---|---|---|---|

| CDG | 0.4:1:1.25 | 6.30% | 79.22% |

| 0.4:1:1 | 2.33% | 65.71% | |

| 0.5:1:1.25 | 6.59% | 151.70% | |

| 0.5:1:1 | 2.90% | 171.43% | |

| 0.7:1:1.25 | 3.16% | 46.88% | |

| 0.7:1:1 | 5.75% | 32.35% | |

| Sand | 0.4:1:1.25 | 4.25% | 11.02% |

| 0.4:1:1 | 4.27% | 15.38% | |

| 0.5:1:1.25 | 1.43% | 52.72% | |

| 0.5:1:1 | 3.24% | 187.43% | |

| 0.7:1:1.25 | 6.66% | 8.42% | |

| 0.7:1:1 | 8.31% | 10.48% |

| Source | Different Methods | Improved Properties |

|---|---|---|

| Roy et al. [7] | a. High temperature of 150 °C and 30 MPa pressurization were applied on fresh concrete. b. 60 MPa pressurization was applied on fresh concrete. | a. Increase the UCS value by up to 88.01%. Increase the homogeneity of hardened concrete specimens. b. Increase the UCS value by up to 17.27%. Increase the homogeneity of hardened concrete specimens. |

| Ipek et al. [10,11] | Six different (0, 5, 10, 15, 20, and 25 MPa) pressures were applied on fresh reactive powder concrete. | Under 25 MPa pre-setting pressurization, the density value of concrete was increased by 7.79%, the UCS value was increased by 103.68%, and the pore structure was improved. |

| Nematzadeh et al. [13,14] | Specific pressure was applied on fresh concrete with varying extra water contents (0%, 10%, 20%, and 30% of initial water content by weight) to expel excess water and air. | The UCS value of hardened concrete was increased by up to 185.9%, the modulus of elasticity was increased by up to 100.5%, and the water absorption was decreased by up to 49.7%. |

| Justs et al. [9] | Five different (10, 20, 30, 40, and 50 MPa) pressures were applied on fresh concrete. | Under 50 MPa pressurization, the density value of hardened concrete was increased by 6.39%, the UCS value was increased by 48%, and the porosity was decreased by 75.64%. |

| Wang et al. [15,16] | Compaction pressurization was applied on fresh concrete in three layers. Each layer of the concrete was compressed to the designated height under the pressurization. | The UCS value of hardened concrete was increased by up to 100%, and the modulus of elasticity was increased by up to 50%. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Yue, Z.Q.; Ding, Y. Improvement in Mechanical Properties of Completely Decomposed Granite Soil Concrete Fabricated with Pre-Setting Pressurization. Materials 2024, 17, 4314. https://doi.org/10.3390/ma17174314

Song Y, Yue ZQ, Ding Y. Improvement in Mechanical Properties of Completely Decomposed Granite Soil Concrete Fabricated with Pre-Setting Pressurization. Materials. 2024; 17(17):4314. https://doi.org/10.3390/ma17174314

Chicago/Turabian StyleSong, Yi, Zhongqi Quentin Yue, and Yanlu Ding. 2024. "Improvement in Mechanical Properties of Completely Decomposed Granite Soil Concrete Fabricated with Pre-Setting Pressurization" Materials 17, no. 17: 4314. https://doi.org/10.3390/ma17174314

APA StyleSong, Y., Yue, Z. Q., & Ding, Y. (2024). Improvement in Mechanical Properties of Completely Decomposed Granite Soil Concrete Fabricated with Pre-Setting Pressurization. Materials, 17(17), 4314. https://doi.org/10.3390/ma17174314