Development of Sustainable Construction Materials from Inert Waste Mixtures Using the Mechanosynthesis Process

Abstract

:1. Introduction

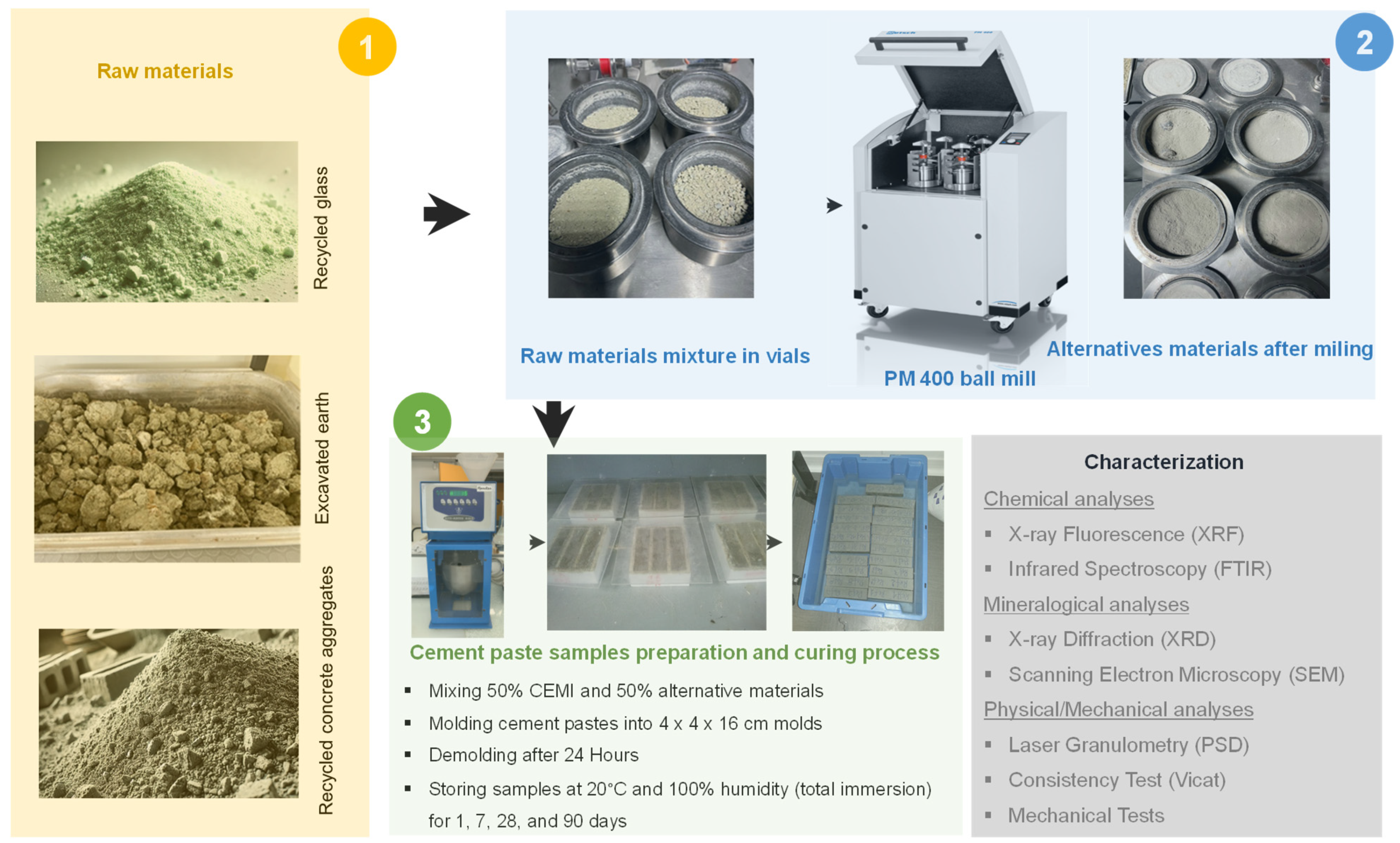

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Alternative Material Powder Preparation

2.2.2. Sample Paste Preparation

2.2.3. Characterization Techniques

3. Results and Discussion

3.1. Characterization of Raw Materials and Alternative Material Powders

- Rearrangement and Stacking: Particles slide past each other with minimal deformation or fracturing, leading to a decrease in particle size and a change in shape.

- Elastic and Plastic Deformation: Particles experience both elastic and plastic deformations, which are often characterized by “cold welding”, where particles stick together, causing an increase in particle size through agglomeration.

- Fracture: Particles are broken apart, resulting in smaller particles and potentially additional fragmentation, leading to a significant reduction in particle size.

3.2. Characterization of Cement Paste and Modified Cement Pastes

4. Conclusions

- Material property enhancements:

- Intensive ball milling (400 rpm, 15 min) significantly amorphized alternative materials, enhancing their reactivity.

- Nanostructuring of quartz and calcite was observed in F1 and F2 formulations after milling.

- Milled materials demonstrated improved compressive strength compared to their unmilled counterparts.

- Compressive strength performance:

- The modified F1 formulation surpassed reference CEM I and CEM III cements in compressive strength tests at 28 and 90 days, achieving particularly high strengths.

- For F1, milling at 400 rpm for 15 min achieved a high compressive strength of 61 MPa at 90 days.

- Additionally, the F1 formulation outperformed the F2 formulation in cement replacement, regardless of milling conditions.

- Impact on CO2 emissions:

- Reducing milling time correlated with lower CO2 equivalent emissions, indicating a positive correlation between milling duration and environmental impact.

- Compared to CEM I and CEM II cements, all formulations exhibited reduced CO2 impacts, with decreases of 49.8% and 29.5%, respectively.

- Strategy for construction waste management:

- Incorporating inert waste (recycled glass, recycled concrete, excavated earth) into cement formulations suggests a promising strategy to reduce the cement industry’s carbon footprint while addressing construction waste management effectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Bernardo, M.; Gomes, M.C.; de Brito, J. Demolition waste generation for development of a regional management chain model. Waste Manag. 2016, 49, 156–169. [Google Scholar] [CrossRef]

- Vegas, I.; Broos, K.; Nielsen, P.; Lambertz, O.; Lisbona, A. Upgrading the quality of mixed recycled aggregates from construction and demolition waste by using near-infrared sorting technology. Constr. Build. Mater. 2015, 75, 121–128. [Google Scholar] [CrossRef]

- Harrison, E; Berenjian, A; Seifan, M. Recycling of waste glass as aggregate in cement-based materials. Environ. Sci. Ecotechnology 2020, 4, 100064. [CrossRef] [PubMed]

- Bouchenafa, O.; Hamzaoui, R.; Florence, C.; Regneau, L. Valorisation of fines recycled concrete obtained by mechanosynthesis for construction materials. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Organisme ADEM. Déchets Chiffres-Clés—L’essentiel Edition en 2023. Available online: https://librairie.ademe.fr/dechets-economie-circulaire/6108-dechets-chiffres-cles-edition-2023.html (accessed on 26 October 2023).

- EUROSTAT, Waste Statistics—Statistics Explained. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics%23Total_waste_generation (accessed on 26 October 2023).

- Official Journal of the European Communities. I (Acts Whose Publication is Obligatory). COUNCIL DIRECTIVE 1999/31/EC on the Landfill of Waste. 16 July 1999. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31999L0031 (accessed on 26 October 2023).

- Zhang, J.; Liu, G.; Chen, B.; Song, D.; Qi, J.; Liu, X. Analysis of CO2 Emission for the cement manufacturing with alternative raw materials: A LCA-based framework. Energy Procedia 2014, 61, 2541–2545. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Sit, S.P.; Layzell, D.B. Alternative fuels co-fired with natural gas in the pre-calciner of a cement plant: Energy and material flows. Fuel 2021, 295, 120544. [Google Scholar] [CrossRef]

- Chen, A.; Chen, Z.; Lin, B. Theoretical evaluation on CO2 removal potential of enhanced weathering based on shrinking core model. Environ. Res. Lett. 2023, 18, 124018. [Google Scholar] [CrossRef]

- CEN-EN 197-1; Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements. AFNOR Editions: La Plaine Saint-Denis, France, 2012.

- NF EN 197-5; Portland Composite Cement CEMII C-M and Composite Cement CEMVI. AFNOR Editions: La Plaine Saint-Denis, France, 2021.

- CEN-EN 197-6; Cement—Part 6: Cement with Recycled Building Materials. AFNOR Editions: La Plaine Saint-Denis, France, 2023.

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Sadiqul Islam, G.M.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Han, D.; Xiong, W.; Chen, Y.; Xu, J. Mechanical properties of excavated soil waste-based cementitious products at normal condition or after water soaked: A liter-ature review of experimental results. Case Stud. Constr. Mater. 2023, 18, 02111. [Google Scholar] [CrossRef]

- Ruth Bola Oliveira, D.; Leite, G.; Possan, E.; Marques Filho, J. Concrete powder waste as a substitution for Portland cement for environment-friendly cement production. Constr. Build. Mater. 2023, 395, 132382. [Google Scholar] [CrossRef]

- Baptiste Luzu, B.; Duc, M.; Assia Djerbi, A.; Gautron, L. High performance illitic clay-based geopolymer: Influence of the mechanochemical activation duration on the strength development. Chapter Calcined Clays Sustain. Concr. 2020, 25, 363–373. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- El-Eskandarany, M.E. Mechanical Alloying for Fabrication of Advanced Engineering Materials; United States of America by Noyes Publications/William Andrew Publishing: Norwich, NY, USA, 2001; pp. 1–254. [Google Scholar]

- Gaffet, E.; Le Caër, G. Mechanical Processing for Nanomaterials. Encycl. Nanosci. Nanotechnol. 2004, 5, 91–129. [Google Scholar]

- Benjamin, J.S.; Volin, E.E. The Mechanism of Mechanical Alloying. Metall. Trans. 1974, 5, 1929–1933. [Google Scholar] [CrossRef]

- Hamzaoui, R.; Elkedim, O.; Gaffet, E.; Greneche, J.M. X-ray diffraction, magnetic and Mössbauer studies of mechanically alloyed Fe-20%Ni powders. J. Magn. Magn. Mater 2005, 294, 145–149. [Google Scholar] [CrossRef]

- Duliana, P.; Bjkb, W.; Kajtoch, C.; Wieczorek-Ciurowa, K. A High-Energy Ball Milling as a Useful Technique for the Synthesis of CaCu3Ti4O12 Electroceramics. Acta Phys. Pol. A 2014, 126, 931–937. [Google Scholar] [CrossRef]

- Hamzaoui, R.; Bouchenafa, O. Equivalent Cement Clinker Obtained by Indirect Mechanosynthesis Process. Materials 2020, 21, 5045. [Google Scholar] [CrossRef] [PubMed]

- NF EN 196-3 Standard; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. AFNOR Editions: La Plaine Saint-Denis, France, 2017.

- NF, EN 196-1 Standard; Methods of Testing Cement Determination of Strength. AFNOR Editions: La Plaine Saint-Denis, France, 2016.

- Ben Maaouia, O.; Hamzaoui, R.; Bennabi, A.; Colin, J.; Colina, C. Chromium stabili-zation and trapping in the cement matrix of recycled concrete aggregates. Constr. Build. Mater. 2018, 191, 667–678. [Google Scholar] [CrossRef]

- Eva Kuzielová, E.; Slaný, M.; Žemlicka, M.; Másilko, J.; Palou, M.T. Phase Composition of Silica Fume—Portland Cement Systems Formed under Hydrothermal Curing Evaluated by FTIR, XRD, and TGA. Materials 2021, 14, 2786. [Google Scholar] [CrossRef] [PubMed]

- Bouchenafa, O. PhD Thesis Report. Mechanosynthesis and Construction Materials: Optimization and Application for Clinkerization and Geopolymerization. Defended in ESTP, Cachan France 22 July 2019. Available online: https://theses.fr/2019PESC1003 (accessed on 26 October 2023).

- ElectricityMaps. Data on Electricity Production and CO2 Emissions in France. 2024. Available online: https://app.electricitymaps.com/zone/FR (accessed on 5 August 2024).

- DIOGEN. Données Spécifiques. 2024. Available online: https://www.afgc.asso.fr/ressources/diogen/diogen/donnees-specifiques/ (accessed on 6 August 2024).

| Samples/Elements (%) | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | TiO2 | SO3 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| Recycled glass | 14.24 | 66.62 | 1.86 | 0.11 | 2.10 | 0,70 | 0.29 | 0.31 | 13.80 |

| Recycled concrete | 42.34 | 42.23 | 7.30 | 3.90 | 1.85 | 1.80 | 0.50 | 1.50 | 0.93 |

| Excavated soils | 13.68 | 53.27 | 15.92 | 8.23 | 4.12 | 5.02 | 1.10 | 0.69 | 0.24 |

| Samples/Elements (%) | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | TiO2 | SO3 | Na2O | PZh | HDh |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 24.25 | 52.93 | 7.47 | 2.70 | 2.70 | 2.00 | 0.47 | 0.79 | 6.1 | 0.40 | 0.38 |

| F2 | 18.57 | 52.37 | 13.12 | 5.83 | 3.50 | 3.72 | 0.86 | 0.50 | 2.6 | 0.28 | 0.26 |

| Milling Time (mm)/Milling Rotation Speed (rpm) | 200 | 400 |

|---|---|---|

| 5 | 91.67 W | 183.33 W |

| 15 | 275.00 W | 550.00 W |

| Samples/Particles Size | D10 [µm] | D50 [µm] | D90 [µm] |

|---|---|---|---|

| F1 200 rpm-5 min | 1.66 | 11.16 | 77.48 |

| F1 200 rpm-15 min | 1.24 | 8.38 | 44.69 |

| F1 400 rpm-5 min | 1.27 | 8.50 | 58.58 |

| F1 400 rpm-15 min | 1.09 | 7.33 | 39.72 |

| F2 200 rpm-5 min | 1.24 | 4.94 | 20.82 |

| F2 200 rpm-15 min | 1.19 | 4.72 | 17.22 |

| F2 400 rpm-5 min | 1.29 | 8.50 | 58.58 |

| F2 400 rpm-15 min | 1.18 | 8.52 | 36.13 |

| Milling Conditions | 200 rpm-5 min | 200 rpm-15 min | 400 rpm-5 min | 400 rpm-15 min |

|---|---|---|---|---|

| KgCO2equi/t | 2.75 | 8.25 | 5.50 | 16.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamzaoui, R.; Bouchenafa, O.; Idir, R.; Djerbi, A.; Fen-Chong, T.; Florence, C.; Boutin, F. Development of Sustainable Construction Materials from Inert Waste Mixtures Using the Mechanosynthesis Process. Materials 2024, 17, 4301. https://doi.org/10.3390/ma17174301

Hamzaoui R, Bouchenafa O, Idir R, Djerbi A, Fen-Chong T, Florence C, Boutin F. Development of Sustainable Construction Materials from Inert Waste Mixtures Using the Mechanosynthesis Process. Materials. 2024; 17(17):4301. https://doi.org/10.3390/ma17174301

Chicago/Turabian StyleHamzaoui, Rabah, Othmane Bouchenafa, Rachida Idir, Assia Djerbi, Teddy Fen-Chong, Céline Florence, and François Boutin. 2024. "Development of Sustainable Construction Materials from Inert Waste Mixtures Using the Mechanosynthesis Process" Materials 17, no. 17: 4301. https://doi.org/10.3390/ma17174301

APA StyleHamzaoui, R., Bouchenafa, O., Idir, R., Djerbi, A., Fen-Chong, T., Florence, C., & Boutin, F. (2024). Development of Sustainable Construction Materials from Inert Waste Mixtures Using the Mechanosynthesis Process. Materials, 17(17), 4301. https://doi.org/10.3390/ma17174301