Research on the Erosion Law and Protective Measures of L360N Steel for Surface Pipelines Used in Shale Gas Extraction

Abstract

:1. Introduction

2. Materials and Methods

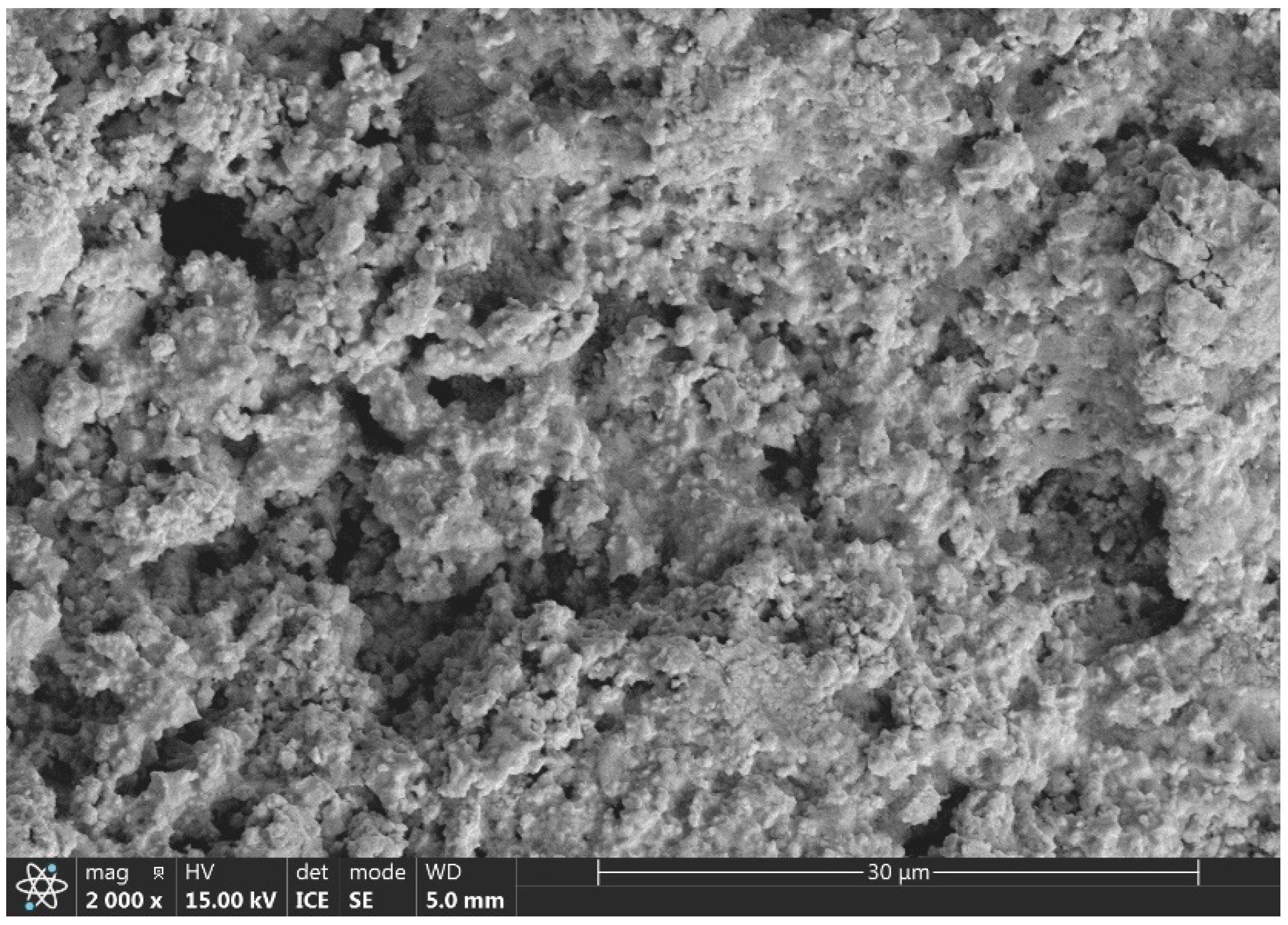

2.1. Materials

2.2. Method

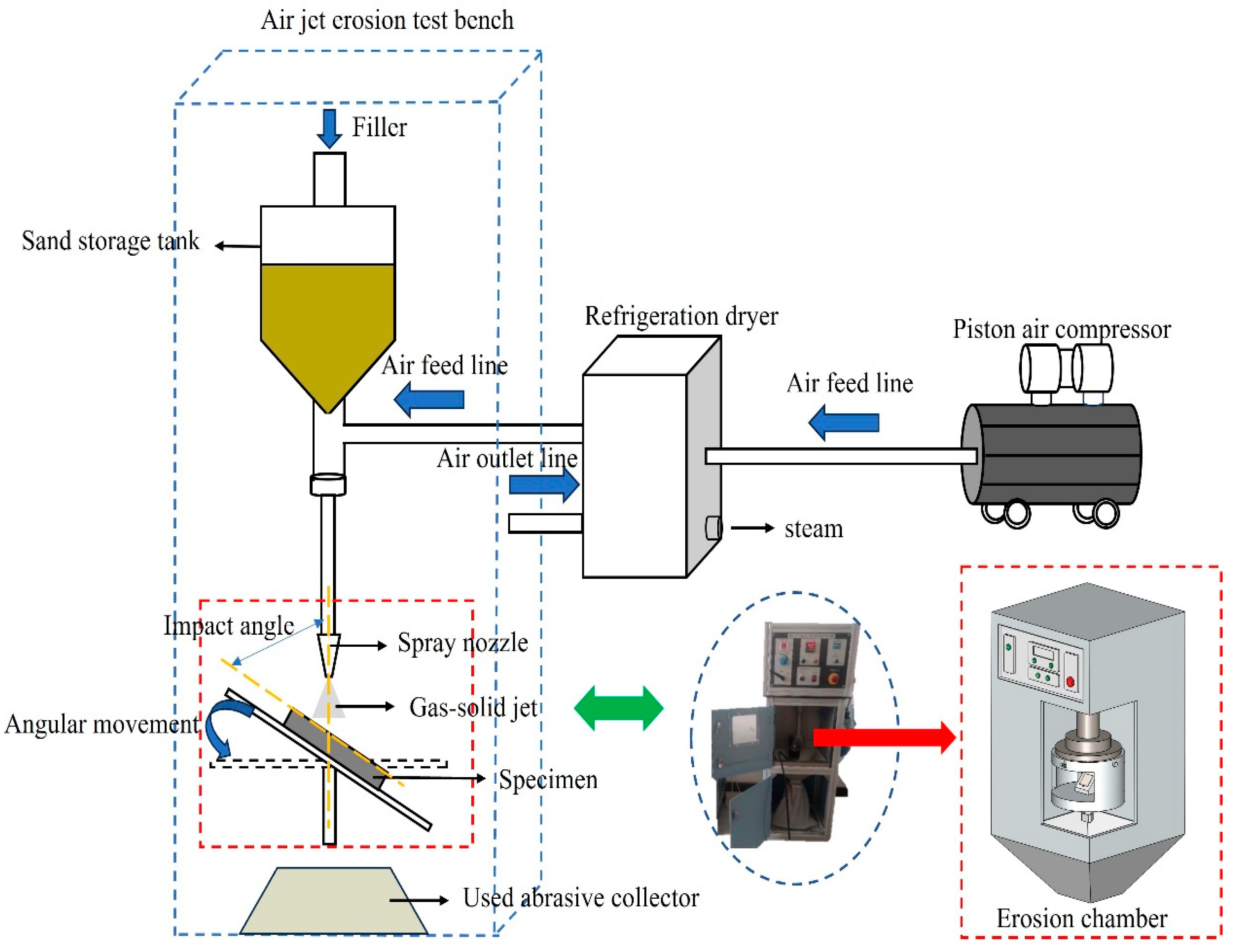

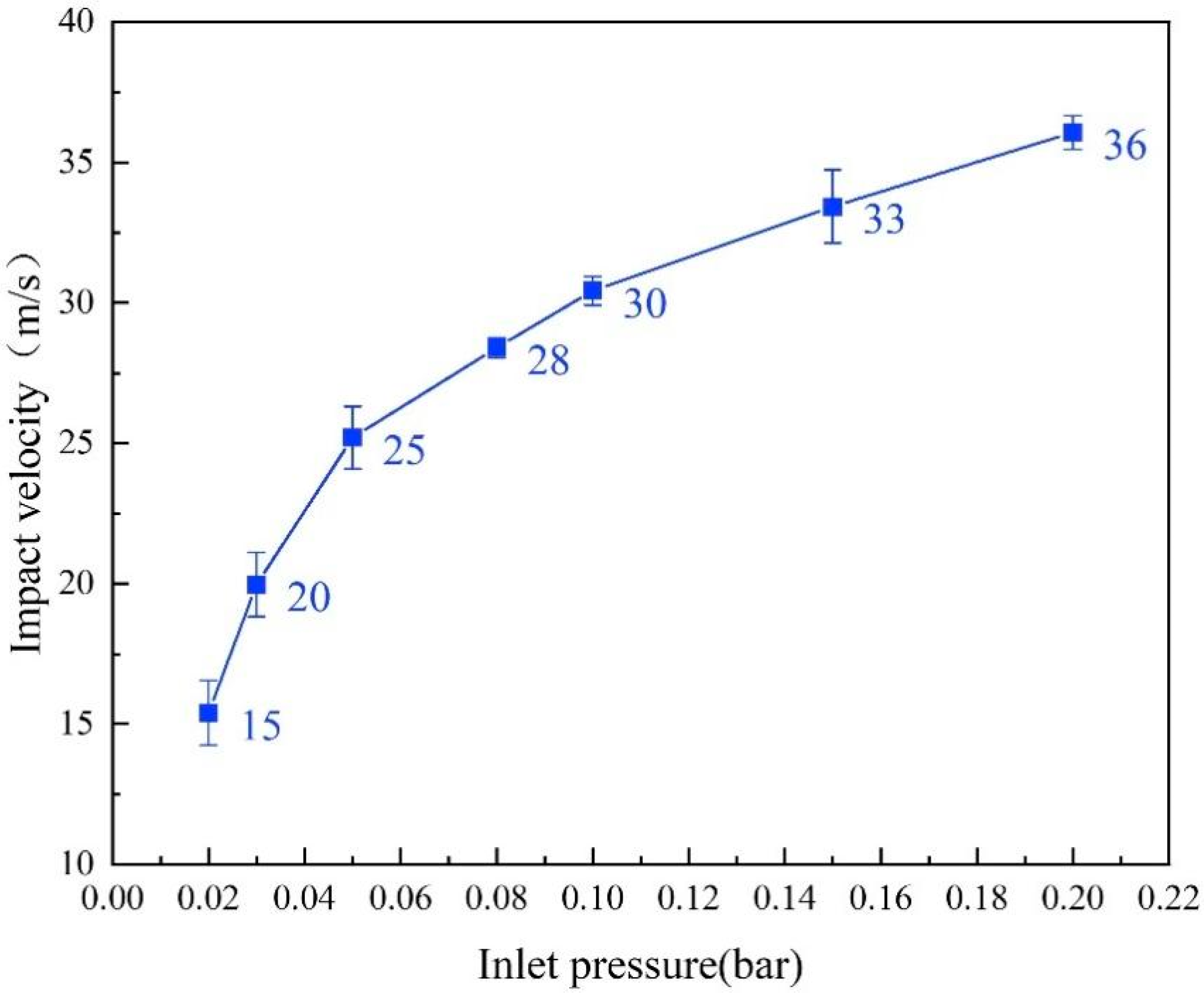

2.2.1. Experimental Device

2.2.2. Measurement Method

2.2.3. Experimental Scheme

3. Results and Discussion

3.1. Vickers Hardness Analysis

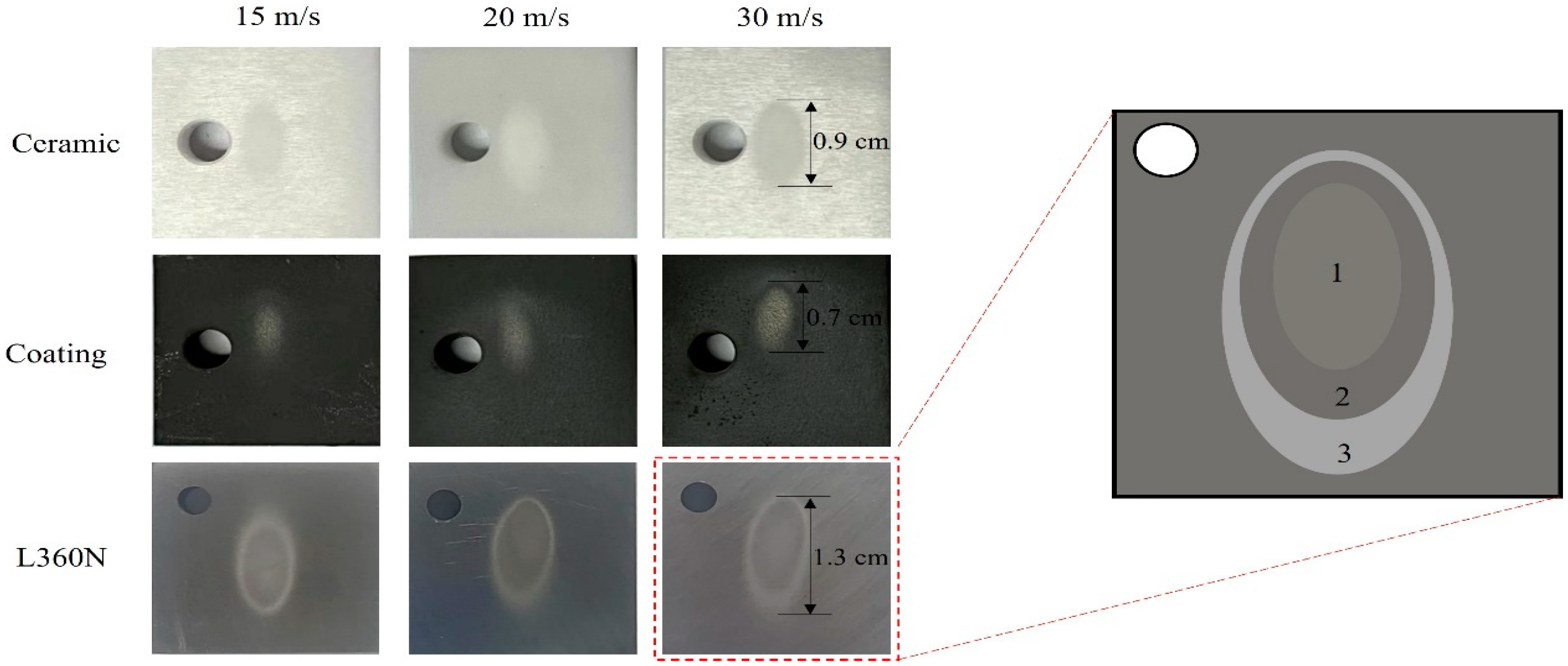

3.2. Macroscopic Morphology Analysis

3.3. Influence of Impact Velocity on Erosion Rate

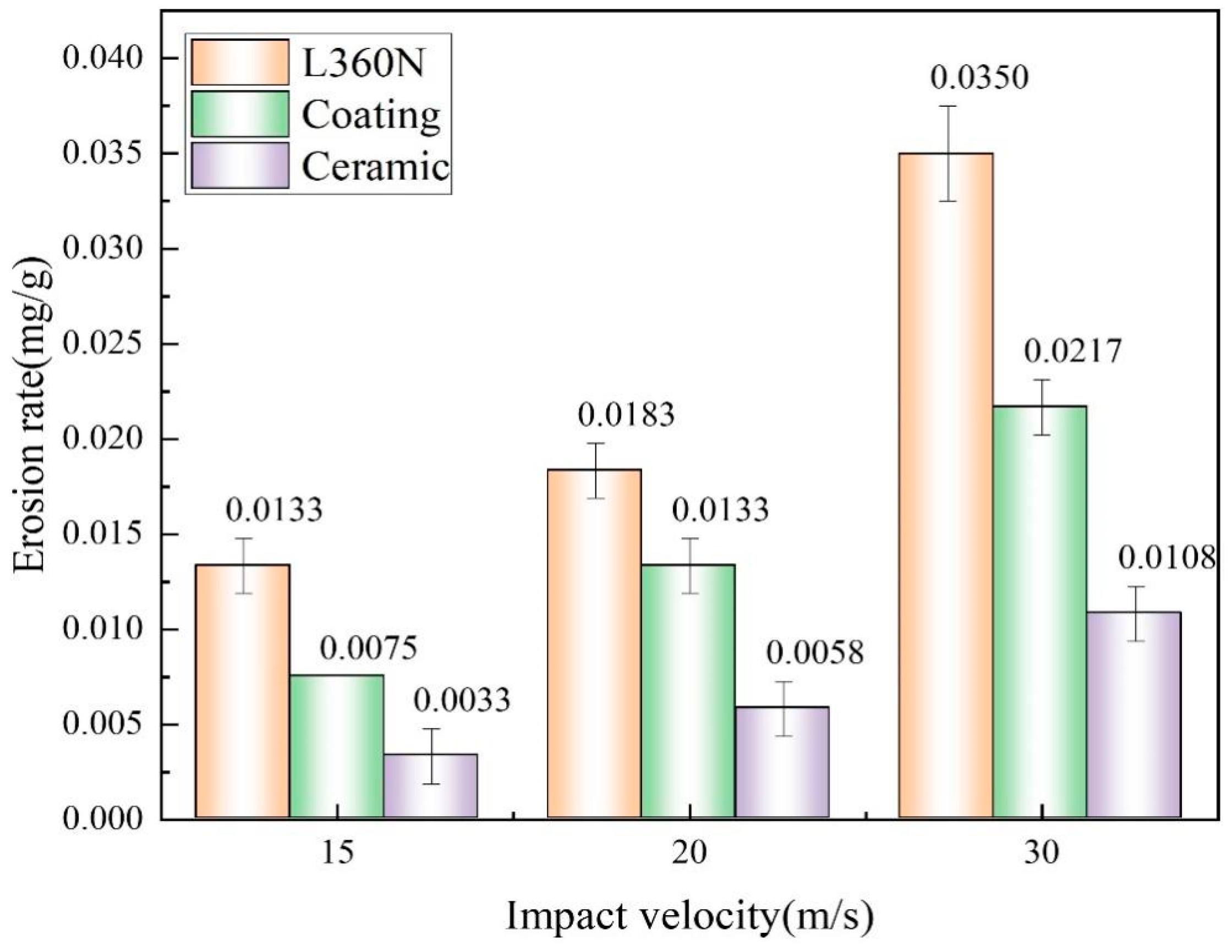

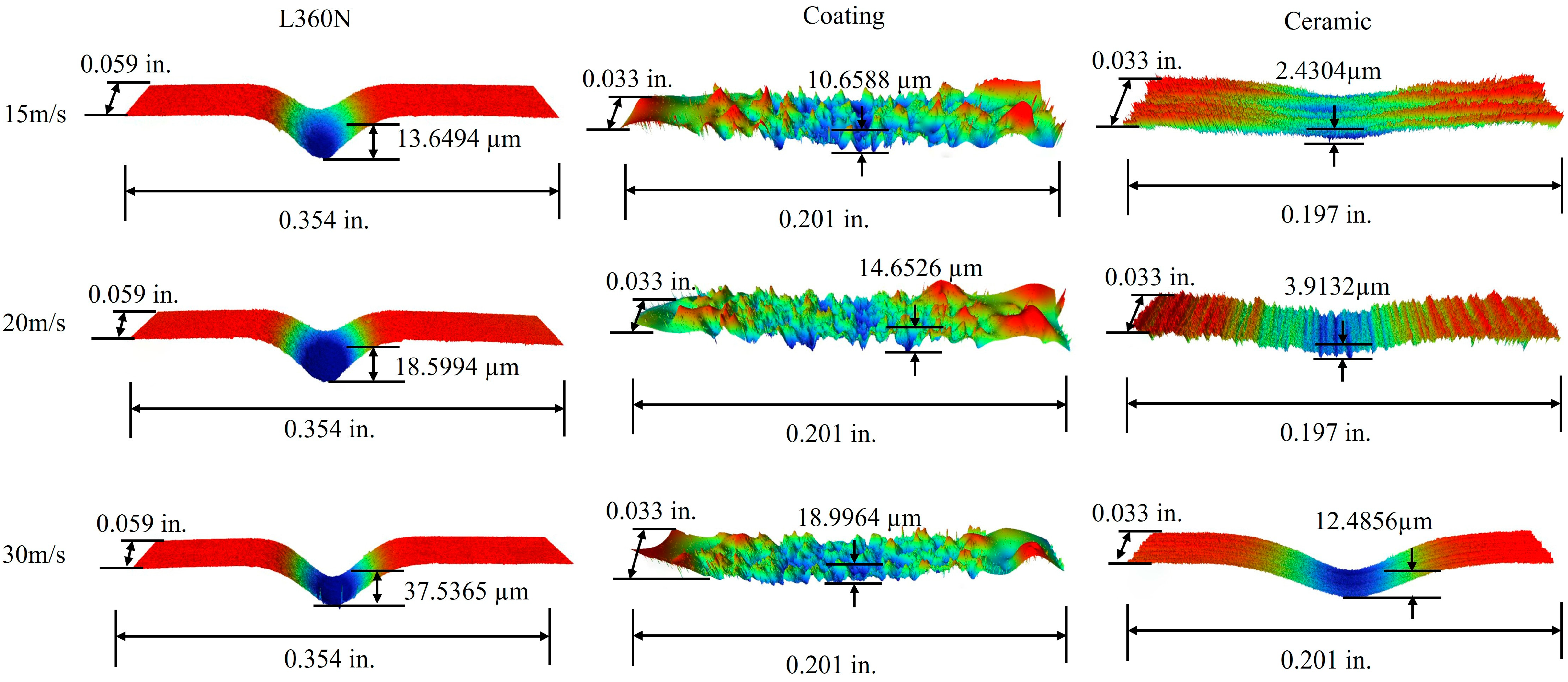

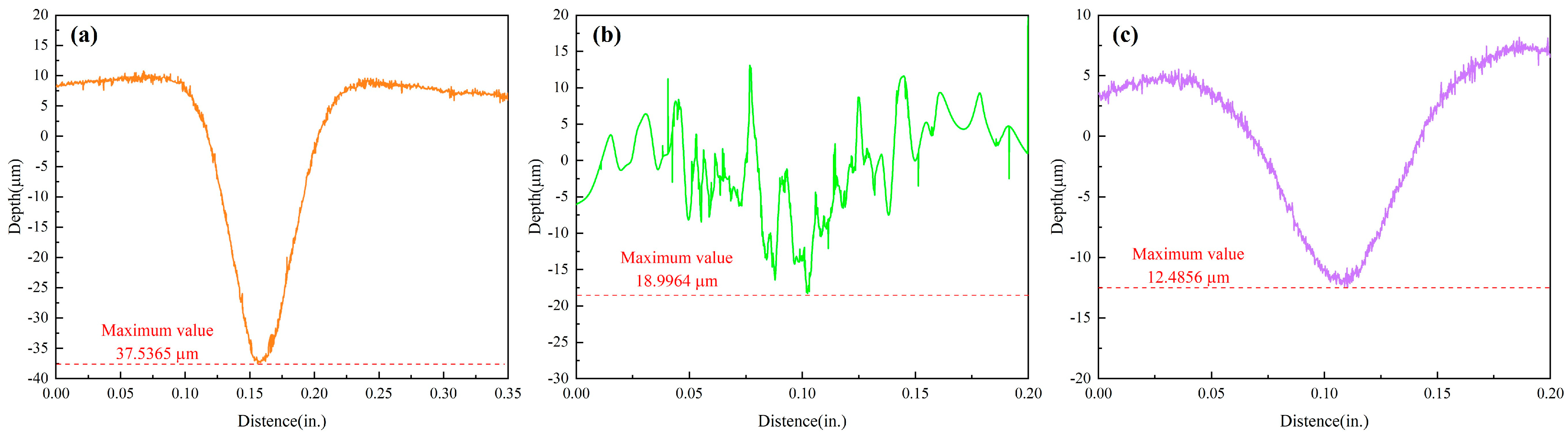

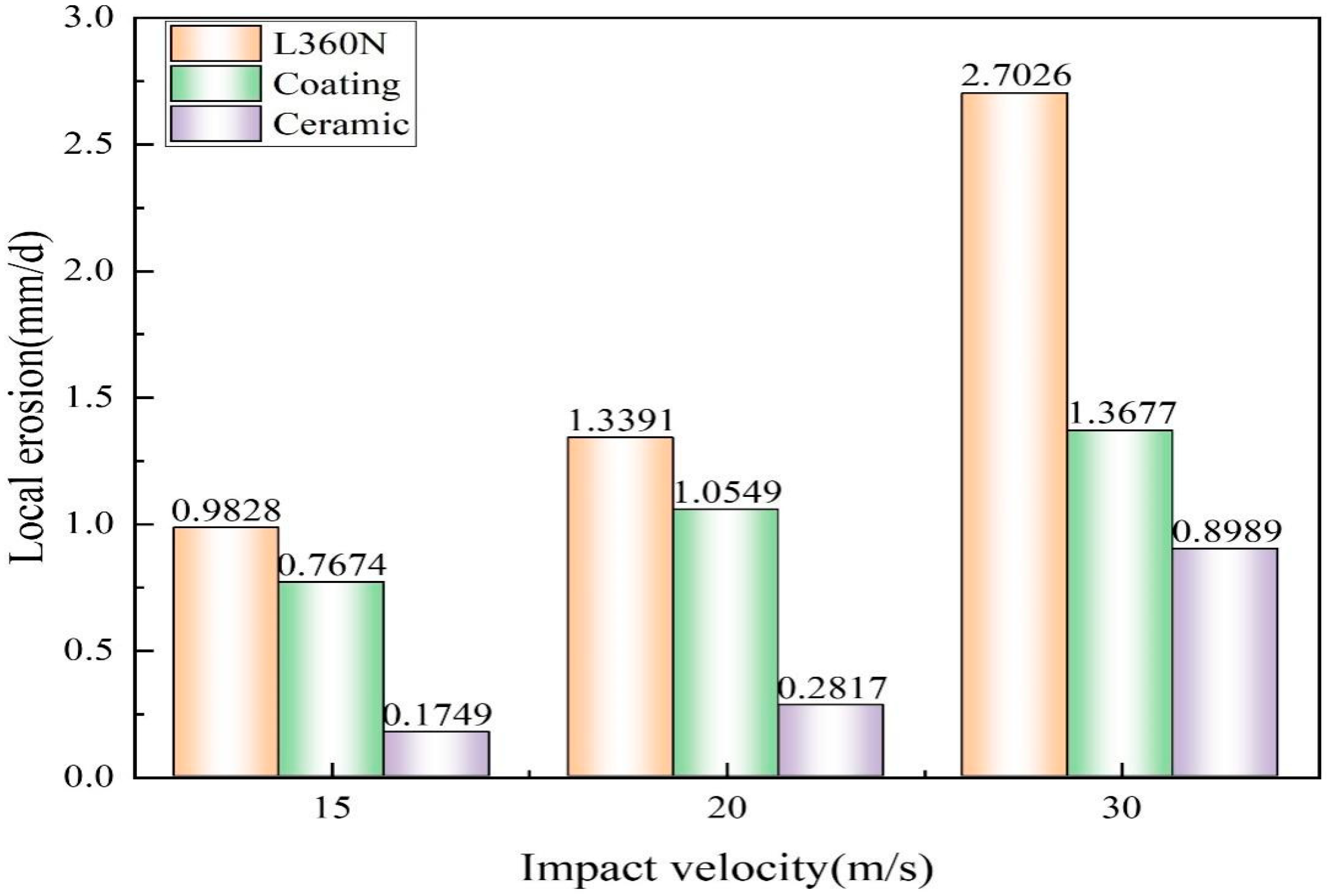

3.4. 3D Surface Profiles

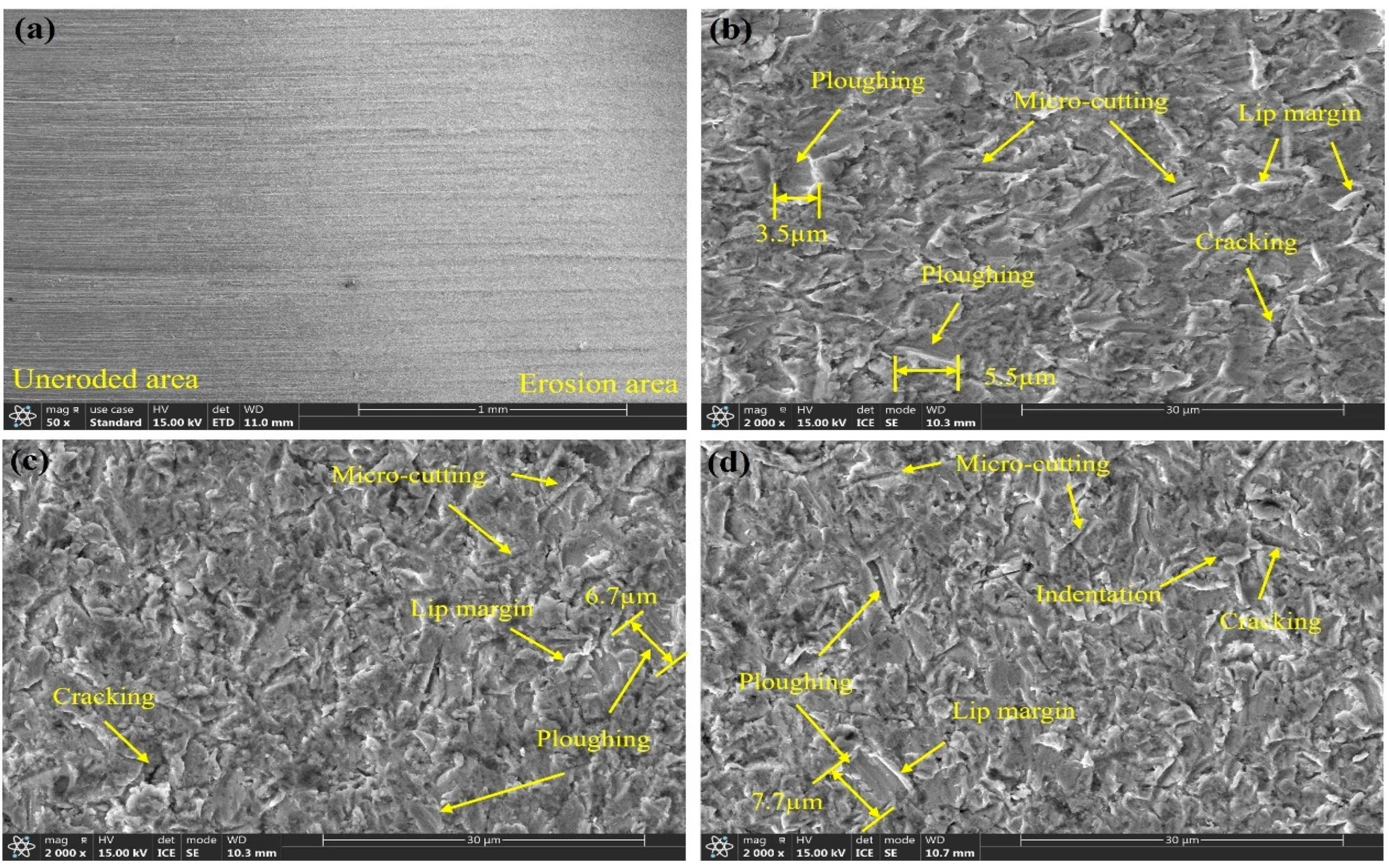

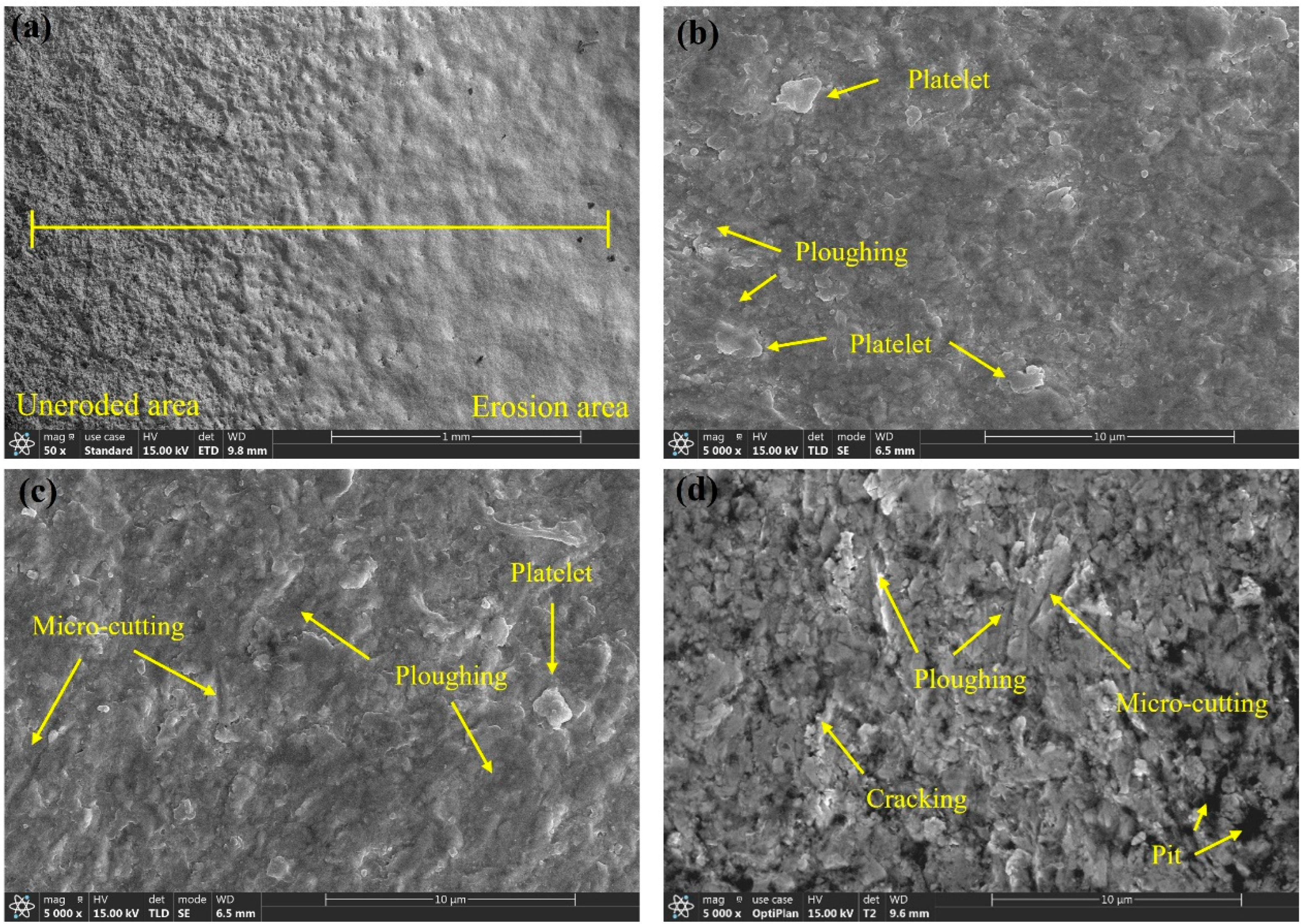

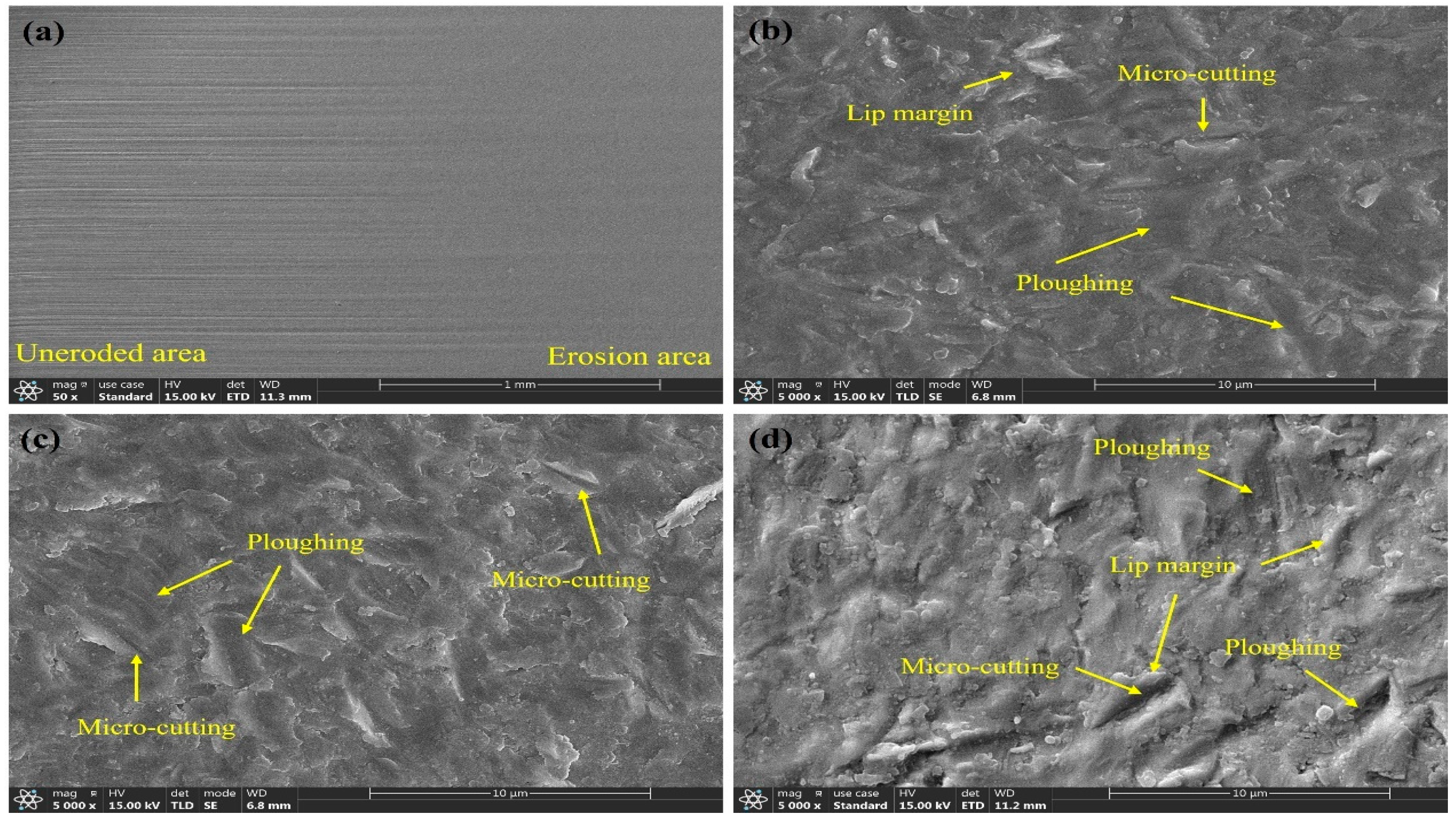

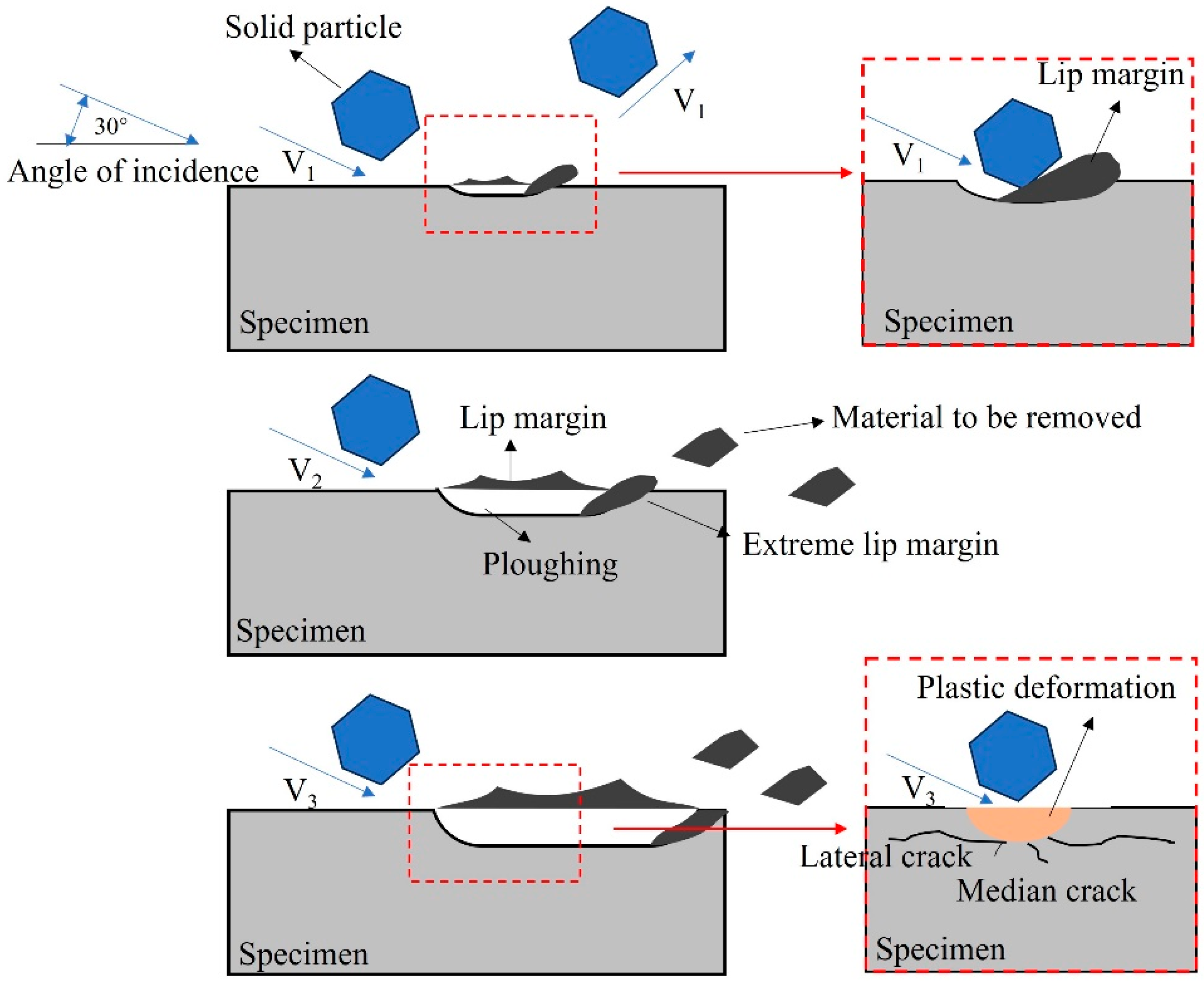

3.5. Erosion Mechanism Analysis

4. Conclusions

- (1)

- Under an impact angle of 30°, the erosion rate, erosion depth, and local erosion rate of L360N, coating, and ceramic increased with the increase in impact velocity. Under an impact velocity of 30 m/s, maximum erosion rates of L360N, coating, and ceramic were, respectively, 0.0350 mg/g, 0.0217 mg/g, and 0.0108 mg/g. Maximum erosion depths of L360N, coating, and ceramic were, respectively, 37.5365 µm, 18.9964 µm, and 12.4856 µm. Due to their high hardness, the erosion rates of the coatings and ceramics were seldom changed with an increase in impact velocity. Among the three materials, ceramic exhibited the best erosion resistance, whereas L360N had the worst erosion resistance.

- (2)

- The erosion mechanisms of the three materials under different flow rates were primarily micro-cutting and plowing. Cracks and indentations appeared on the surface of L360N. The detachment of matrix and hard particles occurs on the coating surface. The ceramic surface remained intact, and no cracks or pits were observed. For the same material, erosion morphology varied with particle impact velocity, but the change in particle impact velocity did not affect the primary erosion mechanism. Increasing the impact velocity increases the impact energy and tangential force of solid particles on the surface, thereby increasing the erosion rate.

- (3)

- The erosion rate, erosion depth, and local erosion rate of high-hardness ceramics were all smaller than those of coating. The erosion resistance of ceramics was much better than that of coatings. Therefore, erosion-resistant components such as zirconia ceramic-lined bends and zirconia ceramic-lined tees were used to protect shale gas surface pipelines. After two years of service, no failure occurred, and the erosion and wear problem of surface pipelines caused by proppant flowback was solved.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, G.Y.; Zhao, W.W.; Wang, Y.R.; Tang, Y.F.; Xie, M. Analysis on corrosion-induced failure of shale gas gathering pipelines in the southern Sichuan Basin of China. Eng. Fail. Anal. 2021, 130, 105796. [Google Scholar] [CrossRef]

- Gregory, K.B.; Vidic, R.D.; Dzombak, D.A. Water management challenges associated with the production of shale gas by hydraulic fracturing. Elements 2011, 7, 181–186. [Google Scholar] [CrossRef]

- Zeng, D.; Zhang, S.; Li, J.; Wang, X.; Tian, G.; Zhang, X.; Yu, H.Y.; Li, X.G. An experimental study on casing perforation erosion during sand fracturing. Wear 2023, 528, 204980. [Google Scholar] [CrossRef]

- Chi, M.H.; Zeng, X.G.; Gao, Y.P.; Li, W.; Jiang, H.Y.; Sun, R.C. The erosion rate prediction for the elbow in shale gas gathering and transportation system: RSM and GA-BP-ANN modeling. Powder Technol. 2024, 435, 119429. [Google Scholar] [CrossRef]

- Parsi, M.; Najmi, K.; Najafifard, F.; Hassani, S.; McLaury, B.S.; Shirazi, S.A. A comprehensive review of solid particle erosion modeling for oil and gas wells and pipelines applications. J. Nat. Gas Sci. Eng. 2014, 21, 850–873. [Google Scholar] [CrossRef]

- Hong, B.Y.; Li, Y.B.; Li, Y.; Gong, J.; Yu, Y.F.; Huang, A.D.; Li, X.P. Numerical simulation of solid particle erosion in the gas-liquid flow of key pipe fittings in shale gas fields. Case Stud. Therm. Eng. 2023, 42, 102742. [Google Scholar] [CrossRef]

- Hong, B.Y.; Li, X.P.; Li, Y.B.; Li, Y.; Yu, Y.F.; Wang, Y.M.; Gong, J.; Ai, D. Numerical simulation of elbow erosion in shale gas fields under gas-solid two-phase flow. Energies 2021, 14, 3804. [Google Scholar] [CrossRef]

- Hong, B.Y.; Li, Y.B.; Li, X.P.; Li, G.; Huang, O.; Ji, S.P.; Li, W.D.; Gong, J.; Guo, J. Experimental investigation of erosion rate for gas-solid two-phase flow in 304 stainless/L245 carbon steel. Petrol. Sci. 2022, 19, 1347–1360. [Google Scholar] [CrossRef]

- Vite-Torres, M.; Laguna-Camacho, J.R.; Baldenebro-Castillo, R.E.; Gallardo-Hernández, E.A.; Vera-Cárdenas, E.E.; Vite-Torres, J. Study of solid particle erosion on AISI 420 stainless steel using angular silicon carbide and steel round grit particles. Wear 2013, 301, 383–389. [Google Scholar] [CrossRef]

- Babu, P.S.; Basu, B.; Sundararajan, G. The influence of erodent hardness on the erosion behavior of detonation sprayed WC-12Co coatings. Wear 2011, 270, 903–913. [Google Scholar] [CrossRef]

- Liu, E.B.; Huang, S.; Tian, D.C.; Shi, L.M.; Peng, S.B.; Zheng, H. Experimental and numerical simulation study on the erosion behavior of the elbow of gathering pipeline in shale gas field. Petrol. Sci. 2024, 21, 1257–1274. [Google Scholar] [CrossRef]

- Zaragoza-Granados, J.; Gallardo-Hernandez, E.A.; Vite-Torres, M.; Sedano-de la Rosa, C. Erosion behaviour of AISI 310 stainless steel at 450 C under turbulent swirling impinging jets. Wear 2019, 426, 637–642. [Google Scholar] [CrossRef]

- Jia, W.L.; Zhang, Y.R.; Li, C.J.; Luo, P.; Song, X.Q.; Wang, Y.Z.; Hu, X.Y. Experimental and numerical simulation of erosion-corrosion of 90 steel elbow in shale gas pipeline. J. Nat. Gas Sci. Eng. 2021, 89, 103871. [Google Scholar] [CrossRef]

- Zhu, H.J.; Zhao, H.N.; Pan, Q.; Li, X. Coupling analysis of fluid-structure interaction and flow erosion of gas-solid flow in elbow pipe. Adv. Mech. Eng. 2014, 2014, 815945. [Google Scholar] [CrossRef]

- Peng, W.S.; Cao, X.W.; Li, M.; Wang, P.; Bian, J.; Lin, C.G. Sand erosion prediction models for two-phase flow pipe bends and their application in gas-liquid-solid multiphase flow erosion. Powder Technol. 2023, 421, 118421. [Google Scholar] [CrossRef]

- Song, X.Q.; Luo, P.; Luo, S.Y.; Huang, S.W.; Wang, Z.L. Numerical simulation study on the influence of incident position on erosion characteristics of gas-particle two-phase flow in 90° elbow. Adv. Mech. Eng. 2017, 9, 1687814017733249. [Google Scholar] [CrossRef]

- Zhang, E.B.; Zeng, D.Z.; Zhu, H.J.; Li, S.G.; Chen, D.B.; Ding, Y.Y.; Tian, G. Numerical simulation for erosion effects of three-phase flow containing sulfur particles on elbows in high sour gas fields. Petroleum 2018, 4, 158–167. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thirumalaikumarasamy, D.; Thirumal, P.; Barathiraja, R. Influences of Mechanical, Corrosion, erosion and tribological performance of cold sprayed Coatings A review. Mater. Today Proc. 2021, 46, 7581–7587. [Google Scholar] [CrossRef]

- Sharma, R.K.; Das, R.K.; Kumar, S.R. Effect of chromium–titanium on corrosion and erosion of HVOF coating. Surf. Eng. 2022, 38, 366–374. [Google Scholar] [CrossRef]

- González, M.A.; Rodríguez, E.; Mojardín, E.; Jiménez, O.; Guillen, H.; Ibarra, J. Study of the erosive wear behaviour of cryogenically and tempered WC-CoCr coating deposited by HVOF. Wear 2017, 376, 595–607. [Google Scholar] [CrossRef]

- Geng, Z.; Hou, S.; Shi, G.; Duan, D.; Li, S. Tribological behaviour at various temperatures of WC-Co coatings prepared using different thermal spraying techniques. Tribol. Int. 2016, 104, 36–44. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.M.; Börner, T.; Koivuluoto, H.; Matikainen, V.; Lusvarghi, L.; Vuoristo, P. Sliding and abrasive wear behaviour of HVOF-and HVAF-sprayed Cr3C2–NiCr hardmetal coatings. Wear 2016, 358, 32–50. [Google Scholar] [CrossRef]

- Ćurković, L.; Landek, D.; Švagelj, Z.; Gabelica, I. The volume erosion rate of the slip cast monolithic and composite ceramics. Adv. Appl. Ceram. 2023, 122, 119–128. [Google Scholar] [CrossRef]

- Bhosale, D.G.; Prabhu, T.R.; Rathod, W.S.; Patil, M.A.; Rukhande, S.W. High temperature solid particle erosion behaviour of SS 316L and thermal sprayed WC-Cr3C2–Ni coatings. Wear 2020, 462, 203520. [Google Scholar] [CrossRef]

- de Portu, G.; Pinasco, P.; Melandri, C.; Capiani, C.; Guardamagna, C.; Lorenzoni, L.; Cernuschi, F. Solid particle erosion behavior of laminated ceramic structures. Wear 2020, 442, 203147. [Google Scholar] [CrossRef]

- Medvedovski, E. Advanced ceramics and coatings for erosion-related applications in mineral and oil and gas production: A technical review. Int. J. Appl. Ceram. Technol. 2023, 20, 612–659. [Google Scholar] [CrossRef]

- ASTM-G76; Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International: West Conshohocken, PA, USA, 2018.

- Deng, K.; Zhou, N.; Lin, Y.; Cheng, J.; Bing, L.; Jing, Z. Experimental and numerical study on the high-speed gas-solid nozzle erosion of choke manifold material in high pressure and high production gas well. Powder Technol. 2024, 438, 119628. [Google Scholar] [CrossRef]

- Erdoğan, A.A.; Feyzullahoğlu, E.; Fidan, S.; Sinmazçelik, T. Investigation of erosive wear behaviors of AA6082-T6 aluminum alloy. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 520–530. [Google Scholar] [CrossRef]

- Verdi, D.; Cortés, R.; Chia, G.Y.; Tay, G. Erosion behaviour of laser cladded Inconel 625-Vanadium carbide metal matrix composites coatings manufactured with different reinforcement contents. Surf. Coat. Tech. 2024, 476, 130282. [Google Scholar] [CrossRef]

- Laguna-Camacho, J.R.; Marquina-Chávez, A.; Mendez-Mendez, J.V.; Vite-Torres, M.; Gallardo-Hernandez, E.A. Solid particle erosion of AISI 304, 316 and 420 stainless steels. Wear 2013, 301, 398–405. [Google Scholar] [CrossRef]

- Modi, O.P.; Prasad, B.K.; Jha, A.K. Influence of alumina dispersoid and test parameters on erosive wear behaviour of a cast zinc–aluminium alloy. Wear 2006, 260, 895–902. [Google Scholar] [CrossRef]

- Liu, B.; Liu, X.; Deng, K.H.; Lin, K.H.; Zhou, N.T.; Mei, Z.B.; Li, S.G. Erosion Mechanism of 30CrMo Steel Impacted by High Speed Solid Particles. Surf. Technol. 2023, 52, 135–145. [Google Scholar] [CrossRef]

- Ribu, D.C.; Rajesh, R.; Thirumalaikumarasamy, D.; Kaladgi, A.R.; Saleel, C.A.; Nisar, K.S.; Afzal, A. Experimental investigation of erosion corrosion performance and slurry erosion mechanism of HVOF sprayed WC-10Co coatings using design of experiment approach. J. Mater. Res. Technol. 2022, 18, 293–314. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Tang, C.Y.; Yao, J.; Zeng, Z.H.; Dong, S.G. Investigation of erosion behavior of 304 stainless steel under solid–liquid jet flow impinging at 30. Pet. Sci. 2020, 17, 1135–1150. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, K.; Wang, Y. Baffle effect of exposed WC particles in the clearance on slurry erosion behavior of cemented carbide surface. Mater. Today Commun. 2024, 39, 109071. [Google Scholar] [CrossRef]

- Kiatisereekul, A.; Fakpan, K. High temperature erosion of T22 steel coated by Cr–Ni electroplating, HVOF sprayed stellite–6 and WC–12Co. Mater. Today Proc. 2022, 52, 2523–2528. [Google Scholar] [CrossRef]

- Grilec, K.; Ćurković, L.; Kumić, I.; Baršić, G. Erosion mechanisms of aluminium nitride ceramics at different impact angles. Mater. Werkst. 2011, 42, 712–717. [Google Scholar] [CrossRef]

- Li, X.; Ding, H.; Huang, Z.; Fang, M.; Liu, B.; Wu, X.; Chen, S. Solid particle erosion-wear behavior of SiC–Si3N4 composite ceramic at elevated temperature. Ceram. Int. 2014, 40, 16201–16207. [Google Scholar] [CrossRef]

| Material | Chemical Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Ni | Cr | Mn | Si | P | S | V | Mo | Cu | Fe | |

| L360N | 0.15 | 0.019 | 0.04 | 1.350 | 0.380 | 0.011 | 0.005 | 0.003 | <0.004 | 0.013 | Bal. |

| Material | Chemical Composition | |||

|---|---|---|---|---|

| O | Y | Hf | Zr | |

| Ceramic | 13.97 | 3.24 | 1.52 | Bal. |

| Material | Chemical Composition | ||||

|---|---|---|---|---|---|

| C | O | Cr | Co | W | |

| Coating | 6.09 | 1.66 | 3.63 | 11.91 | Bal. |

| Experimental Parameters | Setting |

|---|---|

| Erodent | Quartz sand |

| materials | L360N, ceramic, and coating |

| Impact velocity (m/s) | 15, 20, and 30 |

| Experimental temperature (°C) | Room temperature |

| Impact angle (°) | 30 |

| Particle mass flow (g/min) | 2 |

| Test duration (min) | 20 |

| Materials | Vickers Hardness (HV) | |||||

|---|---|---|---|---|---|---|

| Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Means | |

| L360N | 221 | 226 | 202 | 268 | 240 | 231 |

| Ceramic | 1749 | 1703 | 1649 | 1469 | 1652 | 1645 |

| Coating | 1072 | 1065 | 1122 | 1063 | 1036 | 1072 |

| Materials | L360N | Coating | Ceramic |

|---|---|---|---|

| Impact Velocity (m/s) | Maximum Erosion Depths (µm) | ||

| 15 | 13.6494 | 10.6588 | 2.4304 |

| 20 | 18.5994 | 14.6526 | 3.9132 |

| 30 | 37.5365 | 18.9964 | 12.4856 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, S.; Peng, L.; Li, Y.; Xu, Y.; Huang, H.; Yuan, X. Research on the Erosion Law and Protective Measures of L360N Steel for Surface Pipelines Used in Shale Gas Extraction. Materials 2024, 17, 4278. https://doi.org/10.3390/ma17174278

Huo S, Peng L, Li Y, Xu Y, Huang H, Yuan X. Research on the Erosion Law and Protective Measures of L360N Steel for Surface Pipelines Used in Shale Gas Extraction. Materials. 2024; 17(17):4278. https://doi.org/10.3390/ma17174278

Chicago/Turabian StyleHuo, Shaoquan, Lincai Peng, Yunpeng Li, Yong Xu, Hongbing Huang, and Xi Yuan. 2024. "Research on the Erosion Law and Protective Measures of L360N Steel for Surface Pipelines Used in Shale Gas Extraction" Materials 17, no. 17: 4278. https://doi.org/10.3390/ma17174278

APA StyleHuo, S., Peng, L., Li, Y., Xu, Y., Huang, H., & Yuan, X. (2024). Research on the Erosion Law and Protective Measures of L360N Steel for Surface Pipelines Used in Shale Gas Extraction. Materials, 17(17), 4278. https://doi.org/10.3390/ma17174278