A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives

Abstract

1. Introduction

- ▪

- Traditional radical polymerization—conventional, which is characterized by mild reaction conditions and can be used in the presence of most monomers;

- ▪

- Controlled radical polymerization—to which belong: (a) reversible addition-fragmentation chain transfer (RAFT) and (b) atom transfer radical polymerization (ATRP) [9].

2. Physical Stimuli

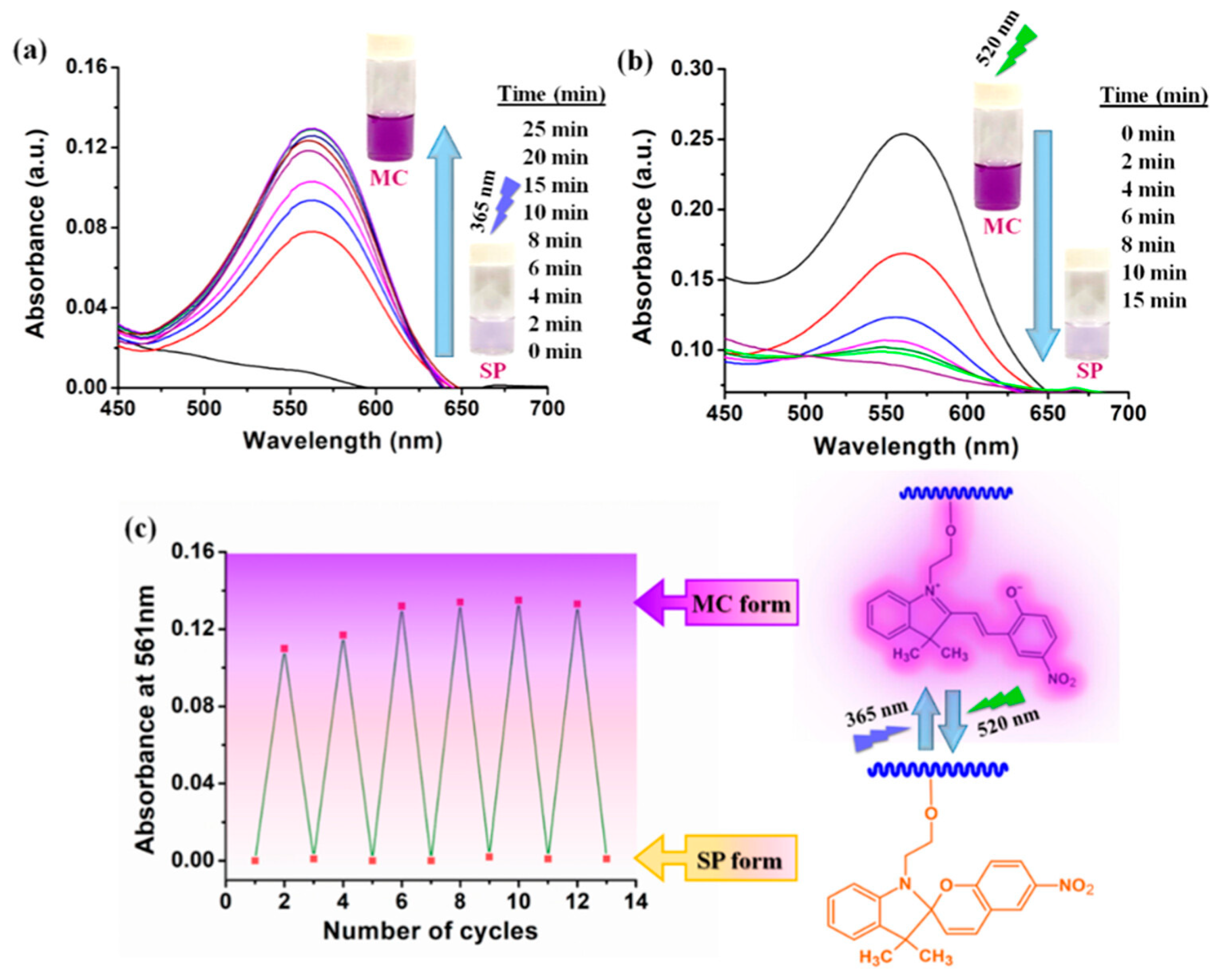

2.1. Light-Responsive Polymers

- ▪

- photocleavage—which involves the occurrence of chemical changes creating a physicochemically changed product;

- ▪

- photochromic—based on the occurrence of isomeric changes based on cis-trans isomerism, intramolecular transfer of groups or a hydrogen atom, or pericyclic changes [11].

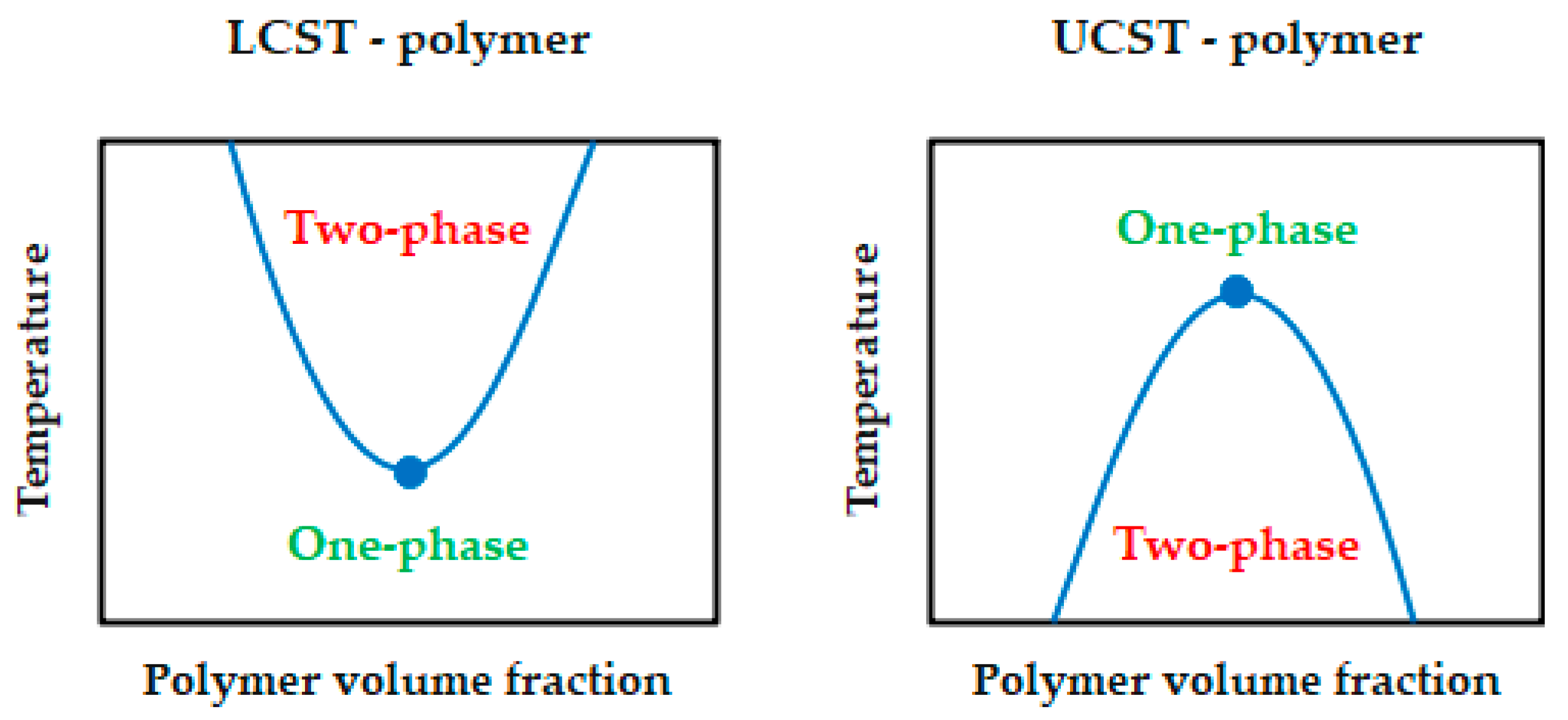

2.2. Temperature-Responsive Polymers

- ▪

- UCST—upper critical solution temperature. UCST—is poorly known.

- ▪

- LCST—lower critical solution temperature—indicates the maximum temperature at which the polymer is soluble, and one phase can be observed. Above it, phase separation takes place [9]. LCST-polymers are well known. The existence of a single phase comes from the interactions between the polymer and solvent units. The most common are hydrogen bonds with water [9,11,20].

2.3. Electric Field-Responsive Polymers

- ▪

- Ionic EAPs (electro-active polymers)—the electric field causes a change in local ion concentrations and the occurrence of electroreactivity. Their characteristic feature is low reaction speed, low reactivity, and the need to use low voltages;

- ▪

- Dielectric EAPs—where the response arises as a result of electrostatic forces arising between two electrodes applied to the system. Their characteristic feature is high reaction speed, high reactivity, and the need to use high voltages [23].

- ▪

- Polypyrrole (PPy)—characterized by high biocompatibility and high conductivity;

- ▪

- Polyaniline (PANI)—characterized by high chemical stability, good processability and conductivity;

- ▪

- Poly(3,4-ethylene dioxythiophene) (PEDOT)—which, in addition to being biocompatible and highly conductivity, is also hydrophobicity;

- ▪

2.4. Magnetic Field-Responsive Polymers

2.5. Chromoactive Polymers

- ▪

- Photochromic materials—which are distinguished by a reversible color change when exposed to light with a high UV content;

- ▪

- Thermochromic materials—the color change occurs as a result of temperature. The dye used determines the permanent or transient occurrence of the color;

- ▪

- Electroactive materials—the occurrence of a potential difference triggers a color change and absorption spectrum [27].

2.6. Ultrasound-Responsive Polymers

3. Chemical Stimuli

3.1. pH-Responsive Polymers

- (a)

- In the case of acidic polymers—protons attach at low pH and release of protons at high pH;

- (b)

- Basic polymers react by ionization/deionization in the pH range of 7–11 [19].

- (1)

- Natural origin polymers:

- ▪

- Alginates: acidic polysaccharides with pKa ca. 3–4 (resulting from the presence of -COOH groups). In the presence of divalent cations (Ca2+, Ba2+, Sr2+ and Zn2+) it gels gently;

- ▪

- Hyaluronic acid—a linear polysaccharide that has a pH of 3–4. It absorbs water up to 1000 times its volume, creating a loose network;

- ▪

- Chitosan—a polysaccharide that owes its pH sensitivity to the presence of amino groups in its structure. At low pH conditions, the amino groups are protonated, which triggers the ability to dissolve at low pH, and poor solubility at high pH;

- (2)

- Synthetic polymers—which include two types of compounds, such as:

- (a)

- Polymers containing a pendant group:

- ▪

- Polyacids—which contain acidic groups in their structure, e.g., carboxylic: poly(acrylic acid)—PAAc, boronic: poly(vinylphenyl boronic acid)—PVPBA, phosphoric: poly(ethylene glycol acrylate phosphate)—PEGAP and sulfonic acid: poly(vinyl sulfonic acid)—PVSA;

- ▪

- Polybases—which contain the following groups in their structure, e.g., amino: poly[(2-dimethylamino)ethylmethacrylate]—PDMA, pyridine: poly(4-vinylpyridine)—P4VP, imidazole group: poly(N-vinylimidazole)—PVI.

- (b)

- Polymers containing labile acid/base linkage—This group contains polymers that are capable of breaking bonds under the influence of pH change, for example:

- ▪

- Hydrazone (decomposing at pH 5.5);

- ▪

- Imine (decomposing at pH 5);

- ▪

- Cis-aconityl (decomposing at pH 4) [31].

3.2. Ion-Responsive Polymers

3.3. Redox-Responsive Polymers

3.4. Water-Responsive Polymers

- ▪

- Solvent-casting—which involves creating a solution with active ingredients (active layers—most often chitosan or sodium alginate), pouring it onto a film (passive layers—most often poly(vinyl chloride) or poly(propylene)) and dry;

- ▪

- Spin coating—an example of which is the formation of a water-responsive poly(3,4-ethylenedioxythiophene):polystyrene sulfonate/poly(dimethylsiloxane)—PEDOT:PSS/PDMS actuator;

- ▪

- Photolithography;

- ▪

- 3D printing;

- ▪

- Fibre spinning [28].

3.5. Reactive Oxygen Species-Responsive Polymers

- ▪

- Thioether group, e.g., poly(propylene sulfide)—PPS;

- ▪

- Selenium;

- ▪

- Tellurium;

- ▪

- Poly(thioketal);

- ▪

- Phenylboronic acid/phenylboronic ester.

4. Biological Stimuli-Responsive Polymer Materials

4.1. Glucose-Responsive Polymers

4.2. Enzyme-Responsive Polymers

5. Multistimuli Polymer Materials

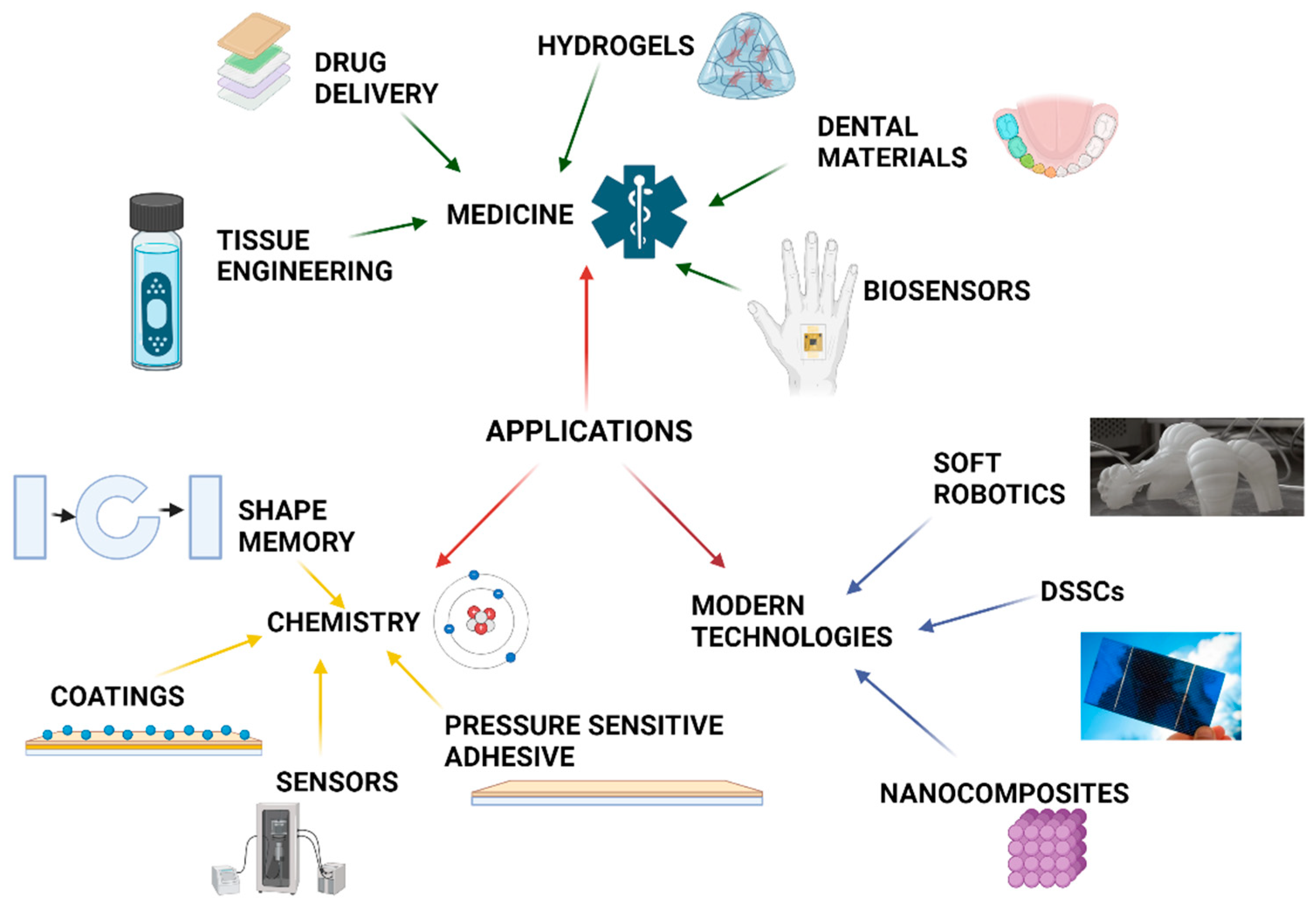

6. Application of Smart Polymer Materials—Latest Advances

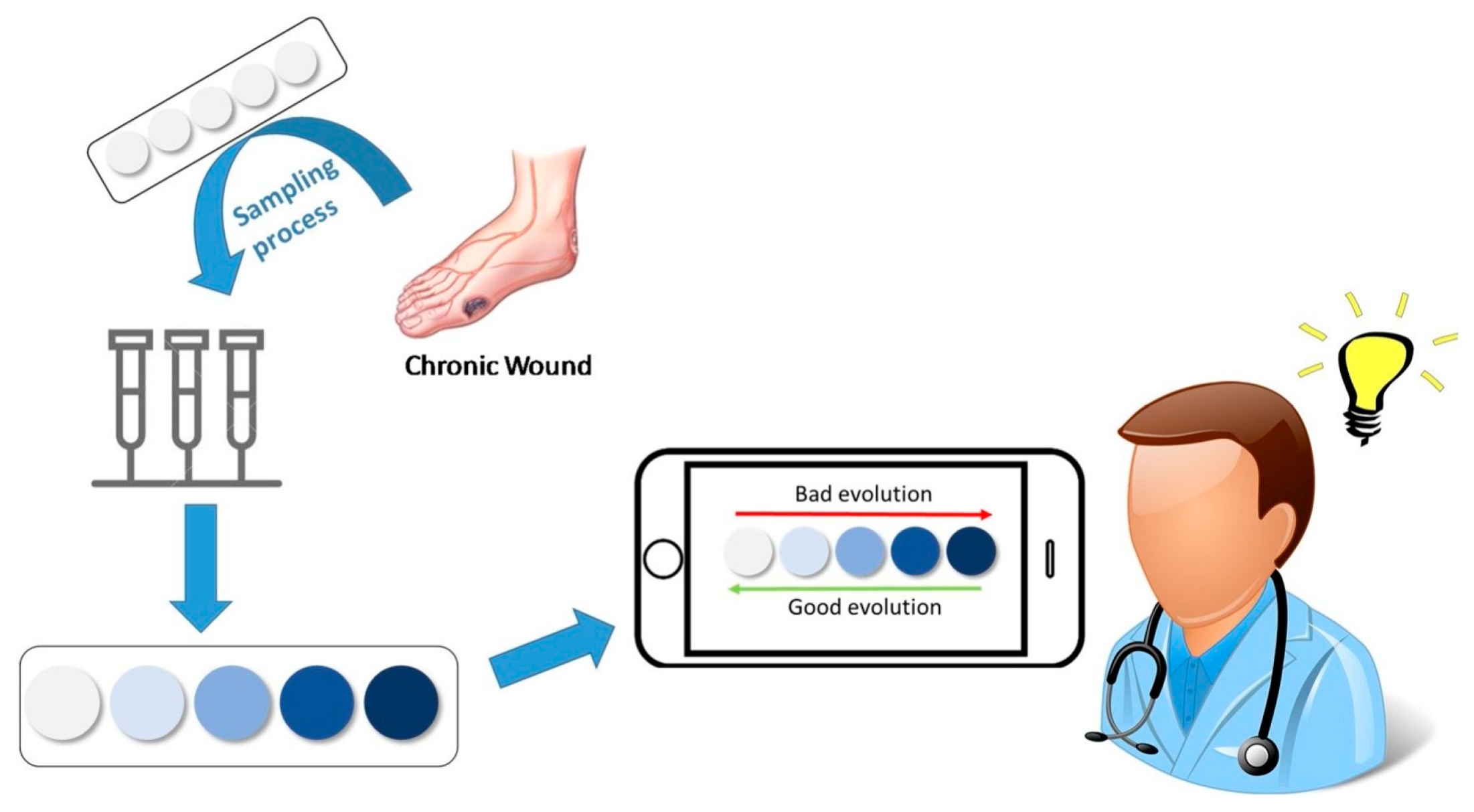

6.1. Medicine

6.2. Chemistry

6.3. Modern Technologies

7. Future Perspectives

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Korolija, J.; Plavsic, J.V.; Mladenovic, I.M.; Mandic, L.M. A contribution to Science for All: Learning about polymers. Probl. Educ. 21st Cent. 2009, 17, 107. Available online: http://oaji.net/articles/2014/457-1399914737.pdf (accessed on 12 August 2024).

- Ma, Z.; Zhang, J.; Liu, L.; Zheng, H.; Dai, J.; Tang, L.C.; Song, P. A highly fire-retardant rigid polyurethane foam capable of fire-warning. Compos. Commun. 2022, 29, 101046. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Jingcheng, L.; Reddy, V.S.; Jayathilaka, W.A.D.M.; Chinnappan, A.; Ramakrishna, S.; Ghosh, R. Intelligent polymers, fibers and applications. Polymers 2021, 13, 1427. [Google Scholar] [CrossRef] [PubMed]

- Fattah-alhosseini, A.; Chaharmahali, R.; Alizad, S.; Kaseem, M.; Dikici, B. A review of smart polymeric materials: Recent developments and prospects for medicine applications. Hybrid Adv. 2024, 5, 100178. [Google Scholar] [CrossRef]

- Bratek-Skicki, A. Towards a new class of stimuli-responsive polymer-based materials–Recent advances and challenges. Appl. Surf. Sci. Adv. 2021, 4, 100068. [Google Scholar] [CrossRef]

- Vera, M.; Mella, C.; Urbano, B.F. Smart polymer nanocomposites: Recent advances and perspectives. J. Chil. Chem. Soc. 2020, 65, 4973–4981. [Google Scholar] [CrossRef]

- Purohit, A.; Jain, S.; Nema, P.; Vishwakarma, H.; Jain, P.K. Intelligent or smart polymers: Advance in novel drug delivery. J. Drug Deliv. Ther. 2022, 12, 208–216. [Google Scholar] [CrossRef]

- Shu, X. A review of thermoresponsive drug delivery systems based on LCST/UCST polymer nanofibers. J. Phys. Conf. Ser. 2023, 2539, 012032. [Google Scholar] [CrossRef]

- Nihalani, S.; Joshi, U.; Meeruty, A. Smart materials for sustainable and smart infrastructure. Mater. Sci. Forum 2019, 969, 278–283. [Google Scholar] [CrossRef]

- Garcia, J.M.; Garcia, F.C.; Vallejos, S.; Trigo, M.; Reglero, J.A. Smart Polymers: Principles and Applications, 1st ed.; De Gruyter: Sotogrande, Spain, 2022. [Google Scholar] [CrossRef]

- Liu, T.; Bao, B.; Li, Y.; Lin, Q.; Zhu, L. Photo-responsive polymers based on ο-Nitrobenzyl derivatives: From structural design to applications. Prog. Polym. Sci. 2023, 146, 101741. [Google Scholar] [CrossRef]

- Xu, F.; Feringa, B.L. Photoresponsive supramolecular polymers: From light-controlled small molecules to smart materials. Adv. Mater. 2023, 35, 2204413. [Google Scholar] [CrossRef]

- Romano, A.; Roppolo, I.; Rossegger, E.; Schlögl, S.; Sangermano, M. Recent trends in applying ortho-nitrobenzyl esters for the design of photo-responsive polymer networks. Materials 2020, 13, 2777. [Google Scholar] [CrossRef] [PubMed]

- Xiaoqi, S.; Di, L.; Xiaoyu, X.; Yifeng, S.; Yanjuan, H.; Zishan, Z.; Meng, X.; Chunshun, Z. NIR-triggered thermo-responsive biodegradable hydrogel with combination of photothermal and thermodynamic therapy for hypoxic tumor. Asian J. Pharm. Sci. 2020, 15, 713–727. [Google Scholar] [CrossRef]

- Gan, S.; Wu, Y.; Zhang, X.; Zheng, Z.; Zhang, M.; Long, L.; Liao, J.; Chen, W. Recent Advances in Hydrogel-Based Phototherapy for Tumor Treatment. Gels 2023, 9, 286. [Google Scholar] [CrossRef]

- Fu, H.; Xue, K.; Zhang, Y.; Xiao, M.; Wu, K.; Shi, L.; Zhu, C. Thermoresponsive hydrogel-enabled thermostatic photothermal therapy for enhanced healing of bacteria-infected wounds. Adv. Sci. 2023, 10, 2206865. [Google Scholar] [CrossRef]

- Algi, M.P.; Sarıgöl, R. Cross-linker engineered poly(hydroxyethyl methacrylate) hydrogel allows photodynamic and photothermal therapies and controlled drug release. Eur. J. Pharm. Biopharm. 2024, 202, 114419. [Google Scholar] [CrossRef]

- Saleh, T.A.; Fadillah, G.; Ciptawati, E. Smart advanced responsive materials, synthesis methods and classifications: From Lab to applications. J. Polym. Res. 2021, 28, 197. [Google Scholar] [CrossRef]

- Niskanen, J.; Tenhu, H. How to manipulate the upper critical solution temperature (UCST)? Polym. Chem. 2017, 8, 220–232. [Google Scholar] [CrossRef]

- Ruiz, A.L.; Ramirez, A.; McEnnis, K. Single and multiple stimuli-responsive polymer particles for controlled drug delivery. Pharmaceutics 2022, 14, 421. [Google Scholar] [CrossRef]

- Kanaan, A.F.; Piedade, A.P. Electro-responsive polymer-based platforms for electrostimulation of cells. Mater. Adv. 2022, 3, 2337–2353. [Google Scholar] [CrossRef]

- Manouras, T.; Vamvakaki, M. Field responsive materials: Photo-, electro-, magnetic-and ultrasound-sensitive polymers. Polym. Chem. 2017, 8, 74–96. [Google Scholar] [CrossRef]

- Ortigosa, R.; Martínez-Frutos, J.; Mora-Corral, C.; Pedregal, P.; Periago, F. Optimal control and design of magnetic field-responsive smart polymer composites. Appl. Math. Model. 2022, 103, 141–161. [Google Scholar] [CrossRef]

- Khizar, S.; Zine, N.; Errachid, A.; Elaissari, A. Introduction to stimuli-responsive materials and their biomedical applications. In Stimuli-Responsive Materials for Biomedical Applications; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2023; Volume 1436, pp. 1–30. [Google Scholar] [CrossRef]

- Yarali, E.; Baniasadi, M.; Zolfagharian, A.; Chavoshi, M.; Arefi, F.; Hossain, M.; Bastola, A.; Ansari, M.; Foyouzat, A.; Dabbagh, A.; et al. Magneto-/electro-responsive polymers toward manufacturing, characterization, and biomedical/soft robotic applications. Appl. Mater. Today 2022, 26, 101306. [Google Scholar] [CrossRef]

- Bhavna; Boora, A.; Sehrawat, S.; Priya; Duhan, S. Smart Materials for Smart Manufacturing. In Handbook of Smart Manufacturing, 1st ed.; Singh, H.A., AlMangour, B.P., Eds.; CRC Press: Boca Raton, FL, USA, 2023; pp. 109–137. [Google Scholar] [CrossRef]

- Park, Y.; Chen, X. Water-responsive materials for sustainable energy applications. J. Mater. Chem. A 2020, 8, 15227–15244. [Google Scholar] [CrossRef]

- Urban, M.W. Handbook of Stimuli-Responsive Materials, 1st ed.; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Ofridam, F.; Tarhini, M.; Lebaz, N.; Gagnière, É.; Mangin, D.; Elaissari, A. pH-sensitive polymers: Classification and some fine potential applications. Polym. Adv. Technol. 2021, 32, 1455–1484. [Google Scholar] [CrossRef]

- Kilic Boz, R.; Aydin, D.; Kocak, S.; Golba, B.; Sanyal, R.; Sanyal, A. Redox-responsive hydrogels for tunable and “On-demand” release of biomacromolecules. Bioconjug. Chem. 2022, 33, 839–847. [Google Scholar] [CrossRef] [PubMed]

- Das, S.S.; Bharadwaj, P.; Bilal, M.; Barani, M.; Rahdar, A.; Taboada, P.; Bungau, S.; Kyzas, G.Z. Stimuli-responsive polymeric nanocarriers for drug delivery, imaging, and theragnosis. Polymers 2020, 12, 1397. [Google Scholar] [CrossRef]

- Guan, W.L.; Adam, K.M.; Qiu, M.; Zhang, Y.M.; Yao, H.; Wei, T.B.; Lin, Q. Research progress of redox-responsive supramolecular gel. Supramol. Chem. 2020, 32, 578–596. [Google Scholar] [CrossRef]

- Xu, Q.; He, C.; Xiao, C.; Chen, X. Reactive oxygen species (ROS) responsive polymers for biomedical applications. Macromol. Biosci. 2016, 16, 635–646. [Google Scholar] [CrossRef]

- Wells, C.M.; Harris, M.; Choi, L.; Murali, V.P.; Guerra, F.D.; Jennings, J.A. Stimuli-responsive drug release from smart polymers. J. Funct. Biomater. 2019, 10, 34. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Zhou, Y.; Dong, Y.; Chen, W. Novel multi-responsive polymer materials: When ionic liquids step in. Eur. Polym. J. 2015, 69, 441–448. [Google Scholar] [CrossRef]

- Altas, B.O.; Goktas, C.; Topcu, G.; Aydogan, N. Multi-stimuli-responsive tadpole-like polymer/lipid Janus microrobots for advanced smart material applications. ACS Appl. Mater. Interfaces 2024, 16, 15533–15547. [Google Scholar] [CrossRef]

- Fu, X.; Hosta-Rigau, L.; Chandrawati, R.; Cui, J. Multi-stimuli-responsive polymer particles, films, and hydrogels for drug delivery. Chem 2018, 4, 2084–2107. [Google Scholar] [CrossRef]

- Rosario, A.J.; Boran, M. Stimuli-responsive polymer networks: Application, design, and computational exploration. ACS Appl. Polym. Mater. 2024. [Google Scholar] [CrossRef]

- Png, Z.M.; Wang, C.-G.; Yeo, J.C.C.; Lee, J.J.C.; Surat’man, N.E.; Tan, Y.L.; Liu, H.; Wang, P.; Tan, B.H.; Xu, J.W.; et al. Stimuli-responsive structure-property switchable polymer materials. Mol. Syst. Des. Eng. 2023, 8, 1097–1129. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Sun, Y.; Sun, S.; Xu, Z.; Li, J.; Li, J.; Gong, X. Multi-stimuli responsive soft actuator with locally controllable and programmable complex shape deformations. ACS Appl. Polym. Mater. 2023, 5, 6199–6211. [Google Scholar] [CrossRef]

- Singh, J.; Nayak, P. pH-responsive polymers for drug delivery: Trends and opportunities. J. Polym. Sci. 2023, 61, 2828–2850. [Google Scholar] [CrossRef]

- Kotsuchibashi, Y. Recent advances in multi-temperature-responsive polymeric materials. Polym. J. 2020, 52, 681–689. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, G.; Liu, S. Enzyme-responsive polymeric assemblies, nanoparticles and hydrogels. Chem. Soc. Rev. 2012, 41, 5933–5949. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Chen, Y.; Zheng, X.; Liu, H.; Li, H. Multiple-stimuli-responsive and cellulose conductive ionic hydrogel for smart wearable devices and thermal actuators. ACS Appl. Mater. Interfaces 2021, 13, 1353–1366. [Google Scholar] [CrossRef] [PubMed]

- Preman, N.K.; Jain, S.; Johnson, R.P. “Smart” polymer nanogels as pharmaceutical carriers: A versatile platform for programmed delivery and diagnostics. ACS Omega 2021, 6, 5075–5090. [Google Scholar] [CrossRef] [PubMed]

- Hunter, A.C.; Moghimi, S.M. Smart polymers in drug delivery: A biological perspective. Polym. Chem. 2017, 8, 41–51. [Google Scholar] [CrossRef]

- Mantha, S.; Pillai, S.; Khayambashi, P.; Upadhyay, A.; Zhang, Y.; Tao, O.; Pham, H.M.; Tran, S.D. Smart hydrogels in tissue engineering and regenerative medicine. Materials 2019, 12, 3323. [Google Scholar] [CrossRef]

- Khan, F.; Tanaka, M. Designing smart biomaterials for tissue engineering. Int. J. Mol. Sci. 2018, 19, 17. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Zhou, C.; Cheng, L.; Gao, X.; Xie, X.; Sun, J.; Wang, H.; Weir, M.D.; Reynolds, M.A.; et al. Advanced smart biomaterials and constructs for hard tissue engineering and regeneration. Bone Res. 2018, 6, 31. [Google Scholar] [CrossRef]

- Brighenti, R.; Li, Y.; Vernerey, F.J. Smart polymers for advanced applications: A mechanical perspective review. Front. Mater. 2020, 7, 196. [Google Scholar] [CrossRef]

- Chen, X.; Li, F.; Liang, R.; Liu, W.; Ma, H.; Lan, T.; Liao, J.; Yang, Y.; Liu, N. A smart benzothiazole-based conjugated polymer nanoplatform with multistimuli response for enhanced synergistic chemo-photothermal cancer therapy. ACS Appl. Mater. Interfaces 2023, 15, 16343–16354. [Google Scholar] [CrossRef]

- Bao, B.; Su, P.; Song, K.; Cui, Y.; Zhai, X.; Xu, Y.; Liu, J.; Wang, L. A smart “sense-and-treat” nanoplatform based on semiconducting polymer nanoparticles for precise phototermal-photodynamic combined therapy. Biomacromolecules 2021, 22, 1137–1146. [Google Scholar] [CrossRef]

- Mathew, A.P.; Cho, K.-H.; Uthaman, S.; Cho, C.-S.; Park, I.-K. Stimuli-regulated smart polymeric systems for gene therapy. Polymers 2017, 9, 152. [Google Scholar] [CrossRef]

- Duarte, A.R.C.; Mano, J.F.; Reis, R.L. Thermosensitive polymeric matrices for three-dimensional cell culture strategies. Acta Biomater. 2011, 7, 526–529. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Sponchioni, M.; Manfredini, N.; Zanoni, A.; Scibona, E.; Morbidelli, M.; Moscatelli, D. Readily adsorbable thermoresponsive polymers for the preparation of smart cell-culturing surfaces on site. ACS Biomater. Sci. Eng. 2020, 6, 5337–5345. [Google Scholar] [CrossRef]

- Huang, H.-J.; Tsai, Y.-L.; Lin, S.-H.; Hsu, S.-h. Smart polymers for cell therapy and precision medicine. J. Biomed. Sci. 2019, 26, 73. [Google Scholar] [CrossRef] [PubMed]

- Neumann, M.; di Marco, G.; Iudin, D.; Viola, M.; van Nostrum, C.F.; van Ravensteijn, B.G.P.; Vermonden, T. Stimuli-responsive hydrogels: The dynamic smart biomaterials of tomorrow. Macromolecules 2023, 56, 8377–8392. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.; Mooney, D. Polymeric tissue adhesives. Chem. Rev. 2021, 121, 11336–11384. [Google Scholar] [CrossRef] [PubMed]

- Kumi, M.; Ejeromedoghene, O.; Sudane, W.D.; Zhang, Z. Unlocking the biological response of smart Stimuli-Responsive hydrogels and their application in biological systems. Eur. Polym. Chem. 2024, 209, 112906. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Tang, M.; Peng, C.; Wang, G.; Wang, J.; Wang, X.; Chang, X.; Guo, J.; Gui, S. Smart stimuli-responsive hydrogels for drug delivery in periodontitis treatment. Biomed. Pharmacother. 2023, 162, 114688. [Google Scholar] [CrossRef]

- Intravaia, J.T.; Graham, T.; Kim, H.S.; Nanda, H.S.; Kumbar, S.G.; Nukavarapu, S.P. Smart orthopedic biomaterials and implants. Curr. Opin. Biomed. Eng. 2023, 25, 100439. [Google Scholar] [CrossRef]

- Xing, Y.; Qiu, L.; Liu, D.; Dai, S.; Sheu, C.-L. The role of smart polymeric biomaterials in bone regeneration: A review. Front. Bioeng. Biotechnol. 2023, 11, 1240861. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, Y.; Han, L.; Lu, X. Biodegradable hydrogel-based tissue adhesives: A review. Biosurf. Biotribol. 2021, 7, 163–179. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Gerhard, E.M.; Zhang, S.; Rodriguez, F.I.P.; Pan, T.; Yang, H.; Lin, Y.; Yang, J.; Cheng, H. Smart bioadhesives for wound healing and closure. Bioact. Mater. 2022, 26, 360–375. [Google Scholar] [CrossRef] [PubMed]

- Hajirasouliha, E.; Zandi, M.; Tabatabaei, M.H.; Zarrinbakhsh, P. Ocular contact lenses: Smart materials for biomedical applications. Polym. Bull. 2024, 81, 7791–7832. [Google Scholar] [CrossRef]

- Kim, T.Y.; Lee, G.-H.; Mun, J.; Cheong, S.; Choi, I.; Kim, H.; Hahn, S.K. Smart contact lens systems for ocular drug delivery and therapy. Adv. Drug Deliv. Rev. 2023, 196, 114817. [Google Scholar] [CrossRef]

- Meng, L.; Liu, S.; Borsa, B.A.; Eriksson, M.; Mak, W.C. A conducting polymer-based array with multiplex sensing and drug delivery capabilities for smart bandages. Commun. Mater. 2024, 5, 28. [Google Scholar] [CrossRef]

- Spychalska, K.; Zając, D.; Baluta, S.; Halicka, K.; Cabaj, J. Functional polymers structures for (bio)sensing application—A review. Polymers 2020, 12, 1154. [Google Scholar] [CrossRef]

- Bordbar-Khiabani, A.; Gasik, M. Smart hydrogels for advanced drug delivery systems. Int. J. Mol. Sci. 2022, 23, 3665. [Google Scholar] [CrossRef] [PubMed]

- Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A.H.; Mujtaba, M.A.; Alghamdi, N.A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental concepts of hydrogels: Synthesis, properties and their applications. Polymers 2020, 12, 2702. [Google Scholar] [CrossRef]

- Zhang, Y.-S.; Liu, X.-J.; Chu, Y.-Z.; Chen, P.-W.; Yeh, Y.-C.; Ni, Y.-F.; Yeh, M.-Y. Composite hydrogel modified with gela-tin-imidazole: A conductive and adhesive hydrogel. ACS Appl. Electron. Mater. 2023, 5, 6114–6123. [Google Scholar] [CrossRef]

- Ahmad, Z.; Salman, S.; Khan, S.A.; Amin, A.; Rahman, Z.U.; Al-Ghamdi, Y.O.; Akhtar, K.; Bakhsh, E.M.; Khan, S.B. Versatility of hydrogels: From synthetic strategies, classification, and properties to biomedical applications. Gels 2022, 8, 167. [Google Scholar] [CrossRef]

- Hu, W.; Wang, Z.; Xiao, Y.; Zhang, S.; Wang, J. Advances in crosslinking strategies of biomedical hydrogels. Biomater. Sci. 2019, 7, 843–855. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Romero-Fierro, D.; Arcentales-Vera, B.; Palomino, K.; Magaña, H.; Bucio, E. Hydrogels classification ac-cording to the physical and chemical interactions and as stimuli-sensitive materials. Gels 2021, 7, 182. [Google Scholar] [CrossRef] [PubMed]

- Hennink, W.E.; van Nostrum, C.F. Novel crosslinking methods to design hydrogels. Adv. Drug Deliv. Rev. 2012, 64, 223–236. [Google Scholar] [CrossRef]

- Xue, X.; Hu, Y.; Wang, S.; Chen, X.; Jiang, Y.; Su, J. Fabrication of physical and chemical crosslinked hydrogels for bone tissue engineering. Bioact. Mater. 2022, 12, 327–339. [Google Scholar] [CrossRef]

- Sajjad, R.; Chauhdary, S.T.; Anwar, M.T.; Zahid, A.; Khosa, A.A.; Imran, M.; Sajjad, M.H. A review of 4D printing—Technologies, shape shifting, smart polymer based materials, and biomedical applications. Adv. Ind. Eng. Polym. Res. 2024, 7, 20–36. [Google Scholar] [CrossRef]

- Wei, B.X.; Cui, Y.T.; Ma, S.C.; Liu, H.H.; Bai, Y.P. Synthesis of stimulus-responsive ABC triblock fluorinated polyether amphiphilic polymer and application as low toxicity smart drug carrier. Eur. Polym. J. 2022, 175, 111389. [Google Scholar] [CrossRef]

- Silva-López, M.S.; Alcántara-Quintana, L.E. The era of biomaterials: Smart implants? ACS Appl. Bio Mater. 2023, 6, 2982–2994. [Google Scholar] [CrossRef]

- Montoya, C.; Du, Y.; Gianforcaro, A.L.; Orrego, S.; Yang, M.; Lelkes, P.I. On the road to smart biomaterials for bone research: Definitions, concepts, advances, and outlook. Bone Res. 2021, 9, 12. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, X.; Wen, X.; Xu, Q.; Zeng, H.; Zhao, Y.; Liu, M.; Wang, Z.; Hu, X.; Wang, Y. Bio-responsive smart polymers and biomedical applications. J. Phys. Mater. 2019, 2, 032004. [Google Scholar] [CrossRef]

- Hrubý, M.; Filippov, S.K.; Štĕpánek, P. Smart polymers in drug delivery systems on crossroads: Which way deserves following? Eur. Polym. J. 2015, 65, 82–97. [Google Scholar] [CrossRef]

- Vargason, A.M.; Anselmo, A.C.; Mitragotri, S. The evolution of commercial drug delivery technologies. Nat. Biomed. Eng. 2021, 5, 951–967. [Google Scholar] [CrossRef]

- Liu, D.; Yang, F.; Xiong, F.; Gu, N. The smart drug delivery system and its clinical potential. Theranostics 2016, 6, 1306–1323. [Google Scholar] [CrossRef] [PubMed]

- Shah, I.U.; Jadhav, S.A.; Belekar, V.M.; Patil, P.S. Smart polymer grafted silica based drug delivery systems. Polym. Adv. Technol. 2023, 34, 24–43. [Google Scholar] [CrossRef]

- Kandula, S.; Singh, P.K.; Kaur, G.A.; Tiwari, A. Trends in smart drug delivery systems for targeting cancer cells. Mater. Sci. Eng. B 2023, 297, 116816. [Google Scholar] [CrossRef]

- Shah, K. Encapsulated system cells for cancer therapy. Biomatter 2013, 3, e24278. [Google Scholar] [CrossRef]

- Sun, M.; Gao, M.; Bi, J.; Zhao, Y.; Gong, J. Highly efficient hydrogel encapsulation of hydrophobic drugs via an organic solvent-free process based on oiling-out crystallization and a mechanism study. ACS Sustain. Chem. Eng. 2024, 12, 4813–4824. [Google Scholar] [CrossRef]

- Thang, N.H.; Chien, T.B.; Cuong, D.X. Polymer-based hydrogels applied in drug delivery: An overview. Gels 2023, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Honey, P.J.; Rijo, J.; Anju, A.; Anoop, K.R. Smart polymers for the controlled delivery of drugs—A concise overview. Acta Pharm. Sin. B 2014, 4, 120–127. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhu, M.; Chi, M.; Lai, Y.; Li, B.; Qian, R.; Chen, Z.; Zhao, G. MXene/TPU hybrid fabrics enable smart wound management and thermoresponsive drug delivery. ACS Appl. Mater. Interfaces 2024, 16, 20105–20118. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Zeng, B.; Yang, W. Light responsive hydrogels for controlled drug delivery. Front. Bioeng. Biotechnol. 2022, 10, 1075670. [Google Scholar] [CrossRef]

- Long, J.; Zhou, Y.X.; Xu, J.; Hu, L.; Pranovich, A.; Yong, Q.; Xie, Z.-H.; Xu, C. Harnessing chemical functionality of xylan hemicellulose towards carbohydrate polymer-based pH/magnetic dual-responsive nanocomposite hydrogel for drug delivery. Carbohydr. Polym. 2024, 343, 122461. [Google Scholar] [CrossRef]

- Patra, R.; Halder, S.; Saha, R.; Jana, K.; Sarkar, K. Highly efficient photoswitchable smart polymeric nanovehicle for gene and anticancer drug delivery in triple-negative breast cancer. ACS Biomater. Sci. Eng. 2024, 10, 2299–2323. [Google Scholar] [CrossRef]

- Selvam, S.P.; Ayyappan, S.; Jamir, S.I.; Sellappan, L.K.; Manoharan, S. Recent advancements of hydroxyapatite and polyethylene glycol (PEG) composites for tissue engineering applications—A comprehensive review. Eur. Polym. J. 2024, 215, 113226. [Google Scholar] [CrossRef]

- Alizadeh, S.; Ameri, Z.; Daemi, H.; Pezeshki-Modaress, M. Sulfated polysaccharide as biomimetic biopolymers for tissue engineering scaffolds fabrication: Challenges and opportunities. Carbohydr. Polym. 2024, 336, 122124. [Google Scholar] [CrossRef]

- Park, S.; Rahaman, K.A.; Kim, Y.-C.; Jeon, H.; Han, H.-S. Fostering tissue engineering and regenerative medicine to treat musculoskeletal disorders in bone and muscle. Bioact. Mater. 2024, 40, 345–365. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, M.; Zhang, Y.; Pei, R. Recent progress of highly adhesive hydrogels as wound dressings. Biomacromolecules 2020, 21, 3966–3983. [Google Scholar] [CrossRef]

- Huang, B.; Hu, D.; Dong, A.; Tian, J.; Zhang, W. Highly antibacterial and adhesive hyaluronic acid hydrogel for wound repair. Biomacromolecules 2022, 23, 4766–4777. [Google Scholar] [CrossRef] [PubMed]

- Khadem, E.; Kharaziha, M.; Bakhsheshi-Rad, H.R.; Das, O.; Berto, F. Cutting-edge progress in stimuli-responsive bioadhesives: From synthesis to clinical applications. Polymers 2022, 14, 1709. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Wu, Q.; Li, X.; Pan, P.; Gu, S.; Tang, T.; Wu, J. Silicone bioadhesive with shear-stiffening effect: Rate-responsive adhesion behavior and wound dressing application. Biomacromolecules 2024, 25, 4510–4522. [Google Scholar] [CrossRef]

- Zhang, M.; An, H.; Gu, Z.; Huang, Z.; Zhang, F.; Jiang, B.-G.; Wen, Y. Mimosa-inspired stimuli-responsive curling bioadhesive tape promotes peripheral nerve regeneration. Adv. Mater. 2023, 35, 2212015. [Google Scholar] [CrossRef]

- Montoya, C.; Roldan, L.; Yu, M.; Valliani, S.; Ta, C.; Yang, M.; Orrego, S. Smart dental materials for antimicrobial applications. Bioact. Mater. 2023, 24, 1–19. [Google Scholar] [CrossRef]

- Subramanian, P.; Dutta, B.; Arya, A.; Azeem, M.; Pavithra, B.N.; Balaji, D.L. Smart material for smarter dentistry. J. Pharm. Bioallied Sci. 2024, 16, S17–S19. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, Q.; Dai, Z.; Zhu, M.; Xiao, L.; Zhao, Z.; Bai, Y.; Zhang, K. Smart dental materials intelligently responding to oral pH to combat caries: A literature review. Polymers 2023, 15, 2611. [Google Scholar] [CrossRef] [PubMed]

- Deng, F.; Sakai, H.; Kitagawa, H.; Kohno, T.; Thongthai, P.; Liu, Y.; Kitagawa, R.; Abe, G.L.; Sasaki, J.-I.; Imazato, S. Fabrication of pH-responsive Zn2+-releasing glass particles for smart antibacterial restoratives. Molecules 2022, 27, 7202. [Google Scholar] [CrossRef] [PubMed]

- Gezawi, M.E.; Wölfle, U.C.; Haridy, R.; Fliefel, R.; Kaisarly, D. Remineralization, regeneration, and repair of natural tooth structure: Influences on the future of restorative dentistry practice. ACS Biomater. Sci. Eng. 2019, 5, 4899–4919. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ye, Y.; Ge, Y.; Qu, J.; Liedberg, B.; Zhang, Q.; Wang, Y. Smart contact lenses for healthcare monitoring and therapy. ACS Nano 2024, 18, 6817–6844. [Google Scholar] [CrossRef]

- Ye, Y.; Ge, Y.; Zhang, Q.; Yuan, M.; Cai, Y.; Li, K.; Li, Y.; Xie, R.; Xu, C.; Jiang, D.; et al. Smart contact lens with dual-sensing platform for monitoring intraocular pressure and matrix metalloproteinase-9. Adv. Sci. 2022, 9, 2104738. [Google Scholar] [CrossRef]

- Liu, S.; Yan, Z.; Huang, Z.; Yang, H.; Li, J. Smart nanocarriers for the treatment of retinal diseases. ACS Appl. Bio Mater. 2024, 7, 2070–2085. [Google Scholar] [CrossRef]

- Seo, H.; Chung, W.G.; Kwon, Y.W.; Kim, S.; Hong, Y.-M.; Park, W.; Kim, E.; Lee, J.; Lee, S.; Kim, M.; et al. Smart contact lenses as wearable ophthalmic devices for disease monitoring and health management. Chem. Rev. 2023, 123, 11488–11558. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, H.; Zhan, L.; Chen, Y.; Wang, J.; Xu, F. Hydrogel-based smart contact lens for highly sensitive wireless intraocular pressure monitoring. ACS Sens. 2022, 7, 3014–3022. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.W.; Bhat, S.I.; Qahtani, H.S.A.; Aamir, M.; Amin, M.N.; Farhan, M.; Aldabal, S.; Khan, M.S.; Jeelani, I.; Nawaz, A.; et al. Recent progress, chellenges, and trends in polymer-based sensors: A review. Polymers 2022, 14, 2164. [Google Scholar] [CrossRef]

- Banitaba, S.N.; Khademolqorani, S.; Jadhav, V.V.; Chamanehpour, E.; Mishra, Y.K.; Mostafavi, E.; Kaushik, A. Recent progress of bio-based smart wearable sensors for healthcare applications. Mater. Today Electonics 2023, 5, 100055. [Google Scholar] [CrossRef]

- Acar, T.; Çimen, K.N.; Özalp, E.; Ilıca, Ö.; Özerol, E.A. Recent advances in biosensors based on conducting polymers for biomedical applications. ChemistrySelect 2023, 8, e202300819. [Google Scholar] [CrossRef]

- Guembe-García, M.; Santaolalla-García, V.; Moradillo-Renuncio, N.; Ibeas, S.; Reglero, J.A.; García, F.C.; Pacheco, J.; Casado, S.; García, J.M.; Vallejos, S. Monitoring of the evolution of human chronic wounds using a ninhydrin-based sensory polymer and smartphone. Sens. Actuators B Chem. 2021, 335, 129688. [Google Scholar] [CrossRef]

- Das, P.P.; Nagraik, R.; Sharma, A.; Upadhyay, T.K.; Lalhlenmawia, H.; Balram, D.; Lian, K.-Y.; Singh, J.; Kumar, D. recent update on biomimetic sensor technology for cancer diagnosis. Talanta Open 2024, 9, 100276. [Google Scholar] [CrossRef]

- Zhang, G.; Dong, M.; Yao, X.; Xia, Y.; Yu, H.; Zhou, Y.; Lian, C.; Zhang, Y.; Cui, Y. Advancing breast cancer diagnosis with a near-infrared fluorescence imaging smart sensor for estrogen/progesterone receptor detection. Sci. Rep. 2023, 13, 21086. [Google Scholar] [CrossRef]

- Karasu, T.; Armuctu, C.; Elkhoury, K.; Özgür, E.; Maziz, A.; Uzun, L. Conducting polymers as a functional recognition interface to design sensors for pathogen and cancer diagnosis. TrAC Trends Anal. Chem. 2024, 175, 117705. [Google Scholar] [CrossRef]

- Saputra, H.A.; Chung, J.H.; Kwon, R.J.; Jannath, K.A.; Park, D.-S.; Shim, Y.-B. Ultrasensitive interferon-gamma sensor with a bifunctionalized conducting polymer nanobioconjugate for therapy-progress monitoring of cancer patients. Sens. Actuators B. Chem. 2024, 398, 134739. [Google Scholar] [CrossRef]

- Fernández-Puig, S.; Lazo-Fraga, A.R.; Korgel, B.A.; Oza, G.; Dutt, A.; Vallejo-Becerra, V.; Valdés-González, A.C.; Chávez-Ramírez, A.U. Molecularly imprinted polymer-silica nanocomposite based potentiometric sensor for early prostate cancer detection. Mater. Lett. 2022, 309, 131324. [Google Scholar] [CrossRef]

- Bahl, S.; Nagar, H.; Singh, I.; Sehgal, S. Smart materials types, properties and applications: A review. Mater. Today Proc. 2020, 28, 1302–1306. [Google Scholar] [CrossRef]

- Islam, M.S.; Chan, K.-Y.; Thien, G.S.H.; Low, P.-L.; Lee, C.-L.; Wong, S.K.; Noor, E.E.M.; Au, B.W.-C.; Ng, Z.-N. Performances of polymer-dispersed liquid crystal films for smart glass applications. Polymers 2023, 15, 3420. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, H.; Koo, J.M.; Oh, D.X.; Park, J. Practical applications of self-healing polymers beyond mechanical and electrical recovery. Adv. Sci. 2024, 11, 2302463. [Google Scholar] [CrossRef]

- Gumyusenge, A. Polymer-based electronics that can learn to drive: That’s smart. Matter 2022, 3, 2397–2561. [Google Scholar] [CrossRef]

- Sahu, S.; Tripathy, K.; Bhattacharjee, M.; Chopra, D. Engineering mechanical compliance in polymers and composites for the design of smart flexible sensors. Chem. Commun. 2024, 60, 4382–4394. [Google Scholar] [CrossRef]

- Hao, B.; Luo, Y.; Chan, W.; Cai, L.; Lyu, S.; Luo, Z. Fabrication of a multiple-self-healing and self-cleaning polymer coating for mechanical-damaged optical glass surface. Chem. Eng. J. 2024, 496, 153750. [Google Scholar] [CrossRef]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Dhanapal, V.; Subhapriya, P.; Nithyanandam, K.P.; Kiruthika, M.V.; Keerthana, T.; Dineshkumar, G. Design, synthesis and evaluation of N,N1-methylenebisacrylamide crosslinked smart polymer hydrogel for the controlled release of water and plant nutrients in agriculture field. Mater. Today Proc. 2021, 45, 2491–2497. [Google Scholar] [CrossRef]

- Bahin, L.; Tourlonias, M.; Bueno, M.-A.; Sharma, K.; Rossi, R.M. Smart textiles with polymer optical fibre implementation for in-situ measurements of compression and bending. Sens. Actuators A Phys. 2023, 350, 114117. [Google Scholar] [CrossRef]

- Gürgen, S.; Yıldız, T. Stab resistance of smart polymer coated textiles reinforced with particle adhesives. Compos. Struct. 2020, 235, 111812. [Google Scholar] [CrossRef]

- Li, L.; Han, L.; Hu, H.; Zhang, R. A review on polymers and their composites for flexible electronics. Mater. Adv. 2023, 4, 726–746. [Google Scholar] [CrossRef]

- Zhang, D.; Tang, Y.; Gong, X.; Chang, Y.; Zheng, J. Highly conductive and tough double-network hydrogels for smart electronics. SmartMat. 2024, 5, e1160. [Google Scholar] [CrossRef]

- Cui, H.; Zhao, Q.; Zhang, L.; Du, X. Intelligent polymer-based bioinspired actuators: From monofunction to multifunction. Adv. Intell. Syst. 2020, 2, 2000138. [Google Scholar] [CrossRef]

- Peng, S.; Yu, Y.; Wu, S.; Wang, C.-H. Conductive polymer nanocomposites for stretchable electronics: Material selection, design, and applications. ACS Appl. Mater. Interfaces 2021, 13, 43831–43854. [Google Scholar] [CrossRef]

- Niu, J.; Chen, Z.; Zhao, J.; Cui, G. Stimulus-responsive polymers for safe batteries and smart electronics. Sci. China Mater. 2022, 65, 2060–2071. [Google Scholar] [CrossRef]

- Olabintan, A.B.; Abdullahi, A.H.S.; Yusuf, B.O.; Ganiyu, S.A.; Saleh, T.A.; Basheer, C. Prospects of polymer nanocomposite-based electrochemical sensors as analytical devices for environmental monitoring: A review. Microchem. J. 2024, 204, 111053. [Google Scholar] [CrossRef]

- Zegebreal, L.T.; Tegegne, N.A.; Hone, F.G. Recent progress in hybrid conducting polymers and metal oxide nanocomposite for room-temperature gas sensor applications: A review. Sens. Actuators A Phys. 2023, 359, 114472. [Google Scholar] [CrossRef]

- Ruiz, J.A.R.; Sanjuán, A.M.; Vallejos, S.; García, F.C.; García, J.M. Smart polymers in micro and nano sensory devices. Chemosensors 2018, 6, 12. [Google Scholar] [CrossRef]

- Alberti, G.; Zanoni, C.; Losi, V.; Magnaghi, L.R.; Biesuz, R. Current trends in polymer based sensors. Chemosensors 2021, 9, 108. [Google Scholar] [CrossRef]

- Babu, A.; Sivakumar, G.; Anandan, M.; Adhya, P.; Akash, T.; Mondal, T.; Nutalapati, V.; Maji, S. Design of smart polymeric sensor based on poly(N-isopropylacrylamide) and anthrapyrazolone derived fluorescent crosslinker for the detection of nitroaromatics in aqueous medium. Eur. Polym. J. 2023, 200, 112527. [Google Scholar] [CrossRef]

- Zheng, X.-Y.; Li, T.; Cai, H.-W.; Wang, X.-H.; Sun, X.-L.; Wan, W.-M. Polymerization-induced emission of borinic acid towards stimuli-responsive luminescent polymers. Polymer 2024, 300, 126996. [Google Scholar] [CrossRef]

- Hu, H.; Chen, Z.; Wang, C.; Wang, L.; Wang, X.; Shi, Y.; Chen, D. Two birds with one stone: An innovative fluorescent cellulose polyacrylamide-hydrogel modified by born/nitrogen-doped carbon dots with sensitive visual sensing and superior extraction capacity toward Ag+. Coll. Surf. A Physicochem. Eng. Asp. 2024, 684, 133163. [Google Scholar] [CrossRef]

- Yang, K.; Li, X.; Cui, J.; Zhang, M.; Wang, Y.; Lou, Z.; Shan, W.; Xiong, Y. Facile synthesis of novel porous graphene-like carbon hydrogel for highly efficient recovery of precious metal and removal of organic dye. Appl. Surf. Sci. 2020, 528, 146928. [Google Scholar] [CrossRef]

- Sharma, R.; Chavan, S.N.; Lee, H.-I. Fluorescent imidazolium hydrogels for tracing and recovering platinum with highest purity from spent auto catalyst. Sens. Actuators B Chem. 2023, 396, 134625. [Google Scholar] [CrossRef]

- Huang, T.; Su, Z.; Hou, K.; Zeng, J.; Zhou, H.; Zhang, L.; Nunes, S.P. Advanced stimuli-responsive membranes for smart separation. Chem. Soc. Rev. 2023, 52, 4173–4207. [Google Scholar] [CrossRef] [PubMed]

- Nicoletta, F.P.; Cupelli, D.; Formoso, P.; De Filpo, G.; Colella, V.; Gugliuzza, A. Light responsive polymer membranes: A review. Membranes 2012, 2, 134–197. [Google Scholar] [CrossRef] [PubMed]

- Musarurwa, H.; Tavengwa, N.T. Recycable polysaccharide/stimuli-responsive polymer composites and their applications in water remediation. Carbohydr. Polym. 2022, 298, 120083. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Qiu, L.; Han, X.; Wang, Z.; Wang, N. Synthesis and characteristics of smart coating materials for reversible double stimulus-responsive oil-water separation. ACS Appl. Polym. Mater. 2024, 6, 6482–6494. [Google Scholar] [CrossRef]

- Guembe-García, M.; Utzeri, G.; Valente, A.J.M.; Ibeas, S.; Trigo-López, M.; García, J.M.; Vallejos, S. Efficient extraction of textile dyes using reusable acrylic-based smart polymers. J. Hazard. Mater. 2024, 476, 135006. [Google Scholar] [CrossRef]

- Wang, K.; Guo, Y.; Wen, J.; Yang, H.; Zhang, H. Magnetic smart polymer gel with directional plugging for conformance control in oil reservoirs. J. Mol. Liq. 2024, 405, 125046. [Google Scholar] [CrossRef]

- Skider, A.; Pearce, A.K.; Parkinson, S.J.; Napier, R.; O’Reilly, R.K. Recent trends in advanced polymer materials in agriculture related applications. ACS Appl. Polym. Mater. 2021, 3, 1203–1217. [Google Scholar] [CrossRef]

- Zanino, A.; Pizzetti, F.; Masi, M.; Rossi, F. Polymers as controlled delivery systems in agriculture: The case of atrazine and other pesticides. Eur. Polym. J. 2024, 203, 112665. [Google Scholar] [CrossRef]

- Mikhailidi, A.; Ungureanu, E.; Tofanica, B.M.; Ungureanu, O.C.; Fortună, M.E.; Belosinschi, D.; Volf, I. Agriculture 4.0: Polymer hydrogels as delivery agents of active ingredients. Gels 2024, 26, 368. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Guan, W.; Lei, C.; Yu, G. Self-irrigation and slow-release fertilizer hydrogels for sustainable agriculture. ACS Mater. Lett. 2024, 6, 3471–3477. [Google Scholar] [CrossRef]

- Bangar, S.P.; Phimolsiripol, Y.; Trif, M. Special Issue “Smart polymeric films and coatings for food packaging applications. Polymers 2023, 15, 4522. [Google Scholar] [CrossRef]

- Habib, S.; Khan, A.; Nawaz, M.; Sliem, M.H.; Shakoor, R.A.; Kahraman, R.; Abdullah, A.M.; Zekri, A. Self-healing performance of multifunctional polymeric smart coatings. Polymers 2019, 11, 1519. [Google Scholar] [CrossRef] [PubMed]

- Vacareanu, L.; Gavril, A.-I.; Damaceanu, M.D. Smart polymer coatings electrogenerated from star-shaped oligomers bearing variable π-spacers with integrated electrochromic characteristics and sensing capability towards harmful nitroaromatic derivatives. Prog. Org. Coat. 2024, 189, 108328. [Google Scholar] [CrossRef]

- Ahmad, S.; Habib, S.; Nawaz, M.; Shakoor, R.A.; Kahraman, R.; Al Tahtamouni, T.M. The role of polymeric matrices on the performance of smart self-healing coatings: A review. J. Ind. Eng. Chem. 2023, 124, 40–67. [Google Scholar] [CrossRef]

- El-Ghaffar, M.A.A.; Abdelwahab, N.A.; Fekry, A.M.; Sanad, M.A.; Sabaa, M.W.; Soliman, S.M.A. Polyester-epoxy resin/conducting polymer/barium sulfate hybrid composite as a smart eco-friendly anti-corrosive powder coating. Prog. Org. Coat. 2020, 144, 105664. [Google Scholar] [CrossRef]

- Al-Senani, G.M.; Al-Qahtani, S.D. Development of smart adhesive using lanthanide-doped phosphor and carboxymethyl cellulose-reinforced gum Arabic. Spectrochim. Acta A Mol. Bimol. Spectrosc. 2024, 317, 124397. [Google Scholar] [CrossRef]

- Zhang, T.; Xue, B.; Yan, Q.; Yuan, Y.; Tan, J.; Guan, Y.; Wen, J.; Li, X.; Zhao, W. New kinds of lignin/non-isocyanate polyurethane hybrid polymers: Facile synthesis, smart properties and adhesive applications. Ind. Crop. Prod. 2023, 199, 116706. [Google Scholar] [CrossRef]

- Cui, X.; Liu, J.; Zhang, E.; Gong, Z.; Liang, L.; Shi, J.; Hao, H.J.; Lu, M. Synthesis and properties of a novel thermally conductive pressure-sensitive adhesive with UV-responsive peelability. Macromol. Rapid Commun. 2023, 44, 2200884. [Google Scholar] [CrossRef]

- Ren, J.; Li, X.; Zhang, E.; Shi, J.; Xiong, X.; Kong, C.; Li, C.; Wang, H.; Wu, K. A humidity-intensitive waterborne polyurethane pressure-sensitive adhesive modified by castor oil and siloxane. ChemistrySelect 2023, 8, e202300699. [Google Scholar] [CrossRef]

- Son, C.H.; Kim, S. Dual adaptation of a flexible shape memory polymer adhesive. ACS Appl. Mater. Interfaces 2021, 13, 27656–27662. [Google Scholar] [CrossRef] [PubMed]

- Bednarczyk, P.; Ossowicz-Rupniewska, P.; Klebeko, J.; Rokicka, J.; Bai, Y.; Czech, Z. Self-healing UV-curable urethane (meth)acrylates with various soft segment chemistry. Coatings 2023, 13, 2045. [Google Scholar] [CrossRef]

- Wang, S.; Urban, M.W. Self-healing polymers. Nat. Rev. Mater. 2020, 5, 562–583. [Google Scholar] [CrossRef]

- Novikov, A.S. Self-healing polymers. Polymers 2022, 14, 2261. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhou, M.; Wang, R.; Han, H.; Huang, Z.; Wang, J. Self-healing polyurethane elastomers: An essential review and prospects for future research. Eur. Polym. J. 2024, 214, 113159. [Google Scholar] [CrossRef]

- Choufi, N.E.; Mustapha, S.; Tehrani, A.; Grady, B.P. An overview of self-healable polymers and recent advances in the field. Macromol. Rapid Commun. 2022, 43, 2200164. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, Z.; Cheng, M.; Pang, W.; Mou, Y.; Meng, F.; Li, C.; Sun, S.; Hu, S.; Di, Z.; et al. Smart polymer with rapid self-healing and early corrosion reporting capabilities: Design, performance and mechanism. Chem. Eng. J. 2023, 456, 141159. [Google Scholar] [CrossRef]

- Yoshimoto, N.; Fathona, I.W.; Yabuki, A. Self-healing polymer coating with efficient delivery for alginates and calcium nitrite to provide corrosion protection for carbon steel. Colloids Surf. A Physicochem. Eng. Asp. 2023, 662, 130970. [Google Scholar] [CrossRef]

- Pang, W.; Jiang, H.; Wang, S.; He, T.; Chen, H.; Yan, T.; Chen, M.; Sun, S.; Li, C. Graphene oxides enhanced polyurethane based composite coating with long term corrosion resistance and self-healing property. Eur. Polym. J. 2024, 207, 112825. [Google Scholar] [CrossRef]

- Paquet, C.; Schmitt, T.; Klemberg-Sapieha, J.E.; Morin, J.-F.; Landry, V. Self-healing UV curable acrylate coatings for wood finishing system, part 1: Impact of the formulation on self-healing efficiency. Coatings 2020, 10, 770. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X.; Chen, L.; Du, J.; Ji, L.; Peng, Y.; Liu, L.; Xu, Z.; Lin, X.; Lin, W.; et al. Rapid self-healing and high-mechanical-strength epoxy resin coatings incorporating dynamic disulfide bonds. ACS Appl. Polym. Mater. 2024, 6, 4778–4788. [Google Scholar] [CrossRef]

- Wilson, A.N.; St John, P.C.; Marin, D.H.; Hoyt, C.B.; Rognerud, E.G.; Nimlos, M.R.; Cywar, R.M.; Rorrer, N.A.; Shebek, K.M.; Broadbelt, L.J.; et al. PolyID: Artificial intelligence for discovering derformance-advantaged and sustainable polymers. Macromolecules 2023, 56, 8547–8557. [Google Scholar] [CrossRef] [PubMed]

- Giro, R.; Hsu, H.; Kishimoto, A.; Hama, T.; Neumann, R.F.; Luan, B.; Takeda, S.; Hamada, L.; Steiner, M.B. AI powered, automated discovery of polymer membranes for carbon capture. NPJ Comput. Mater. 2023, 9, 133. [Google Scholar] [CrossRef]

- Schmitt, F.; Piccin, O.; Barbé, L.; Bayle, B. Soft robots manufacturing: A review. Front. Robot. AI 2018, 5, 84. [Google Scholar] [CrossRef]

- Schara, S.; Blau, R.; Church, D.C.; Pokorski, J.K.; Lipomi, D.J. Polymer chemistry for haptics, soft robotics, and human-machine interfaces. Adv. Funct. Mater. 2021, 31, 2008375. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, S.; Fang, B.; Sun, F.; Liu, H.; Li, H. A review of smart materials for the boost of soft actuators, soft sensors, and robotics applications. Chin. J. Mech. Eng. 2022, 35, 37. [Google Scholar] [CrossRef]

- Kim, J.; Park, H.; Yoon, C.K. Advances in biodegradable soft robots. Polymers 2022, 14, 4574. [Google Scholar] [CrossRef]

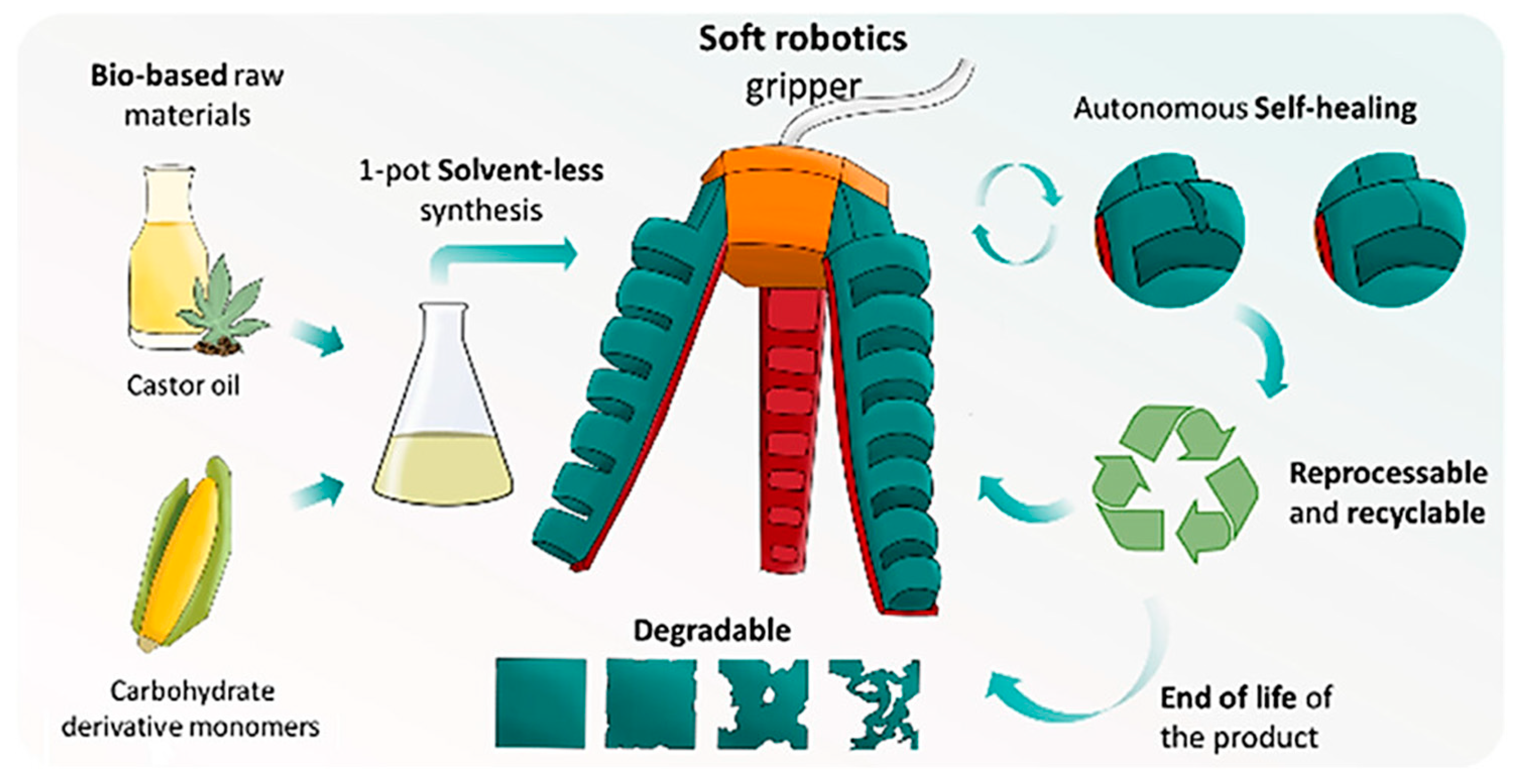

- Cornellà, A.C.; Tabrizian, S.K.; Ferrentino, P.; Roels, E.; Terryn, S.; Vanderborght, B.; Assche, G.V.; Brancart, J. Self-healing, recyclable, and degradable castor oil-based elastomers for sustainable soft robotics. ACS Sustain. Chem. Eng. 2023, 11, 3437–3450. [Google Scholar] [CrossRef]

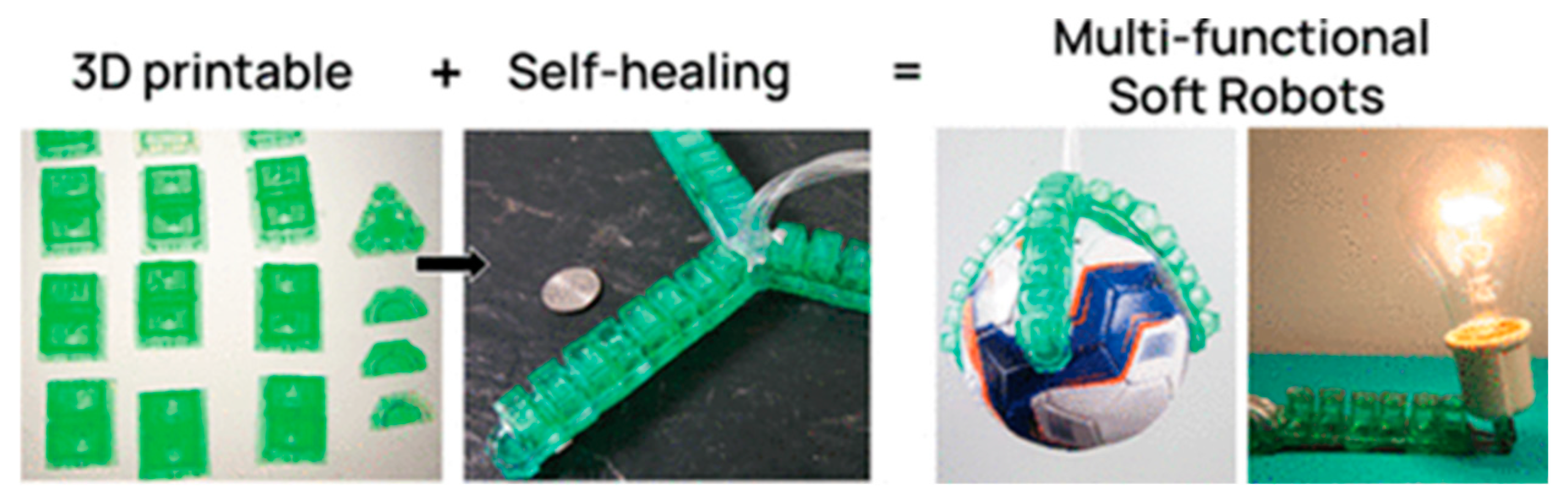

- Gomez, E.F.; Wanasinghe, S.V.; Flynn, A.E.; Dodo, O.J.; Sparks, J.L.; Baldwin, L.A.; Tabor, C.E.; Durstock, M.F.; Konkolewicz, D.; Trasher, C.J. 3D-printed self-healing elastomers for modular soft robotics. ACS Appl. Mater. Interfaces 2021, 13, 28870–28877. [Google Scholar] [CrossRef]

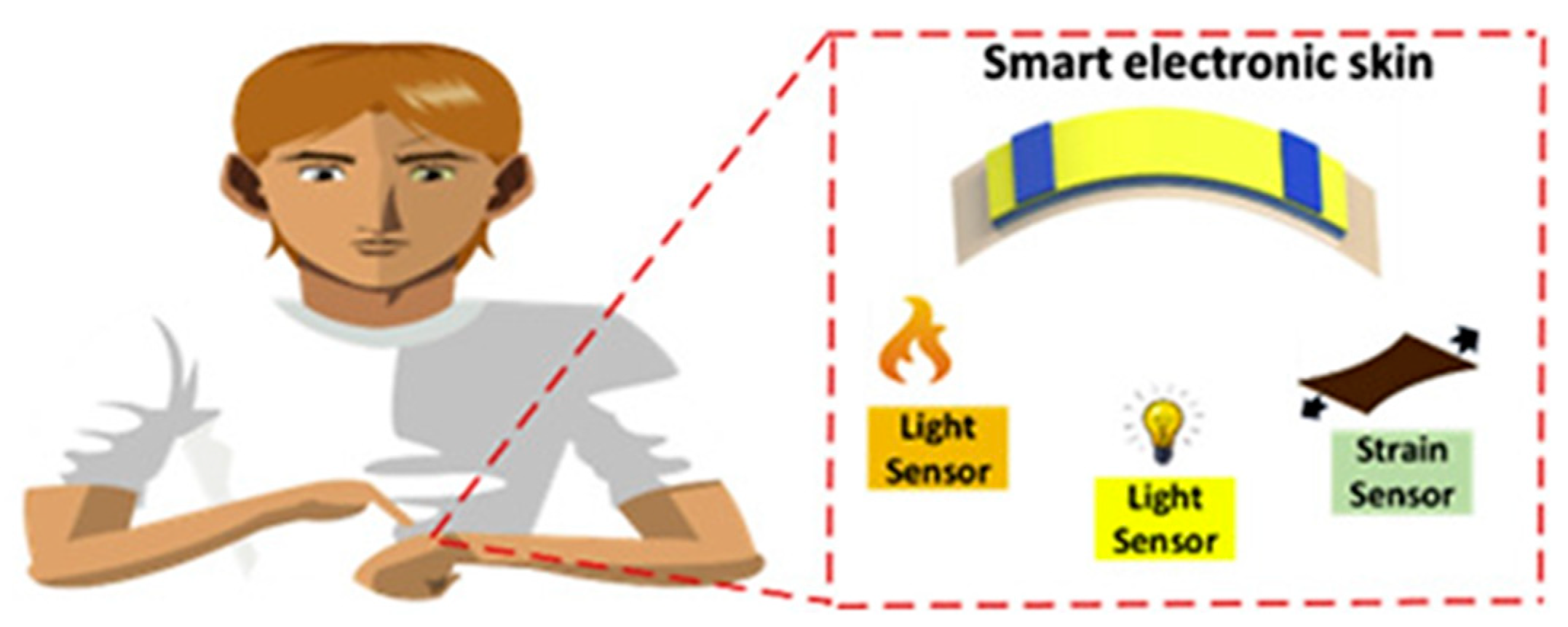

- Chen, J.; Wang, L.; Xu, X.; Liu, G.; Liu, H.; Qiao, Y.; Chen, J.; Cao, S.; Cha, Q.; Wang, T. Self-healing materials-based electronic skin: Mechanism, development and applications. Gels 2022, 8, 356. [Google Scholar] [CrossRef]

- García Núñez, C.; Manjakkal, L.; Dahiya, R. Energy autonomous electronic skin. NPJ Flex Electron 2019, 3, 1. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, P.; Zhang, F.; Li, P.; Hauang, W.; Li, C.; Han, N.; Mu, S.; Zhou, H.; Mao, Y. Intrinsically stretchable polymer semiconductor based electronic skin for multiple perceptions of force, temperature, and visible light. Nano Res. 2023, 16, 1196–1204. [Google Scholar] [CrossRef]

- Yin, F.; Niu, H.; Kim, E.-S.; Shin, Y.K.; Li, Y.; Kim, N.-Y. Advanced polymer materials-based electronic skins for tactile and non-contact sensing applications. InfoMat 2023, 5, e12424. [Google Scholar] [CrossRef]

- Ahmed, A.; Guan, Y.-S.; Hassan, I.; Ling, C.; Li, Z.; Mosa, I.; Phadke, G.; Selvaganapathy, P.R.; Chang, S.; Ren, S. Multifunctional smart electronic skin fabricated from two-dimensional like polymer film. Nano Energy 2020, 75, 105044. [Google Scholar] [CrossRef]

- Huang, H.; Trentle, M.; Liu, Z.; Xiang, K.; Higgins, W.; Wang, Y.; Xue, B.; Yang, S. Polymer complex fiber: Property, functionality, and applications. ACS Appl. Mater. Interfaces 2023, 15, 7639–7662. [Google Scholar] [CrossRef]

- Tanasa, F.; Teaca, C.-A.; Nechifor, M.; Ignat, M.; Duceac, I.A.; Ignat, L. Highly specialized textiles with antimicrobial functionality—Advances and challenges. Textiles 2023, 3, 219–245. [Google Scholar] [CrossRef]

- Lipovka, A.; Fatkullin, M.; Shchadenko, S.; Petrov, I.; Chernova, A.; Plotnikov, E.; Menzelintsev, V.; Li, S.; Qui, L.; Cheng, C.; et al. Textile electronics with laser-induced graphene/polymer hybrid fibers. ACS Appl. Mater. Interfaces 2023, 15, 38946–38955. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Ma, W.; Li, H.; Yang, M.; Yu, Y.; Liu, S.; Zeng, X.; Huang, F.; Yang, Y.; Li, Z. Phase-changing polymer film for smart windows with highly adaptive solar modulation. ACS Appl. Mater. Interfaces 2023, 15, 5836–5844. [Google Scholar] [CrossRef]

- Zhang, L.; Xia, H.; Xia, F.; Du, Y.; Wu, Y.; Gao, Y. Energy-Saving Smart Windows with HPC/PAA Hybrid Hydrogels as Thermochromic Materials. ACS Appl. Energy Mater. 2021, 4, 9783–9791. [Google Scholar] [CrossRef]

- Dai, M.; Zhao, J.; Zhang, Y.; Li, H.; Zhang, L.; Liu, Y.; Ye, Z.; Zhu, S. Dual-responsive hydrogels with three-stage optical modulation for smart windows. ACS Appl. Mater. Interfaces 2022, 14, 53314–53322. [Google Scholar] [CrossRef]

- Li, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S. Deformable thermo-responsive smart windows based on shape memory polymer for adaptive solar modulations. ACS Appl. Mater. Interfaces 2021, 13, 61196–61204. [Google Scholar] [CrossRef]

- Zhang, M.; Sitti, M. Perspective on smart materials for empowering small-scale manipulation. Sci. Bull. 2024, 69, 718–721. [Google Scholar] [CrossRef]

- Yildirim, M.; Candan, Z. Smart materials: The next generation in science and engineering. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. From static to dynamic: Smart materials pioneering additive manufacturing in regenerative medicine. Int. J. Mol. Sci. 2023, 24, 15748. [Google Scholar] [CrossRef] [PubMed]

- Kumari, S.; Avais, M.; Chattopadhyay, S. Microgels as smart polymer colloids for sensing and environmental remediation. ACS Appl. Polym. Mater. 2023, 5, 1626–1645. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

| Biocompatible, robust, flexible, easy to color, mild—cause fewer complications for patients. | There are difficulties in sterilizing them. |

| Facilitate dosing for patients—possibility of producing individualized products, e.g., tablets. | Lack of high mechanical resistance. |

| Simple synthesis method. | Sometimes it is difficult to load drugs and cells in a ready-made matrix. |

| They support/facilitate the transport of ingredients into cells. | |

| Provide prolonged drug release time and cause fewer side effects. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balcerak-Woźniak, A.; Dzwonkowska-Zarzycka, M.; Kabatc-Borcz, J. A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives. Materials 2024, 17, 4255. https://doi.org/10.3390/ma17174255

Balcerak-Woźniak A, Dzwonkowska-Zarzycka M, Kabatc-Borcz J. A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives. Materials. 2024; 17(17):4255. https://doi.org/10.3390/ma17174255

Chicago/Turabian StyleBalcerak-Woźniak, Alicja, Monika Dzwonkowska-Zarzycka, and Janina Kabatc-Borcz. 2024. "A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives" Materials 17, no. 17: 4255. https://doi.org/10.3390/ma17174255

APA StyleBalcerak-Woźniak, A., Dzwonkowska-Zarzycka, M., & Kabatc-Borcz, J. (2024). A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives. Materials, 17(17), 4255. https://doi.org/10.3390/ma17174255