Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

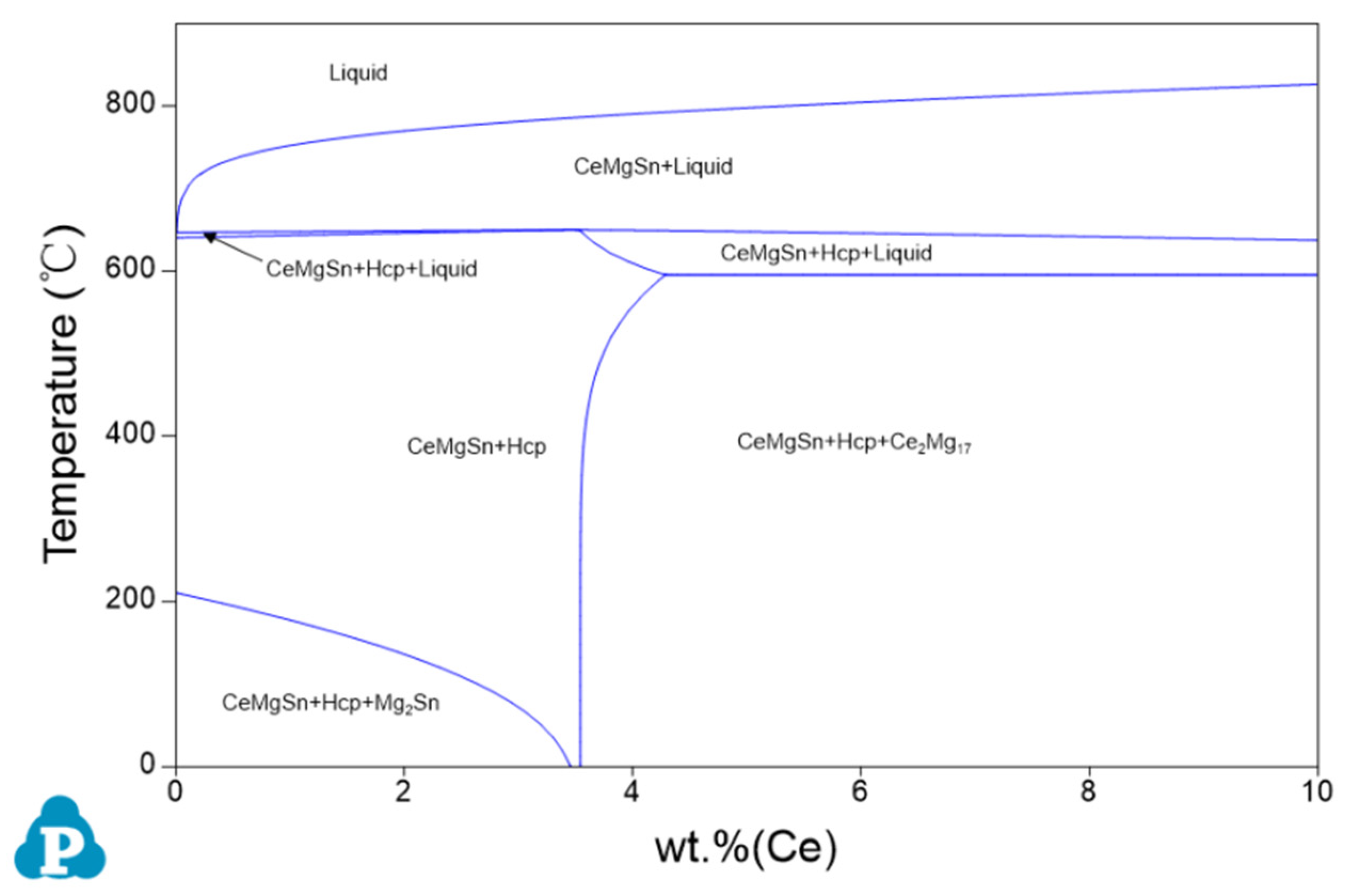

3.1. Microstructure Analysis of As-Cast Alloys

3.2. Microstructure and Textures of As-Extruded Alloys

3.3. Thermal Conductivity of As-Cast and As-Extruded Alloys

3.4. Mechanical Properties of As-Cast and As-Extruded Alloys

4. Conclusions

- A new second MgSnCe phase appeared after adding Ce to the as-cast Mg-3Sn alloy, and the Mg17Ce2 phase emerged as the Ce content increased to 4%.

- The addition of Ce reduced the number of solute atoms of Sn, resulting in a significant improvement in the thermal conductivity of as-cast Mg-3Sn alloys. However, an excess of Ce causes a formation of the Mg17Ce2 phase, which has a negative effect on the thermal conductivity.

- After extrusion, the thermal conductivity is improved, owing to the added Ce, which weakens the texture of the deformed grains.

- The addition of Ce increased the yield strength of the as-cast alloy. This is because Ce could refine the grains, as well as form the second phase MgSnCe to hinder the dislocation movement. The properties are further enhanced after extrusion due to the recrystallization process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys. 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Li, S.B.; Yang, X.Y.; Hou, J.T.; Du, W.B. A review on thermal conductivity of magnesium and its alloys. J. Magnes. Alloys. 2020, 8, 78–90. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Stanford, N.; Davies, C.H.J.; Nie, J.F.; Birbilis, N. Magnesium extrusion alloys: A review of developments and prospects. Int. Mater. Rev. 2019, 64, 27–62. [Google Scholar] [CrossRef]

- Emadi, P.; Andilab, B.; Ravindran, C. Engineering lightweight aluminum and magnesium alloys for a sustainable future. J. Indian Inst. Sci. 2022, 102, 405–420. [Google Scholar] [CrossRef]

- Ambroziński, M.; Rauch, Ł.; Paćko, M.; Gronostajski, Z.; Jaskiewicz, K.; Chorzepa, W. Computer aided design of manufacturing of automotive part made of magnesium alloy. Comput. Methods. Mater. Sci. 2016, 4, 177–186. [Google Scholar] [CrossRef]

- Milenin, A.; Kustra, P.; Du, P.; Furusawa, S.; Furushima, T. Computer aided design of the laser dieless drawing process of tubes from magnesium alloy with take into account ductility of the material. Procedia Manuf. 2018, 15, 302–310. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. Magnesium and Magnesium Alloys, ASM Speciality Handbook; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Zhuo, X.R.; Zhao, L.Y.; Gao, W.; Wu, Y.; Liu, H.; Zhang, P.; Hu, Z.C.; Jiang, J.H.; Ma, A.B. Recent progress of Mg-Sn based alloys: The relationship between aging response and mechanical performance. J. Mater. Res. Technol. 2022, 21, 186–211. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Yuan, Y.; Chen, T.; Zheng, Z.B.; Ma, L.F.; Jiang, B.; Tang, A.T.; Pan, F.S. The effects of second-alloying-element on the formability of Mg-Sn alloys in respect of the stacking fault energies of slip systems. Mater. Today Commun. 2021, 29, 102829. [Google Scholar] [CrossRef]

- Chen, Y.A.; Li, J.; Song, Y.; Liu, H.; Ye, R.Y. Effect of Zn on microstructure and mechanical property of Mg-3Sn-1Al alloys. Mater. Sci. Eng. A 2014, 612, 96–101. [Google Scholar] [CrossRef]

- Pan, H.C.; Qin, G.W.; Xu, M.; Fu, H.; Ren, Y.P.; Pan, F.S.; Gao, Z.Y.; Zhao, C.Y.; Yang, Q.S.; She, J.; et al. Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn. Mater. Des. 2015, 83, 736–744. [Google Scholar] [CrossRef]

- Zhao, H.D.; Qin, G.W.; Ren, Y.P.; Pei, W.L.; Chen, D.; Guo, Y. Microstructure and tensile properties of as-extruded Mg-Sn-Y alloys. Trans. Nonferrous Met. Soc. China 2010, 20, 493–497. [Google Scholar] [CrossRef]

- Su, C.Y.; Li, D.J.; Luo, A.A.; Ying, T.; Zeng, X.Q. Effect of solute atoms and second phases on the thermal conductivity of Mg-RE alloys: A quantitative study. J. Alloys Compd. 2018, 747, 431–437. [Google Scholar] [CrossRef]

- Zhou, X.; Mo, L.; Du, J.; Luo, G. Microstructure evolution and improvement of thermal conductivity in Mg-2Sn alloy induced by La addition. J. Mater. Res. Technol. 2022, 17, 1380–1389. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, J.W.; Kim, Y.H.; Yoo, H.S.; Woo, K.D.; Lee, S.H.; Son, H.T. Microstructures and Thermal Properties of Mg-Sn-Ca Alloys: Casts and Extrusions. Int. J. Thermophys. 2015, 36, 2666–2673. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Z.; Xiao, S.; Chen, Y. Effects of Sn, Ca additions on thermal conductivity of Mg matrix alloys. Mater. Sci. Technol. 2016, 32, 581–587. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, T.; Wu, S.S.; Lü, S.Q.; Yang, X.; Guo, W. Effects of Si Content and Ca Addition on Thermal Conductivity of As-Cast Mg–Si Alloys. Materials 2018, 11, 2376. [Google Scholar] [CrossRef]

- Peng, J.; Zhong, L.P.; Wang, Y.J.; Yang, J.; Lu, Y.; Pan, F.S. Effect of Ce addition on thermal conductivity of Mg-2Zn-1Mn alloy. J. Alloys Compd. 2015, 639, 556–562. [Google Scholar] [CrossRef]

- Liu, Y.F.; Jia, X.J.; Qiao, X.G.; Xu, S.W.; Zheng, M.Y. Effect of La content on microstructure, thermal conductivity and mechanical properties of Mg–4Al magnesium alloys. J. Alloys Compd. 2019, 806, 71–78. [Google Scholar] [CrossRef]

- Yang, C.B.; Zhang, Z.; Jiang, X.Y.; Lin, X.; Luo, N.; Han, B.J.; Zhang, X.L. Comparison of the thermal conductivity of Sm-containing AZ31 and ZK30 Alloys. Int. J. Thermophys. 2019, 40, 81. [Google Scholar] [CrossRef]

- Özarslan, S.; Şevik, H.; Sorar, İ. Microstructure, mechanical and corrosion properties of novel Mg-Sn-Ce alloys produced by high pressure die casting. Mater. Sci. Eng. C 2019, 105, 110064. [Google Scholar] [CrossRef]

- Yarkadaş, G.; Kumruoğlu, L.C.; Şevik, H. The effect of Cerium addition on microstructure and mechanical properties of high pressure die cast Mg-5Sn alloy. Mater. Charact. 2018, 136, 152–156. [Google Scholar] [CrossRef]

- Kozlov, A.; Gröbner, J.; Schmid-Fetzer, R. Phase formation in Mg-Sn alloys modified by Ca and Ce. J. Phase Equilib. Diffus. 2014, 35, 502–517. [Google Scholar] [CrossRef]

- Manfrinetti, P.; Provino, A.; Gschneidner Jr, K.A. On the RMgSn rare earth compounds. J. Alloys Compd. 2009, 482, 81–85. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Sawston Cambridge, UK, 2002. [Google Scholar]

- Grimvall, G. Thermophysical Properties of Materials; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Schick, M.; Watson, A.; to Baben, M.; Hack, K. A modified Neumann-Kopp treatment of the heat capacity of stoichiometric phases for use in computational thermodynamics. J. Phase Equilib. Diffus. 2019, 40, 104–114. [Google Scholar] [CrossRef]

- Hao, M.J.; Cheng, W.L.; Wang, L.F.; Mostaed, E.; Bian, L.P.; Wang, H.X.; Niu, X.F. Texture evolution induced by twinning and dynamic recrystallization in dilute Mg-1Sn-1Zn-1Al alloy during hot compression. J. Magnes. Alloys. 2020, 8, 899–909. [Google Scholar] [CrossRef]

- Yang, C.B.; Pan, F.S.; Chen, X.H.; Luo, N.; Han, B.J.; Zhou, T.Y. Thermal conductivity and mechanical properties of Sm-containing Mg-Zn-Zr alloys. Mater. Sci. Technol. 2018, 34, 138–144. [Google Scholar] [CrossRef]

- Yamasaki, M.; Kawamura, Y. Thermal diffusivity and thermal conductivity of Mg-Zn-rare earth element alloys with long-period stacking ordered phase. Scr. Mater. 2009, 60, 264–267. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Liu, F.; Hu, W.X.; Yang, Z.H.; Wang, W.; He, W. Microstructure evolution and age-hardening response in Mg-Sn-Sm alloys under a wide range of Sm/Sn ratio. China Foundry 2022, 19, 211–217. [Google Scholar] [CrossRef]

- Yuan, J.W.; Zhang, K.; Li, T.; Li, X.G.; Li, Y.J.; Ma, M.L.; Luo, P.; Luo, G.Q.; Hao, Y.H. Anisotropy of thermal conductivity and mechanical properties in Mg–5Zn–1Mn alloy. Mater. Des. 2012, 40, 257–261. [Google Scholar] [CrossRef]

| Alloys | Composition (wt.%) | ||

|---|---|---|---|

| Sn | Ce | Mg | |

| x = 0 | 2.91 | - | Bal. |

| x = 1.0 | 2.90 | 1.22 | Bal. |

| x = 3.4 | 3.34 | 3.33 | Bal. |

| x = 4.0 | 3.10 | 3.90 | Bal. |

| Alloys | Grain Size (μm) |

|---|---|

| Mg-3Sn | 25.99 ± 4.79 |

| Mg-3Sn-1.0Ce | 17.37 ± 3.59 |

| Mg-3Sn-3.4Ce | 15.70 ± 3.63 |

| Mg-3Sn-4.0Ce | 14.39 ± 3.35 |

| Points | Mg | Sn | Ce | |||

|---|---|---|---|---|---|---|

| wt.% | at.% | wt.% | at.% | wt.% | at.% | |

| A | 89.17 | 97.57 | 10.83 | 2.43 | - | - |

| B | 30.73 | 68.42 | 69.27 | 31.58 | - | - |

| C | 91.37 | 98.10 | 8.63 | 1.90 | - | - |

| D | 61.38 | 89.41 | 18.25 | 5.44 | 20.37 | 5.15 |

| E | 21.12 | 58.72 | 37.30 | 21.23 | 41.58 | 20.05 |

| F | 97.90 | 99.61 | 0.74 | 0.15 | 1.36 | 0.24 |

| G | 78.76 | 95.53 | - | - | 21.24 | 4.47 |

| H | 98.02 | 99.64 | 0.35 | 0.07 | 1.64 | 0.29 |

| I | 43.30 | 80.25 | 26.30 | 9.98 | 30.39 | 9.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.-y.; Hu, W.-x.; Liu, L.-j.; He, W.; Ma, S.-b.; Zhang, X.-d.; Yang, Z.-h.; Wang, W. Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys. Materials 2024, 17, 4251. https://doi.org/10.3390/ma17174251

He F-y, Hu W-x, Liu L-j, He W, Ma S-b, Zhang X-d, Yang Z-h, Wang W. Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys. Materials. 2024; 17(17):4251. https://doi.org/10.3390/ma17174251

Chicago/Turabian StyleHe, Fei-yu, Wen-xin Hu, Li-juan Liu, Wei He, Shao-bo Ma, Xu-dong Zhang, Zheng-hua Yang, and Wei Wang. 2024. "Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys" Materials 17, no. 17: 4251. https://doi.org/10.3390/ma17174251

APA StyleHe, F.-y., Hu, W.-x., Liu, L.-j., He, W., Ma, S.-b., Zhang, X.-d., Yang, Z.-h., & Wang, W. (2024). Effect of Ce Addition on Microstructure, Thermal Conductivity, and Mechanical Properties of As-Cast and As-Extruded Mg–3Sn Alloys. Materials, 17(17), 4251. https://doi.org/10.3390/ma17174251