Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques

Abstract

1. Introduction

2. Materials and Methods

2.1. Filament Material

- -

- Density of the filament (1.29 g/cm3);

- -

- Izod notched impact strength (4.7 kJ/m2);

- -

- Tensile strength (20 MPa);

- -

- Modulus of elasticity in tension (2980 MPa).

2.2. Object of the Study

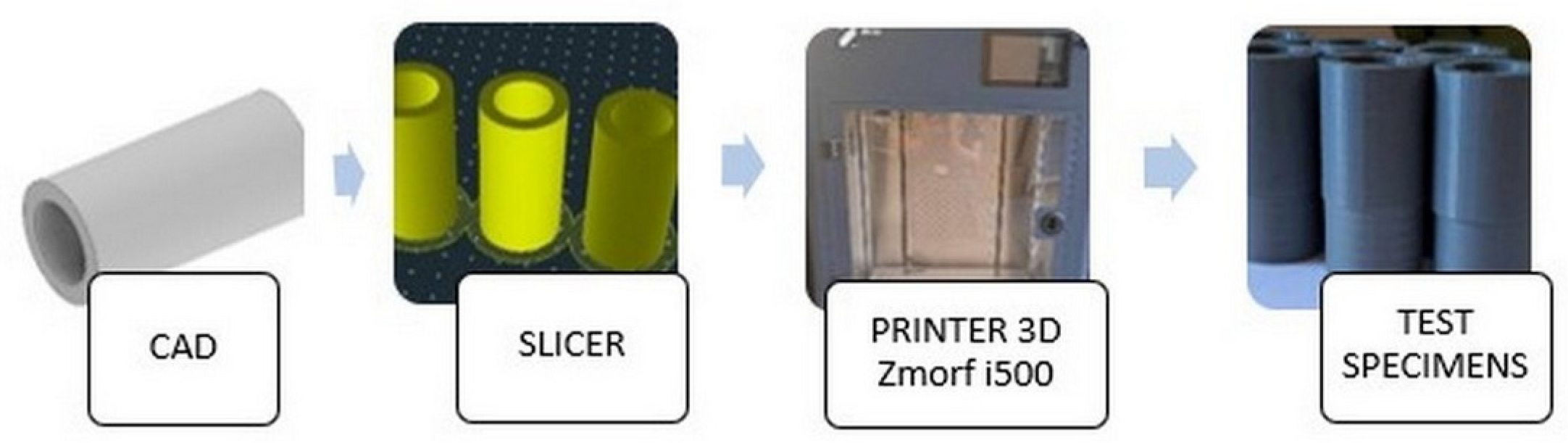

2.3. Fused Deposition Modelling

2.4. Testing Algorithm

- Testing the surface roughness of a test sample printed on a 3D printer using a Mitutoyo SJ-301S profilometer (Mitutoyo, Tokyo, Japan). Preparation of surface profiles related to the surface.

- Examination of the state of the surface structure and its evaluation using a Zeiss Axio Vert A1 MAT microscope (Zeiss, Jena, Germany).

- Longitudinal turning on a conventional lathe UT410 × 1000.

- Examination of the surface structure and its evaluation using a scanning electron microscope.

- Examination of the surface roughness of the specimen after turning using a Mitutoyo Pro-Filometer SJ-301S (Mitutoyo, Tokyo, Japan).

- Roundness contour test with optical profilometer Keyence VR 6200 (KEYENCE, Itasca, IL, USA).

2.4.1. Surface Roughness Measurement of Printed Samples

2.4.2. Microstructure

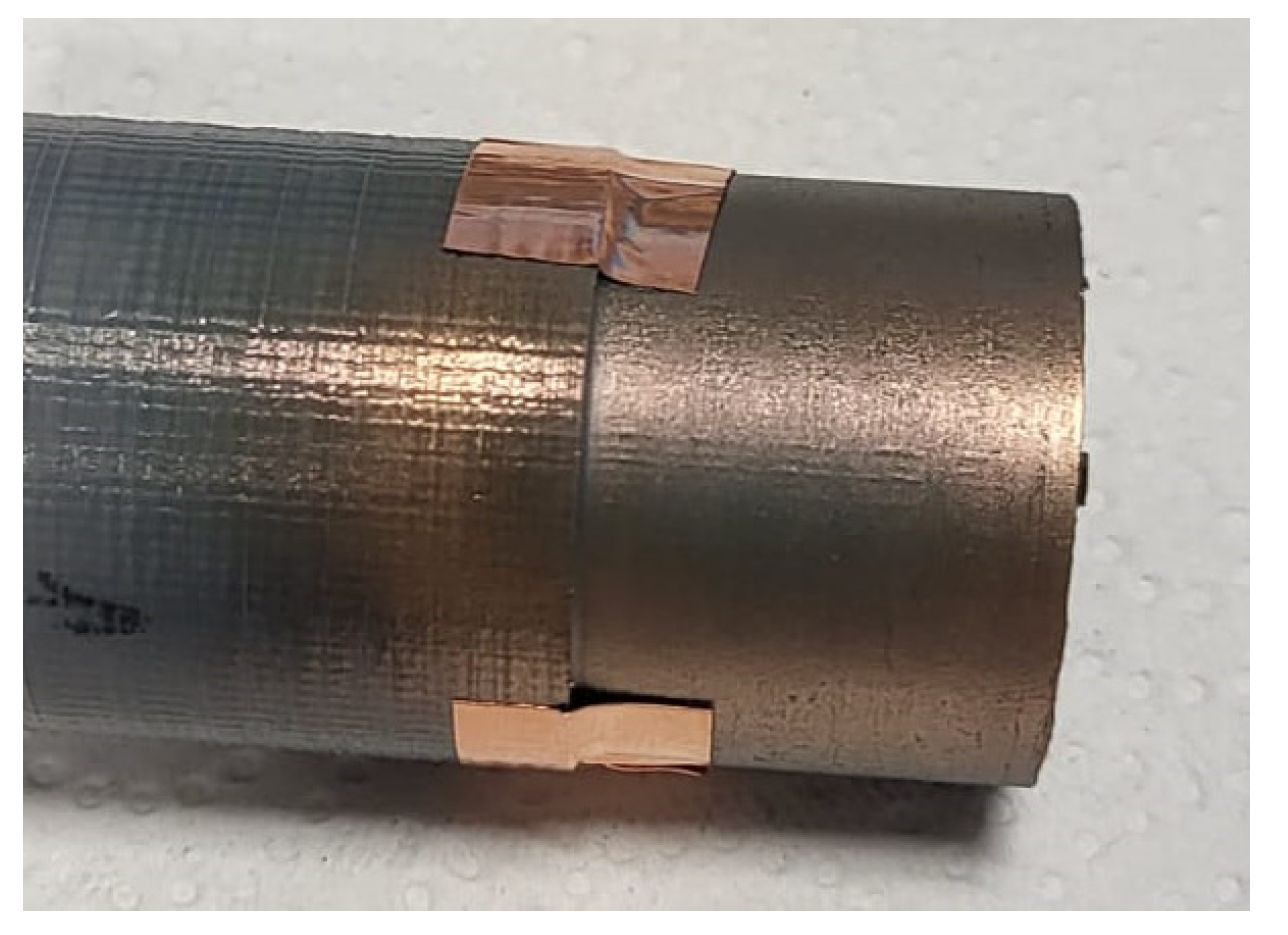

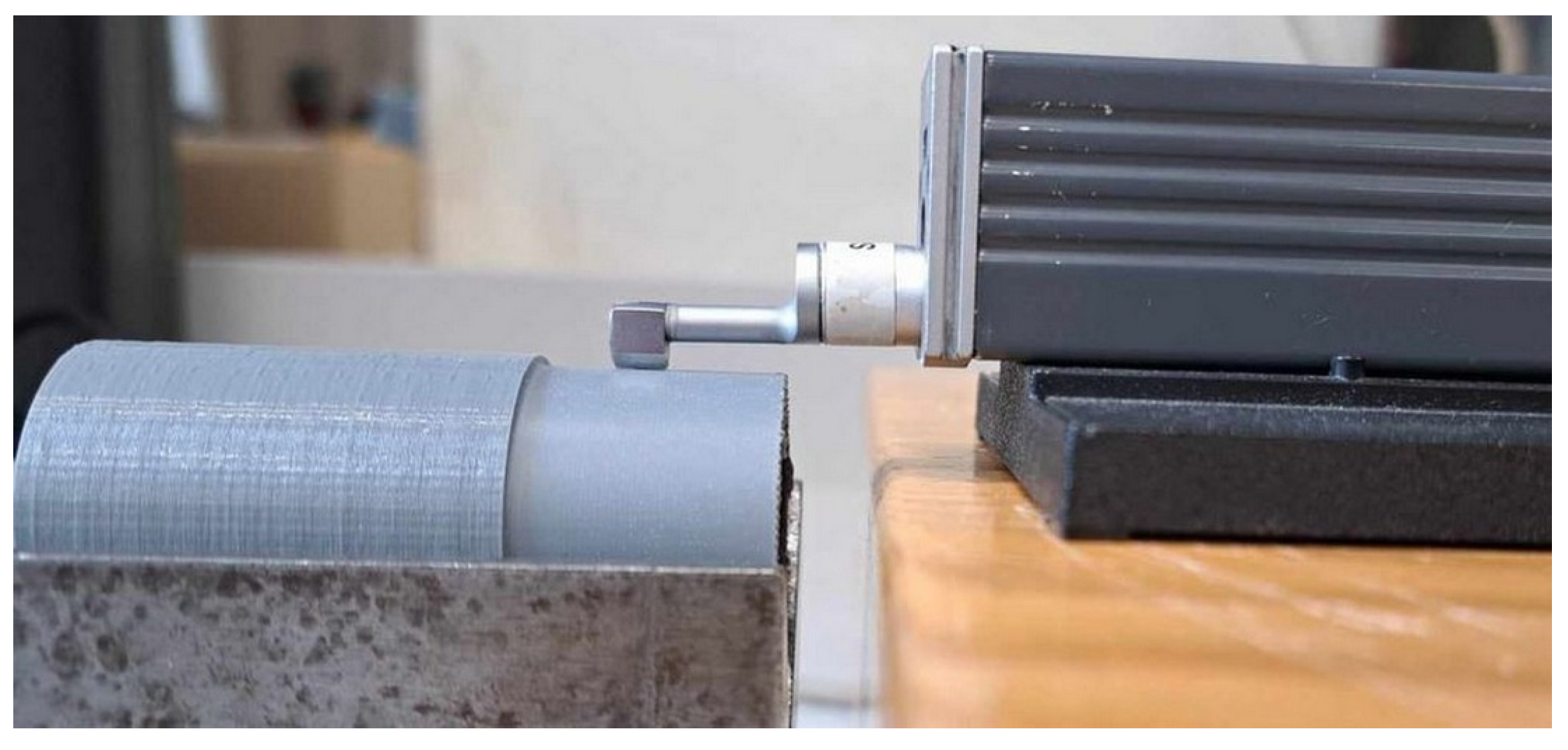

2.4.3. Turning Process

2.4.4. Texture Testing

2.4.5. Roundness Measurement of the Workpieces

3. Results and Discussion

3.1. Surface Roughness Measurement of Printed Samples

3.2. Microstructure

3.3. Measurement of Surface Roughness after Turning

3.4. Texture Testing

3.5. Roundness Measurement of the Workpieces

4. Conclusions

- The research programme carried out allowed detailed conclusions to be drawn.

- Samples printed at a layer height of 0.1 mm had lower roughness parameters compared to samples for which a layer height of 0.2 mm was used. These amounted to Ra = 7.95 μm and Ra = 12.94 μm, respectively.

- The hybrid technology developed enabled a component surface parameter for a 0.1 Ra printing layer height of 2.52 μm, and for a 0.2 mm Ra layer height of 2.56 μm to be obtained.

- Comparing the surface microstructure of the element with 0.1 mm and 0.2 mm layer heights, it can be observed that better bonding of the printing layers occurred with the samples where a 0.1 mm height was used. Greater adhesion between the layers also translated into a more accurate representation of the model geometry and a lower surface roughness parameter.

- The results confirmed that the surface roughness parameter decreases as the tool feed rate decreases. Using a layer height of 0.1 mm and a feed rate of 0.0506 mm/rev, the Ra parameter was 1.94 μm, at 0.1138 mm/rev, it was 2.22 μm, and at 0.2226 mm/rev, it was equal to 2.39 μm. Maintaining the height of the 0.2 mm printing layer, the Ra parameter was 2.13 μm for a feed rate of 0.0506 mm/rev, 2.25 μm for 0.1138 mm/rev, and 2.25 μm for 0.2226 mm/rev.

- Specimen 2, with a lower printing layer height (0.1 mm) and lower feed rate (0.0506 mm/rev), showed the smallest roundness deviation of 0.022 mm. In contrast, specimen 6, with a higher printing layer height (0.2 mm) and higher feed rate (0.2276 mm/rev), had a higher roundness deviation of 0.07 mm. Increasing the height of the printing layer during printing and using a higher feed rate during turning can lead to larger roundness deviations. This may be due to higher cutting forces and vibrations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO/ASTM 5290; Additive Manufacturing—General Principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 2015.

- Jabłońska, M.; Jurczak, W.; Ozimina, D.; Adamiak, M. Increasing the operational reliability of a ship by using a composite impeller in the event of hydrophore pump failure. Eksploat. Niezawodn.—Maint. Reliab. 2023, 25, 18. [Google Scholar] [CrossRef]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Zawadzki, P.; Buń, P. Strength of ABS parts produced by fused deposition modelling technology—A critical orientation problem. Adv. Sci. Technol. Res. J. 2015, 9, 12–19. [Google Scholar] [CrossRef]

- Nagaraju, D.S.; Krupakaran, R.L.; Sripadh, C.; Nitin, G.; Joy Joseph Emmanuel, G. Mechanical properties of 3D printed specimen using FDM (Fused deposition modelling) and SLA (Stereolithography) technologies. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Chaidas, D.; Kitsakis, K.; Kechagias, J.; Maropoulos, S. The impact of temperature changing on surface roughness of FFF process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012033. [Google Scholar] [CrossRef]

- Kovan, V.; Tezel, T.; Topal, E.; Camurlu, H. Printing Parameters Effect on Surface Characteristics of 3D Printed Pla Materials. Int. Sci. J. Mach. Technol. Mater. 2018, 12, 266–269. [Google Scholar]

- Srinivasan, R.; Prathap, P.; Raj, A.; Aswinth Kannan, S.; Deepak, V. Influence of fused deposition modeling process parameters on the mechanical properties of PETG parts. Mater. Today Proc. 2020, 27, 1877–1883. [Google Scholar] [CrossRef]

- Loskot, J.; Jezbera, D.; Loskot, R.; Bušovský, D.; Barylski, A.; Glowka, K.; Duda, P.; Aniołek, K.; Voglová, K.; Zubko, M. Influence of print speed on the microstructure, morphology, and mechanical properties of 3D-printed PETG products. Polym. Test. 2023, 123, 108055. [Google Scholar] [CrossRef]

- García, E.; Núñez, P.J.; Caminero, M.A.; Chacón, J.M.; Kamarthi, S. Effects of carbon fibre reinforcement on the geometric properties of PETG-based filament using FFF additive manufacturing. Compos. Part B Eng. 2022, 235, 109766. [Google Scholar] [CrossRef]

- Głowacki, M.; Mazurkiewicz, A.; Słomion, M.; Skórczewska, K. Resistance of 3D-Printed Components, Test Specimens and Products to Work under Environmental Conditions—Review. Materials 2022, 15, 6162. [Google Scholar] [CrossRef]

- Ciecieląg, K. Analysis of the Surface Layer and Feed Force after Milling Polymer Composites with Coated and Uncoated Tools. Adv. Sci. Technol. Res. J. 2023, 17, 70–78. [Google Scholar] [CrossRef]

- Al-Sabur, R.; Kubit, A.; Khalaf, H.I.; Jurczak, W.; Dzierwa, A.; Korzeniowski, M. Analysis of Surface Texture and Roughness in Composites Stiffening Ribs Formed by SPIF Process. Materials 2023, 16, 2901. [Google Scholar] [CrossRef]

- Mertkan, İ.A.; Tezel, T.; Kovan, V. Improving surface and dimensional quality with an additive manufacturing-based hybrid technique. Int. J. Adv. Manuf. Technol. 2023, 128, 1957–1963. [Google Scholar] [CrossRef]

- Djurović, S.; Lazarević, D.; Mišić, M.; Šarkoćević, Ž.; Golubović, Z. 3D Printing and CNC Machining: Materials, Technologies, and Process Parameters. In New Trends in Engineering Research; Mitrovic, N., Mladenovic, G., Mitrovic, A., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 271–276. [Google Scholar]

- Tejada Martinez, L.V.; Witz, J.-F.; Najjar, D.; Boidin, X.; Lesaffre, F.; Martin, V.; Badin, S.; Berte, E. Hybrid FFF/CNC: An open source hardware & software system. HardwareX 2024, 18, e00536. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Mukherjee, T.; Finch, N.; De, A.; DebRoy, T. High-throughput screening of surface roughness during additive manufacturing. J. Manuf. Process. 2022, 81, 65–77. [Google Scholar] [CrossRef]

- He, C.L.; Zong, W.J.; Zhang, J.J. Influencing factors and theoretical modeling methods of surface roughness in turning process: State-of-the-art. Int. J. Mach. Tools Manuf. 2018, 129, 15–26. [Google Scholar] [CrossRef]

- Miko, E.; Nowakowski, Ł. Analysis and Verification of Surface Roughness Constitution Model after Machining Process. Procedia Eng. 2012, 39, 395–404. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling parts by CNC machining. Robot. Comput.-Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- Wahab Hashmi, A.; Ahmad, S.; Gulam Mustafa, M.; Tian, Y.; Iqbal, F.; Singh Mali, H.; Kamyab, H.; Yusuf, M. Abrasive flow finishing of 3D-Printed Aerofoils: Design, numerical Simulation, and experimental analysis. Opt. Laser Technol. 2024, 174, 110578. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. Laser assisted finishing process for improved surface finish of fused deposition modelled parts. J. Manuf. Process. 2017, 30, 161–177. [Google Scholar] [CrossRef]

- Karunakaran, K.P.; Suryakumar, S.; Pushpa, V.; Akula, S. Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput.-Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A Hybrid Multi-tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Z.; Liu, B.; Yang, S.; Kuai, Z.; Li, J.; Li, H.; Chen, Y.; Wu, H.; Bai, P. Microstructure and mechanical properties of CNC-SLM hybrid manufacturing 316L parts. J. Manuf. Process. 2022, 79, 432–441. [Google Scholar] [CrossRef]

- Hur, J.; Lee, K.; Zhu-hu Kim, J. Hybrid rapid prototyping system using machining and deposition. Comput.-Aided Des. 2002, 34, 741–754. [Google Scholar] [CrossRef]

- Kulkarni, P.; Dutta, D. On the Integration of Layered Manufacturing and Material Removal Processes. J. Manuf. Sci. Eng. 1999, 122, 100–108. [Google Scholar] [CrossRef]

- Amanullah, A.; Murshiduzzaman; Saleh, T.; Khan, R. Design and Development of a Hybrid Machine Combining Rapid Prototyping and CNC Milling Operation. Procedia Eng. 2017, 184, 163–170. [Google Scholar] [CrossRef]

- Lee, W.; Wei, C.; Chung, S.-C. Development of a hybrid rapid prototyping system using low-cost fused deposition modeling and five-axis machining. J. Mater. Process. Technol. 2014, 214, 2366–2374. [Google Scholar] [CrossRef]

- Mehtedi, M.E.; Buonadonna, P.; Mohtadi, R.E.; Aymerich, F.; Carta, M. Surface quality related to machining parameters in 3D-printed PETG components. Procedia Comput. Sci. 2024, 232, 1212–1221. [Google Scholar] [CrossRef]

- Pandey, P.M.; Venkata Reddy, N.; Dhande, S.G. Improvement of surface finish by staircase machining in fused deposition modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Potnis, M.S.; Singh, A.; Jatti, V.S.; Sapre, M.S.; Pathak, S.; Joshi, S.; Jatti, A.V. Part quality investigation in fused deposition modelling using machine learning classifiers. Int. J. Interact. Des. Manuf. 2024, 18, 305–329. [Google Scholar] [CrossRef]

- Grzesik, W. Influence of Surface Roughness on Fatigue Life of Machine Elements—The Development in Experimental Investigations and Simulations. In Mechanik Miesięcznik Naukowo-Techniczny. Available online: https://www.mechanik.media.pl/artykuly/wplyw-chropowatosci-powierzchni-na-trwalosc-zmeczeniowa-elementow-maszyn-postep-w-dziedzinie-badan-i-symulacji.html (accessed on 26 July 2024).

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- EN ISO 21920-2:2022; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2022. Available online: https://sklep.pkn.pl/pn-en-iso-21920-2-2022-06e.html (accessed on 26 August 2024).

- Ahn, D.; Kim, H.; Lee, S. Surface roughness prediction using measured data and interpolation in layered manufacturing. J. Mater. Process. Technol. 2009, 209, 664–671. [Google Scholar] [CrossRef]

- Zubrzycki, J.; Estrada, Q.; Staniszewski, M.; Marchewka, M. Influence of 3D Printing Parameters by FDM Method on the Mechanical Properties of Manufactured Parts. Adv. Sci. Technol. Res. J. 2022, 16, 52–63. [Google Scholar] [CrossRef]

- Tamrin, K.F.; Nukman, Y.; Sheikh, N.A. Laser Spot Welding of Thermoplastic and Ceramic: An Experimental Investigation. Mater. Manuf. Process. 2015, 30, 1138–1145. [Google Scholar] [CrossRef]

- Mahesh, V.; George, J.P.; Mahesh, V.; Chakraborthy, H.; Mukunda, S.; Ponnusami, S.A. Dry-sliding wear properties of 3D printed PETG/SCF/OMMT nanocomposites: Experimentation and model predictions using artificial neural network. J. Reinf. Plast. Compos. 2023, 43, 682–693. [Google Scholar] [CrossRef]

- Ajay Kumar, M.; Khan, M.S.; Mishra, S.B. Effect of machine parameters on strength and hardness of FDM printed carbon fiber reinforced PETG thermoplastics. Mater. Today Proc. 2020, 27, 975–983. [Google Scholar] [CrossRef]

- Zaleski, K.; Matuszak, J. Comparative study of the influence of technological parameters of milling of selected titanium alloys on cutting torque and surface roughness of machined surface. Adv. Mech. Mater. Eng. 2017, 34, 563–572. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive manufacturing: Expanding 3D printing horizon in industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Görçün, Ö.F.; Mishra, A.R.; Aytekin, A.; Simic, V.; Korucuk, S. Evaluation of Industry 4.0 strategies for digital transformation in the automotive manufacturing industry using an integrated fuzzy decision-making model. J. Manuf. Syst. 2024, 74, 922–948. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. Current trends and research opportunities in hybrid additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 623–648. [Google Scholar] [CrossRef]

- Lathe Operator’s Manual UT 410x1000. 2018. Available online: https://www.cormak.pl/gb/universal-lathes/263-410x1000-universal-lathe-5906800305619.html?srsltid=AfmBOorHx0NQfYfD0a0JlJRQpc6rVITBGUnJrqhbM6yzwppJ0a76pfEV (accessed on 22 August 2024).

- Sepahi, M.T.; Abusalma, H.; Jovanovic, V.; Eisazadeh, H. Mechanical Properties of 3D-Printed Parts Made of Polyethylene Terephthalate Glycol. J. Mater. Eng. Perform. 2021, 30, 6851–6861. [Google Scholar] [CrossRef]

- Marshal, R.M.; Patzek, M.; Rüsch, O. Characterization of the micrometer scale surface roughness of meteoritic samples. Icarus 2024, 412, 115984. [Google Scholar] [CrossRef]

- Gapiński, B. Recommendations for the roundness measurement with, CMM. Pomiary Autom. Kontrola R 2007, 53, 9. [Google Scholar]

- Labuda, W.; Dargacz, M.; Klecha, M.; Kozłowska, S. The influence of changing the side angle of the cutting tool by wiper technology on the value of surface roughness parameters of shaft pins made of austenitic steel. Sci. J. Gdyn. Marit. Univ. 2015, 64–77. Available online: https://sj.umg.edu.pl/artykul-377.html (accessed on 22 August 2024).

- Lakshman Sri, S.V.; Karthick, A.; Dinesh, C. Evaluation of mechanical properties of 3D printed PETG and Polyamide (6) polymers. Chem. Phys. Impact 2024, 8, 100491. [Google Scholar] [CrossRef]

- de Menezes, E.A.W.; Friedrich, L.; Colpo, A.; Amico, S.C. Chapter 5—Micromechanics of Short-Fiber and Particulate Composites. In Unsaturated Polyester Resins; Thomas, S., Hosur, M., Chirayil, C.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 125–152. [Google Scholar]

| Parameter | Value |

|---|---|

| Filament | PETG |

| Extruder temperature maintained during printer operation | 225 °C |

| Temperature of the table for all extruded printing layers | 70 °C |

| Infill density of the sample | 100% |

| Number of outer layers of the printed object | 4 |

| Printing layer height | 0.1 and 0.2 mm |

| First printing layer height | 0.25 mm |

| First printing layer width | 0.4 mm |

| Infill pattern inside the sample | linear |

| Feed rate during which the filament layer is extruded | 30 mm/s |

| Infill angle | 45° |

| Infill type | rectilinear |

| Sample | h (mm) | Ra (μm) | Rz (μm) | Rq (μm) | |||

|---|---|---|---|---|---|---|---|

| σ | σ | σ | |||||

| 1 | 0.1 | 9.70 | 2.22 | 49.51 | 11.07 | 11.80 | 2.70 |

| 2 | 0.1 | 7.95 | 0.76 | 42.64 | 2.84 | 9.65 | 0.90 |

| 3 | 0.1 | 16.09 | 3.5 | 87.33 | 19.19 | 20.68 | 4.36 |

| 4 | 0.2 | 13.55 | 1.82 | 65.75 | 8.89 | 16.48 | 2.38 |

| 5 | 0.2 | 12.94 | 1.00 | 62.21 | 5.33 | 15.65 | 1.20 |

| 6 | 0.2 | 12.85 | 0.71 | 64.44 | 3.92 | 15.70 | 0.96 |

| Sample | h (mm) | fn (mm/rev) | Ra (μm) | Rz (μm) | ||||

|---|---|---|---|---|---|---|---|---|

| σ | CV | σ | CV | |||||

| 1 | 0.1 | 0.1138 | 2.85 | 0.64 | 0.22 | 17.03 | 5.15 | 0.30 |

| 2 | 0.1 | 0.0506 | 2.52 | 0.72 | 0.28 | 15.05 | 5.37 | 0.35 |

| 3 | 0.1 | 0.2276 | 2.90 | 0.61 | 0.21 | 18.04 | 4.17 | 0.23 |

| 4 | 0.2 | 0.1138 | 2.74 | 0.30 | 0.11 | 16.94 | 2.00 | 0.11 |

| 5 | 0.2 | 0.0506 | 2.88 | 0.45 | 0.15 | 17.13 | 2.88 | 0.16 |

| 6 | 0.2 | 0.2276 | 2.56 | 0.29 | 0.11 | 15.47 | 3.14 | 0.20 |

| Distance from the Plane of Roundness to the Face of the Specimen [mm] | Roundness Deviation Specimen | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 16 | 0.034 | 0.033 | 0.035 | 0.032 | 0.028 | 0.033 |

| 10 | 0.029 | 0.049 | 0.055 | 0.03 | 0.038 | 0.07 |

| 4 | 0.045 | 0.022 | 0.048 | 0.025 | 0.05 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabłońska, M.; Łastowska, O. Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques. Materials 2024, 17, 4250. https://doi.org/10.3390/ma17174250

Jabłońska M, Łastowska O. Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques. Materials. 2024; 17(17):4250. https://doi.org/10.3390/ma17174250

Chicago/Turabian StyleJabłońska, Monika, and Olga Łastowska. 2024. "Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques" Materials 17, no. 17: 4250. https://doi.org/10.3390/ma17174250

APA StyleJabłońska, M., & Łastowska, O. (2024). Enhancing of Surface Quality of FDM Moulded Materials through Hybrid Techniques. Materials, 17(17), 4250. https://doi.org/10.3390/ma17174250