Nanocrystalline Cellulose to Reduce Superplasticizer Demand in 3D Printing of Cementitious Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. CNC Characterization

2.2. Flocculation Trials

2.3. Tests in Mortar Specimens

3. Results and Discussion

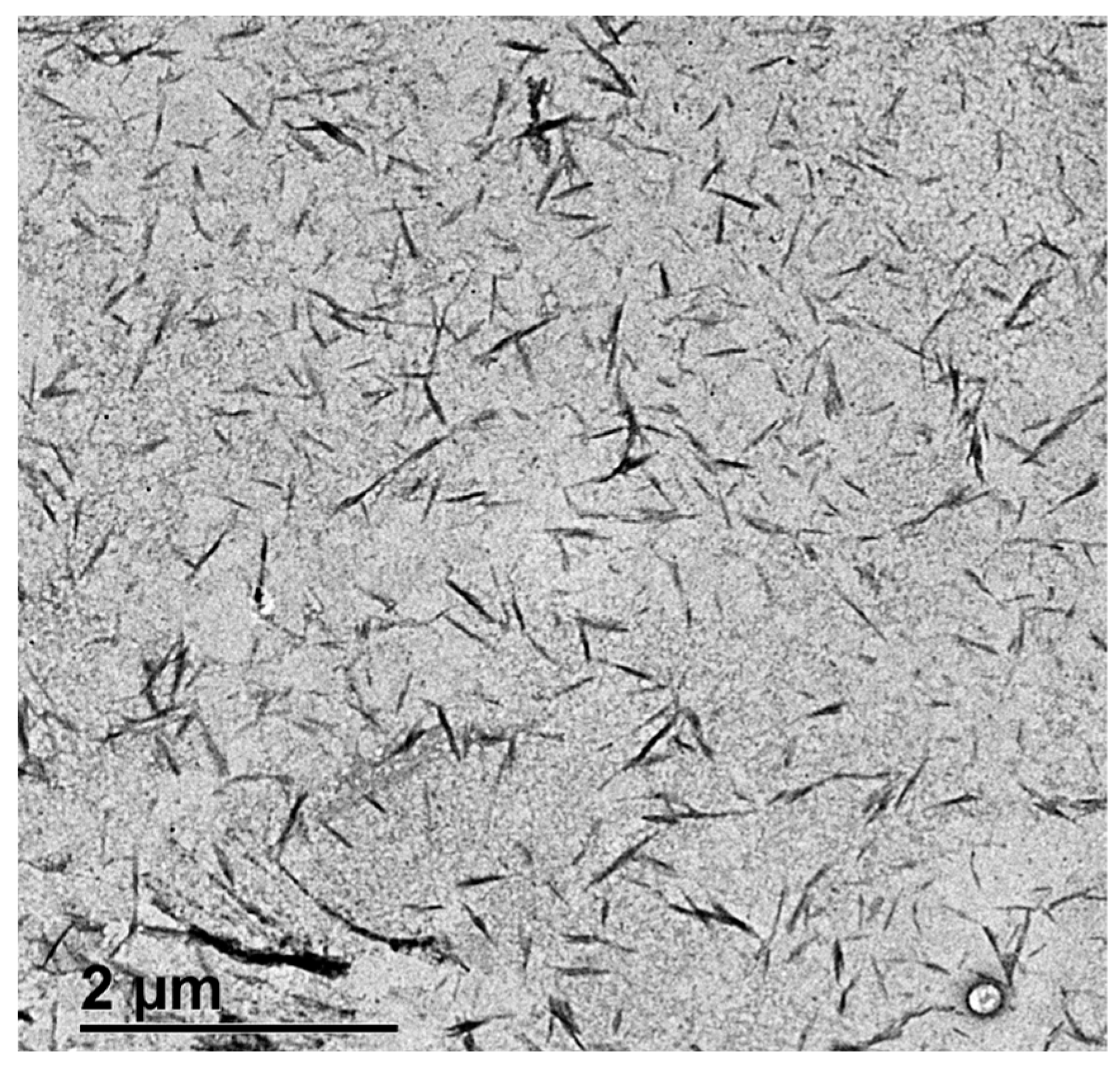

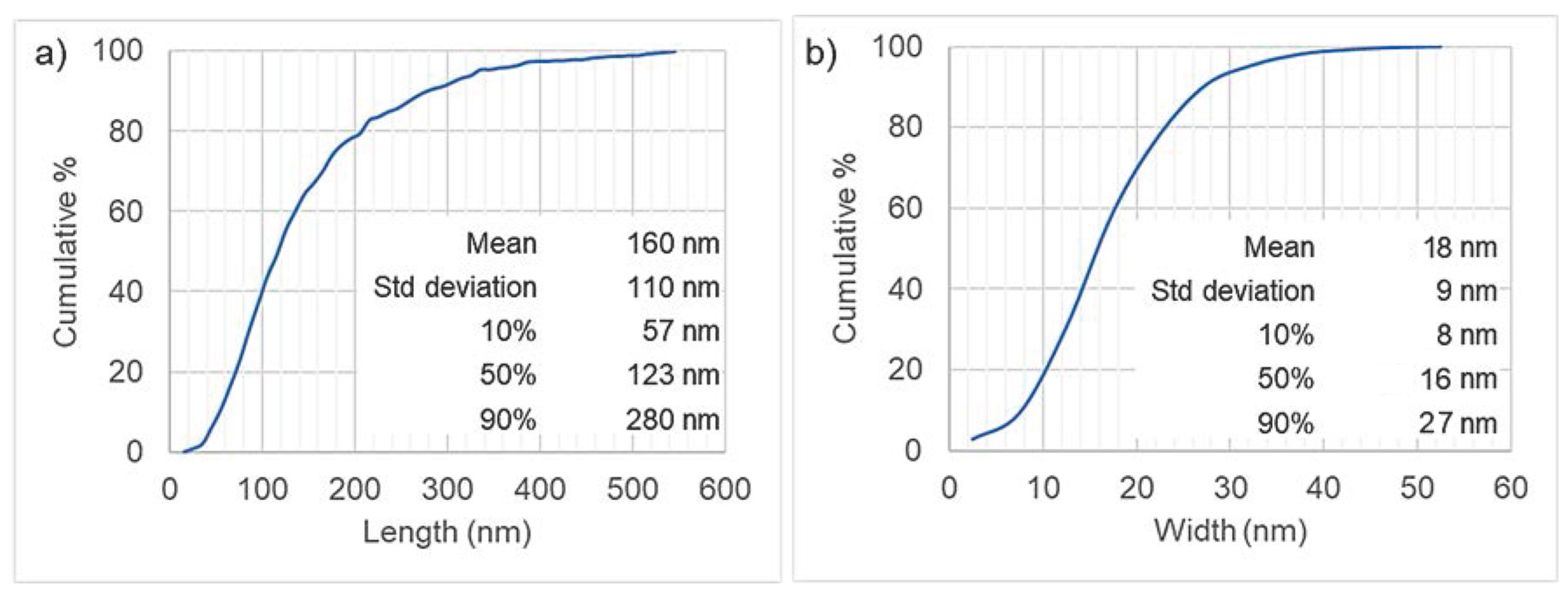

3.1. CNC Characterization

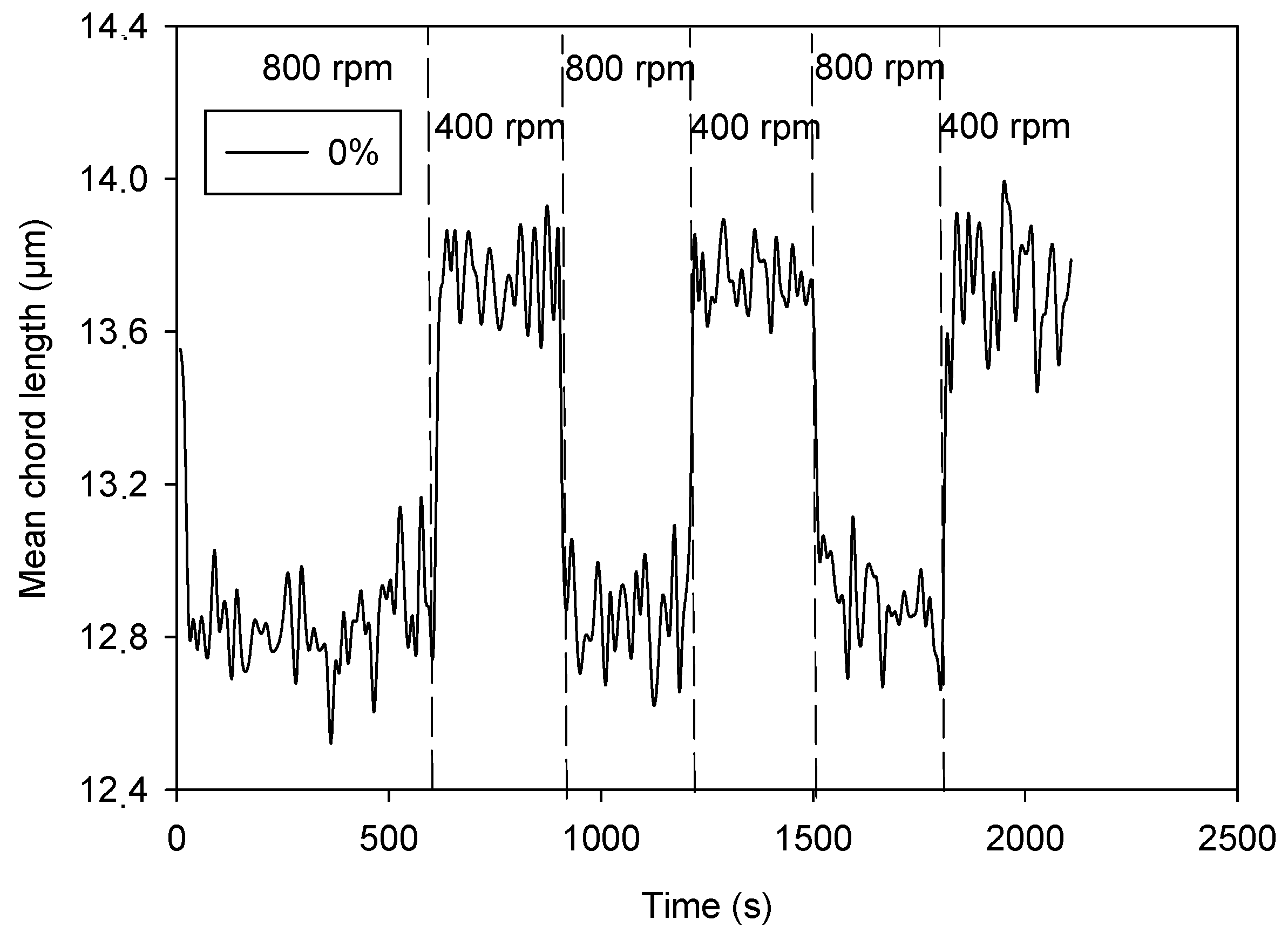

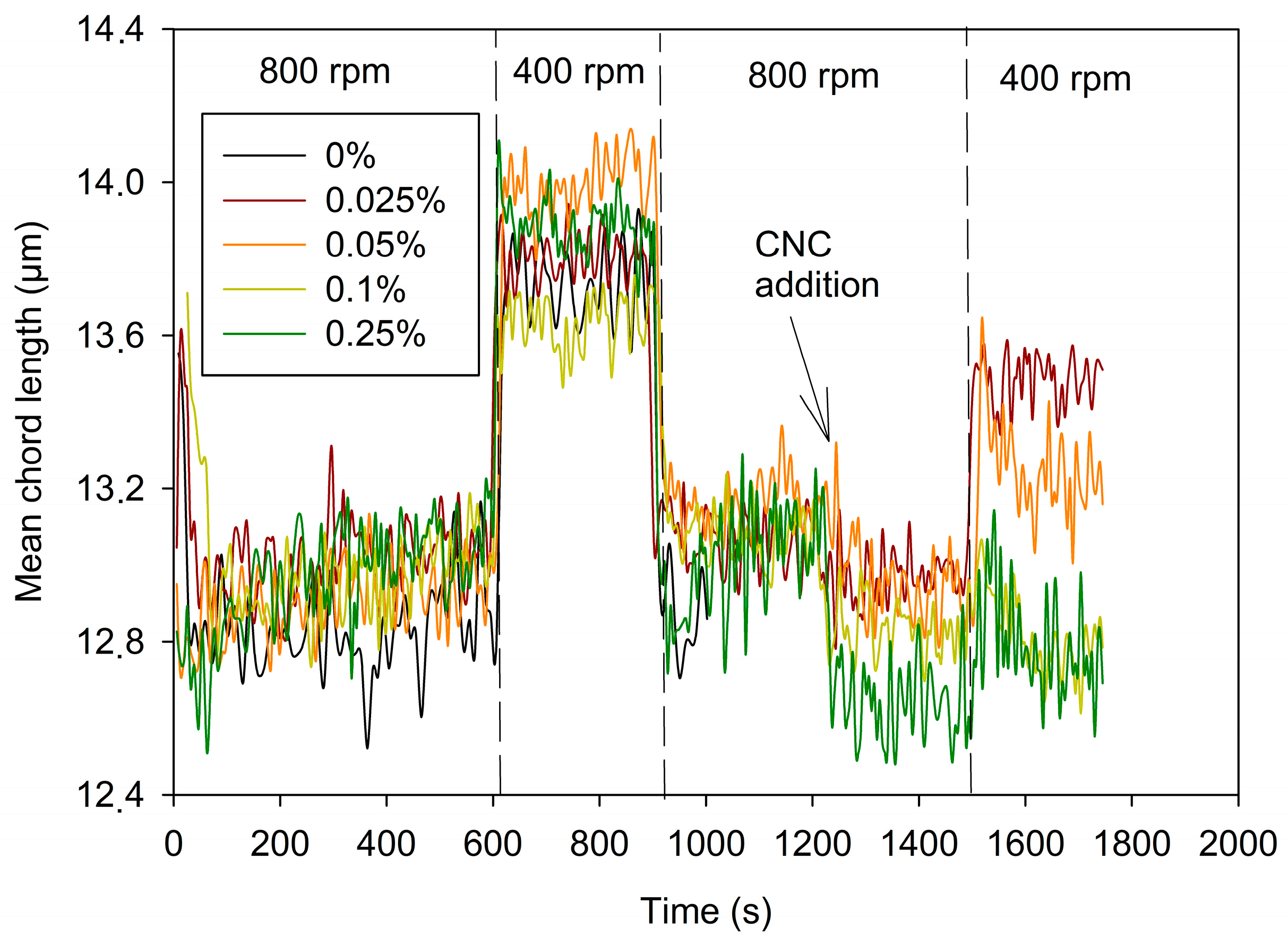

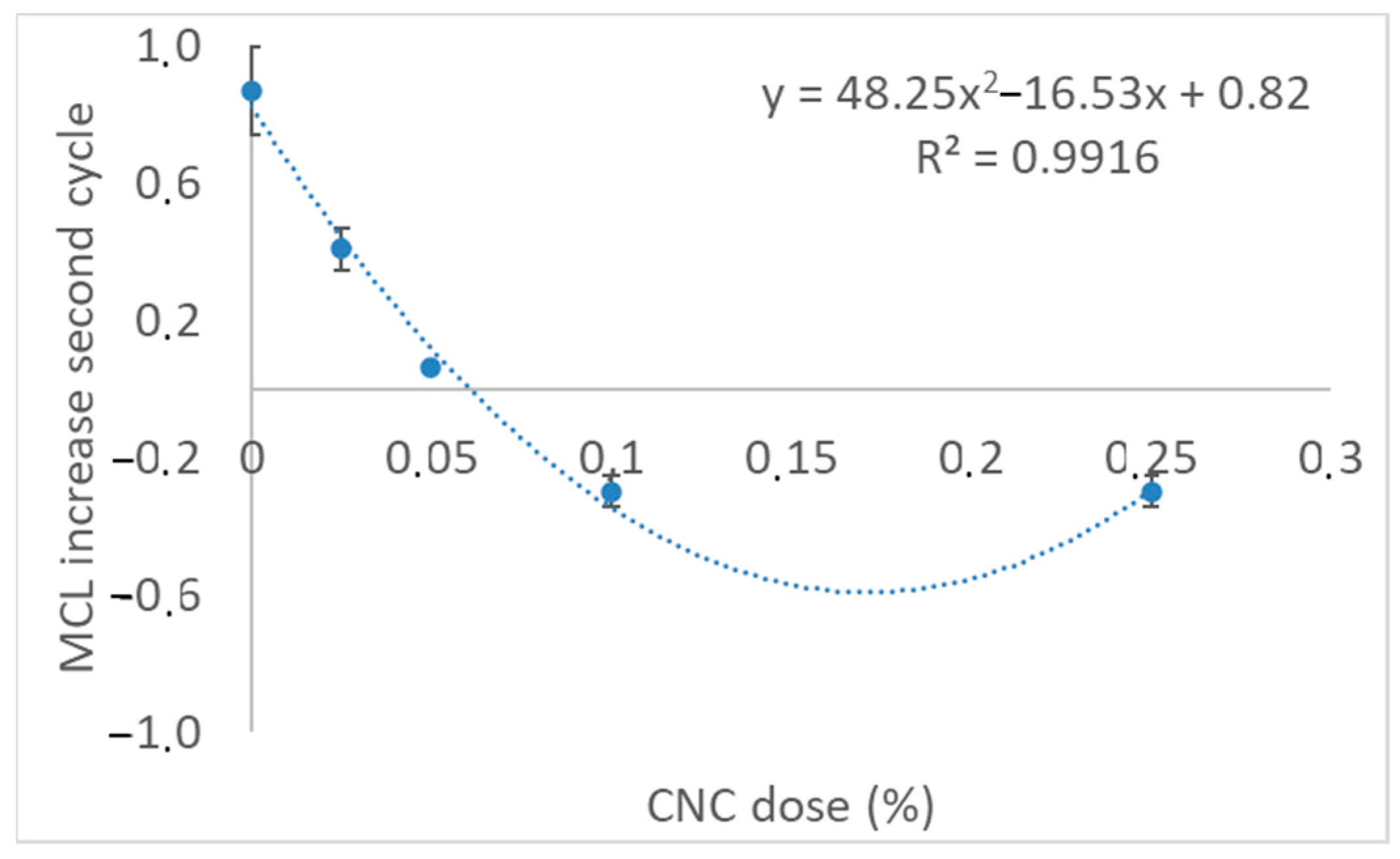

3.2. Effect of CNCs on Cement Suspension Behavior

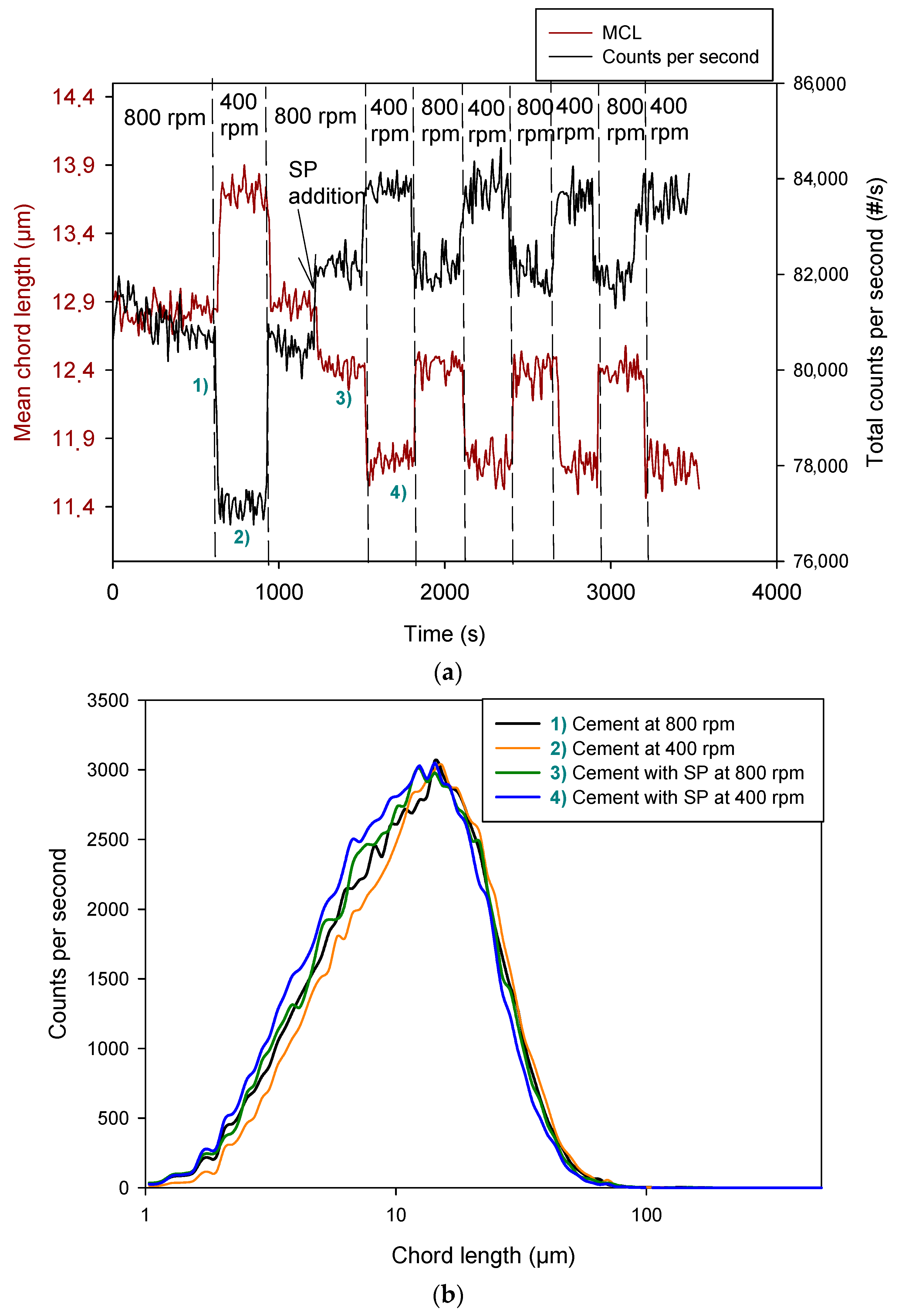

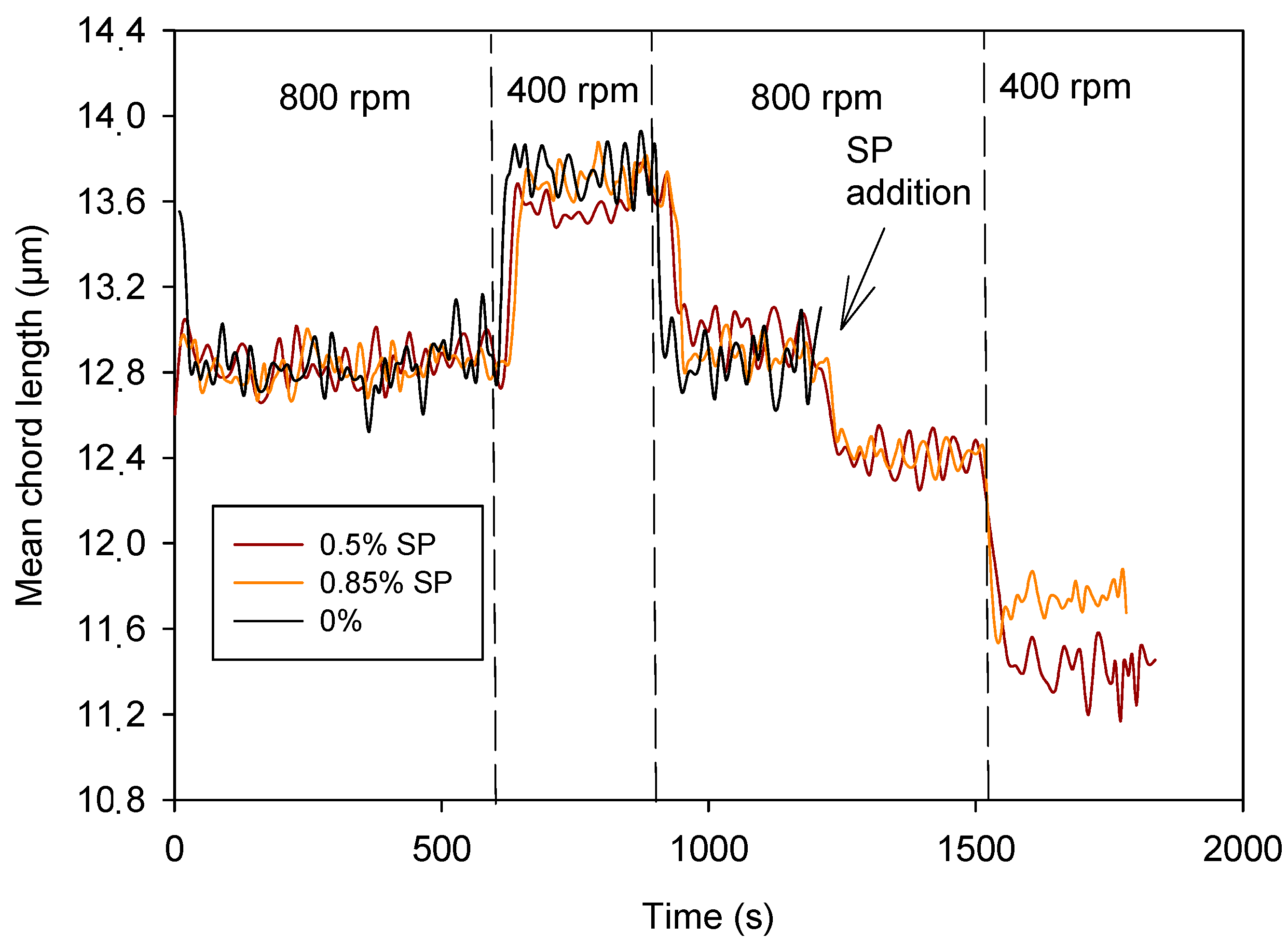

3.3. Effect of SPs on Cement Suspension

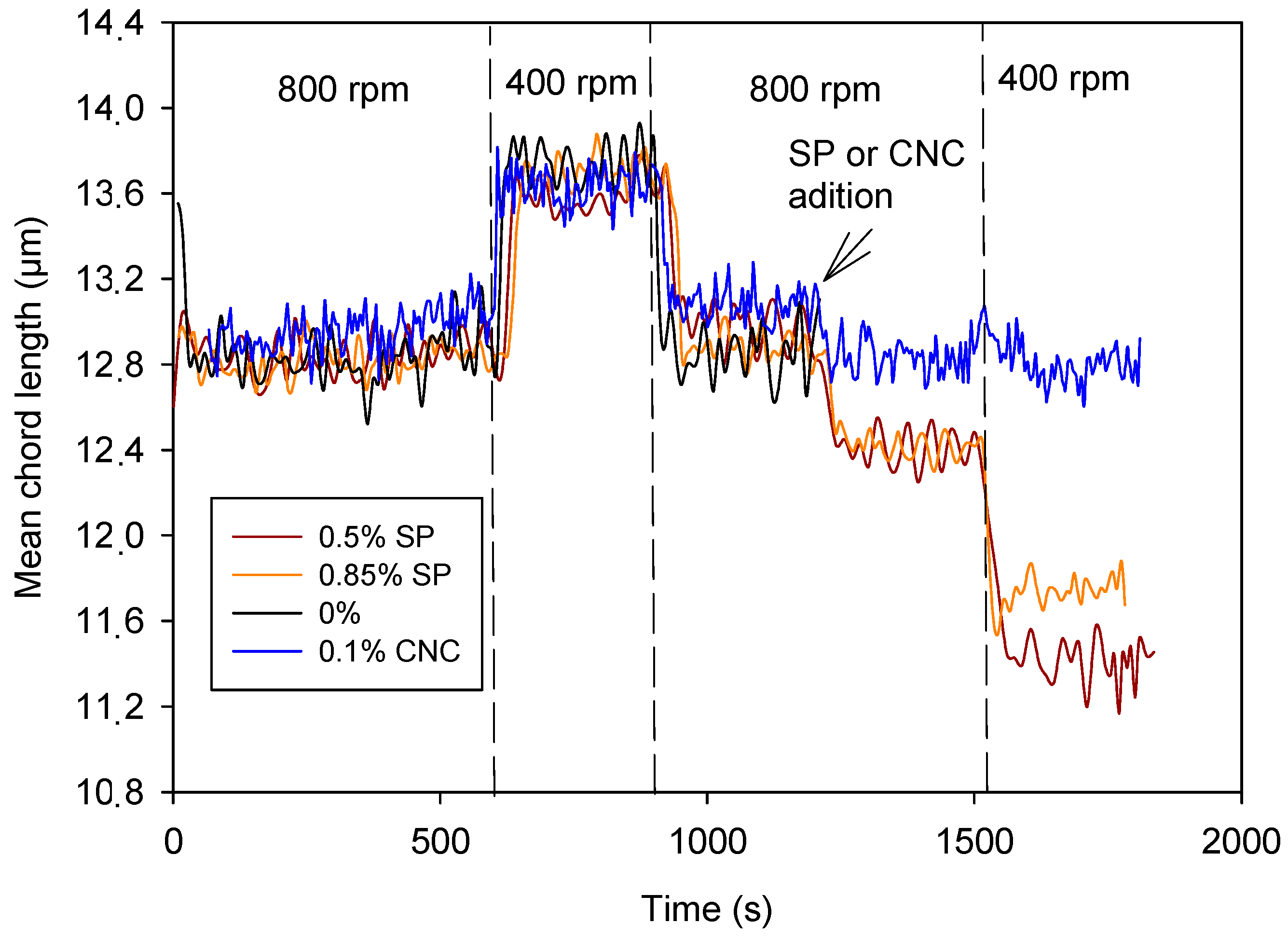

3.4. Synergic Effect of SP and CNCs on Cement Suspension

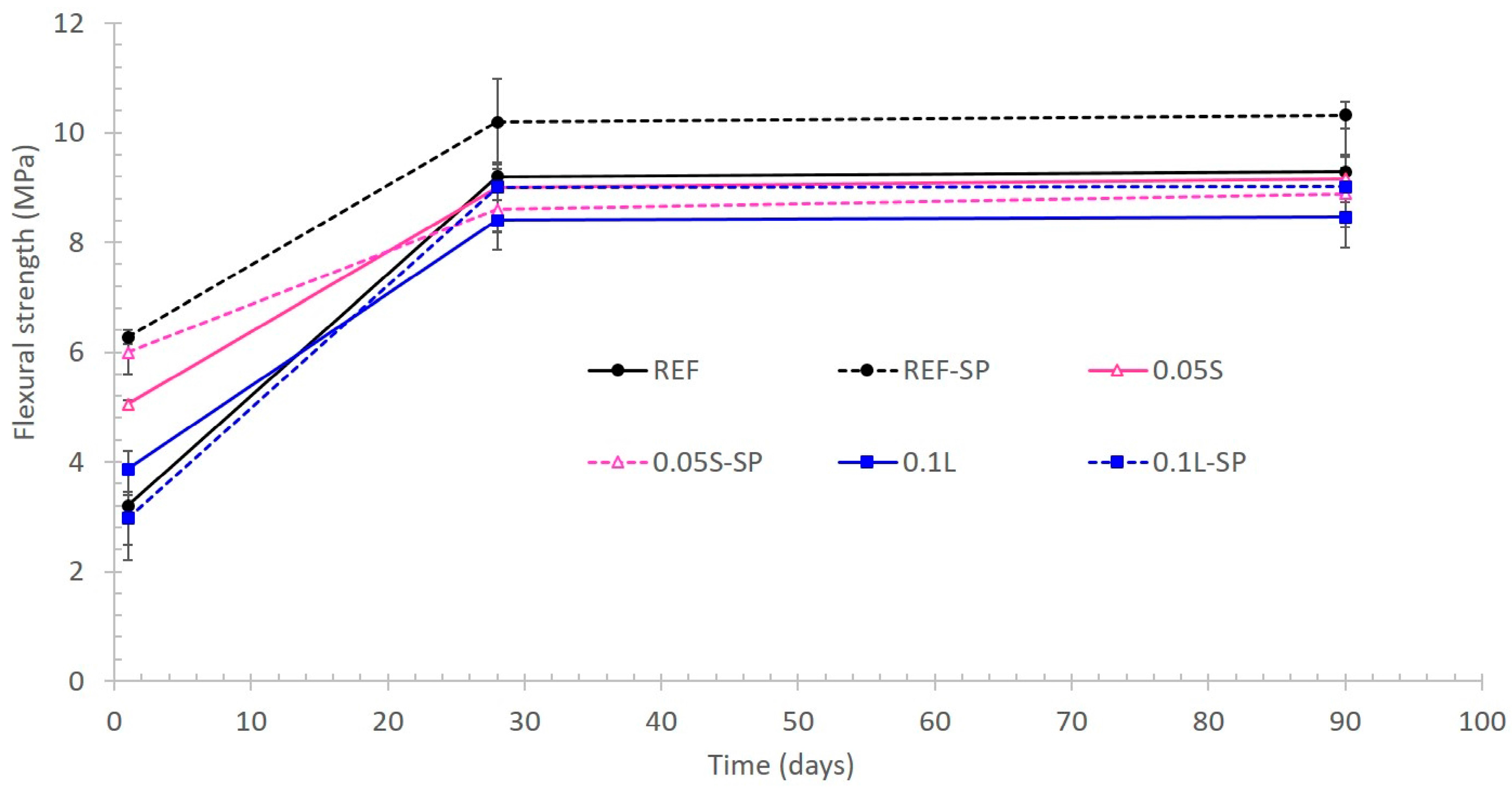

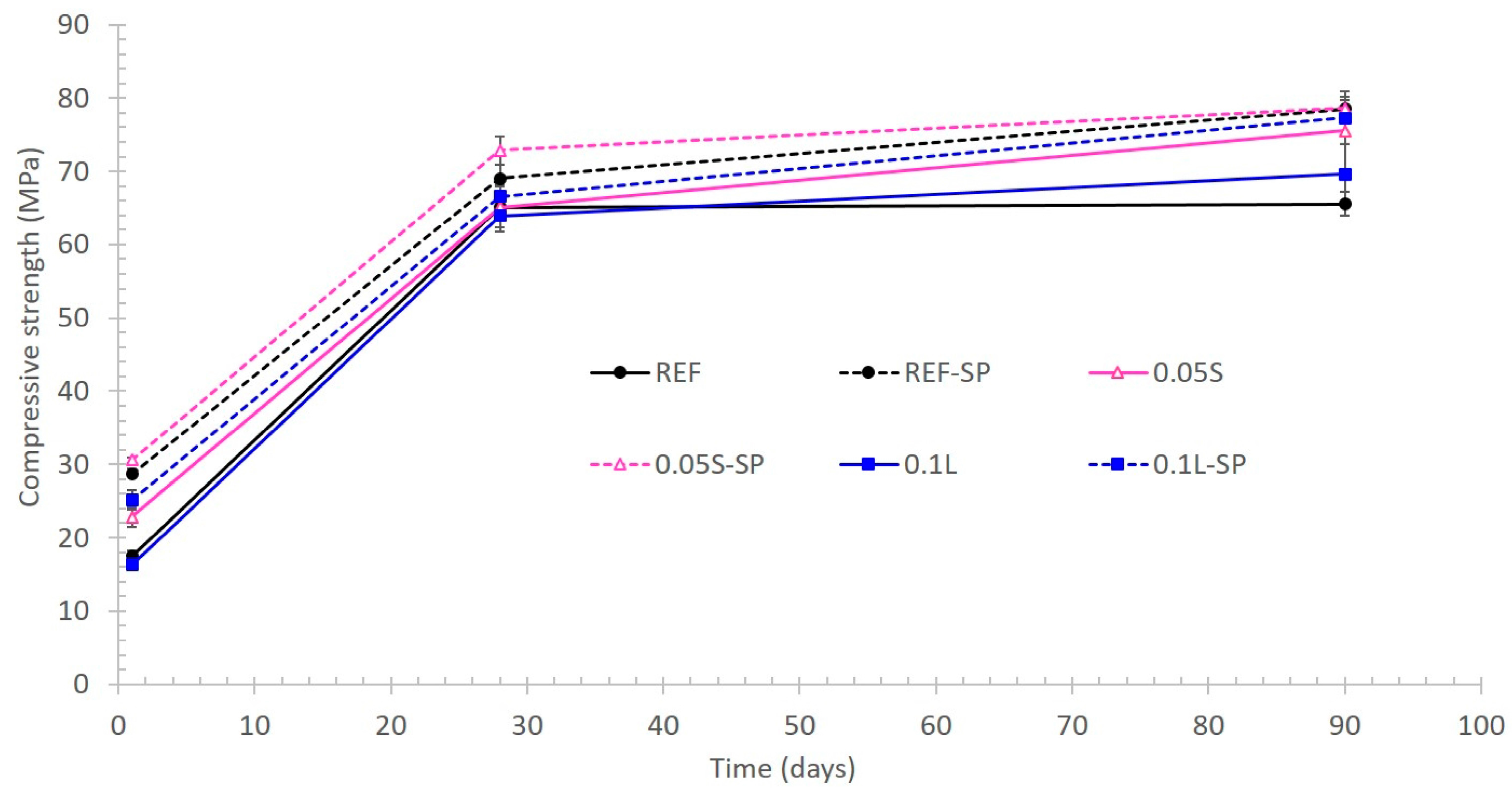

3.5. Effect of CNCs on the Performance of Cementitious Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Das, A.; Song, Y.; Mantellato, S.; Wangler, T.; Lange, D.A.; Flatt, R.J. Effect of processing on the air void system of 3D printed concrete. Cem. Concr. Res. 2022, 156, 106789. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phy. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Salman, N.M.; Ma, G.; Ijaz, N.; Wang, L. Importance and potential of cellulosic materials and derivatives in extrusion-based 3D concrete printing (3DCP): Prospects and challenges. Constr. Build. Mater. 2021, 291, 123281. [Google Scholar] [CrossRef]

- Tian, H.; Kong, X.; Sun, J.; Wang, D.; Huang, C. Fluidizing effects of polymers with various anchoring groups in cement pastes and their sensitivity to environmental temperatures. J. Appl. Polym. Sci. 2019, 136, 47494. [Google Scholar] [CrossRef]

- Ma, Y.; Shi, C.; Lei, L.; Sha, S.; Zhou, B.; Liu, Y.; Xiao, Y. Research progress on polycarboxylate based superplasticizers with tolerance to clays-a review. Constr. Build. Mater. 2020, 255, 119386. [Google Scholar] [CrossRef]

- Balea Martín, A.; Blanco Suárez, Á.; Negro Álvarez, C.M. Nanocelluloses: Natural-based materials for fiber-reinforced cement composites. A critical review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef]

- Liu, Q.; Peng, Y.; Liang, L.; Dong, X.; Li, H. Effect of cellulose nanocrystals on the properties of cement paste. J. Nanomater. 2019, 2019, 8318260. [Google Scholar] [CrossRef]

- Ghahari, S.; Assi, L.N.; Alsalman, A.; Alyamaç, K.E. Fracture properties evaluation of cellulose nanocrystals cement paste. Materials 2020, 13, 2507. [Google Scholar] [CrossRef]

- Roopchund, R.; Andrew, J.; Sithole, B. Using cellulose nanocrystals to improve the mechanical properties of fly ash-based geopolymer construction materials. Eng. Sci. Technol. Int. J. 2022, 25, 100989. [Google Scholar] [CrossRef]

- de Souza, L.O.; Cordazzo, M.; de Souza, L.M.S.; Tonoli, G.; de Andrade Silva, F.; Mechtcherine, V. Investigation of dispersion methodologies of microcrystalline and nano-fibrillated cellulose on cement pastes. Cem. Concr. Compos. 2022, 126, 104351. [Google Scholar] [CrossRef]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef]

- Montes, F.; Fu, T.; Youngblood, J.P.; Weiss, J. Rheological impact of using cellulose nanocrystals (CNC) in cement pastes. Constr. Build. Mater. 2020, 235, 117497. [Google Scholar] [CrossRef]

- Zheng, D.; Yang, H.; Feng, W.; Fang, Y.; Cui, H. Modification mechanism of cellulose nanocrystals in cement. Cem. Concr. Res. 2023, 165, 107089. [Google Scholar] [CrossRef]

- Ferrara, L.; Ferreira, S.R.; Torre, M.D.; Krelani, V.; de Silva, F.A.; Filho, R.D.T. Effect of cellulose nanopulp on autogenous and drying shrinkage of cement based composites. In Nanotechnology in Construction: Proceedings of NICOM5; Springer International Publishing: Cham, Switzerland, 2015; pp. 325–330. [Google Scholar]

- Nasir, M.; Aziz, M.A.; Zubair, M.; Ashraf, N.; Hussein, T.N.; Allubli, M.K.; Manzar, M.S.; Al-Kutti, W.; Al-Harthi, M.A. Engineered cellulose nanocrystals-based cement mortar from office paper waste: Flow, strength, microstructure, and thermal properties. J. Build. Eng. 2022, 51, 104345. [Google Scholar] [CrossRef]

- Guo, A.; Sun, Z.; Sathitsuksanoh, N.; Shang, H. Dispersion of Sonicated Sulfated Cellulose Nanocrystals and Their Effect on the Mechanical Properties of Cement Mortars. J. Mater. Civ. Eng. 2023, 35, 04023149. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.A.A.; Ferdous, W.; Saha, A.K.; Alyousef, R. 3D-printed concrete: Applications, performance, and challenges. J. Sustain. Cem.-Based Mater. 2020, 9, 127–164. [Google Scholar] [CrossRef]

- Ghantous, R.M.; Valadez-Carranza, Y.; Reese, S.R.; Weiss, W.J. Drying behavior of 3D printed cementitious pastes containing cellulose nanocrystals. Cement 2022, 9, 100035. [Google Scholar] [CrossRef]

- Campano, C.; Miranda, R.; Merayo, N.; Negro, C.; Blanco, A. Direct production of cellulose nanocrystals from old newspapers and recycled newsprint. Carbohydr. Polym. 2017, 173, 489–496. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Zhu, J.Y.; Reiner, R.S.; Verrill, S.P.; Baxa, U.; McNeil, S.E. Approaching zero cellulose loss in cellulose nanocrystal (CNC) production: Recovery and characterization of cellulosic solid residues (CSR) and CNC. Cellulose 2012, 19, 2033–2047. [Google Scholar] [CrossRef]

- ISO 5351:2010; Swedish Standards Insitute. Pulps-Determination of Limiting Viscosity Number in Cupri Ethylenediamine (CED) Solution. SIS Förlag AB: Stockholm, Sweden, 2010.

- Henriksson, M.; Berglund, L.A.; Isaksson, P.; Lindström, T.; Nishino, T. Cellulose nanopaper structures of high toughness. Biomacromolecules 2008, 9, 1579–1585. [Google Scholar] [CrossRef]

- Segal, L.G.J.M.A.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Moral, A.; Blanco, Á.; Izquierdo, L.; Negro, C. Effect of sepiolite on the flocculation of suspensions of fibre-reinforced cement. Cem. Concr. Res. 2010, 40, 1524–1530. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Monte, M.C.; Savastano, H., Jr.; Mutjé, P.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage and product properties. Ind. Crops Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef]

- UNE-EN 1015-3:2000; Methods of Tests for Masonry—Part 3. Determination of Consistence of Fresh Mortar by Flow Table. Asociación Española de Normalización: Madrid, Spain, 2000.

- UNE-EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. Asociación Española de Normalización: Madrid, Spain, 2016.

- Campano, C.; Lopez-Exposito, P.; Gonzalez-Aguilera, L.; Blanco, Á.; Negro, C. In-depth characterization of the aggregation state of cellulose nanocrystals through analysis of transmission electron microscopy images. Carbohydr. Polym. 2021, 254, 117271. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- Ferron, R.D.; Shah, S.; Fuente, E.; Negro, C. Aggregation and breakage kinetics of fresh cement paste. Cem. Concr. Res. 2013, 50, 1–10. [Google Scholar] [CrossRef]

- Flatt, R.; Schober, I. Superplasticizers and the rheology of concrete. In Understanding the Rheology of Concrete; Roussel, N., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 144–208. [Google Scholar]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete-A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Sha, S.; Wang, M.; Shi, C.; Xiao, Y. Influence of the structures of polycarboxylate superplasticizer on its performance in cement-based materials—A review. Constr. Build. Mater. 2020, 233, 117257. [Google Scholar] [CrossRef]

- Lei, L.; Hirata, T.; Plank, J. 40 years of PCE superplasticizers-History, current state-of-the-art and an outlook. Cem. Concr. Res. 2022, 157, 106826. [Google Scholar] [CrossRef]

- Marchon, D.; Sulser, U.; Eberhardt, A.; Flatt, R.J. Molecular design of comb-shaped polycarboxylate dispersants for environmentally friendly concrete. Soft Matter 2013, 9, 10719–10728. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, H.; Gao, X.; Wu, W. Adsorption and desorption of polycarboxylate ether superplasticizer in fresh cementitious materials blended with mineral admixtures. J. Mater. Res. Technol. 2022, 17, 1740–1751. [Google Scholar] [CrossRef]

- Mollah, M.Y.A.; Adams, W.J.; Schennach, R.; Cocke, D.L. A review of cement–superplasticizer interactions and their models. Adv. Cem. Res. 2000, 12, 153–161. [Google Scholar] [CrossRef]

- Yoshioka, K.; Tazawa, E.I.; Kawai, K.; Enohata, T. Adsorption characteristics of superplasticizers on cement component minerals. Cem. Concr. Res. 2002, 32, 1507–1513. [Google Scholar] [CrossRef]

- El-Gamal, S.M.; Al-Nowaiser, F.M.; Al-Baity, A.O. Effect of superplasticizers on the hydration kinetic and mechanical properties of Portland cement pastes. J. Adv. Res. 2012, 3, 119–124. [Google Scholar] [CrossRef]

- El-Tahlawy, K.F.; El-Bendary, M.A.; Elhendawy, A.G.; Hudson, S.M. The antimicrobial activity of cotton fabrics treated with different crosslinking agents and chitosan. Carbohydr. Polym. 2005, 60, 421–430. [Google Scholar] [CrossRef]

- El Bakkari, M.; Bindiganavile, V.; Goncalves, J.; Boluk, Y. Preparation of cellulose nanofibers by TEMPO-oxidation of bleached chemi-thermomechanical pulp for cement applications. Carbohydr. Polym. 2019, 203, 238–245. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Omran, A.F.; Tagnit-Hamou, A. Influence of cellulose filaments on cement pastes and concrete. J. Mater. Civ. Eng. 2018, 30, 04018109. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Wilson, W.; Sorelli, L.; Tolnai, B.; Tagnit-Hamou, A. Nanocellulose for improved concrete performance: A macro-to-micro investigation for disclosing the effects of cellulose filaments on strength of cement systems. Constr. Build. Mater. 2019, 206, 84–96. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Szymańska-Chargot, M.; Łagód, G. Effect of eco-friendly cellulose nanocrystals on physical properties of cement mortars. Polymers 2019, 11, 2088. [Google Scholar] [CrossRef] [PubMed]

- Hisseine, O.A.; Soliman, N.A.; Tolnai, B.; Tagnit-Hamou, A. Nano-engineered ultra-high performance concrete for controlled autogenous shrinkage using nanocellulose. Cem. Concr. Res. 2020, 137, 106217. [Google Scholar] [CrossRef]

| Trial Name | SP (%) | CNC (%) | SP 1 (g) | CNC 2 (g) |

|---|---|---|---|---|

| REF (0%) | 0 | 0 | 0 | 0 |

| 0.025% CNC | 0 | 0.025 | 0 | 0.02 |

| 0.05% CNC | 0 | 0.05 | 0 | 0.04 |

| 0.10% CNC | 0 | 0.1 | 0 | 0.08 |

| 0.25% CNC | 0 | 0.25 | 0 | 0.2 |

| 0.5% SP | 0.5 | 0 | 0.4 | 0 |

| 0.85% SP | 0.85 | 0 | 0.68 | 0 |

| 0.25% CNC + 0.5% SP | 0.5 | 0.25 | 0.4 | 0.2 |

| Raw Material | REF | REF-SP | 0.05S | 0.05S-SP | 0.1L | 0.1L-SP |

|---|---|---|---|---|---|---|

| Cement (g) | 450 | 450 | 450 | 450 | 450 | 450 |

| Water (g) | 225 | 180 | 225 | 180 | 225 | 180 |

| Siliceous sand (g) | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |

| SP (g) | --- | 3.8 | --- | 3.8 | --- | 3.8 |

| Suspended CNCs (dry g) | --- | --- | 0.41 | 0.41 | --- | --- |

| Lyophilized CNCs (g) | --- | --- | --- | --- | 0.82 | 0.82 |

| Yield (%) | 61.1 ± 6.0 |

| DAC (%) | 32.6 ± 2.5 |

| PD | 224.2 ± 4.1 |

| Zeta potential (mV) | −27 ± 4 |

| CrI (%) | 94.4 ± 0.5 |

| Length (nm) | 160 ± 110 |

| Width (nm) | 18 ± 9 |

| Raw Material | REF | REF-SP | 0.05S | 0.05S-SP | 0.1L | 0.1L-SP |

|---|---|---|---|---|---|---|

| Consistency (mm) | 195 | 185 | 200 | 185 | 205 | 190 |

| w/c | 0.5 | 0.4 | 0.5 | 0.4 | 0.5 | 0.4 |

| Setting Time (s) | REF | 0.05S |

|---|---|---|

| Initial | 160 | 150 |

| Final | 440 | 440 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jarabo, R.; Fuente, E.; García Calvo, J.L.; Carballosa, P.; Negro, C. Nanocrystalline Cellulose to Reduce Superplasticizer Demand in 3D Printing of Cementitious Materials. Materials 2024, 17, 4247. https://doi.org/10.3390/ma17174247

Jarabo R, Fuente E, García Calvo JL, Carballosa P, Negro C. Nanocrystalline Cellulose to Reduce Superplasticizer Demand in 3D Printing of Cementitious Materials. Materials. 2024; 17(17):4247. https://doi.org/10.3390/ma17174247

Chicago/Turabian StyleJarabo, Rocío, Elena Fuente, José Luis García Calvo, Pedro Carballosa, and Carlos Negro. 2024. "Nanocrystalline Cellulose to Reduce Superplasticizer Demand in 3D Printing of Cementitious Materials" Materials 17, no. 17: 4247. https://doi.org/10.3390/ma17174247

APA StyleJarabo, R., Fuente, E., García Calvo, J. L., Carballosa, P., & Negro, C. (2024). Nanocrystalline Cellulose to Reduce Superplasticizer Demand in 3D Printing of Cementitious Materials. Materials, 17(17), 4247. https://doi.org/10.3390/ma17174247