Effect of Extrusion Ratio on Mechanical Behavior and Microstructure Evolution of 7003 Aluminum Alloy at High-Speed Impact

Abstract

1. Introduction

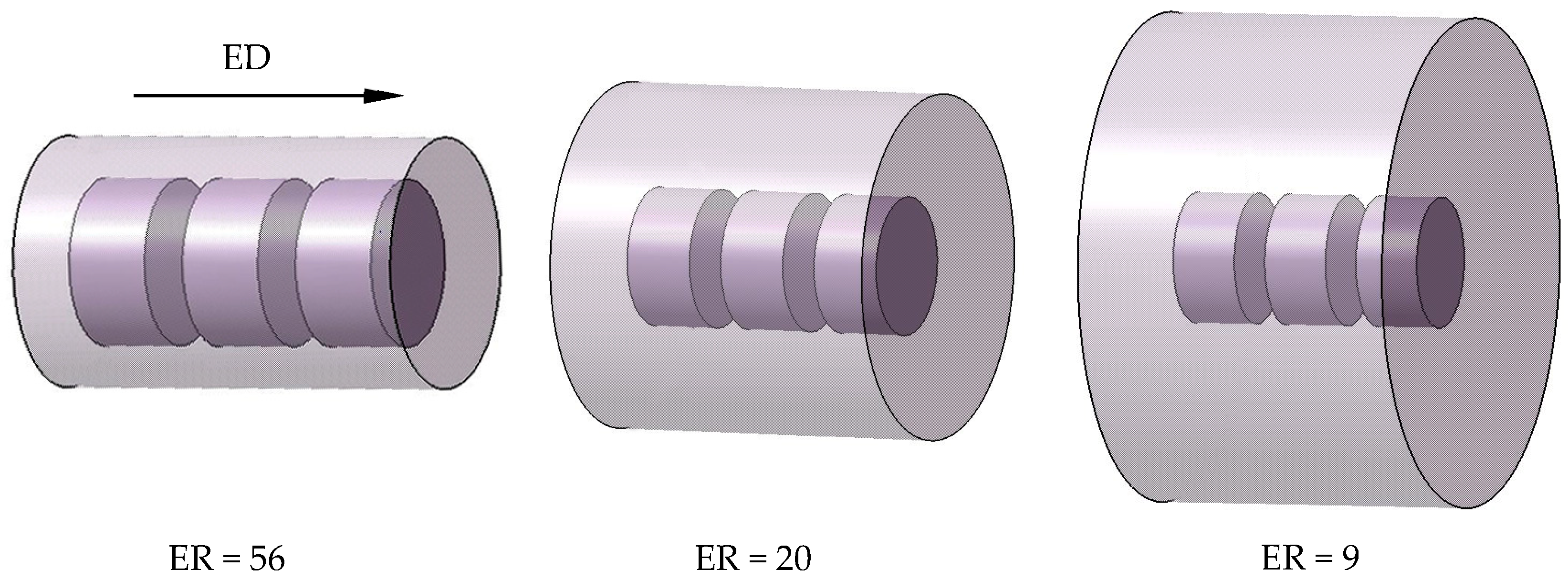

2. Experimental Procedure

3. Results

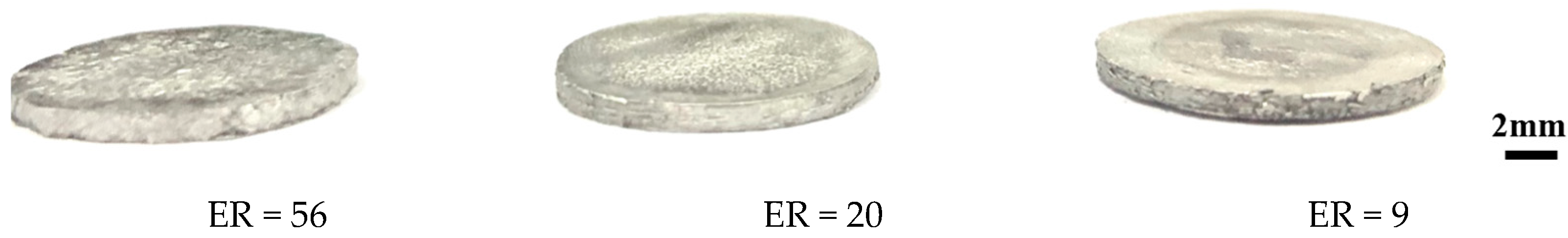

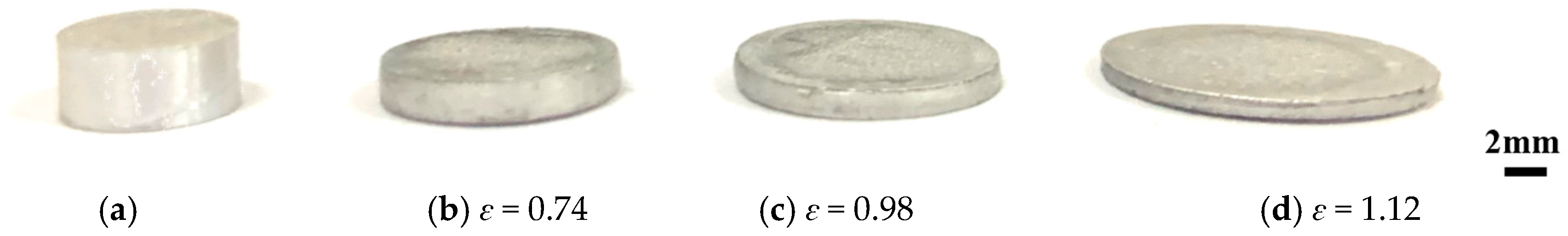

3.1. Macroscopic Morphology

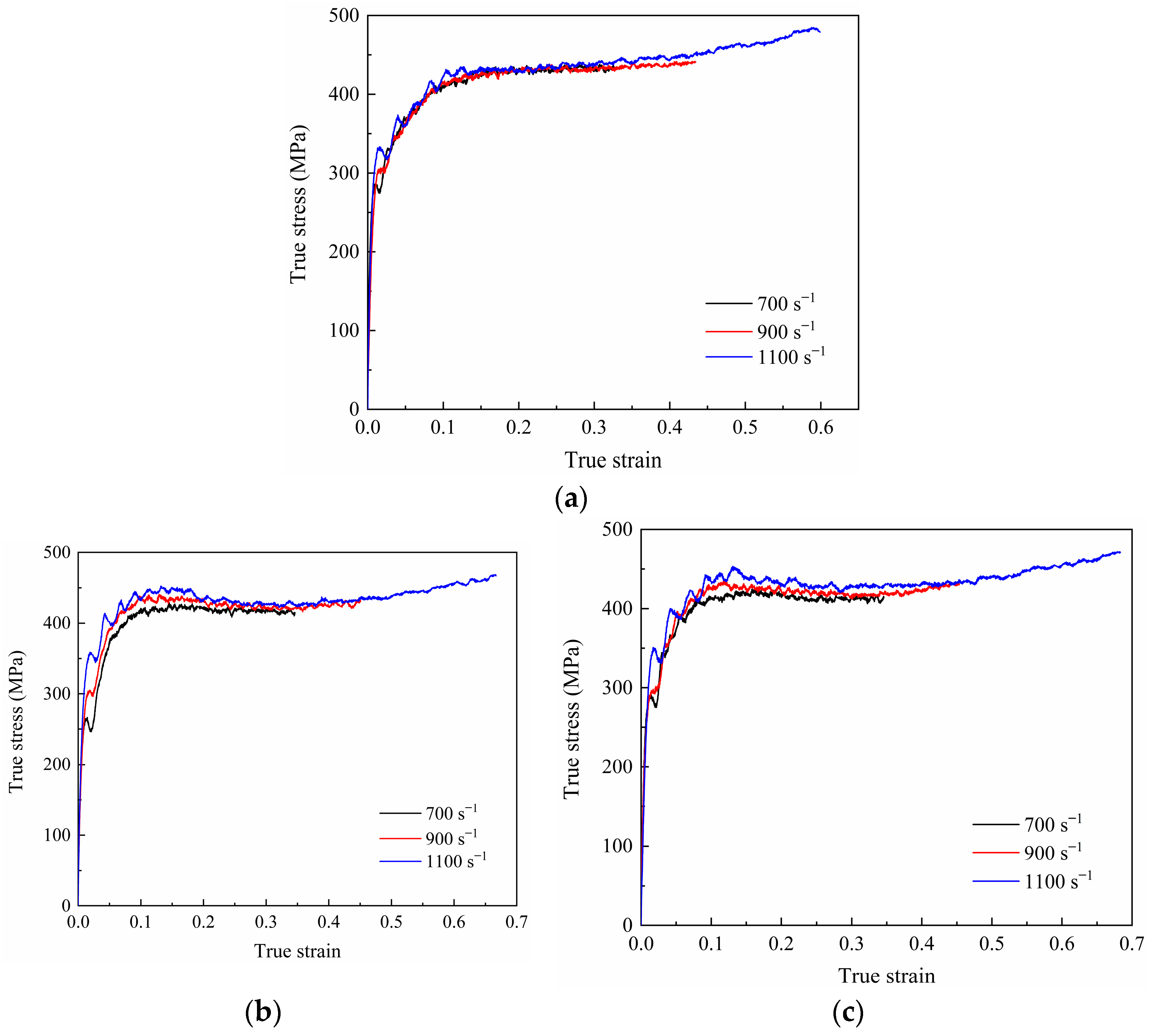

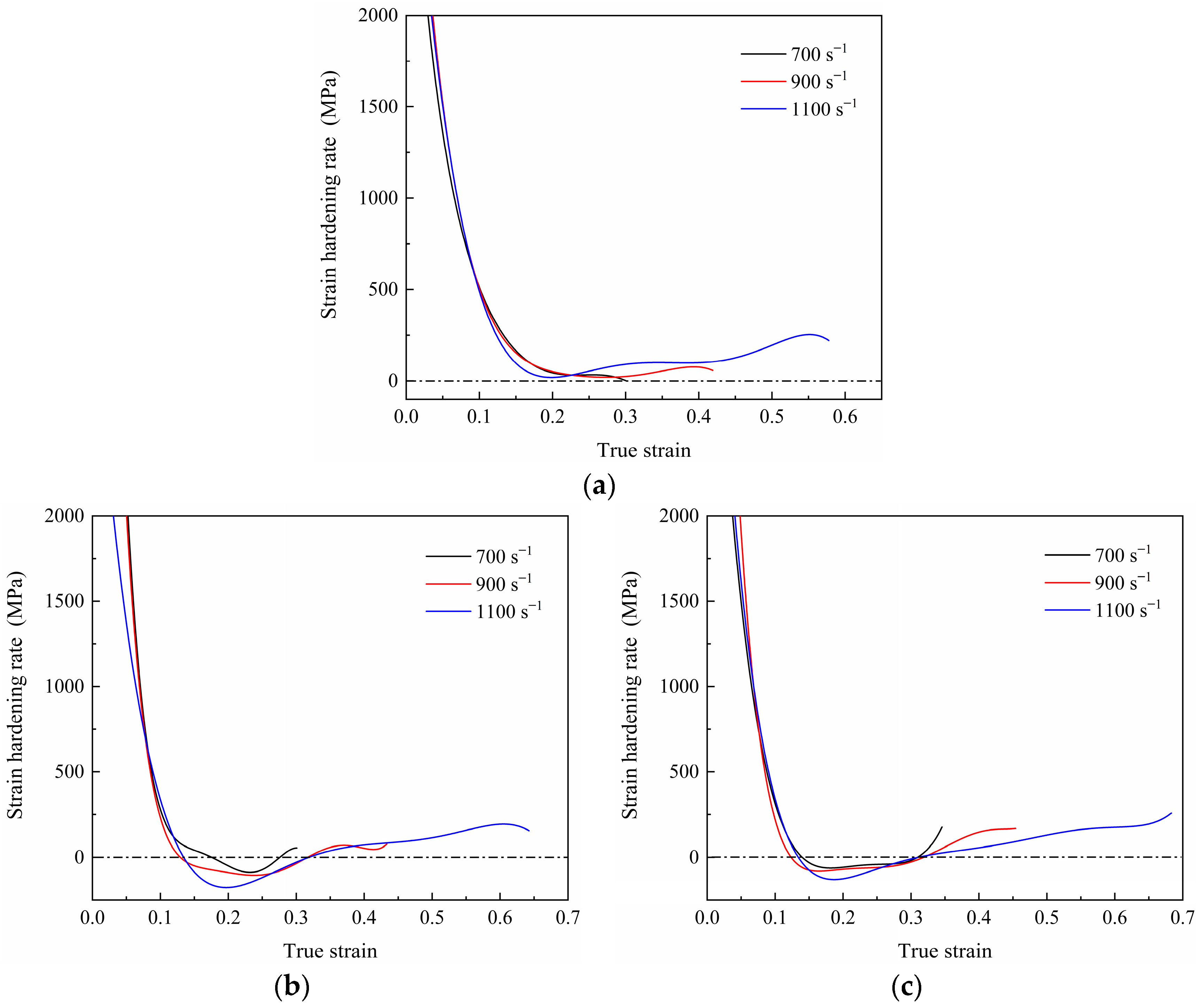

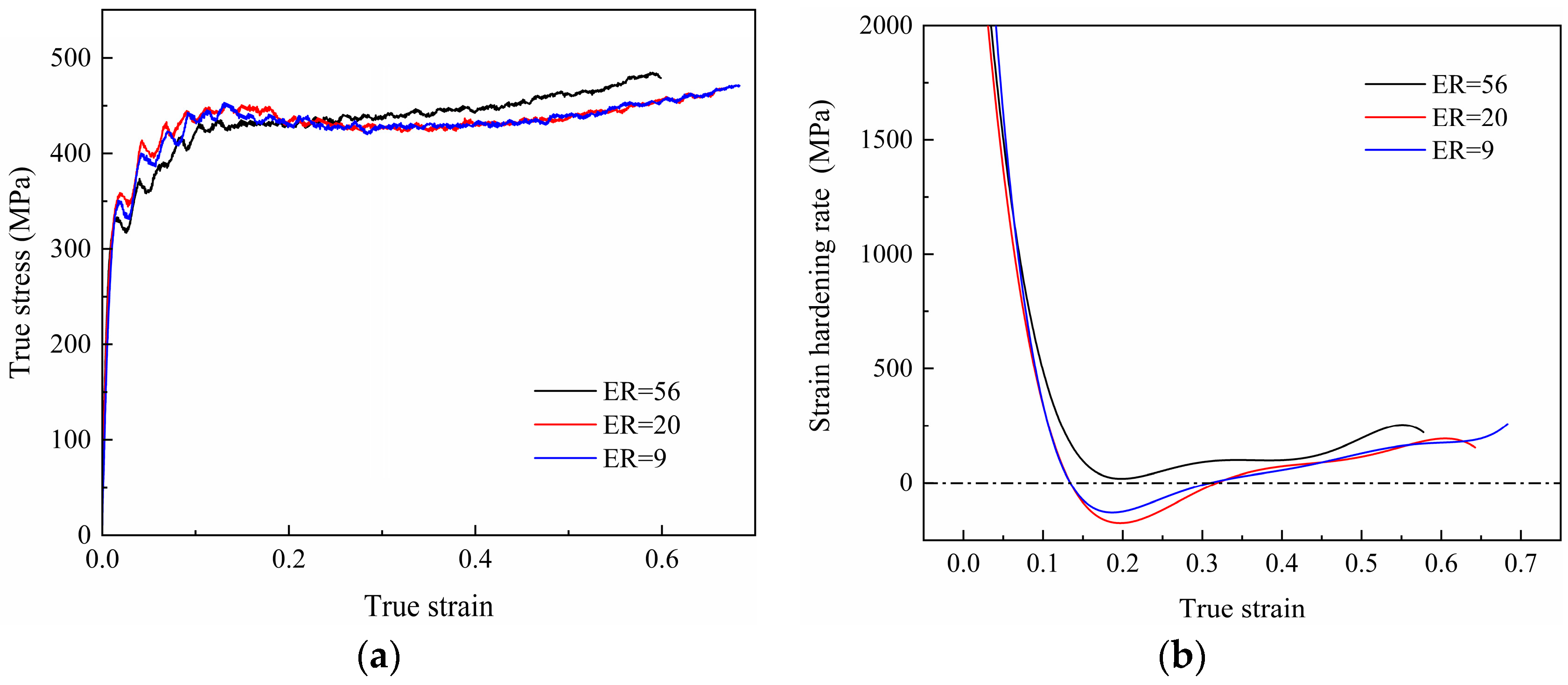

3.2. Stress Response Behavior

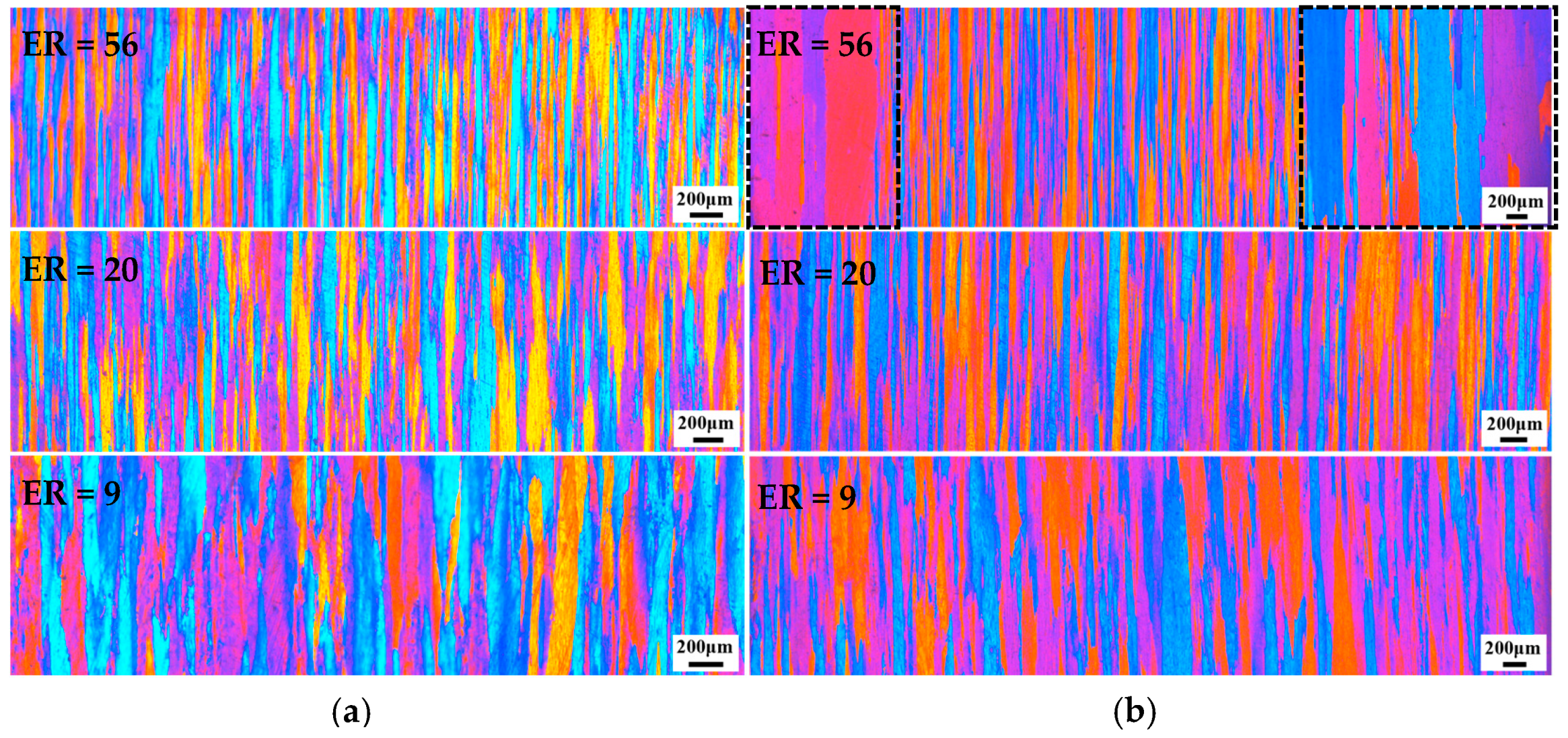

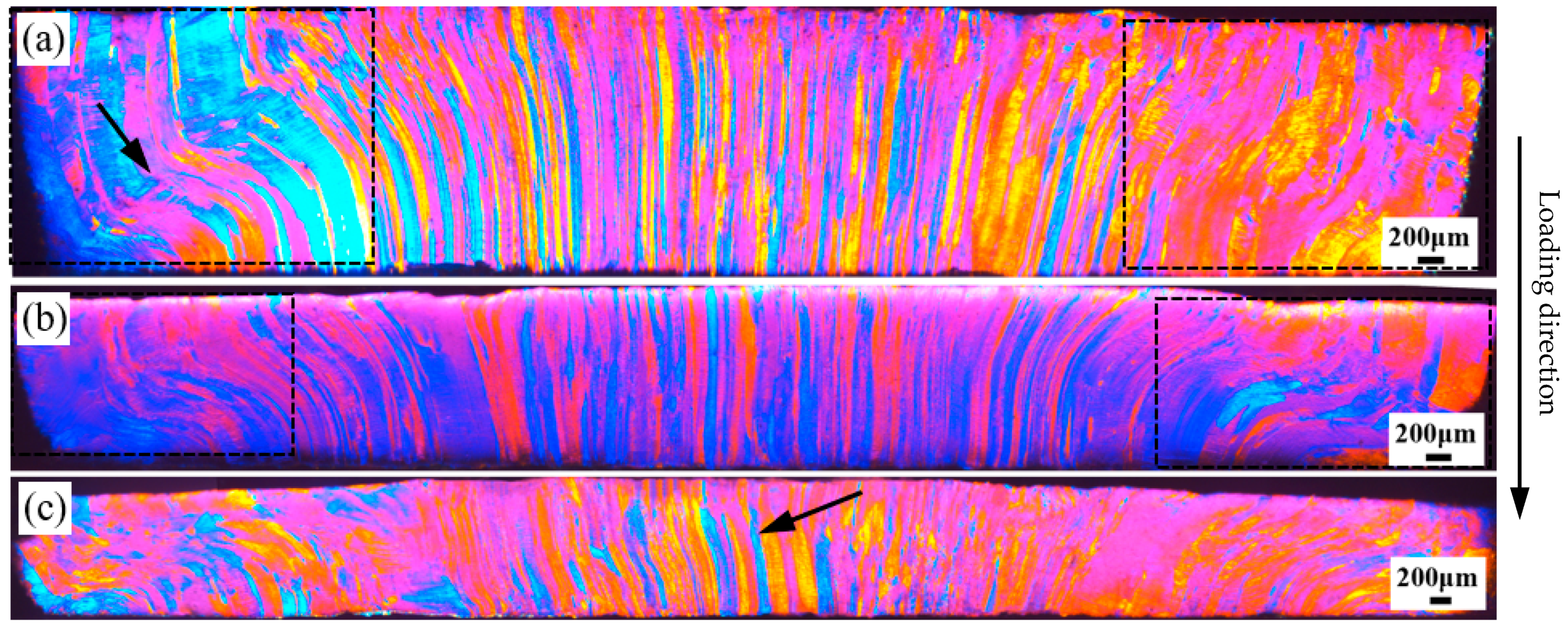

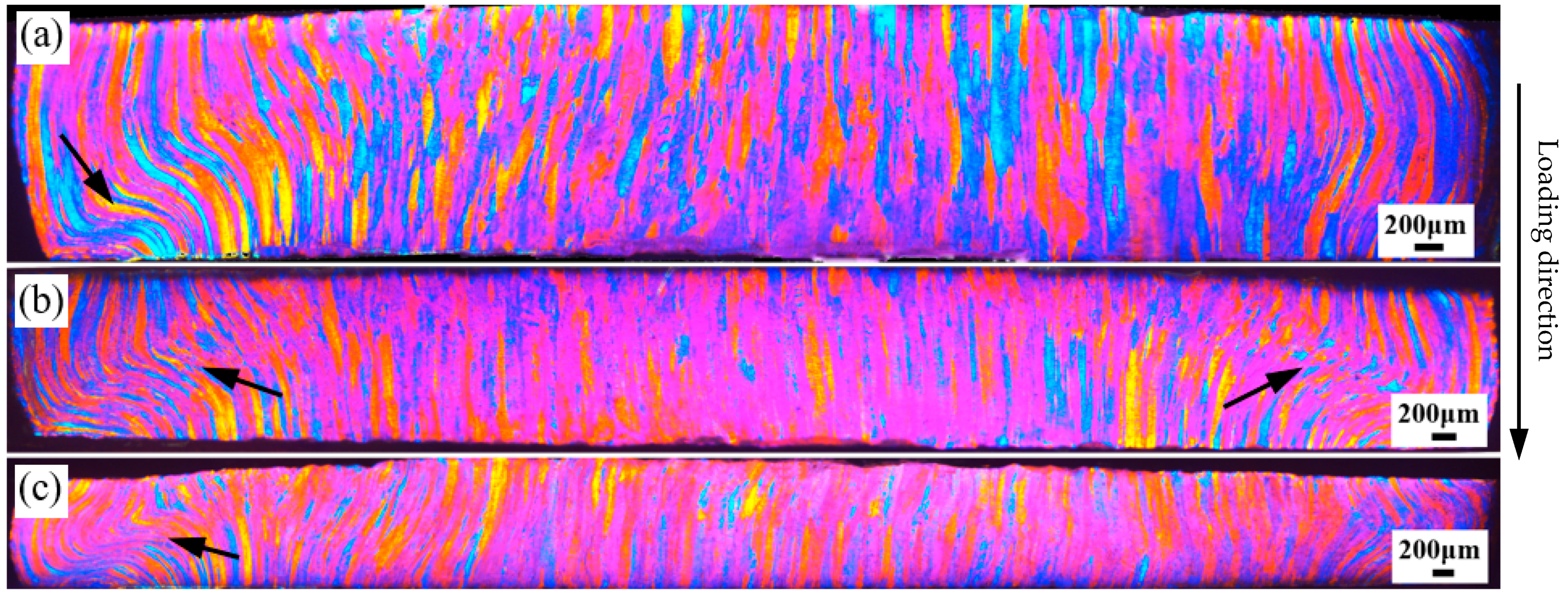

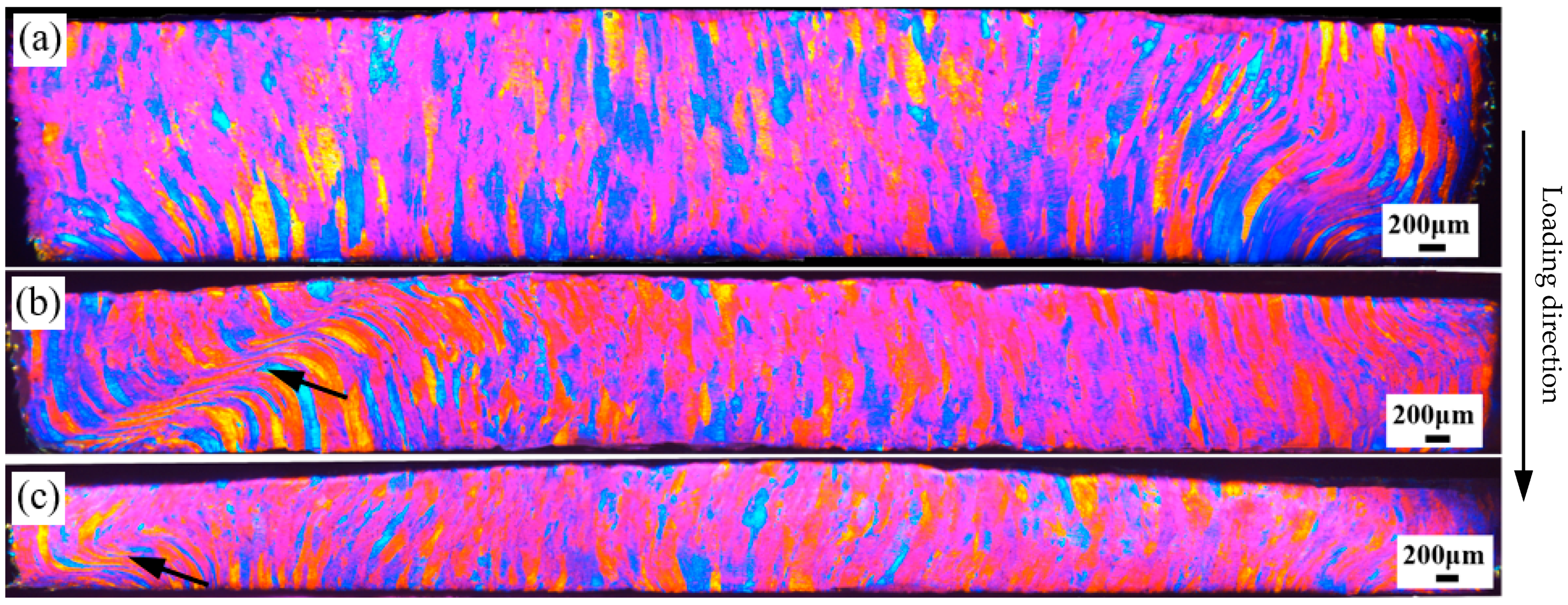

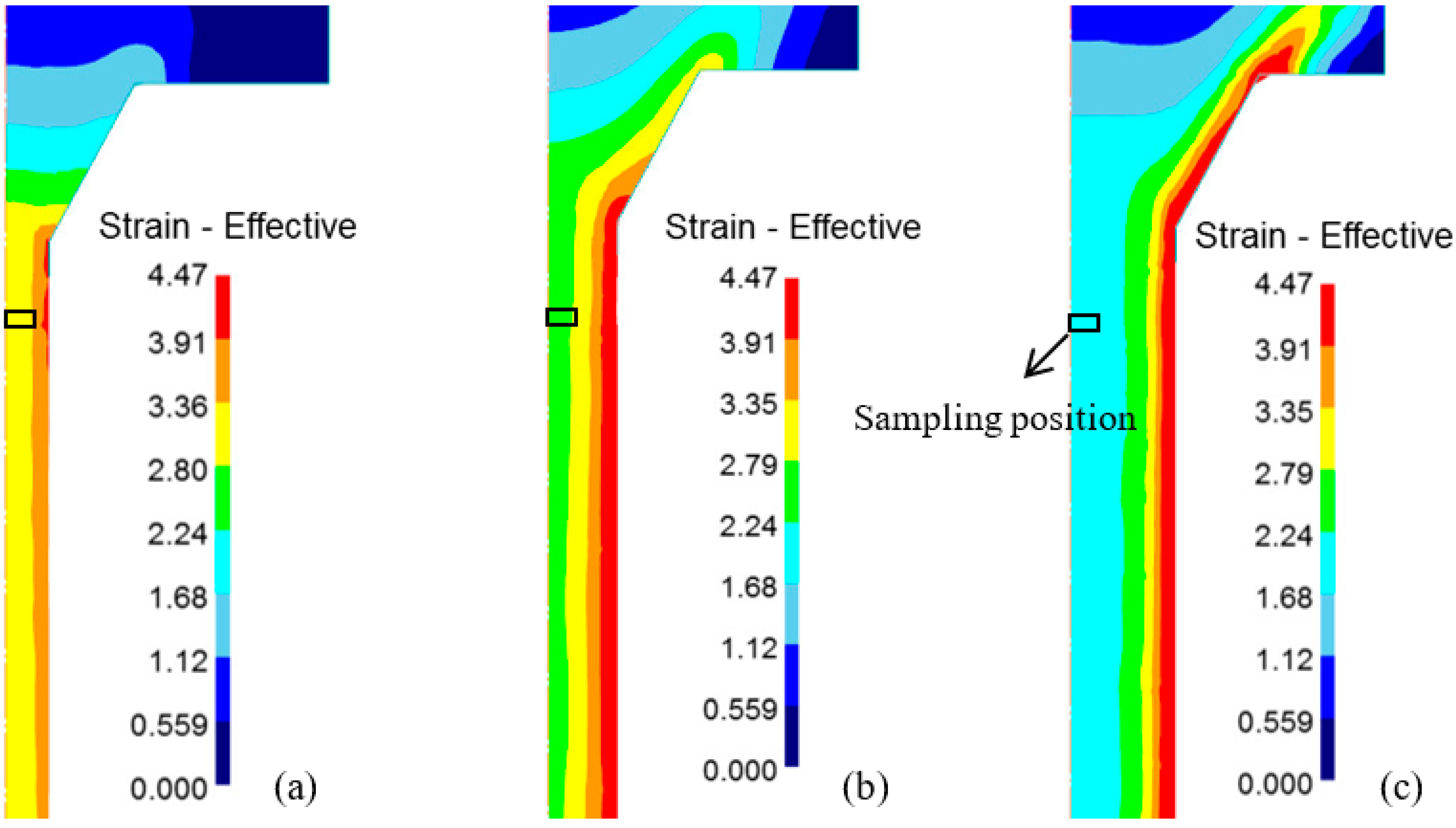

3.3. Deformed Microstructure

4. Discussion

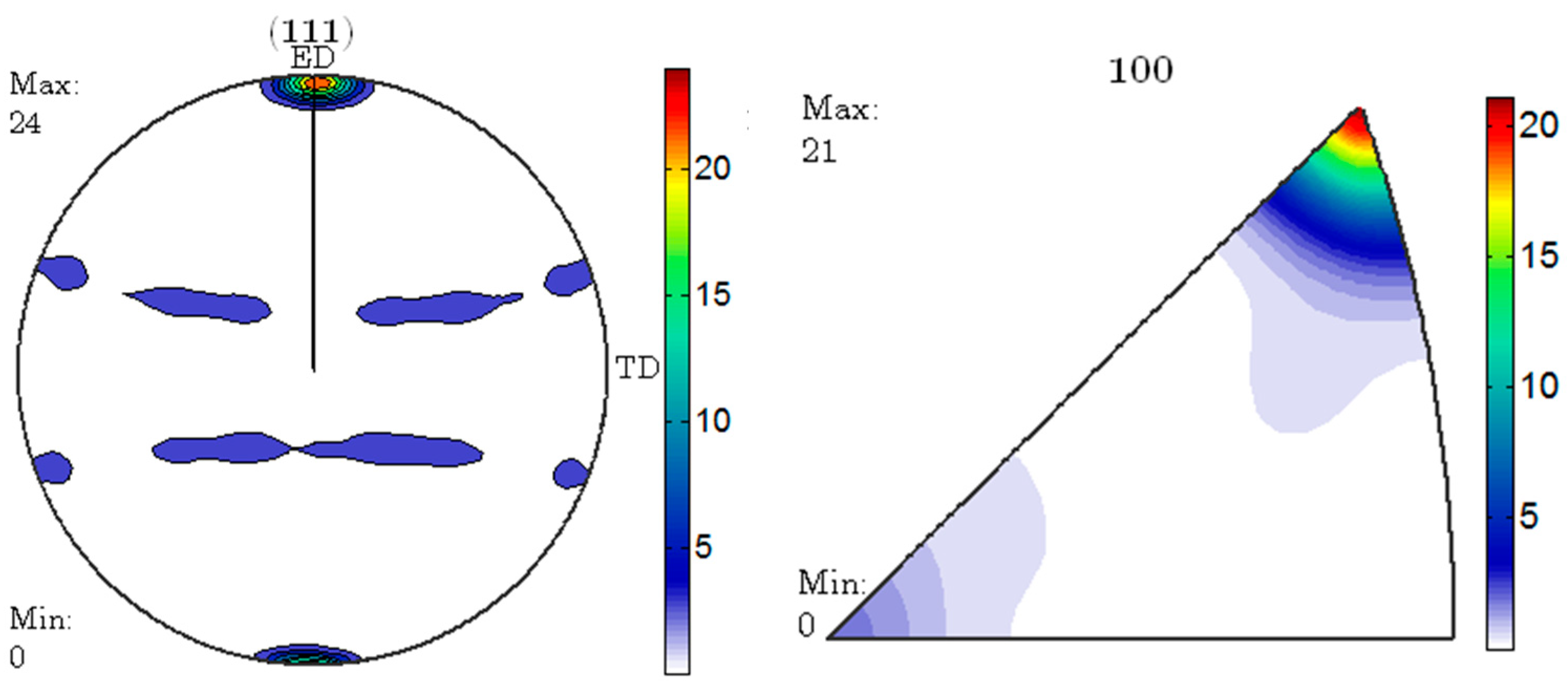

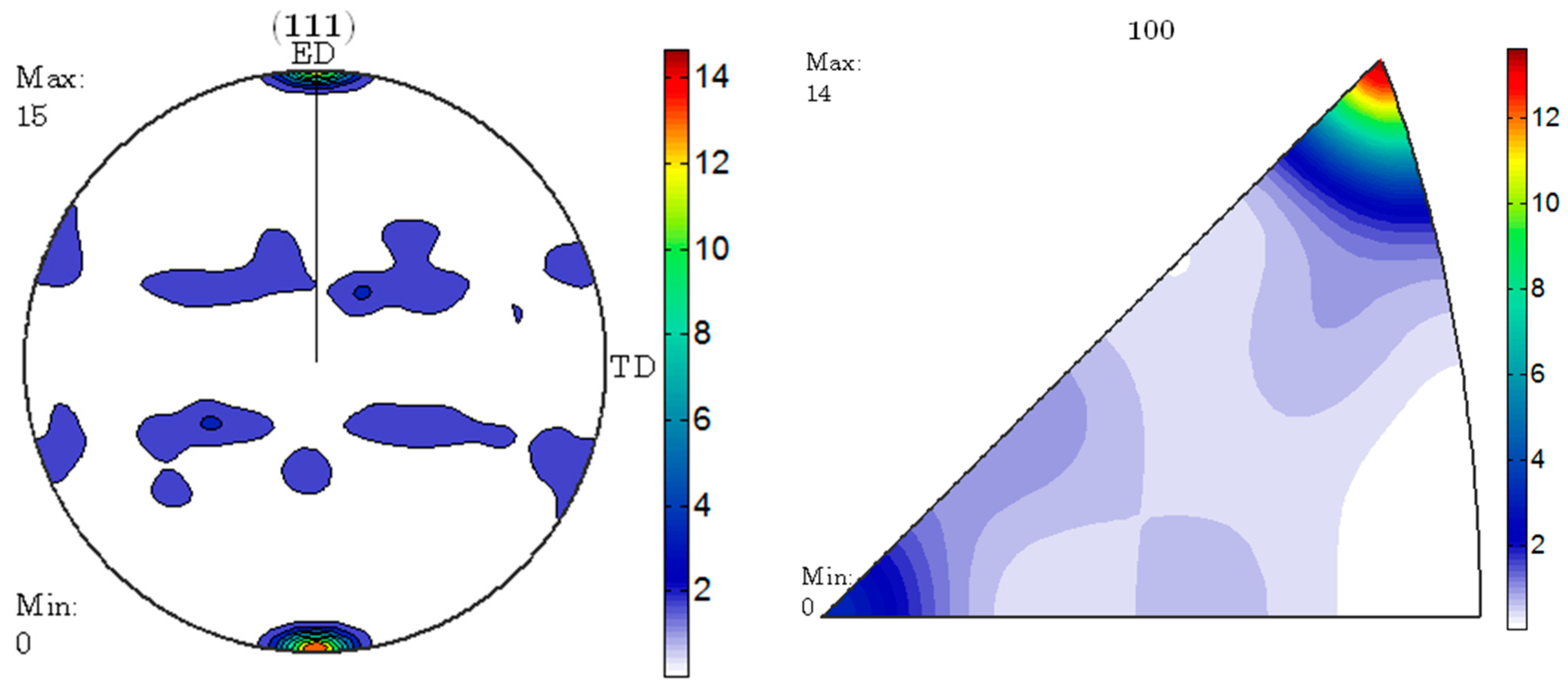

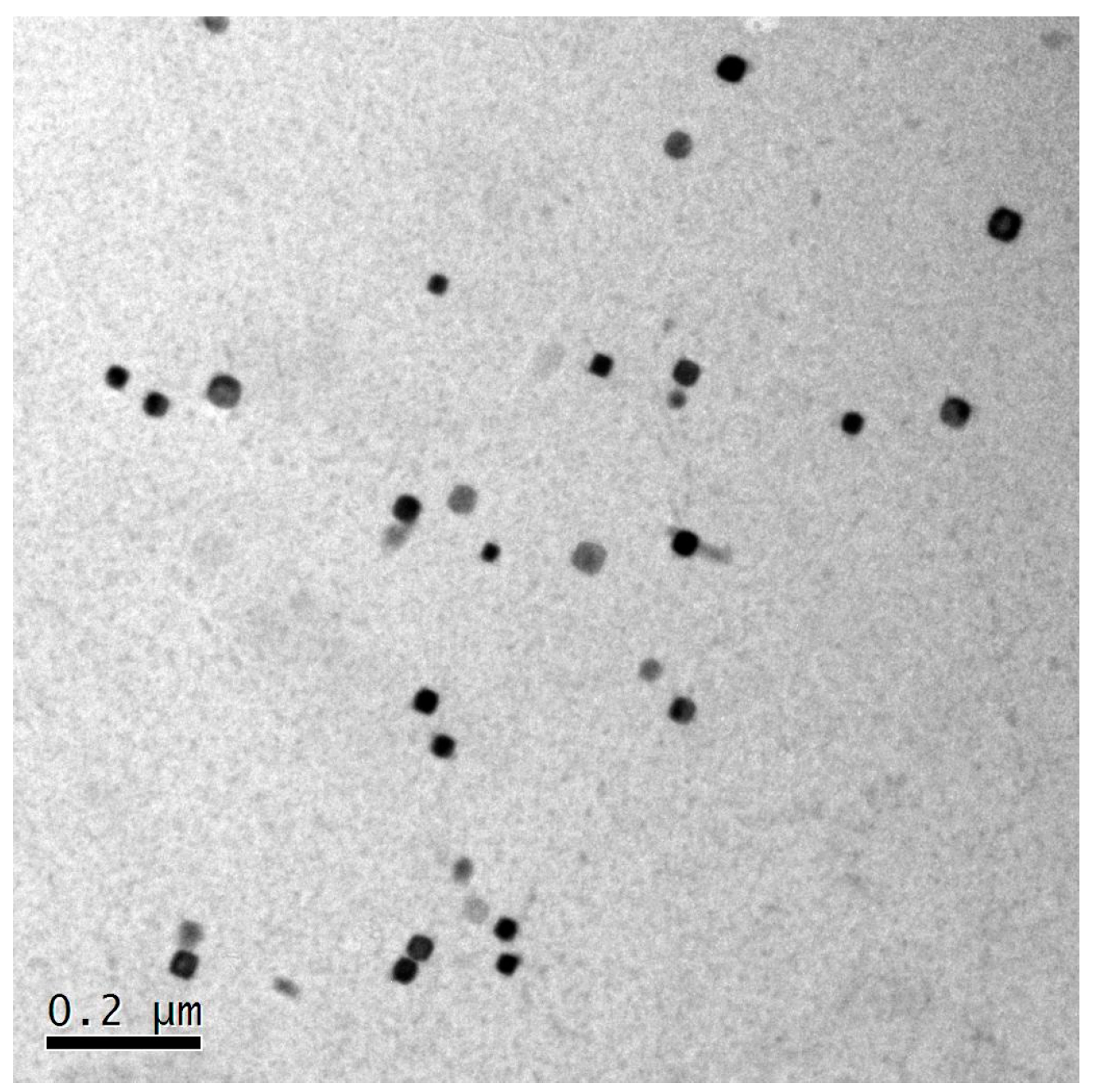

4.1. Influence of ER on Microstructure

4.2. Influence of Mcrostructure on Plastic Deformation

5. Conclusions

- The microstructure shows significant differences in 7003-T6 alloys with various ERs. The larger ER resulted in partial recrystallization and formation of coarse grain ring in the alloy with an ER of 56 after T6 treatment, leading to an inhomogeneous microstructure. Due to the absence of recrystallization, the microstructure of the alloys with ERs of 20 and 9 is homogeneous, consisting of fibrous grains with average widths of 66 μm and 122 μm, respectively.

- Due to the different initial microstructures, the mechanical behavior of the 7003-T6 alloy with various ERs exhibits obvious differences at strain rates ranging from 700 s−1 to 1100 s−1. For the alloy with an ER of 56, strain hardening is the main deformation behavior. For ones with ERs of 20 and 9, the flow stress slightly decreased after the peak stress, and then exhibited strain hardening again as the applied strain increased.

- At strain rates ranging from 700 s−1 to 1100 s−1, the plastic deformation of the alloy with an ER of 56 is uneven, with larger deformation concentrated in the coarse grain at the edges and smaller deformation at the center with slender grains. The plastic deformation of the alloys with ERs of 20 and 9 is relatively homogeneous, while the center and edges exhibit different features, with concentrated deformation occurring near the edge and uniform deformation occurring in the center. In comparison, the concentrated deformation is more significant in the alloy with an ER of 20.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahmaan, T.; Butcher, C.; Kim, S.; Worswick, M.J. Characterization and Prediction of Fracture in 6000- and 7000-Series Aluminum Alloy Sheet under Various Stress States. Thin-Walled Struct. 2022, 173, 108958. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent Development in Aluminium Alloys for the Automotive Industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Wang, H.; Lee, H.W.; Kang, S.H.; Kim, D.K. Crystal Plasticity Finite Element Analyses on the Formability of AA6061 Aluminum Alloy with Different Ageing Treatments. Metals 2024, 14, 503. [Google Scholar] [CrossRef]

- Chakraborty, P.; Singha, M.K.; Tiwari, V. Dynamic Tensile and Compressive Behaviour of AA7475-T7351 Alloy under Different Strain Rates and Temperatures. Structures 2022, 46, 49–63. [Google Scholar] [CrossRef]

- Zheng, J.; Yang, G.; Shao, C.W.; Li, H.; Hogan, J.D. Impact of Alternating Corrosion and Fatigue on the Fatigue Life of a 7475-T7351 Aluminum Alloy in an Aircraft Beam Structure. Int. J. Fract. 2024, 246, 333–344. [Google Scholar] [CrossRef]

- Marín, M.M.; Camacho, A.M.; Pérez, J.A. Influence of the Temperature on AA6061 Aluminum Alloy in a Hot Extrusion Process. Procedia Manuf. 2017, 13, 327–334. [Google Scholar] [CrossRef]

- Xu, X.F.; Zhao, Y.G.; Zhang, M.; Ning, Y.H.; Wang, X.D. Effect of Extrusion Ratio on the Microstructure and Mechanical Properties in an Al-Cu-Mg-Ag Alloy. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2018, 33, 710–714. [Google Scholar] [CrossRef]

- Liu, Z.W.; Li, L.X.; Yi, J.; Li, S.K.; Wang, G. Influence of Extrusion Speed on the Seam Weld Quality in the Porthole Die Extrusion of AZ31 Magnesium Alloy Tube. Int. J. Adv. Manuf. Technol. 2017, 92, 1039–1052. [Google Scholar] [CrossRef]

- Ji, H.C.; Qiao, J.H.; Kang, N.Z.; Wang, X.L.; Huang, J.H. Optimization of Hot Extrusion Process Parameters for 7075 Aluminum Alloy Rims Based on HyperXtrude. J. Mater. Res. Technol. 2023, 25, 4913–4928. [Google Scholar] [CrossRef]

- Chen, Y.J.; Wang, Q.D.; Peng, J.G.; Zhai, C.Q.; Ding, W.J. Effects of Extrusion Ratio on the Microstructure and Mechanical Properties of AZ31 Mg Alloy. J. Mater. Process. Technol. 2007, 182, 281–285. [Google Scholar] [CrossRef]

- Wu, P.F.; Dai, X.J. Effects of Extrusion Speed and Extrusion Ratio on Microstructure and Mechanical Properties of AZ31B Magnesium Alloy. Hot Work. Technol. 2017, 21, 4. [Google Scholar] [CrossRef]

- Guan, K.; Ma, R.; Zhang, J.H.; Wu, R.Z.; Yang, Q.; Meng, J. Modifying Microstructures and Tensile Properties of Mg-Sm Based Alloy via Extrusion Ratio. J. Magnes. Alloys 2021, 9, 1098–1109. [Google Scholar] [CrossRef]

- Zhao, T.S.; Dai, Y.X.; Zheng, T.X.; Hu, Y.B.; Jiang, B.; Pan, F.S. The Extrusion Ratios Modification of Mg-2Gd-xMn Alloys to Exploration of the Strengthening Mechanisms. J. Mater. Res. Technol. 2024, 30, 2147–2157. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.Y.; Lu, Y.L.; Li, X.P. Microstructure and Mechanical Properties of As-Extruded Mg-Sn-Zn-Ca Alloy with Different Extrusion Ratios. Trans. Nonferrous Met. Soc. China 2018, 28, 2190–2198. [Google Scholar] [CrossRef]

- Mu, T.; Yuan, J.W.; Zhang, K.; Li, Y.J.; Li, X.G.; Ma, M.L.; Shi, G.L.; Sun, Z.Q.; Zhang, K. Effect of Extrusion Ratio on Microstructures, Mechanical Properties, and High Cycle Fatigue Behavior of Mg–5Zn–1Mn Alloy. J. Mater. Res. Technol. 2024, 30, 992–1008. [Google Scholar] [CrossRef]

- Guo, P.C.; Li, L.X.; Liu, X.; Liu, W.H.; Wang, G. Room-Temperature Microstructural Evolution of Extruded AM80 Magnesium Alloys under Dynamic Loading. J. Mater. Eng. Perform. 2019, 28, 3430–3437. [Google Scholar] [CrossRef]

- Kim, Y.G.; Ko, Y.G.; Shin, D.H.; Lee, S. Effect of Equal-Channel Angular Pressing Routes on High-Strain-Rate Deformation Behavior of Ultra-Fine-Grained Aluminum Alloy. Acta Mater. 2010, 58, 2545–2554. [Google Scholar] [CrossRef]

- Owolabi, G.M.; Odeshi, A.G.; Singh, M.N.K.; Bassim, M.N. Dynamic Shear Band Formation in Aluminum 6061-T6 and Aluminum 6061-T6/Al2O3 Composites. Mater. Sci. Eng. A 2007, 457, 114–119. [Google Scholar] [CrossRef]

- Tiamiyu, A.A.; Odeshi, A.G.; Szpunar, J.A. Crash-Worthiness of a Recently-Developed AA 2624 Aluminum Alloy: Experimental Studies. Mater. Sci. Eng. A 2019, 766, 138389. [Google Scholar] [CrossRef]

- Gao, Z.G.; Zhang, X.M.; Chen, M.A. Influence of Strain Rate on the Precipitate Microstructure in Impacted Aluminum Alloy. Scr. Mater. 2008, 59, 983–986. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.X.; Liu, X.; Liu, W.H.; Guo, P.C.; Tang, X. Anisotropic Deformation Behavior of As-Extruded 6063-T4 Alloy under Dynamic Impact Loading. Mater. Sci. Eng. A 2016, 666, 149–155. [Google Scholar] [CrossRef]

- Jonas, J.J.; Ghosh, C.; Quelennec, X.; Basabe, V.V. The Critical Strain for Dynamic Transformation in Hot Deformed Austenite. ISIJ Int. 2013, 53, 145–151. [Google Scholar] [CrossRef]

- Yu, Y.N. Principles of Metal Science; Metallurgical Industry Press: Beijing, China, 2013. [Google Scholar]

- Xing, R.; Guo, P.C.; Xu, C.C.; Wang, D.C.; Li, L.X. Unveiling the Initiation and Evolution Mechanisms of Adiabatic Shear Band in Extruded 7003 Aluminum Alloy under High-Speed Impact Load. J. Alloys Compd. 2024, 983, 173915. [Google Scholar] [CrossRef]

- Zhang, J.J.; Yi, Y.P.; Huang, S.Q.; He, H.L.; Dong, F.; Wang, D. Mechanism and Kinetics of Static Recrystallization of 2195 Aluminum Alloy under Medium Temperature Deformation. Mater. Rep. 2024, 38, 22040369-9. [Google Scholar] [CrossRef]

- Xu, L.; Pei, Y.S.; Liu, Z.W.; Gao, C.; Xie, P.F.; Xu, C.C.; Li, L.X. Manufacturing of Curved Profiles Using an Extrusion-Bending Continuous Forming Process. Thin-Walled Struct. 2024, 199, 111831. [Google Scholar] [CrossRef]

- Tang, Z.Y.; Huang, C.Z.; Shi, Z.Y.; Li, B.H.; Liu, H.; Niu, J.H.; Chen, Z.; Jiang, G.Y. A New Characterisation Method for Stress, Hardness, Microstructure, and Slip Lines Using the Stored Energy Field in the Cutting Deformation Zones of Workpiece. Int. J. Mach. Tools Manuf. 2022, 178, 103891. [Google Scholar] [CrossRef]

- Lv, L.X. Phase Field and Crystal Plasticity Simulations and Related Coupled Models of Microstructure Change and Deformation in Metals; Harbin Institute of Technology: Harbin, China, 2011. [Google Scholar]

- Dash, S.S.; Li, D.J.; Zeng, X.Q.; Li, D.Y.; Chen, D.L. On the Origin of Deformation Mechanisms in a Heterostructured Aluminum Alloy via Slip Trace and Lattice Rotation Analyses. Mater. Sci. Eng. A 2023, 867, 144723. [Google Scholar] [CrossRef]

- Wang, J.W.; Chen, Y.B.; Zhu, Q.; Hong, Z.; Zhang, Z. Grain Boundary Dominated Plasticity in Metallic Materials. Available online: https://www.ams.org.cn/article/2022/0412-1961/0412-1961-2022-58-6-726.shtml (accessed on 20 July 2024).

- Kocks, W.F. Thermodynamics and Kinetics of Slip. Prog. Mater. Sci. 1975, 19, 308. [Google Scholar]

- Austin, R.A.; Mcdowell, D.L. A Dislocation-Based Constitutive Model for Viscoplastic Deformation of Fcc Metals at Very High Strain Rates. Int. J. Plast. 2011, 27, 1–24. [Google Scholar] [CrossRef]

- Lee, T.C.; Robertson, I.M.; Birnbaum, H.K. TEM in Situ Deformation Study of the Interaction of Lattice Dislocations with Grain Boundaries in Metals. Philos. Mag. Part A 1990, 62, 131–153. [Google Scholar] [CrossRef]

- Yan, N.; Li, Z.Z.; Xu, Y.B.; Meyers, M.A. Shear Localization in Metallic Materials at High Strain Rates. Prog. Mater. Sci. 2021, 119, 100755. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.; Zhuo, B.; Li, P.; He, L. Effect of Strain Rate and Temperature on Dynamic Mechanical Behavior and Microstructure Evolution of Ultra-High Strength Aluminum Alloy. Mater. Sci. Eng. A 2018, 730, 336–344. [Google Scholar] [CrossRef]

- Xu, Y.B.; Bai, Y.L.; Meyers, M.A. Deformation, Phase Transformation and Recrystallization in the Shear Bands Induced by High Strain Rate Loading in Titanium and Its Alloys. J. Mater. Sci. Technol. 2006, 6, 737–746. [Google Scholar]

| Zn | Mg | Cu | Fe | Si | Mn | Zr | Cr | Ti | V | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5.87 | 0.70 | 0.06 | 0.14 | 0.05 | 0.13 | 0.15 | 0.07 | 0.03 | 0.01 | Bal. |

| Extrusion Speed (mm s−1) | Billet Temperature (°C) | Die Temperature (°C) | Container Temperature (°C) | ER |

|---|---|---|---|---|

| 1 | 450 | 450 | 430 | 56/20/9 |

| ER | As-Extruded State | T6 Treated State |

|---|---|---|

| 56 | 27 µm | center: 29 µm edge: 221 µm |

| 20 | 64 µm | 66 µm |

| 9 | 110 µm | 112 µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, R.; Guo, P. Effect of Extrusion Ratio on Mechanical Behavior and Microstructure Evolution of 7003 Aluminum Alloy at High-Speed Impact. Materials 2024, 17, 4219. https://doi.org/10.3390/ma17174219

Xing R, Guo P. Effect of Extrusion Ratio on Mechanical Behavior and Microstructure Evolution of 7003 Aluminum Alloy at High-Speed Impact. Materials. 2024; 17(17):4219. https://doi.org/10.3390/ma17174219

Chicago/Turabian StyleXing, Rui, and Pengcheng Guo. 2024. "Effect of Extrusion Ratio on Mechanical Behavior and Microstructure Evolution of 7003 Aluminum Alloy at High-Speed Impact" Materials 17, no. 17: 4219. https://doi.org/10.3390/ma17174219

APA StyleXing, R., & Guo, P. (2024). Effect of Extrusion Ratio on Mechanical Behavior and Microstructure Evolution of 7003 Aluminum Alloy at High-Speed Impact. Materials, 17(17), 4219. https://doi.org/10.3390/ma17174219