Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials

Abstract

:1. Introduction

2. Conventional Stimulus Electro-Responsive Polymer Materials

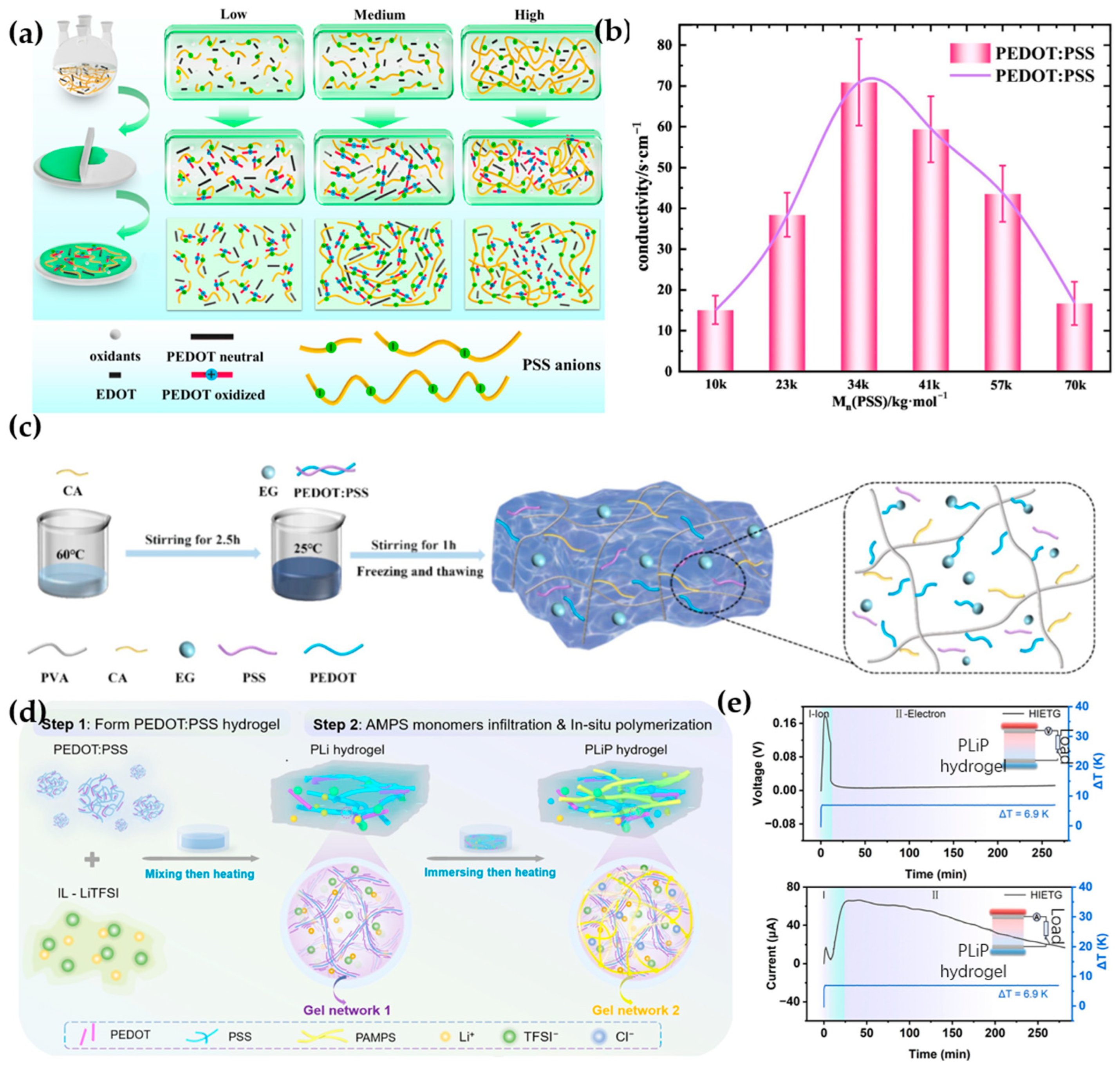

2.1. Thermal Stimulus Electro-Responsive Polymer Materials

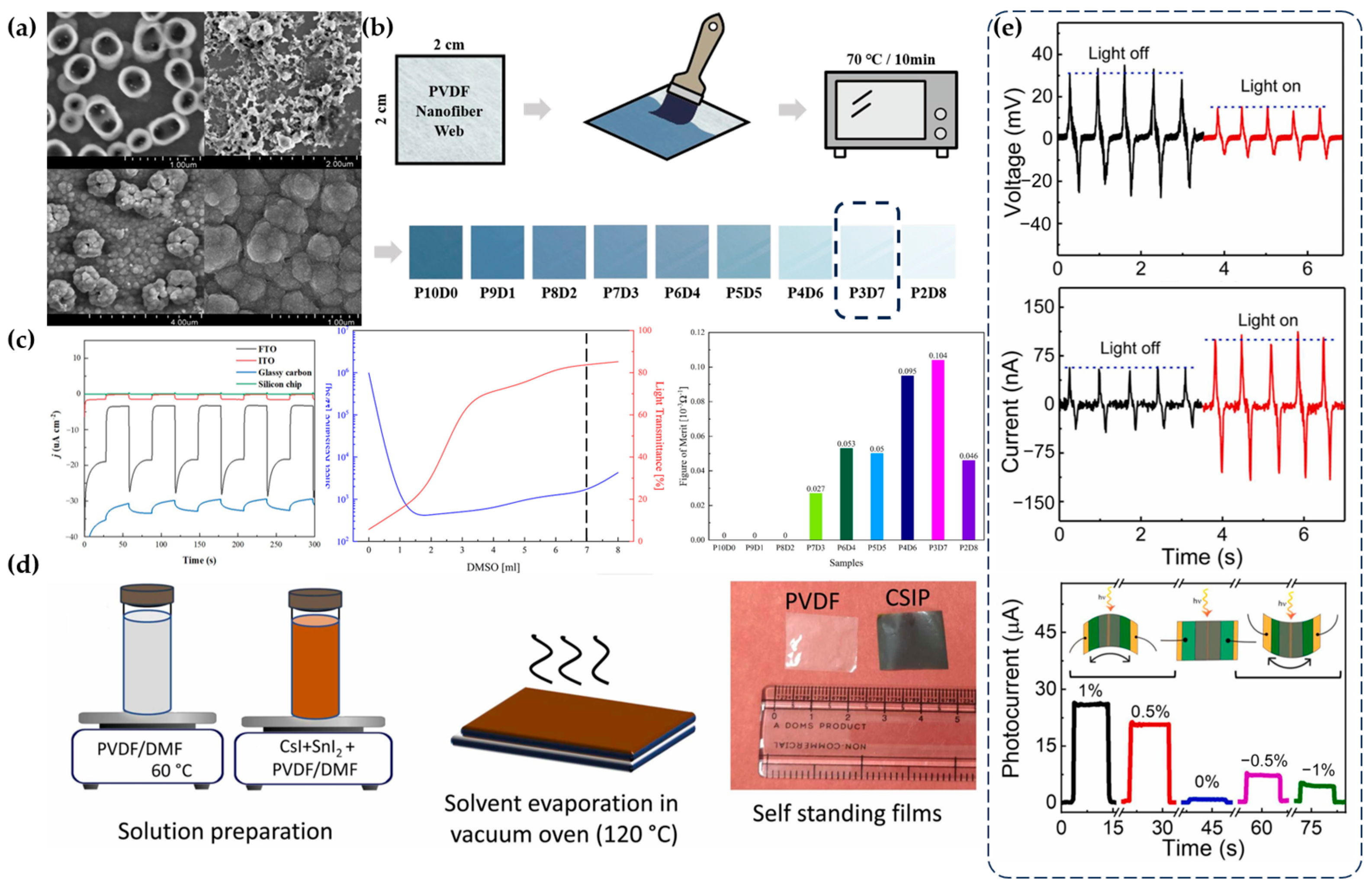

2.2. Light-Stimulus Electro-Responsive Polymer Materials

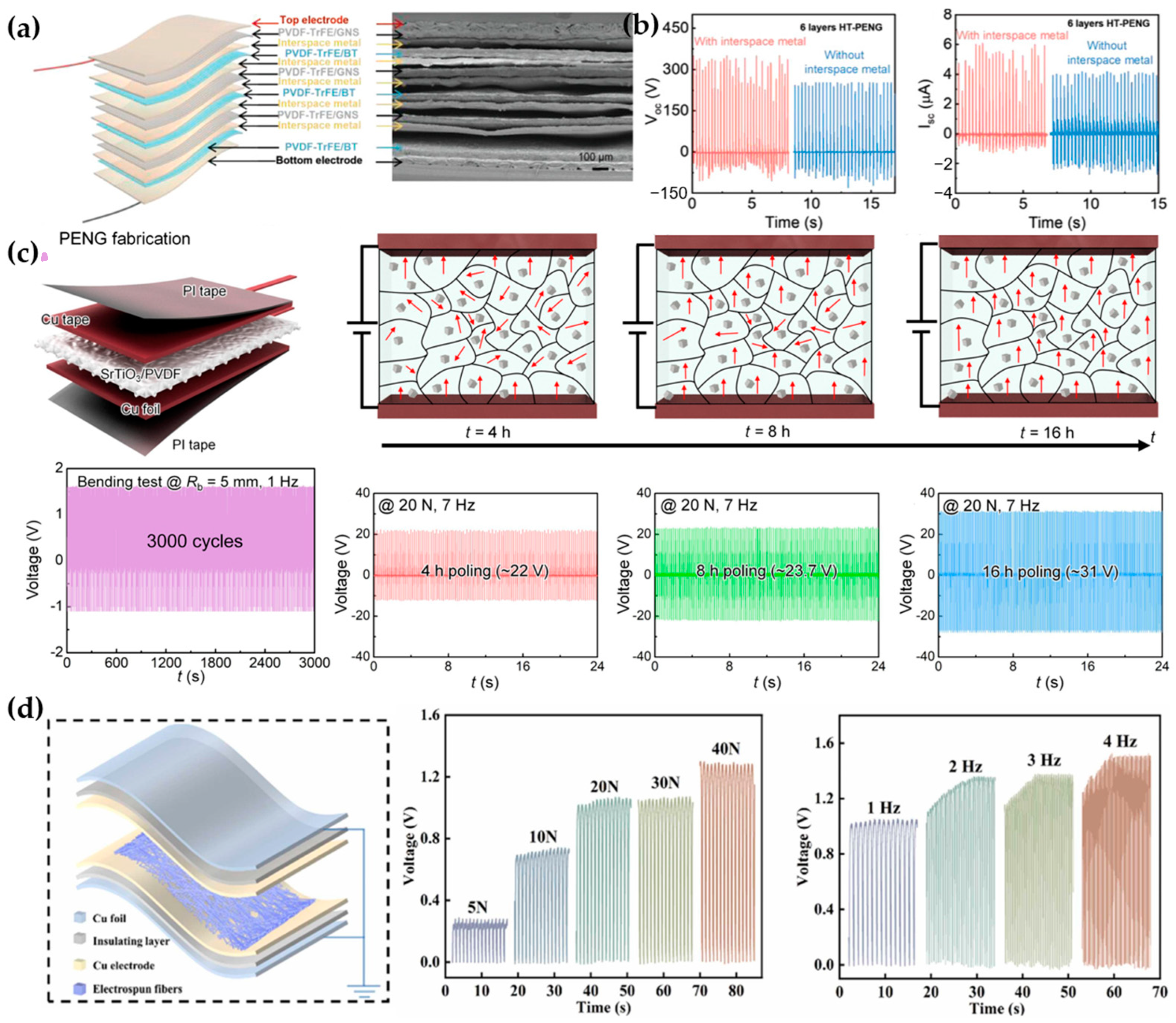

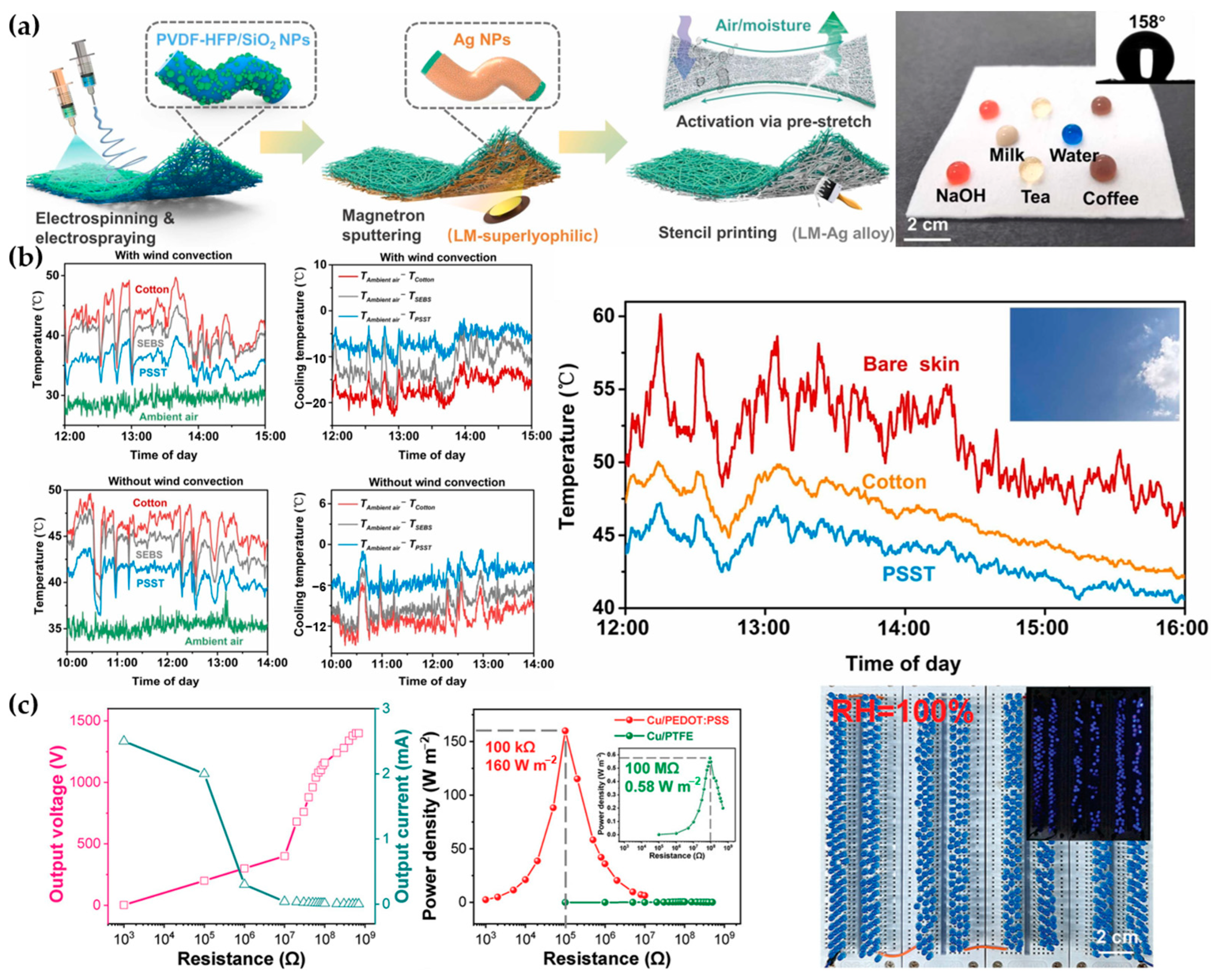

2.3. Mechanical-Stimulus Electro-Responsive Polymer Materials

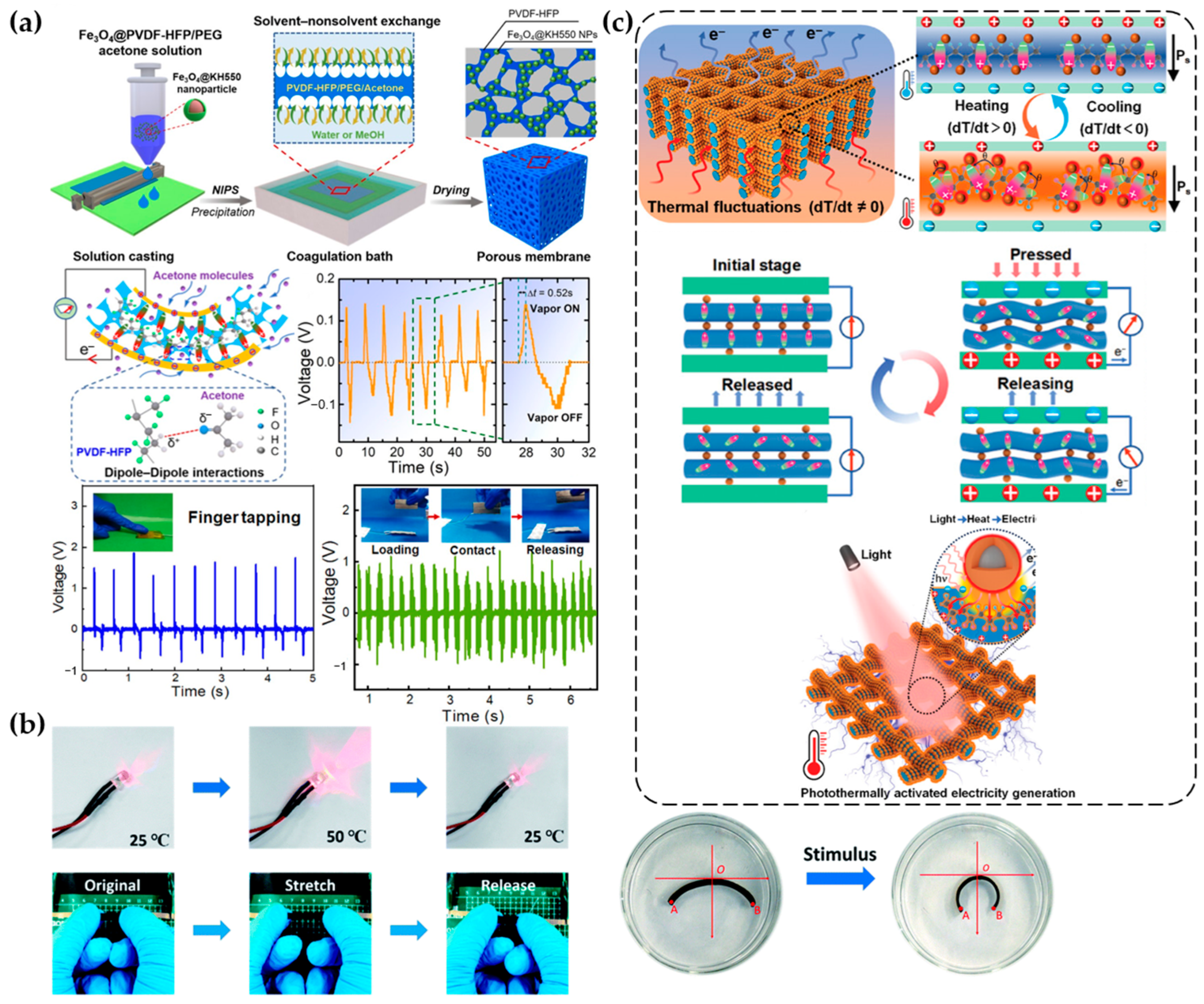

2.4. Magneto-Stimulus Electro-Responsive Polymer Materials

3. New Directions in Stimulus Electro-Responsive Polymer Materials

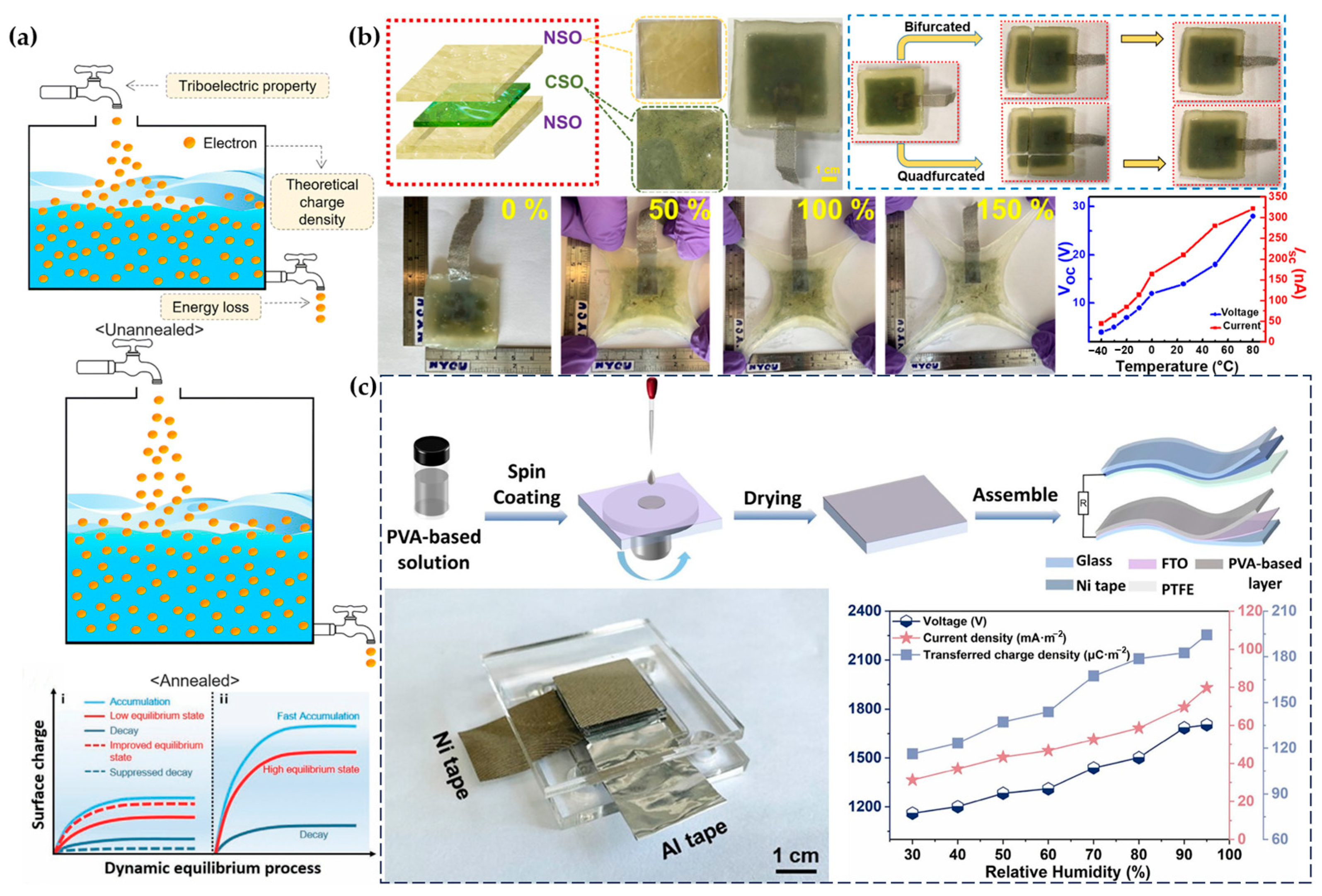

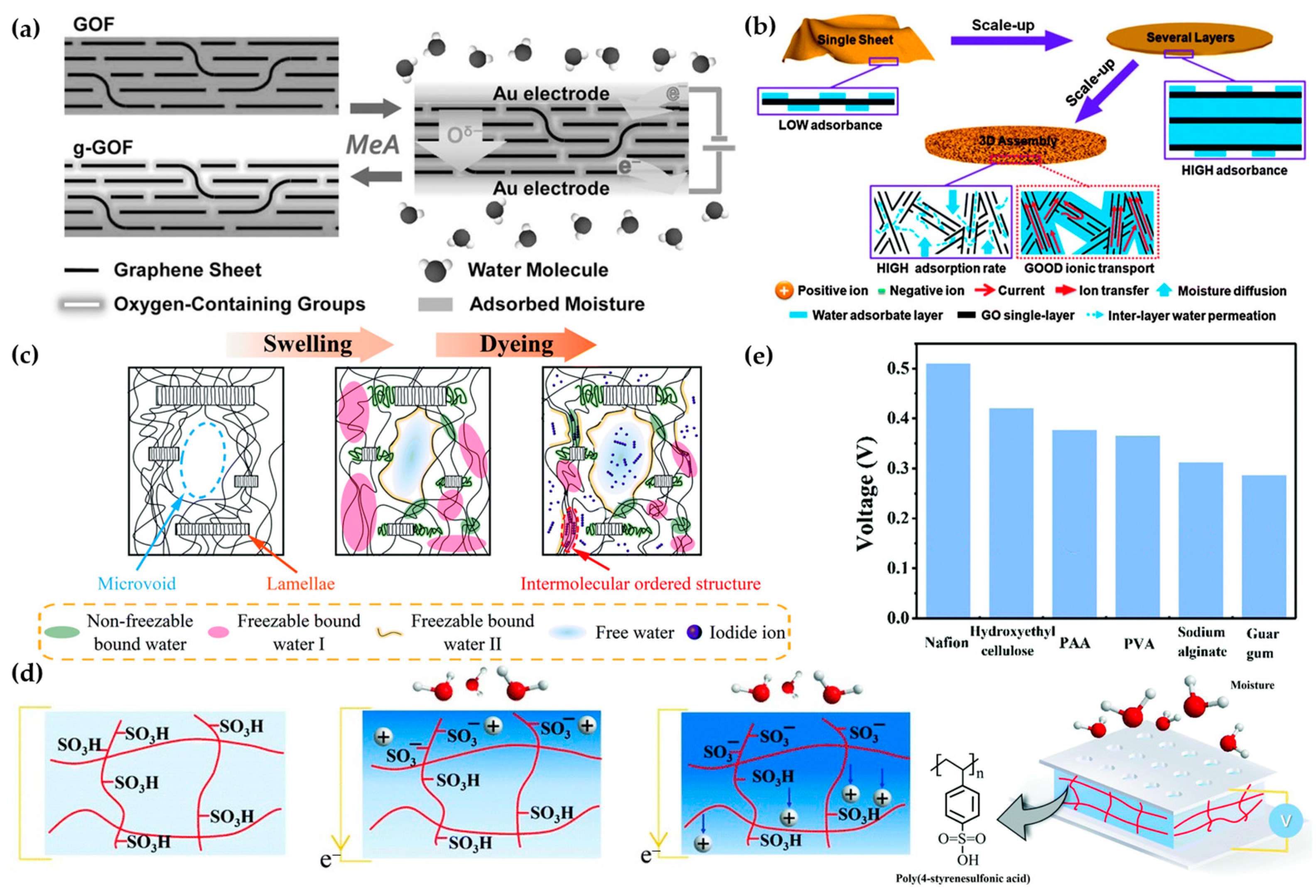

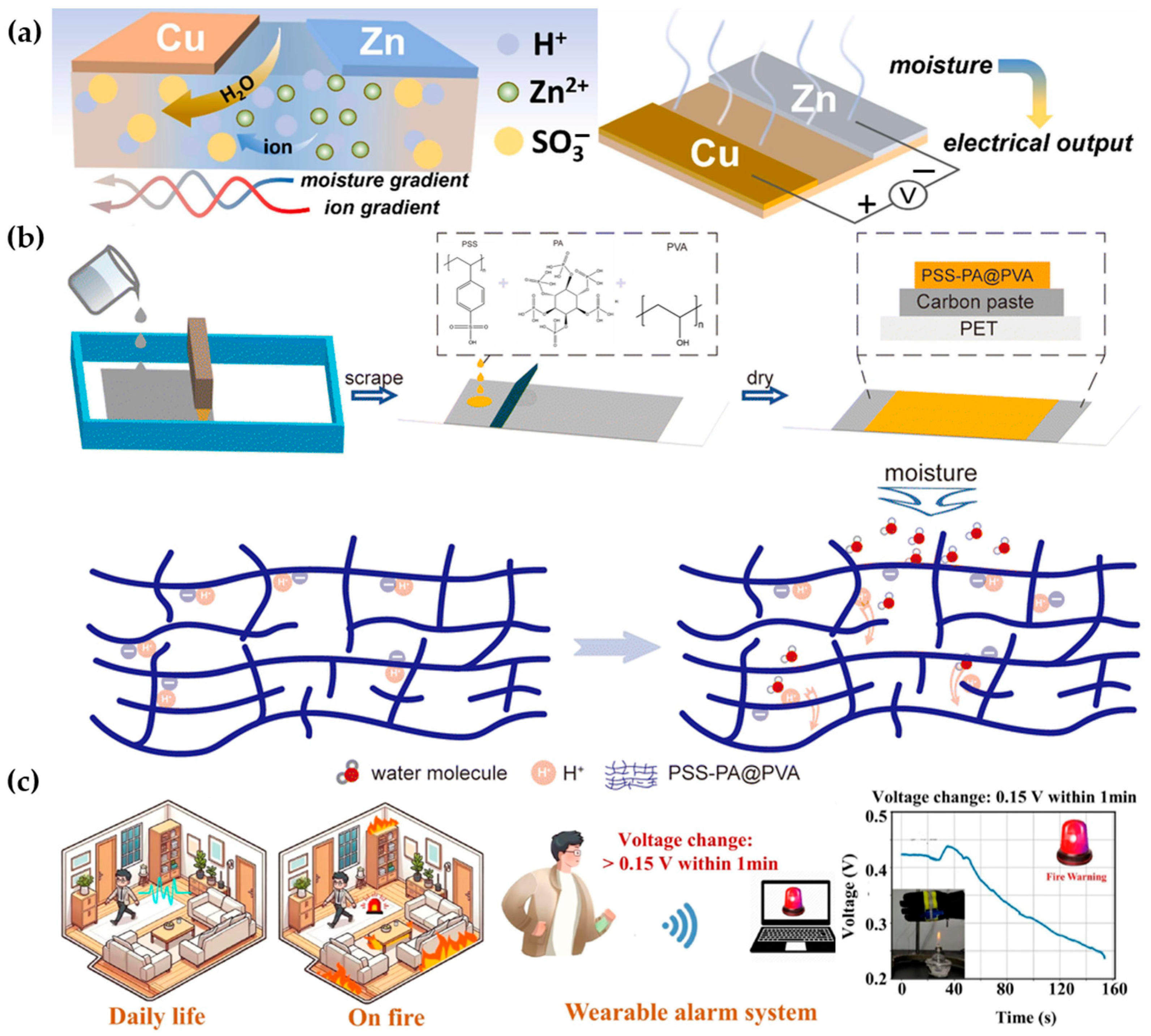

3.1. Humidity-Stimulus Electro-Responsive Polymer Materials

3.2. Multi-Stimulus Electro-Responsive Polymer Materials

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, F.; Guo, Z. Inspired smart materials with external stimuli responsive wettability: A review. RSC Adv. 2016, 6, 36623–36641. [Google Scholar] [CrossRef]

- Schoeller, J.; Itel, F.; Wuertz-Kozak, K.; Fortunato, G.; Rossi, R.M. pH-Responsive Electrospun Nanofibers and Their Applications. Polym. Rev. 2021, 62, 351–399. [Google Scholar] [CrossRef]

- Xue, H.; Liu, F.; Wang, Z.; Liu, D.; Zhou, L.; Su, W.; Niu, S.; Han, Z.; Ren, L. Bio-inspired dual-responsive photonic crystal with smart responsive hydrogel for pH and temperature detection. Mater. Des. 2023, 233, 112242. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, S.; Liang, L.; Du, C.; Ye, Z.; Chen, G. PEDOT-based thermoelectric composites: Preparation, mechanism and applications. Chin. Chem. Lett. 2024, 35, 109804. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Xu, Z.; Zhang, X.; Yang, Y.; Guo, J.; Zhang, B.; Zhao, W. Diversiform sensors and sensing systems driven by triboelectric and piezoelectric nanogenerators. Coord. Chem. Rev. 2021, 427, 213597. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, C.; Shao, C.; Wang, B.; Chen, N.; Jin, H.; Cheng, H.; Qu, L. Graphene Oxide Assemblies for Sustainable Clean-Water Harvesting and Green-Electricity Generation. Acc. Mater. Res. 2021, 2, 97–107. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, Z.; Xu, L.; Gao, F.; Zhao, B.; Kang, Z.; Liao, Q.; Zhang, Y. Tumbler-shaped hybrid triboelectric nanogenerators for amphibious self-powered environmental monitoring. Nano Energy 2020, 76, 104960. [Google Scholar] [CrossRef]

- Shafique, H.; de Vries, J.; Strauss, J.; Khorrami Jahromi, A.; Siavash Moakhar, R.; Mahshid, S. Advances in the Translation of Electrochemical Hydrogel-Based Sensors. Adv. Healthc. Mater. 2022, 12, 2201501. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Bai, J.; Ma, H.; Tian, X.; Xu, B. All-3D-printed multifunctional wearable energy systems with embodied zinc-ion storage capability and smart responsive effect. Energy Storage Mater. 2023, 55, 12–20. [Google Scholar] [CrossRef]

- Priyadarshini, B.S.; Mitra, R.; Manju, U. Titania Nanoparticle-Stimulated Ultralow Frequency Detection and High-Pass Filter Behavior of a Flexible Piezoelectric Nanogenerator: A Self-Sustaining Energy Harvester for Active Motion Tracking. ACS Appl. Mater. Interfaces 2023, 15, 45812–45822. [Google Scholar] [CrossRef] [PubMed]

- El-Desoky, H.S.; Mashaly, E.; Gaber, M.; Bakr, E.A. A novel ZrO2@PVA-PPy nanocomposite based electrochemical sensor for detection of anti Covid-19 drug Favipiravir in formulation, human plasma and various wastewater samples. Microchem. J. 2024, 200, 110216. [Google Scholar] [CrossRef]

- Mondal, S.; Maiti, S.; Paul, T.; Poddar, S.; Das, B.K.; Chattopadhyay, K.K. CsPbI3–PVDF Composite-Based Multimode Hybrid Piezo-Triboelectric Nanogenerator: Self-Powered Moisture Monitoring System. ACS Appl. Mater. Interfaces 2024, 16, 9231–9246. [Google Scholar] [CrossRef] [PubMed]

- Brighenti, R.; Li, Y.; Vernerey, F.J. Smart Polymers for Advanced Applications: A Mechanical Perspective Review. Front. Mater. 2020, 7, 00196. [Google Scholar] [CrossRef]

- Saleh, T.A.; Fadillah, G.; Ciptawati, E. Smart advanced responsive materials, synthesis methods and classifications: From Lab to applications. J. Polym. Res. 2021, 28, 197. [Google Scholar] [CrossRef]

- Wang, X.; Qin, Q.; Lu, Y.; Mi, Y.; Meng, J.; Zhao, Z.; Wu, H.; Cao, X.; Wang, N. Smart Triboelectric Nanogenerators Based on Stimulus-Response Materials: From Intelligent Applications to Self-Powered Systems. Nanomaterials 2023, 13, 1316. [Google Scholar] [CrossRef]

- Banerjee, P.; Anas, M.; Jana, S.; Mandal, T.K. Recent developments in stimuli-responsive poly(ionic liquid)s. J. Polym. Res. 2020, 27, 177. [Google Scholar] [CrossRef]

- Huang, C.; Xiao, M.; Li, Z.; Fu, Z.; Shi, R. Bioinspired breathable biodegradable bioelastomer-based flexible wearable electronics for high-sensitivity human-interactive sensing. Chem. Eng. J. 2024, 486, 150013. [Google Scholar] [CrossRef]

- Yu, Q.; Pan, J.; Jiang, Z.; Guo, Z.; Jiang, J. Stretchable multimodal textile sensor based on core-sheath CB/PDMS/MXene sensing yarn for efficiently distinguishing mechanical stimulus. Chem. Eng. J. 2024, 493, 152462. [Google Scholar] [CrossRef]

- Yang, P.; Zhu, F.; Zhang, Z.; Cheng, Y.; Wang, Z.; Li, Y. Stimuli-responsive polydopamine-based smart materials. Chem. Soc. Rev. 2021, 50, 8319–8343. [Google Scholar] [CrossRef]

- Llacer-Wintle, J.; Renz, J.; Hertle, L.; Veciana, A.; von Arx, D.; Wu, J.; Bruna, P.; Vukomanovic, M.; Puigmartí-Luis, J.; Nelson, B.J.; et al. The magnetopyroelectric effect: Heat-mediated magnetoelectricity in magnetic nanoparticle-ferroelectric polymer composites. Mater. Horiz. 2023, 10, 2627–2637. [Google Scholar] [CrossRef]

- Guchait, S.; Zhong, Y.; Brinkmann, M. High-Temperature Rubbing: An Effective Method to Fabricate Large-Scale Aligned Semiconducting and Conducting Polymer Films for Applications in Organic Electronics. Macromolecules 2023, 56, 6733–6757. [Google Scholar] [CrossRef]

- Wei, M.; Gao, Y.; Li, X.; Serpe, M.J. Stimuli-responsive polymers and their applications. Polym. Chem. 2017, 8, 127–143. [Google Scholar] [CrossRef]

- Wang, S.; Urban, M.W. Redefining polymer science via multi-stimulus responsiveness. Chem 2023, 9, 1362–1377. [Google Scholar] [CrossRef]

- Li, H.; Lian, W.; Cheng, T.; Zhang, W.; Lu, B.; Tan, K.; Liu, C.; Shen, C. Highly Tunable Piezoelectricity of Flexible Nanogenerators Based on 3D Porously Architectured Membranes for Versatile Energy Harvesting and Self-Powered Multistimulus Sensing. ACS Sustain. Chem. Eng. 2021, 9, 17128–17141. [Google Scholar] [CrossRef]

- Yu, D.; Teng, Y.; Feng, H.; Lin, X.; Li, J.; Wang, Q.; Xue, C. Multi-responsive and conductive bilayer hydrogel and its application in flexible devices. RSC Adv. 2022, 12, 7898–7905. [Google Scholar] [CrossRef] [PubMed]

- Cui, D.; Wang, J.; Zhang, M.; Cheng, T.; Yue, N.; Qiu, D.; Lu, B.; Dong, B.; Shen, C.; Liu, C. Bioinspired Multistimulus-Responsive Piezoelectric Polymeric Nanoheterostructures via Interface-Confined Configurations. Adv. Funct. Mater. 2024, 2404503. [Google Scholar] [CrossRef]

- Zhao, F.; Cheng, H.; Zhang, Z.; Jiang, L.; Qu, L. Direct Power Generation from a Graphene Oxide Film under Moisture. Adv. Mater. 2015, 27, 4351–4357. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-S.; Li, J.; Wang, F.; Shi, J.-D.; Chen, W.; Tao, X.-M. Flexible stimuli-responsive materials for smart personal protective equipment. Mater. Sci. Eng. R Rep. 2021, 146, 100629. [Google Scholar] [CrossRef]

- Moulin, E.; Faour, L.; Carmona-Vargas, C.C.; Giuseppone, N. From Molecular Machines to Stimuli-Responsive Materials. Adv. Mater. 2020, 32, 1906036. [Google Scholar] [CrossRef]

- Liu, M.; Yang, M.; Wan, X.; Tang, Z.; Jiang, L.; Wang, S. From Nanoscopic to Macroscopic Materials by Stimuli-Responsive Nanoparticle Aggregation. Adv. Mater. 2023, 35, e2208995. [Google Scholar] [CrossRef]

- Zhang, K.Y.; Liu, S.; Zhao, Q.; Huang, W. Stimuli–responsive metallopolymers. Coord. Chem. Rev. 2016, 319, 180–195. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, H.; Zhang, M.; Zhao, Y.; Qu, L.; Shi, G. Graphene-based smart materials. Nat. Rev. Mater. 2017, 2, 17046. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Wan, S.; Wang, W.; Fu, L. Stimuli-Responsive 2D Materials Beyond Graphene. Adv. Funct. Mater. 2018, 28, 1802500. [Google Scholar] [CrossRef]

- Yang, J.; Huang, W.; Peng, K.; Cheng, Z.; Lin, L.; Yuan, J.; Sun, Y.; Cho, N.J.; Chen, Y. Versatile Agar-Zwitterion Hybrid Hydrogels for Temperature Self-Sensing and Electro-Responsive Actuation. Adv. Funct. Mater. 2024, 34, 2313725. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, X.-S.; Gong, S.-H.; Liu, C.; Liu, Y.; Liu, T.-F. Stable hydrogen-bonded organic frameworks and their photo- and electro-responses. Nano Res. 2024, 17, 7675–7699. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, J.C.; Zhou, H.; Liu, Y.Q.; Han, D.D.; Sun, H.B. Electro-responsive actuators based on graphene. Innovation 2021, 2, 100168. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Zhang, D.; Yang, Y.; Leng, D. Large deformation, high energy density dielectric elastomer actuators: Principles, factors, optimization, applications, and prospects. Chem. Eng. J. 2024, 489, 151402. [Google Scholar] [CrossRef]

- Yang, J.; Wei, K.; Yao, J.; Yu, T.; Jiang, Z.; Fang, M.; Sha, T. Regulatory and enhancement mechanism of a micro-nano material of sodium polystyrene sulfonate on the electro-responsive fatigue resistance of ion gel artificial muscles by cross-linking reaction. Sens. Actuators B Chem. 2024, 412, 135844. [Google Scholar] [CrossRef]

- Du, Y.; Shen, S.Z.; Cai, K.; Casey, P.S. Research progress on polymer–inorganic thermoelectric nanocomposite materials. Prog. Polym. Sci. 2012, 37, 820–841. [Google Scholar] [CrossRef]

- Zhou, H.; Chua, M.H.; Zhu, Q.; Xu, J. High-performance PEDOT:PSS-based thermoelectric composites. Compos. Commun. 2021, 27, 100877. [Google Scholar] [CrossRef]

- Jiang, F.; Xu, J.; Lu, B.; Xie, Y.; Huang, R.; Li, L. Thermoelectric Performance of Poly(3,4-ethylenedioxythiophene): Poly(styrenesulfonate). Chin. Phys. Lett. 2008, 25, 2202. [Google Scholar]

- Fan, Q.; Zhang, K.; Peng, S.; Liu, Y.; Wei, L.; Qin, S.; He, M.; Guo, J.; Luo, T.; Yu, J. The mechanism of enhancing the conductivity of PEDOT: PSS films through molecular weight optimization of PSS. Prog. Org. Coat. 2024, 189, 108308. [Google Scholar] [CrossRef]

- Zhu, Y.; Yao, D.; Gao, X.; Chen, J.; Wang, H.; You, T.; Lu, C.; Pang, X. Recyclable Bimodal Polyvinyl Alcohol/PEDOT:PSS Hydrogel Sensors for Highly Sensitive Strain and Temperature Sensing. ACS Appl. Mater. Interfaces 2024, 16, 32466–32480. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Fu, Q.; Deng, H. A double network facilitated ion-electron conductor for thermoelectric harvesting with high energy density. Chem. Eng. J. 2024, 486, 150307. [Google Scholar] [CrossRef]

- Liu, M.; Li, N.; Liu, P.; Xu, J.; Chen, Z.; Zhao, W.; Liu, H.; Zhou, W.; Jiang, F. Electrochemically tuning the thermoelectric performance of flexible polythiophene films by ionic liquid. Electrochim. Acta 2024, 473, 143462. [Google Scholar] [CrossRef]

- Zhang, A.; Yuan, S.; Du, Y.; Dou, W.; Cai, W.; Zhang, F.; Zhu, J.; Ye, Z. A flat radiative cooling thermoelectric generator for high performance power generation. Energy 2024, 290, 130138. [Google Scholar] [CrossRef]

- Malik, Y.T.; Akbar, Z.A.; Seo, J.Y.; Cho, S.; Jang, S.Y.; Jeon, J.W.J.A.E.M. Self-Healable Organic–Inorganic Hybrid Thermoelectric Materials with Excellent Ionic Thermoelectric Properties. Adv. Energy Mater. 2022, 12, 2103070. [Google Scholar] [CrossRef]

- Li, M.; Xu, H.; Luo, M.; Qing, X.; Wang, W.; Zhong, W.; Liu, Q.; Wang, Y.; Yang, L.; Zhu, X.; et al. Wearable ionogel fiber-based ionic thermoelectric device for low-grade human body heat harvesting. Chem. Eng. J. 2024, 485, 149784. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, H.; He, H.; Li, J.; Ouyang, J. Significant Enhancement in the Thermoelectric Properties of Ionogels through Solid Network Engineering. Adv. Funct. Mater. 2021, 32, 2109772. [Google Scholar] [CrossRef]

- Duan, J.; Yu, B.; Liu, K.; Li, J.; Yang, P.; Xie, W.; Xue, G.; Liu, R.; Wang, H.; Zhou, J. P-N conversion in thermogalvanic cells induced by thermo-sensitive nanogels for body heat harvesting. Nano Energy 2019, 57, 473–479. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, H.; Chen, W.; Li, Q.; Yan, B.; Jin, X.; Ma, A.; Liu, H.; Zhao, W. Dually Synergetic Network Hydrogels with Integrated Mechanical Stretchability, Thermal Responsiveness, and Electrical Conductivity for Strain Sensors and Temperature Alertors. ACS Appl. Mater. Interfaces 2018, 10, 14045–14054. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, Y.; Fu, D.; Wang, G.; Wei, H.; Ma, N. Photo-thermal converting polyaniline/ionic liquid inks for screen printing highly-sensitive flexible uncontacted thermal sensors. Eur. Polym. J. 2021, 147, 110305. [Google Scholar] [CrossRef]

- Mehmood, U.; Al-Ahmed, A.; Hussein, I.A. Review on recent advances in polythiophene based photovoltaic devices. Renew. Sustain. Energy Rev. 2016, 57, 550–561. [Google Scholar] [CrossRef]

- Gao, J.; Chu, Y.; Yan, Y.; Zhou, S.; Li, X.; Li, C.-B. Preparation, characterization, and photoelectric properties of poly(1,3,5-tri (thiophene-2-yl) benzene) film electrodes. Polymer 2024, 290, 126576. [Google Scholar] [CrossRef]

- Cha, S.; Lee, E.; Cho, G. Fabrication of Poly(3,4-ethylenedioxythiophene): Poly(styrenesulfonate)/Poly(vinylidene fluoride) Nanofiber-Web-Based Transparent Conducting Electrodes for Dye-Sensitized Photovoltaic Textiles. ACS Appl. Mater. Interfaces 2021, 13, 28855–28863. [Google Scholar] [CrossRef]

- Mallick, Z.; Saini, D.; Sarkar, R.; Kundu, T.K.; Mandal, D. Piezo-phototronic effect in highly stable lead-free double perovskite Cs2SnI6-PVDF nanocomposite: Possibility for strain modulated optical sensor. Nano Energy 2022, 100, 107451. [Google Scholar] [CrossRef]

- Tavakoli, M.M.; Park, J.H.; Mwaura, J.; Saravanapavanantham, M.; Bulović, V.; Kong, J. Monolayer Hexagonal Boron Nitride: An Efficient Electron Blocking Layer in Organic Photovoltaics. Adv. Funct. Mater. 2021, 31, 2101238. [Google Scholar] [CrossRef]

- Mehta, M.A.; Fujinami, T.; Konno, A.; Kobayashi, H.; Mabuchi, T.; Ogita, M. Long-lived visible light induced voltages in all-polymeric thin film systems. J. Electroanal. Chem. 1998, 458, 257–261. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, X.; Hang, G.; Duan, J.; Zhang, J.; Zhang, W.; Liu, Z. Recent progress on flexible poly(vinylidene fluoride)-based piezoelectric nanogenerators for energy harvesting and self-powered electronic applications. Renew. Sustain. Energy Rev. 2024, 193, 114285. [Google Scholar] [CrossRef]

- Sasmal, A.; Seetharaman, A.; Maiti, P.; Sudhakar, S.; Arockiarajan, A. Charge-defect tuned PVDF based ternary biocompatible composite as skin touch actuated single electrode triboelectric nanogenerator for wireless healthcare monitoring. Chem. Eng. J. 2024, 487, 150573. [Google Scholar] [CrossRef]

- Mahanty, B.; Ghosh, S.K.; Prasad, G.; Shanmugasundaram, A.; Lee, D.W. Giant Energy Harvesting via Maxwell Displacement Current Enhancement Using Metal Sheet Interspaced Hetero-Layer Structured Piezo-Composite Nanofiber Device. Adv. Funct. Mater. 2023, 34, 2307723. [Google Scholar] [CrossRef]

- Park, C.; Lim, W.; Joshi, B.; Kim, T.; Samuel, E.; Aldalbahi, A.; Periyasami, G.; Ding, B.; Yoon, S.S. Enhancing the piezoelectric coefficient of SrTiO3 nanocubes and PVDF film deposited by supersonic spraying for energy-harvesting nanogenerators. Chem. Eng. J. 2024, 491, 151945. [Google Scholar] [CrossRef]

- Wang, S.; Tong, W.; Li, Y.; Zhang, P.; Liu, Y.; Chen, Y.; Zhang, Y. Contributions of piezoelectricity and triboelectricity to a hydroxyapatite/PVDF–HFP fiber-film nanogenerator. Nano Energy 2023, 105, 108026. [Google Scholar] [CrossRef]

- Haldar, R.; Sarkar, U.; Kumar, A.; Mandal, D.; Shanmugam, M. Inducing Polar Phase in Poly(Vinylidene Fluoride) with a Molecular Ferroelectric Copper(II) Complex for Piezoelectric Energy Harvesting. Adv. Funct. Mater. 2024, 2407611. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, B.; Dong, G.; Wang, Y.; Yang, G.; Zhang, J.; Peng, B.; Zhao, Y.; Liu, M. Enhanced Piezoelectric Energy Harvester by Employing Freestanding Single-Crystal BaTiO3 Films in PVDF-TrFE Based Composites. Adv. Funct. Mater. 2024, 34, 2316519. [Google Scholar] [CrossRef]

- Poddar, S.; Mondal, S.; Bhattacharjee, S.; Pal, P.; Maiti, S.; Banerjee, A.; Chattopadhyay, K.K. Bi-functional Rb4Ag2BiBr9-PVDF composite based Piezoelectric mechanical energy harvester and light assisted self-charging power unit. Nano Energy 2024, 123, 109380. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Deng, H.; Shi, S.; Tian, S.; Wu, H.; Tang, J.; Zhang, C.; Zhang, X.; Zha, J.W.; et al. Advanced Dielectric Materials for Triboelectric Nanogenerators: Principles, Methods, and Applications. Adv. Mater. 2024, 2314380. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Liu, L.; Zhou, L.; Liu, D.; Li, S.; Chen, S.; Dai, Y.; Wang, J.; Wang, Z.L. Improved Output Performance of Triboelectric Nanogenerator by Fast Accumulation Process of Surface Charges. Adv. Energy Mater. 2021, 11, 2100050. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Z.; Gao, Y.; Nan, Y.; Hu, Y.; Guo, Z.; Qiao, W.; Wang, J.; Zhou, L.; Wang, Z.L.; et al. Triboelectric nanogenerators exhibiting ultrahigh charge density and energy density. Energy Environ. Sci. 2024, 17, 3819–3831. [Google Scholar] [CrossRef]

- Khan, A.; Ginnaram, S.; Wu, C.-H.; Lu, H.-W.; Pu, Y.-F.; Wu, J.I.; Gupta, D.; Lai, Y.-C.; Lin, H.-C. Fully self-healable, highly stretchable, and anti-freezing supramolecular gels for energy-harvesting triboelectric nanogenerator and self-powered wearable electronics. Nano Energy 2021, 90, 106525. [Google Scholar] [CrossRef]

- Wang, J.; Xia, Z.; Yao, H.; Zhang, Q.; Yang, H. Self-Powered TENG with High Humidity Sensitivity from PVA Film Modified by LiCl and MXene. ACS Appl. Mater. Interfaces 2023, 15, 47208–47220. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xu, F.; Wang, J.; Zhang, J.; Wang, H.; Li, Y.; Sun, J. Self-healing fluorinated poly(urethane urea) for mechanically and environmentally stable, high performance, and versatile fully self-healing triboelectric nanogenerators. Nano Energy 2023, 108, 108243. [Google Scholar] [CrossRef]

- Mariappan, V.K.; Krishnamoorthy, K.; Pazhamalai, P.; Manoharan, S.; Kim, S.-J. Decoupling Contact and Rotary Triboelectrification vs Materials Property: Toward Understanding the Origin of Direct-Current Generation in TENG. ACS Appl. Mater. Interfaces 2022, 14, 34593–34602. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Long, Z.; Zhang, Y.; Mensah, A.; He, H.; Wei, Q.; Lv, P. Robust integration of energy harvesting with daytime radiative cooling enables wearing thermal comfort self-powered electronic devices. Nano Energy 2023, 116, 108842. [Google Scholar] [CrossRef]

- Pan, J.; Jin, A. Improvement of Output Performance of the TENG Based on PVDF by Doping Tourmaline. ACS Sustain. Chem. Eng. 2024, 12, 2092–2099. [Google Scholar] [CrossRef]

- Sun, Q.; Liang, F.; Ren, G.; Zhang, L.; He, S.; Gao, K.; Gong, Z.; Zhang, Y.; Kang, X.; Zhu, C.; et al. Density-of-States Matching-Induced Ultrahigh Current Density and High-Humidity Resistance in a Simply Structured Triboelectric Nanogenerator. Adv. Mater. 2023, 35, 2210915. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Chatterjee, C.; Fatma, B.; Brajesh, K.; Bhunia, R.; Sowmya, N.S.; Roy, S.; Kulkarni, A.; Gupta, R.K.; Gupta, R.; et al. Functionality Tuning in Hierarchically Engineered Magnetoelectric Nanocomposites for Energy-Harvesting Applications. ACS Appl. Mater. Interfaces 2023, 15, 26563–26575. [Google Scholar] [CrossRef]

- Nam, C.; Na, Y.; Park, S.C.; Kim, H.; Jeong, C.K.; Hwang, G.-T.; Park, K.-I. Energy harvesting of fully-flexible magnetoelectric composites using a piezoelectric P(VDF-TrFE) and magnetostrictive CoFe2O4 nanofiber. J. Mater. Chem. A 2023, 11, 559–568. [Google Scholar] [CrossRef]

- Zhao, F.; Liang, Y.; Cheng, H.; Jiang, L.; Qu, L. Highly efficient moisture-enabled electricity generation from graphene oxide frameworks. Energy Environ. Sci. 2016, 9, 912–916. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, S.; Kang, J.; Chen, J.; Cao, Y. Water absorption dependence of the formation of poly(vinyl alcohol)-iodine complexes for poly(vinyl alcohol) films. RSC Adv. 2021, 11, 28785–28796. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Ding, X.; Huang, Y.; Shao, C.; Song, L.; Gao, X.; Zhang, Z.; Qu, L. An efficient polymer moist-electric generator. Energy Environ. Sci. 2019, 12, 972–978. [Google Scholar] [CrossRef]

- Sui, C.; Preece, J.A.; Zhang, Z. Novel polystyrene sulfonate–silica microspheres as a carrier of a water soluble inorganic salt (KCl) for its sustained release, via a dual-release mechanism. RSC Adv. 2017, 7, 478–481. [Google Scholar] [CrossRef]

- Feng, J.-C.; Wei, N.; Sun, Z.; Li, S.-X.; Li, X.; Xia, H. Multifunctionally moist-electric generator for self-powered ultra-fast sensing based on laterally dual gradient. Nano Energy 2024, 123, 109409. [Google Scholar] [CrossRef]

- Zhang, T.; Han, X.; Peng, Y.; Yu, H.; Pu, J. Modified Wood Fibers Spontaneously Harvest Electricity from Moisture. Polymers 2024, 16, 260. [Google Scholar] [CrossRef]

- Othayoth, A.K.; Paul, S.; Muralidharan, K. Polyvinyl alcohol-phytic acid polymer films as promising gas/vapor sorption materials. J. Polym. Res. 2021, 28, 249. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Y.; Wang, M.; Lv, Z.; Zhang, Z.; He, H. Selective ion migration in a polyelectrolyte driving a high-performance flexible moisture-electric generator. Chem. Commun. 2024, 60, 6178–6181. [Google Scholar] [CrossRef]

- Xing, R.; Liu, Y.; Yan, J.; Wang, R.; Zhuang, X.; Yang, G. High-performance, breathable and flame-retardant moist-electric generator based on asymmetrical nanofiber membrane assembly. J. Colloid Interface Sci. 2024, 671, 205–215. [Google Scholar] [CrossRef]

- Duan, W.; Shao, B.; Wang, Z.; Ni, K.; Liu, S.; Yuan, X.; Wang, Y.; Sun, B.; Zhang, X.; Liu, R. Silicon nanowire/ionic hydrogel-based hybrid moist-electric generators with enhanced voltage output and operational stability. Energy Environ. Sci. 2024, 17, 3788–3796. [Google Scholar] [CrossRef]

- Zhang, R.; Qu, M.; Wang, H.; Li, S.; Song, Y.; Tang, P.; Bin, Y. Sodium alginate based skin-core fibers with profoundly enhanced moisture-electric generation performance and their multifunctionality. J. Mater. Chem. A 2023, 11, 3616–3624. [Google Scholar] [CrossRef]

- Feng, J.-C.; Li, S.-X.; Zhang, Z.-P.; An, Y.; Gao, Q.-S.; Sun, Z.; Xia, H. High output power moist-electric generator based on synergistic nanoarchitectonics for effective ion regulation. Nano Energy 2024, 119, 109103. [Google Scholar] [CrossRef]

- Yang, S.; Tao, X.; Chen, W.; Mao, J.; Luo, H.; Lin, S.; Zhang, L.; Hao, J. Ionic Hydrogel for Efficient and Scalable Moisture-Electric Generation. Adv. Mater. 2022, 34, 2200693. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhou, K.; Cheng, H.; He, T.; Wang, H.; Bai, J.; Yang, C.; Guang, T.; Yao, H.; Li, F.; et al. Three-Dimensional Printing of High-Performance Moisture Power Generators. Adv. Funct. Mater. 2023, 34, 2308620. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, L.; Zhai, Y.; Pan, L.; Cao, W.; Tian, M.; Qu, L.; Jiang, Y. Waterborne Polyurethane: An easily available material for moist-electric generator with unique stretchability and water resistant. J. Mater. Chem. A 2024, 12, 18519–18527. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, H.; Huang, Y.; Yang, C.; Wang, D.; Li, C.; Qu, L. Transparent, self-healing, arbitrary tailorable moist-electric film generator. Nano Energy 2020, 67, 104238. [Google Scholar] [CrossRef]

- Shi, M.; Yang, Y.N.; Han, Y.; Wang, J.; Wang, Y.; Li, D.; Lv, J.; Wu, W.; Wang, Z.; Wei, X.; et al. Long Cycle Life Rechargeable Moisture-Enabled Electricity Cell. Adv. Energy Mater. 2023, 14, 2303815. [Google Scholar] [CrossRef]

- Liu, C.; Wang, S.; Wang, X.; Mao, J.; Chen, Y.; Fang, N.X.; Feng, S.-P. Hydrovoltaic energy harvesting from moisture flow using an ionic polymer–hydrogel–carbon composite. Energy Environ. Sci. 2022, 15, 2489–2498. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Z.; Wei, X.; He, X.; Wang, Z.; Zhao, Z.; He, H.; Yang, Y.; Chen, N. Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials. Materials 2024, 17, 4204. https://doi.org/10.3390/ma17174204

Jin Z, Wei X, He X, Wang Z, Zhao Z, He H, Yang Y, Chen N. Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials. Materials. 2024; 17(17):4204. https://doi.org/10.3390/ma17174204

Chicago/Turabian StyleJin, Zifeng, Xiaoyan Wei, Xiaojun He, Zhenglin Wang, Zhibo Zhao, Huan He, Ya’nan Yang, and Nan Chen. 2024. "Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials" Materials 17, no. 17: 4204. https://doi.org/10.3390/ma17174204

APA StyleJin, Z., Wei, X., He, X., Wang, Z., Zhao, Z., He, H., Yang, Y., & Chen, N. (2024). Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials. Materials, 17(17), 4204. https://doi.org/10.3390/ma17174204