Cutting-Edge Perovskite-Based Flexible Pressure Sensors Made Possible by Piezoelectric Innovation

Abstract

1. Introduction

2. Important Components for Flexible Pressure Sensors

2.1. Sensing Elements

2.2. Electrodes

2.3. Casing

2.4. Insulating and Encapsulation Material

2.5. Signal Conditioning Circuitry

2.6. Connectors and Wiring

2.7. Calibration Elements

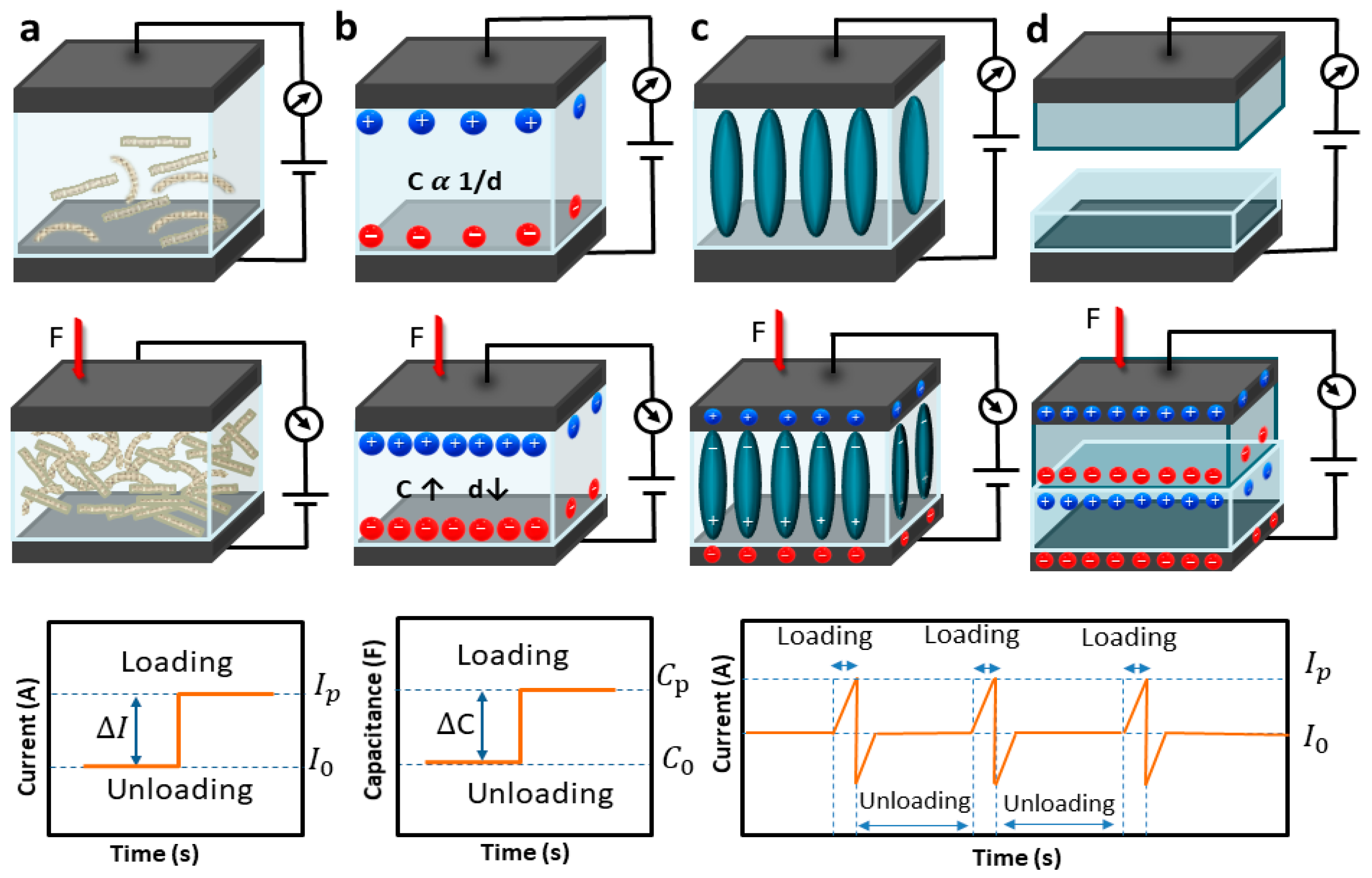

3. Sensing Mechanisms for Flexible Pressure Sensors

3.1. Piezoelectric Mechanism

3.2. Capacitive Mechanism

3.3. Piezoresistive Mechanism

3.4. Triboelectric Mechanism

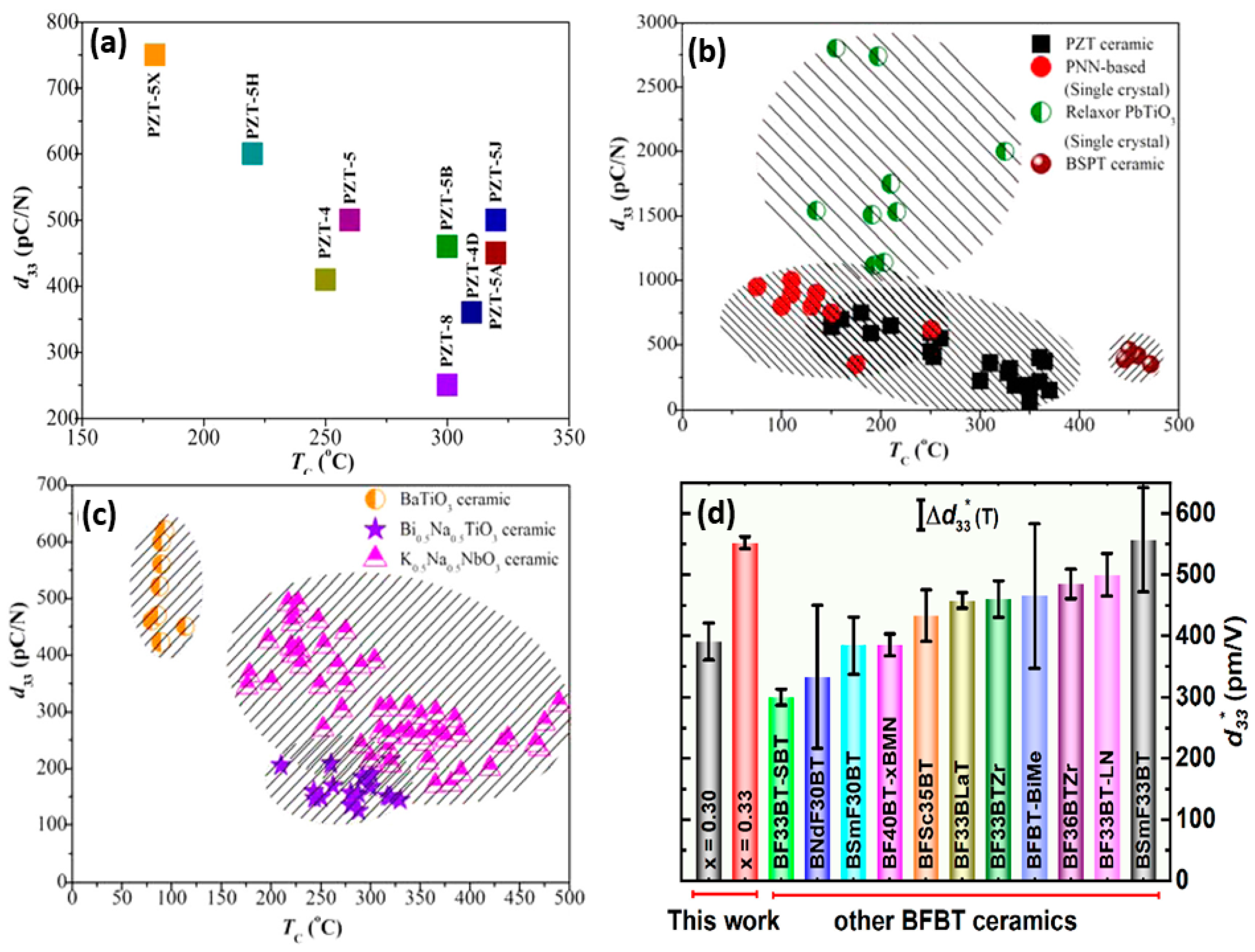

4. Piezoelectric Property of Ceramic Perovskite Material for Flexible Pressure Sensors

| Material | d33 (pCN−1) | Tc (°C) | Kp | References |

|---|---|---|---|---|

| (Bi0.5Na0.5) TiO3 | 72.9 | 325 | 0.168 | [79] |

| 0.01% Co-BNT | 105 | 25 | - | [80] |

| 0.03% Eu-BNT | 110 | 324 | - | [81] |

| 0.5%ZnO-BNT | 110 | - | 0.17 | [82] |

| 0.985BaTiO3–0.015Sr(Cu1/3Nb2/3)O3 | 333 | 97 | - | [83] |

| NN-BT 10% | 147 | 235 | - | [84] |

| BNT-BTx, x = 0.04 | 87 | 230 | 0.21 | [85] |

| BNT-BTx, x = 0.02 | 78 | 265 | 0.20 | [85] |

| BNT-BTx, x = 0.08 | 112 | 250 | 0.13 | [85] |

| BNT-BT0.06 | 103 | 262 | - | [86] |

| Sm-BNT-BT0.06 | 202 | 280 | 0.30 | [87] |

| Eu-BNT-BT0.06 | 149 | 310 | - | [88] |

| Er-BNT-BT0.06 | 9 | 303 | 0.13 | [89] |

| 0.5 Ta-BNT-BT0.06 | 170 | 260 | - | [90] |

| La-BNT-BT0.06 | 167 | 280 | 0.30 | [91] |

| BNT-BT0.06-xBFO, x = 0.03 | 80 | 290 | - | [92] |

| (BaCa)(Hf-Ti)O3 | 336 | 106 | - | [93] |

| BCZT | 225 | 77.2 | - | [94] |

| Ba0.93Ca0.07Ti0.975Sn0.025O3 | 216 | 122 | - | [95] |

| BCSnT | 478 | 63 | - | [96] |

| Ba0.88Ca0.12Ti0.94Sn0.06O3 | 220 | 68 | - | [97] |

| Ba0.95Ca0.05Ti0.95Sn0.05O3 | 431 | 72 | - | [98] |

| (NbxSb0.08)O3-xLiTaO3-xBaZrO3 | 365 | 170 | 0.45 | [99] |

| (KxNax)0.98Lix(Nb0.77Ta0.18Sb0.05)O3 | 413 | 225 | 0.50 | [100] |

| K0.5Na0.5NbO3 | 160 | 423 | - | [101] |

| ((KNaLi)1+x NbSbTa)O3 (x = 0.01) | 310 | - | 0.6 | [102] |

| 0.95K0.46NaxNb0.95Sb0.05O3-xBi0.5(Na0.82K0.18)0.5ZrO3 | 465 | 233 | 0.43 | [103] |

| K0.5Na0.5NbO3-Bi0.5Na0.5TiO3)-LiSbO3 | 250 | 339 | 0.29 | [104] |

| (KxNax)0.95Li0.05Nb1−xSbxO3-BaZrO3 | 425 | 197 | 0.50 | [105] |

| ((K0.48Nax)(Nb0.95Sbx)O3)-xBNKLZr | 380 | 290 | 0.46 | [106] |

4.1. Bismuth Ferrite (BiFeO3)

4.2. Sodium Titanate (SrTiO3)

4.3. Barium Titanate (BaTiO3)

4.4. Potassium Sodium Niobate (K0.5Na0.5NbO3)

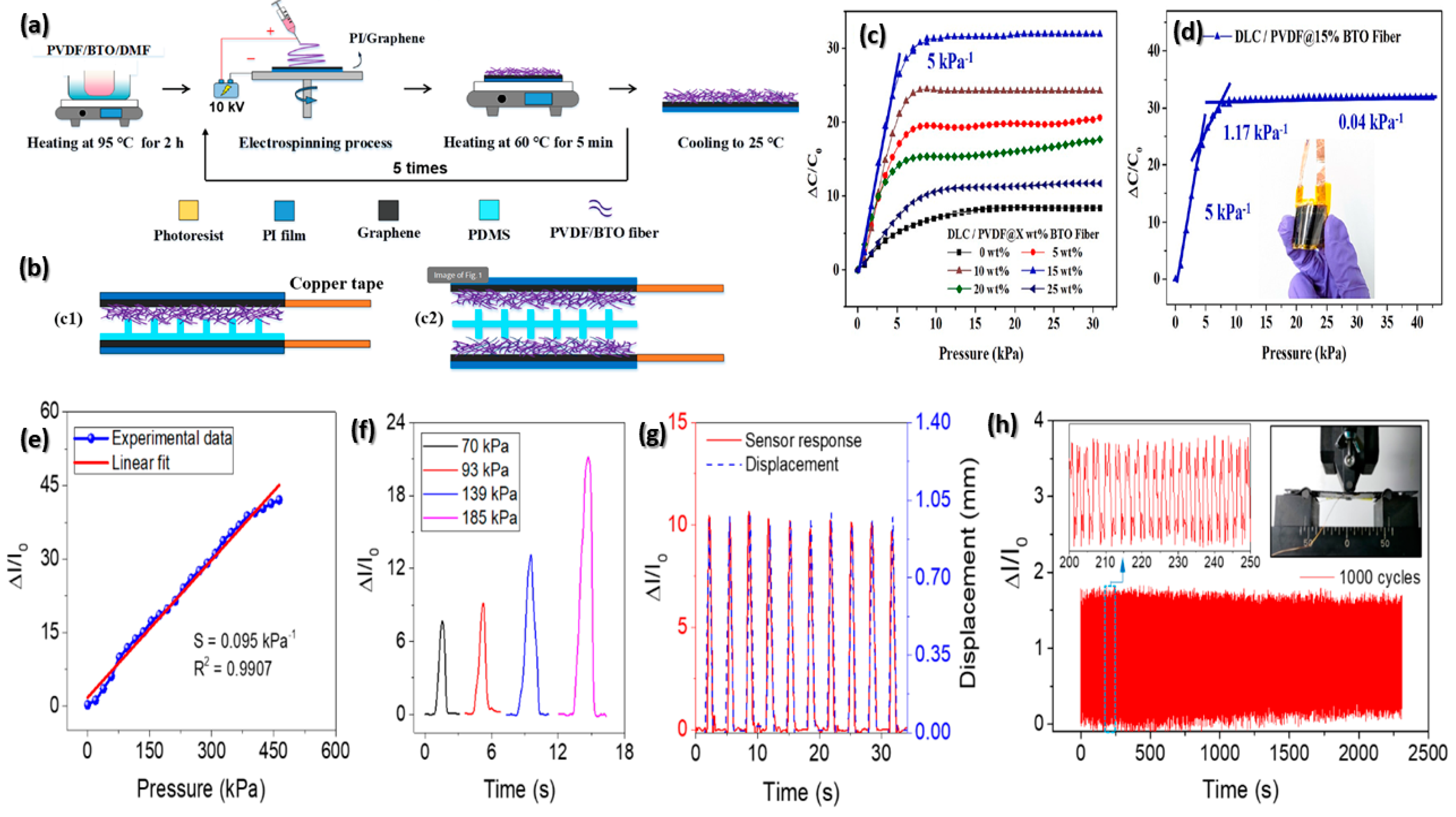

5. Performance of Perovskite Materials in Flexible Pressure Sensors

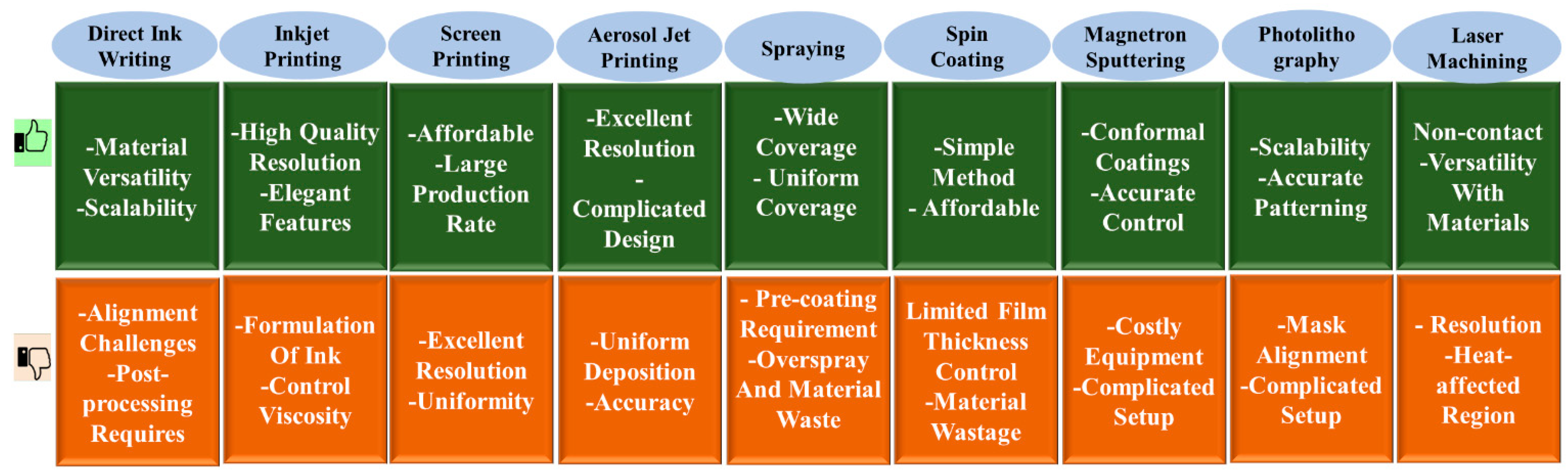

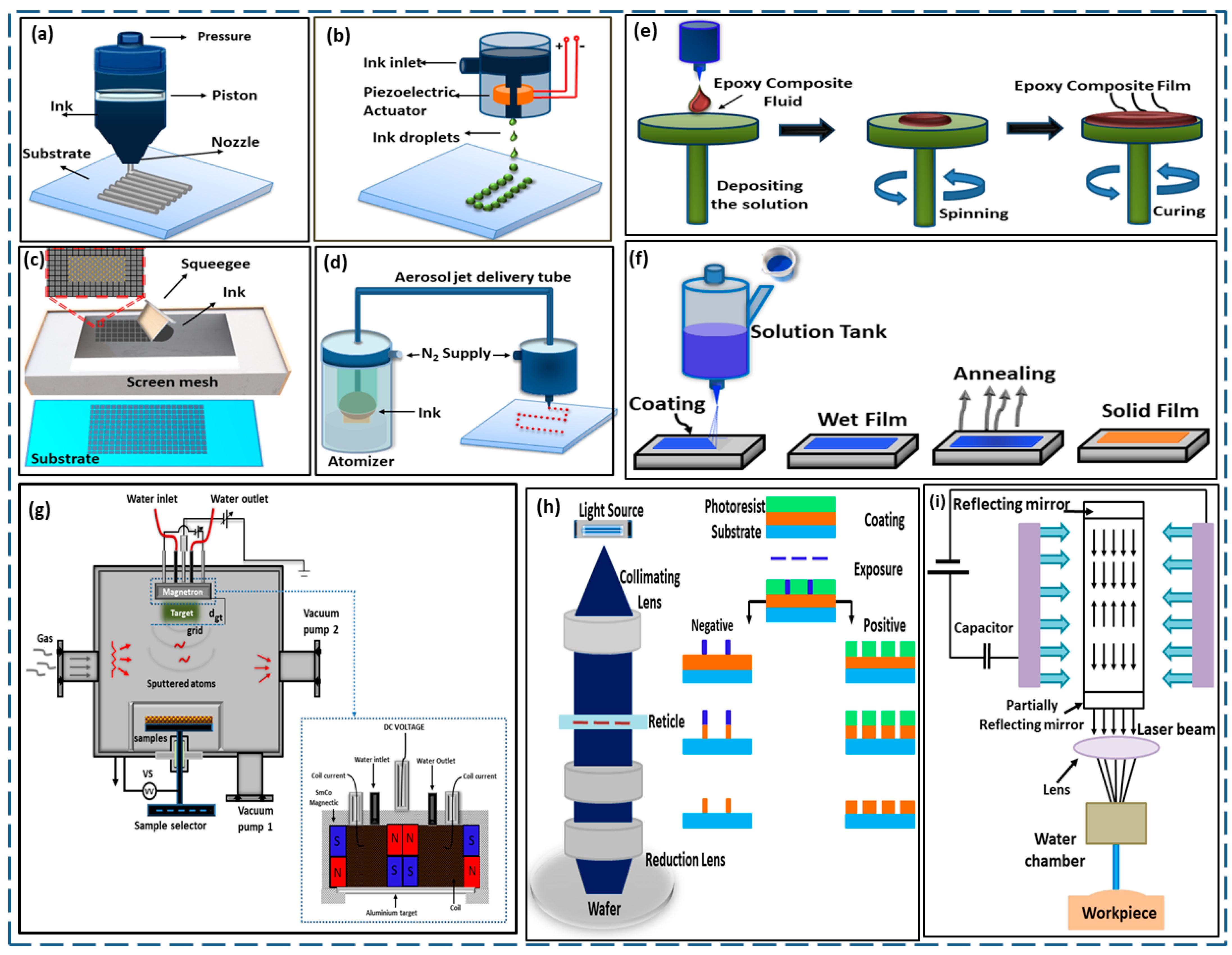

6. Fabrication Techniques for Flexible Pressure Sensors

7. Application of Perovskite-Based Flexible Pressure Sensors

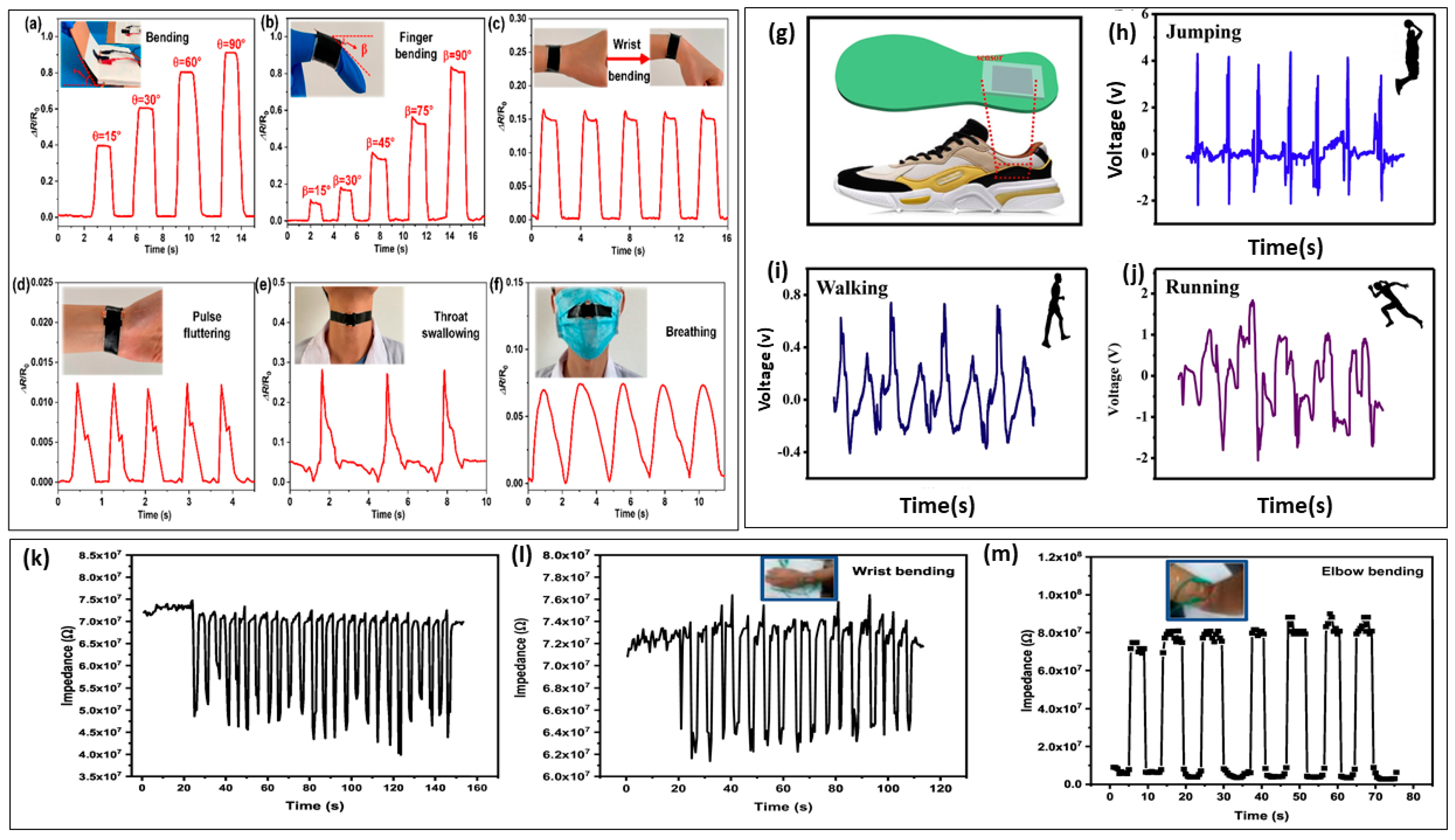

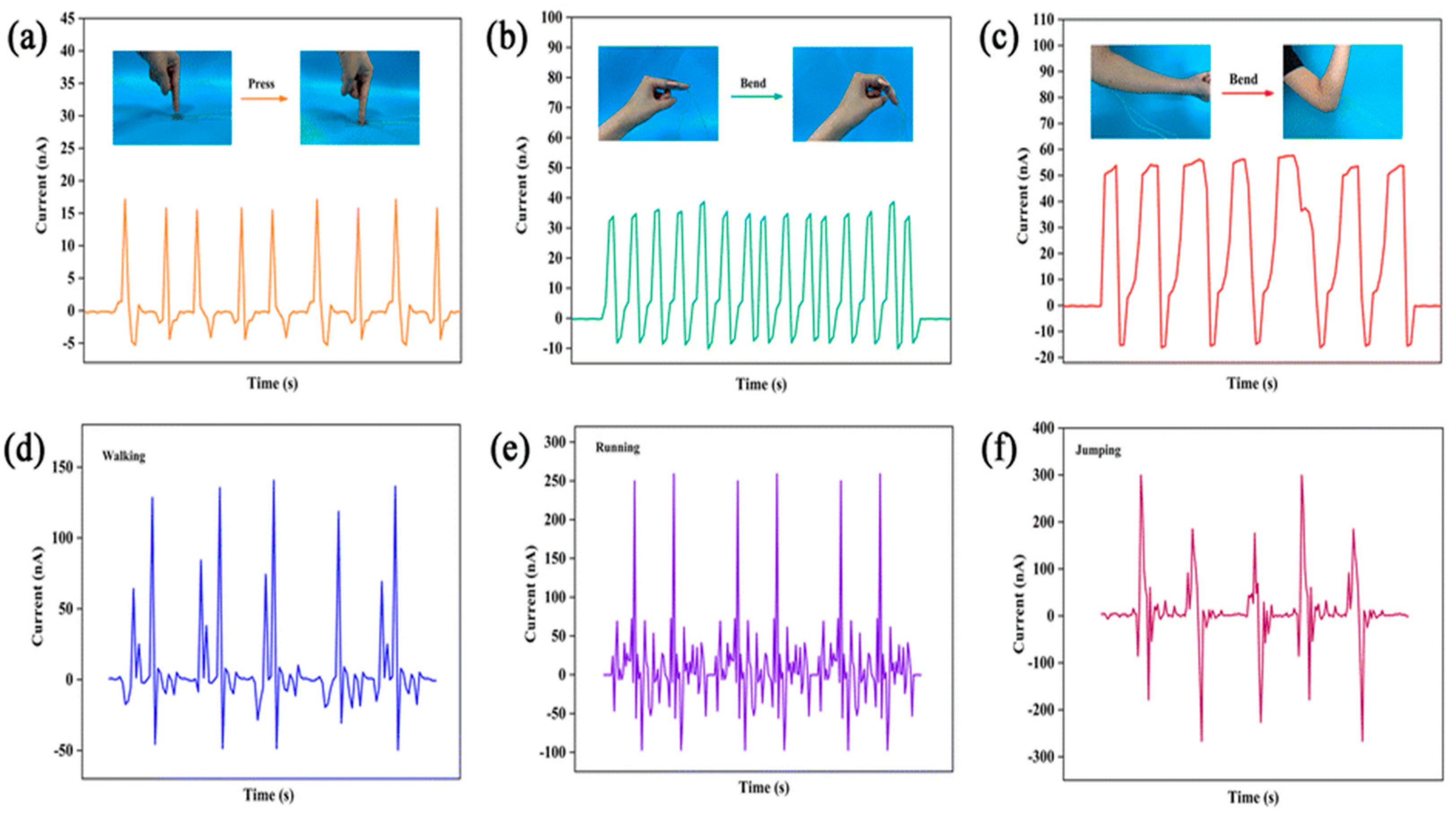

7.1. Human Motion Detection

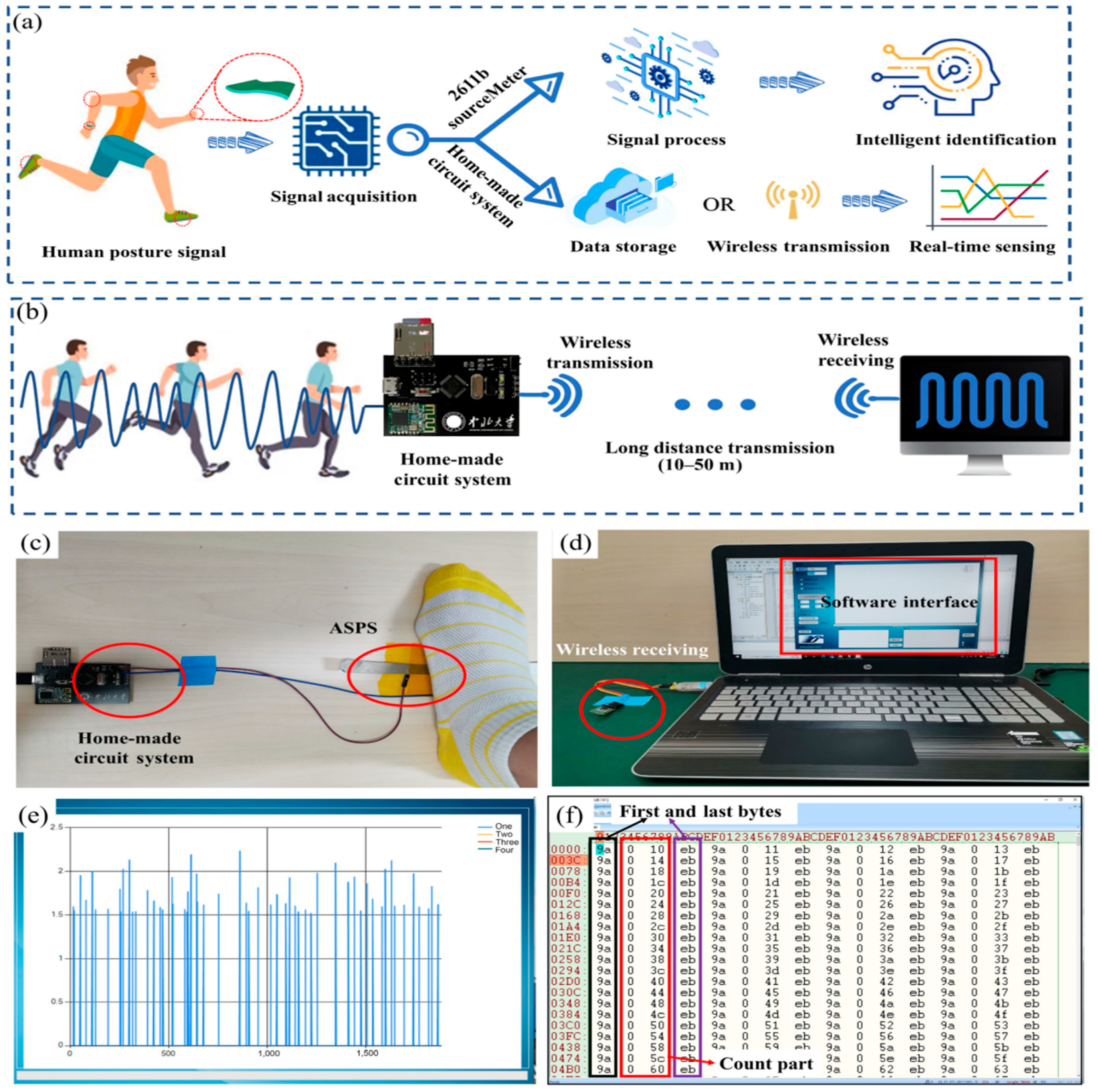

7.2. Intelligent Sensing and Recognition Applications

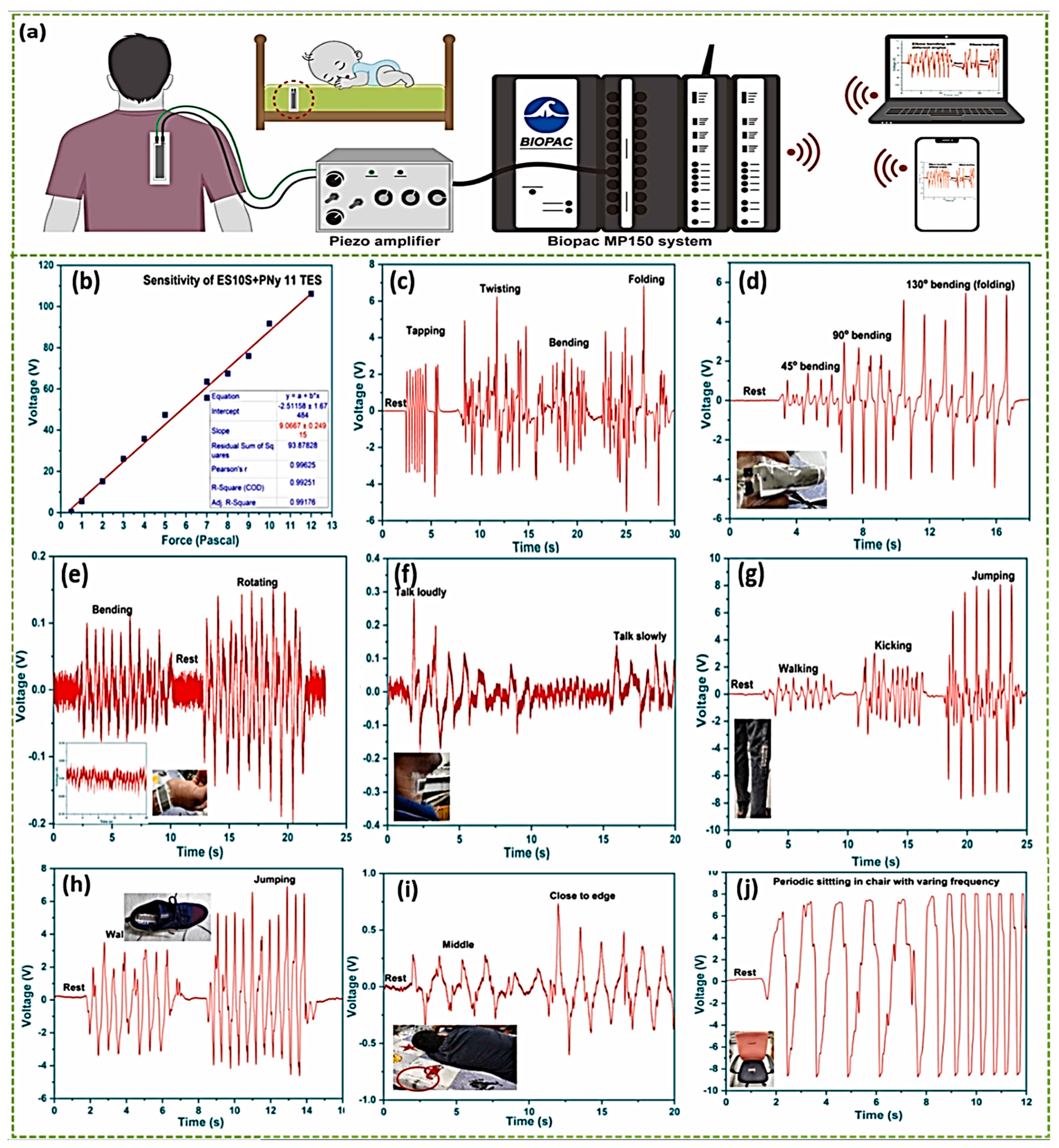

7.3. Wearable Applications

8. Challenges and Future Perspectives

9. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, S.; Kim, J.H.; Kim, J.; Choi, S.; Lee, J.; Park, I.; Hyeon, T.; Kim, D.-H. Reverse-micelle-induced porous pressure-sensitive rubber for wearable human-machine interfaces. Adv. Mater. 2014, 26, 4825–4830. [Google Scholar] [CrossRef]

- Zang, Y.; Zhang, F.; Di, C.-a.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Reeder, J.; Kaltenbrunner, M.; Ware, T.; Arreaga-Salas, D.; Avendano-Bolivar, A.; Yokota, T.; Inoue, Y.; Sekino, M.; Voit, W.; Sekitani, T. Mechanically adaptive organic transistors for implantable electronics. Adv. Mater. 2014, 26, 4967–4973. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.; Wang, J.; Ma, Z.; Yan, K.; Wang, Y.; Wang, H.; Li, S.; Li, Y.; Pan, L.; Shi, Y. Flexible pressure sensor with high sensitivity and low hysteresis based on a hierarchically microstructured electrode. IEEE Electron Device Lett. 2017, 39, 288–291. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.; Hong, J.; Lee, H.; Lee, Y.; Cho, S.; Kim, S.-W.; Kim, J.J.; Kim, S.Y.; Ko, H. Tailoring force sensitivity and selectivity by microstructure engineering of multidirectional electronic skins. NPG Asia Mater. 2018, 10, 163–176. [Google Scholar] [CrossRef]

- Li, Z.-J.; Hou, Z.-L.; Song, W.-L.; Liu, X.-D.; Wang, D.-W.; Tang, J.; Shao, X.-H. Mg-substitution for promoting magnetic and ferroelectric properties of BiFeO3 multiferroic nanoparticles. Mater. Lett. 2016, 175, 207–211. [Google Scholar] [CrossRef]

- Garain, S.; Jana, S.; Sinha, T.K.; Mandal, D. Design of in situ poled Ce3+-doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl. Mater. Interfaces 2016, 8, 4532–4540. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Chen, J.; Li, Y.; Shi, G. High-performance strain sensors with fish-scale-like graphene-sensing layers for full-range detection of human motions. ACS Nano 2016, 10, 7901–7906. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, J.-H.; Ko, H.J.; Lee, S.; Bae, G.Y.; Kim, D.; Lee, G.; Lee, S.G.; Cho, K. Mechanically Robust and Linearly Sensitive Soft Piezoresistive Pressure Sensor for a Wearable Human–Robot Interaction System. ACS Nano 2024, 18, 3151–3160. [Google Scholar] [CrossRef]

- Bai, N.; Wang, L.; Wang, Q.; Deng, J.; Wang, Y.; Lu, P.; Huang, J.; Li, G.; Zhang, Y.; Yang, J.; et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity. Nat. Commun. 2020, 11, 209. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, Q.; Zhou, T.; Wu, W.; Li, H.; Yin, Z.; Ma, J.; Jiao, T. Progress and challenges in flexible capacitive pressure sensors: Microstructure designs and applications. Chem. Eng. J. 2024, 485, 149926. [Google Scholar] [CrossRef]

- Choi, T.Y.; Hwang, B.-U.; Kim, B.-Y.; Trung, T.Q.; Nam, Y.H.; Kim, D.-N.; Eom, K.; Lee, N.-E. Stretchable, transparent, and stretch-unresponsive capacitive touch sensor array with selectively patterned silver nanowires/reduced graphene oxide electrodes. ACS Appl. Mater. Interfaces 2017, 9, 18022–18030. [Google Scholar] [CrossRef] [PubMed]

- Ho, D.H.; Sun, Q.; Kim, S.Y.; Han, J.T.; Kim, D.H.; Cho, J.H. Stretchable and multimodal all graphene electronic skin. Adv. Mater. 2016, 28, 2601–2608. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Wu, N.; Ma, L.; Lin, S.; Yuan, F.; Xu, Z.; Li, W.; Wang, B.; Zhou, J. Noncontact heartbeat and respiration monitoring based on a hollow microstructured self-powered pressure sensor. ACS Appl. Mater. Interfaces 2018, 10, 3660–3667. [Google Scholar] [CrossRef]

- Chen, W.; Yan, X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef]

- Qin, J.; Yin, L.J.; Hao, Y.N.; Zhong, S.L.; Zhang, D.L.; Bi, K.; Zhang, Y.X.; Zhao, Y.; Dang, Z.M. Flexible and stretchable capacitive sensors with different microstructures. Adv. Mater. 2021, 33, 2008267. [Google Scholar] [CrossRef]

- Zhou, K.; Zhang, C.; Xiong, Z.; Chen, H.Y.; Li, T.; Ding, G.; Yang, B.; Liao, Q.; Zhou, Y.; Han, S.T. Template-directed growth of hierarchical MOF hybrid arrays for tactile sensor. Adv. Funct. Mater. 2020, 30, 2001296. [Google Scholar] [CrossRef]

- Camilli, L.; Passacantando, M. Advances on sensors based on carbon nanotubes. Chemosensors 2018, 6, 62. [Google Scholar] [CrossRef]

- Chen, S.; Song, Y.; Xu, F. Flexible and highly sensitive resistive pressure sensor based on carbonized crepe paper with corrugated structure. ACS Appl. Mater. Interfaces 2018, 10, 34646–34654. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Shao, J.; Chen, S.; Chen, X.; Tian, H.; Li, X.; Wang, L.; Wang, D.; Lu, B. Flexible Capacitive Pressure Sensor Enhanced by Tilted Micropillar Arrays. ACS Appl. Mater. Interfaces 2019, 11, 17796–17803. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Gao, S.; Yue, W.; Zhang, C.; Li, Y. Anodized aluminum oxide-assisted low-cost flexible capacitive pressure sensors based on double-sided nanopillars by a facile fabrication method. ACS Appl. Mater. Interfaces 2019, 11, 48594–48603. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Recent development in lead-free perovskite piezoelectric bulk materials. Prog. Mater. Sci. 2018, 98, 552–624. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Z.; Li, X.; Lin, Y.; Luo, N.; Long, M.; Zhao, N.; Xu, J.-B. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. Acs Nano 2017, 11, 4507–4513. [Google Scholar] [CrossRef]

- Chu, Y.; Zhong, J.; Liu, H.; Ma, Y.; Liu, N.; Song, Y.; Liang, J.; Shao, Z.; Sun, Y.; Dong, Y. Human pulse diagnosis for medical assessments using a wearable piezoelectret sensing system. Adv. Funct. Mater. 2018, 28, 1803413. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D printing of soft electronics. Adv. Mater. 2017, 29, 1703817. [Google Scholar] [CrossRef]

- Hwang, B.-U.; Zabeeb, A.; Trung, T.Q.; Wen, L.; Lee, J.D.; Choi, Y.-I.; Lee, H.-B.; Kim, J.H.; Han, J.G.; Lee, N.-E. A transparent stretchable sensor for distinguishable detection of touch and pressure by capacitive and piezoresistive signal transduction. NPG Asia Mater. 2019, 11, 23. [Google Scholar] [CrossRef]

- Park, D.Y.; Joe, D.J.; Kim, D.H.; Park, H.; Han, J.H.; Jeong, C.K.; Park, H.; Park, J.G.; Joung, B.; Lee, K.J. Self-Powered Real-Time Arterial Pulse Monitoring Using Ultrathin Epidermal Piezoelectric Sensors. Adv. Mater. 2017, 29, 1702308. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Y.; Wang, Y.; Hu, X.; Yan, W.; Ke, X.; Zhong, L.; He, Y.; Ren, X. Designing high dielectric permittivity material in barium titanate. J. Phys. Chem. C 2017, 121, 13106–13113. [Google Scholar] [CrossRef]

- Chhetry, A.; Yoon, H.; Park, J.Y. A flexible and highly sensitive capacitive pressure sensor based on conductive fibers with a microporous dielectric for wearable electronics. J. Mater. Chem. C 2017, 5, 10068–10076. [Google Scholar] [CrossRef]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef]

- Wang, D.; Wang, M.; Liu, F.; Cui, Y.; Zhao, Q.; Sun, H.; Jin, H.; Cao, M. Sol–gel synthesis of Nd-doped BiFeO3 multiferroic and its characterization. Ceram. Int. 2015, 41, 8768–8772. [Google Scholar] [CrossRef]

- Parameswaran, C.; Gupta, D. Large area flexible pressure/strain sensors and arrays using nanomaterials and printing techniques. Nano Converg. 2019, 6, 28. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Xu, W.; Huang, F.; Chen, D.; Wei, Q. Polyester fabric coated with Ag/ZnO composite film by magnetron sputtering. Appl. Surf. Sci. 2016, 390, 863–869. [Google Scholar] [CrossRef]

- Wang, Z.; Si, Y.; Zhao, C.; Yu, D.; Wang, W.; Sun, G. Flexible and washable poly (ionic liquid) nanofibrous membrane with moisture proof pressure sensing for real-life wearable electronics. ACS Appl. Mater. Interfaces 2019, 11, 27200–27209. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, Y.; Cheng, J.; Chen, S.; Hu, R.; Yan, X.; Liao, X.; Xu, C.; Yu, J.; Li, L. Supersensitive all-fabric pressure sensors using printed textile electrode arrays for human motion monitoring and human–machine interaction. J. Mater. Chem. C 2018, 6, 13120–13127. [Google Scholar] [CrossRef]

- Lian, Y.; Yu, H.; Wang, M.; Yang, X.; Zhang, H. Ultrasensitive wearable pressure sensors based on silver nanowire-coated fabrics. Nanoscale Res. Lett. 2020, 15, 70. [Google Scholar] [CrossRef]

- Shi, Z.; Meng, L.; Shi, X.; Li, H.; Zhang, J.; Sun, Q.; Liu, X.; Chen, J.; Liu, S. Morphological engineering of sensing materials for flexible pressure sensors and artificial intelligence applications. Nano-Micro Lett. 2022, 14, 141. [Google Scholar] [CrossRef]

- Farooq, M.; Iqbal, T.; Vazquez, P.; Farid, N.; Thampi, S.; Wijns, W.; Shahzad, A. Thin-film flexible wireless pressure sensor for continuous pressure monitoring in medical applications. Sensors 2020, 20, 6653. [Google Scholar] [CrossRef] [PubMed]

- Poeggel, S.; Tosi, D.; Duraibabu, D.; Leen, G.; McGrath, D.; Lewis, E. Optical fibre pressure sensors in medical applications. Sensors 2015, 15, 17115–17148. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Hu, X.; Li, K.; Sun, J.; Liu, Z.; An, B.; Zhou, X.; Liu, Z. Self-assembly of dendritic-lamellar MXene/Carbon nanotube conductive films for wearable tactile sensors and artificial skin. Carbon 2020, 164, 111–120. [Google Scholar] [CrossRef]

- Yao, S.; Swetha, P.; Zhu, Y. Nanomaterial-Enabled Wearable Sensors for Healthcare. Adv. Healthc. Mater. 2018, 7, 1700889. [Google Scholar] [CrossRef]

- Ding, Y.; Xu, T.; Onyilagha, O.; Fong, H.; Zhu, Z. Recent Advances in Flexible and Wearable Pressure Sensors Based on Piezoresistive 3D Monolithic Conductive Sponges. ACS Appl. Mater. Interfaces 2019, 11, 6685–6704. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Fan, X.; Chen, S.-C.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Chen, P.-Y.; Ren, H. A Review of Printable Flexible and Stretchable Tactile Sensors. Research 2019, 2019, 3018568. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, D.J.; Park, J.S.; Kim, S.W.; Song, T.K.; Kim, M.-H.; Kim, W.-J.; Jeong, I.-K. High-Performance Lead-Free Piezoceramics with High Curie Temperatures. Adv. Mater. 2015, 27, 6976–6982. [Google Scholar] [CrossRef]

- Wang, S.; Liu, H.; Wang, Y.; Qin, H.; Zhao, J.; Lu, Z.; Mao, Z.; Wang, D. Microstructure, dielectric, and piezoelectric properties of BiFeO3–SrTiO3 lead-free ceramics. J. Am. Ceram. Soc. 2024, 107, 205–213. [Google Scholar] [CrossRef]

- Dong, X.; Li, X.; Chen, X.; Tan, Z.; Wu, J.; Zhu, J.; Zhou, H. (1-x)[0.90NN-0.10Bi(Mg2/3Nb1/3)O3]-x (Bi0.5Na0.5)0.7Sr0.3TiO3 ceramics with core–shell structures: A pathway for simultaneously achieving high polarization and breakdown strength. Nano Energy 2022, 101, 107577. [Google Scholar] [CrossRef]

- Dong, K.; Wu, Z.; Deng, J.; Wang, A.C.; Zou, H.; Chen, C.; Hu, D.; Gu, B.; Sun, B.; Wang, Z.L. A Stretchable Yarn Embedded Triboelectric Nanogenerator as Electronic Skin for Biomechanical Energy Harvesting and Multifunctional Pressure Sensing. Adv. Mater. 2018, 30, 1804944. [Google Scholar] [CrossRef] [PubMed]

- Steinem, C.; Janshoff, A. Piezoelectric Sensors; Springer Science & Business Media: Berlin, Germany, 2007; Volume 5. [Google Scholar]

- Flanagan, J.R.; Wing, A.M. Modulation of grip force with load force during point-to-point arm movements. Exp. Brain Res. 1993, 95, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Lang, S.B.; Muensit, S. Review of some lesser-known applications of piezoelectric and pyroelectric polymers. Appl. Phys. A 2006, 85, 125–134. [Google Scholar] [CrossRef]

- Song, A.; Han, Y.; Hu, H.; Li, J. A novel texture sensor for fabric texture measurement and classification. IEEE Trans. Instrum. Meas. 2013, 63, 1739–1747. [Google Scholar] [CrossRef]

- Chamankar, N.; Khajavi, R.; Yousefi, A.A.; Rashidi, A.; Golestanifard, F. A flexible piezoelectric pressure sensor based on PVDF nanocomposite fibers doped with PZT particles for energy harvesting applications. Ceram. Int. 2020, 46, 19669–19681. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.-S.; Huang, Y.; Damadoran, A.R.; Xia, J.; Martin, L.W.; et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 2014, 5, 4496. [Google Scholar] [CrossRef]

- Park, J.; Ghosh, R.; Song, M.S.; Hwang, Y.; Tchoe, Y.; Saroj, R.K.; Ali, A.; Guha, P.; Kim, B.; Kim, S.-W.; et al. Individually addressable and flexible pressure sensor matrixes with ZnO nanotube arrays on graphene. NPG Asia Mater. 2022, 14, 40. [Google Scholar] [CrossRef]

- Mokhtari, F. Highly stretchable self-powered wearable electrical energy generator and sensors. In Self-Powered Smart Fabrics for Wearable Technologies; Springer: Cham, Switzerland, 2022; pp. 125–152. [Google Scholar]

- Ahmed, T.; Khan, S.A.; Bae, J.; Habib, M.; Akram, F.; Choi, S.Y.; Hussain, A.; Song, T.K.; Sung, Y.S.; Kim, M.-H. Role of Bi chemical pressure on electrical properties of BiFeO3–BaTiO3–based ceramics. Solid State Sci. 2021, 114, 106562. [Google Scholar] [CrossRef]

- Zhu, L.-F.; Zhang, B.-P.; Duan, J.-Q.; Xun, B.-W.; Wang, N.; Tang, Y.-C.; Zhao, G.-L. Enhanced piezoelectric and ferroelectric properties of BiFeO3-BaTiO3 lead-free ceramics by optimizing the sintering temperature and dwell time. J. Eur. Ceram. Soc. 2018, 38, 3463–3471. [Google Scholar] [CrossRef]

- Shi, K.; Huang, X.; Sun, B.; Wu, Z.; He, J.; Jiang, P. Cellulose/BaTiO3 aerogel paper based flexible piezoelectric nanogenerators and the electric coupling with triboelectricity. Nano Energy 2019, 57, 450–458. [Google Scholar] [CrossRef]

- Shahzad, A.; Chen, Z.; Haidary, A.A.; Mehmood, A.; Khan, Z.M. Piezoelectric pressure sensors based on GO-modified P (VDF-TrFE) fibers for vacuum applications. J. Mater. Sci. Mater. Electron. 2020, 31, 18627–18639. [Google Scholar] [CrossRef]

- Shirley, J.A.; Florence, S.E.; Sreeja, B.; Padmalaya, G.; Radha, S. Zinc oxide nanostructure-based textile pressure sensor for wearable applications. J. Mater. Sci. Mater. Electron. 2020, 31, 16519–16530. [Google Scholar] [CrossRef]

- Takamatsu, S.; Kobayashi, T.; Shibayama, N.; Miyake, K.; Itoh, T. Meter-scale surface capacitive type of touch sensors fabricated by weaving conductive-polymer-coated fibers. In Proceedings of the 2011 Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS (DTIP), Aix-en-Provence, France, 11–13 May 2011; pp. 142–147. [Google Scholar]

- Gurarslan, A.; Özdemir, B.; Bayat, İ.H.; Yelten, M.B.; Karabulut Kurt, G. Silver nanowire coated knitted wool fabrics for wearable electronic applications. J. Eng. Fibers Fabr. 2019, 14, 1558925019856222. [Google Scholar] [CrossRef]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef] [PubMed]

- Qi, K.; Wang, H.; You, X.; Tao, X.; Li, M.; Zhou, Y.; Zhang, Y.; He, J.; Shao, W.; Cui, S. Core-sheath nanofiber yarn for textile pressure sensor with high pressure sensitivity and spatial tactile acuity. J. Colloid Interface Sci. 2020, 561, 93–103. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, X.-S.; Wang, Y.; Gong, W.; Zhang, Q.; Wang, H.; Brugger, J. All-fiber hybrid piezoelectric-enhanced triboelectric nanogenerator for wearable gesture monitoring. Nano Energy 2018, 48, 152–160. [Google Scholar] [CrossRef]

- Cira, N.J.; Benusiglio, A.; Prakash, M. Vapour-mediated sensing and motility in two-component droplets. Nature 2015, 519, 446–450. [Google Scholar] [CrossRef]

- Wang, B.; Thukral, A.; Xie, Z.; Liu, L.; Zhang, X.; Huang, W.; Yu, X.; Yu, C.; Marks, T.J.; Facchetti, A. Flexible and stretchable metal oxide nanofiber networks for multimodal and monolithically integrated wearable electronics. Nat. Commun. 2020, 11, 2405. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, C.; Russell, T.P. Multi-length-scale morphologies in PCPDTBT/PCBM bulk-heterojunction solar cells. Adv. Energy Mater. 2012, 2, 683–690. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Kang, H.B.; Chang, J.; Koh, K.; Lin, L.; Cho, Y.S. High Quality Mn-Doped (Na,K)NbO3 Nanofibers for Flexible Piezoelectric Nanogenerators. ACS Appl. Mater. Interfaces 2014, 6, 10576–10582. [Google Scholar] [CrossRef]

- Ko, Y.J.; Kim, D.Y.; Won, S.S.; Ahn, C.W.; Kim, I.W.; Kingon, A.I.; Kim, S.-H.; Ko, J.-H.; Jung, J.H. Flexible Pb(Zr0.52Ti0.48)O3 Films for a Hybrid Piezoelectric-Pyroelectric Nanogenerator under Harsh Environments. ACS Appl. Mater. Interfaces 2016, 8, 6504–6511. [Google Scholar] [CrossRef]

- Jian, G.; Jiao, Y.; Meng, Q.; Guo, Y.; Wang, F.; Zhang, J.; Wang, C.; Moon, K.-S.; Wong, C.-P. Excellent high-temperature piezoelectric energy harvesting properties in flexible polyimide/3D PbTiO3 flower composites. Nano Energy 2021, 82, 105778. [Google Scholar] [CrossRef]

- Hosseini, E.S.; Manjakkal, L.; Shakthivel, D.; Dahiya, R. Glycine–Chitosan-Based Flexible Biodegradable Piezoelectric Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 9008–9016. [Google Scholar] [CrossRef]

- Gagliardi, M. Lead-Free Piezoelectric Ceramics: Technologies and Global Opportunities; NAN063A; BCC Publishing: Boston, MA, USA, 2019. [Google Scholar]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Thermal depoling process and piezoelectric properties of bismuth sodium titanate ceramics. J. Appl. Phys. 2009, 105, 084112. [Google Scholar] [CrossRef]

- Buntham, S.; Boonsong, P.; Jaiban, P.; Keawprak, N.; Watcharapasorn, A. Effects of cobalt dopant on microstructure and electrical properties of Bi0.5Na0.5TiO3 ceramics. Chiang Mai J. Sci. 2018, 45, 2481–2490. [Google Scholar]

- Lun, M.; Wang, W.; Xing, Z.; Wan, Z.; Wu, W.; Song, H.; Wang, Y.; Li, W.; Chu, B.; He, Q. Luminescence and electrical properties of Eu-modified Bi0.5Na0.5TiO3 multifunctional ceramics. J. Am. Ceram. Soc. 2019, 102, 5243–5252. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Lee, T.-K.; Jan, J.-H. Piezoelectric properties and microstructures of ZnO-doped Bi0.5Na0.5TiO3 ceramics. J. Eur. Ceram. Soc. 2011, 31, 3145–3152. [Google Scholar] [CrossRef]

- Maurya, D.; Kumar, A.; Petkov, V.; Mahaney, J.E.; Katiyar, R.S.; Priya, S. Local structure and piezoelectric instability in lead-free (1−x) BaTiO3-x A (Cu1/3Nb2/3)O3 (A=Sr, Ca, Ba) solid solutions. RSC Adv. 2014, 4, 1283–1292. [Google Scholar] [CrossRef]

- Zeng, J.; Kwok, K.W.; Chan, H. Ferroelectric and piezoelectric properties of Na1−xBaxNb1−xTixO3 ceramics. J. Am. Ceram. Soc. 2006, 89, 2828–2832. [Google Scholar] [CrossRef]

- Chu, B.-J.; Chen, D.-R.; Li, G.-R.; Yin, Q.-R. Electrical properties of Na1/2Bi1/2TiO3–BaTiO3 ceramics. J. Eur. Ceram. Soc. 2002, 22, 2115–2121. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Fan, H.; Long, C.; Liu, X. Ferroelectric, electromechanical, and dielectric properties of (Na0.5 Bi0.5)0.94Ba0.06TiO3 co-doped MnO2 and La2O3 lead-free ceramics. J. Mater. Sci. 2014, 49, 211–217. [Google Scholar] [CrossRef]

- Fu, P.; Xu, Z.; Chu, R.; Li, W.; Zang, G.; Hao, J. Piezoelectric, ferroelectric and dielectric properties of Sm2O3-doped (Bi0.5Na0.5)0.94Ba0.06TiO3 lead-free ceramics. Mater. Chem. Phys. 2010, 124, 1065–1070. [Google Scholar] [CrossRef]

- Ma, X.; Yin, J.; Zhou, Q.; Xue, L.; Yan, Y. Effect of Eu doping on structure and electrical properties of lead-free (Bi0.5Na0.5)0.94Ba0.06TiO3 ceramics. Ceram. Int. 2014, 40, 7007–7013. [Google Scholar] [CrossRef]

- Hu, B.; Pan, Z.; Dai, M.; Guo, F.F.; Ning, H.; Gu, Z.B.; Chen, J.; Lu, M.H.; Zhang, S.T.; Yang, B. Photoluminescence and Temperature Dependent Electrical Properties of Er-Doped 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 Ceramics. J. Am. Ceram. Soc. 2014, 97, 3877–3882. [Google Scholar] [CrossRef]

- Han, W.-H.; Koh, J.-H. Shrinkage mechanism and enhanced piezoelectric properties of Ta doped 0.94Bi0.5Na0.5TiO3–0.06BaTiO3 lead free ceramics. Ceram. Int. 2018, 44, 5352–5358. [Google Scholar] [CrossRef]

- Balakt, A.M.; Shaw, C.P.; Zhang, Q. Giant pyroelectric properties in La and Ta co-doped lead-free 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 ceramics. J. Alloys Compd. 2017, 709, 82–91. [Google Scholar] [CrossRef]

- Chen, X.; Gong, X.; Li, T.; He, Y.; Liu, P. Microstructure, dielectric and ferroelectric properties of (1−x)(0.94Bi0.5Na0.5TiO3–0.06BaTiO3)–xBiFeO3 lead-free ceramics synthesized via a high energy ball milling method. J. Alloys Compd. 2010, 507, 535–541. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, Z.; Yang, B.; Zhang, S.; Zhang, M.; Guo, F.; Cao, W. Phase transition behavior and high piezoelectric properties in lead-free BaTiO3–CaTiO3–BaHfO3 ceramics. J. Mater. Sci. 2014, 49, 62–69. [Google Scholar] [CrossRef]

- Chaiyo, N.; Cann, D.P.; Vittayakorn, N. Phase transitions, ferroelectric, and piezoelectric properties of lead-free piezoelectric x BaZrO3–(0.25−x)CaTiO3–0.75BaTiO3 ceramics. J. Mater. Sci. 2015, 50, 6171–6179. [Google Scholar] [CrossRef]

- Kadhane, P.S.; Baraskar, B.G.; Darvade, T.C.; James, A.R.; Kambale, R.C. Ferroelectric and piezoelectric properties of Ca2+ and Sn4+ substituted BaTiO3 lead-free electroceramics on the emphasis of phase coexistence. Solid State Commun. 2020, 306, 113797. [Google Scholar] [CrossRef]

- Xue, D.; Zhou, Y.; Bao, H.; Gao, J.; Zhou, C.; Ren, X. Large piezoelectric effect in Pb-free Ba(Ti,Sn)O3-x(Ba,ca)TiO3 ceramics. Appl. Phys. Lett. 2011, 99, 122901. [Google Scholar] [CrossRef]

- Laishram, R.; Rajput, S.; Singh, K.C. Particle-size-induced high piezoelectricity in (Ba0.88Ca0.12)(Ti0.94Sn0.06)O3 piezoceramics prepared from nanopowders. J. Alloys Compd. 2020, 812, 152128. [Google Scholar]

- Kar, B.; Kumar, P.; Panigrahi, S.; Sahu, D.P.; Mahesh, M.; James, A. Development of mixed phase with improved dielectric and piezoelectric properties in Ca and Sn modified BaTiO3 ceramics. J. Alloys Compd. 2024, 983, 173786. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J. Rhombohedral–tetragonal phase coexistence and piezoelectric properties of (NaK)(NbSb)O3–LiTaO3–BaZrO3 lead-free ceramics. J. Am. Ceram. Soc. 2011, 94, 1467–1470. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, J.; Qing, Y.; Tan, Y.; Zhang, Z.; Hao, X. Remarkably Strong Piezoelectricity of Lead-Free (K0.5Na0.55)0.98Li0.02(Nb0.77Ta0.18Sb0.05)O3 Ceramic. J. Am. Ceram. Soc. 2011, 94, 2968–2973. [Google Scholar] [CrossRef]

- Lin, D.; Li, Z.; Zhang, S.; Xu, Z.; Yao, X. Influence of MnO2 doping on the dielectric and piezoelectric properties and the domain structure in (K0.5Na0.5)NbO3 single crystals. J. Am. Ceram. Soc. 2010, 93, 941–944. [Google Scholar] [CrossRef]

- Lin, D.; Kwok, K.W.; Chan, H.L.w. Effect of Alkali Elements Content on the Structure and Electrical Properties of (K0.48Na0.48Li0.04)(Nb0.90Ta0.04Sb0.06)O3 Lead-Free Piezoelectric Ceramics. J. Am. Ceram. Soc. 2009, 92, 2765–2767. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Cheng, X.; Zheng, T.; Zhang, B.; Xiao, D.; Zhu, J.; Lou, X. New potassium-sodium niobate lead-free piezoceramic: Giant-d33 vs. sintering temperature. J. Appl. Phys. 2014, 115, 114104. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y.; Du, H.; Li, H.; Zhang, G. Crystal structure and properties of K0.5Na0.5NbO3–Bi0.5Na0.5TiO3–LiSbO3 lead-free piezoelectric ceramics. J. Alloys Compd. 2010, 506, 407–411. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, J.; Cheng, X.; Wang, X.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Lead-free piezoelectrics based on potassium–sodium niobate with giant d33. ACS Appl. Mater. Interfaces 2013, 5, 7718–7725. [Google Scholar] [CrossRef]

- Cheng, X.; Wu, J.; Wang, X.; Zhang, B.; Zhu, J.; Xiao, D.; Wang, X.; Lou, X. Giant d33 in (K, Na)(Nb, Sb)O3-(Bi, Na, K, Li)ZrO3 based lead-free piezoelectrics with high Tc. Appl. Phys. Lett. 2013, 103, 052906. [Google Scholar] [CrossRef]

- Hussain, A.; Jabeen, N.; ul Hassan, N.; Rasheed, S.; Idrees, A.; Eldin, S.M.; Ouladsmane, M.; Khan, S.; Akkinepally, B.; Javed, M.S. Structural, piezoelectric and ferroelectric analysis of 0.96Bi0.5Na0.5TiO3-0.06BaTiO3: Xwt% MnO2 ceramics for high-tech applications. Ceram. Int. 2023, 49, 27848–27854. [Google Scholar] [CrossRef]

- Hussain, A.; Zheng, P.; Xu, X.; Chen, X.; Li, T.; Wang, Y.; Yuan, G.; Yin, J.; Liu, Z. Structural and electrical properties of multiferroic (1−x) BiFeO3−xBi0.5K0.5TiO3 ceramics. J. Alloys Compd. 2016, 678, 228–233. [Google Scholar] [CrossRef]

- Qaiser, M.A.; Hussain, A.; Zhang, J.; Wang, Y.; Zhang, S.; Chen, L.; Yuan, G. 0–3 type Bi3TaTiO9: 40wt% BiFeO3 composite with improved high-temperature piezoelectric properties. J. Alloys Compd. 2018, 740, 1–6. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, J.; Ahmad, H.; Yuan, G.; Yin, J.; Liu, Z. Improved ferroelectricity of (1−x)Na0.5Bi0.5TiO3–xBaTiO3 ceramics rapidly sintered at low temperature. Ceram. Int. 2014, 40, 11819–11824. [Google Scholar] [CrossRef]

- Habib, M.; Tang, L.; Xue, G.; Zhou, X.; Zhang, D. Improvement in piezoelectric performance of the lead-free BiFeO3-BaTiO3 ceramics by synergistic approach. J. Mater. Sci. Technol. 2023, 160, 55–65. [Google Scholar] [CrossRef]

- Habib, M.; Akram, F.; Rahman, A.; Ahmad, P.; Iqbal, M.J.; Liu, Q.; Zeb, A.; Zhang, D. Defects dipoles control strategy for temperature-insensitive piezoelectricity in the lead-free BiFeO3-BaTiO3 ceramics. Mater. Chem. Phys. 2022, 287, 126326. [Google Scholar] [CrossRef]

- Nguyen, H.T.K.; Duong, T.A.; Erkinov, F.; Kang, H.; Kim, B.W.; Ahn, C.W.; Han, H.-S.; Lee, J.-S. Effect of SrTiO3 modification on dielectric, phase transition and piezoelectric properties of lead-free Bi0.5Na0.5TiO3–CaTiO3–SrTiO3 piezoelectric ceramics. J. Korean Ceram. Soc. 2020, 57, 570–577. [Google Scholar] [CrossRef]

- Duong, T.A.; Ahn, C.W.; Kim, B.W.; Bafandeh, M.R.; Han, H.-S.; Lee, J.-S. Effects of SrTiO3 modification on the piezoelectric and strain properties of lead-free K0.5Na0.5NbO3-based ceramics. J. Electron. Mater. 2022, 51, 1490–1497. [Google Scholar] [CrossRef]

- Muhammad, M.; Habib, M.; Khan, S.A.; Myong-Ho, K.; Lee, S.; Tae-Kwon, S.; Baluch, A.H.; Ayse, T.; Hussain, A. Energy storage and piezoelectric properties of lead-free SrTiO3-modified 0.965Bi0.5Na0.5TiO3–0.035BaTiO3 ceramics. J. Mater. Science. Mater. Electron. 2021, 32, 10712–10725. [Google Scholar]

- Li, W.; Li, P.; Zeng, H.; Hao, J.; Zhai, J. Enhanced dielectric and piezoelectric properties in lead-free Bi0.5Na0.5TiO3–BaTiO3–SrTiO3 thin films with seed layer. Ceram. Int. 2015, 41, S356–S360. [Google Scholar] [CrossRef]

- Gaur, A.; Sharma, M.; Chauhan, V.S.; Vaish, R. Solar/visible light photocatalytic dye degradation using BaTi1−xFexO3 ceramics. J. Am. Ceram. Soc. 2022, 105, 5140–5150. [Google Scholar] [CrossRef]

- Zhao, C.; He, T.; Lin, C.; Wu, X.; Lin, T.; Gao, M.; Tao, H.; Wu, W.; Wu, B. Comparison of electric field-dependent property in BaTiO3-based piezoceramics between single and coexisting phases. J. Am. Ceram. Soc. 2023, 106, 5381–5391. [Google Scholar] [CrossRef]

- Abebe, M.; Brajesh, K.; Mishra, A.; Senyshyn, A.; Ranjan, R. Structural perspective on the anomalous weak-field piezoelectric response at the polymorphic phase boundaries of (Ba,Ca)(Ti,M)O3 lead-free piezoelectrics (M=Zr, Sn, Hf). Phys. Rev. B 2017, 96, 014113. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, H.; Li, F.; Cai, Y.; Zhang, Y.; Song, D.; Wu, J.; Lyu, X.; Yin, J.; Xiao, D. Practical high piezoelectricity in barium titanate ceramics utilizing multiphase convergence with broad structural flexibility. J. Am. Chem. Soc. 2018, 140, 15252–15260. [Google Scholar] [CrossRef]

- Yang, L.; Chen, C.; Jiang, X.; Huang, X.; Nie, X.; Chang, S. Enhanced ferroelectric and piezoelectric properties of BiFeO3–BaTiO3 lead-free ceramics by simultaneous optimization of Bi compensation and sintering conditions. Ceram. Int. 2022, 48, 12866–12874. [Google Scholar] [CrossRef]

- Liu, H.; Wu, H.; Ong, K.P.; Yang, T.; Yang, P.; Das, P.K.; Chi, X.; Zhang, Y.; Diao, C.; Wong, W.K.A. Giant piezoelectricity in oxide thin films with nanopillar structure. Science 2020, 369, 292–297. [Google Scholar] [CrossRef]

- Lv, X.; Zhu, J.; Xiao, D.; Zhang, X.-x.; Wu, J. Emerging new phase boundary in potassium sodium-niobate based ceramics. Chem. Soc. Rev. 2020, 49, 671–707. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, R.; Qu, J.; Gao, S.; Zhang, Y.; Yan, J.; Hao, J.; Li, P.; Li, W. Enhanced piezoelectric properties and temperature stability in KNN-based textured ceramics. J. Adv. Dielectr. 2022, 12, 2244006. [Google Scholar] [CrossRef]

- Wen, Y.; Fan, G.; Hao, M.; Wang, Y.; Chen, X.; Zhang, Q.; Lv, W. Balanced Development of Piezoelectricity and Curie Temperature in KNN-BC-xBNH Lead-Free Ceramics. J. Electron. Mater. 2020, 49, 931–936. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Zhu, J. Potassium–sodium niobate lead-free piezoelectric materials: Past, present, and future of phase boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef]

- Yang, C.-R.; Lin, M.-F.; Huang, C.-K.; Huang, W.-C.; Tseng, S.-F.; Chiang, H.-H. Highly sensitive and wearable capacitive pressure sensors based on PVDF/BaTiO3 composite fibers on PDMS microcylindrical structures. Measurement 2022, 202, 111817. [Google Scholar] [CrossRef]

- Shohag, M.A.S.; Eze, V.O.; Braga Carani, L.; Okoli, O.I. Fully integrated mechanoluminescent devices with nanometer-thick perovskite film as self-powered flexible sensor for dynamic pressure sensing. ACS Appl. Nano Mater. 2020, 3, 6749–6756. [Google Scholar] [CrossRef]

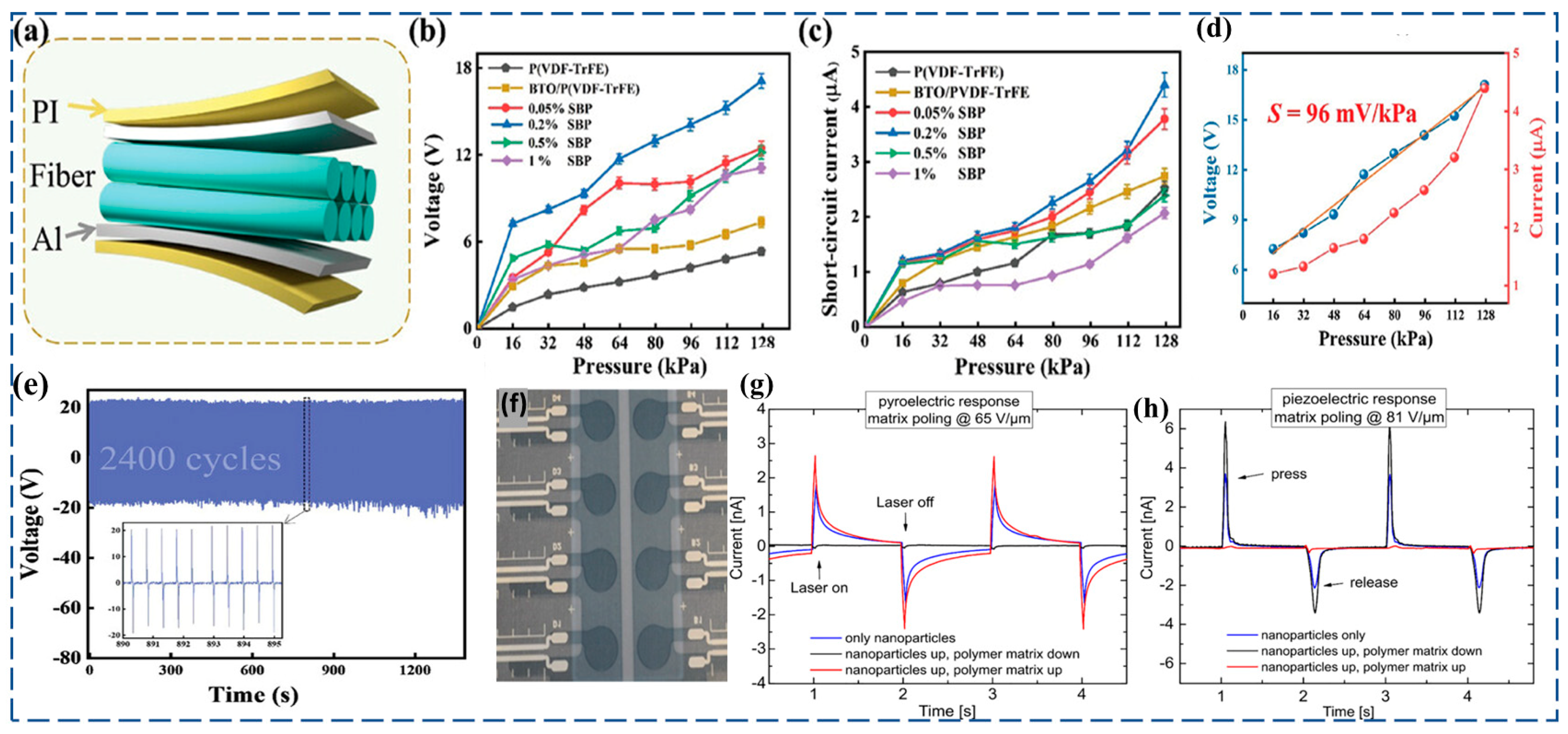

- Wang, J.; Zhao, C.; Cao, C.; Liu, M.; Liu, Z.; Zhou, P.; Wang, G.; Zhang, T.; Zhang, L.; Qi, Y. Boosting Sensing Performance of Flexible Piezoelectric Pressure Sensors by Sb Nanosheets and BaTiO3 Nanoparticles Co-Doping in P (VDF-TrFE) Nanofibers Mat. Adv. Electron. Mater. 2023, 10, 2300718. [Google Scholar] [CrossRef]

- Ali, T.A.; Groten, J.; Clade, J.; Collin, D.; Schaffner, P.; Zirkl, M.; Coclite, A.-M.; Domann, G.; Stadlober, B. Screen-printed ferroelectric P (VDF-TrFE)-co-PbTiO3 and P (VDF-TrFE)-co-NaBiTi2O6 nanocomposites for selective temperature and pressure sensing. ACS Appl. Mater. Interfaces 2020, 12, 38614–38625. [Google Scholar] [CrossRef]

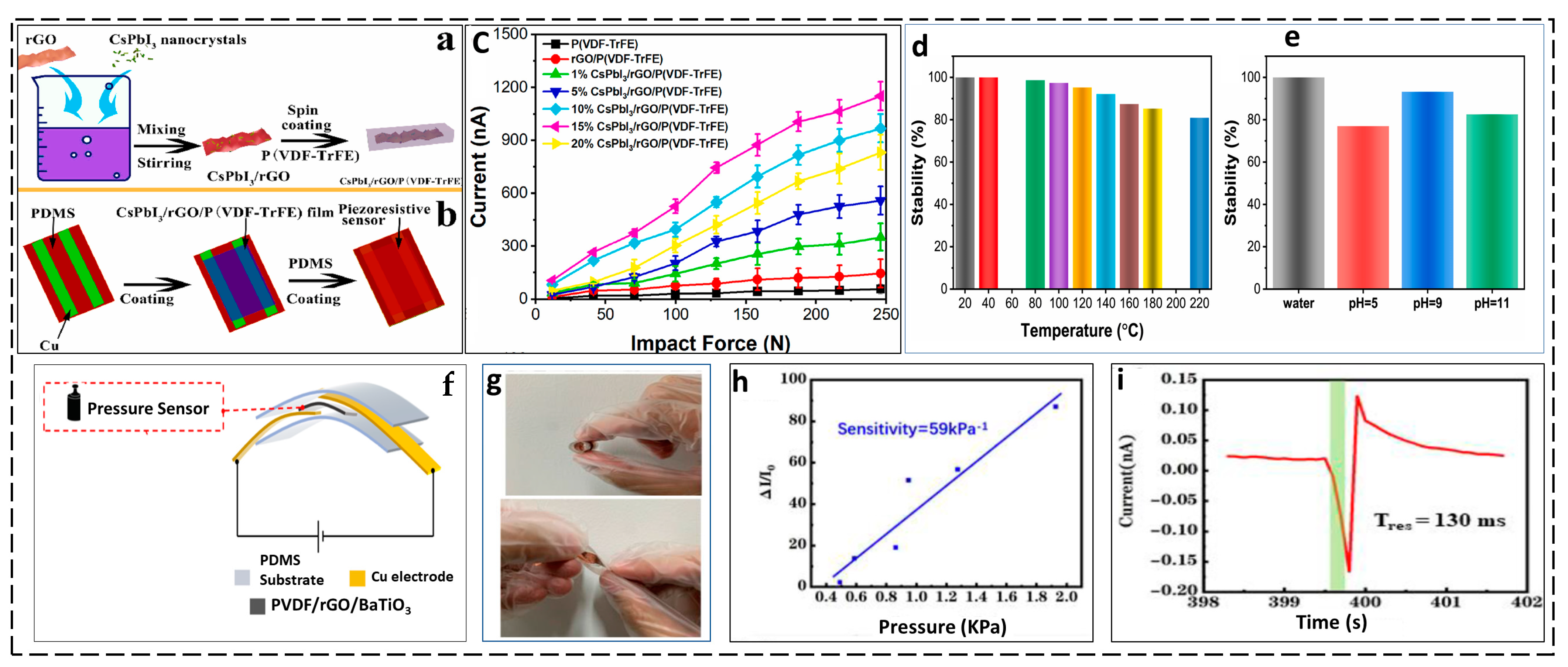

- Zhu, C.; Peng, Z.; Guo, Z.; Peng, L.; Zhao, C. Flexible self-powered CsPbI3/rGO/P (VDF-TrFE) pressure sensor and photodetector based on piezo-phototronic effect with long-Term stability. Phys. B Condens. Matter 2022, 646, 414264. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, L.; Wu, T.; Song, H.; Tang, C.; Huang, F.; Zuo, C. Flexible electronic skin with high performance pressure sensing based on PVDF/rGO/BaTiO3 composite thin film. Org. Electron. 2021, 98, 106296. [Google Scholar] [CrossRef]

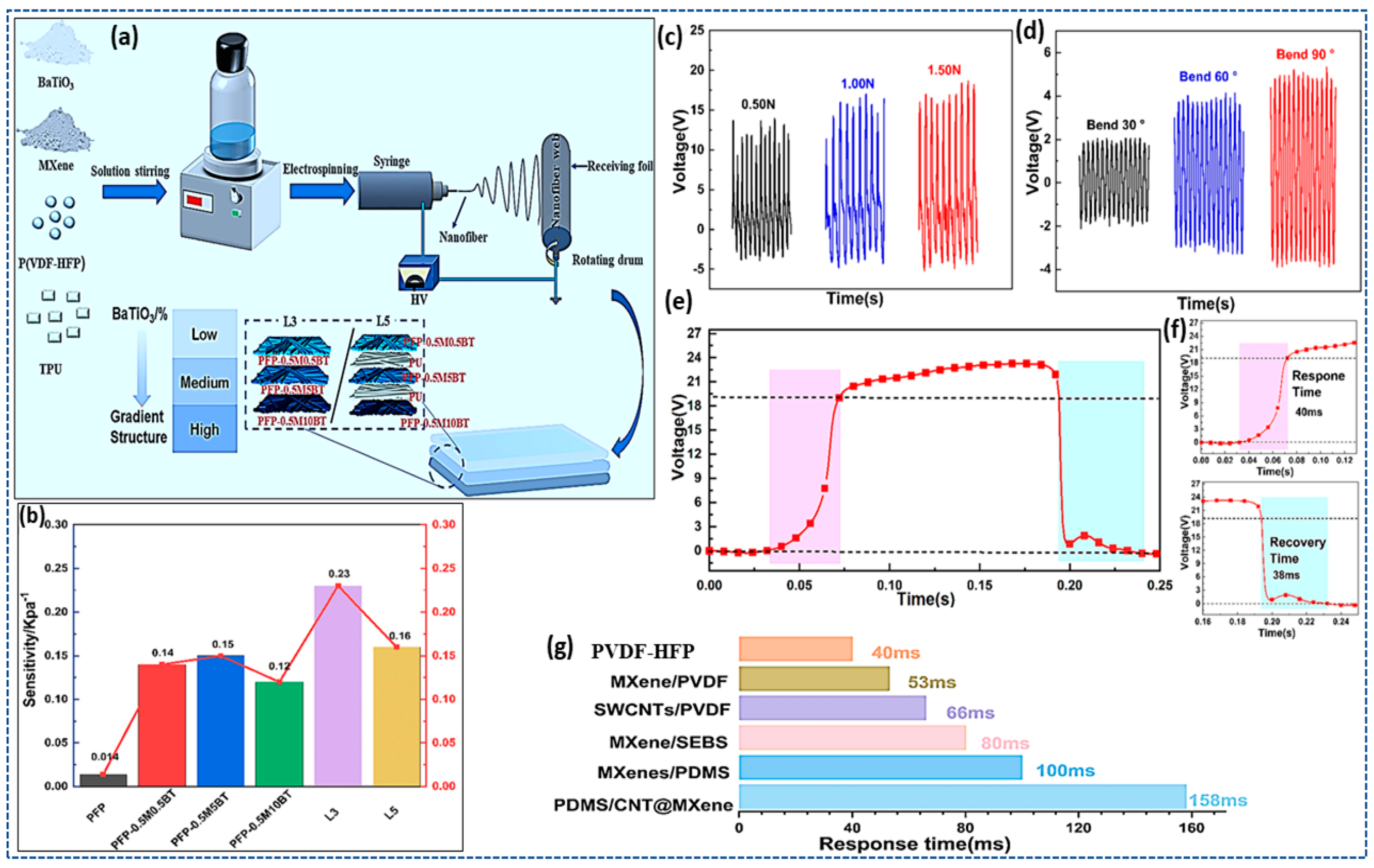

- He, Y.; Huang, Y.; Xue, R.; Shi, Q.; Wu, Y.; Liu, R. Flexible pressure sensor based on multi-layer with gradient structure P (VDF-HFP)/MXene/BaTiO3 composite film for human motion monitoring. Diam. Relat. Mater. 2023, 140, 110536. [Google Scholar] [CrossRef]

- Liu, X.; Tong, J.; Wang, J.; Lu, S.; Yang, D.; Li, H.; Liu, C.; Song, Y. BaTiO3/MXene/PVDF-TrFE composite films via an electrospinning method for flexible piezoelectric pressure sensors. J. Mater. Chem. C 2023, 11, 4614–4622. [Google Scholar] [CrossRef]

- Li, Y.; Li, B. Direct ink writing 3D printing of polydimethylsiloxane-based soft and composite materials: A mini review. Oxf. Open Mater. Sci. 2022, 2, itac008. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.; He, W.; Liu, Y.; Sang, X.; Liu, R. 3D printing of unsupported multi-scale and large-span ceramic via near-infrared assisted direct ink writing. Nat. Commun. 2023, 14, 2381. [Google Scholar] [CrossRef] [PubMed]

- Zub, K.; Hoeppener, S.; Schubert, U.S. Inkjet printing and 3D printing strategies for biosensing, analytical, and diagnostic applications. Adv. Mater. 2022, 34, 2105015. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Duan, Q.; Zang, J.; Zhao, Y.; Zheng, W.; Xiao, R.; Zhang, Z.; Hu, L.; Wu, G.; Nan, X. Boron nitride-enabled printing of a highly sensitive and flexible iontronic pressure sensing system for spatial mapping. Microsyst. Nanoeng. 2023, 9, 68. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, K.; Pei, Z.; Wu, Y.; Sang, S.; Zhang, Q.; Jiao, H. A highly accurate flexible sensor system for human blood pressure and heart rate monitoring based on graphene/sponge. RSC Adv. 2022, 12, 2391–2398. [Google Scholar] [CrossRef]

- Renault, T.; Vardelle, M.; Grimaud, A.; Fauchais, P.; Hoffman, H. On-line control of particle spray jet and residual stresses in plasma sprays. In Proceedings of the ITSC 2000, Montreal, QC, Canada, 8–11 May 2000; pp. 1383–1391. [Google Scholar]

- Wang, X.; Li, H.; Wang, T.; Niu, X.; Wang, Y.; Xu, S.; Jiang, Y.; Chen, L.; Liu, H. Flexible and high-performance piezoresistive strain sensors based on multi-walled carbon nanotubes@ polyurethane foam. RSC Adv. 2022, 12, 14190–14196. [Google Scholar] [CrossRef]

- Pang, X.; Zhang, Q.; Shao, Y.; Liu, M.; Zhang, D.; Zhao, Y. A flexible pressure sensor based on magnetron sputtered mos2. Sensors 2021, 21, 1130. [Google Scholar] [CrossRef]

- Cheng, L.; Hao, X.; Liu, G.; Zhang, W.; Cui, J.; Zhang, G.; Yang, Y.; Wang, R. A flexible pressure sensor based on silicon nanomembrane. Biosensors 2023, 13, 131. [Google Scholar] [CrossRef]

- Guo, X.; Ma, L.; Wu, W.; Li, S.; Lei, X.; Wu, X.; Yu, X.; Liu, F. Ultra-sensitive flexible piezoresistive pressure sensor prepared by laser-assisted copper template for health monitoring. Sens. Actuators A Phys. 2022, 334, 113325. [Google Scholar] [CrossRef]

- Tong, Z.; Sun, C.; Ma, Y.; Wang, M.; Jia, S.; Chen, X. Facile fabrication of microstructured surface using laser speckle for high-sensitivity capacitive pressure sensors. Sci. China Technol. Sci. 2023, 66, 155–164. [Google Scholar] [CrossRef]

- Su, Y.; Ma, K.; Yuan, F.; Tang, J.; Liu, M.; Zhang, X. High-performance flexible piezoresistive sensor based on Ti3C2Tx MXene with a honeycomb-like structure for human activity monitoring. Micromachines 2022, 13, 821. [Google Scholar] [CrossRef]

- Hu, G.; Huang, F.; Tang, C.; Gu, J.; Yu, Z.; Zhao, Y. High-performance flexible piezoresistive pressure sensor printed with 3D microstructures. Nanomaterials 2022, 12, 3417. [Google Scholar] [CrossRef] [PubMed]

- Hoefler, S.F.; Trimmel, G.; Rath, T. Progress on lead-free metal halide perovskites for photovoltaic applications: A review. Monatshefte Für Chem.-Chem. Mon. 2017, 148, 795–826. [Google Scholar] [CrossRef] [PubMed]

- Tonui, P.; Oseni, S.O.; Sharma, G.; Yan, Q.; Mola, G.T. Perovskites photovoltaic solar cells: An overview of current status. Renew. Sustain. Energy Rev. 2018, 91, 1025–1044. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, F.; Li, M.; Wang, X.; Chen, S.; Yu, J. Flexible stannum-doped SrTiO3 nanofiber membranes for highly sensitive and reliable piezoresistive pressure sensors. ACS Appl. Mater. Interfaces 2021, 13, 52811–52821. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Pan, H.; Xie, G.; Jiang, Y.; Chen, C.; Su, Y.; Wang, Y.; Tai, H. Flexible piezoelectric pressure sensor based on polydopamine-modified BaTiO3/PVDF composite film for human motion monitoring. Sens. Actuators A Phys. 2020, 301, 111789. [Google Scholar] [CrossRef]

- Madbouly, A.I.; Hassanien, W.S.; Morsy, M. Tailoring the polyurethane foam/rGO/BaTiO3 pressure sensor for human activities. Diam. Relat. Mater. 2023, 136, 109940. [Google Scholar] [CrossRef]

- Xuan, W.; Fang, Y.; Teng, S.; Huang, S.; Zou, L.; Gao, S.; Cheng, Y.; Zheng, L. In situ fabrication of porous polymer films embedded with perovskite nanocrystals for flexible superhydrophobic piezoresistive sensors. J. Colloid Interface Sci. 2024, 669, 358–365. [Google Scholar] [CrossRef]

- Yu, J.; Xian, S.; Zhang, Z.; Hou, X.; He, J.; Mu, J.; Geng, W.; Qiao, X.; Zhang, L.; Chou, X. Synergistic piezoelectricity enhanced BaTiO3/polyacrylonitrile elastomer-based highly sensitive pressure sensor for intelligent sensing and posture recognition applications. Nano Res. 2023, 16, 5490–5502. [Google Scholar] [CrossRef]

- He, F.; You, X.; Gong, H.; Yang, Y.; Bai, T.; Wang, W.; Guo, W.; Liu, X.; Ye, M. Stretchable, biocompatible, and multifunctional silk fibroin-based hydrogels toward wearable strain/pressure sensors and triboelectric nanogenerators. ACS Appl. Mater. Interfaces 2020, 12, 6442–6450. [Google Scholar] [CrossRef] [PubMed]

- Prasad, G.; Graham, S.A.; Yu, J.S.; Kim, H.; Lee, D.-W. Investigated a PLL surface-modified Nylon 11 electrospun as a highly tribo-positive frictional layer to enhance output performance of triboelectric nanogenerators and self-powered wearable sensors. Nano Energy 2023, 108, 108178. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, D.; An, Y.; Chen, W.; Huang, Z.; Jiang, B. Wearable flexible pressure sensors: An intriguing design towards microstructural functionalization. J. Mater. Chem. A 2024, 12, 6826–6874. [Google Scholar] [CrossRef]

| Type | Mechanism | Advantages | Limitations | Example | References |

|---|---|---|---|---|---|

| Piezoresistive | Resistance change | Simple design, high sensitivity | Hysteresis, temperature dependence | Textile-based FPS | [70] |

| Capacitive | Capacitance change | High sensitivity, low power | Complex circuitry, external interference | Flexible capacitive pressure sensors | [71] |

| Piezoelectric | Electric charge generation | High sensitivity, fast response | Limited to dynamic pressure, complex fabrication | Ultrahigh sensitivity FPS | [72] |

| Triboelectric | contact electrification | High output voltage, simple structure | Wear and tear, environmental sensitivity | FPS based on bionic-microstructures | [73] |

| Materials | Fabrication Techniques | Sensitivity | Response Time | Pressure Range | Operating Voltage | Cycles | Ref. |

|---|---|---|---|---|---|---|---|

| PVDF-BTO | Electrospinning | 5 kPa−1 | - | 0.11 Pa | - | 5000 | [128] |

| SbNSs/BTO/PVDF-TrFE (SBP) | Electrospinning | 96 mV kPa−1 | 2 ms. | 128 kPa | 17.1 V | 2400 | [130] |

| P(VDF-TrFE)-NaBiTi2O6(BNT) | Screen printing | good | - | - | 12.5 V | - | [131] |

| CsPbI3/rGO/P(VDF-TrFE) | Spin coating | excellent | - | - | self-powered operation | - | [132] |

| PVDF/rGO/BTO | Direct ink writing | 59 kPa−1 | 130 ms | - | - | - | [133] |

| P(VDF-HFP)/MXene/BTO | Electrospinning | 0.23 kPa−1 | - | <1 kPa | - | 500 | [134] |

| Stannum-IV-doped SrTiO3 | Sol-gel electrospinning | high | - | rapid response | - | - | [151] |

| PDA@BTO/PVDF | Facial solution-casting method | - | 61 ms | - | 9.3 V | - | [152] |

| PU-BTO-rGO | Hummer method | 2.63 kPa−1 | 560 ms | 0–60 kPa | - | 500 | [153] |

| BTO/MXene/PVDF-TrFE | Electrospinning | 0.2–400 kPa | 56 ms | 0.2–400 kPa | - | 5000 | [135] |

| ASPS | Mixing | excellent | - | 10–900 kPa | 0.93 V/104 Pa | 10,000 | [155] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naz, A.; Meng, Y.; Luo, J.; Khan, I.A.; Abbas, R.; Yu, S.; Wei, J. Cutting-Edge Perovskite-Based Flexible Pressure Sensors Made Possible by Piezoelectric Innovation. Materials 2024, 17, 4196. https://doi.org/10.3390/ma17174196

Naz A, Meng Y, Luo J, Khan IA, Abbas R, Yu S, Wei J. Cutting-Edge Perovskite-Based Flexible Pressure Sensors Made Possible by Piezoelectric Innovation. Materials. 2024; 17(17):4196. https://doi.org/10.3390/ma17174196

Chicago/Turabian StyleNaz, Adeela, Yuan Meng, Jingjing Luo, Imtiaz Ahmad Khan, Rimsha Abbas, Suzhu Yu, and Jun Wei. 2024. "Cutting-Edge Perovskite-Based Flexible Pressure Sensors Made Possible by Piezoelectric Innovation" Materials 17, no. 17: 4196. https://doi.org/10.3390/ma17174196

APA StyleNaz, A., Meng, Y., Luo, J., Khan, I. A., Abbas, R., Yu, S., & Wei, J. (2024). Cutting-Edge Perovskite-Based Flexible Pressure Sensors Made Possible by Piezoelectric Innovation. Materials, 17(17), 4196. https://doi.org/10.3390/ma17174196