Freeze–Thaw Cycle Durability and Mechanism Analysis of Zeolite Powder-Modified Recycled Concrete

Abstract

1. Introduction

2. Materials and Methods

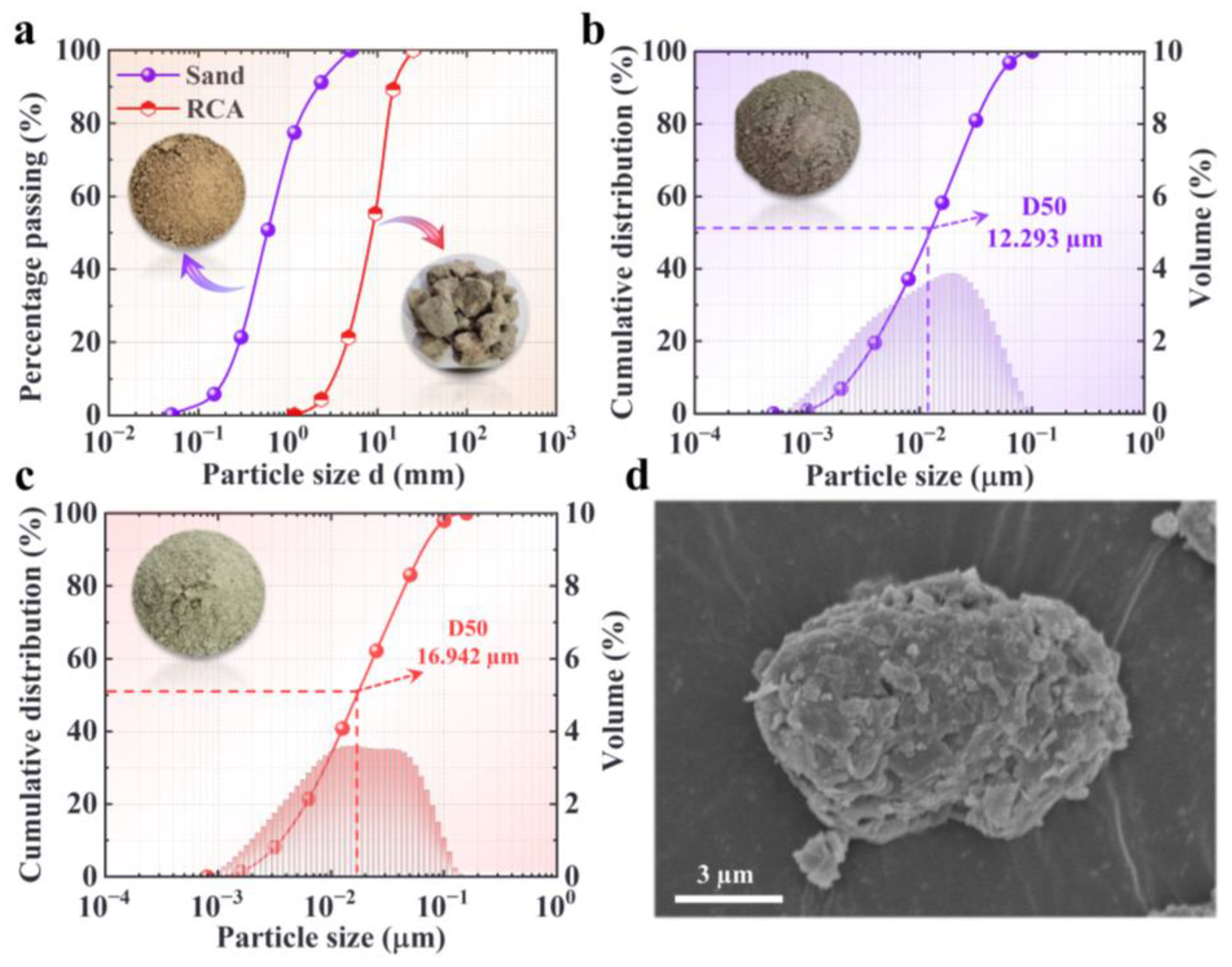

2.1. Materials

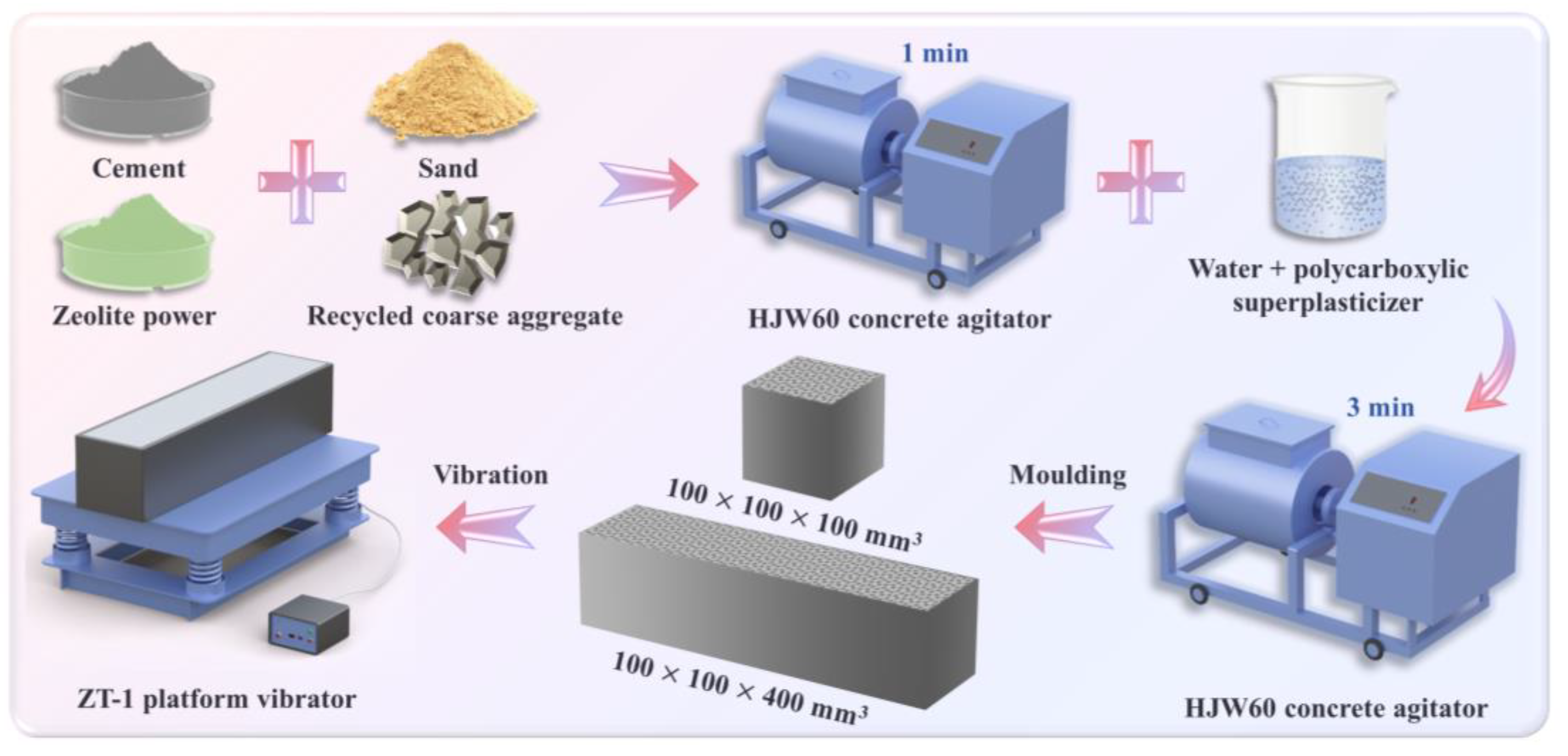

2.2. Sample Preparation

2.3. Test Methods

2.3.1. Slump Test

2.3.2. Water Absorption Test

2.3.3. FT Cycle Test

2.3.4. Compressive and Flexural Strength Tests

2.3.5. SEM Analysis

2.3.6. XRD Analysis

3. Results and Discussion

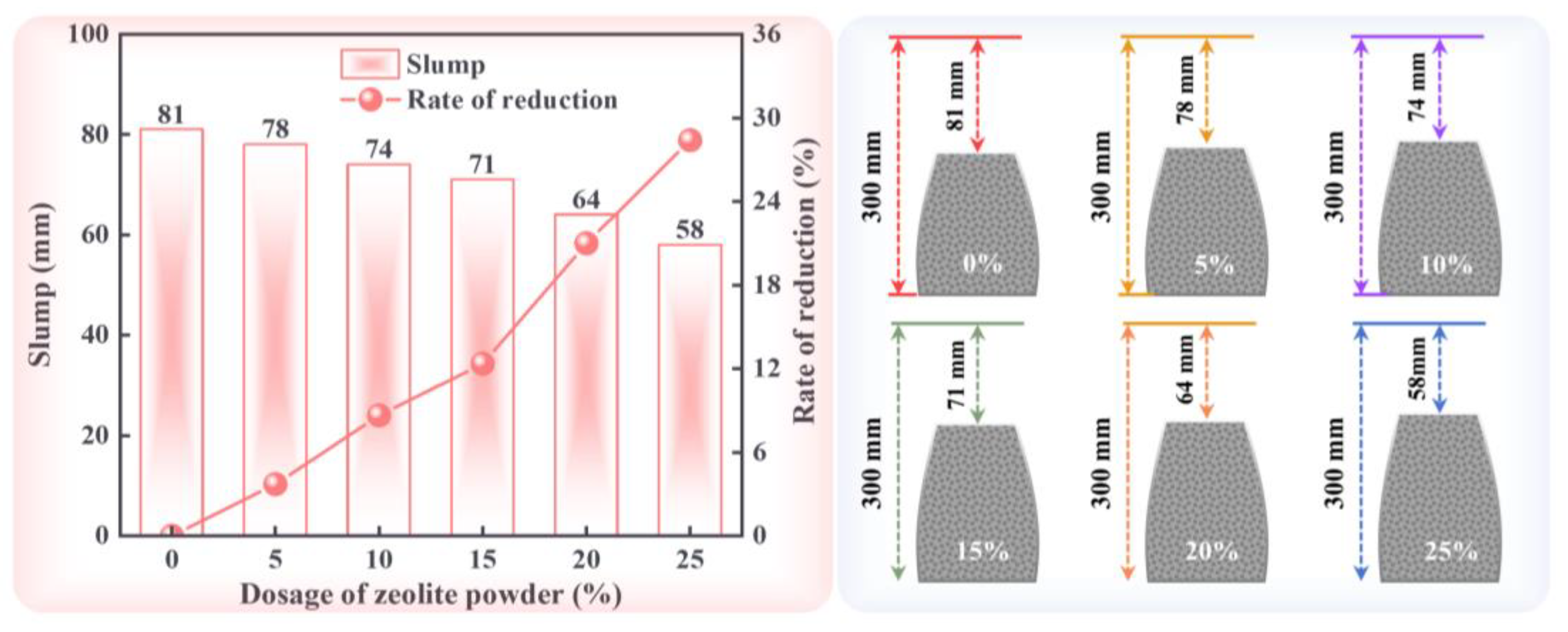

3.1. Slump Test Results

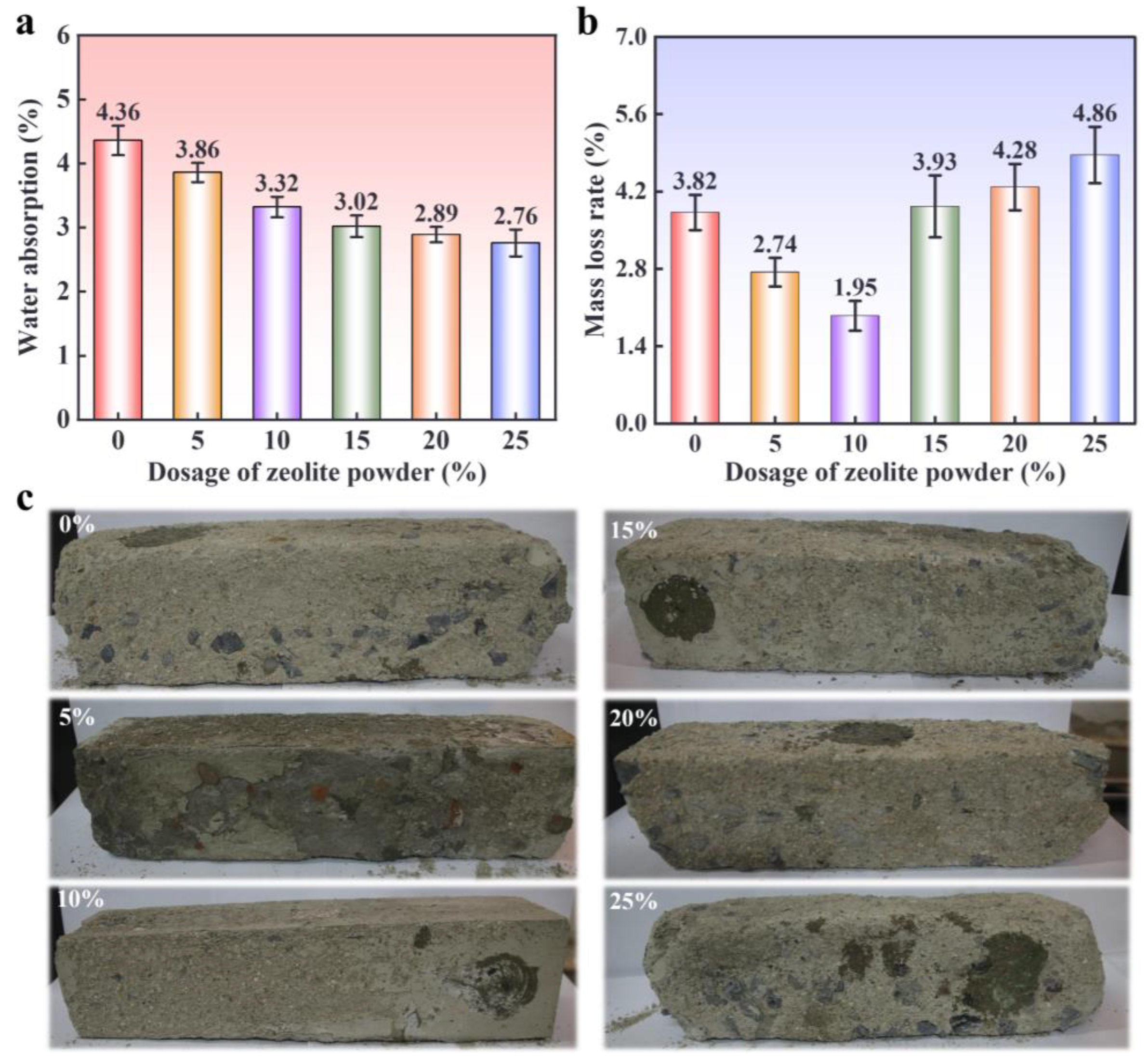

3.2. Water Absorption and FT Durability

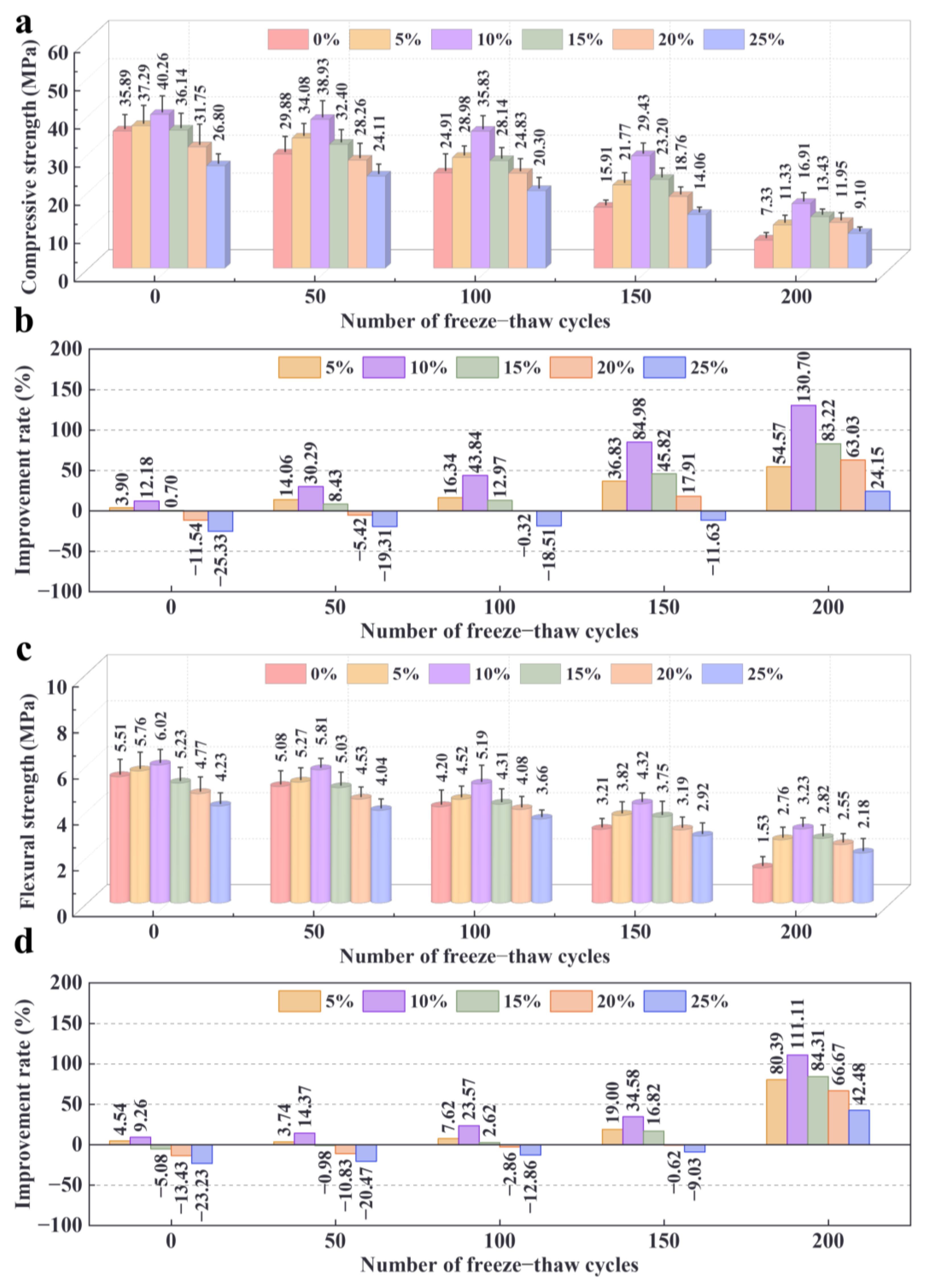

3.3. Mechanical Properties of ZPRC

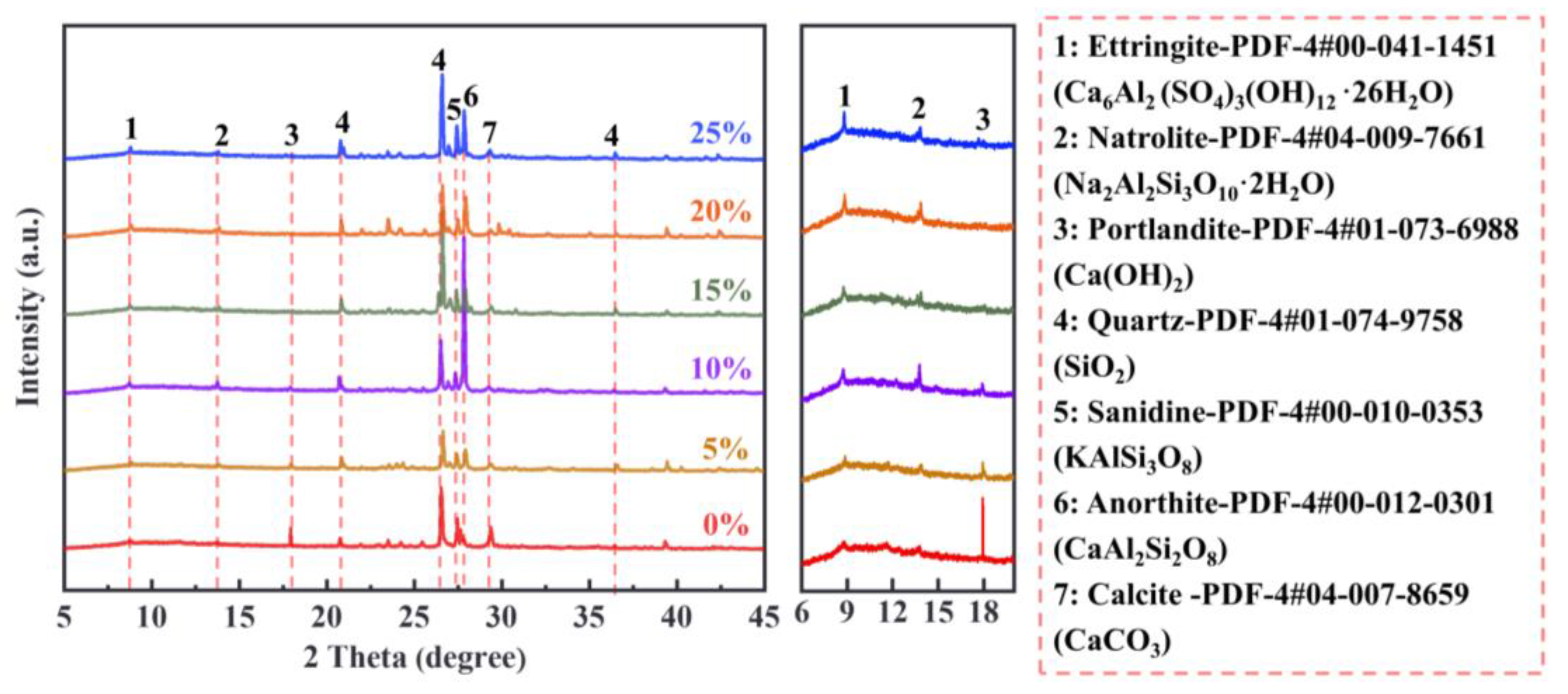

3.4. The Phase Composition of the ZPRC

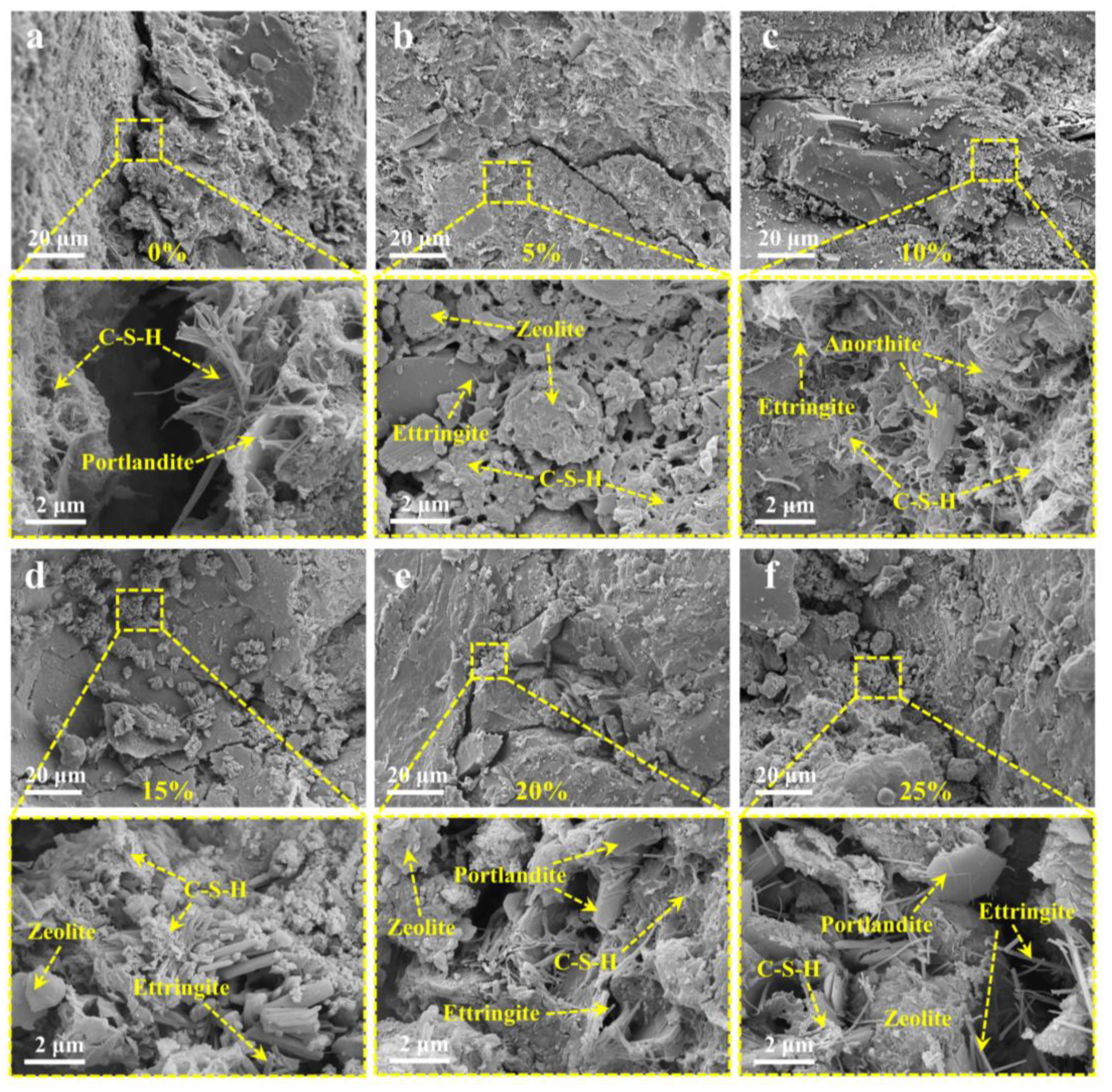

3.5. Microstructural Characteristics of ZPRC

4. Conclusions

- The addition of zeolite powder increases the viscosity of recycled concrete, leading to a gradual decrease in the slump of ZPRC as the zeolite powder content increases.

- Zeolite powder reduces the water absorption of ZPRC and improves FT durability and mechanical properties at dosages of 0 to 10%. In this study, the lowest specimen mass loss of 1.95% and the best compressive and flexural strength enhancement of 43.84% and 23.57% after 100 FT cycles were obtained with a zeolite powder dosage of 10%.

- The addition of zeolite powder promotes the formation of a new hydration product, anorthite, which has a positive effect on the mechanical performance and FT durability of ZPRC.

- When the zeolite powder content is 10%, the interconnection of C-S-H gel, ettringite, and anorthite in specimens makes the microstructure most dense. However, when the zeolite powder content is 15–25%, the C-S-H gel in ZPRC decreases, causing a loose microstructure.

- The mechanism of action of zeolite powder, including its particle-filling effect, water storage function, and pozzolanic reaction. The above effects can make the microstructure of ZPRC denser especially when the addition of zeolite powder is 10%.

- Overall, the results of this study provide a new design scheme for the application of zeolite powder-modified recycled concrete in cold regions. Moreover, due to its low carbon content and cost-effectiveness, zeolite powder can further reduce the carbon emissions and costs of recycled concrete, which is important for low-carbon construction in the construction industry. In future research, we will focus on the dynamic mechanical properties of zeolite powder-modified recycled concrete and its curing effect on radioactive elements in nuclear waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghorbani, S.; Sharifi, S.; Ghorbani, S.; Tam, V.W.; Brito, J.D.; Kurda, R. Effect of crushed concrete waste’s maximum size as partial replacement of natural coarse aggregate on the mechanical and durability properties of concrete. Resour. Conserv. Recycl. 2019, 149, 664–673. [Google Scholar] [CrossRef]

- Liu, T.; Qin, S.; Zou, D.; Song, W. Experimental investigation on the durability performances of concrete using cathode ray tube glass as fine aggregate under chloride ion penetration or sulfate attack. Constr. Build. Mater. 2018, 163, 634–642. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Zou, D.; Zhou, A.; Du, J. Strength enhancement of recycled aggregate pervious concrete using a cement paste redistribution method. Cem. Concr. Res. 2019, 122, 72–82. [Google Scholar] [CrossRef]

- Song, W.; Zou, D.; Liu, T.; Teng, J.; Li, L. Effects of recycled CRT glass fine aggregate size and content on mechanical and damping properties of concrete. Constr. Build. Mater. 2019, 202, 332–340. [Google Scholar] [CrossRef]

- Tang, Q.; Xiao, P.; Kou, C.; Lou, K.; Kang, A.; Wu, Z. Physical, chemical and interfacial properties of modified recycled concrete aggregates for asphalt mixtures: A review. Constr. Build. Mater. 2021, 312, 125357. [Google Scholar] [CrossRef]

- Lin, D.; Wu, J.; Yan, P.; Chen, Y. Effect of residual mortar on compressive properties of modeled recycled coarse aggregate concrete. Constr. Build. Mater. 2023, 402, 132511. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, H.; Yan, X.; Yang, L.; Zhu, L.; Liu, H. Recycled coarse aggregate from parent concrete with supplementary cementitious materials under freeze-thaw environment: Recyclability, environment and economic evaluation. J. Build. Eng. 2024, 84, 108699. [Google Scholar] [CrossRef]

- Jalilifar, H.; Sajedi, F. Micro-structural analysis of recycled concretes made with recycled coarse concrete aggregates. Constr. Build. Mater. 2021, 267, 121041. [Google Scholar] [CrossRef]

- Sunayana, S.; Barai, S.V. Partially fly ash incorporated recycled coarse aggregate based concrete: Microstructure perspectives and critical analysis. Constr. Build. Mater. 2021, 278, 122322. [Google Scholar] [CrossRef]

- Gao, S.; Guo, X.; Ban, S.; Ma, Y.; Yu, Q.; Sui, S. Influence of supplementary cementitious materials on ITZ characteristics of recycled concrete. Constr. Build. Mater. 2023, 363, 129736. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete. Constr. Build. Mater. 2021, 304, 124659. [Google Scholar] [CrossRef]

- Liu, X.; Xie, X.; Liu, R.; Lyu, K.; Zuo, J.; Li, S.; Liu, L.; Shah, S.P. Research on the durability of nano-SiO2 and sodium silicate co-modified recycled coarse aggregate (RCA) concrete. Constr. Build. Mater. 2023, 378, 131185. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, J.; Guo, H.; Li, L. Effect of nano-SiO2 modified recycled coarse aggregate on the mechanical properties of recycled concrete. Constr. Build. Mater. 2023, 395, 132319. [Google Scholar] [CrossRef]

- Zhan, P.; Xu, J.; Wang, J.; Zuo, J.; He, Z. A review of recycled aggregate concrete modified by nanosilica and graphene oxide: Materials, performances and mechanism. J. Clean. Prod. 2022, 375, 134116. [Google Scholar] [CrossRef]

- Lu, D.; Wang, D.; Wang, Y.; Zhong, J. Nano-engineering the interfacial transition zone between recycled concrete aggregates and fresh paste with graphene oxide. Constr. Build. Mater. 2023, 384, 131244. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, H.; Luo, Z.; Liu, S.; Zhou, C.; Liu, H. Properties evaluation of concrete made with recycled coarse aggregate modified by graphene oxide. J. Build. Eng. 2024, 84, 108546. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Cao, Z.; Guo, M.; Zheng, J. Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J. Clean. Prod. 2019, 233, 421–428. [Google Scholar] [CrossRef]

- Peng, X.; Shi, F.; Yang, J.; Yang, Q.; Wang, H.; Zhang, J. Modification of construction waste derived recycled aggregate via CO2 curing to enhance corrosive freeze-thaw durability of concrete. J. Clean. Prod. 2023, 405, 137016. [Google Scholar] [CrossRef]

- Luo, S.; Lin, Q.; Lin, T.; Wang, D.; Wang, S. Effects of pressurized carbonation with presoaking in calcium hydroxide solution on the fracture behaviours of recycled coarse aggregate concrete. Constr. Build. Mater. 2023, 397, 132386. [Google Scholar] [CrossRef]

- Liu, J.; Ma, K.; Shen, J.; Xie, Y.; Long, G. Influence of CO2 enhancement of recycled aggregate on microstructure of ITZs in recycled concrete. J. Build. Eng. 2023, 65, 105805. [Google Scholar] [CrossRef]

- Thaue, W.; Iwanami, M.; Nakayama, K.; Yodsudjai, W. Influence of acetic acid treatment on microstructure of interfacial transition zone and performance of recycled aggregate concrete. Constr. Build. Mater. 2024, 417, 135355. [Google Scholar] [CrossRef]

- Panghal, H.; Kumar, A. Enhancing concrete performance: Surface modification of recycled coarse aggregates for sustainable construction. Constr. Build. Mater. 2024, 411, 134432. [Google Scholar] [CrossRef]

- Wang, R.; Jin, P.; Ding, Z.; Zhang, W. Surface modification of recycled coarse aggregate based on Microbial Induced Carbonate Precipitation. J. Clean. Prod. 2021, 328, 129537. [Google Scholar] [CrossRef]

- Liu, Z.; Chin, C.S.; Xia, J. Novel method for enhancing freeze-thaw resistance of recycled coarse aggregate concrete via two-stage introduction of denitrifying bacteria. J. Clean. Prod. 2022, 346, 131159. [Google Scholar] [CrossRef]

- Tang, Q.; Tian, A.; Ling, C.; Huang, Y.; Gu, F. Physical and mechanical properties of recycled aggregates modified by microbially induced calcium carbonate precipitation. J. Clean. Prod. 2023, 382, 135409. [Google Scholar] [CrossRef]

- Shekarchi, M.; Ahmadi, B.; Azarhomayun, F.; Shafei, B.; Kioumarsi, M. Natural zeolite as a supplementary cementitious material—A holistic review of main properties and applications. Constr. Build. Mater. 2023, 409, 133766. [Google Scholar] [CrossRef]

- Hua, X.; Gao, Z.; Shi, Y.; Hao, W.; Liu, X.; Li, R. Transforming industrial solid wastes into eco-friendly zeolite material for efficient heavy metal ion stabilization through host-guest combination. Chem. Eng. Res. Des. 2023, 196, 656–670. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, L.; Li, Y.; Zha, J.; Tian, G.; Wang, F.; Zhang, H.; Liang, J. Synthesis of zeolites by in-situ conversion of geopolymers and their performance of heavy metal ion removal in wastewater: A review. J. Clean. Prod. 2022, 349, 131441. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, K.; Gao, S.; Wang, F.; Wu, Z. Effect of pozzolanic reaction of zeolite on its internal curing performance in cement-based materials. J. Build. Eng. 2023, 63, 105503. [Google Scholar] [CrossRef]

- Caputo, D.; Liguori, B.; Colella, C. Some advances in understanding the pozzolanic activity of zeolites: The effect of zeolite structure. Cem. Concr. Compos. 2008, 30, 455–462. [Google Scholar] [CrossRef]

- Ahmadi, B.; Shekarchi, M. Use of natural zeolite as a supplementary cementitious material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Hu, H.; He, Z.; Fan, K.; Shibro, T.; Liu, B.; Shi, J. Properties enhancement of recycled coarse aggregates by pre-coating/pre-soaking with zeolite powder/calcium hydroxide. Constr. Build. Mater. 2021, 286, 122888. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, J.; Ding, X.; Chu, H.; Zhang, J. Frost resistance of internal curing concrete with calcined natural zeolite particles. Constr. Build. Mater. 2021, 288, 123062. [Google Scholar] [CrossRef]

- Shekarchi, M.; Ahmadi, B.; Najimi, M. Use of natural zeolite as pozzolanic material in cement and concrete composites. In Handbook of Natural Zeolites; Buy Chapter; Inglezakis, V.J., Zorpas, A.A., Eds.; Bentham Science Publishers: Karachi, Pakistan, 2012; pp. 665–694. [Google Scholar]

- Bai, W.; Ye, D.; Yuan, C.; Guan, J.; Xie, C.; Cao, K. The effect of curing age on mechanical properties and mesoscopic damage mechanism of recycled aggregate concrete modified with zeolite powder. J. Build. Eng. 2024, 85, 108694. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Papynov, E.K.; Nepomnyushchaya, V.A.; Ivanets, A.I.; Belov, A.A.; Dran’kov, A.N.; Yarusova, S.B.; Buravlev, I.Y.; Tarabanova, A.E.; Fedorets, A.N.; et al. Hydrothermal synthesis and spark plasma sintering of NaY zeolite as solid-state matrices for cesium-137 immobilization. J. Eur. Ceram. Soc. 2022, 42, 3004–3014. [Google Scholar] [CrossRef]

- Jin, H.-Y.; Yao, X.-Y.; Tang, C.-C.; Zhou, A.-J.; Liu, W.; Ren, Y.-X.; Li, Z.; Wang, A.; He, Z. Magnetite modified zeolite as an alternative additive to promote methane production from anaerobic digestion of waste activated sludge. Renew. Energy 2024, 224, 120181. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Papynov, E.K.; Maiorov, V.Y.; Belov, A.A.; Modin, E.B.; Buravlev, I.Y.; Azarova, Y.A.; Golub, A.V.; Gridasova, E.A.; Sukhorada, A.E.; et al. Spark Plasma Sintering of Aluminosilicate Ceramic Matrices for Immobilization of Cesium Radionuclides. Radiochemistry. 2019, 61, 185–191. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Construction, People’s Republic of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Construction, People’s Republic of China: Beijing, China, 2019.

- Nagrockiene, D.; Girskas, G. Research into the properties of concrete modified with natural zeolite addition. Constr. Build. Mater. 2016, 113, 964–969. [Google Scholar] [CrossRef]

- GB/T50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Construction, People’s Republic of China: Beijing, China, 2009.

- Cao, L.; Shi, F.; Qiu, M.; Chen, W.; Cao, P.; Zhou, C. Effects of air entraining agent on the rheological properties and electrochemical parameters of cement mortar. Constr. Build. Mater. 2022, 344, 128233. [Google Scholar] [CrossRef]

- Cao, L.; Cao, P.; Tan, Z.; Shi, F.; Liu, J.; Wang, J. Mechanical performance prediction of air-entrained mortar by coupling electrochemical testing with back propagation neural network modelling. Constr. Build. Mater. 2024, 411, 134606. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, X.; Yuan, Q.; Shi, C. The change of phase assemblage and desorption of bound chloride for seawater cement paste under sulfate attack. Cem. Concr. Compos. 2023, 139, 105033. [Google Scholar] [CrossRef]

- Cao, L.; Cao, P.; Tan, Z.; Shi, F.; Liu, J.; Wang, J. Application of SCMs and seawater to cement-bonded calcareous sand: Macro performance, micro mechanism, and strength prediction. Constr. Build. Mater. 2024, 419, 135560. [Google Scholar] [CrossRef]

- Hemstad, P.; Lothenbach, B.; Kjellsen, K.O.; Weerdt, K.D. The effect of varying cement replacement level on alkali metal distribution in cement pastes. Cem. Concr. Compos. 2024, 146, 105344. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Xia, P.; Yang, L.; Wang, S.; Gong, F.; Cao, W.; Zhao, Y. Improved freeze-thaw modification of recycled concrete aggregate originally from frost resistive concrete. Cem. Concr. Compos. 2023, 144, 105302. [Google Scholar] [CrossRef]

- Jiang, Z.W.; He, B.; Zhu, X.P.; Ren, Q.; Zhang, Y. State-of-the-art review on properties evolution and deterioration mechanism of concrete at cryogenic temperature. Constr. Build. Mater. 2020, 257, 119456. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Zhang, R.; Wang, Y. Hardened properties of 3D printed concrete with recycled coarse aggregate. Cem. Concr. Res. 2022, 159, 106868. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze-thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Li, Y.; Wang, K.; Zhang, H. Review on the deterioration and approaches to enhance the durability of concrete in the freeze-thaw environment. Constr. Build. Mater. 2022, 321, 126371. [Google Scholar] [CrossRef]

- Zolghadri, A.; Ahmadi, B.; Taherkhani, H. Influence of natural zeolite on fresh properties, compressive strength, flexural strength, abrasion resistance, Cantabro-loss and microstructure of self-consolidating concrete. Constr. Build. Mater. 2022, 334, 127440. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Gao, X. Incorporation of self-ignited coal gangue in steam cured precast concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- Silva, R.V.; Brito, J.D.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Yammine, A.; Hamdadou, M.; Leklou, N.; Bignonnet, F.; Choinska-Colombel, M. Effect of recycled concrete aggregates and recycled filler on delayed ettringite formation: An experimental study compared to chemical modelling. Cem. Concr. Compos. 2022, 132, 104636. [Google Scholar] [CrossRef]

- Tran, Y.T.; Lee, J.; Kumar, P.; Kim, K.-H.; Lee, S.S. Natural zeolite and its application in concrete composite production. Compos. B. Eng. 2019, 165, 354–364. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, L.; Xu, S.; Zhao, X.; Cao, P.; Wang, J. Strength mechanism and electrochemical characterization of cement-bonded calcareous sand in different water environments. Constr. Build. Mater. 2023, 389, 131751. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, Z.; Shen, L.; Sheng, D. Development of sustainable concrete incorporating seawater: A critical review on cement hydration, microstructure and mechanical strength. Cem. Concr. Compos. 2021, 121, 104100. [Google Scholar] [CrossRef]

- Zeng, M.-H.; Wang, H.-W.; Wang, Y.-J.; Zheng, J.-J.; Wu, Z.-M. Meso-crack propagation process of concrete based on macro-fracture parameters: Numerical and experimental. Theor. Appl. Fract. Mech. 2024, 129, 104216. [Google Scholar] [CrossRef]

- Yang, S.; Poon, C.S.; Cui, H. Alkali-silica reactivity of lightweight aggregates in alkali-activated slag cement and ordinary Portland cement systems. J. Clean. Prod. 2023, 390, 136187. [Google Scholar] [CrossRef]

| Type | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| Cement | 62.25 | 20.55 | 5.36 | 3.95 | 1.96 | 2.64 | 0.72 | 0.48 |

| Zeolite power | 2.62 | 68.96 | 12.45 | 0.92 | 0.88 | 0.17 | 2.68 | 1.12 |

| Zeolite Ratio (%) | Zeolite Mass (kg) | Cement (kg) | Sand (kg) | Recycled Aggregate (kg) | Water (kg) | Water Reducer (%) |

|---|---|---|---|---|---|---|

| 0 | 0 | 370 | 832.5 | 1189.3 | 148 | 1.0 |

| 5 | 18.5 | 351.5 | 832.5 | 1189.3 | 148 | 1.0 |

| 10 | 37 | 333 | 832.5 | 1189.3 | 148 | 1.0 |

| 15 | 55.5 | 314.5 | 832.5 | 1189.3 | 148 | 1.0 |

| 20 | 74 | 296 | 832.5 | 1189.3 | 148 | 1.0 |

| 25 | 92.5 | 277.5 | 832.5 | 1189.3 | 148 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, T.; Zhang, Y.; Cao, L.; Cao, P.; Zhou, C.; Gu, S. Freeze–Thaw Cycle Durability and Mechanism Analysis of Zeolite Powder-Modified Recycled Concrete. Materials 2024, 17, 2671. https://doi.org/10.3390/ma17112671

Yu T, Zhang Y, Cao L, Cao P, Zhou C, Gu S. Freeze–Thaw Cycle Durability and Mechanism Analysis of Zeolite Powder-Modified Recycled Concrete. Materials. 2024; 17(11):2671. https://doi.org/10.3390/ma17112671

Chicago/Turabian StyleYu, Teng, Yimeng Zhang, Liang Cao, Peng Cao, Changjun Zhou, and Shenglong Gu. 2024. "Freeze–Thaw Cycle Durability and Mechanism Analysis of Zeolite Powder-Modified Recycled Concrete" Materials 17, no. 11: 2671. https://doi.org/10.3390/ma17112671

APA StyleYu, T., Zhang, Y., Cao, L., Cao, P., Zhou, C., & Gu, S. (2024). Freeze–Thaw Cycle Durability and Mechanism Analysis of Zeolite Powder-Modified Recycled Concrete. Materials, 17(11), 2671. https://doi.org/10.3390/ma17112671