Comparison of Thermal Behaviors of Carbon and Stainless Steel Billets during the Heating Process

Abstract

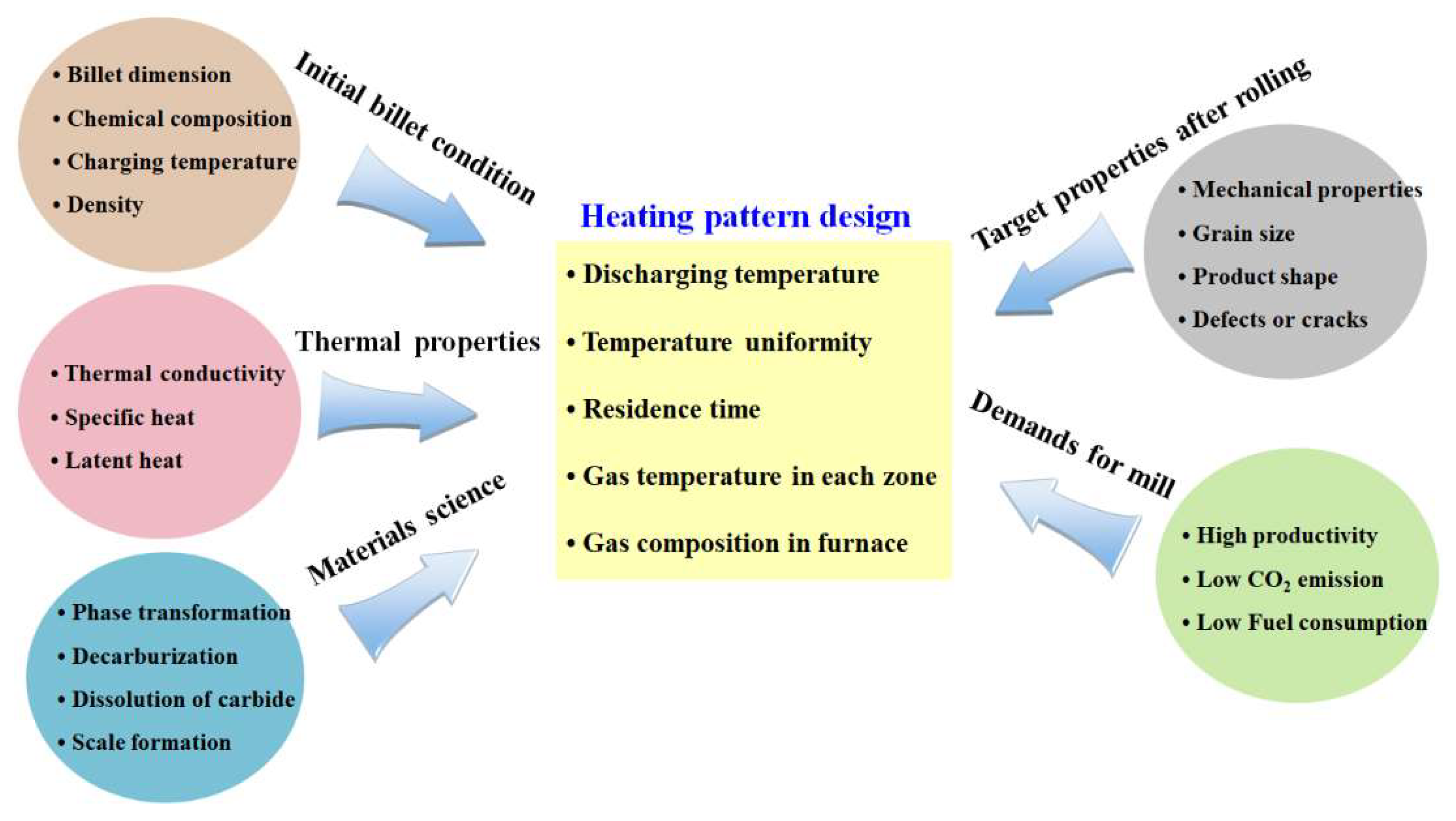

:1. Introduction

- To achieve temperature uniformity in the discharged billet, the residence time of the billet tends to increase in the reheating furnace. In such cases, the reheating furnace can become a bottleneck in the rolling process, leading to a decrease in the productivity of the mill [1].

- The increased residence time of the billet increases the oxide scale formation on the billet surface, resulting in a high scale loss, and eventually leading to a decrease in the productivity of the mill [8].

- The setting of a high gas temperature in the reheating furnace to ensure the target temperature with acceptable uniformity in the discharged billet induces the distortion of the billet in the reheating furnace due to the temperature deviations of the billet within the region [9].

- The temperature deviations of the billet with region during the aforementioned heating process induce thermal cracks in the billet owing to thermal stress, potentially leading to the fracture of the billet in the reheating furnace [10].

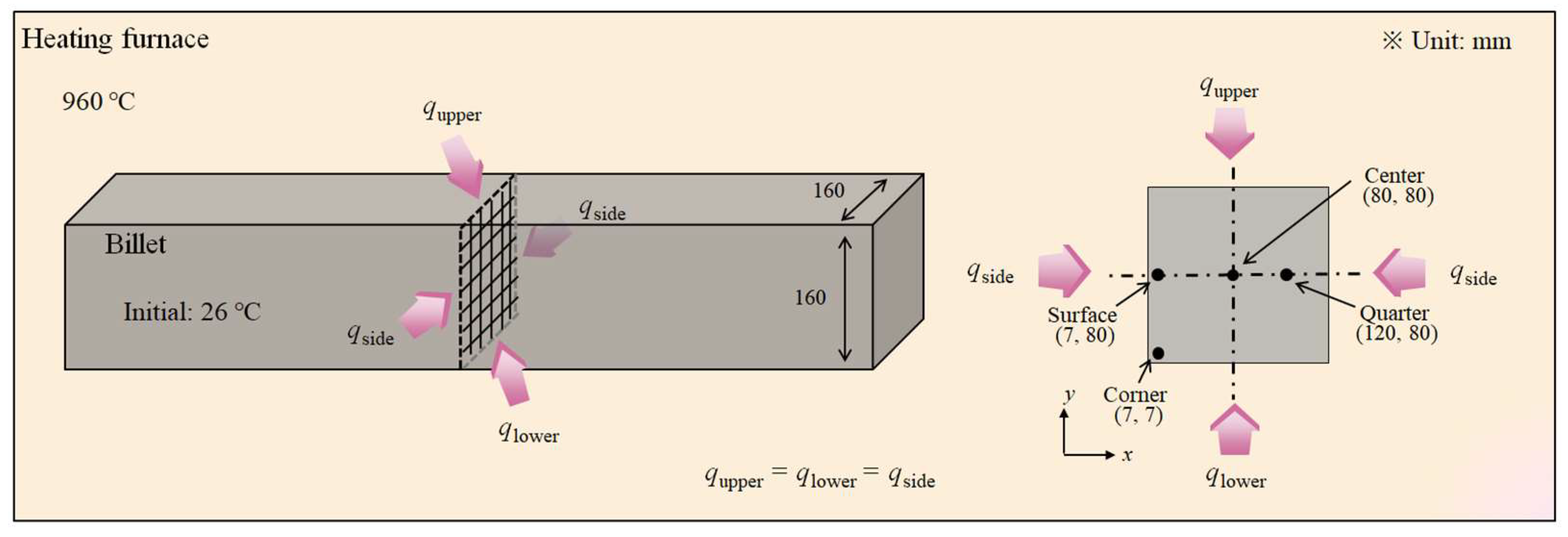

2. Numerical Model

2.1. Governing Equation

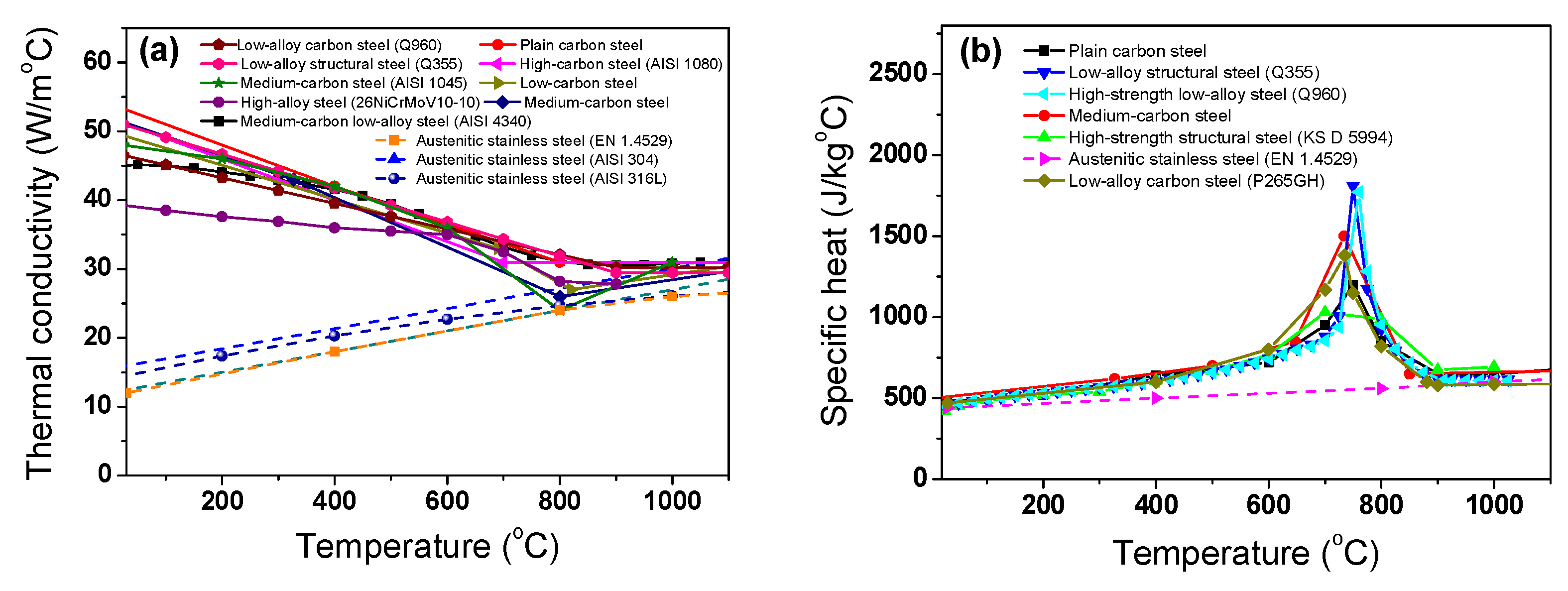

2.2. Thermal Properties

2.3. Boundary and Initial Conditions

2.4. Numerical Method and Determination of φ

3. Results and Discussion

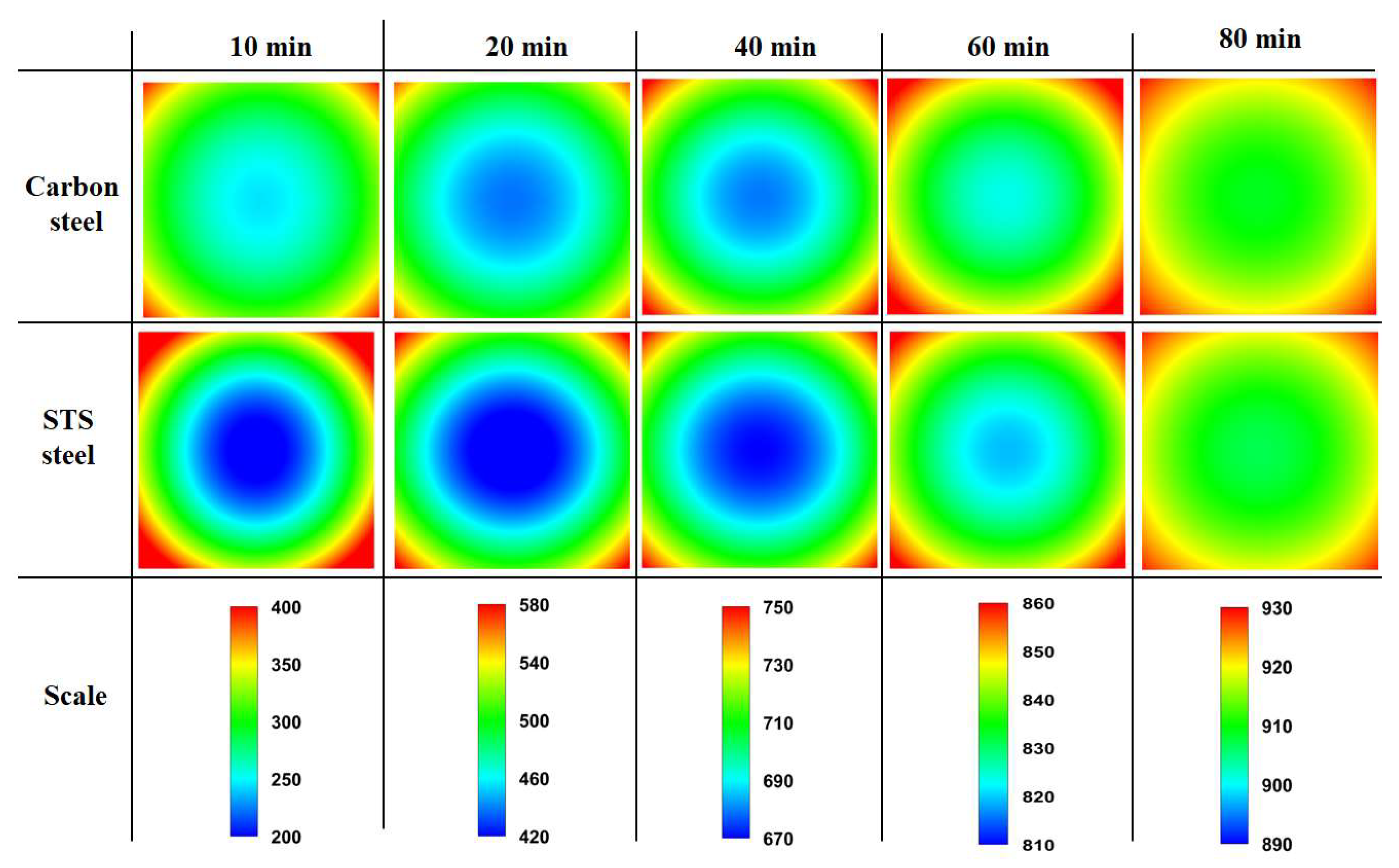

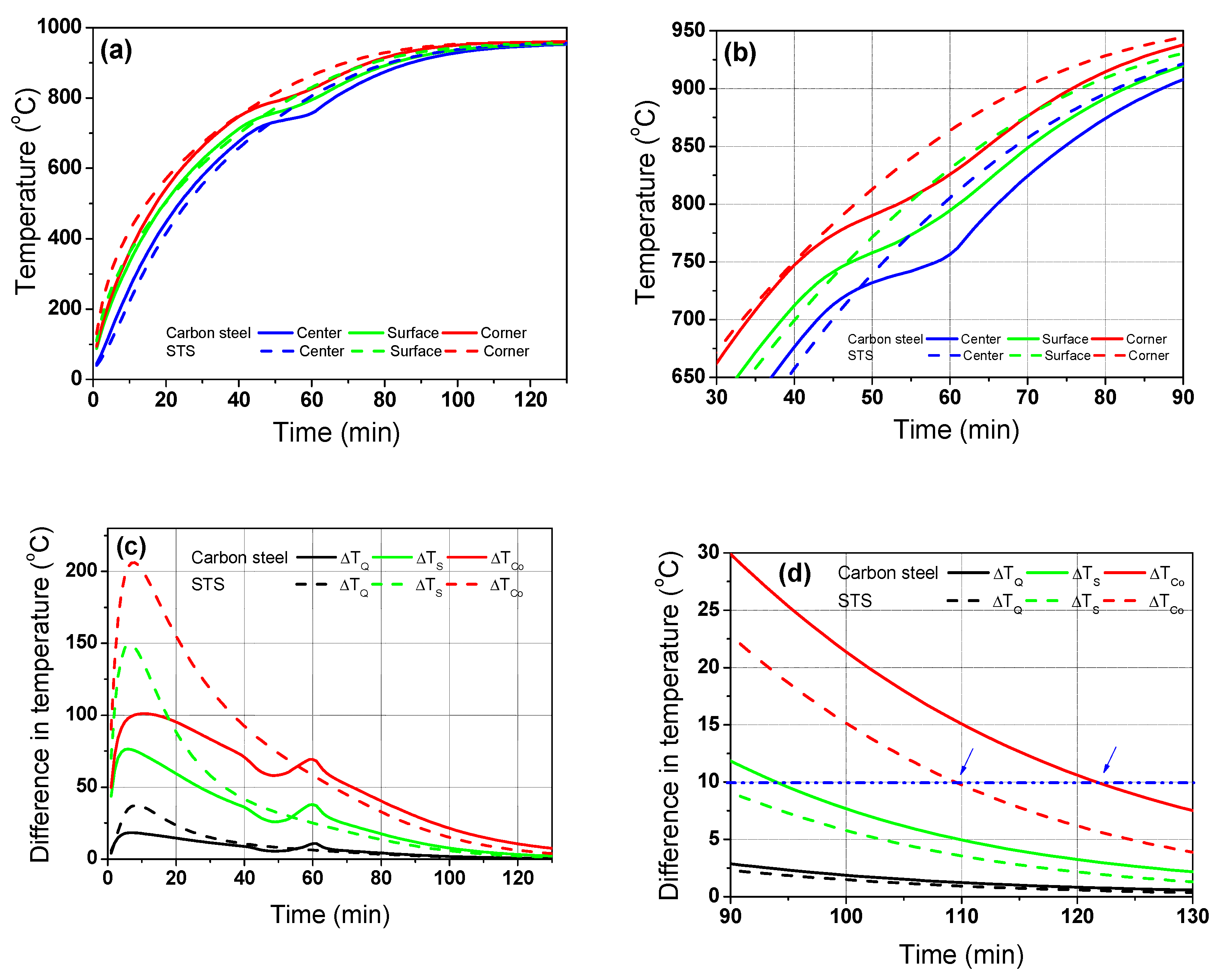

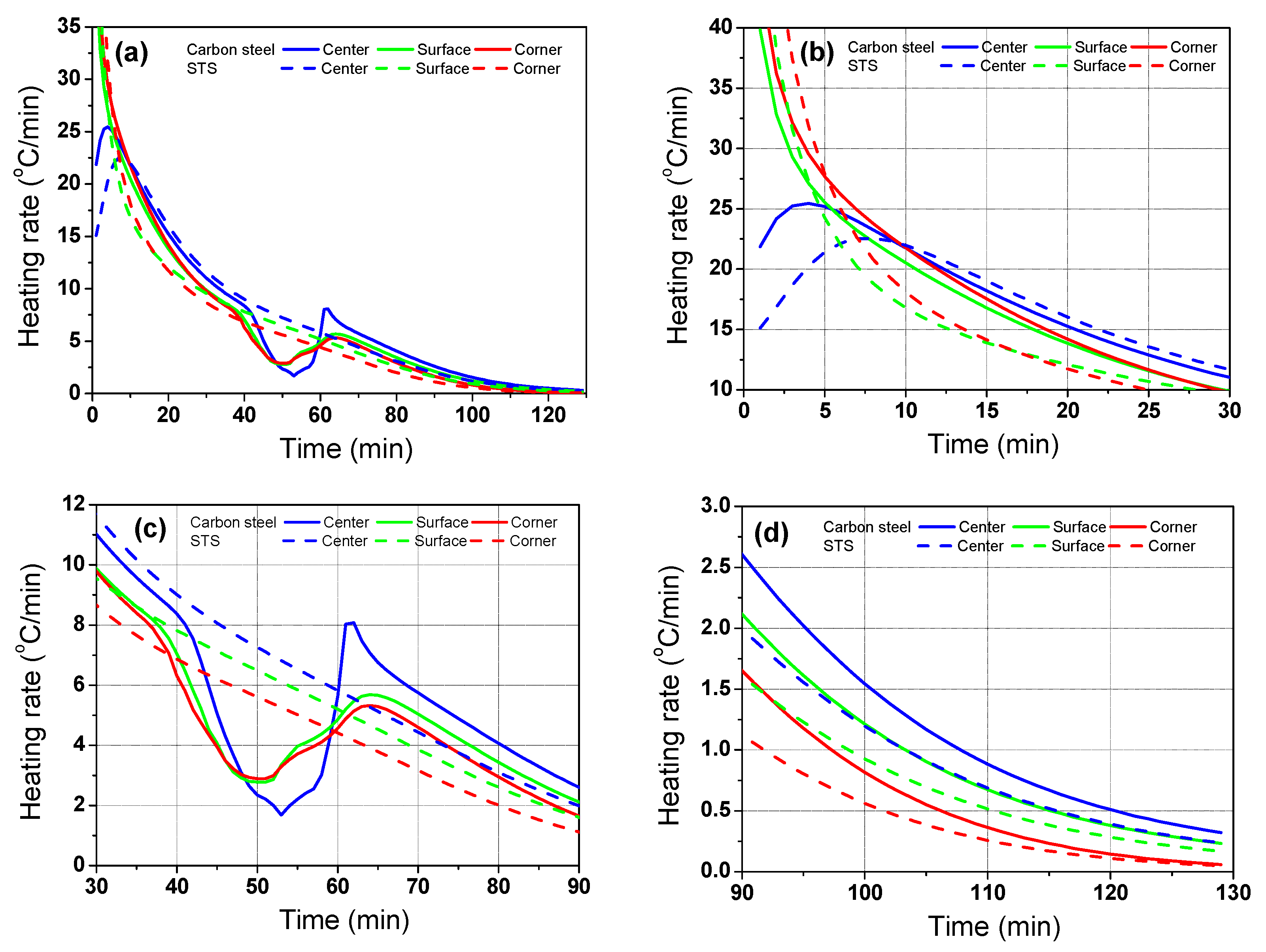

3.1. Influence of Thermal Conductivity

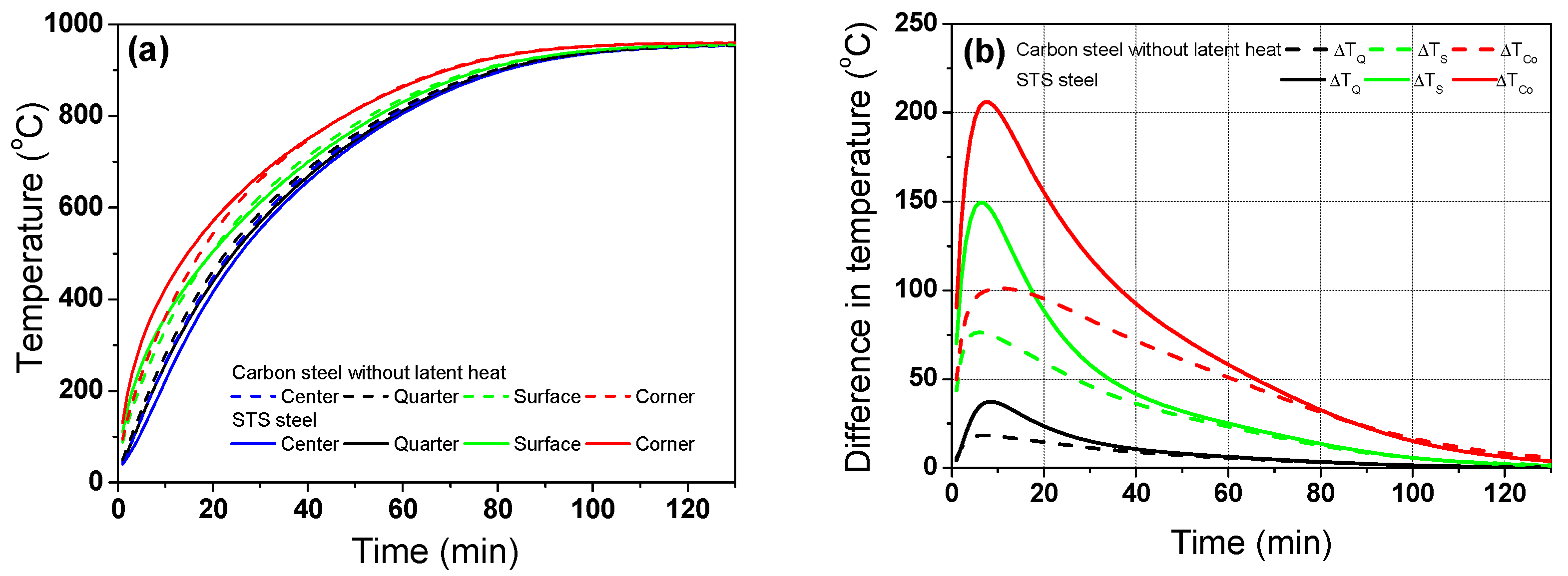

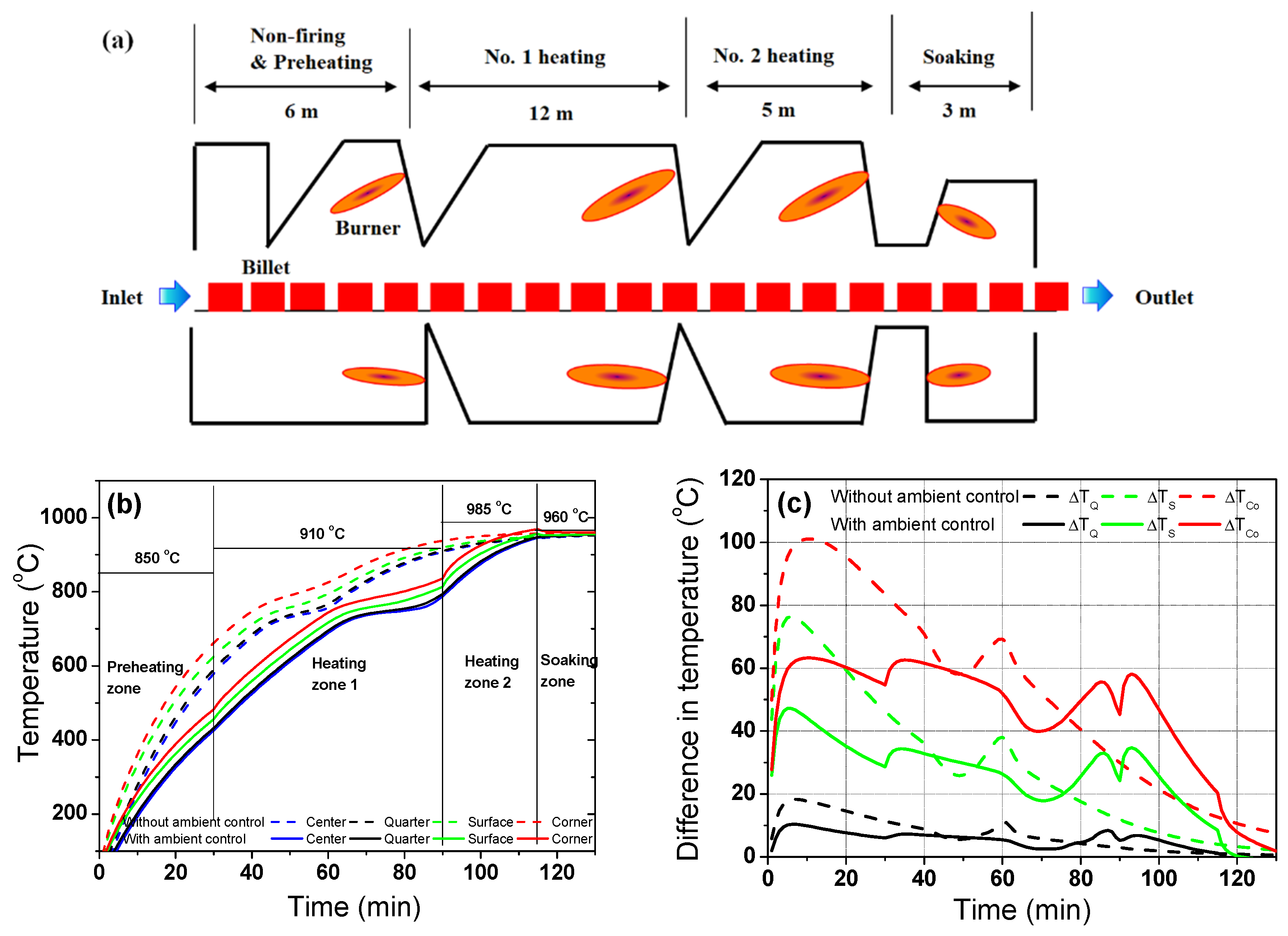

3.2. Comparison of Thermal Behaviors of Carbon Steel and STS

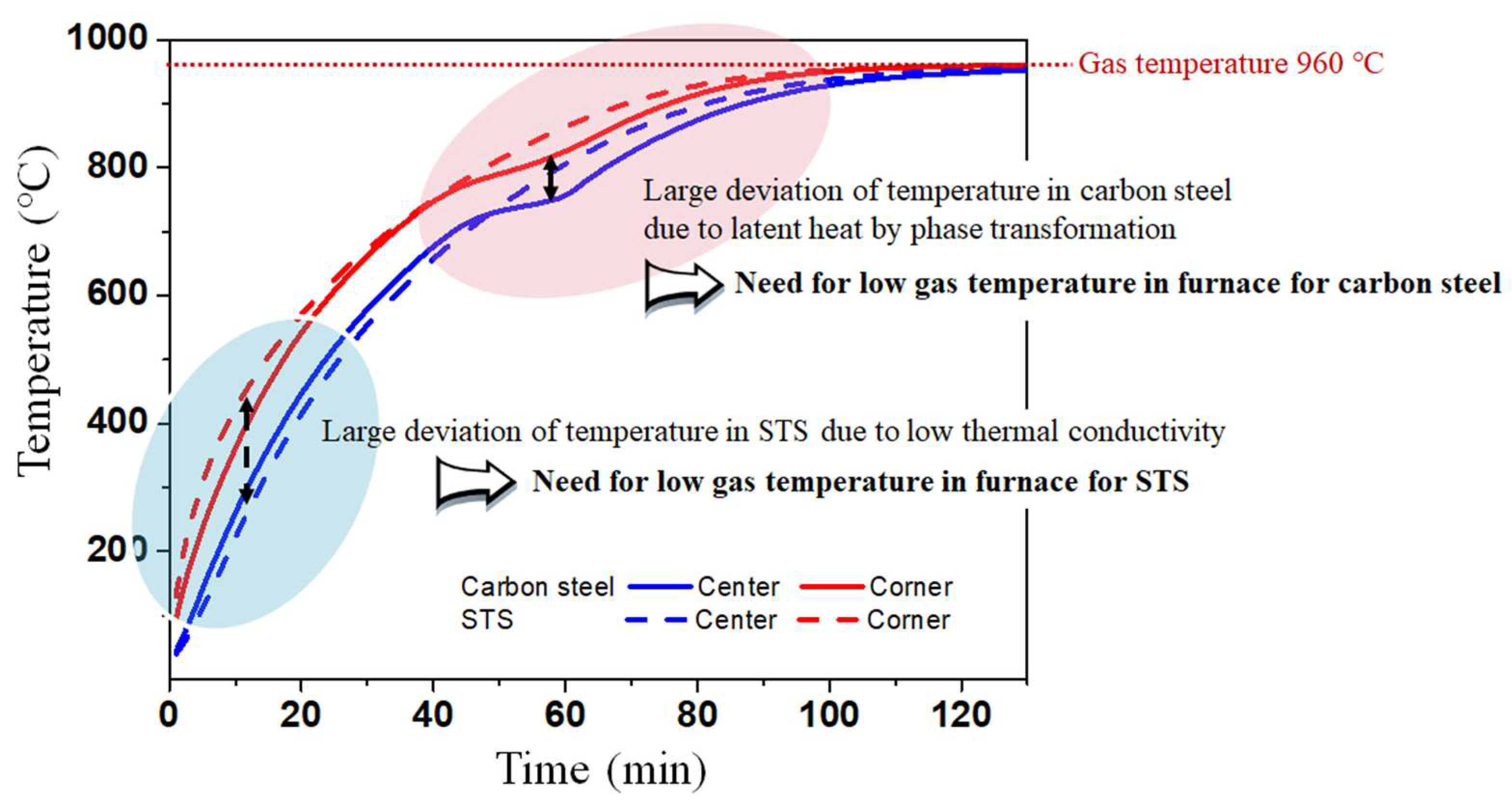

3.3. Suggestion for Gas Temperature Control in Industrial Reheating Furnace

4. Conclusions

- The thermal conductivity affected the thermal behavior of the billet in the initial stage of heating due to the high temperature difference between the surface of the billet and the gas in the reheating furnace. In this case, the heat flux from the gas to the billet was high, originating from the radiative heat transfer mechanism and resulting in a high Bi in this heating stage.

- A non-firing zone and/or a preheating zone with a low gas temperature are necessary to reduce the Bi of the billet, especially for the high-alloyed steels, including STSs, because the thermal conductivity of these steels was relatively low.

- The phase transformation of the carbon steels needs to occur in the primary heating zone, and this zone needs to have a relatively low temperature to reduce the temperature deviation or thermal stress in the billet.

- The heating pattern of the carbon steels and STSs in the reheating furnace should be designed differently considering the thermal conductivity and latent heat by phase transformation of the steels to obtain a high heating quality for the billet.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, G.; Wu, B.; Bai, D.; Wang, Y.; Bodnar, R.; Zhou, C. CFD modeling and validation of a dynamic slab heating process in an industrial walking beam reheating furnace. Appl. Therm. Eng. 2018, 132, 779–789. [Google Scholar] [CrossRef]

- Kim, M.Y. A heat transfer model for the analysis of transient heating of the slab in a direct-fired walking beam type reheating furnace. Int. J. Heat Mass Transf. 2007, 50, 3740–3748. [Google Scholar] [CrossRef]

- Luo, X.; Yang, Z. A new approach for estimation of total heat exchange factor in reheating furnace by solving an inverse heat conduction problem. Int. J. Heat Mass Transf. 2017, 112, 1062–1071. [Google Scholar] [CrossRef]

- Jang, Y.J.; Kim, S.W. An estimation of a billet temperature during reheating furnace operation. Int. J. Control Autom. 2007, 5, 43–50. [Google Scholar]

- Ji, W.; Li, G.; Wei, L.; Yi, Z. Modeling and determination of total heat exchange factor of regenerative reheating furnace based on instrumented slab trials. Case Stud. Therm. Eng. 2021, 24, 100838. [Google Scholar] [CrossRef]

- Özgür, A.; Uygun, Y.; Hütt, M.T. A review of planning and scheduling methods for hot rolling mills in steel production. Comput. Ind. Eng. 2021, 151, 106606. [Google Scholar] [CrossRef]

- Steinboeck, A.; Graichen, K.; Wild, D.; Kiefer, T.; Kugi, A. Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace. J. Process Control 2011, 21, 279–292. [Google Scholar] [CrossRef]

- Schwotzer, C.; Schnitzler, M.; Pfeifer, H. Low scale reheating of semi-finished metal products in furnaces with recuperative burners. Appl. Therm. Eng. 2018, 128, 586–594. [Google Scholar] [CrossRef]

- Alam, M.K.; Goetz, R.L.; Semiatin, S.L. Modeling of thermal stresses and thermal cracking during heating of large ingots. J. Manuf. Sci. Eng. 1996, 118, 235–243. [Google Scholar] [CrossRef]

- Huang, Y.H.; Wu, L.W.; Chen, C.H. Fracture prediction of electromagnetic silicon steel in reheating furnace. J. Therm. Stress. 2016, 39, 571–588. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, L.; Zayed, M.E.; Elsheikh, A.H.; Li, W.; Yan, Q.; Wang, J. Industrial reheating furnaces: A review of energy efficiency assessments, waste heat recovery potentials, heating process characteristics and perspectives for steel industry. Process Saf. Environ. Prot. 2021, 147, 1209–1228. [Google Scholar] [CrossRef]

- Okaniwa, K.; Noguchi, Y.; Ikeda, H.; Yakabe, M. Installation of New Reheating Furnaces for Wire Rod Mills. Nippon Steel Tech. Rep. 1992, 53, 83–90. [Google Scholar]

- Jaklič, A.; Vode, F.; Kolenko, T. Online simulation model of the slab-reheating process in a pusher-type furnace. Appl. Therm. Eng. 2007, 27, 1105–1114. [Google Scholar] [CrossRef]

- Han, S.H.; Chang, D.; Huh, C. Efficiency analysis of radiative slab heating in a walking-beam-type reheating furnace. Energy 2011, 36, 1265–1272. [Google Scholar] [CrossRef]

- Peet, M.J.; Hasan, H.S.; Bhadeshia, H. Prediction of thermal conductivity of steel. Int. J. Heat Mass Transf. 2011, 54, 2602–2608. [Google Scholar] [CrossRef]

- Hwang, J.K. Comparison of Temperature Distribution between TWIP and Plain Carbon Steels during Wire Drawing. Materials 2022, 15, 8696. [Google Scholar] [CrossRef]

- Gardner, L.; Insausti, K.T.; Ng, A.; Ashraf, M. Elevated temperature material properties of stainless steel alloys. J. Constr. Steel Res. 2010, 66, 634–647. [Google Scholar] [CrossRef]

- Faini, F.; Attanasio, A.; Ceretti, E. Experimental and FE analysis of void closure in hot rolling of stainless steel. J. Mater. Process. Technol. 2018, 259, 235–242. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, W.; Al-azzani, H. Assessment of thermal properties of various types of high-strength steels at elevated temperatures. Fire Saf. J. 2021, 122, 103348. [Google Scholar] [CrossRef]

- Li, H.; Zhao, G.; Niu, S.; Huang, C. FEM simulation of quenching process and experimental verification of simulation results. Mater. Sci. Eng. A 2007, 452–453, 705–714. [Google Scholar]

- Edalatpour, S.; Saboonchi, A.; Hassanpour, S. Effect of phase transformation latent heat on prediction accuracy of strip laminar cooling. J. Mater. Process. Technol. 2011, 211, 1776–1782. [Google Scholar] [CrossRef]

- Jung, M.; Kang, M.; Lee, Y.K. Finite-element simulation of quenching incorporating improved transformation kinetics in a plain medium-carbon steel. Acta Mater. 2012, 60, 525–536. [Google Scholar] [CrossRef]

- Hwang, J.K. Effect of latent heat by phase transformation on the thermal behavior of steel billet during heating. Materials 2023, 16, 7598. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.K.; Talukdar, P. Comparisons of different heat transfer models of a walking beam type reheat furnace. Int. Commun. Heat Mass Transf. 2013, 47, 20–26. [Google Scholar] [CrossRef]

- Wikström, P.; Yang, W.; Blasiak, W. The influence of oxide scale on heat transfer during reheating of steel. Steel Res. Int. 2008, 79, 765–775. [Google Scholar] [CrossRef]

- Mayr, B.; Prieler, R.; Demuth, M.; Moderer, L.; Hochenauer, C. CFD analysis of a pusher type reheating furnace and the billet heating characteristic. Appl. Therm. Eng. 2017, 115, 986–994. [Google Scholar] [CrossRef]

- García, A.M.; Colorado, A.F.; Obando, J.E.; Arrieta, C.E.; Amell, A.A. Effect of the burner position on an austenitizing process in a walking-beam type reheating furnace. Appl. Therm. Eng. 2019, 153, 633–645. [Google Scholar] [CrossRef]

- Choi, I.R.; Chung, K.S.; Kim, D.H. Thermal and mechanical properties of high-strength structural steel HSA800 at elevated temperatures. Mater. Des. 2014, 63, 544–551. [Google Scholar] [CrossRef]

- Wang, K.Y.; Jin, Y.J.; Xu, M.J.; Chen, J.S.; Lu, H. Estimation of heat transfer coefficient and phase transformation latent heat by modified pattern search method. Int. Commun. Heat Mass Transf. 2015, 68, 14–19. [Google Scholar] [CrossRef]

- Emadi, A.; Saboonchi, A.; Taheri, M.; Hassanpour, S. Heating characteristics of billet in a walking hearth type reheating furnace. Appl. Therm. Eng. 2014, 63, 396–405. [Google Scholar] [CrossRef]

- Fakir, R.; Barka, N.; Brousseau, J. Case study of laser hardening process applied to 4340 steel cylindrical specimens using simulation and experimental validation. Case Stud. Therm. Eng. 2018, 11, 15–25. [Google Scholar]

- Mayrhofer, M.; Koller, M.; Seemann, P.; Prieler, R.; Hochenauer, C. CFD investigation of a vertical annealing furnace for stainless steel and non-ferrous alloys strips–A comparative study on air-staged & MILD combustion. Therm. Sci. Eng. Prog. 2022, 28, 101056. [Google Scholar]

- Casal, J.M.; Porteiro, J.; Míguez, J.L.; Vázquez, A. New methodology for CFD three-dimensional simulation of a walking beam type reheating furnace in steady state. Appl. Therm. Eng. 2015, 86, 69–80. [Google Scholar] [CrossRef]

- Hwang, J.K. Effect of Air Temperature on the Thermal Behavior and Mechanical Properties of Wire Rod Steel during Stelmor Cooling. ISIJ Int. 2022, 62, 2343–2354. [Google Scholar] [CrossRef]

- Steau, E.; Mahendran, M.; Poologanathan, K. Elevated temperature thermal properties of carbon steels used in cold-formed light gauge steel frame systems. J. Build. Eng. 2020, 28, 101074. [Google Scholar] [CrossRef]

- Yang, Z.; Luo, X. Optimal set values of zone modeling in the simulation of a walking beam type reheating furnace on the steady-state operating regime. Appl. Therm. Eng. 2016, 101, 191–201. [Google Scholar] [CrossRef]

- García, A.M.; Amell, A.A. A numerical analysis of the effect of heat recovery burners on the heat transfer and billet heating characteristics in a walking-beam type reheating furnace. Int. J. Heat Mass Transf. 2018, 127, 1208–1222. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Tayor & Francis: Boca Raton, FL, USA, 1980. [Google Scholar]

- Kirihara, K. Modernization and Introduction of New Technologies in The Wire Rod Mill at Kakogawa Works. SEAISI Q. J. 2009, 38, 23–29. [Google Scholar]

- Tan, C.K.; Jenkins, J.; Ward, J.; Broughton, J.; Heeley, A. Zone modelling of the thermal performances of a large-scale bloom reheating furnace. Appl. Therm. Eng. 2013, 50, 1111–1118. [Google Scholar] [CrossRef]

- Lee, D.E.; Kim, M.Y. Optimum residence time for steel productivity and energy saving in a hot rolled reheating furnace. J. Mech. Sci. Technol. 2013, 27, 2869–2877. [Google Scholar] [CrossRef]

- Jang, J.Y.; Huang, J.B. Optimization of a slab heating pattern for minimum energy consumption in a walking-beam type reheating furnace. Appl. Therm. Eng. 2015, 85, 313–321. [Google Scholar] [CrossRef]

- Jahazi, M.; Egbali, B. The influence of hot rolling parameters on the microstructure and mechanical properties of an ultra-high strength steel. J. Mater. Process. Technol. 2000, 103, 276–279. [Google Scholar] [CrossRef]

- Xu, J.; Li, B.; Qi, F.; Rong, W.; Kuang, S. Modeling effects of skid buttons and dislocated skids on the heating quality of slabs in an industrial walking-beam reheating furnace. Int. J. Heat Mass Transf. 2023, 211, 124245. [Google Scholar] [CrossRef]

- Dubey, S.K.; Srinivasan, P. Development of three dimensional transient numerical heat conduction model with growth of oxide scale for steel billet reheat simulation. Int. J. Therm. Sci. 2014, 84, 214–227. [Google Scholar] [CrossRef]

| Steels | Zone in Reheating Furnace (Tg, °C) | ||||

|---|---|---|---|---|---|

| Non-Firing | Preheating | No. 1 Heating | No. 2 Heating | Soaking | |

| Carbon steels | Not necessary | 850 | 910 | 985 | 960 |

| Stainless steels | 750 | 850 | 960 | 990 | 960 |

| Zone in Furnace | Design Factor | Strategy for Gas Temperature Control |

|---|---|---|

| Non-firing | • Thermal conductivity • Billet cross-section size (mass effect) • Initial billet temperature (cold or hot charge) • Thermal stress including high-temperature toughness of billet | • Necessary for the billet with large size and/or high alloyed steels including STS |

| Preheating | • Low temperature for high-alloyed steels including STS | |

| Primary heating (No. 1 heating) | • Latent heat by phase transformation • Volume expansion by structural change • Thermal stress including the high-temperature toughness of the billet | • Low temperature for carbon steels with phase transformation |

| Secondary heating (No. 2 heating) | • Temperature uniformity of the discharged billet and residence time • Dissolution of carbides or nitrides • Formation of oxidation scale and decarburization | • Billet target temperature + (10~60 °C) |

| Soaking | • Target temperature of billet • Dissolution of carbides or nitrides • Grain size • Skid button effect • Formation of oxidation scale and decarburization | • Billet target temperature |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.-K. Comparison of Thermal Behaviors of Carbon and Stainless Steel Billets during the Heating Process. Materials 2024, 17, 183. https://doi.org/10.3390/ma17010183

Hwang J-K. Comparison of Thermal Behaviors of Carbon and Stainless Steel Billets during the Heating Process. Materials. 2024; 17(1):183. https://doi.org/10.3390/ma17010183

Chicago/Turabian StyleHwang, Joong-Ki. 2024. "Comparison of Thermal Behaviors of Carbon and Stainless Steel Billets during the Heating Process" Materials 17, no. 1: 183. https://doi.org/10.3390/ma17010183

APA StyleHwang, J.-K. (2024). Comparison of Thermal Behaviors of Carbon and Stainless Steel Billets during the Heating Process. Materials, 17(1), 183. https://doi.org/10.3390/ma17010183