Improving the Surface Integrity of 316L Steel in the Context of Bioimplant Applications

Abstract

1. Introduction

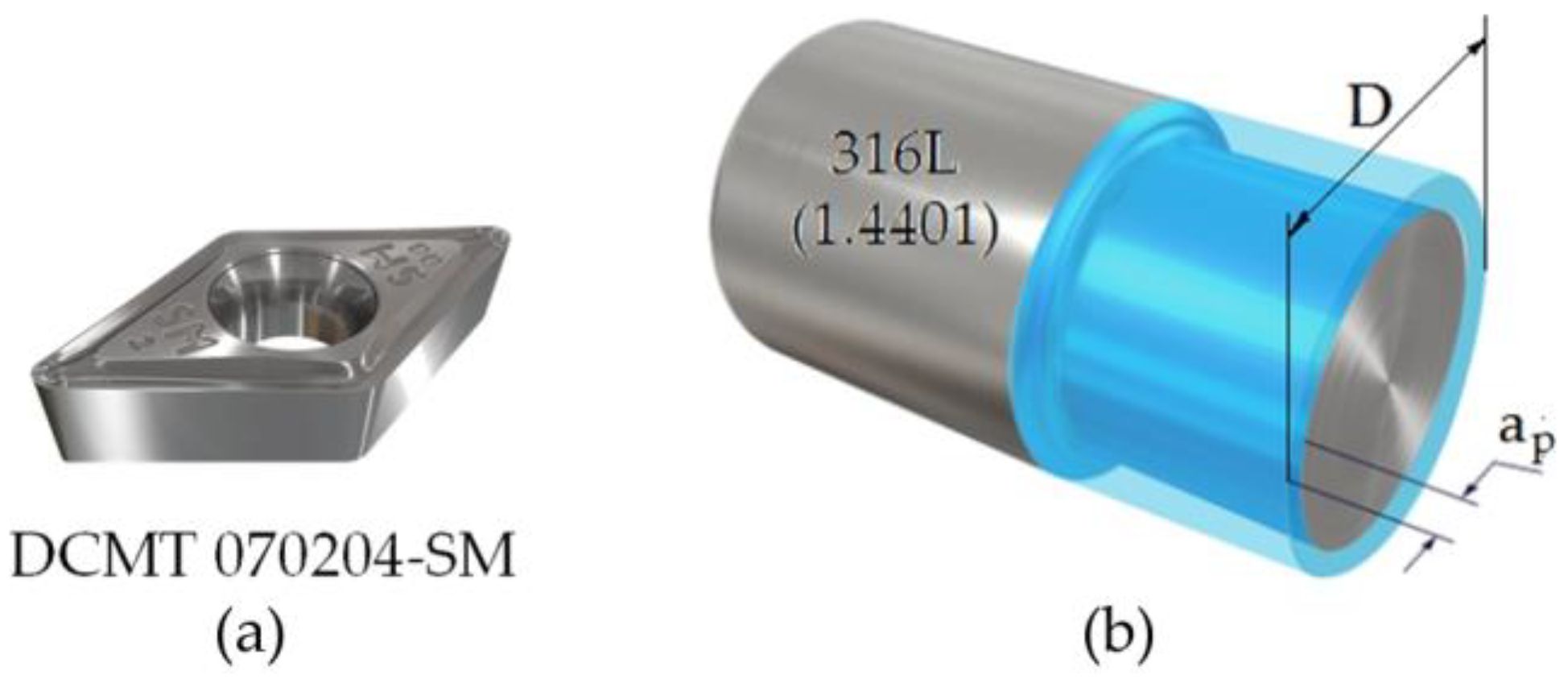

2. Methods and Materials

2.1. Materials

2.2. Cutting Procedure

3. Results

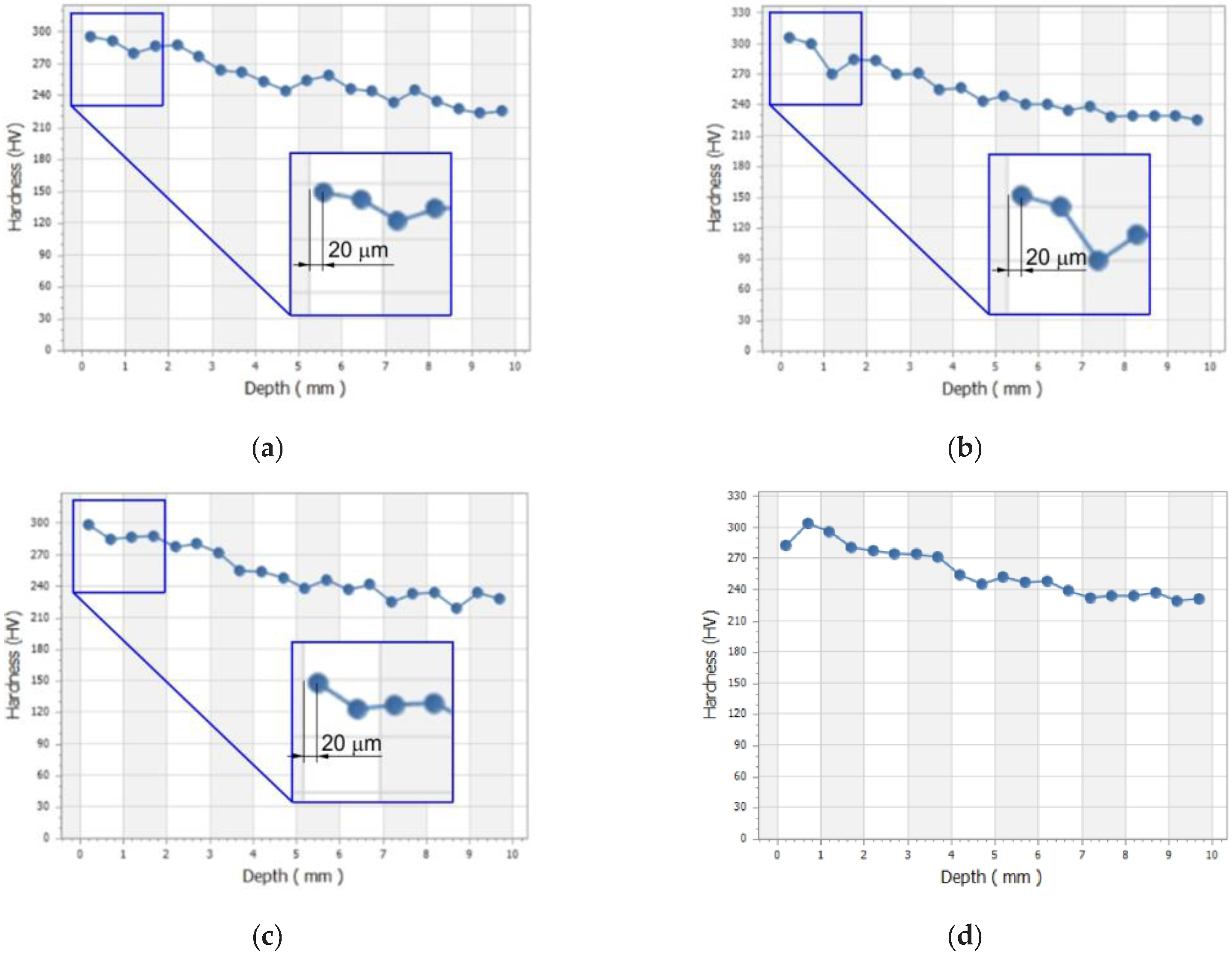

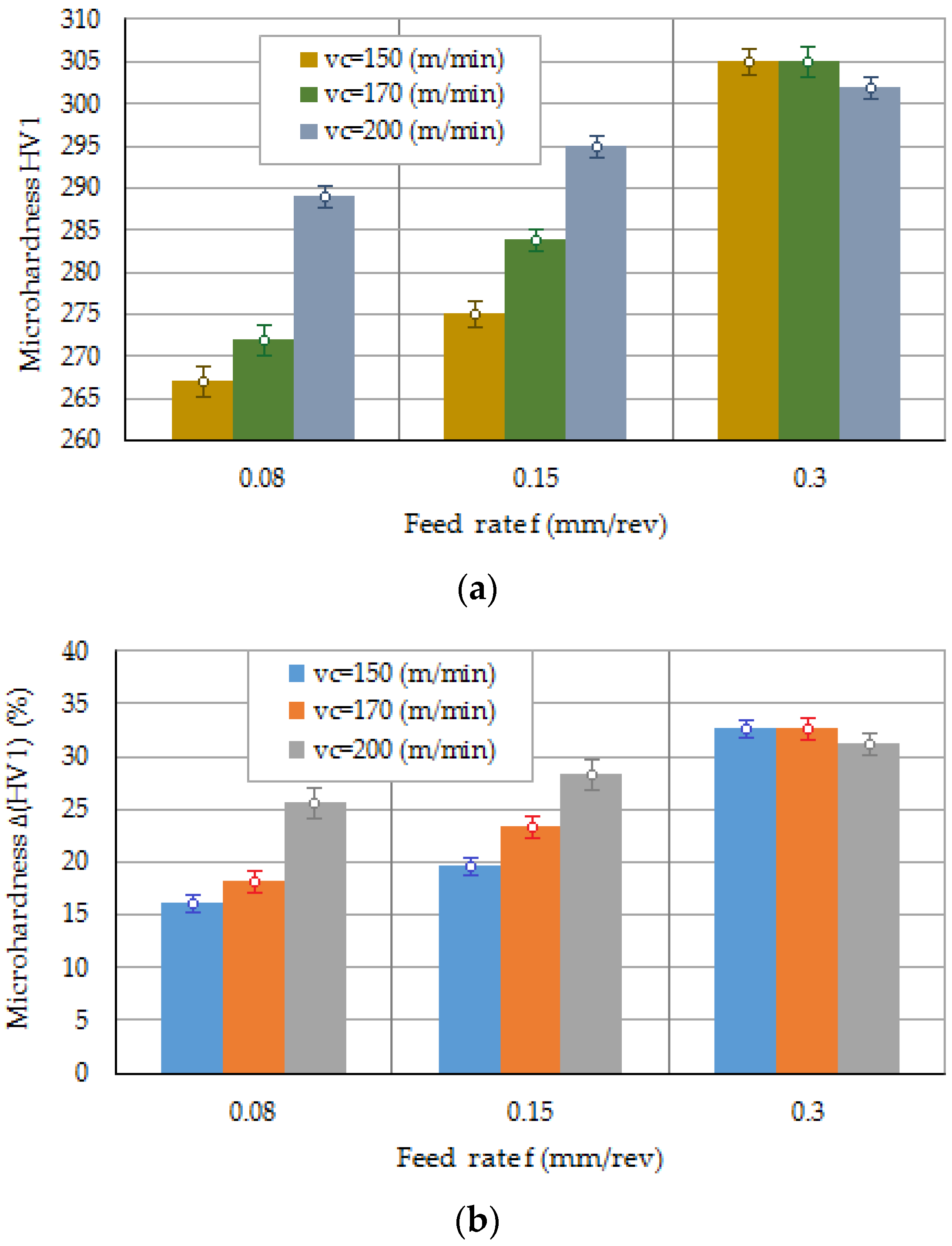

3.1. Hardness

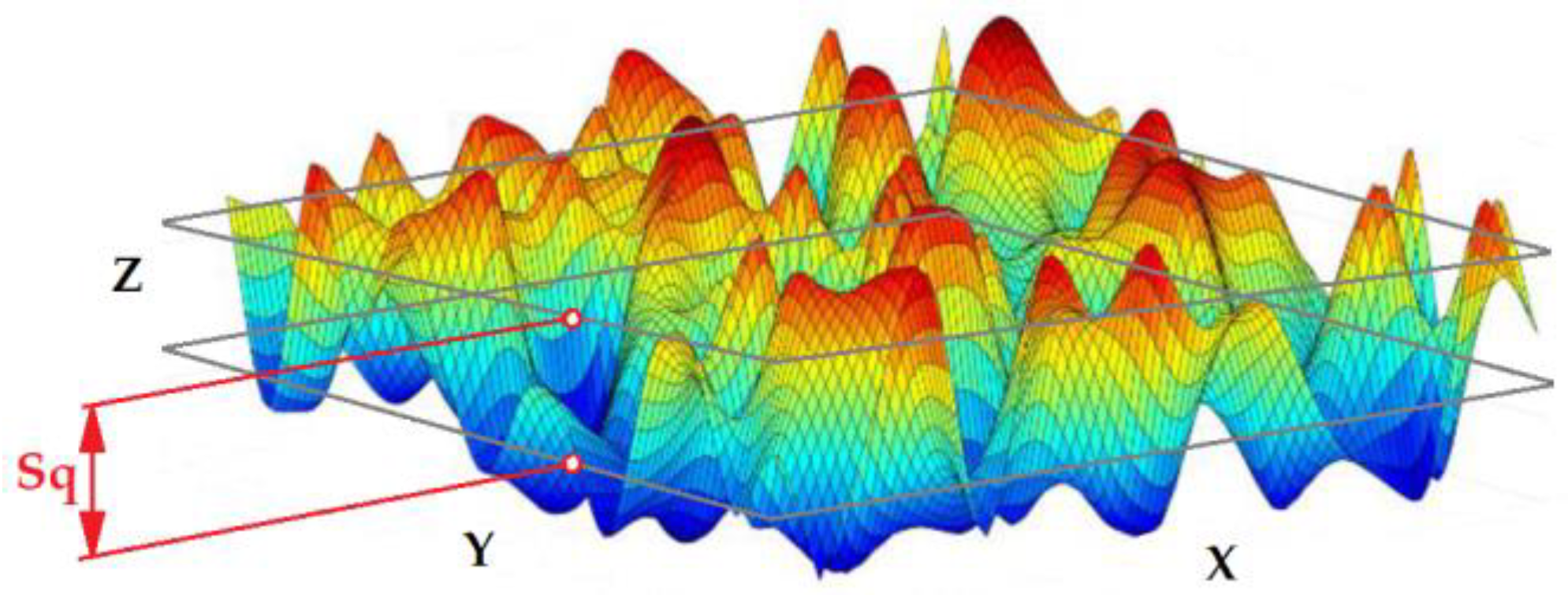

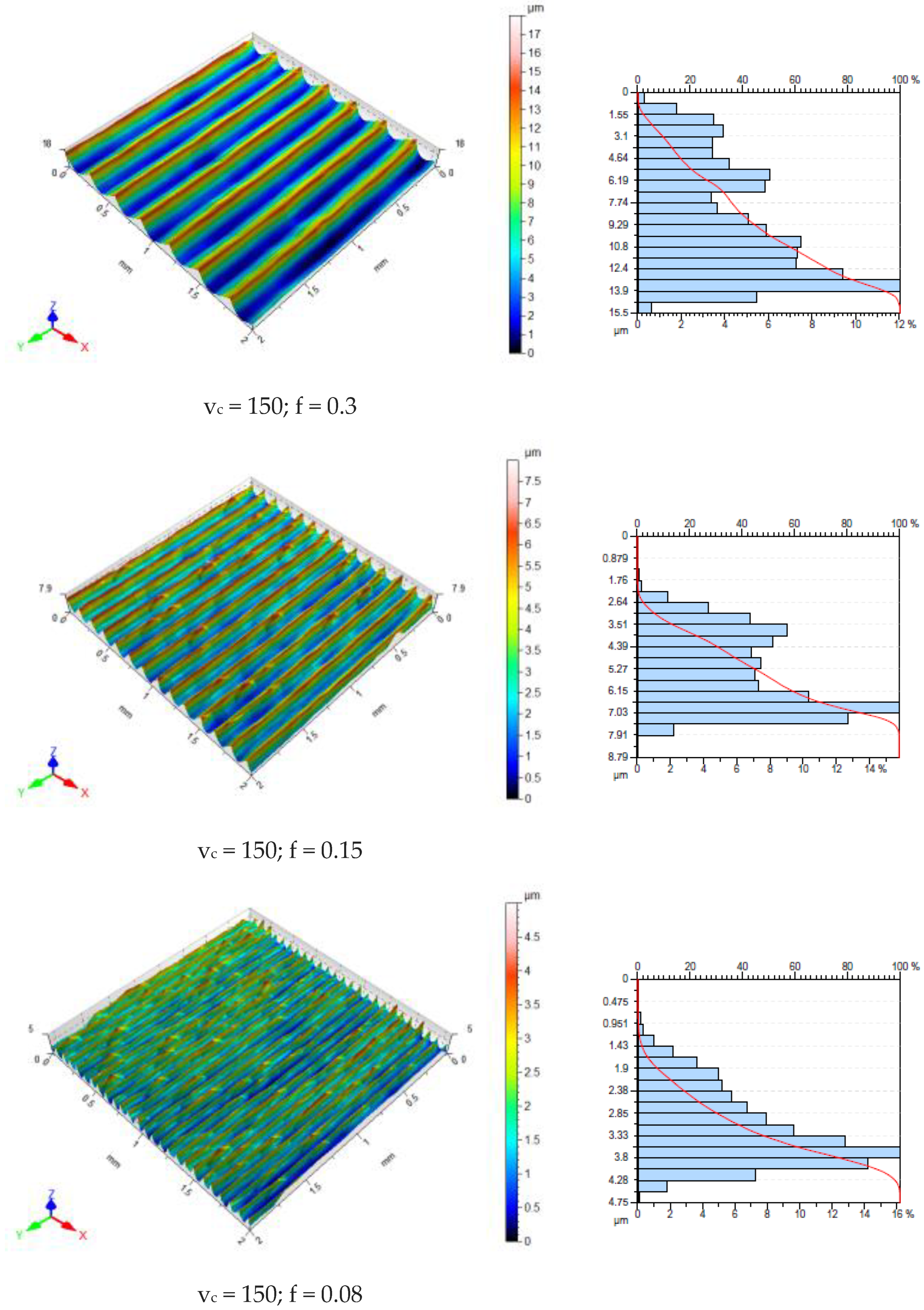

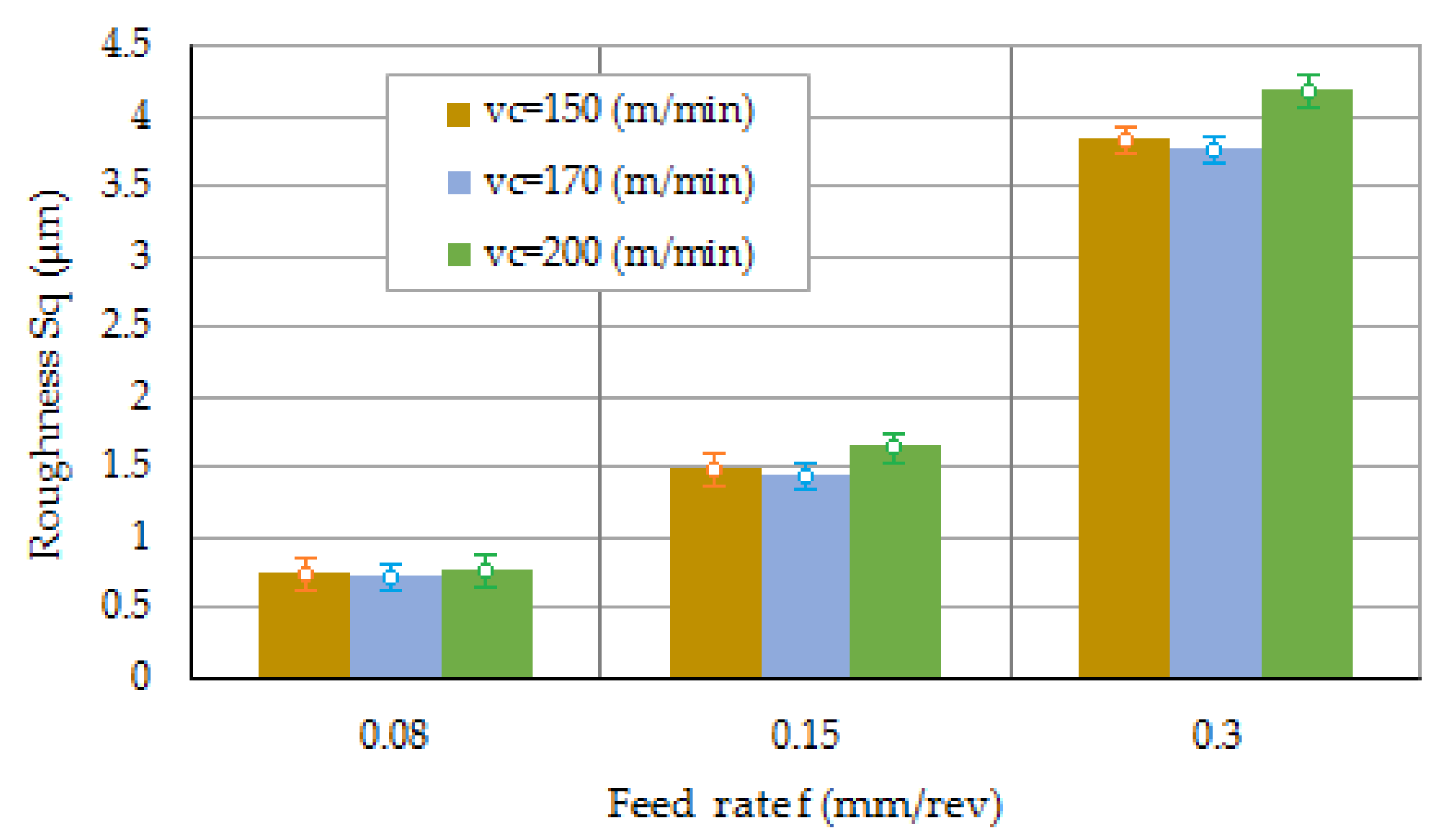

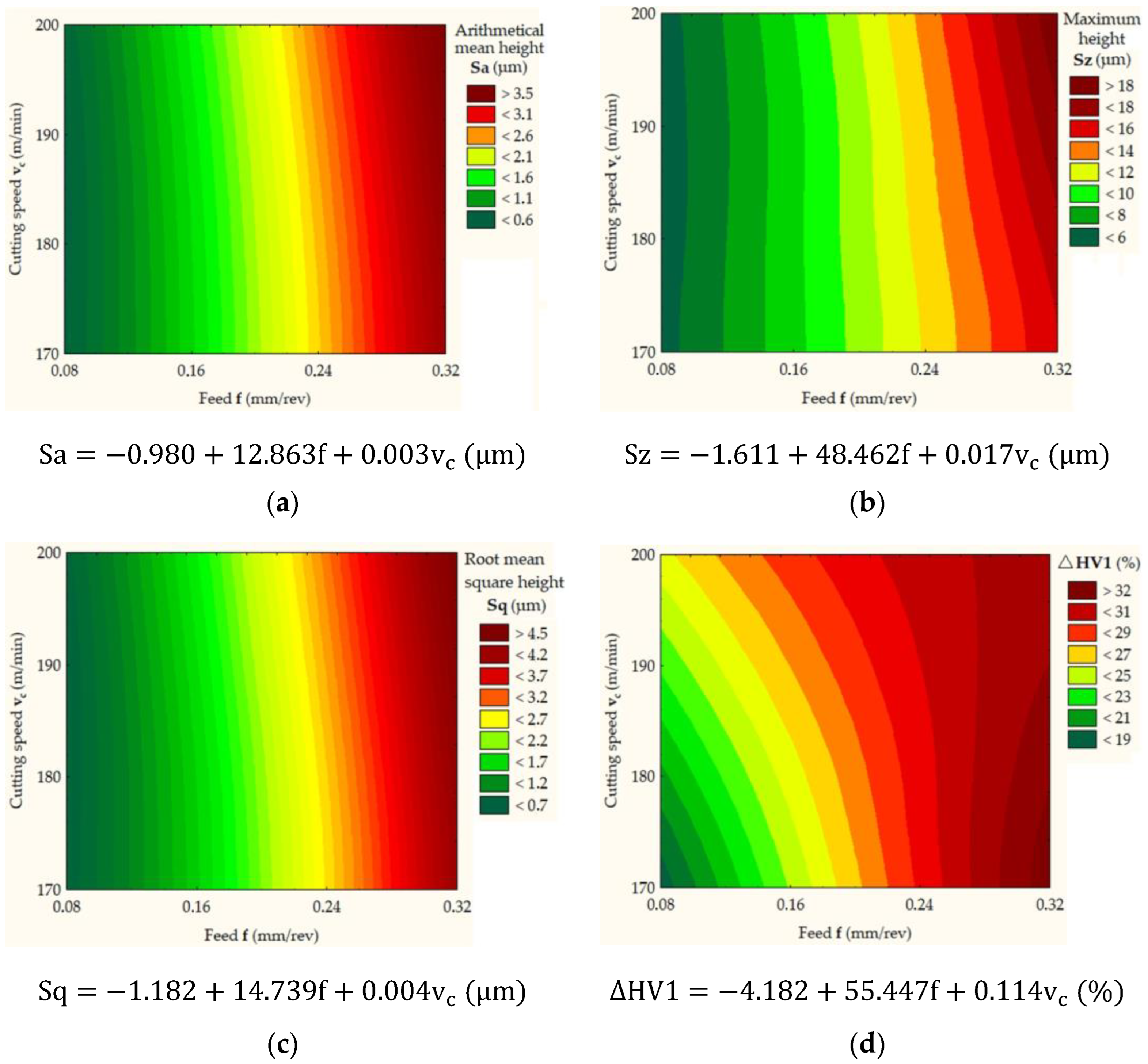

3.2. Surface Topography Analysis

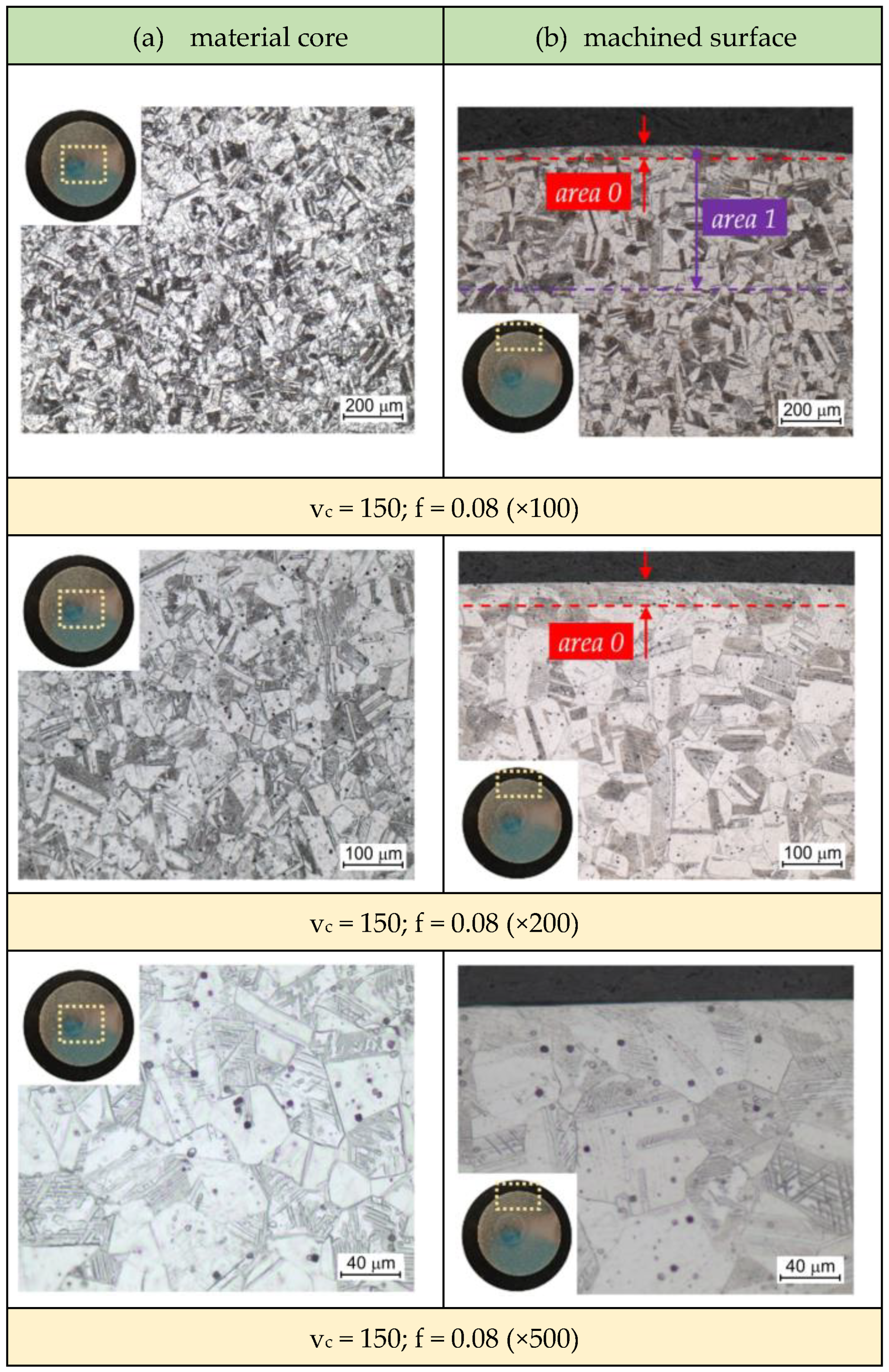

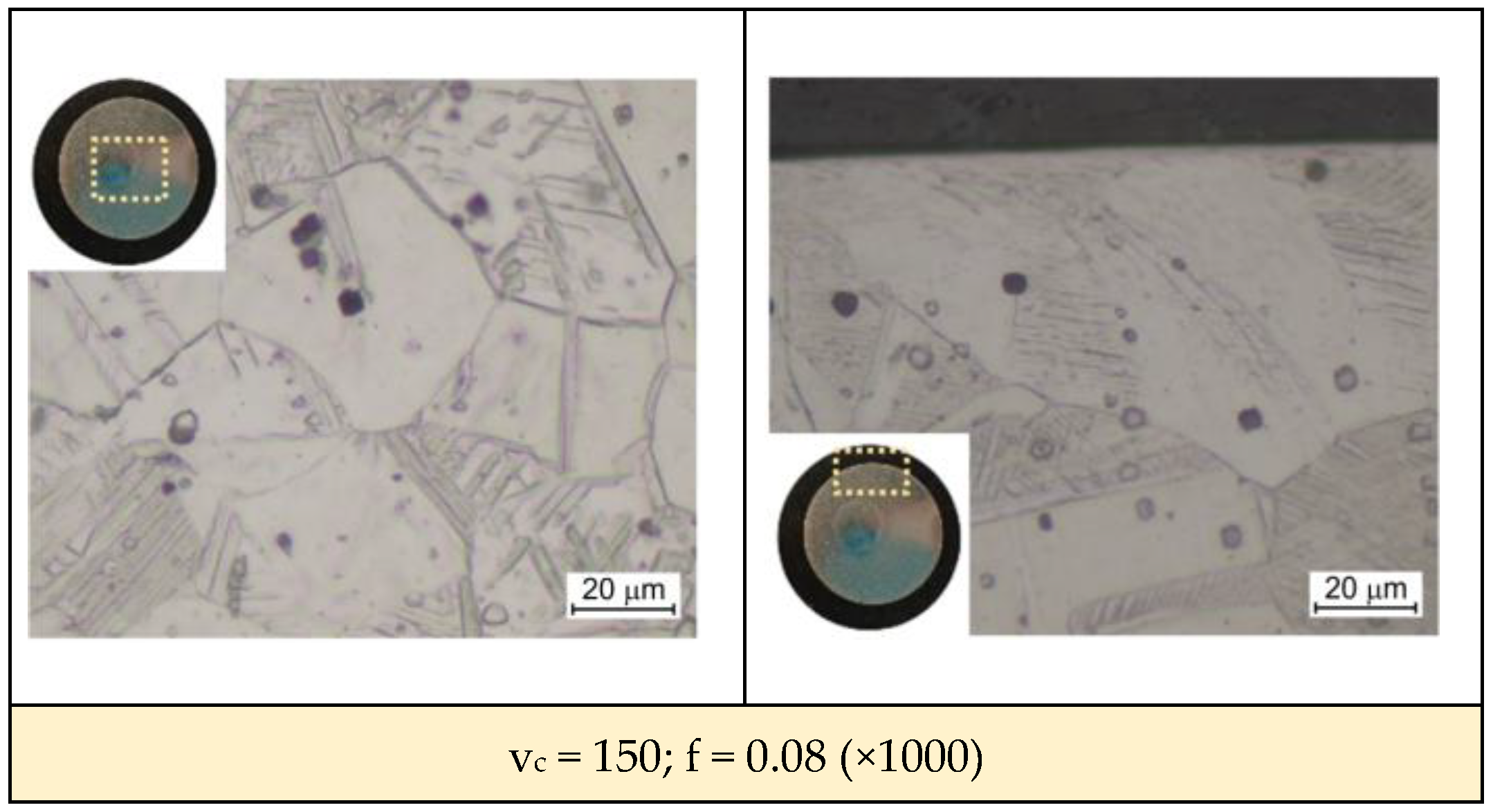

3.3. Optical Microscopy

3.4. Statistical Analysis

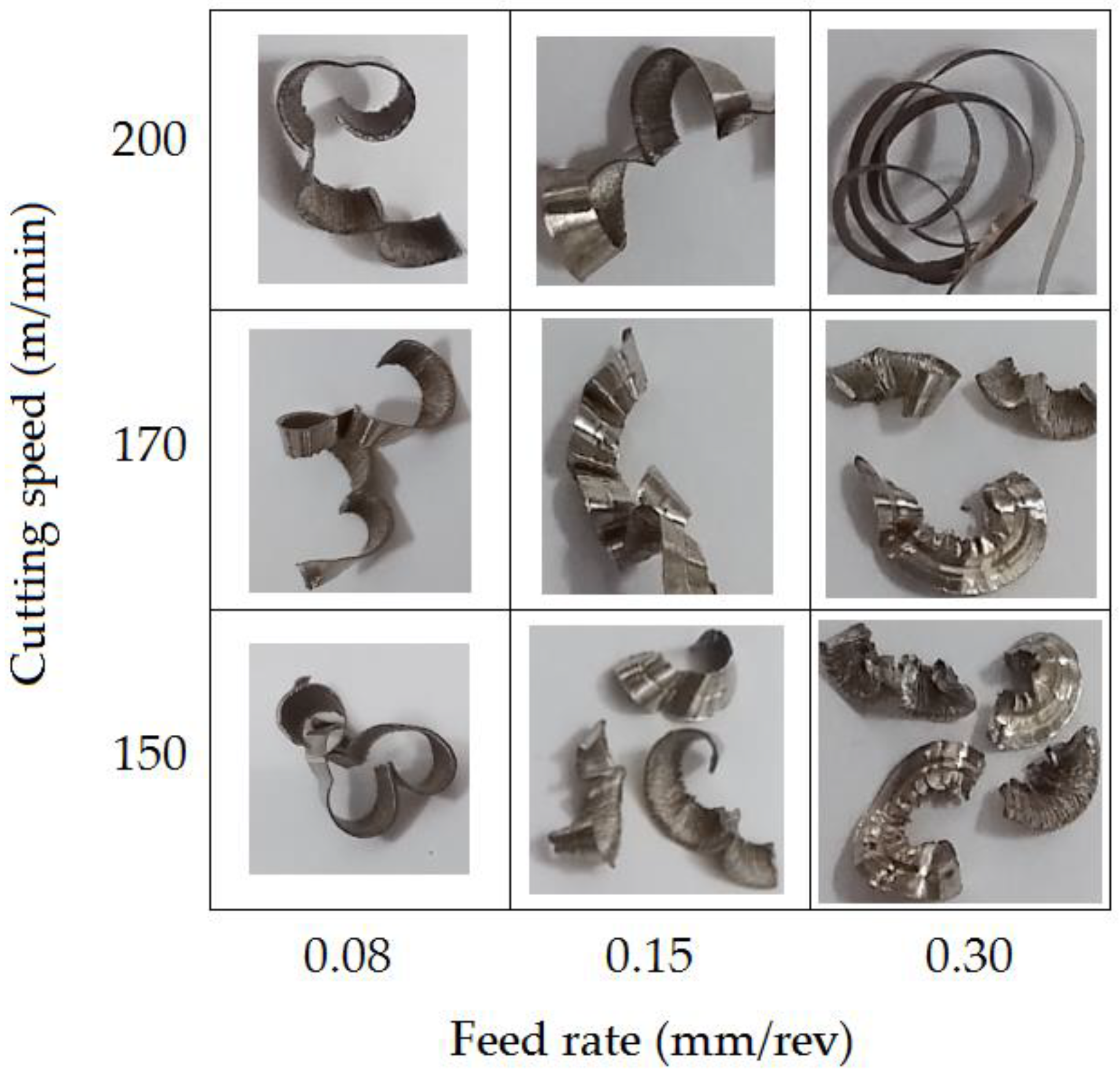

3.5. Chip Forms

4. Conclusions

- Based on the analysis of variance, the feed rate was the most important cutting parameter affecting the parameters Sa, Sz and Sq of the machined surface.

- A statistically significant effect of the CS and the FR on the parameter ΔHV1 was observed.

- The maximum value of hardness is reached at a depth of 20 μm and decreases with the depth of measurement. It was also noted that at a depth of up to 240 μm, the maximum hardness of 270–305 HV1 was reached, hence the height of the machining impact zone can be determined, which is approximately 240 μm for almost all machining conditions.

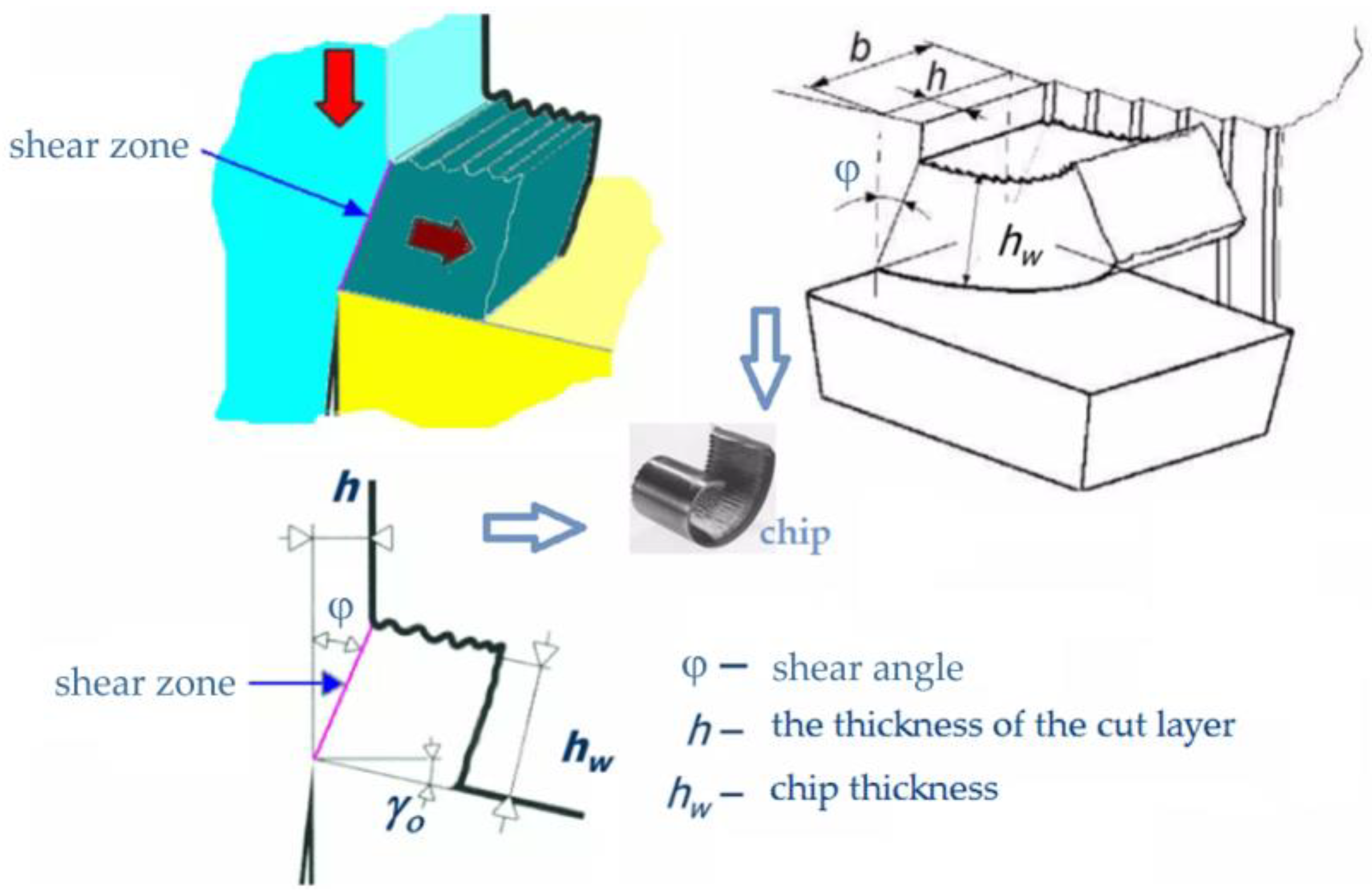

- The FR affects the cutting ratio significantly, while the influence of the CS is insignificant.

- The cutting ratio Λh has a significant impact on the grain size increase.

- Decreasing the CS from 200 m/min to 150 m/min resulted in decreasing the average grain size from 52 μm to approximately 31 μm.

- Machined surfaces are characterized by mean roughness in the range of 0.73–4.19 μm.

- The evolution of the microstructure is correlated with the change in the value of the cutting speed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saini, M.; Sing, Y.; Arora, P.; Arora, V.; Jain, K. Implant biomaterials: A comprehensive review. World J. Clin. Cases 2015, 3, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Majumdar, J.D.; Kumar, A.; Pityana, S.; Manna, I. Laser surface melting of AISI 316L stainless steel for bio-implant applications. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2018, 88, 387–403. [Google Scholar] [CrossRef]

- Barber, C.C.; Burnham, M.; Ojameruaye, O.; McKee, M.D. A systematic review of the use of titanium versus stainless steel implants for fracture fixation. OTA Int. 2021, 4, e138. [Google Scholar] [CrossRef] [PubMed]

- Marcomini, J.B.; Baptista, C.A.; Pascon, J.P.; Teixeira, R.L.; Reis, F.P. Investigation of a fatigue failure in a stainless steel femoral plate. J. Mech. Behav. Biomed. Mater. 2014, 38, 52–58. [Google Scholar] [CrossRef]

- Krasicka-Cydzik, E.; Mstowski, J.; Ciupik, F.L. Materiały Implantowe: Stal a Stopy tytanu. Rozwój Technik Operacyjnego Leczenia Kręgosłupa. Available online: https://lfc.com.pl/wp-content/uploads/2016/08/materialy-implantowe.pdf (accessed on 13 April 2023).

- Ali, S.; Rani, A.M.A.; Mufti, R.A.; Azam, F.I.; Hastuty, S.; Baig, Z.; Hussain, M.; Shehzad, N. The influence of nitrogen absorption on microstructure, properties and cytotoxicity assessment of 316L stainless steel alloy reinforced with boron and niobium. Processing 2019, 7, 506. [Google Scholar] [CrossRef]

- Niinomi, M.; Makai, M. Biomedical Implant Devices Fabricated from Low Young’s Modulus Titanium Alloys Demonstrating High Mechanical Biocompatibility. Available online: https://www.sigmaaldrich.com/PL/pl/technical-documents/technical-article/materials-science-and-engineering/tissue-engineering/biomedical-implant-devices (accessed on 13 April 2023).

- Talha, M.; Behera, C.; Sinha, O.P. A review on nickel-free nitrogen containing austenitic stainless steels for biomedical applications. Mater. Sci. Eng. C 2013, 33, 3563–3575. [Google Scholar] [CrossRef]

- Ali, S.; Irfan, M.; Niazi, U.M.; Rani, A.M.A.; Rashedi, A.; Rahman, S.; Khan, M.K.A.; Alsaiari, M.A.; Legutko, S.; Petrů, J.; et al. Microstructure and Mechanical Properties of Modified 316 L Stainless Steel Alloy for Biomedical Applications Using Powder Metallurgy. Materials 2022, 15, 2822. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Hu, Y.; Wang, S. Quantitative studies of machining-induced microstructure alteration and plastic deformation in aisi 316 stainless steel using EBSD. J. Mater. Eng. Perform. 2018, 27, 434–446. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Brinksmeier, E.; M’saoubi, R.; Aspinwall, D.K.; Outeiro, J.C.; Meyer, D.; Umbrello, D.; Jayal, A.D. Surface integrity in material removal processes: Recent advances. CIRP Ann. 2011, 60, 603–626. [Google Scholar]

- Rech, J.; Hamdi, H.; Valette, S. Workpiece surface integrity. In Machining-Fundamentals and Recent Advances; Davim, J.P., Ed.; Springer: London, UK, 2008; pp. 59–96. [Google Scholar]

- M’Saoubi, R.; Outeiro, J.C.; Chandrasekaran, H.; Dillon, O.W., Jr.; Jawahir, I.S. A review of surface integrity in machining and its impact on functional performance and life of machined products. Int. J. Sustain. Manuf. 2008, 1, 203. [Google Scholar] [CrossRef]

- Chomienne, V.; Verdu, C.; Rech, J.; Valiorgue, F. Influence of surface integrity of 15-5PH on the fatigue life. Procedia Eng. 2013, 66, 274–281. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Herbert, C.; Hardy, M.; Salmon, P. Surface integrity of nickel-based alloys subjected to severe plastic deformation by abusive drilling. CIRP Ann. 2014, 63, 61–64. [Google Scholar] [CrossRef]

- Maurotto, A.; Tsivoulas, D.; Gu, Y.; Burke, M.G. Effects of machining abuse on the surface properties of AISI 316L stainless steel. Int. J. Press. Vessel. Pip. 2017, 151, 35–44. [Google Scholar] [CrossRef]

- Javidi, A.; Rieger, U.; Eichlseder, W. The effect of machining on the surface integrity and fatigue life. Int. J. Fatigue 2008, 30, 2050–2055. [Google Scholar] [CrossRef]

- Abellán-Nebot, J.V.; Siller, H.R.; Vila, C.; Rodríguez, C.A. An experimental study of process variables in turning operations of Ti–6Al–4V and Cr–Co spherical prostheses. Int. J. Adv. Manuf. Technol. 2012, 63, 887–902. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B.; Ge, Q.; Vedani, M.; Wu, W.; Migliavacca, F.; Petrini, L.; Biffi, C.A.; Bestetti, M. Biodegradable magnesium coronary stents: Material, design and fabrication. Int. J. Comput. Integr. Manuf. 2014, 27, 936–945. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Smith, C.; Sankar, J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014, 10, 4561–4573. [Google Scholar] [CrossRef]

- Ahirwar, H.; Zhou, Y.; Mahapatra, C.; Ramakrishna, S.; Kumar, P.; Nanda, H.S. Materials for Orthopedic Bioimplants: Modulating Degradation and Surface Modification Using Integrated Nanomaterials. Coatings 2020, 10, 264. [Google Scholar] [CrossRef]

- Goutham, M.V.P. A review on suface coatings on 316 L stainless steel to improve biomedical properties. Int. J. New Innov. Eng. Technol. 2015, 4, 1–8. [Google Scholar]

- Odedeyi, P.B.; Abou-El-Hossein, K.; Liman, M. An experimental study of flank wear in the end milling of AISI 316 stainless steel with coated carbide inserts. J. Phys.-Conf. Proc. 2017, 843, 012058. [Google Scholar] [CrossRef]

- Shalabi, M.M. Implant surface roughness and bone healing: A systematic review. J. Dent. Res. 2006, 85, 496–500. [Google Scholar] [CrossRef] [PubMed]

- Rønold, H.J.; Lyngstadaas, S.P.; Ellingsen, J.E. Analysing the optimal value for titanium implants roughness in bone attachment using a tensile test. Biomaterials 2003, 24, 4559–4564. [Google Scholar] [CrossRef] [PubMed]

- Murray, D.; Rae, T.; Rushton, N. The influence of the surface energy and roughness of implants on bone resorption. J. Bone Jt. Surg. Br. 1989, 71, 632–637. [Google Scholar] [CrossRef] [PubMed]

- Kadi, R.K. Optimization of dry turning parameters on surface roughness and hardness of austenitic stainless steel (AISI 316) by Taguchi technique. J. Eng. Fundam. 2015, 2, 30–41. [Google Scholar] [CrossRef]

- Ali, A.M.; Hamidon, N.E.; Zaki, N.K.M.; Mokhtar, S.; Azhar, A.Z.A.; Bahar, R.; Ahmad, Z.A. The effect of cutting parameters on the performance of ZTA-MgO cutting tool. IOP Conf. Ser. Mater. Sci. Eng. 2018, 290, 012072. [Google Scholar] [CrossRef]

- Tamayo, Y.M.; Reyna, R.F.B.; Bustamante, R.J.L.; Hernández, Y.Z.; Cedeño, K.M.L.; Herrera, H.C.T. Comparison of two methods for predicting surface roughness in turning stainless steel AISI 316L. Ingeniare. Rev. Chil. De Ing. 2018, 26, 56–58. [Google Scholar]

- Basmaci, G. Optimization of Machining Parameters for the Turning Process of AISI 316 L Stainless Steel and Taguchi Design. Acta Phys. Polonica A 2018, 134, 260–264. [Google Scholar] [CrossRef]

- Tekiner, Z.; Yeşilyurt, S. Investigation of the cutting parameters depending on process sound during turning of AISI 304 austenitic stainless steel. Mater. Des. 2004, 25, 507–513. [Google Scholar] [CrossRef]

- Toggui, Y.; Belhadi, S.; Mechraoui, S.E.; Uysal, A.; Yallese, M.A.; Temmar, M. Multi-objective optimization of turning parameters for targeting surface roughness and maximizing material removal rate in dry turning of AISI 316L with PVD-coated cermet insert. SN Appl. Sci. 2020, 2, 1360. [Google Scholar] [CrossRef]

- Nur, R.; Noordin, M.Y.; Izman, S.; Kurniawn, D. Machining parameters effect in dry turning of AISI 316L stainless steel using coated carbide tools. J. Process Mech. Eng. 2017, 231, 676–683. [Google Scholar] [CrossRef]

- Ay, M. Effect of cutting parameters on surface roughness, tool temperature and vibration in turning of AISI 316 Ti stainless steel. Mater. Test. 2009, 61, 71–79. [Google Scholar] [CrossRef]

- Dambhare, S.G.; Kore, S.K.; Pathan, F.Z.; Kurne, S. Effect of Machining Parameters on Tool Wear and Surface Roughness in Dry and Wet Machining of AISI 316 Austenitic Stainless Steel by Taguchi Method. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 3292–3298. [Google Scholar] [CrossRef]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- Han, J.; Zheng, W.; Chen, Q.; Sun, J.; Xu, S. Study on Size Effect of Surface Roughness Based on the 3D Voronoi Model and Establishment of Roughness Prediction Model in Micro-Metal Forming. Coatings 2022, 12, 1659. [Google Scholar] [CrossRef]

- Devillez, A.; Coz, G.L.; Dominiak, S.; Dudzinski, D. Dry machining of Inconel 718 workpiece surface integrity. J. Mater. Process. Technol. 2011, 211, 1590–1598. [Google Scholar] [CrossRef]

- Amirtharaj Mosas, K.K.; Chandrasekar, A.R.; Dasan, A.; Pakseresht, A.; Galusek, D. Recent Advancements in Materials and Coatings for Biomedical Implants. Gels 2022, 8, 323. [Google Scholar] [CrossRef]

- Khan, S.A.; Ahmad, M.A.; Saleem, M.Q.; Ghulam, Z.; Qureshi, M.A.M. High-feed turning of AISI D2 tool steel using multi-radii tool inserts: Tool life, material removed, and workpiece surface integrity evaluation. Mater. Manuf. Process. 2017, 32, 670–677. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Maddu, J.; Karrolla, B.; Shaik, R.U.; Vuppala, S. Comparative Study of Optimization Models for Evaluation of EDM Process Parameters on Ti-6Al-4V. Modelling 2021, 2, 555–566. [Google Scholar] [CrossRef]

- Yasir, M.; Ginta, T.L.; Alkali, A.U.; Danish, M. Experimental investigation to improve surface integrity of biomedical devices by end-milling AISI 316L stainless steel. Appl. Mech. Mater. 2015, 789–790, 141–145. [Google Scholar] [CrossRef]

- Matuszewski, M. Nośność powierzchni a rodzaj jej obróbki. Tribologia 2011, 6, 143–150. [Google Scholar]

- Obróbka Skrawaniem Stali Nierdzewnych. Available online: http://www.stalenierdzewne.pl/1030/obrobka-skrawaniem-stali-nierdzewnych (accessed on 10 March 2023).

- ISO 3685:1993; Tool-Life Testing with Single-Point Turning Tools. International Organization for Standardization: Geneva, Switzerland, 1993.

| C | Si | Mn | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 0.5 | 1.6 | 0.035 | 0.025 | 17.4 | 2.2 | 9.6 | balance |

| Parameter | Value | Unit |

|---|---|---|

| Young’s modulus | 200,000 | MPa |

| Ultimate tensile strength | 485 | Mpa |

| Hardness | 210 | HV |

| Heat conductivity | 14.6 | W/m·K |

| Experiment | Cutting Speed vc (m/min) | Feed Rate f (mm/rev) | Depth of Cut ap (mm) |

|---|---|---|---|

| E1 | 150 | 0.08 | 1.5 |

| E2 | 150 | 0.15 | 1.5 |

| E3 | 150 | 0.30 | 1.5 |

| E4 | 170 | 0.08 | 1.5 |

| E5 | 170 | 0.15 | 1.5 |

| E6 | 170 | 0.30 | 1.5 |

| E7 | 200 | 0.08 | 1.5 |

| E8 | 200 | 0.15 | 1.5 |

| E9 | 200 | 0.30 | 1.5 |

| Experiment | vc (m/min) | f (mm/rev) | gs (μm) |

|---|---|---|---|

| 1 | 150 | 0.08 | 31.18 ± 1.21 |

| 2 | 150 | 0.15 | 31.89 ± 0.45 |

| 3 | 150 | 0.30 | 31.13 ± 1.09 |

| 4 | 170 | 0.08 | 43.22 ± 2.56 |

| 5 | 170 | 0.15 | 44.31 ± 2.54 |

| 6 | 170 | 0.30 | 45.89 ± 2.24 |

| 7 | 200 | 0.08 | 50.31 ± 1.74 |

| 8 | 200 | 0.15 | 51.82 ± 1.67 |

| 9 | 200 | 0.30 | 52.55 ± 1.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwajka, K.; Zielińska-Szwajka, J.; Trzepieciński, T. Improving the Surface Integrity of 316L Steel in the Context of Bioimplant Applications. Materials 2023, 16, 3460. https://doi.org/10.3390/ma16093460

Szwajka K, Zielińska-Szwajka J, Trzepieciński T. Improving the Surface Integrity of 316L Steel in the Context of Bioimplant Applications. Materials. 2023; 16(9):3460. https://doi.org/10.3390/ma16093460

Chicago/Turabian StyleSzwajka, Krzysztof, Joanna Zielińska-Szwajka, and Tomasz Trzepieciński. 2023. "Improving the Surface Integrity of 316L Steel in the Context of Bioimplant Applications" Materials 16, no. 9: 3460. https://doi.org/10.3390/ma16093460

APA StyleSzwajka, K., Zielińska-Szwajka, J., & Trzepieciński, T. (2023). Improving the Surface Integrity of 316L Steel in the Context of Bioimplant Applications. Materials, 16(9), 3460. https://doi.org/10.3390/ma16093460