Analyze the Wear Mechanism of the Longwall Shearer Haulage System

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructural Analysis

2.3. Mechanical Testing

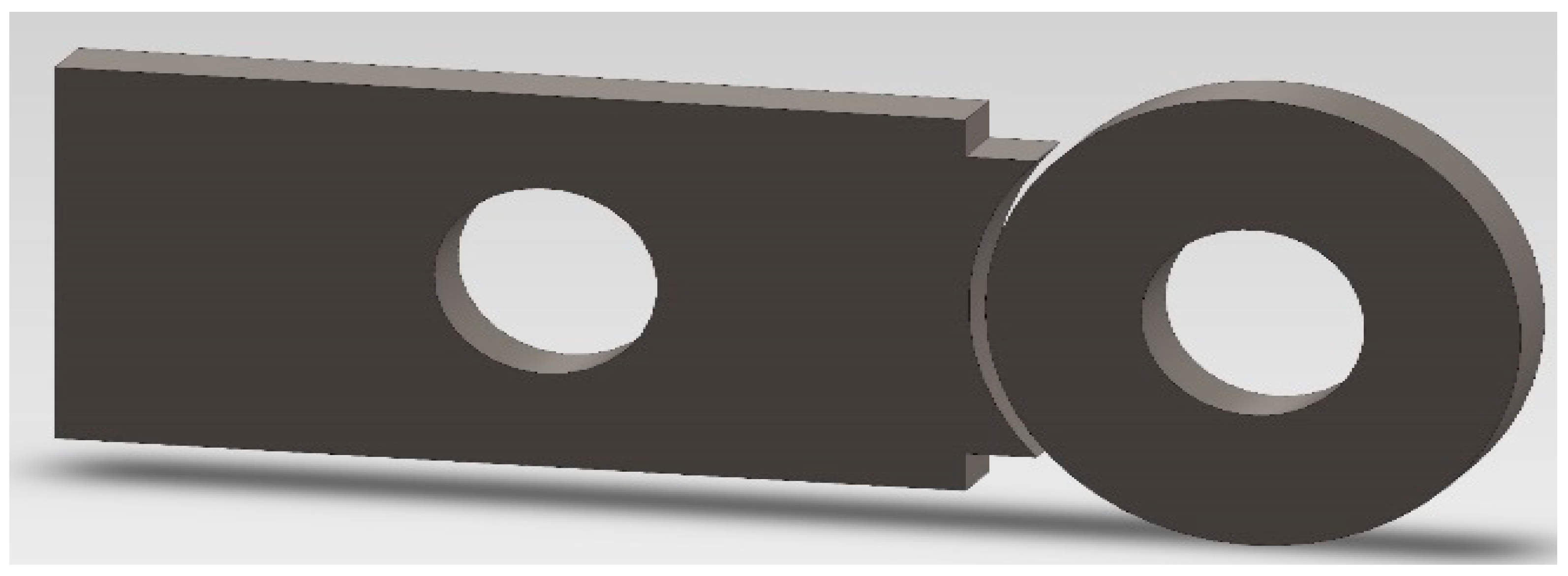

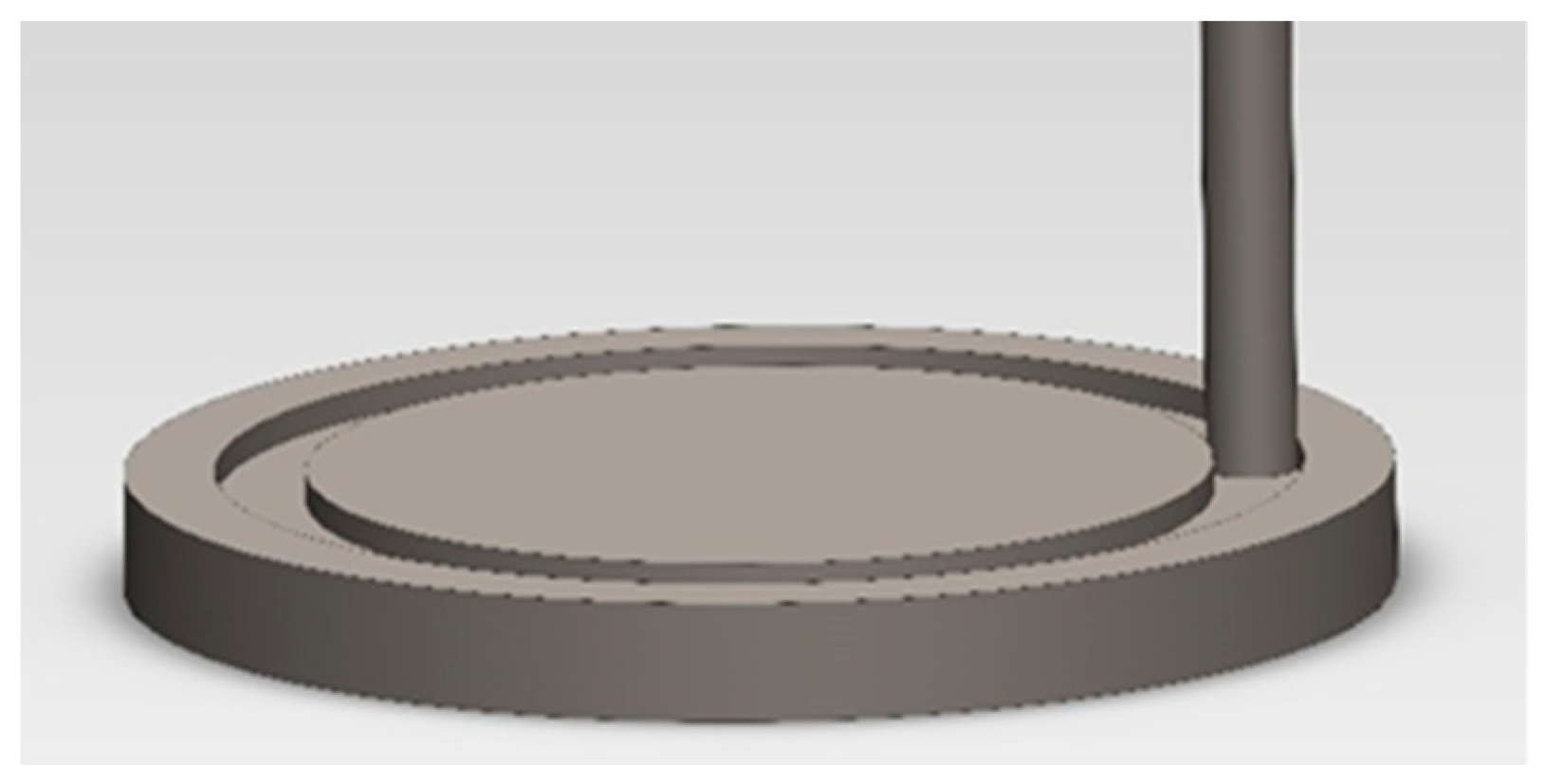

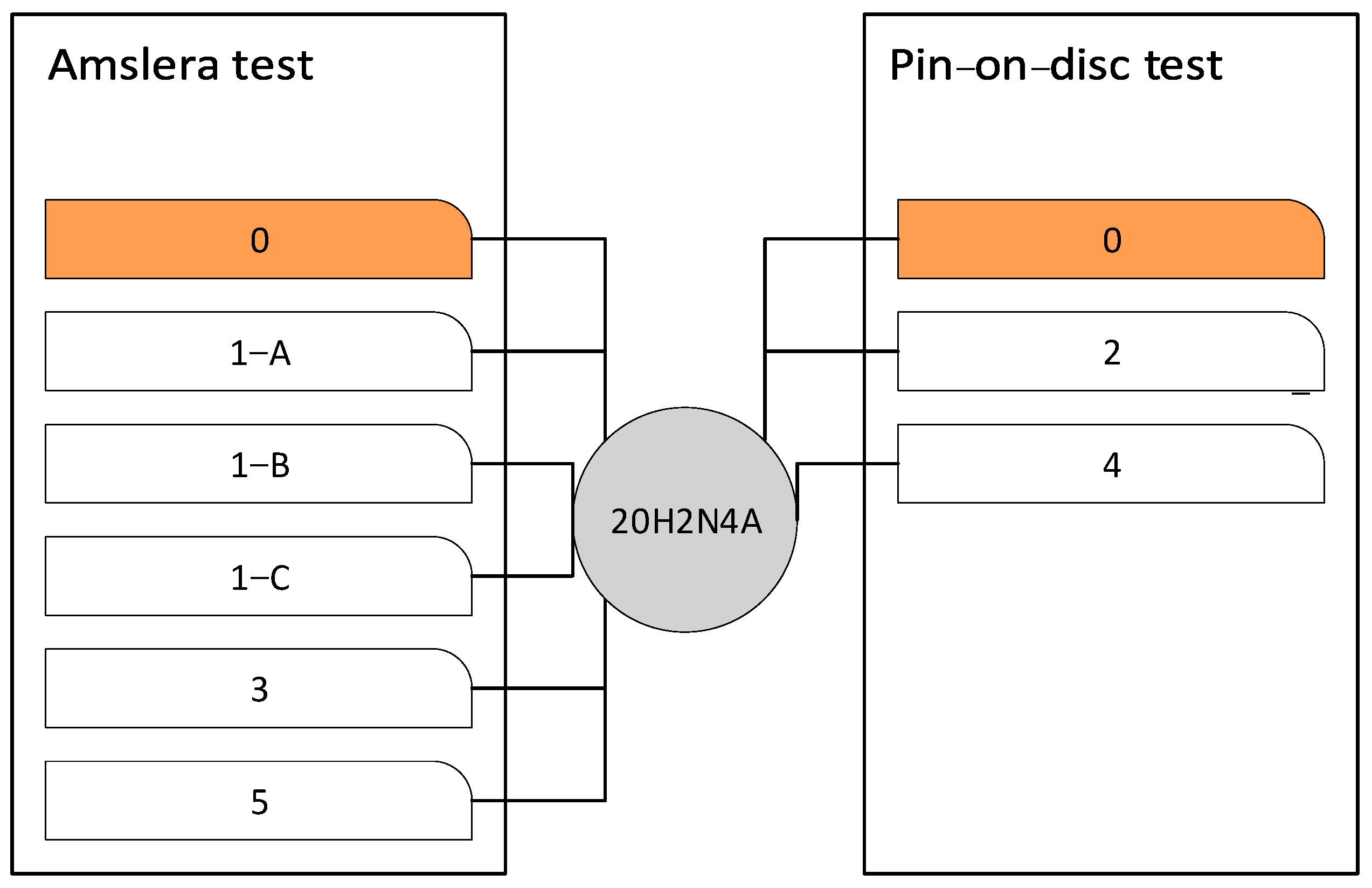

2.4. Wear Testing

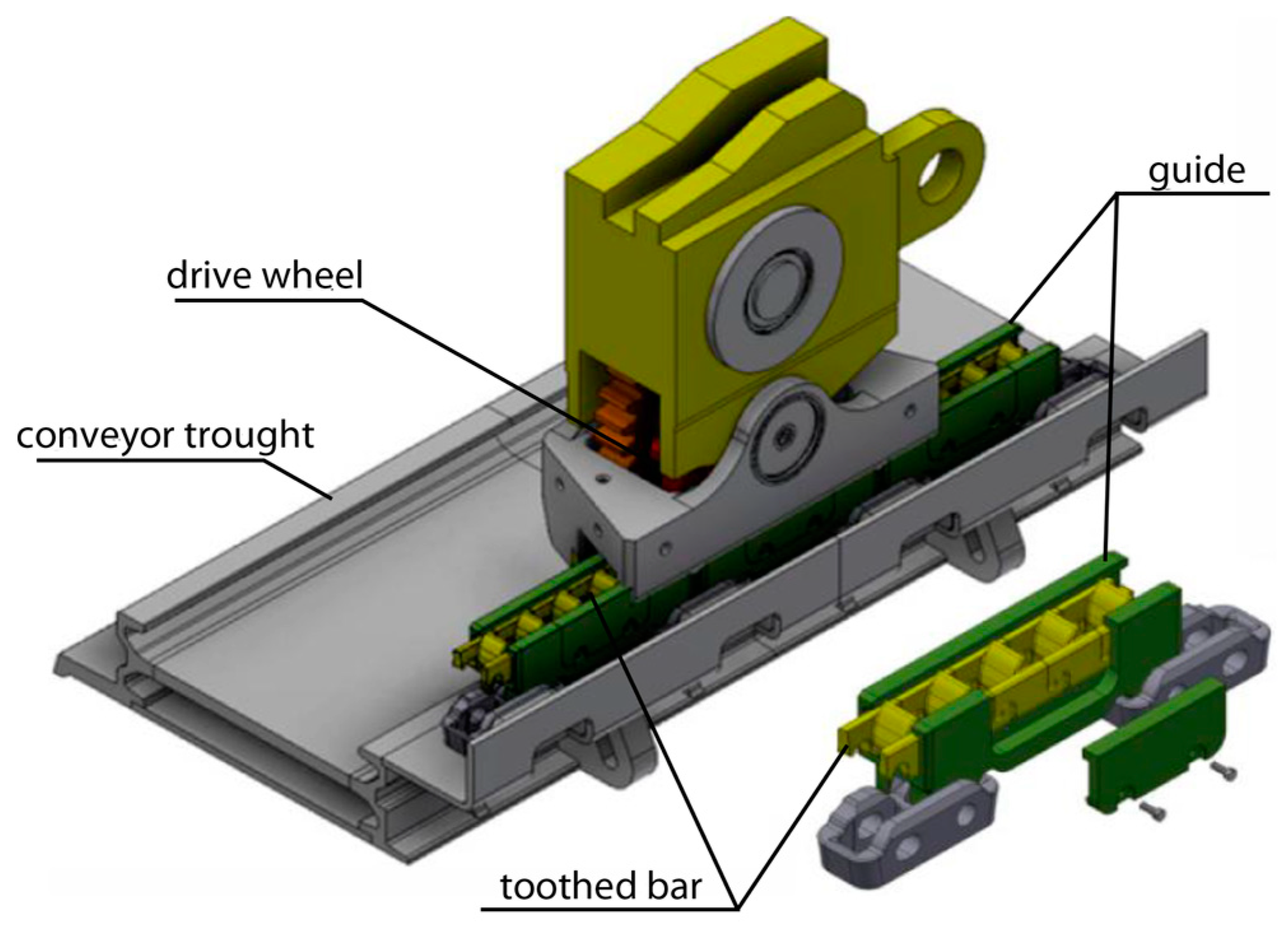

2.5. Longwall Shearer Test Stand

3. Results and Discussion

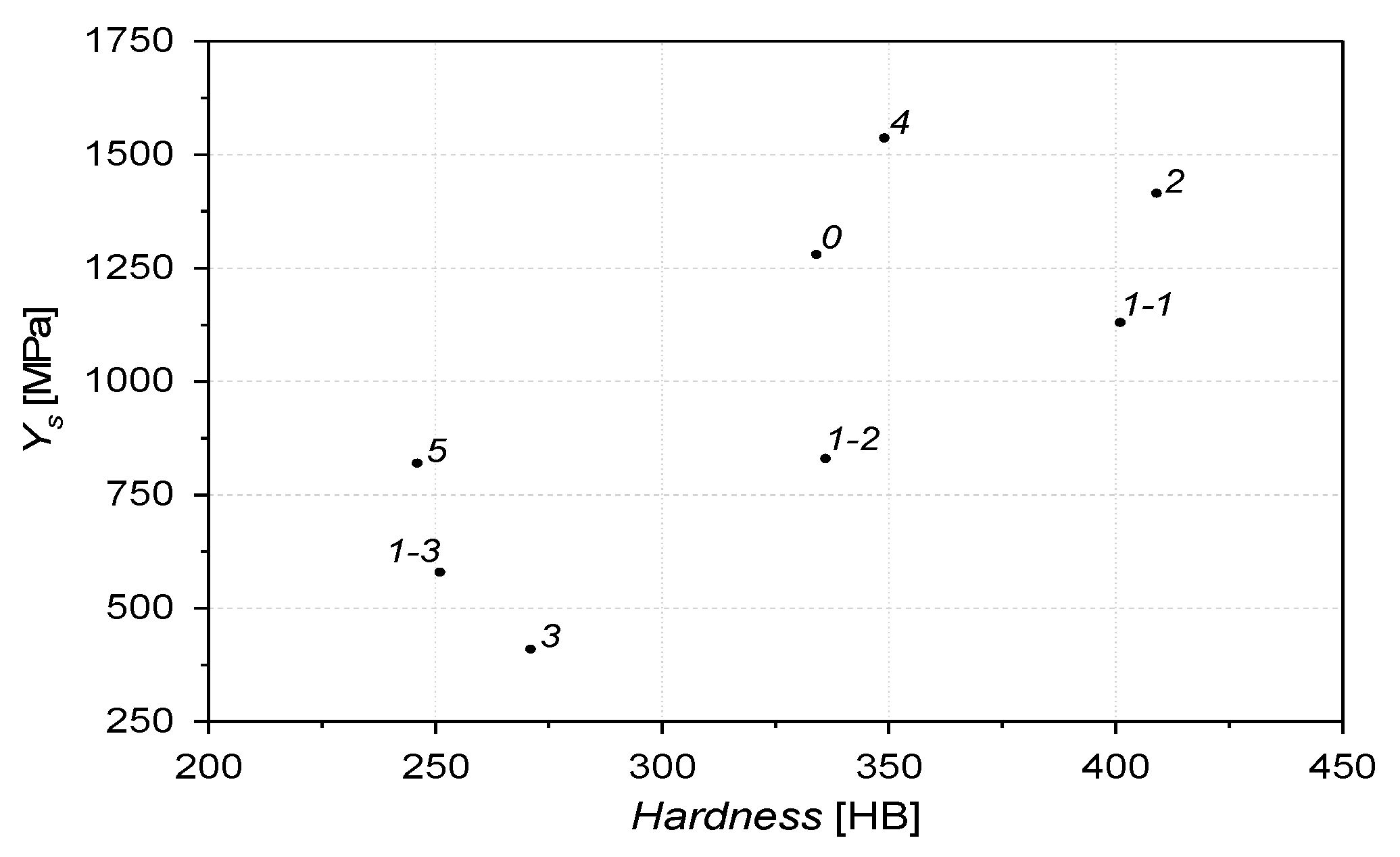

3.1. Mechanical Properties

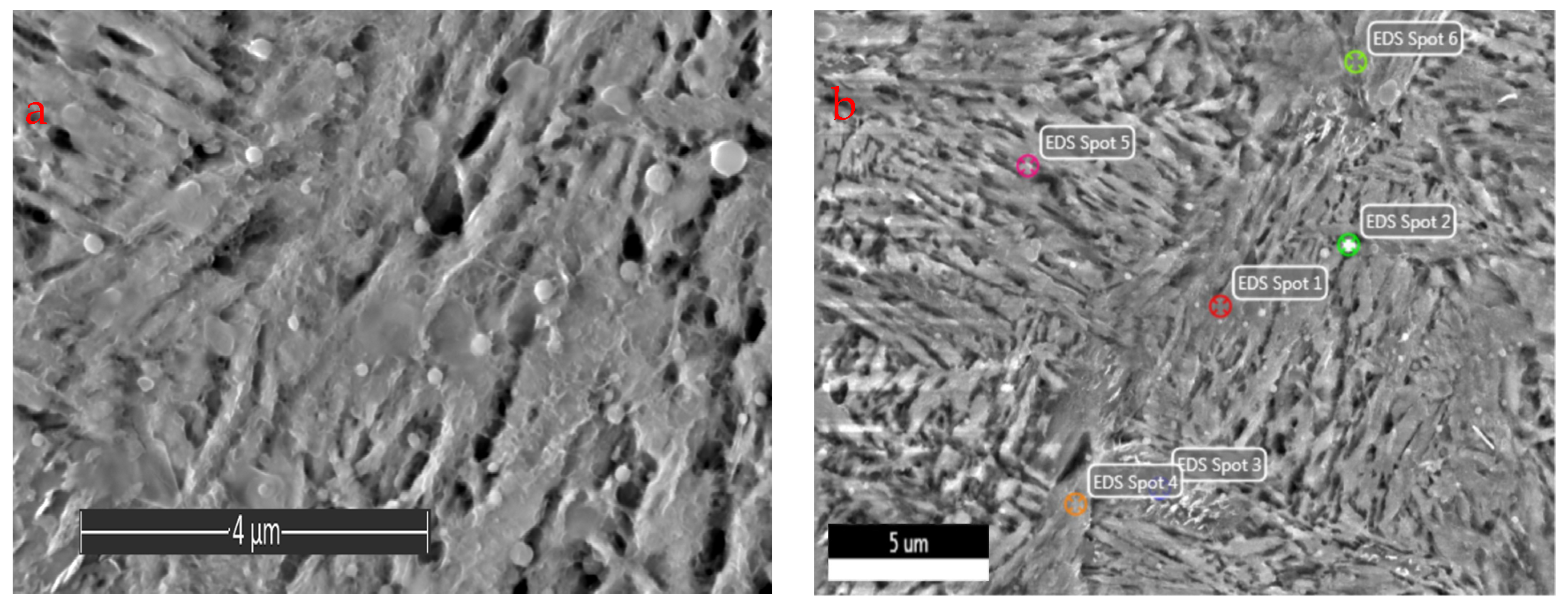

3.2. Microstructure of 20H2N4A

3.3. Distribution of the Microhardness of the Carburized Layer of the 20H2N4A Alloy

3.4. Wear Behavior

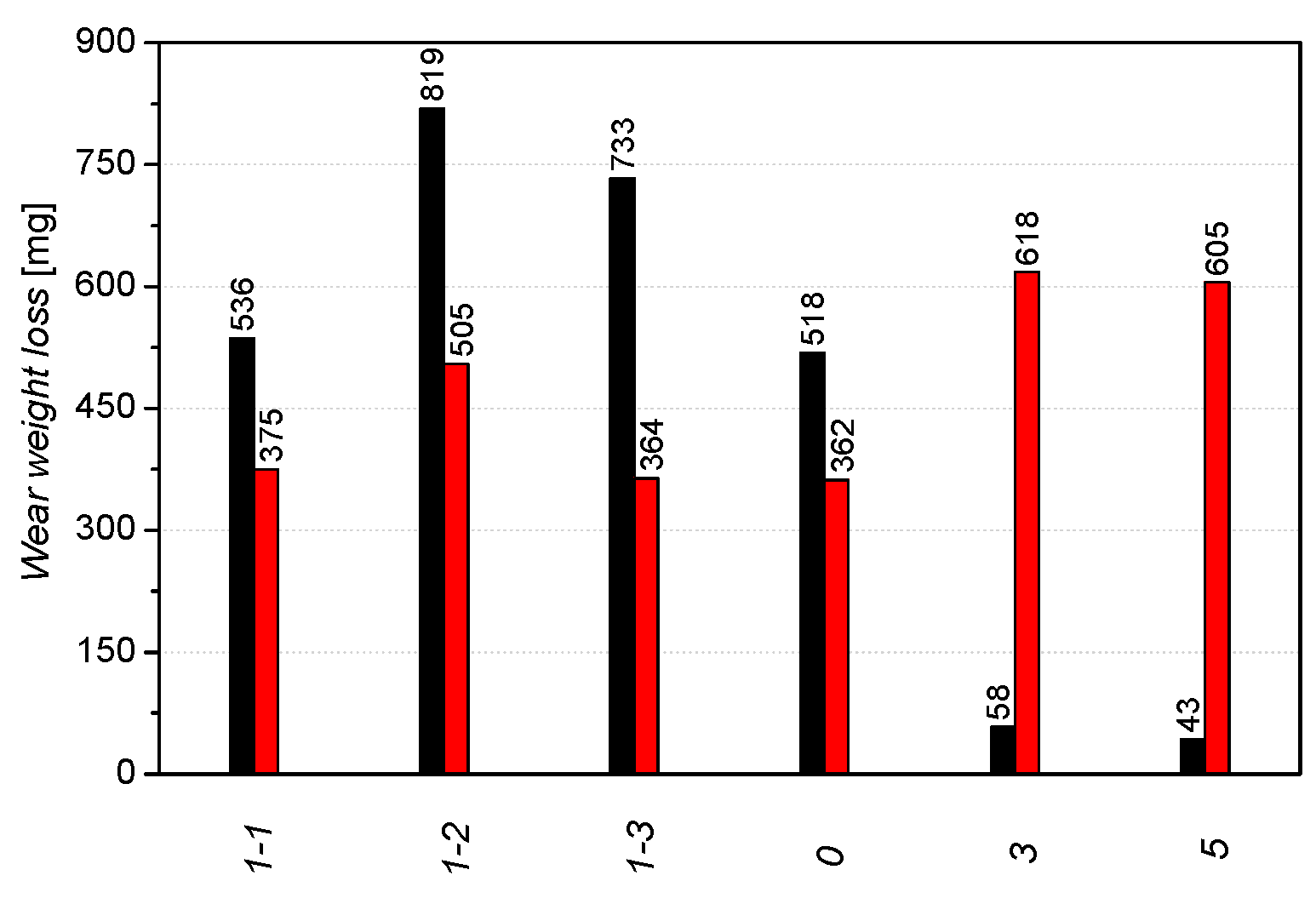

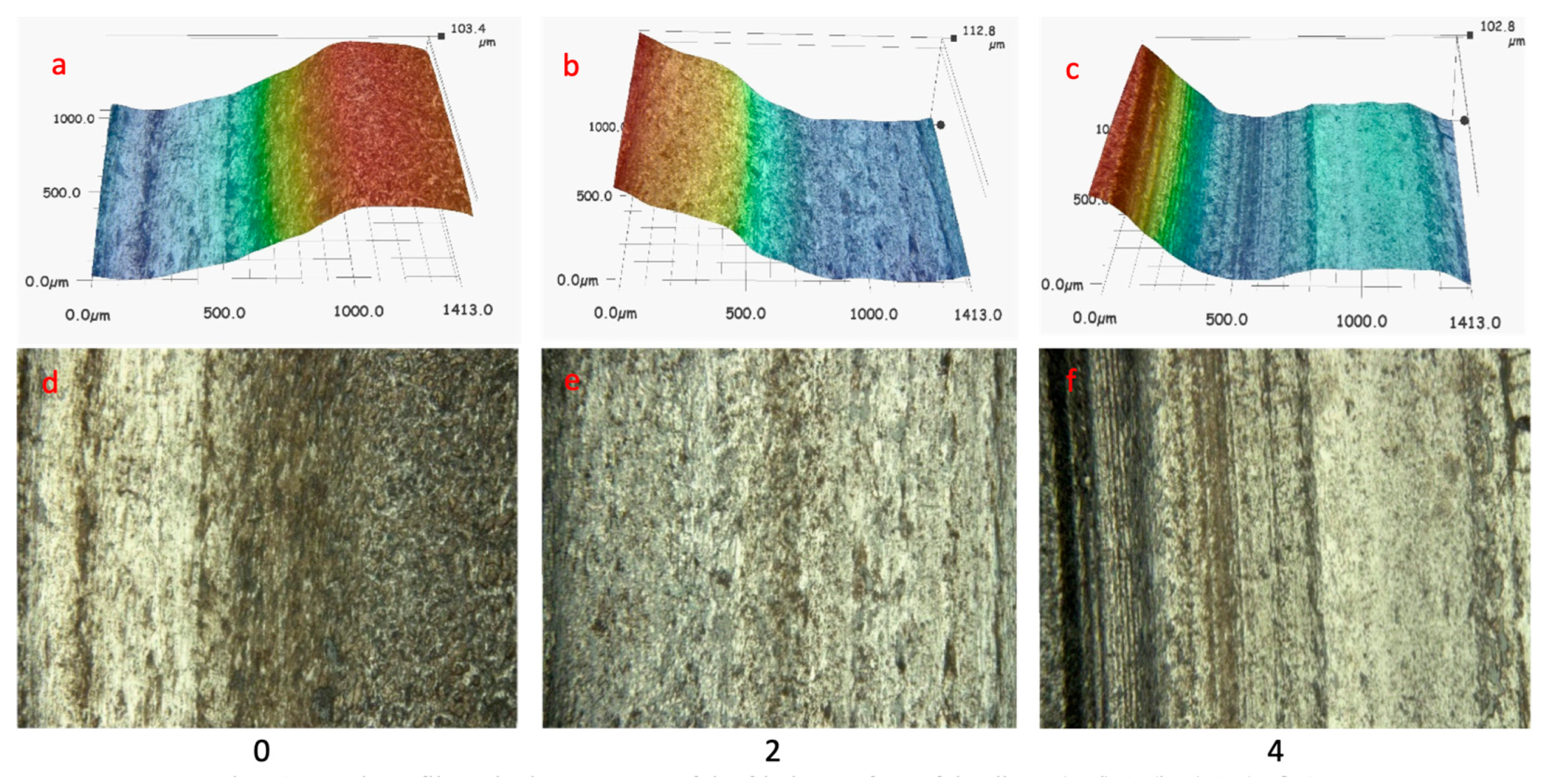

3.4.1. Amsler Test

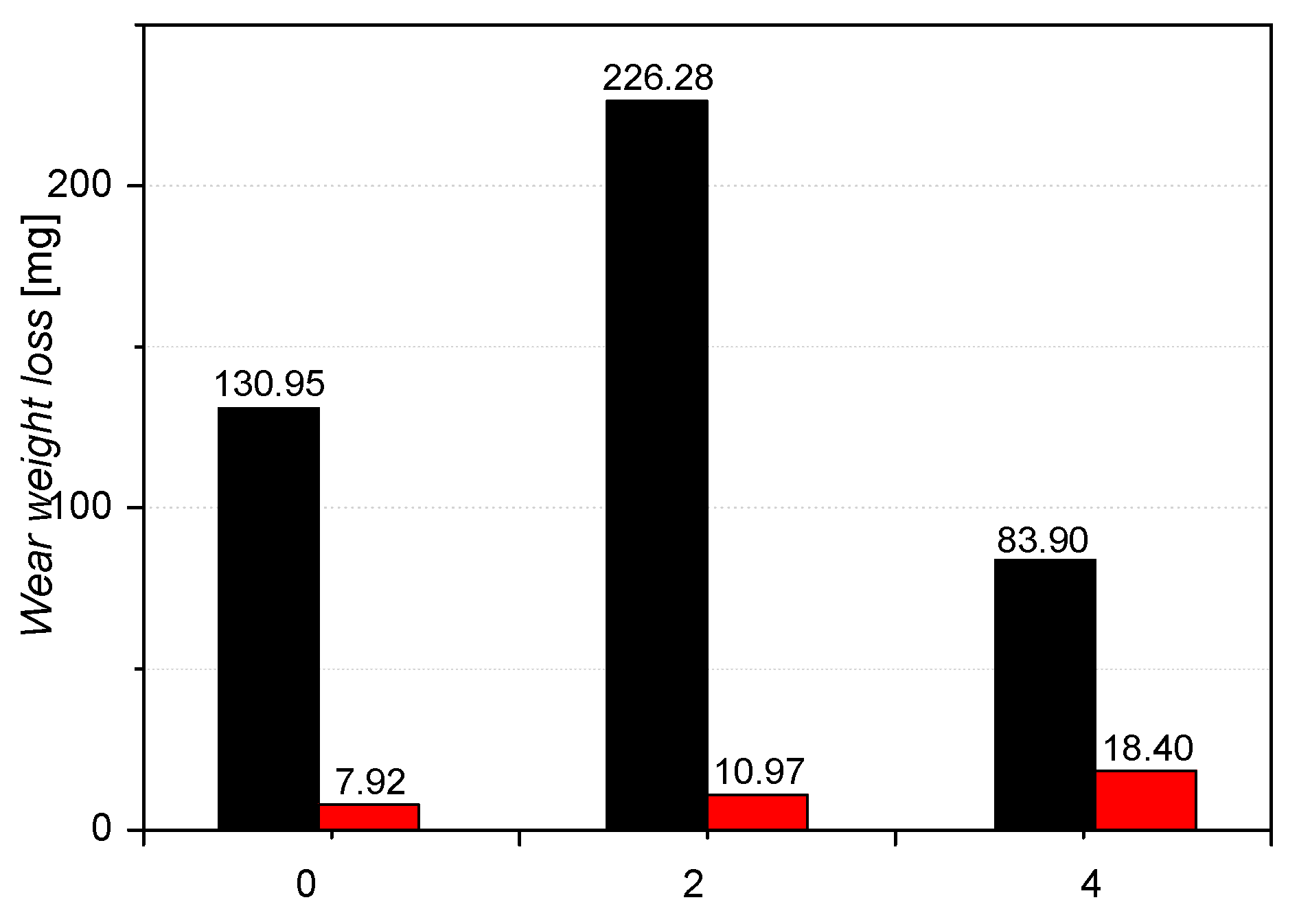

3.4.2. Pin-on-Disc Test

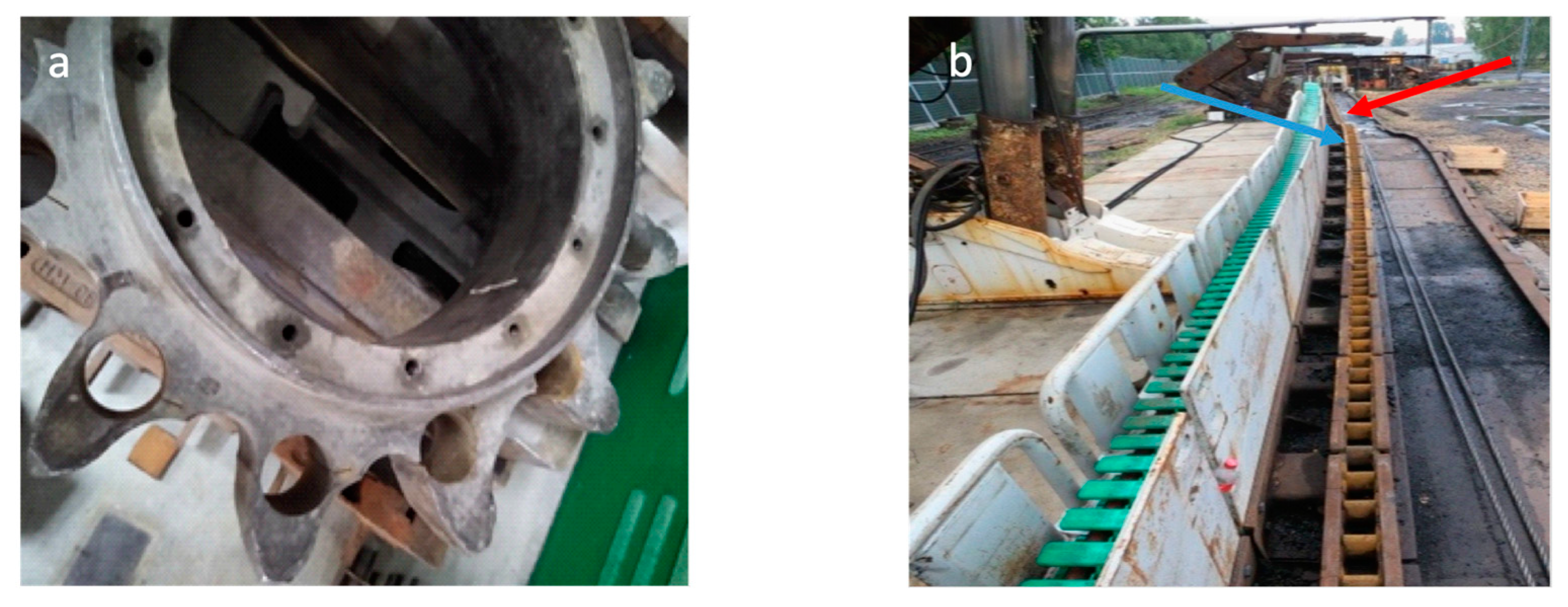

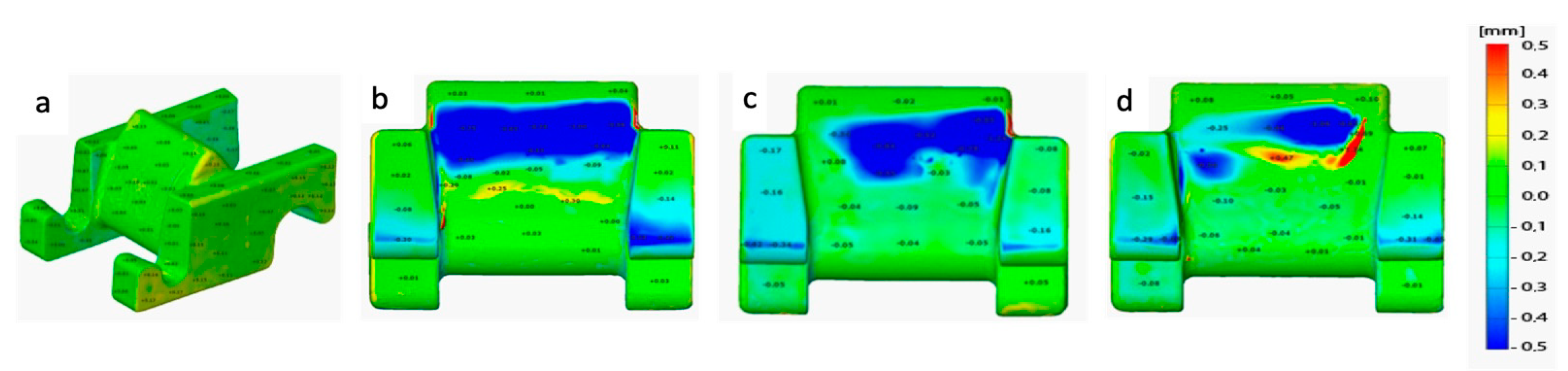

3.5. Test Stand

4. Conclusions

- The tests performed using the pin-on-disc as well as the Amsler method were consistent for sample 0, and in both cases, the pair of 0/20H2N4A alloys showed the lowest wear under dry friction.

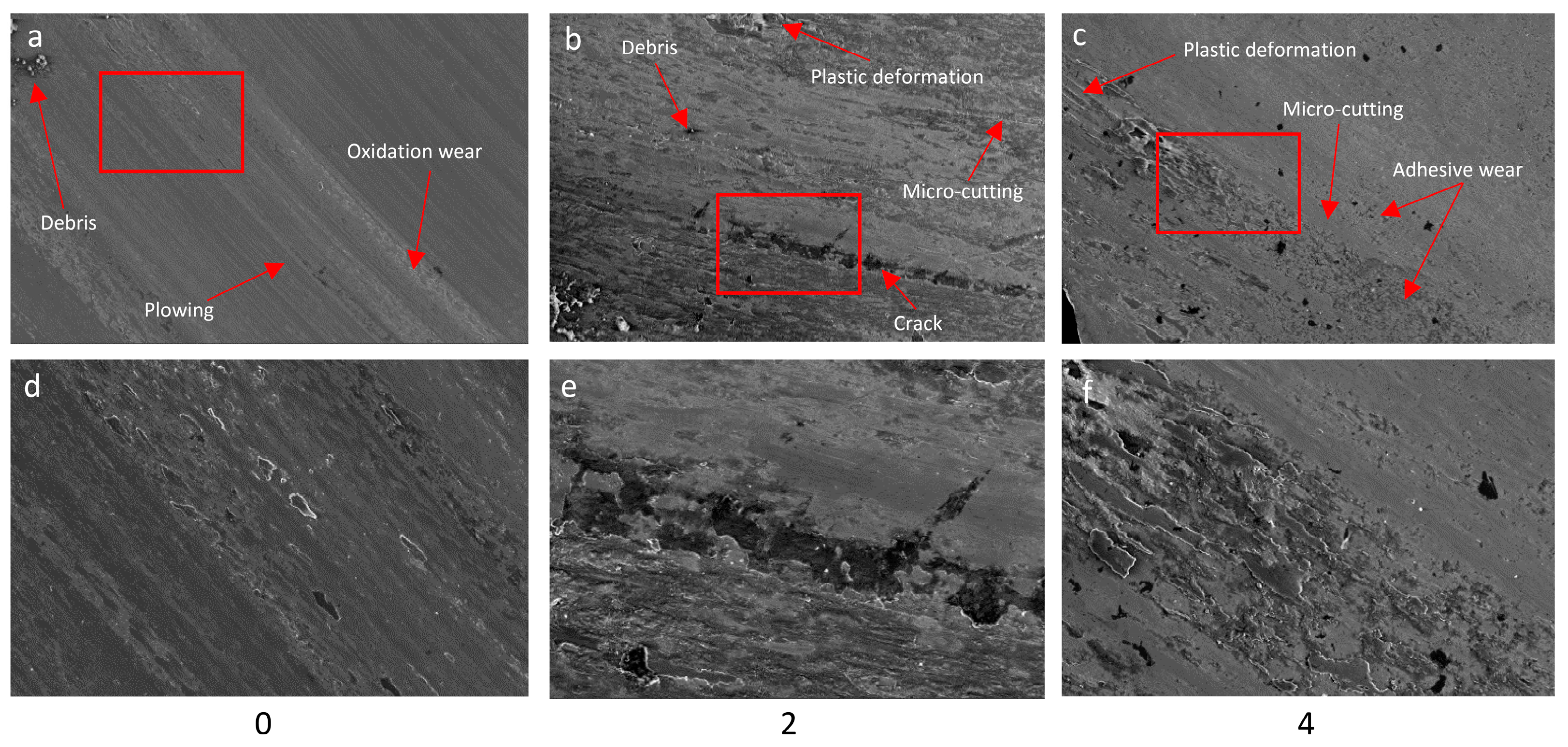

- The wear of the carburized layer of the wheel material for all the tests carried out is associated with plowing, micro-cutting, adhesive wear, oxidation wear and fatigue. However, the share of individual wear mechanisms for the tested friction pairs using the pin-on-disk method is significantly different.

- A relationship was found between the temperature and the wear of the drive wheel alloy; the higher temperature recorded during the Amsler test also causes greater wear. ADI grade 1–1 cast iron is an exception here.

- In the case of pin-on-disc tests, an important mechanism causing the highest wear of drive wheel material (20H2N4A) was adhesive wear.

- In the case of hardness and yield strength of the tested alloys, no relationship was found between these properties and the degree of wear.

- Toothed segments in places of track guide bending wear more than 2.5 times faster than in straight sections. These areas become critical places that can potentially be a source of failure of the Longwall Shearer Haulage System.

- The analysis confirmed that the drive wheel was not subjected to the process of wear, which extends the service life of the entire system.

Author Contributions

Funding

Conflicts of Interest

References

- Eshaghian, O.; Hoseinie, S.H.; Maleki, A. Multi-Attribute Failure Analysis of Coal Cutting Picks on Longwall Shearer Machine. Eng. Fail. Anal. 2021, 120, 105069. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global Energy Consumption Due to Friction and Wear in the Mining Industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Peng, S.S.; Du, F.; Cheng, J.; Li, Y. Automation in U.S. Longwall Coal Mining: A State-of-the-Art Review. Int. J. Min. Sci. Technol. 2019, 29, 151–159. [Google Scholar] [CrossRef]

- Zachura, A.; Żuczek, R. Innovative Design of a Longwall Shearer’s Haulage System with Highly Loaded Components of a Tribological Pair Manufactured According to the Precise Casting Technology. Solid State Phenom. 2015, 223, 171–180. [Google Scholar] [CrossRef]

- Shi, Z.; Zhu, Z. Case Study: Wear Analysis of the Middle Plate of a Heavy-Load Scraper Conveyor Chute under a Range of Operating Conditions. Wear 2017, 380–381, 36–41. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Buranich, V.V.; Satbayeva, Z.A.; Sagdoldina, Z.B.; Kozhanova, R.S.; Pogrebnjak, A.D. The Cathodic Electrolytic Plasma Hardening of the 20Cr2Ni4A Chromium-Nickel Steel. J. Mater. Res. Technol. 2020, 9, 6969–6976. [Google Scholar] [CrossRef]

- Astashchenko, V.I.; Purtova, E.V. New Technology of Hardening of Chromium-Nickel Steel Parts. Solid State Phenom. 2018, 284, 1221–1225. [Google Scholar] [CrossRef]

- Rakoczy, Ł.; Hoefer, K.; Grudzień-Rakoczy, M.; Rutkowski, B.; Goły, M.; Auerbach, T.; Cygan, R.; Abstoss, K.G.; Zielińska-Lipiec, A.; Mayr, P. Characterization of the Microstructure, Microsegregation, and Phase Composition of Ex-Situ Fe–Ni–Cr–Al–Mo–TiCp Composites Fabricated by Three-Dimensional Plasma Metal Deposition on 10CrMo9–10 Steel. Arch. Civ. Mech. Eng. 2020, 20, 127. [Google Scholar] [CrossRef]

- Ojala, N.; Valtonen, K.; Heino, V.; Kallio, M.; Aaltonen, J.; Siitonen, P.; Kuokkala, V.T. Effects of Composition and Microstructure on the Abrasive Wear Performance of Quenched Wear Resistant Steels. Wear 2014, 317, 225–232. [Google Scholar] [CrossRef]

- Rendón, J.; Olsson, M. Abrasive Wear Resistance of Some Commercial Abrasion Resistant Steels Evaluated by Laboratory Test Methods. Wear 2009, 267, 2055–2061. [Google Scholar] [CrossRef]

- Xu, X.; Xu, W.; Ederveen, F.H.; Zwaag, S. van der Design of Low Hardness Abrasion Resistant Steels. Wear 2013, 301, 89–93. [Google Scholar] [CrossRef]

- Florea, V.A.; Pasculescu, D.; Pasculescu, V.M. Reliability and Maintainability of Scraper Conveyor Used in Coal Mining in the Jiu Valley. Min. Miner. Depos. 2021, 15, 16–21. [Google Scholar] [CrossRef]

- Kotwica, K.; Stopka, G.; Kalita, M.; Bałaga, D.; Siegmund, M. Impact of Geometry of Toothed Segments of the Innovative Komtrack Longwall Shearer Haulage System on Load and Slip during the Travel of a Track Wheel. Energies 2021, 14, 2720. [Google Scholar] [CrossRef]

- Maciej, S.; Becker, F.G.; Cleary, M.; Team, R.M.; Holtermann, H.; The, D.; Agenda, N.; Science, P.; Sk, S.K.; Hinnebusch, R.; et al. Wpływ Zużycia Zębów Koła Napędowego i Zmiany Podziałki Zębatki Na Charakter Zazębienia i Prędkość Posuwu Kombajnu. P.3351 2005, 7, 343–354. [Google Scholar] [CrossRef]

- Machines, J.K.-M. Longwall Shearer Haulage Systems—A Historical Review. Part 2—First Cordless Haulage Systems Solutions. Min. Mach. 2021, 39, 24–33. [Google Scholar]

- Petrica, M.; Badisch, E.; Peinsitt, T. Abrasive Wear Mechanisms and Their Relation to Rock Properties. Wear 2013, 308, 86–94. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, D.; Ge, S. Effect of Fretting Amplitudes on Fretting Wear Behavior of Steel Wires in Coal Mines. Min. Sci. Technol. 2010, 20, 803–808. [Google Scholar] [CrossRef]

- Yu-xing, P.; Xiang-dong, C.; Zhen-cai, Z.; Da-gang, W.; Xian-sheng, G.; Sheng-yong, Z.; Shi-sheng, S.; Wen-xue, X. Sliding Friction and Wear Behavior of Winding Hoisting Rope in Ultra-Deep Coal Mine under Different Conditions. Wear 2016, 368–369, 423–434. [Google Scholar] [CrossRef]

- Silva, K.H.S.; Carneiro, J.R.; Coelho, R.S.; Pinto, H.; Brito, P. Influence of Shot Peening on Residual Stresses and Tribological Behavior of Cast and Austempered Ductile Iron. Wear 2019, 440–441, 203099. [Google Scholar] [CrossRef]

- Jaśkowiec, K.; Wilk-kołodziejczyk, D.; Bartłomiej, Ś.; Reczek, W.; Bitka, A.; Małysza, M.; Doroszewski, M.; Pirowski, Z.; Boroń, Ł. Assessment of the Quality and Mechanical Parameters of Castings Using Machine Learning Methods. Materials 2022, 15, 2884. [Google Scholar] [CrossRef]

- Jafarian, H.R.; Sabzi, M.; Mousavi Anijdan, S.H.; Eivani, A.R.; Park, N. The Influence of Austenitization Temperature on Microstructural Developments, Mechanical Properties, Fracture Mode and Wear Mechanism of Hadfield High Manganese Steel. J. Mater. Res. Technol. 2021, 10, 819–831. [Google Scholar] [CrossRef]

- Varela, L.B.; Tressia, G.; Masoumi, M.; Bortoleto, E.M.; Regattieri, C.; Sinatora, A. Roller Crushers in Iron Mining, How Does the Degradation of Hadfield Steel Components Occur? Eng. Fail. Anal. 2021, 122, 105295. [Google Scholar] [CrossRef]

- Chakraborty, J.; Bhattacharjee, D.; Manna, I. Development of Ultrafine Bainite + Martensite Duplex Microstructure in SAE 52100 Bearing Steel by Prior Cold Deformation. Scr. Mater. 2009, 61, 604–607. [Google Scholar] [CrossRef]

- Phetlam, P.; Uthaisangsuk, V. Microstructure Based Flow Stress Modeling for Quenched and Tempered Low Alloy Steel. Mater. Des. 2015, 82, 189–199. [Google Scholar] [CrossRef]

- Tao, X.; Li, C.; Han, L.; Gu, J. Microstructure Evolution and Mechanical Properties of X12CrMoWVNbN10-1-1 Steel during Quenching and Tempering Process. J. Mater. Res. Technol. 2016, 5, 45–57. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties; Butterworth-Heinemann: Oxford, UK, 2006; p. 344. [Google Scholar]

- Grudzień-Rakoczy, M.; Rakoczy, Ł.; Cygan, R.; Kromka, F.; Pirowski, Z.; Milkovič, O. Fabrication and Characterization of the Newly Developed Superalloys Based on Inconel 740. Materials 2020, 13, 2362. [Google Scholar] [CrossRef]

- Trevisiol, C.; Jourani, A.; Bouvier, S. Effect of Martensite Morphology on Tribological Behaviour of a Low-Alloy Steel. Metallogr. Microstruct. Anal. 2018, 8, 123–134. [Google Scholar] [CrossRef]

- Weiss, G. (Ed.) Multiagent Systems: A Modern Approach to Distributed Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1999; ISBN 0262232030. [Google Scholar]

- Zhang, C.; Li, P.; Dong, H.; Jin, D.; Huang, J.; Mao, F.; Chen, C. Repetitive Impact Wear Behaviors of the Tempered 25Cr3Mo2NiWV Fe-Based Steel. Coatings 2020, 10, 107. [Google Scholar] [CrossRef]

- Li, C.; Deng, X.; Huang, L.; Jia, Y.; Wang, Z. Effect of Temperature on Microstructure, Properties and Sliding Wear Behavior of Low Alloy Wear-Resistant Martensitic Steel. Wear 2020, 442–443, 203125. [Google Scholar] [CrossRef]

- Reid, A.W.; McAree, P.R.; Meehan, P.A.; Gurgenci, H. Longwall Shearer Cutting Force Estimation. J. Dyn. Syst. Meas. Control. Trans. ASME 2014, 136, 031008. [Google Scholar] [CrossRef]

- Xuan, H.; Cui, G. Tribological Properties of Fe-Cr-B Alloy for Sliding Boot in Coal Mining Machine under Dry Sliding Condition. Ind. Lubr. Tribol. 2017, 69, 142–148. [Google Scholar] [CrossRef]

- StecuĹ‚a, K.; Brodny, J.; Palka, D. Analysis of Reasons for Unplanned Stoppages of Machines in the Example of the Longwall Shearer. CBU Int. Conf. Proc. 2017, 5, 1210–1214. [Google Scholar] [CrossRef]

- Harzallah, R.; Mouftiez, A.; Felder, E.; Hariri, S.; Maujean, J.P. Rolling Contact Fatigue of Hadfield Steel X120Mn12. Wear 2010, 269, 647–654. [Google Scholar] [CrossRef]

- Zhang, F.C.; Yang, Z.N.; Qian, L.H.; Liu, F.C.; Lv, B.; Zhang, M. High Speed Pounding: A Novel Technique for the Preparation of a Thick Surface Layer with a Hardness Gradient Distribution on Hadfield Steel. Scr. Mater. 2011, 64, 560–563. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.C.; Qiu, F.; Zou, Q.; Yang, H. A Review: Phase Transformation and Wear Mechanisms of Single-Step and Dual-Step Austempered Ductile Irons. J. Mater. Res. Technol. 2020, 9, 1054–1069. [Google Scholar] [CrossRef]

- Zambrano, O.A.; Gómez, J.A.; Coronado, J.J.; Rodríguez, S.A. The Sliding Wear Behaviour of Steels with the Same Hardness. Wear 2019, 418–419, 201–207. [Google Scholar] [CrossRef]

- Bruce, T.; Rounding, E.; Long, H.; Dwyer-Joyce, R.S. Characterisation of White Etching Crack Damage in Wind Turbine Gearbox Bearings. Wear 2015, 338–339, 164–177. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Z.; Zhang, F.; Qin, Y.; Wang, X.; Lv, B. Microstructures and Properties of a Novel Carburizing Nanobainitic Bearing Steel. Mater. Sci. Eng. A 2020, 777, 139086. [Google Scholar] [CrossRef]

- ISO 18203:2016(En); Steel—Determination of the Thickness of Surface-Hardened Layers. ISO: London, UK, 2016. Available online: https://www.iso.org/obp/ui/es/#iso:std:iso:18203:ed-1:v1:en (accessed on 13 December 2021).

- Sellamuthu, P.; Samuel, D.G.H.; Dinakaran, D.; Premkumar, V.P.; Li, Z.; Seetharaman, S. Austempered Ductile Iron (ADI): Influence of Austempering Temperature on Microstructure, Mechanical and Wear Properties and Energy Consumption. Metals 2018, 8, 53. [Google Scholar] [CrossRef]

- Kumari, U.R.; Rao, P.P. Study of Wear Behaviour of Austempered Ductile Iron. J. Mater. Sci. 2009, 44, 1082–1093. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Pan, Y.; Cui, W.; Wang, R. Microstructure, Wear Behavior and Surface Hardening of Austempered Ductile Iron. J. Mater. Res. Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Rahiman, A.H.S.; Smart, D.S.R.; Wilson, B.; Ebrahim, I.; Eldhose, B.; Mathew, B.; Murickan, R.T. Dry Sliding Wear Analysis OF Al5083/CNT/Ni/MoB Hybrid Composite Using DOE Taguchi Method. Wear 2020, 460–461, 203471. [Google Scholar] [CrossRef]

- Ashby, M.F.; Abulawi, J.; Kong, H.S. Temperature Maps for Frictional Heating in Dry Sliding. Tribol. Trans. 2008, 34, 577–582. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Kelly, G.; Rolfe, B.F.; Pereira, M.P. The Effect of Sliding Speed on the Wear of Steel-Tool Steel Pairs. Tribol. Int. 2016, 97, 218–227. [Google Scholar] [CrossRef]

- Aktas, B.; Balak, V.; Carboga, C. Dry Sliding Wear Behavior of Boron-Doped AISI 1020 Steels. Acta Phys. Pol. A 2017, 132, 455–457. [Google Scholar] [CrossRef]

- Krešák, J.; Peterka, P.; Ambriško, Ľ.; Mantič, M. Friction Lining Coefficient of the Drive Friction Pulley. Eksploat. i Niezawodn.—Maint. Reliab. 2021, 23, 338–345. [Google Scholar] [CrossRef]

- Mondal, J.; Das, K.; Das, S. An Investigation of Mechanical Property and Sliding Wear Behaviour of 400Hv Grade Martensitic Steels. Wear 2020, 458–459, 203436. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.C.; Wu, C.H.; Cui, Z.X.; Niu, C.; Wang, Y. Debris Effect on the Surface Wear and Damage Evolution of Counterpart Materials Subjected to Contact Sliding. Adv. Manuf. 2022, 10, 72–86. [Google Scholar] [CrossRef]

- Valizadeh Moghaddam, P.; Hardell, J.; Vuorinen, E.; Prakash, B. Dry Sliding Wear of Nanostructured Carbide-Free Bainitic Steels—Effect of Oxidation-Dominated Wear. Wear 2020, 454–455, 203317. [Google Scholar] [CrossRef]

- Gates, J.D. Two-Body and Three-Body Abrasion: A Critical Discussion. Wear 1998, 214, 139–146. [Google Scholar] [CrossRef]

- Wang, J.; Zafar, M.Q.; Chen, Y.; Pan, P.; Zuo, L.; Zhao, H.; Zhang, X. Tribological Properties of Brake Disc Material for a High-Speed Train and the Evolution of Debris. Lubricants 2022, 10, 168. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, K.; Luo, Z.; Wang, M.; Wang, X. Effect of Cryogenic Treatment on Microstructure, Mechanical Properties and Distortion of Carburized Gear Steels. Metals 2021, 11, 1940. [Google Scholar] [CrossRef]

| Alloy | Chemical Composition Analysis Results; wt% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Symbol | C | SI | MN | P | S | CR | NI | MO | MG | V | B |

| Steel—drive wheel—surface | 20H2N4A | 0.59 | 0.22 | 0.37 | 0.009 | 0.012 | 1.34 | 3.14 | 0.026 | - | - | - |

| Steel—drive wheel—core | 20H2N4A | 0.17 | 0.22 | 0.37 | 0.008 | 0.010 | 1.32 | 3.08 | 0.025 | - | - | - |

| Cast steel—toothed segment | 0 | 0.24 | 0.80 | 0.97 | 0.014 | 0.004 | 0.86 | 1.18 | 0.16 | - | - | - |

| ADI—toothed segment | 1 | 3.6 | 2.45 | 0.32 | 0.040 | 0.018 | - | 1.9 | - | 0.65 | - | - |

| Cast steel—toothed segment | 2 | 0.25 | 0.37 | 1.41 | 0.023 | 0.023 | 1.54 | 0.05 | 0.44 | - | - | 0.007 |

| Hadfield cast steel—toothed segment | 3 | 0.90 | 1.10 | 12.61 | 0.030 | 0.009 | 1.20 | 0.36 | 0.44 | |||

| Cast steel—toothed segment | 4 | 0.47 | 1.76 | 0.72 | 0.017 | 0.012 | 0.94 | 1.740 | 0.570 | - | 0.140 | - |

| Cast steel—toothed segment | 5 | 0.23 | 0.42 | 1.08 | 0.02 | 0.005 | 0.92 | 1.02 | 0.61 | - | 0.250 | - |

| Symbol | Heat Treatment Process Parameters |

|---|---|

| 20H2N4A |

|

| 0 |

|

| 1–1 |

|

| 1–2 |

|

| 1–3 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Symbol | 0 | 1–1 | 1–2 | 1–3 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|

| TS [MPa] | 1070 | 1480 | 1170 | 950 | 1514 | 1040 | 1683 | 1270 |

| YS [MPa] | 970 | 1130 | 830 | 580 | 1415 | 410 | 1537 | 820 |

| A [%] | 9.5 | 2.4 | 5.6 | 8.2 | 8.4 | 4 | 2.5 | 10 |

| Elements | Weight, % | |||||

|---|---|---|---|---|---|---|

| Spot 1 | Spot 2 | Spot 3 | Spot 4 | Spot 5 * | Spot 6 | |

| C | 8.2 | 14.5 | 10.0 | 10.5 | 9.6 | 8.2 |

| Si | 0.3 | 0.3 | - | 0.4 | - | - |

| Cr | 1.0 | 3.0 | 0.4 | 1.1 | 1.0 | 0.5 |

| Ni | 2.9 | 0.6 | - | 3.0 | 2.5 | 0.9 |

| Fe | 87.5 | 81.5 | 89.3 | 84.9 | 81.6 | 90.4 |

| Mark | A | B | C | D | E | F | G | H | J | |

|---|---|---|---|---|---|---|---|---|---|---|

| Weigh loss | [g] | 11 | 37 | 27 | 92 | 38 | 36 | 38 | 27 | 36 |

| Nr | Si | Mn | Cr | Mo | Ni |

|---|---|---|---|---|---|

| Chemical Composition; wt.% | |||||

| 1 | 0.858 | 1.023 | 0.914 | 0.161 | 1.204 |

| 2 | 0.896 | 0.982 | 0.767 | 0.147 | 1.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaśkowiec, K.; Pirowski, Z.; Głowacki, M.; Bisztyga-Szklarz, M.; Bitka, A.; Małysza, M.; Wilk-Kołodziejczyk, D. Analyze the Wear Mechanism of the Longwall Shearer Haulage System. Materials 2023, 16, 3090. https://doi.org/10.3390/ma16083090

Jaśkowiec K, Pirowski Z, Głowacki M, Bisztyga-Szklarz M, Bitka A, Małysza M, Wilk-Kołodziejczyk D. Analyze the Wear Mechanism of the Longwall Shearer Haulage System. Materials. 2023; 16(8):3090. https://doi.org/10.3390/ma16083090

Chicago/Turabian StyleJaśkowiec, Krzysztof, Zenon Pirowski, Mirosław Głowacki, Magdalena Bisztyga-Szklarz, Adam Bitka, Marcin Małysza, and Dorota Wilk-Kołodziejczyk. 2023. "Analyze the Wear Mechanism of the Longwall Shearer Haulage System" Materials 16, no. 8: 3090. https://doi.org/10.3390/ma16083090

APA StyleJaśkowiec, K., Pirowski, Z., Głowacki, M., Bisztyga-Szklarz, M., Bitka, A., Małysza, M., & Wilk-Kołodziejczyk, D. (2023). Analyze the Wear Mechanism of the Longwall Shearer Haulage System. Materials, 16(8), 3090. https://doi.org/10.3390/ma16083090