Multidimensional Study on the Wear of High-Speed, High-Temperature, Heavy-Load Bearings

Abstract

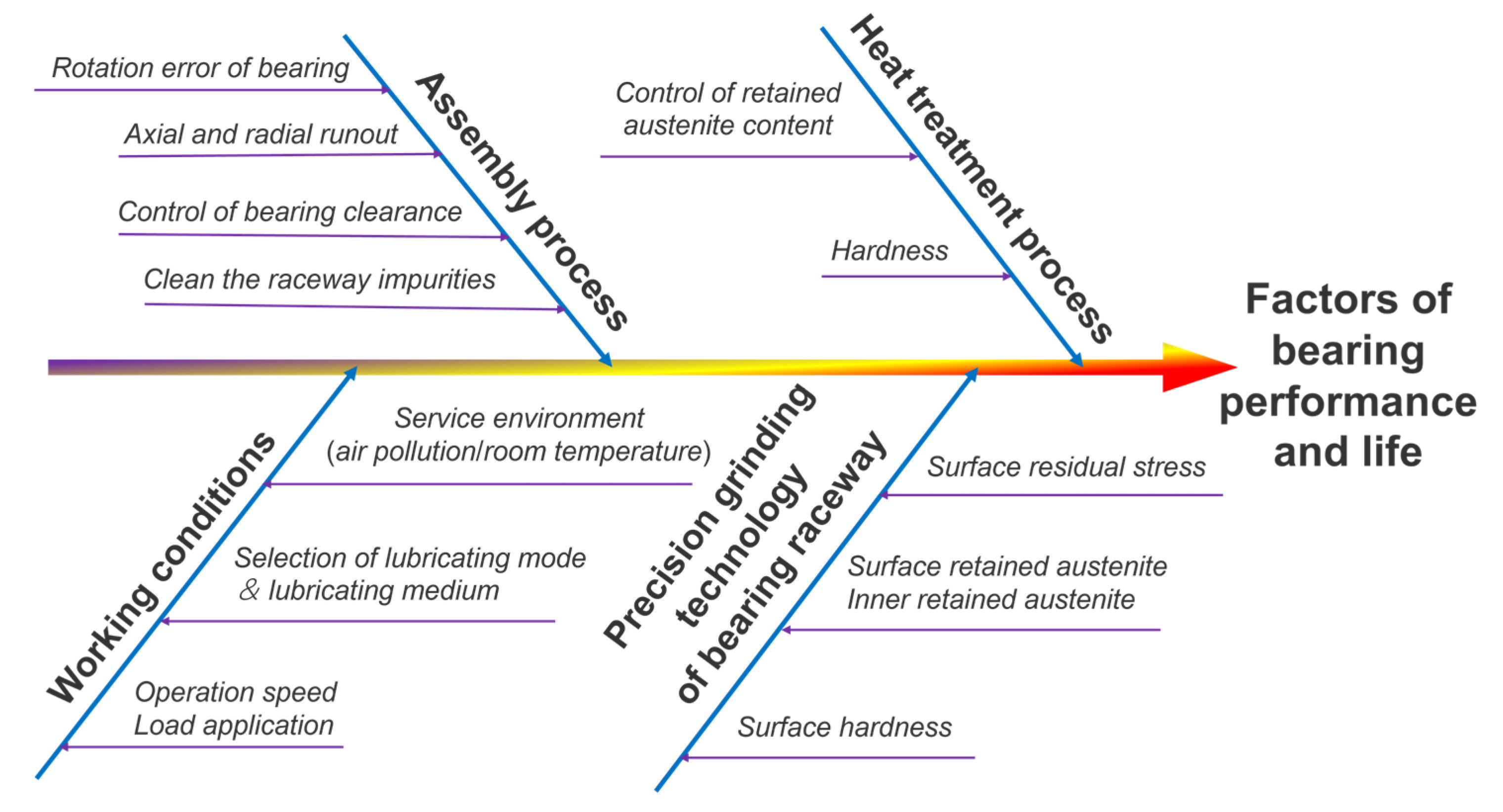

1. Introduction

2. Multidimensional Experimental Analysis

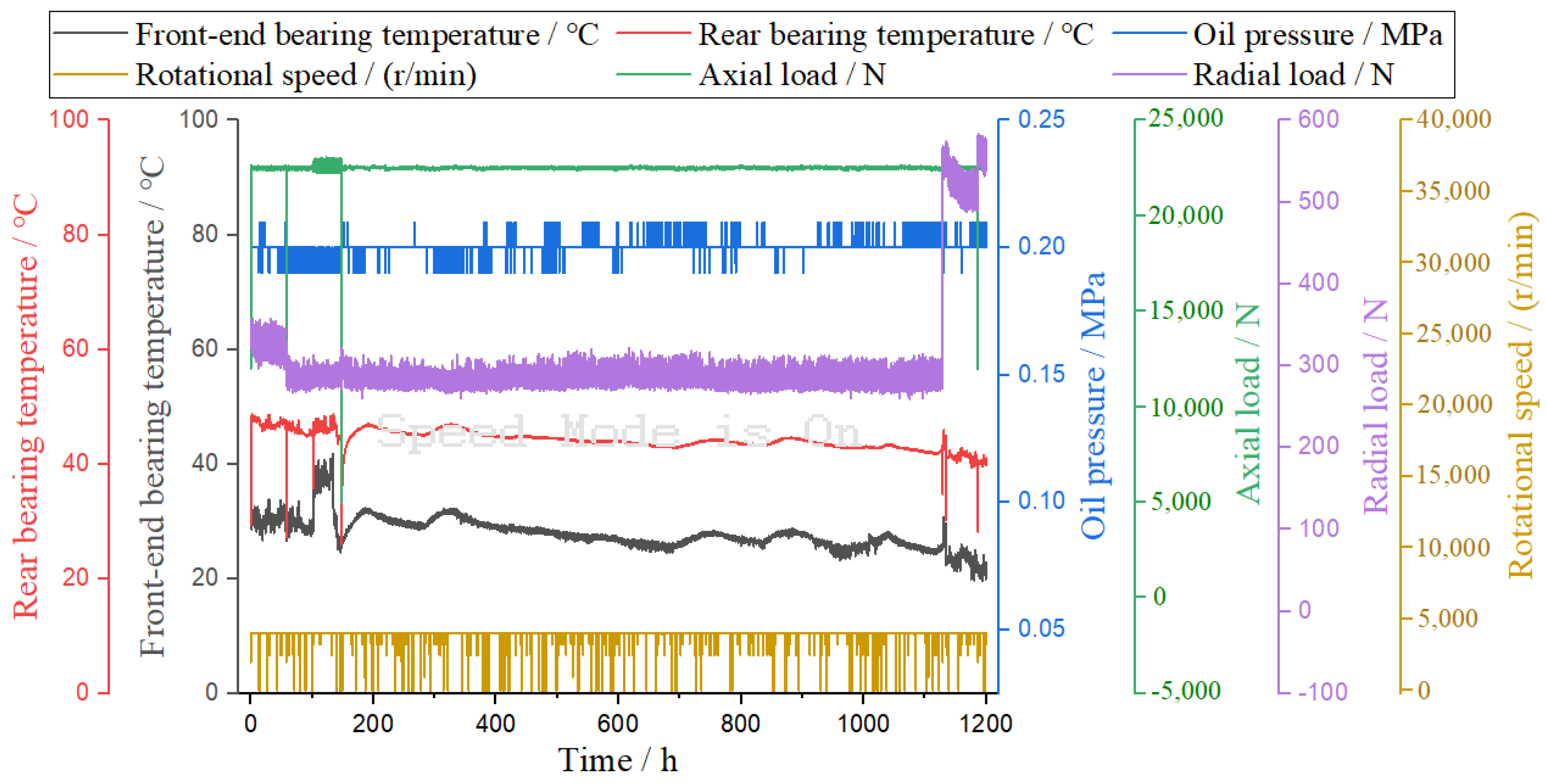

2.1. High-Speed Durability Experiment

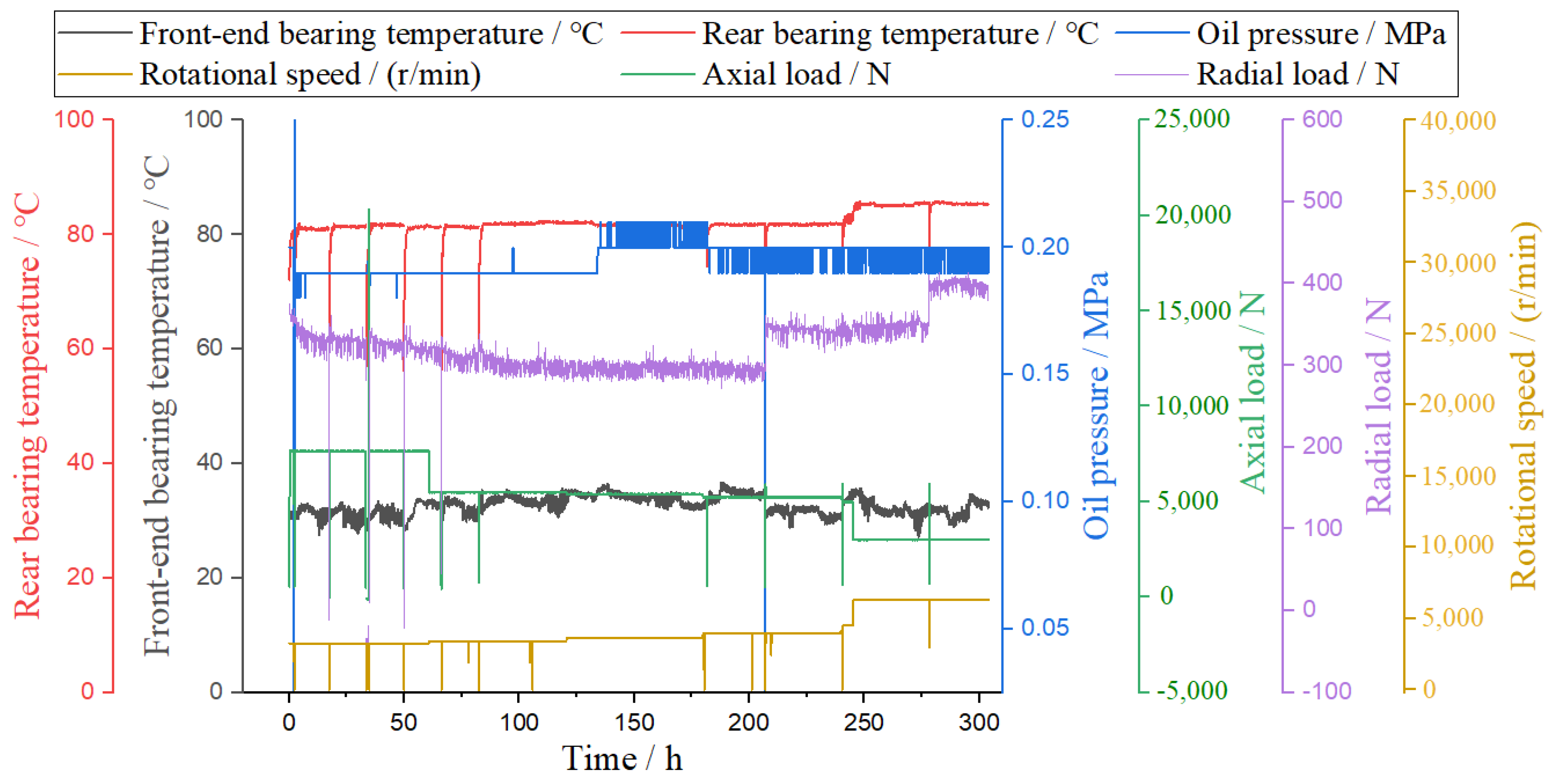

2.2. High-Temperature Durability Experiment

2.3. Heavy-Load Durability Experiment

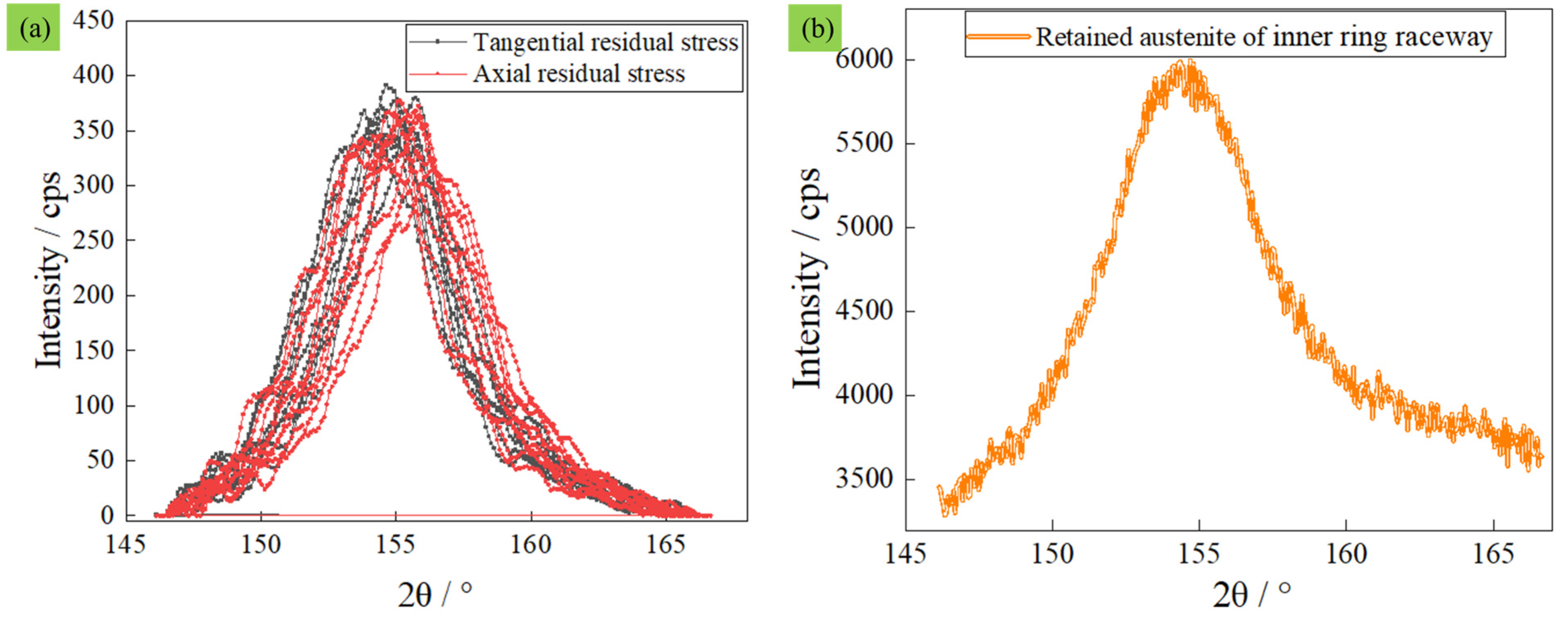

3. Comparative Analysis of the Surface Integrity of High-Performance Bearings

3.1. Surface Wear

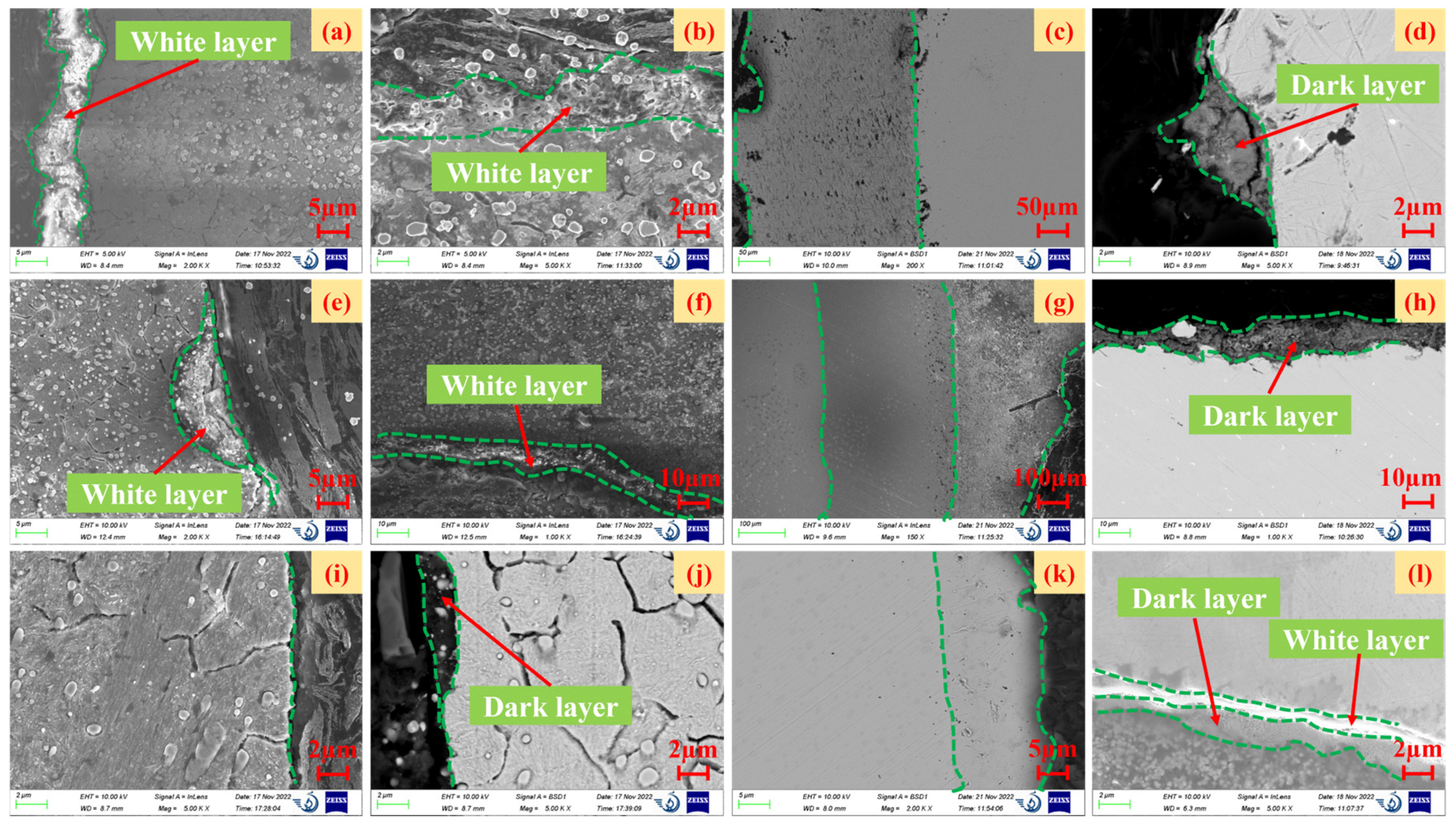

3.2. Metamorphic Layers

3.3. Damage (Microscopic)

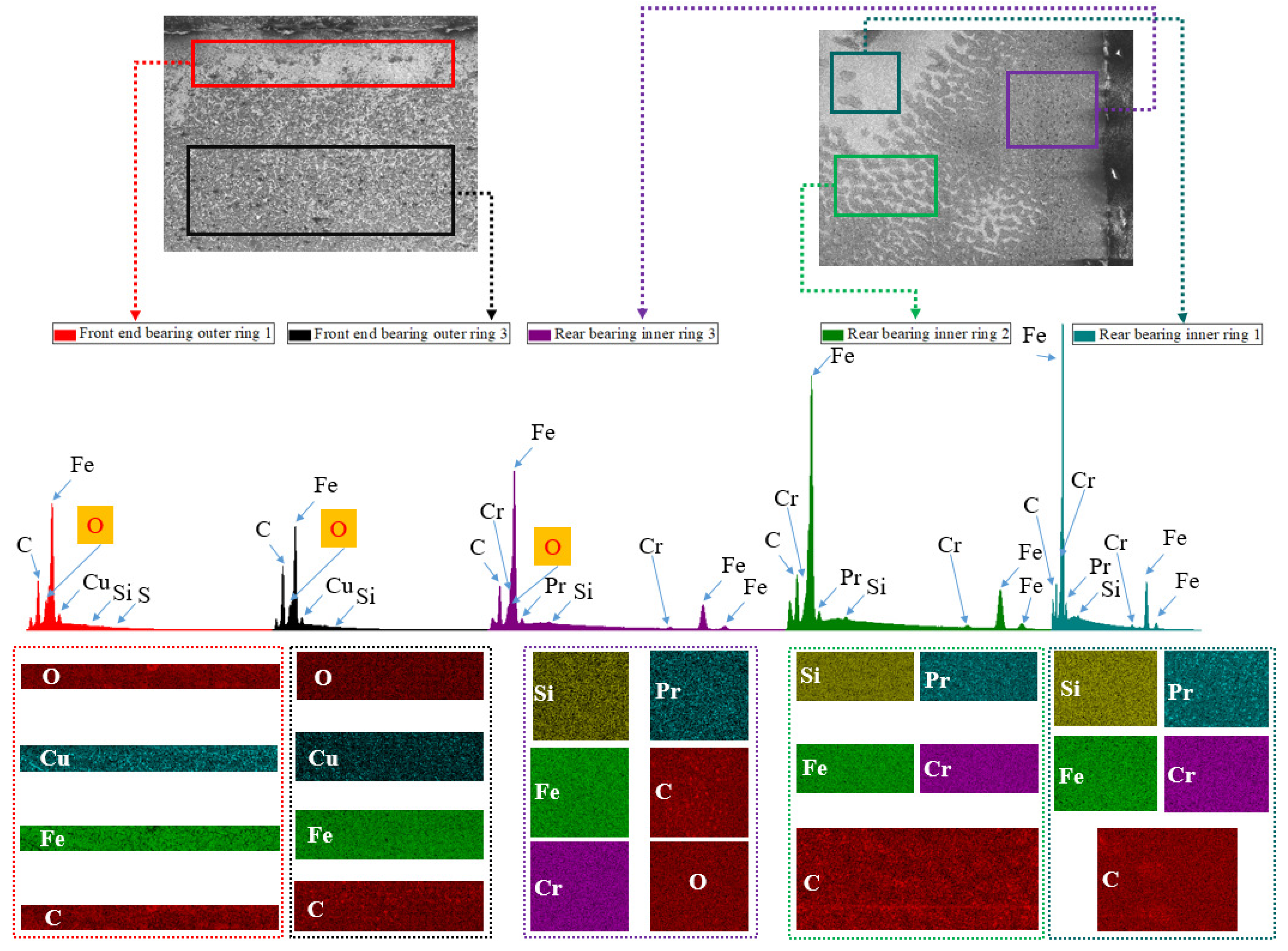

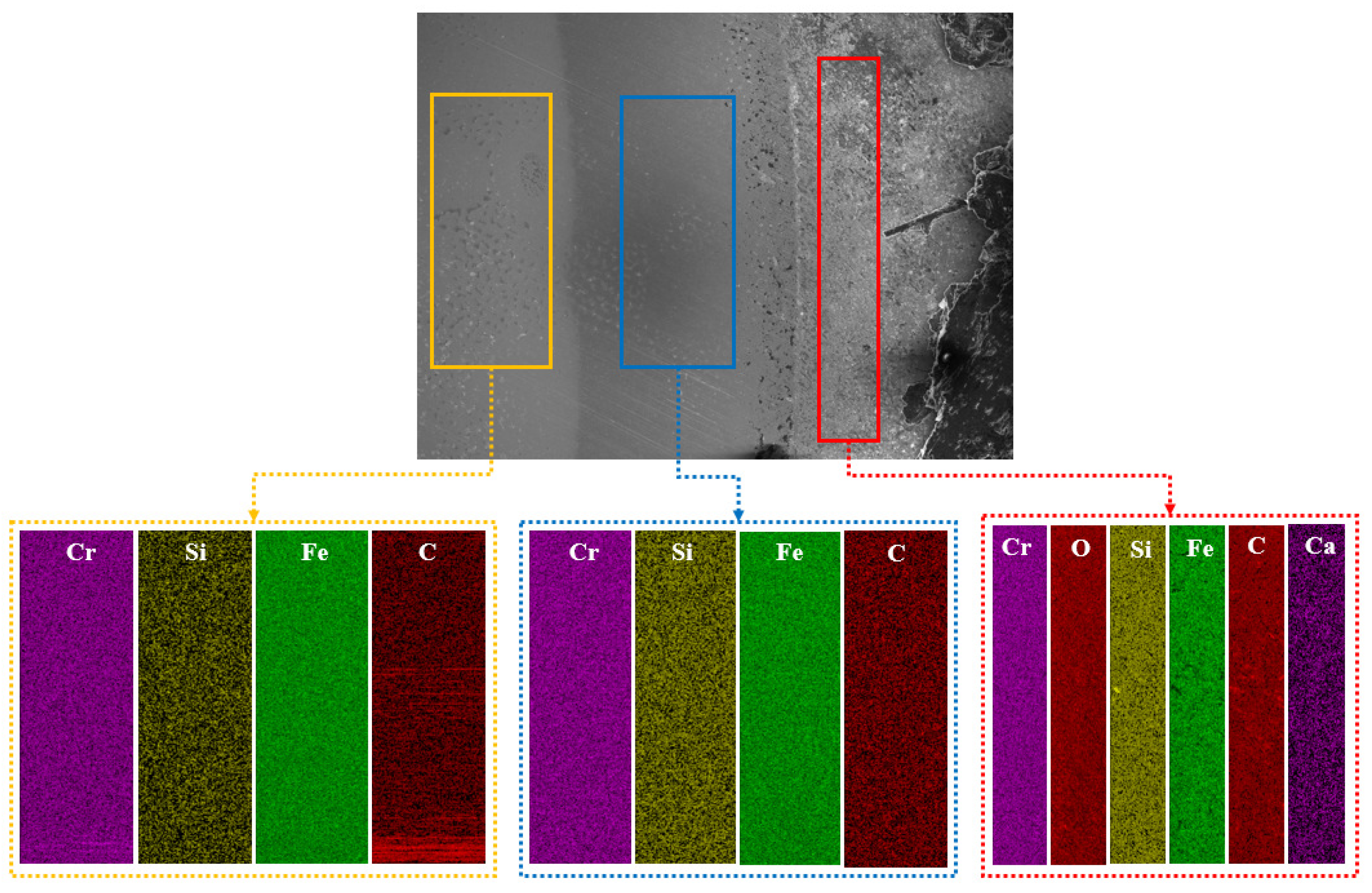

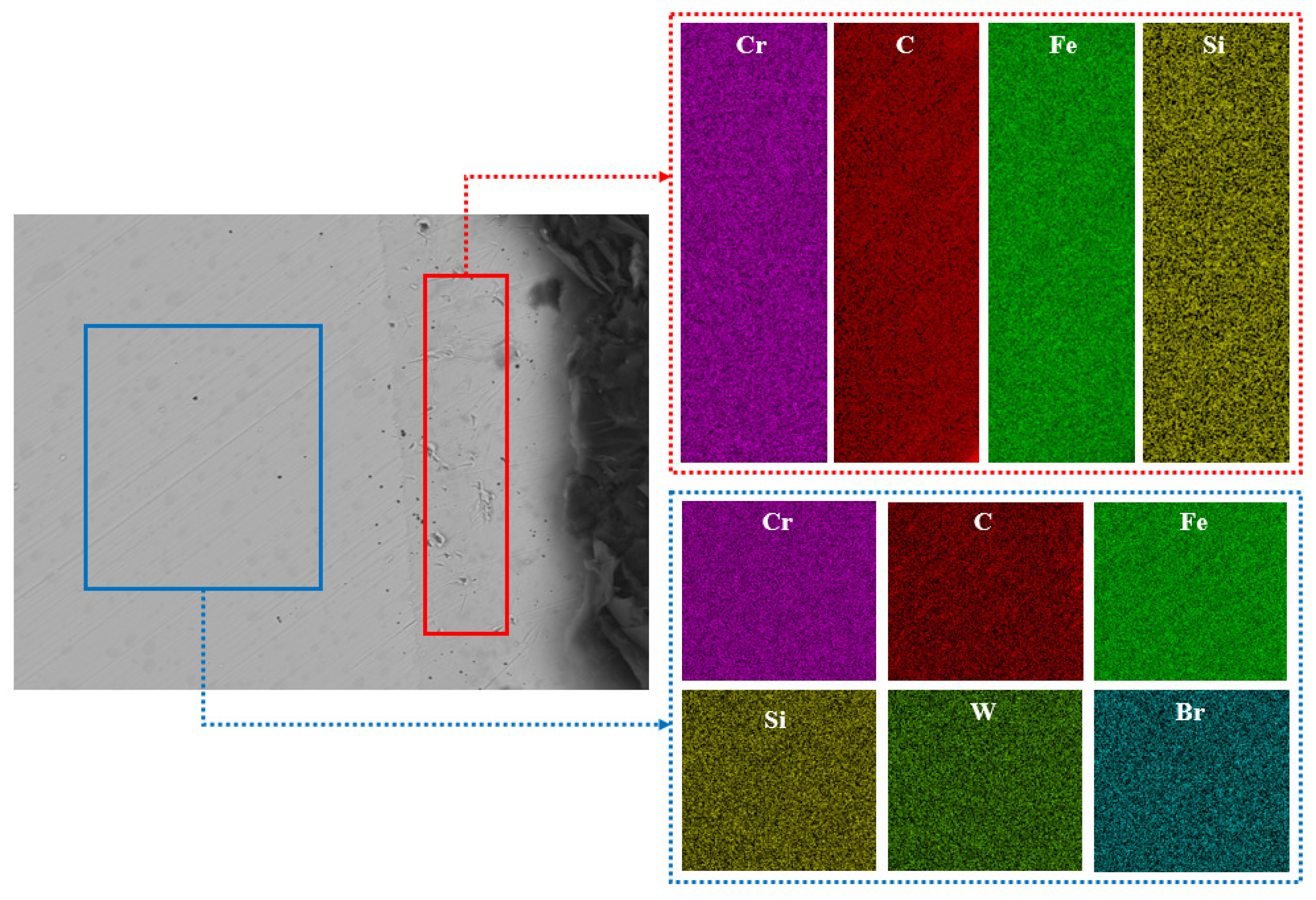

3.4. EDS Analysis

4. Comprehensive Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, H.; An, G.; Huang, M. Application of Ensemble Local Mean Decomposition in Tank Gearbox Rolling Bearing Fault Diagnosis. J. Acad. Armored Force Eng. 2013, 27, 37–42. [Google Scholar]

- Wang, Q. An Analysis of the Evolution of the Modelling of Military Products: Taking Main Battle Tank as an Example. Beijing Inst. Technol. 2018. [Google Scholar] [CrossRef]

- Wang, P.; Li, D.; Zhang, N. Research on early warning of rolling bearing wear failure based on empirical mode decomposition. Int. J. Mater. Prod. Technol. 2021, 63, 72. [Google Scholar] [CrossRef]

- Alves, D.S.; Fieux, G.; Machado, T.H.; Keogh, P.S.; Cavalca, K.L. A parametric model to identify hydrodynamic bearing wear at a single rotating speed. Tribol. Int. 2021, 153, 106640. [Google Scholar] [CrossRef]

- Shi, X.-J.; Wang, L.-Q.; Mao, Y.-Z.; Qin, F.-Q. Coupling study on dynamics and TEHL behavior of high-speed and heavy-load angular contact ball bearing with spinning. Tribol. Int. 2015, 88, 76–84. [Google Scholar] [CrossRef]

- Zmarzy, P. Multi-Dimensional Mathematical Wear Models of Vibration Generated by Rolling Ball Bearings Made of AISI 52100 Bearing Steel. Materials 2020, 13, 5440. [Google Scholar] [CrossRef]

- Shi, X.; Lu, X.; Feng, Y.; Qiu, Z. Tribo-dynamic analysis for aero ball bearing with 3D measured surface roughness. Eng. Fail. Anal. 2021, 131, 105848. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, H.; Chang, W.; Xi, H.; Pei, S.; Meng, W.; Li, H.; Xu, S. A dynamic contact wear model of ball bearings without or with distributed defects. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4827–4843. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Zhang, K.; Li, S. Wear Analysis of Angular Contact Ball Bearing in Multiple-Bearing Spindle System Sub-jected to Uncertain Initial Angular Misalignment. J. Tribol. 2020, 143, 091703. [Google Scholar]

- Shi, X.; Wang, L.; Qin, F. Relative fatigue life prediction of high-speed and heavy-load ball bearing based on surface texture. Tribol. Int. 2016, 101, 364–374. [Google Scholar] [CrossRef]

- Hiraki, K.; Mizobe, K.; Matsueda, T.; Kashima, Y.; Kida, K. Friction Coefficient and Wear of PEEK-PTFE Hybrid Radial Ball Bearings under Dry Conditions. Mater. Sci. Forum 2021, 1020, 114–119. [Google Scholar] [CrossRef]

- Yang, Z.; Li, C.; Zhou, N.; Zhang, J. Research on the cage stability of high-precision ball bearing with image acquirement and error separation. Measurement 2021, 186, 110149. [Google Scholar] [CrossRef]

- Trivedi, H.K.; Rosado, L. Interaction of anti-wear additive TCP with advanced bearing steels. Lubr. Sci. 2022, 34, 169–181. [Google Scholar] [CrossRef]

- Cheng, Y.; Hu, K.; Wu, J.; Zhu, H.; Lee, C.K.M. A deep learning-based two-stage prognostic approach for remaining useful life of rolling bearing. Appl. Intell. 2021, 52, 5880–5895. [Google Scholar] [CrossRef]

- Chen, X.; Hillegersberg, J.V.; Topan, E.; Smith, S.; Roberts, M. Application of Data-driven Models to Predictive Maintenance: Bearing Wear Pre-diction at TATA Steel. Expert Syst. Appl. 2021, 186, 115699. [Google Scholar] [CrossRef]

- Deng, H.; Hu, C.; Wang, Q.; Wang, L.; Wang, C. Friction and wear analysis of the external return spherical bearing pair of axial piston pump/motor. Mech. Ind. 2020, 21, 104. [Google Scholar] [CrossRef]

- Yang, S. Topside Axial Bearing Wear Under the Eccentric Load of a Single-Anchor Leg Mooring System in Bohai Bay. J. Mar. Sci. Appl. 2021, 20, 371–380. [Google Scholar] [CrossRef]

- Yu, X.; Li, S.; Chen, M.; Wang, S.; Han, Z.; Tang, B.; Wang, J.; Jiang, H.; Jia, W. Prediction and improvement on anti-eccentric load characteristics of high-speed and heavy-type hydrostatic bearing. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 558. [Google Scholar] [CrossRef]

- El Laithy, M.; Wang, L.; Harvey, T.J.; Schwedt, A.; Vierneusel, B.; Mayer, J. White etching bands formation mechanisms due to rolling contact fatigue. Acta Mater. 2022, 232, 117932. [Google Scholar] [CrossRef]

- Abdullah, M.U.; Khan, Z.A.; Kruhoeffer, W. Evaluation of Dark Etching Regions for Standard Bearing Steel under Accelerated Rolling Contact Fatigue. Tribol. Int. 2020, 152, 106579. [Google Scholar] [CrossRef]

- Jouini, N.; Revel, P.; Thoquenne, G. Influence of surface integrity on fatigue life of bearing rings finished by precision hard turning and grinding. J. Manuf. Process. 2020, 57, 444–451. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, T.; Yu, F.; Cao, W.; Zhang, X.; Weng, Y. Carburization induced extra-long rolling contact fatigue life of high carbon bearing steel. Int. J. Fatigue 2019, 131, 105351. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y. Research on the rolling contact fatigue life of the bearing considering the friction effect. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 2238–2264. [Google Scholar] [CrossRef]

- Watanuki, D.; Tsutsumi, M.; Hidaka, H.; Wada, K.; Matsunaga, H. Fracture mechanics-based criteria for fatigue fracture of rolling bearings under the influence of defects. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 952–966. [Google Scholar] [CrossRef]

- Lorenz, S.J.; Sadeghi, F.; Wang, C. Effect of spatial hardness distribution in rolling contact fatigue performance of bearing contacts. Tribol. Int. 2022, 171, 107550. [Google Scholar] [CrossRef]

- Schwendemann, S.; Amjad, Z.; Sikora, A. A survey of machine-learning techniques for condition monitoring and predictive maintenance of bearings in grinding machines. Comput. Ind. 2020, 125, 103380. [Google Scholar] [CrossRef]

- Paiva, R.; Ruzzi, R.; Silva, R. Contribution to the selection of cutting fluid type and its application technique for grinding of bearing steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 603–613. [Google Scholar] [CrossRef]

- Sridharan, U.; Bedekar, V.; Kolarits, F.M. A functional approach to integrating grinding temperature modeling and Barkhausen noise analysis for prediction of surface integrity in bearing steels. CIRP Ann. 2017, 66, 333–336. [Google Scholar] [CrossRef]

- Cui, L.; Su, Y. Contact fatigue life prediction of rolling bearing considering machined surface integrity. Ind. Lubr. Tribol. 2022, 74, 73–80. [Google Scholar] [CrossRef]

- Duan, H.; Song, J.; Wang, Z. Lubrication and Fatigue Life Evaluation of High-Speed Cylindrical Roller Bearing under Misalign-ment. Math. Probl. Eng. 2020, 2020, 2068924. [Google Scholar]

- Kong, X.; Ding, H.; Tang, J.; Hu, Z.; Chen, S. Bearing internal load analysis and fatigue life estimation based on nonlinear dynamic model of a gear system. J. Vib. Control 2021, 28, 1635–1642. [Google Scholar] [CrossRef]

- Zhuang, C.; Chen, G. Effects of Ball’s Rolling, Gyroscopic, and Spin Slide in a Ball Bearing on Raceway’s Stress and Fatigue Life. J. Tribol. 2020, 142, 1–43. [Google Scholar]

- Liu, Z.; Yang, B.; Wang, X.; Zhang, L. Acoustic Emission Analysis for Wind Turbine Blade Bearing Fault Detection Under Time-Varying Low-Speed and Heavy Blade Load Conditions. IEEE Trans. Ind. Appl. 2021, 57, 2791–2800. [Google Scholar] [CrossRef]

- Wu, C.; Sun, H.; Zhang, Z. Stages prediction of the remaining useful life of rolling bearing based on regularized extreme learning machine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6599–6610. [Google Scholar] [CrossRef]

- Semenov, M.Y.; Ding, K.J.; Smirnov, A.E.; Fedorova, L.V.; Polyakova, A.V. Wear of Bearing Parts from Precision Nickel Alloys After Glow Discharge Nitriding. Met. Sci. Heat Treat. 2020, 62, 220–223. [Google Scholar] [CrossRef]

- Eknath, K.G.; Diwakar, G. Prediction of Remaining useful life of Rolling Bearing using Hybrid DCNN-BiGRU Model. J. Vib. Eng. Technol. 2022, 1–14. [Google Scholar] [CrossRef]

- Wang, H.Y.; Yang, T.; Gao, L.H. Research on Fatigue Life Prediction Technique for Tank’s Load-bearing Parts Based on Virtual Prototype. J. Acad. Armored Force Eng. 2007, 21, 40–44. [Google Scholar]

| Project | C (wt%) | O (wt%) | Fe (wt%) | Si (wt%) | S (wt%) | Cu (wt%) | Cr (wt%) | Pr (wt%) |

|---|---|---|---|---|---|---|---|---|

| Front-end bearing outer ring 1 | 9.99 | 3.03 | 81.32 | 0.24 | 0.30 | 5.12 | ||

| Front-end bearing outer ring 3 | 15.36 | 3.10 | 77.16 | 0.24 | 4.14 | |||

| Rear bearing inner ring 3 | 8.82 | 1.04 | 57.56 | 0.17 | 2.68 | 29.73 | ||

| Rear bearing inner ring 2 | 6.25 | 56.84 | 0.18 | 6.68 | 30.04 | |||

| Rear bearing inner ring 1 | 3.97 | 52.73 | 0.17 | 5.18 | 37.94 |

| Figure | Color | C (wt%) | O (wt%) | Fe (wt%) | Si (wt%) | Ca (wt%) | P (wt%) | Br (wt%) | Cr (wt%) | Al (wt%) | W (wt%) | Sr (wt%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Figure 9 | Red | 10.98 | 6.23 | 77.03 | 0.72 | 0.24 | 4.79 | |||||

| Blue | 3.76 | 90.71 | 0.21 | 5.11 | 0.05 | 0.16 | ||||||

| Figure 10 | Red | 9.23 | 4.63 | 81.59 | 0.50 | 0.21 | 0.35 | 0.61 | ||||

| Blue | 3.6 | 91.00 | 0.29 | 0.06 | 4.79 | 0.08 | 0.19 | |||||

| Yellow | 3.8 | 90.09 | 0.20 | 5.91 | ||||||||

| Figure 11 | Red | 6.78 | 84.54 | 0.26 | 0.07 | 4.62 | 0.1 | |||||

| Blue | 4.87 | 89.93 | 0.22 | 0.21 | 4.62 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Yuan, J.; Hu, L.; Lyu, B. Multidimensional Study on the Wear of High-Speed, High-Temperature, Heavy-Load Bearings. Materials 2023, 16, 2714. https://doi.org/10.3390/ma16072714

Wang D, Yuan J, Hu L, Lyu B. Multidimensional Study on the Wear of High-Speed, High-Temperature, Heavy-Load Bearings. Materials. 2023; 16(7):2714. https://doi.org/10.3390/ma16072714

Chicago/Turabian StyleWang, Dongfeng, Julong Yuan, Lai Hu, and Binghai Lyu. 2023. "Multidimensional Study on the Wear of High-Speed, High-Temperature, Heavy-Load Bearings" Materials 16, no. 7: 2714. https://doi.org/10.3390/ma16072714

APA StyleWang, D., Yuan, J., Hu, L., & Lyu, B. (2023). Multidimensional Study on the Wear of High-Speed, High-Temperature, Heavy-Load Bearings. Materials, 16(7), 2714. https://doi.org/10.3390/ma16072714