Effect of Si on Microstructure and Mechanical Properties of FeCrNi Medium Entropy Alloys

Abstract

1. Introduction

2. Experimental Procedures

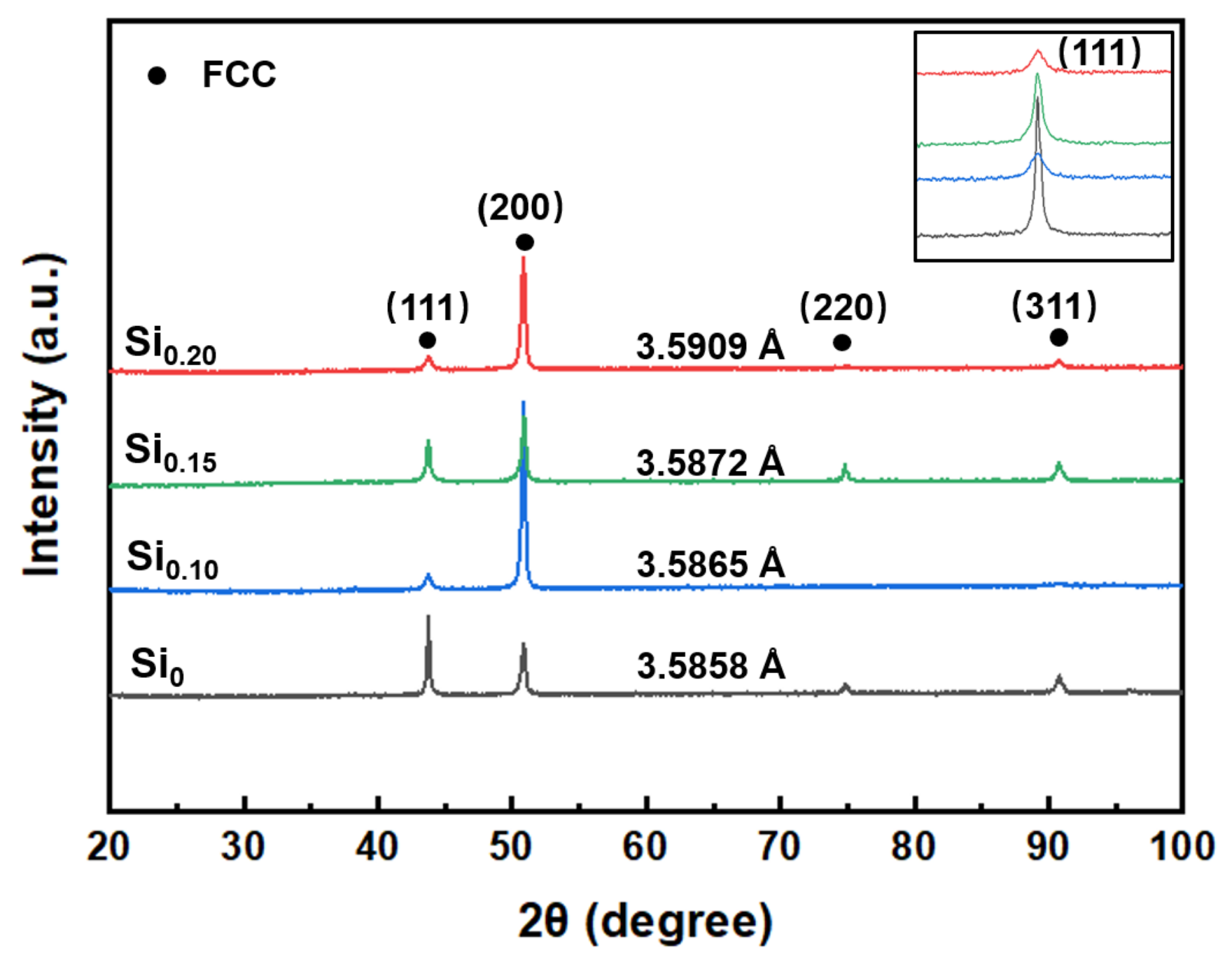

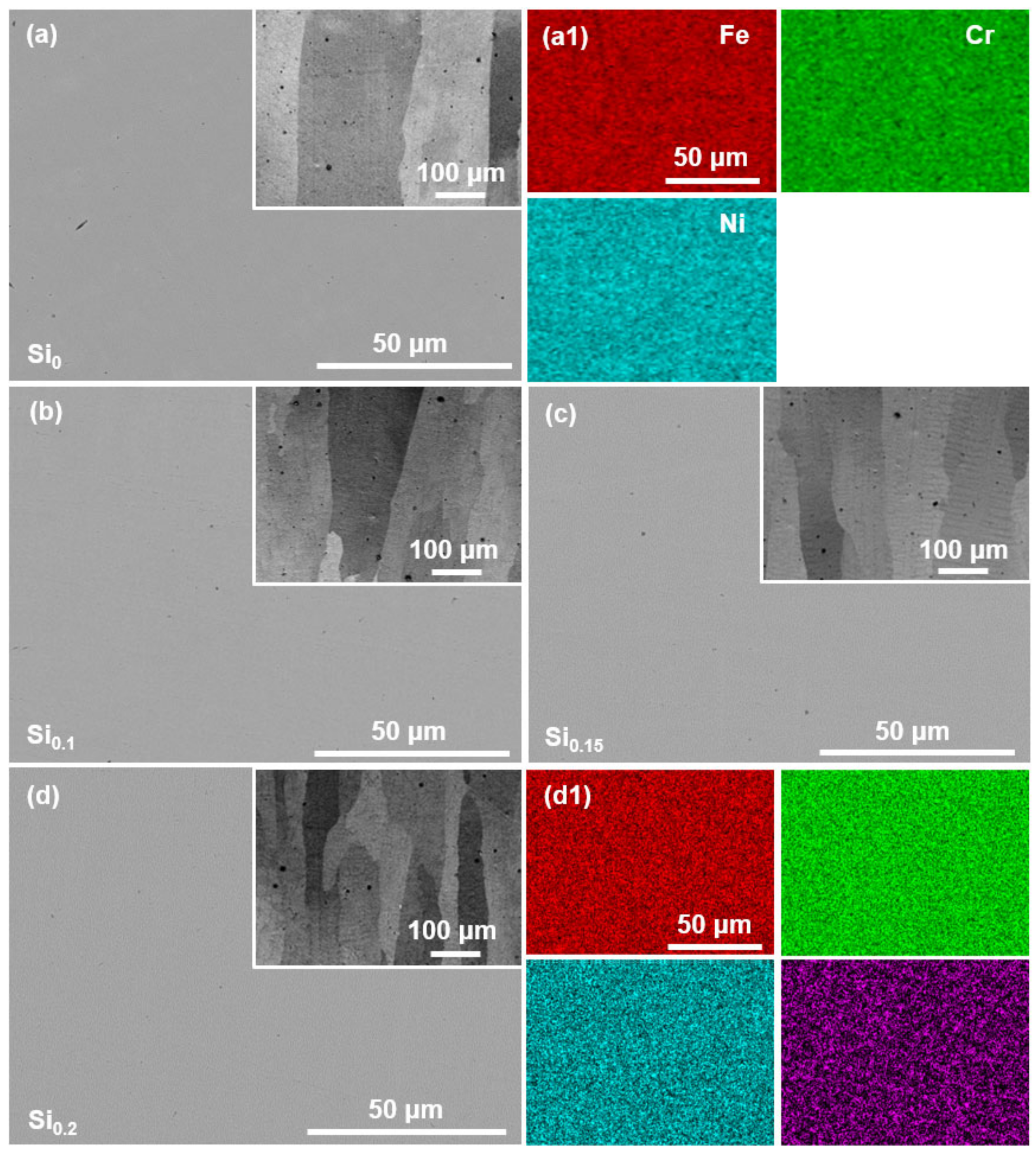

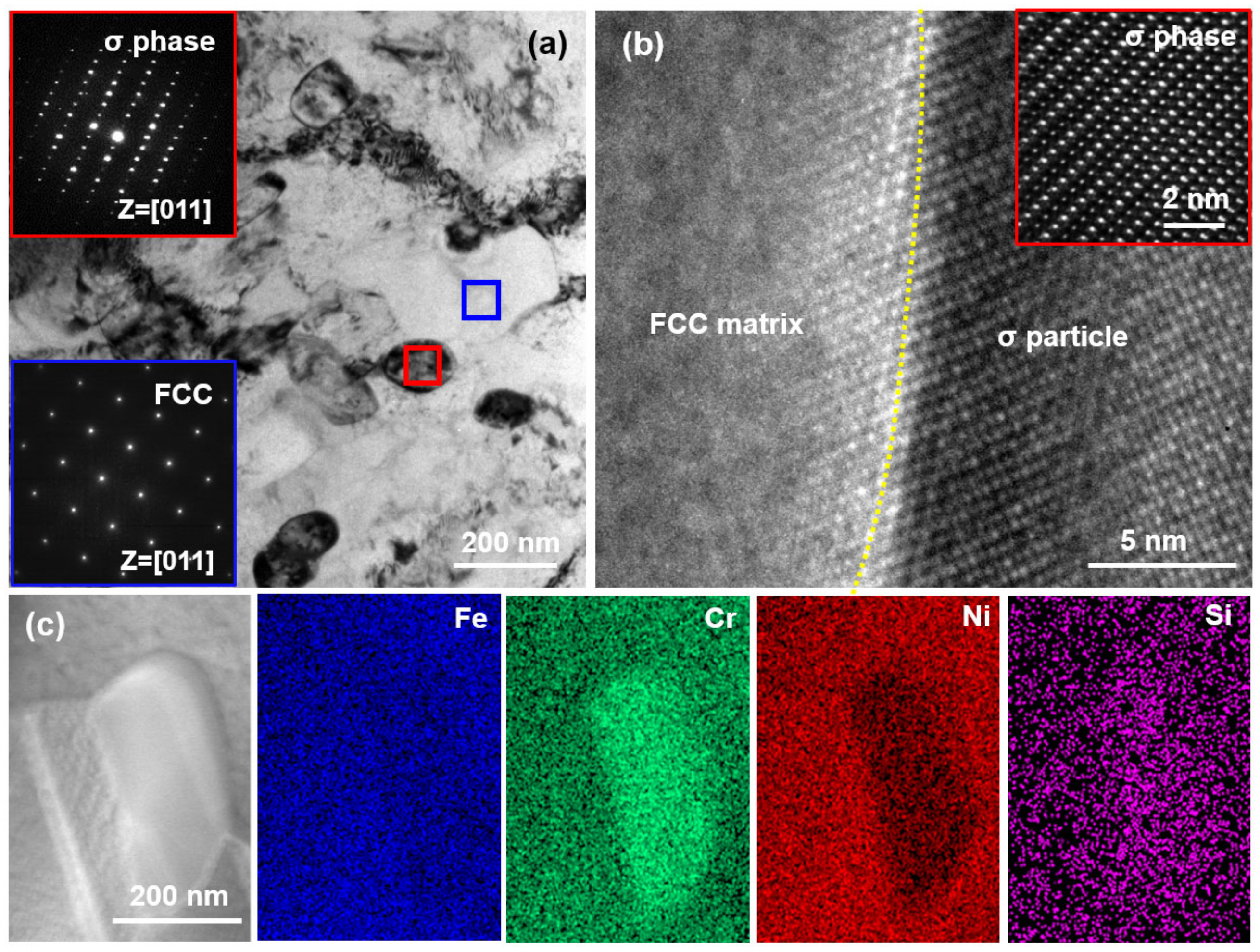

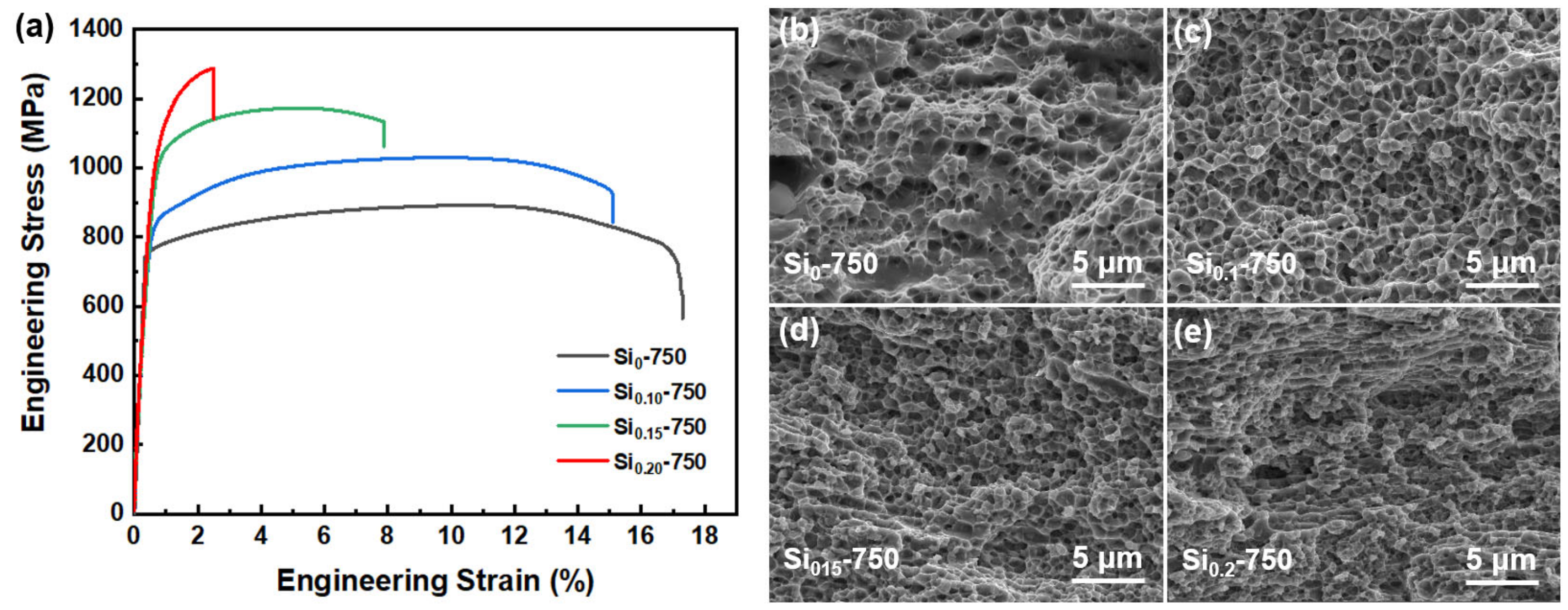

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sathiyamoorthi, P.; Kim, H. High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties. Prog. Mater. Sci. 2022, 123, 100709. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Liu, B.; Cao, Y.; Wang, J.; Liao, T.; Li, J.; Fang, Q.; Liaw, P.; Liu, Y. A novel cobalt-free oxide dispersion strengthened medium-entropy alloy with outstanding mechanical properties and irradiation resistance. J. Mater. Sci. Technol. 2023, 152, 192–200. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; He, Q.; Xu, X.; Wang, H.; Jiang, C.; Liu, B.; Fang, Q.; Liu, Y.; Yang, Y.; et al. Heterogeneous lattice strain strengthening in severely distorted crystalline solids. Proc. Natl. Acad. Sci. USA 2022, 119, e2200607119. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Zhao, C.; Zhu, W.; Wei, P.; Jiang, F.; Zhang, Y.; Sun, Q.; Ren, F. Overcoming the strength-ductility trade-off via the formation of nanoscale Cr-rich precipitates in an ultrafine-grained FCC CrFeNi medium entropy alloy matrix. Mater. Sci. Eng. A 2019, 762, 138107. [Google Scholar] [CrossRef]

- Zhang, G.; Khanlari, K.; Huang, S.; Li, X.; Zhao, D.; Wu, H.; Cao, Y.; Liu, B.; Huang, Q. Dual-structured oxide coatings with enhanced wear and corrosion resistance prepared by plasma electrolytic oxidation on Ti-Nb-Ta-Zr-Hf high-entropy alloy. Surf. Coat. Technol. 2023, 456, 129254. [Google Scholar] [CrossRef]

- Li, Z.; Ma, S.; Zhao, S.; Zhang, W.; Peng, F.; Li, Q.; Yang, T.; Wu, C.; Wei, D.; Chou, Y.-C.; et al. Achieving superb strength in single-phase FCC alloys via maximizing volume misfit. Mater. Today 2023. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Y.; Han, J.; Wang, X.; Jiang, W.; Liu, C.; Zhang, Z.; Liaw, P. Nanoprecipitate-strengthened high-entropy alloys. Adv. Sci. 2021, 8, 2100870. [Google Scholar] [CrossRef]

- Fu, A.; Cao, Y.; Xie, Z.; Wang, J.; Liu, B. Microstructure and mechanical properties of Al-Fe-Co-Cr-Ni high entropy alloy fabricated via powder extrusion. J. Alloys Compd. 2023, 943, 169052. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scr. Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Schneider, M.; Laplanche, G. Effects of temperature on mechanical properties and deformation mechanisms of the equiatomic CrFeNi medium-entropy alloy. Acta Mater. 2021, 204, 116470. [Google Scholar] [CrossRef]

- He, M.; Shen, Y.; Jia, N.; Liaw, P. C and N doping in high-entropy alloys: A pathway to achieve desired strength-ductility synergy. Appl. Mater. Today 2021, 25, 101162. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, K.; Wang, Z.; Zhou, H.; Gao, K.; Du, Y.; Su, Y. Microstructure and mechanical properties of novel Si-added CrFeNi medium-entropy alloy prepared via vacuum arc-melting. J. Alloys Compd. 2022, 904, 164136. [Google Scholar] [CrossRef]

- Chen, J.; Yao, Z.; Wang, X.; Lu, Y.; Wang, X.; Liu, Y.; Fan, X. Effect of C content on microstructure and tensile properties of as-cast CoCrFeMnNi high entropy alloy. Mater. Chem. Phys. 2018, 210, 136–145. [Google Scholar] [CrossRef]

- Xin, B.; Zhang, A.; Han, J.; Zhang, J.; Meng, J. Enhancing mechanical properties of the boron doped Al0.2Co1.5CrFeNi1.5Ti0.5 high entropy alloy via tuning composition and microstructure. J. Alloys Compd. 2022, 896, 162852. [Google Scholar] [CrossRef]

- Peng, J.; Li, Z.; Fu, L.; Ji, X.; Pang, Z.; Shan, A. Carbide precipitation strengthening in fine-grained carbon-doped FeCoCrNiMn high entropy alloy. J. Alloys Compd. 2019, 803, 491–498. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, L.; Yu, P.; Zhang, M.; Liu, D.; Zhou, Z.; Cui, P.; Ma, M.; Jing, Q.; Li, G.; et al. Improved the microstructure and mechanical properties of AlFeCoNi high-entropy alloy by carbon addition. Mater. Sci. Eng. A 2018, 728, 30–39. [Google Scholar] [CrossRef]

- Li, N.; Gu, J.; Gan, B.; Qiao, Q.; Ni, S.; Song, M. Effects of Mo-doping on the microstructure and mechanical properties of CoCrNi medium entropy alloy. J. Mater. Res. 2020, 35, 2726–2736. [Google Scholar] [CrossRef]

- Nutor, R.; Cao, Q.; Wang, X.; Zhang, D.; Jiang, J. Tunability of the mechanical properties of (Fe50Mn27Ni10Cr13)100-xMox high-entropy alloys via secondary phase control. J. Mater. Sci. Technol. 2021, 73, 210–217. [Google Scholar] [CrossRef]

- Liu, W.; Lu, Z.; He, J.; Luan, J.; Wang, Z.; Liu, B.; Liu, Y.; Chen, M.; Liu, C. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016, 116, 332–342. [Google Scholar] [CrossRef]

- Jo, Y.; Choi, W.; Kim, D.; Zargaran, A.; Lee, K.; Sung, H.; Sohn, S.; Kim, H.; Lee, B.; Lee, S. Utilization of brittle σ phase for strengthening and strain hardening in ductile VCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2019, 743, 665–674. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, T.; Ma, S.; Zhao, D.; Xiong, R.; Wang, T.; Li, Z.; Wang, Z. Novel Si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater. Des. 2021, 197, 109202. [Google Scholar] [CrossRef]

- Tsuru, T.; Lobzenko, I.; Wei, D. Synergetic effect of Si addition on mechanical properties in face-centered-cubic high entropy alloys: A first-principles study. Model. Simul. Matter. Sci. Eng. 2022, 30, 024003. [Google Scholar] [CrossRef]

- Sathiaraj, G.; Skrotzki, W.; Pukenas, A.; Schaarschuch, R.; Immanuel, R.; Panigrahi, S.; Chelvane, J.; Kumar, S. Effect of annealing on the microstructure and texture of cold rolled CrCoNi medium-entropy alloy. Intermetallics 2018, 101, 87–98. [Google Scholar] [CrossRef]

- Kim, J.; Lim, K.; Won, J.; Na, Y.; Kim, H. Mechanical properties and deformation twinning behavior of as-cast CoCrFeMnNi high-entropy alloy at low and high temperatures. Mater. Sci. Eng. A 2018, 712, 108–113. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Li, X.; Jing, H.; Qin, G.; Pang, H.; Minami, F. A Si-containing FeCoCrNi high-entropy alloy with high strength and ductility synthesized in situ via selective laser melting. Addit. Manuf. 2020, 35, 101340. [Google Scholar] [CrossRef]

- Li, J.; Lu, K.; Zhao, X.; Ma, X.; Li, F.; Pan, H.; Chen, J. A superior strength-ductility synergy of Al0.1CrFeCoNi high-entropy alloy with fully recrystallized ultrafine grains and annealing twins. J. Mater. Sci. Technol. 2022, 131, 185–194. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.; Ma, S.; Liaw, P.; Zhang, Y.; Qiao, J. Strengthening in Al0.25CoCrFeNi high-entropy alloys by cold rolling. Mater. Sci. Eng. A 2017, 707, 593–601. [Google Scholar] [CrossRef]

- Ming, K.; Bi, X.; Wang, J. Precipitation strengthening of ductile Cr15Fe20Co35Ni20Mo10 alloys. Scr. Mater. 2017, 137, 88–93. [Google Scholar] [CrossRef]

- Laplanche, G. Growth kinetics of σ-phase precipitates and underlying diffusion processes in CrMnFeCoNi high-entropy alloys. Acta Mater. 2020, 199, 193–208. [Google Scholar] [CrossRef]

- Watanabe, H.; Murata, T.; Nakamura, S.; Ikeo, N.; Mukai, T.; Tsuchiya, K. Effect of cold-working on phase formation during heat treatment in CrMnFeCoNi system high-entropy alloys with Al addition. J. Alloys Compd. 2021, 872, 159668. [Google Scholar] [CrossRef]

- Zhang, J.; Muralikrishna, G.; Asabre, A.; Kalchev, Y.; Mueller, J.; Butz, B.; Hilke, S.; Rösner, H.; Laplanche, G.; Divinski, S.V.; et al. Tracer diffusion in the σ phase of the CoCrFeMnNi system. Acta Mater. 2021, 203, 116498. [Google Scholar] [CrossRef]

- Tong, Y.; Chen, D.; Han, B.; Wang, J.; Feng, R.; Yang, T.; Zhao, C.; Zhao, Y.; Guo, W.; Shimizu, Y.; et al. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures. Acta Mater. 2019, 165, 228–240. [Google Scholar] [CrossRef]

- Lu, W.; Luo, X.; Yang, Y.; Le, W.; Huang, B.; Li, P. Co-free non-equilibrium medium-entropy alloy with outstanding tensile properties. J. Alloys Compd. 2020, 833, 155074. [Google Scholar] [CrossRef]

- Antonov, S.; Huo, J.; Feng, Q.; Isheim, D.; Seidman, D.; Helmink, R.; Sun, E.; Tin, S. σ and η Phase formation in advanced polycrystalline Ni-base superalloys. Mater. Sci. Eng. A 2017, 687, 232–240. [Google Scholar] [CrossRef]

- Lin, H.; Guo, X.; Song, K.; Li, S.; Feng, J.; Zhang, X.; Feng, M. Synergistic strengthening effect of tungsten carbide (WC) particles and silicon carbide whiskers (SiCw) on mechanical properties of Cu–Al2O3 composite. J. Mater. Res. Technol. 2021, 15, 2837–2847. [Google Scholar] [CrossRef]

- Li, J.; Ren, X.; Zhang, Y.; Hou, H.; Gao, X. Effect of superplastic deformation on precipitation behavior of sigma phase in 3207 duplex stainless steel. Prog. Nat. Sci. Mater. 2021, 31, 334–340. [Google Scholar] [CrossRef]

- Laplanche, G.; Gadaud, P.; Bärsch, C.; Demtröder, K.; Reinhart, C.; Schreuer, J.; George, E. Elastic moduli and thermal expansion coefficients of medium-entropy subsystems of the CrMnFeCoNi high-entropy alloy. J. Alloys Compd. 2018, 746, 244–255. [Google Scholar] [CrossRef]

- Liu, W.; Yang, T.; Liu, C. Precipitation hardening in CoCrFeNi-based high entropy alloys. Mater. Chem. Phys. 2018, 210, 2–11. [Google Scholar] [CrossRef]

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Choi, N.; Lim, K.; Na, Y.; Glatzel, U.; Park, J. Characterization of non-metallic inclusions and their influence on the mechanical properties of a FCC single-phase high-entropy alloy. J. Alloys Compd. 2018, 763, 546–557. [Google Scholar] [CrossRef]

| Regions | Fe (at%) | Cr (at%) | Ni (at%) | Si (at%) |

|---|---|---|---|---|

| Matrix | 32.59 | 28.34 | 33.55 | 5.52 |

| σ particle | 24.47 | 47.38 | 12.86 | 15.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, F.; Cao, Y.; Fu, A.; Wang, J.; Zhang, W.; Qiu, J.; Liu, B. Effect of Si on Microstructure and Mechanical Properties of FeCrNi Medium Entropy Alloys. Materials 2023, 16, 2697. https://doi.org/10.3390/ma16072697

Ding F, Cao Y, Fu A, Wang J, Zhang W, Qiu J, Liu B. Effect of Si on Microstructure and Mechanical Properties of FeCrNi Medium Entropy Alloys. Materials. 2023; 16(7):2697. https://doi.org/10.3390/ma16072697

Chicago/Turabian StyleDing, Fang, Yuankui Cao, Ao Fu, Jian Wang, Weidong Zhang, Jingwen Qiu, and Bin Liu. 2023. "Effect of Si on Microstructure and Mechanical Properties of FeCrNi Medium Entropy Alloys" Materials 16, no. 7: 2697. https://doi.org/10.3390/ma16072697

APA StyleDing, F., Cao, Y., Fu, A., Wang, J., Zhang, W., Qiu, J., & Liu, B. (2023). Effect of Si on Microstructure and Mechanical Properties of FeCrNi Medium Entropy Alloys. Materials, 16(7), 2697. https://doi.org/10.3390/ma16072697