The Characteristic Microstructures and Properties of Steel-Based Alloy via Additive Manufacturing

Abstract

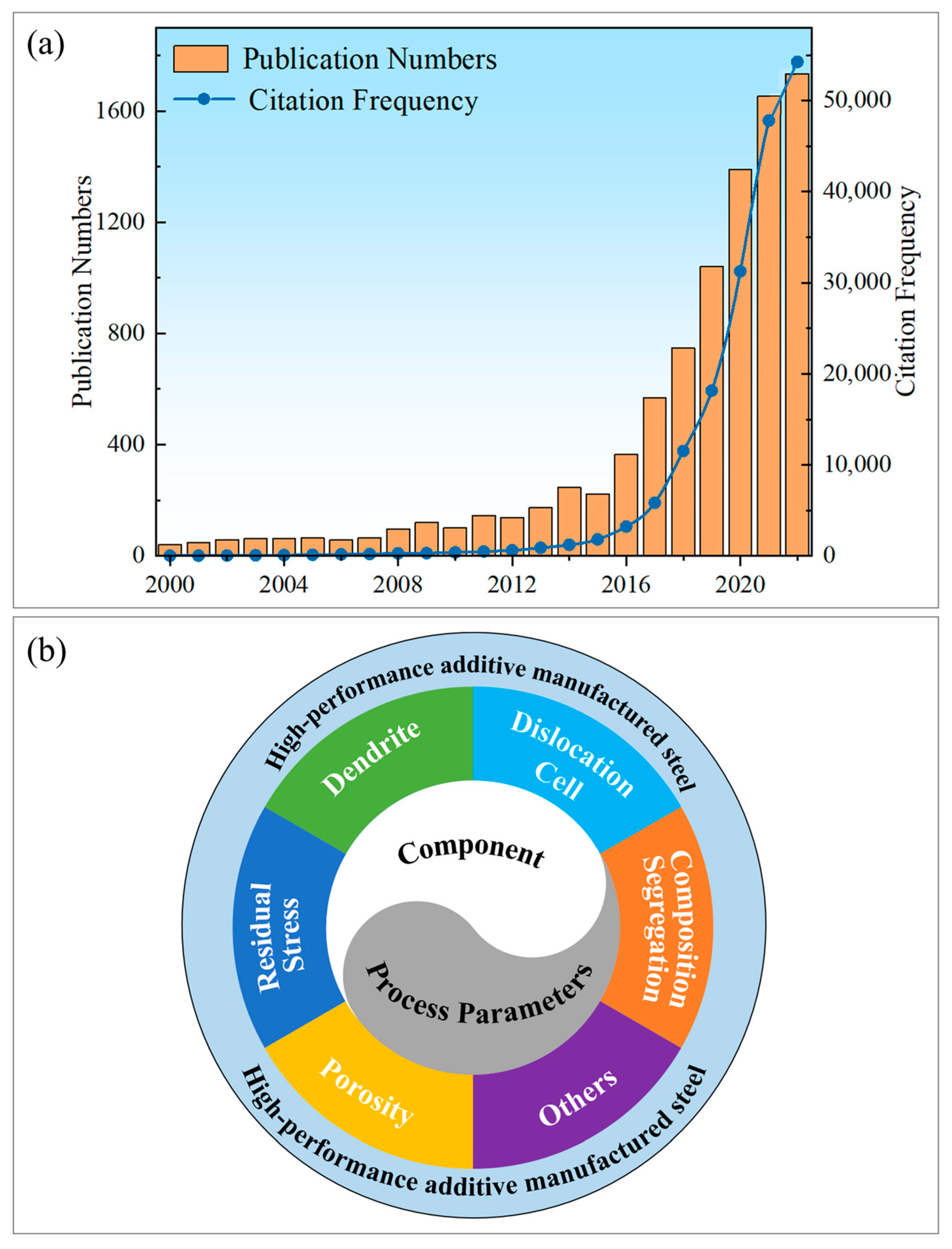

1. Introduction

2. Advanced Additive Manufacturing Techniques

2.1. Powder Bed Fusion

2.1.1. Selective Laser Melting

2.1.2. Electron Beam Melting

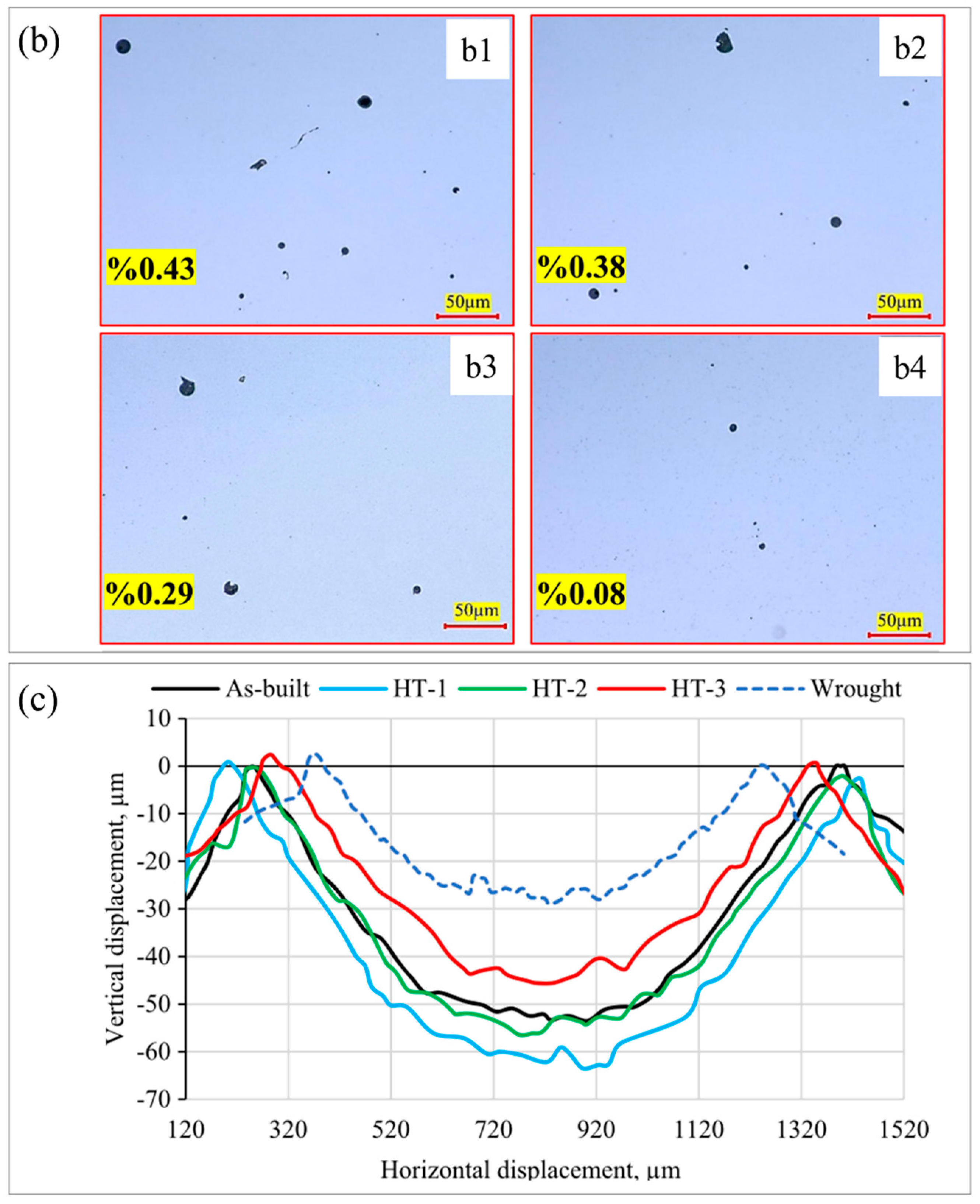

2.2. Direct Energy Deposition

3. Characteristic Microstructures of Steel Prepared via AM

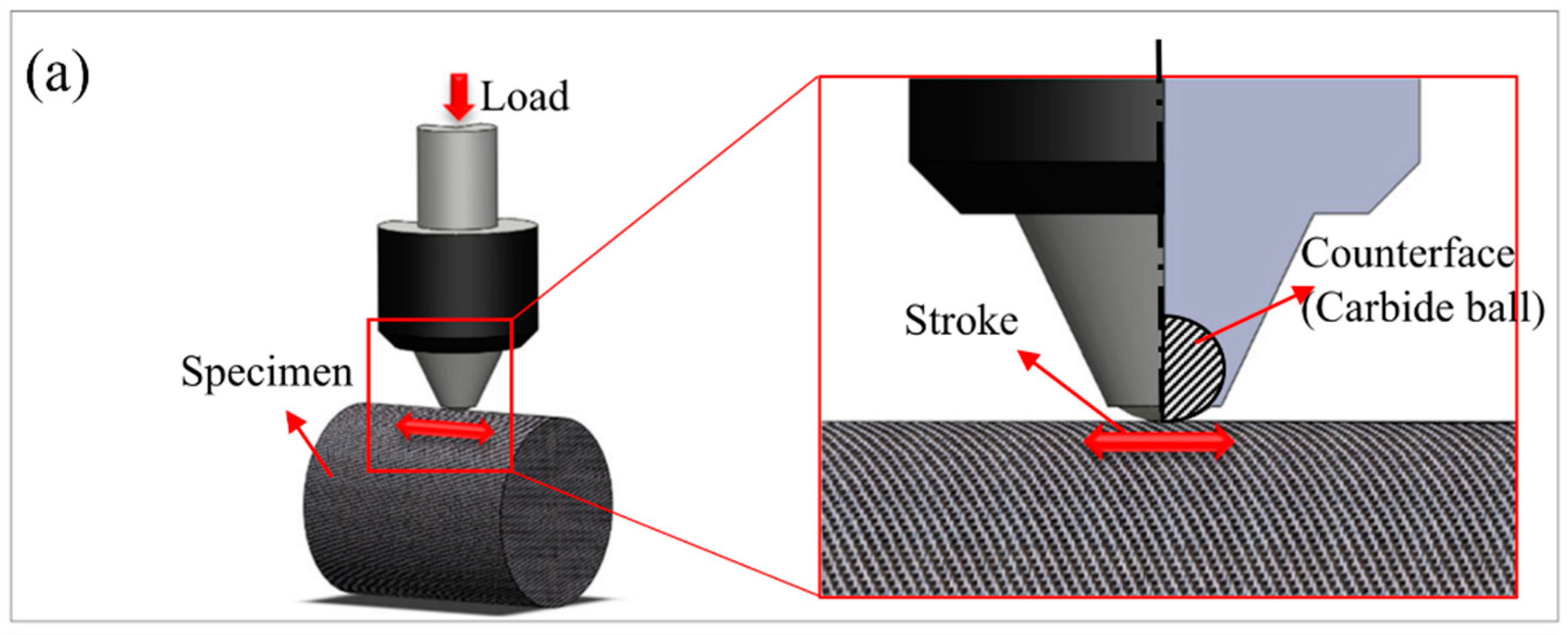

3.1. Porosity in Additively Manufactured Steel

3.2. Dendrite Structures in Additively Manufactured Steel

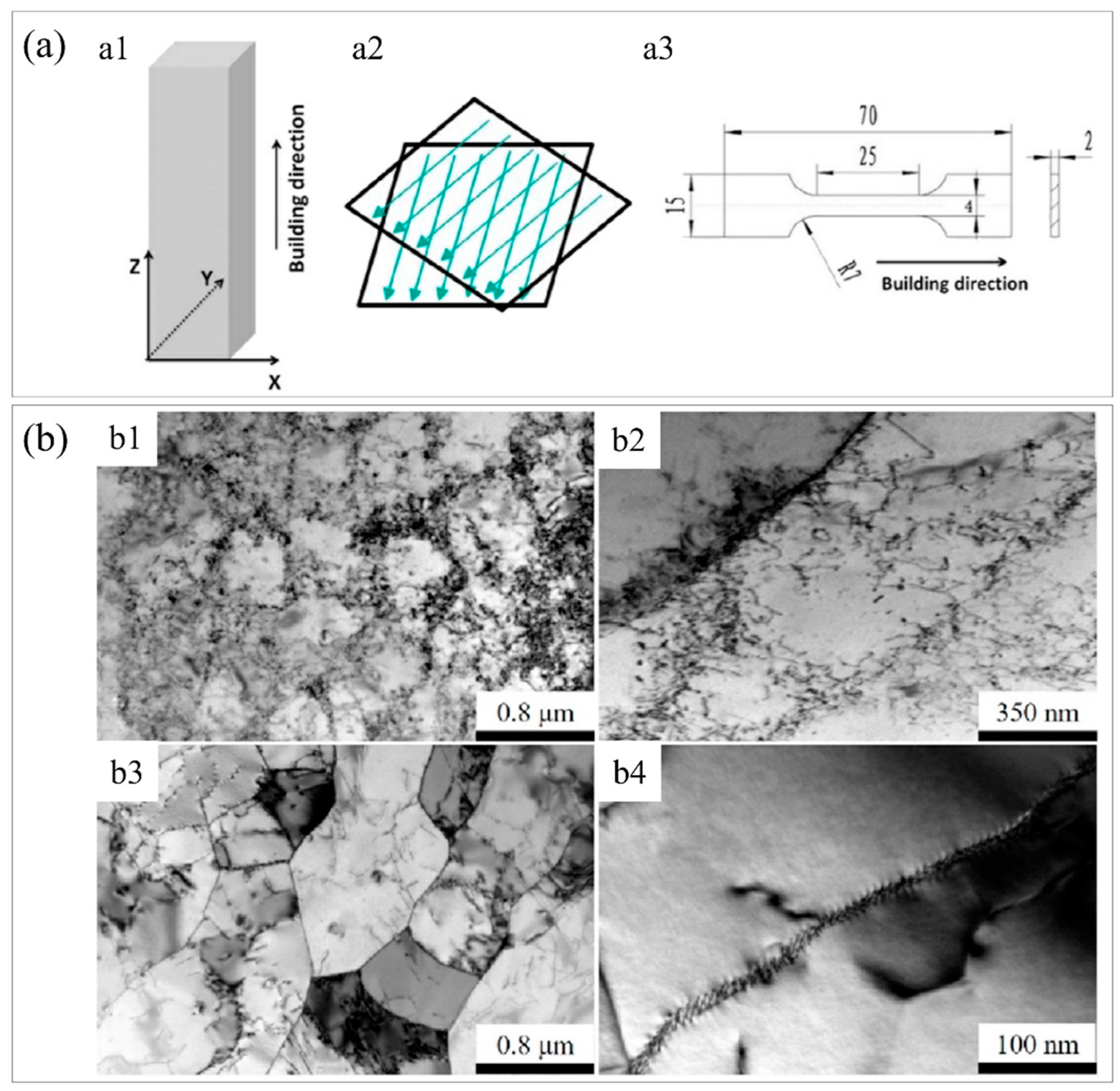

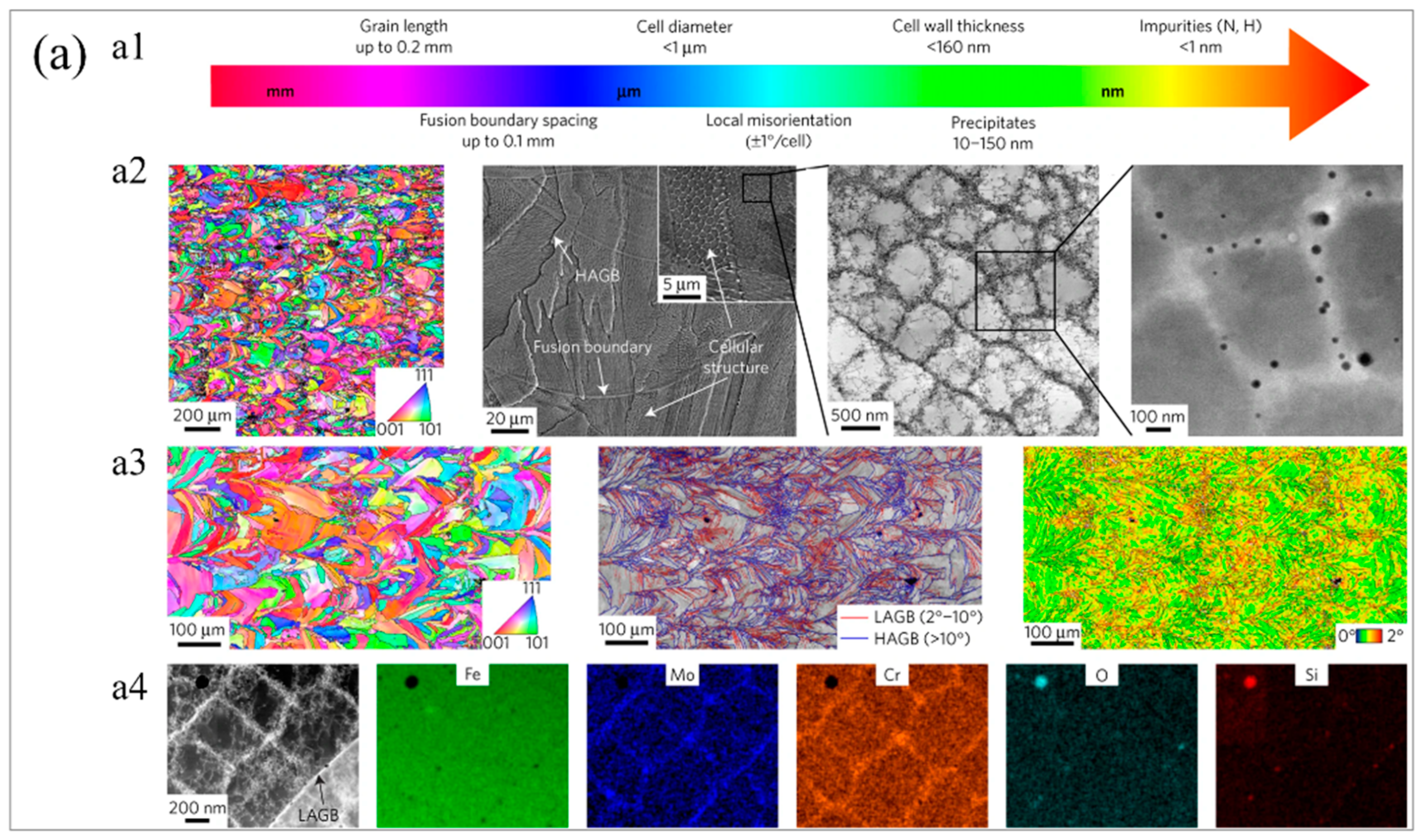

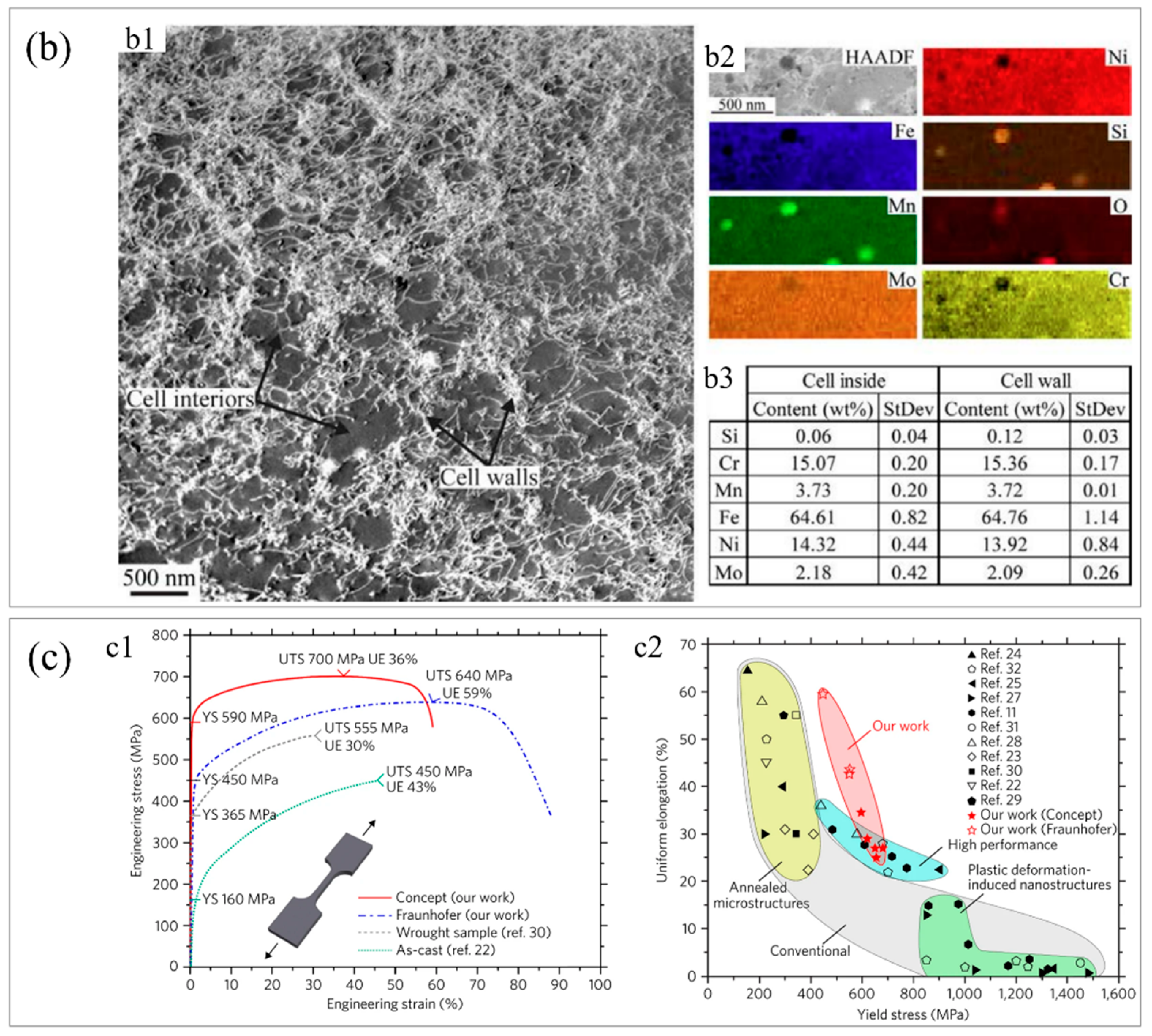

3.3. Dislocation Cells in Additively Manufactured Steel

3.4. Residual Stress in Additively Manufactured Steel

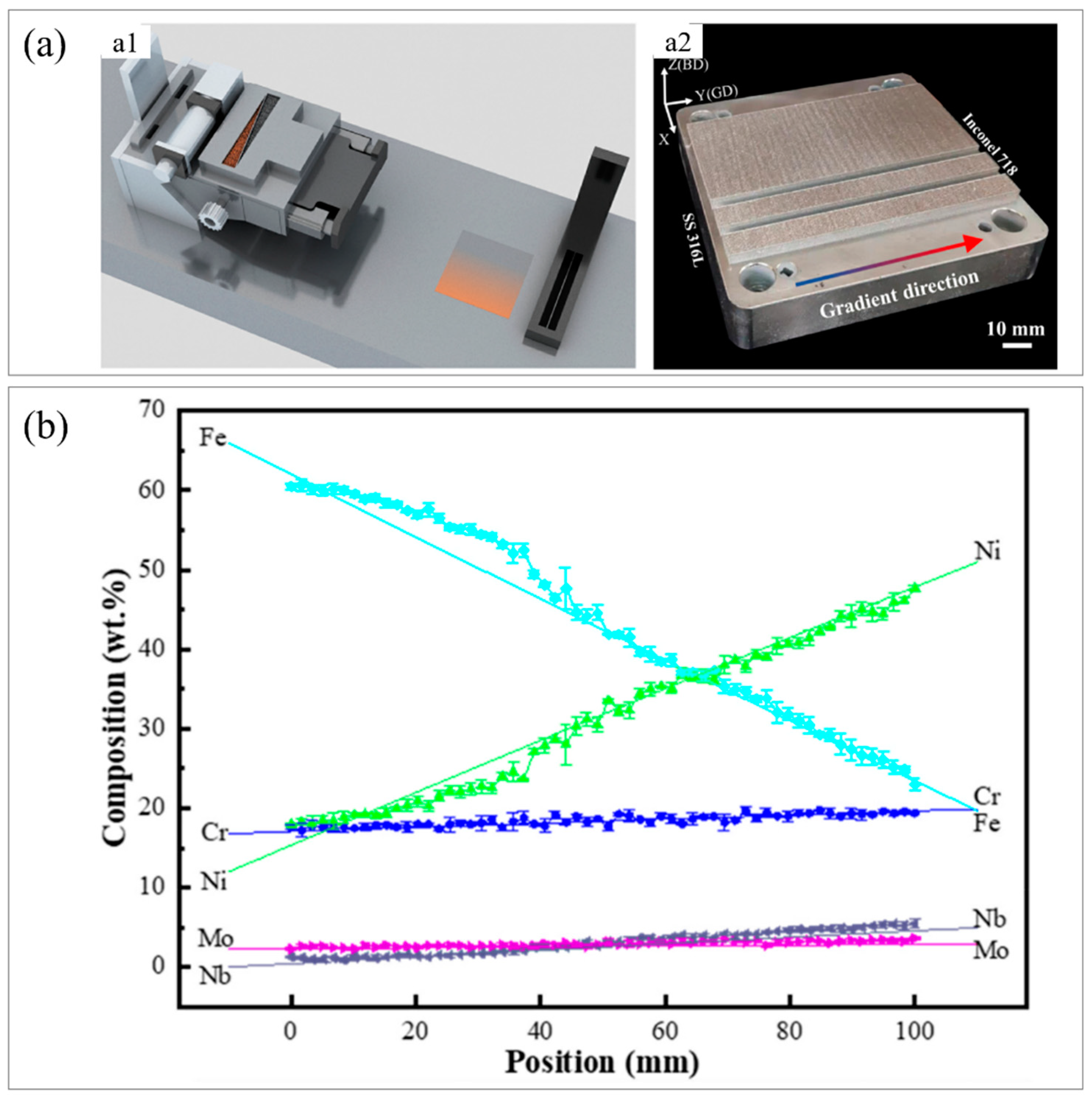

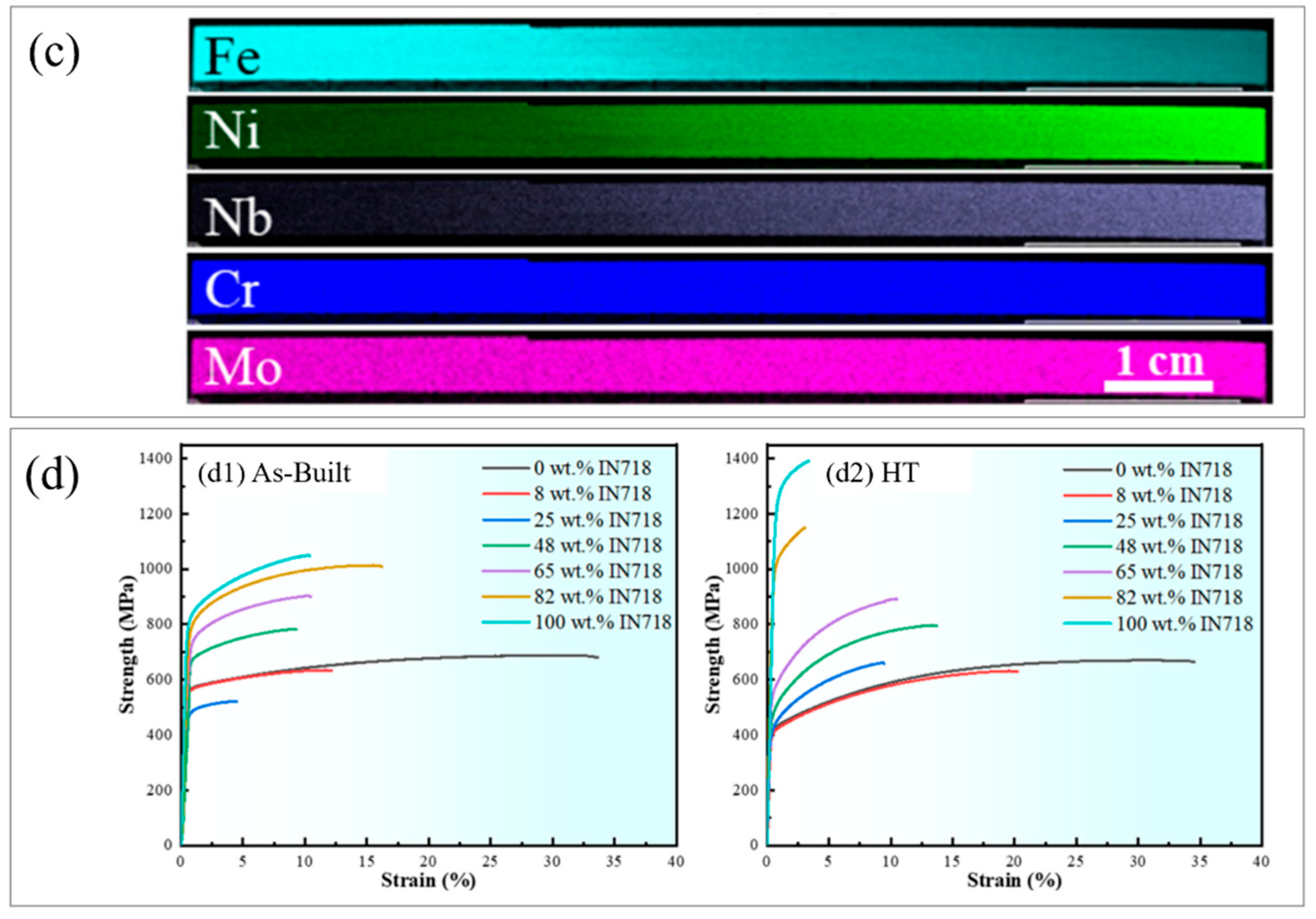

3.5. Element Segregation in Additively Manufactured Steel

3.6. Other Structural Characteristics in Additively Manufactured Steel

4. Conclusions and Perspectives

- The additive manufacturing technique is a non−equilibrium solidification process, and the microstructure structure exhibits multi−level and cross−scale characteristics. It is difficult to quantitatively characterize the microscopic mechanism of additively manufactured products in experiments. Therefore, it is highly desirable to develop advanced multi−scale computing techniques to shed light on the complex mechanism of microstructure evolution and thus improve the macro−performance.

- As a potential high−throughput experimental method, the additive manufacturing technique can effectively accelerate the composition and process optimization design of high−performance steel−based materials by gradient printing.

- Steel is born with complex solid−state phase transition; therefore, learning from the abundant traditional heat treatment experience and developing a heat treatment scheme suitable for additive manufacturing is one of the future research directions.

- At present, all grades of steel are proposed for traditional steel preparation processes, but it is urgent to establish a set of steel grades suitable for additively manufactured steel.

- Data−driven additive manufacturing technology is another future direction. Unlike traditional steel preparation, 3D printing of metal specimens lacks a large amount of high−quality data at present, thus it is also urgent to develop a database and data−driven strategies for additive manufacturing.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- He, B.; Wu, W.; Zhang, L.; Lu, L.; Yang, Q.; Long, Q.; Chang, K. Microstructural characteristic and mechanical property of Ti6Al4V alloy fabricated by selective laser melting. Vacuum 2018, 150, 79–83. [Google Scholar] [CrossRef]

- Cui, L.; Deng, D.; Jiang, F.; Peng, R.; Xin, T.; Mousavian, R.; Yang, Z. Superior low cycle fatigue property from cell structures in additively manufactured 316L stainless steel. J. Mater. Sci. Technol. 2022, 111, 268–278. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Gao, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, M.; Tu, J.; Jiang, Y.; Jiao, S.-Q. Reduction of residual stress in porous Ti6Al4V by in situ double scanning during laser additive manufacturing. Int. J. Miner. Metall. Mater. 2021, 28, 1844–1853. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Tang, W.; Yang, X.; Tian, C.; Xu, Y. Microstructural heterogeneity and bonding strength of planar interface formed in additive manufacturing of Al−Mg−Si alloy based on friction and extrusion. Int. J. Miner. Metall. Mater. 2022, 29, 1755–1769. [Google Scholar] [CrossRef]

- Wei, K.; Gao, M.; Wang, Z.; Zeng, X. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy. Mater. Sci. Eng. A 2014, 611, 212–222. [Google Scholar] [CrossRef]

- Yue, H.Y.; Peng, H.; Su, Y.J.; Wang, X.-P.; Chen, Y.-Y. Microstructure and high-temperature tensile property of TiAl alloy produced by selective electron beam melting. Rare Metals 2021, 40, 3635–3644. [Google Scholar] [CrossRef]

- Li, H.G.; Che, P.C.; Yang, X.K.; Huang, Y.-J.; Ning, Z.-L.; Sun, J.-F.; Fan, H.-B. Enhanced tensile properties and wear resistance of additively manufactured CoCrFeMnNi high-entropy alloy at cryogenic temperature. Rare Metals 2022, 41, 1210–1216. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Zhao, X.Y.; Wu, Y.W.; Chen, Q.; Yang, B.-H.; Wang, P.; Chen, Z.-W.; Yang, C. Homogenization heat treatment for an additively manufactured precipitation-hardening high-entropy alloy. Rare Metals 2022, 41, 2853–2863. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Design, Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Materials 2013, 52, 638–647. [Google Scholar]

- Wang, H. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components. Acta Aeronaut. Astronaut. Sin. 2014, 35, 2690–2698. [Google Scholar]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef]

- Caiazzo, F.; Cardaropoli, F.; Alfieri, V.; Sergi, V.; Cuccaro, L. In Experimental analysis of selective laser melting process for Ti-6Al-4V turbine blade manufacturing. In XIX International Symposium on High-Power Laser Systems and Applications; SPIE: Bellingham, WA, USA, 2012; pp. 381–390. [Google Scholar]

- Andersson, J.; Sjöberg, G.P. Repair welding of wrought superalloys: Alloy 718, Allvac 718plus and Waspaloy. Sci. Technol. Weld. Join. 2012, 17, 49–59. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, Y.; Li, X.; Hu, X.; Xu, Z.; Dong, E.; Zhu, Q.; Ward, R.M. A comparing study of defect generation in IN738LC superalloy fabricated by laser powder bed fusion: Continuous-wave mode versus pulsed-wave mode. J. Mater. Sci. Technol. 2021, 90, 45–57. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Ribeiro, K.S.; Mariani, F.E.; Coelho, R.T. A study of different deposition strategies in direct energy deposition (DED) processes. Procedia Manuf. 2020, 48, 663–670. [Google Scholar] [CrossRef]

- Chen, H.; Gu, D.; Ge, Q.; Shi, X.; Zhang, H.; Wang, R.; Zhang, H.; Kosiba, K. Role of laser scan strategies in defect control, microstructural evolution and mechanical properties of steel matrix composites prepared by laser additive manufacturing. Int. J. Miner. Metall. Mater. 2021, 28, 462–474. [Google Scholar] [CrossRef]

- Veiga, F.; Arizmendi, M.; Suarez, A.; Bilbao, J.; Uralde, V. Different path strategies for directed energy deposition of crossing intersections from stainless steel SS316L-Si. J. Manuf. Process. 2022, 84, 953–964. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Walczak, M.; Sánchez-Sánchez, X.; Guerra, C.; Debut, A.; Haro, E. Microstructure simulation and experimental evaluation of the anisotropy of 316 L stainless steel manufactured by laser powder bed fusion. Rapid Prototyp. J. 2022; ahead-of-print. [Google Scholar]

- Basak, A.; Lee, A.; Pramanik, A.; Neubauer, K.; Prakash, C.; Shankar, S. Material extrusion additive manufacturing of 17–4 PH stainless steel: Effect of process parameters on mechanical properties. Rapid Prototyp. J. 2023; ahead-of-print. [Google Scholar]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- Helmer, H.; Bauereiß, A.; Singer, R.; Körner, C. Grain structure evolution in Inconel 718 during selective electron beam melting. Mater. Sci. Eng. A 2016, 668, 180–187. [Google Scholar] [CrossRef]

- Zhao, C.; Bai, Y.; Zhang, Y.; Wang, X.; Xue, J.M.; Wang, H. Influence of scanning strategy and building direction on microstructure and corrosion behaviour of selective laser melted 316L stainless steel. Mater. Des. 2021, 209, 109999. [Google Scholar] [CrossRef]

- Yang, X.; Ren, Y.; Liu, S.; Wang, Q.; Shi, M. Microstructure and tensile property of SLM 316L stainless steel manufactured with fine and coarse powder mixtures. J. Cent. South Univ. 2020, 27, 334–343. [Google Scholar] [CrossRef]

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Hadavi, E.; Rolfe, B. Laser subtractive and laser powder bed fusion of metals: Review of process and production features. Rapid Prototyp. J. 2023; ahead-of-print. [Google Scholar]

- Luecke, W.E.; Slotwinski, J.A. Mechanical properties of austenitic stainless steel made by additive manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 398. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research status of laser additive manufacturing for metal: A review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. U.S. Patent 5340656A, 23 August 1994. [Google Scholar]

- Ladd, C.; So, J.H.; Muth, J.; Dickey, M.D. 3D printing of free standing liquid metal microstructures. Adv. Mater. 2013, 25, 5081–5085. [Google Scholar] [CrossRef]

- Henry, T.C.; Morales, M.A.; Cole, D.P.; Shumeyko, C.M.; Riddick, J.C. Mechanical behavior of 17-4 PH stainless steel processed by atomic diffusion additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 114, 2103–2114. [Google Scholar] [CrossRef]

- White, D. Ultrasonic Object Consolidation. U.S. Patent US6519500B1, 11 February 2003. [Google Scholar]

- White, D.R. Ultrasonic consolidation of aluminum tooling. Adv. Mater. Process. 2003, 161, 64–66. [Google Scholar]

- Zenou, M.; Sa’Ar, A.; Kotler, Z. Laser jetting of femto-liter metal droplets for high resolution 3D printed structures. Sci. Rep. 2015, 5, 17265. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3% Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Wang, Y.; Wei, Y.; Zhang, L.; Wang, J.; Yang, X. Selective laser melting of WC-Co reinforced AISI 1045 steel composites: Microstructure characterization and mechanical properties. J. Mater. Res. Technol. 2022, 19, 1821–1835. [Google Scholar] [CrossRef]

- Lehmann, T.; Rose, D.; Ranjbar, E.; Ghasri-Khouzani, M.; Tavakoli, M.; Henein, H.; Wolfe, T.; Jawad Qureshi, A. Large-scale metal additive manufacturing: A holistic review of the state of the art and challenges. Int. Mater. Rev. 2022, 67, 410–459. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Pinkerton, A.; Liu, Z.; Manna, I.; Li, L. Microstructure characterisation and process optimization of laser assisted rapid fabrication of 316L stainless steel. Appl. Surf. Sci. 2005, 247, 320–327. [Google Scholar] [CrossRef]

- Griffith, M.L.; Ensz, M.T.; Puskar, J.D.; Robino, C.V.; Brooks, J.A.; Philliber, J.A.; Smugeresky, J.E.; Hofmeister, W. Understanding the microstructure and properties of components fabricated by laser engineered net shaping (LENS). MRS Online Proc. Libr. 2000, 9, 625. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G. Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition. Mater. Des. 2013, 45, 228–235. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Angelastro, A.; Signorile, C.G.; Casalino, G. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterisation. Int. J. Adv. Manuf. Technol. 2017, 89, 885–895. [Google Scholar] [CrossRef]

- Yang, N.; Yee, J.; Zheng, B.; Gaiser, K.; Reynolds, T.; Clemon, L.; Lu, W.; Schoenung, J.; Lavernia, E. Process-structure-property relationships for 316L stainless steel fabricated by additive manufacturing and its implication for component engineering. J. Therm. Spray Technol. 2017, 26, 610–626. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by laser metal deposition shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- El Moghazi, S.N.; Wolfe, T.; Ivey, D.G.; Henein, H. Plasma transfer arc additive manufacturing of 17-4 PH: Assessment of defects. Int. J. Adv. Manuf. Technol. 2020, 108, 2301–2313. [Google Scholar] [CrossRef]

- Liberini, M.; Astarita, A.; Campatelli, G.; Scippa, A.; Montevecchi, F.; Venturini, G.; Durante, M.; Boccarusso, L.; Minutolo, F.M.C.; Squillace, A. Selection of optimal process parameters for wire arc additive manufacturing. Procedia Cirp 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Rafieazad, M.; Ghaffari, M.; Vahedi Nemani, A.; Nasiri, A. Microstructural evolution and mechanical properties of a low-carbon low-alloy steel produced by wire arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 2121–2134. [Google Scholar] [CrossRef]

- Mai, D.S. Microstructural and mechanical characteristics of 308L stainless steel manufactured by gas metal arc welding-based additive manufacturing. Mater. Lett. 2020, 271, 127791. [Google Scholar]

- Elmer, J.W.; Gibbs, G. The effect of atmosphere on the composition of wire arc additive manufactured metal components. Sci. Technol. Weld. Join. 2019, 24, 367–374. [Google Scholar] [CrossRef]

- Lunde, J.; Kazemipour, M.; Salahi, S.; Nasiri, A. In Microstructure and mechanical properties of AISI 420 stainless steel produced by wire arc additive manufacturing. In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2020; pp. 413–424. [Google Scholar]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Ganguly, S.; Williams, S. Wire+ Arc Additive Manufacture of 17-4 PH stainless steel: Effect of different processing conditions on microstructure, hardness, and tensile strength. J. Mater. Process. Technol. 2019, 268, 54–62. [Google Scholar] [CrossRef]

- Wu, W.; Xue, J.; Wang, L.; Zhang, Z.; Hu, Y.; Dong, C. Forming process, microstructure, and mechanical properties of thin-walled 316L stainless steel using speed-cold-welding additive manufacturing. Metals 2019, 9, 109. [Google Scholar] [CrossRef]

- Silwal, B.; Santangelo, M. Effect of vibration and hot-wire gas tungsten arc (GTA) on the geometric shape. J. Mater. Process. Technol. 2018, 251, 138–145. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive manufacturing of metallic materials: A review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; Volume 17. [Google Scholar]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Gu, D.; Wang, H.; Zhang, G. Selective laser melting additive manufacturing of Ti-based nanocomposites: The role of nanopowder. Metall. Mater. Trans. A 2014, 45, 464–476. [Google Scholar] [CrossRef]

- Kelly, S.; Kampe, S. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part I. Microstructural characterization. Metall. Mater. Trans. A 2004, 35, 1861–1867. [Google Scholar] [CrossRef]

- Jägle, E.A.; Choi, P.-P.; Van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef]

- Pham, M.; Dovgyy, B.; Hooper, P. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Pokharel, R.; Balogh, L.; Brown, D.; Clausen, B.; Gray III, G.; Livescu, V.; Vogel, S.; Takajo, S. Signatures of the unique microstructure of additively manufactured steel observed via diffraction. Scr. Mater. 2018, 155, 16–20. [Google Scholar] [CrossRef]

- Wu, W.; Lai, K. Process analysis of rapid prototyping with selective laser melting. J. South China Univ. Technol. 2007, 3, 22–27. [Google Scholar]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V additively manufactured by selective laser melting with superior mechanical properties. Jom 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect formation mechanisms in selective laser melting: A review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Li, Y.; Lin, X.; Hu, Y.; Yu, J.; Zhao, J.; Dong, H.; Huang, W. Seynergistic effect of Mo and Zr additions on microstructure and mechanical properties of Nb-Ti-Si-based alloys additively manufactured by laser directed energy deposition. J. Mater. Sci. Technol. 2022, 103, 84–97. [Google Scholar] [CrossRef]

- Zhang, X.; Dang, X.; Yang, L. Study on balling phenomena in selective laser melting. Laser Optoelectron. Prog. 2014, 6, 131–136. [Google Scholar]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. Manuf. Rev. 2014, 1, 2. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of metal and alloy components by additive manufacturing: Examples of 3D materials science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Mudge, R.P.; Wald, N.R. Laser engineered net shaping advances additive manufacturing and repair. Weld. J. 2007, 86, 44. [Google Scholar]

- Yong, L.; Xianghui, R.; Yunlong, C. Research status of metal additive manufacturing technology. Hot Work. Technol. 2018, 47, 15–19. [Google Scholar]

- Liu, J.; Zheng, Y.; Ma, Y.; Qureshi, A.; Ahmad, R. A topology optimization method for hybrid subtractive–additive remanufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 939–953. [Google Scholar] [CrossRef]

- Yang, X.; Ma, W.; Zhang, Z.; Liu, S.; Tang, H. Ultra-high specific strength Ti6Al4V alloy lattice material manufactured via selective laser melting. Mater. Sci. Eng. A 2022, 840, 142956. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Ma, L.; Wang, J.; Fu, X.; Chen, J.; Huang, W. Influence of laser deposition patterns on part distortion, interior quality and mechanical properties by laser solid forming (LSF). Mater. Sci. Eng. A 2011, 528, 1094–1104. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Mertens, A.; Reginster, S.; Contrepois, Q.; Dormal, T.; Lemaire, O.; Lecomte-Beckers, J. Microstructures and Mechanical Properties of Stainless Steel AISI 316L Processed by Selective Laser Melting. Mater. Sci. Forum 2014, 783–786, 898–903. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E. Additively manufactured nitrogen-atomized 17-4 PH stainless steel with mechanical properties comparable to wrought. Metall. Mater. Trans. A 2019, 50, 1619–1624. [Google Scholar] [CrossRef]

- Kudzal, A.; McWilliams, B.; Hofmeister, C.; Kellogg, F.; Yu, J.; Taggart-Scarff, J.; Liang, J.J.M. Design, Effect of scan pattern on the microstructure and mechanical properties of Powder Bed Fusion additive manufactured 17-4 stainless steel. Mater. Des. 2017, 133, 205–215. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Rafi, H.K.; Pal, D.; Patil, N.; Starr, T.L.; Stucker, B.E. Microstructure and mechanical behavior of 17-4 precipitation hardenable steel processed by selective laser melting. J. Mater. Eng. Perform. 2014, 23, 4421–4428. [Google Scholar] [CrossRef]

- Hermann Becker, T.; Dimitrov, D. The achievable mechanical properties of SLM produced Maraging Steel 300 components. Rapid Prototyp. J. 2016, 22, 487–494. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.; Contuzzi, N.; Ludovico, A. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Casavola, C.; Campanelli, S.; Pappalettere, C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process. J. Strain Anal. Eng. Des. 2009, 44, 93–104. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Tuissi, A.; Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Metals 2016, 6, 218. [Google Scholar] [CrossRef]

- Yasa, E.; Kempen, K.; Kruth, J.-P. Microstructure and Mechanical Properties of Maraging Steel 300 after Selective Laser Melting. In Proceedings of the 2010 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010. [Google Scholar]

- Yu, S.; Liu, J.; Wei, M.; Luo, Y.; Zhu, X.; Liu, Y. Compressive property and energy absorption characteristic of open-cell ZA22 foams. Mater. Des. 2009, 30, 87–90. [Google Scholar] [CrossRef]

- Mazur, M.; Brincat, P.; Leary, M.; Brandt, M. Numerical and experimental evaluation of a conformally cooled H13 steel injection mould manufactured with selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 93, 881–900. [Google Scholar] [CrossRef]

- Xue, L.; Chen, J.; Wang, S.-H. Freeform laser consolidated H13 and CPM 9V tool steels. Metallogr. Microstruct. Anal. 2013, 2, 67–78. [Google Scholar] [CrossRef]

- Dörfert, R.; Zhang, J.; Clausen, B.; Freiße, H.; Schumacher, J.; Vollertsen, F. Comparison of the fatigue strength between additively and conventionally fabricated tool steel 1.2344. Addit. Manuf. 2019, 27, 217–223. [Google Scholar] [CrossRef]

- Mertens, R.; Vrancken, B.; Holmstock, N.; Kinds, Y.; Kruth, J.-P.; Van Humbeeck, J. Influence of powder bed preheating on microstructure and mechanical properties of H13 tool steel SLM parts. Phys. Procedia 2016, 83, 882–890. [Google Scholar] [CrossRef]

- Holzweissig, M.J.; Taube, A.; Brenne, F.; Schaper, M.; Niendorf, T. Microstructural characterization and mechanical performance of hot work tool steel processed by selective laser melting. Metall. Mater. Trans. B 2015, 46, 545–549. [Google Scholar] [CrossRef]

- Karlsson, D.; Chou, C.-Y.; Pettersson, N.H.; Helander, T.; Harlin, P.; Sahlberg, M.; Lindwall, G.; Odqvist, J.; Jansson, U. Additive manufacturing of the ferritic stainless steel SS441. Addit. Manuf. 2020, 36, 101580. [Google Scholar] [CrossRef]

- Liu, Z.; Chua, C.; Leong, K.; Kempen, K.; Thijs, L.; Yasa, E.; Van-Humbeeck, J.; Kruth, J. A preliminary investigation on selective laser melting of M2 high speed steel. In Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping, Leiria, Portugal, 16 September 2011; pp. 339–346. [Google Scholar]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating. J. Manuf. Sci. Eng. 2014, 136, 061026. [Google Scholar] [CrossRef]

- Papula, S.; Song, M.; Pateras, A.; Chen, X.-B.; Brandt, M.; Easton, M.; Yagodzinskyy, Y.; Virkkunen, I.; Hänninen, H. Selective laser melting of duplex stainless steel 2205: Effect of post-processing heat treatment on microstructure, mechanical properties, and corrosion resistance. Materials 2019, 12, 2468. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Tröster, T.; Hoyer, K.-P.; Schaper, M. Duplex stainless steel fabricated by selective laser melting-Microstructural and mechanical properties. Mater. Des. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Saeidi, K.; Alvi, S.; Lofaj, F.; Petkov, V.I.; Akhtar, F. Advanced mechanical strength in post heat treated SLM 2507 at room and high temperature promoted by hard/ductile sigma precipitates. Metals 2019, 9, 199. [Google Scholar] [CrossRef]

- Saeidi, K.; Kevetkova, L.; Lofaj, F.; Shen, Z. Novel ferritic stainless steel formed by laser melting from duplex stainless steel powder with advanced mechanical properties and high ductility. Mater. Sci. Eng. A 2016, 665, 59–65. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Yin, Y.; Tan, Q.; Bermingham, M.; Mo, N.; Zhang, J.; Zhang, M. Laser additive manufacturing of steels. Int. Mater. Rev. 2022, 67, 487–573. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, Y.; Lai, R.; Wen, Y.; Wang, P.; Liu, C.; Chen, Z.; Yang, C.; Li, S.; Chen, W. Abnormal three-stage plastic deformation in a 17-4 PH stainless steel fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2022, 858, 144160. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Sander, G.; Tan, J.; Balan, P.; Gharbi, O.; Feenstra, D.; Singer, L.; Thomas, S.; Kelly, R.; Scully, J.R.; Birbilis, N. Corrosion of additively manufactured alloys: A review. Corrosion 2018, 74, 1318–1350. [Google Scholar] [CrossRef]

- Itzhak, D.; Aghion, E. Corrosion behaviour of hot-pressed austenitic stainless steel in H2SO4 solutions at room temperature. Corros. Sci. 1983, 23, 1085–1094. [Google Scholar] [CrossRef]

- Prieto, C.; Singer, M.; Cyders, T.; Young, D. Investigation of pitting corrosion initiation and propagation of a type 316L stainless steel manufactured by the direct metal laser sintering process. Corrosion 2019, 75, 140–143. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Xu, W.; Gibson, I.; Tan, M.Y. Unexpected erosion-corrosion behaviour of 316L stainless steel produced by selective laser melting. Corros. Sci. 2019, 155, 67–74. [Google Scholar] [CrossRef]

- Sun, Y.; Moroz, A.; Alrbaey, K. Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel. J. Mater. Eng. Perform. 2014, 23, 518–526. [Google Scholar] [CrossRef]

- Tascioglu, E.; Karabulut, Y.; Kaynak, Y. Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1947–1956. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Cheng, X.; He, B.; Wang, H.; Huang, Z. Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater. Sci. Eng. A 2017, 703, 567–577. [Google Scholar] [CrossRef]

- Ji, L.; Lu, J.; Liu, C.; Jing, C.; Fan, H.; Ma, S. Microstructure and mechanical properties of 304L steel fabricated by arc additive manufacturing. MATEC Web Conf. 2017, 128, 03006. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J. The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Hong, Y.; Zhou, C.; Zheng, Y.; Zhang, L.; Zheng, J. The cellular boundary with high density of dislocations governed the strengthening mechanism in selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2021, 799, 140279. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. MaTerialS 2017, 18, 584–610. [Google Scholar] [CrossRef]

- Andresen, P.; Morra, M. Stress corrosion cracking of stainless steels and nickel alloys in high-temperature water. Corrosion 2008, 64, 15–29. [Google Scholar] [CrossRef]

- Andresen, P. Environmentally assisted growth rate response of nonsensitized AISI 316 grade stainless steels in high temperature water. Corrosion 1988, 44, 450–460. [Google Scholar] [CrossRef]

- Andresen, P.; Briant, C. Environmentally assisted cracking of types 304L/316L/316NG stainless steel in 288 C water. Corrosion 1989, 45, 448–463. [Google Scholar] [CrossRef]

- Lou, X.; Song, M.; Emigh, P.W.; Othon, M.A.; Andresen, P.L. On the stress corrosion crack growth behaviour in high temperature water of 316L stainless steel made by laser powder bed fusion additive manufacturing. Corros. Sci. 2017, 128, 140–153. [Google Scholar] [CrossRef]

- Wen, D.; Long, P.; Li, J.; Huang, L.; Zheng, Z. Effects of linear heat input on microstructure and corrosion behavior of an austenitic stainless steel processed by wire arc additive manufacturing. Vacuum 2020, 173, 109131. [Google Scholar] [CrossRef]

- Tokita, S.; Kadoi, K.; Aoki, S.; Inoue, H. Relationship between the microstructure and local corrosion properties of weld metal in austenitic stainless steels. Corros. Sci. 2020, 175, 108867. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally graded material of 304L stainless steel and inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Lewis, G.K.; Schlienger, E. Practical considerations and capabilities for laser assisted direct metal deposition. Mater. Des. 2000, 21, 417–423. [Google Scholar] [CrossRef]

- Udupa, G.; Rao, S.S.; Gangadharan, K. Functionally graded composite materials: An overview. Procedia Mater. Sci. 2014, 5, 1291–1299. [Google Scholar] [CrossRef]

- Shakil, M.; Ahmad, M.; Tariq, N.; Hasan, B.; Akhter, J.; Ahmed, E.; Mehmood, M.; Choudhry, M.; Iqbal, M. Microstructure and hardness studies of electron beam welded Inconel 625 and stainless steel 304L. Vacuum 2014, 110, 121–126. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Roberts, S.; Otis, R.; Kolodziejska, J.; Dillon, R.P.; Suh, J.; Shapiro, A.A.; Liu, Z.; Borgonia, J. Developing gradient metal alloys through radial deposition additive manufacturing. Sci. Rep. 2014, 4, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.; Gao, J.; Narayan, R.L.; Wang, P.; Zhang, L.; Zhang, B.; Ramamurty, U.; Qu, X. Microstructure-property correlations in as-built and heat-treated compositionally graded stainless steel 316L-Inconel 718 alloy fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2022, 862, 144515. [Google Scholar] [CrossRef]

| Process | Material Shape | Travel Speed (mm s−1) | Spot Size (mm) | Layer Height (mm) | Heat Input (W) | Material Feed Speed (mm s−1) | Ref. |

|---|---|---|---|---|---|---|---|

| Laser DED | powder | 2.5–20 | 1.2–2 | 0.25–0.5 | 360–2600 | 2–20.4 | [40,41,42,43,44,45] |

| PTA | 1.3–1.7 | / | / | / | 25–35 | [46] | |

| GMAW | wire | 2.5–30 | / | 0.5–2 | 3500–8400 | 28–166 | [47,48,49,50,51,52,53,54] |

| GTAW | 2.92–7 | / | / | 1920 | 16.67–58 | [55] | |

| PTA | 0.6–2 | / | / | 350–3510 | 9–28 | [55] |

| Steel Type | Elements (wt%) | 3D Printing Techniques | Heat Treatment Process | Mechanical Properties | Ref. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Mo | Mn | Si | Ti | Al | Others | YS (MPa) | UTS (MPa) | Elongation (%) | Hardness (HV or HRC) | ||||

| 316L | <0.03 | 16–18 | 10–14 | 2–3 | <2 | <0.75 | / | / | N < 0.1 | L−PBF | AP | 450 | 640 | 59 | [77] | |

| L−PBF | AP | 590 | 700 | 36 | ||||||||||||

| L−DED | AP | 470 | 675 | 52.5 | [78] | |||||||||||

| L−DED | AP | 535 | 665 | 35 | ||||||||||||

| L−DED | AP | 405 | 655 | 57 | ||||||||||||

| L−DED | AP | 505 | 670 | 41.58 | ||||||||||||

| L−PBF | AP | 602 | 664 | 30 | [79] | |||||||||||

| L−PBF | AP | 557 | 591 | 42 | ||||||||||||

| L−PBF | AP | 534 | 653 | 16.2 | [80] | |||||||||||

| L−PBF | AP | 444 | 567 | 8 | ||||||||||||

| L−DED | AP | 490 | 685 | 51 | [42] | |||||||||||

| L−DED | AP | 280 | 580 | 62 | ||||||||||||

| 17-4 PH | <0.07 | 15–17.5 | 3–5 | <1.0 | <1.0 | / | / | Nb 0.15–0.45 | L−PBF | L−PBF | 452 | 1119 | 15.2 | [81] | ||

| L−PBF | AP | 798 | 1101 | 15.8 | 346.3 HV | [82] | ||||||||||

| L−PBF | AP | 824 | 916 | 4.2 | 356.1 HV | |||||||||||

| L−PBF | AP | 810 | 948 | 4.8 | 350.2 HV | |||||||||||

| L−PBF | AP | 773 | 1043 | 17.6 | 355.3 HV | |||||||||||

| L−PBF | AP | 873 | 951 | 5.3 | 346.7 HV | |||||||||||

| L−PBF | AP | 866 | 935 | 3.3 | 350.3 HV | |||||||||||

| L−PBF | AP | 1190 | 1370 | 8.3 | 380 HV | [83] | ||||||||||

| L−PBF | AP | 570 | 944 | 50 | [84] | |||||||||||

| 18Ni−300 | <0.03 | <0.5 | 17–19 | 4.5–5.2 | <0.1 | <0.1 | 0.6–0.8 | 0.05–0.15 | Co 8.5–9.5 | L−PBF | AP | 815–1080 | 1010–1205 | 8.3–12 | 420 HV | [85] |

| L−PBF | SA | 800 | 950 | 13.5 | 320 HV | |||||||||||

| L−PBF | AH | 1750 | 1850 | 5.1 | 600 HV | |||||||||||

| L−PBF | AP | 1085–1192 | 5–8 | 33 HRC | [86] | |||||||||||

| L−PBF | AP | 985 | 1152 | 7.6 | 34 HRC | [87] | ||||||||||

| L−PBF | AP | 915 | 1188 | 6.1 | 371 HV | [88] | ||||||||||

| L−PBF | AH | 1957 | 2017 | 1.5 | 600 HV | |||||||||||

| L−PBF | AP | 1290 | 13.3 | 40 HRC | [89] | |||||||||||

| L−PBF | AH | 2217 | 1.6 | 58 HRC | ||||||||||||

| L−PBF | AP | 915 | 1165 | 12.4 | 35 HRC | [90] | ||||||||||

| L−PBF | AH | 1967 | 2014 | 3.3 | 54 HRC | |||||||||||

| L−PBF | SA | 962 | 1025 | 14.4 | 28 HRC | |||||||||||

| L−PBF | SA+AH | 1882 | 1943 | 5.6 | 53 HRC | |||||||||||

| H13 | 0.32–0.45 | 4.75–5.5 | 1.1–1.75 | 0.2–0.6 | 0.8–1.2 | / | / | V0.8 –1.2 | L−PBF | AP | 1003 | 1370 | 1.7 | 59 HRC | [91] | |

| L−PBF | AH | 1580 | 1860 | 2.2 | 51 HRC | |||||||||||

| DED | AP | 1288–1564 | 2033–2064 | 5–6 | 660 HV | [92] | ||||||||||

| L−PBF | AP(BP 240 °C) | 892 | 1440 | 1.5 | 575 HV | [93] | ||||||||||

| L−PBF | AP | 1236 | 1712 | 4.1 | [94] | |||||||||||

| L−PBF | AP(BP 200 °C) | 835 | 1620 | 4.1 | ||||||||||||

| L−PBF | AP(BP 400 °C) | 1073 | 1965 | 3.7 | ||||||||||||

| L−PBF | AP 100 °C | 1150–1275 | 1550–1650 | 1.5–2.25 | [95] | |||||||||||

| Ferritic SS 441 | <0.03 | 18 | <1.0 | <1 | <1 | / | / | Nb < 0.9, Ti0.1–0.5 | L−PBF | AP | 679 | 874 | 30 | [96,97] | ||

| L−PBF | AP | 741 | 896 | 28 | [96,98] | |||||||||||

| Duplex SS 2205 | <0.03 | 21–23 | 4.5–6.5 | 2.5–3.5 | <2.0 | <1.0 | / | N0.08–0.2 | L−PBF | AP | 950 | 1071.3 | 16 | [99] | ||

| L−PBF | AP | 940 | 12 | [100] | ||||||||||||

| Duplex SS 2507 | <0.03 | 24–26 | 6–8 | 3–5 | <1.2 | <0.8 | Cu < 0.5, N 0.24–0.32 | L−PBF | AP | 1214 | 1321 | 8 | 450 HV | [101,102] | ||

| Other steels | Also includes duplex stainless steel (SAF2705), ODS steel (PM200), tool steel (M2), etc. | [103,104,105] | ||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, C.; Wu, H.; Pan, G.; Zhu, J.; Wang, S.; Wu, G.; Gao, J.; Liu, Z.; Li, R.; Mao, X. The Characteristic Microstructures and Properties of Steel-Based Alloy via Additive Manufacturing. Materials 2023, 16, 2696. https://doi.org/10.3390/ma16072696

Shang C, Wu H, Pan G, Zhu J, Wang S, Wu G, Gao J, Liu Z, Li R, Mao X. The Characteristic Microstructures and Properties of Steel-Based Alloy via Additive Manufacturing. Materials. 2023; 16(7):2696. https://doi.org/10.3390/ma16072696

Chicago/Turabian StyleShang, Chunlei, Honghui Wu, Guangfei Pan, Jiaqi Zhu, Shuize Wang, Guilin Wu, Junheng Gao, Zhiyuan Liu, Ruidi Li, and Xinping Mao. 2023. "The Characteristic Microstructures and Properties of Steel-Based Alloy via Additive Manufacturing" Materials 16, no. 7: 2696. https://doi.org/10.3390/ma16072696

APA StyleShang, C., Wu, H., Pan, G., Zhu, J., Wang, S., Wu, G., Gao, J., Liu, Z., Li, R., & Mao, X. (2023). The Characteristic Microstructures and Properties of Steel-Based Alloy via Additive Manufacturing. Materials, 16(7), 2696. https://doi.org/10.3390/ma16072696