Abstract

Porous (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C high-entropy ceramics (HEC) with a dual-porosity structure were fabricated by pressureless sintering using a mixture powder of ceramic precursor and SiO2 microspheres. The carbothermal reduction in the ceramic precursor led to the formation of pores with sizes of 0.4–3 μm, while the addition of SiO2 microspheres caused the appearance of pores with sizes of 20–50 μm. The porous HECs exhibit competitive thermal insulation (4.12–1.11 W·m−1 k−1) and extraordinary compressive strength (133.1–41.9 MPa), which can be tailored by the porosity of the ceramics. The excellent properties are ascribed to the high-entropy effects and dual-porosity structures. The severe lattice distortions in the HECs lead to low intrinsic thermal conductivity and high compressive strength. The dual-porosity structure is efficient at phonon scattering and inhabiting crack propagations, which can further improve the thermal insulation and mechanical properties of the porous HECs.

1. Introduction

Porous ultra-high temperature ceramics (UHTCs) are considered as promising materials for aerospace thermal protection systems (TPS) [1,2,3] because they not only possess the inherent property of UHTCs (such as high melting point, outstanding ablation resistance, and excellent high temperature stability) [4,5,6,7,8] but also present the distinguished characteristics of porous ceramics (such as low density and low thermal conductivity) [9,10,11].

Significant efforts have been made to tailor the thermal conductivity and compressive strength of porous UHTCs to meet the strict requirements for aerospace TPS. Various methods have been employed in the fabrication of porous UHTCs, including partial sintering [12], sol-gel [13], direct foaming [14], freeze-drying [15], and template methods [16,17]. Among these methods, the template method is attractive for fabricating porous UHTCs with controllable pore structure, tunable compressive strength, and thermal conductivity. Wang et al. [18] prepared porous ZrB2-SiC ceramics by a partial sintering method using KCl as the space holder. The KCl content and particle size could tune the porosity of these ceramics. The porous ZrB2-SiC ceramics exhibited high porosity (45–67%), low average pore sizes (3–7 μm), high compressive strength (32–106 MPa), and low thermal conductivity (13–34 W·m−1 k−1). Fu et al. [19] reported a porous ZrC ceramic prepared using carbon black as a sacrificial template. The porosity of these ceramics ranged from 12.47 to 4.83 μm and could be regulated by the sintering pressure. At the same time, the compressive strength decreased from 31.3 to 5.7 MPa, and thermal conductivity decreased from 2.8 to 0.5 W·m−1 k−1. Zhao et al. [20] prepared porous ZrC ceramics by adopting ZrC hollow microspheres (HMs) as the pore-forming agent to form submicron pores in the ceramic. They found that the pore structure of the porous ZrC ceramics is complex. Besides the pores formed by ZrC HMs, there are also many pores formed by the powder overlapping during the sintering process. The complex pore structure led the porous ZrC ceramics to achieve excellent thermal insulation at relatively low porosity.

Besides the effort in controlling pore structure, developing novel material is another way to meet the strict requirements of the TPS. Recently, high-entropy ceramics (HECs) have drawn significant attention from researchers due to their low thermal conductivity, good high temperature stability, slow diffusion rate, and serious lattice distortion [21,22,23,24]. Higher mixing entropy promotes the formation of single-phase solid solutions and leads to more homogeneous organization and higher thermophysical properties [25,26,27,28]. The emergence of high entropy ceramics (HECs) offers more possibilities to modulate the performance of ultra-high temperature materials and to overcome bottlenecks in material applications [29,30,31,32]. High-entropy carbides (HECs), such as (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C, (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)B-2, (Ti, Zr, Nb, Ta, Mo)C, and (Ti, Ta, Nb, Zr, W)(C,N), are considered to be potential UHTCs for TPS because they exhibit lower thermal conductivity, higher mechanical strength, hardness, melting point, and thermal stability than single transition metal carbide components such as ZrC, HfC, NbC, TaC, and TiC [33,34,35,36,37].

In this work, porous (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C high-entropy ceramics were prepared by pressureless sintering with the in situ carbothermal reduction method. SiO2 microspheres were employed as pore-forming agents to tailor the porosity and pore structure. The effect of SiO2 content on the microstructure, comprehensive strength, and thermal conductivity of the obtained HECs was discussed. The fabrication method reported in this work is a universal approach to preparing HECs with controllable pore structure, tunable compressive strength, and thermal conductivity. The obtained HECs, possessing low thermal conductivity and superior compressive strength, can be competitive materials for TPS applications.

2. Materials and Methods

2.1. Materials

Commercially available tantalum chloride (TaCl5, 99.9%), niobium chloride (NbCl5, 99.9%), titanium chloride (TiCl4, 99.9%), zirconium chloride (ZrCl4, 99.9%), and hafnium chloride (HfCl4, 99.9%) were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. (Shanghai, China). Furfuryl alcohol (C5H6O2, 99.0%) was employed as the carbon source, and ethanol (C2H6O, analytical reagent) was used as the solvent. Silica microspheres with a diameter of 10 μm were employed as the pore-forming agent.

2.2. Synthetic Procedure

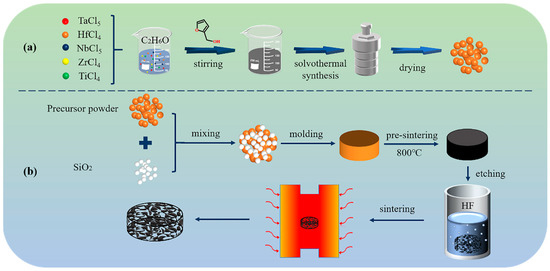

The synthesis procedure of the precursor powder is illustrated in Figure 1a. TaCl5 (0.05 mol), NbCl5 (0.05 mol), TiCl4 (0.05 mol), ZrCl4 (0.05 mol), and HfCl4 (0.05 mol) were dissolved in 500 mL ethanol to obtain a transparent solution. Furfuryl alcohol (10 mL) was added to the metal chloride solution and stirred in a water bath at 60 °C for 30 min to obtain a precursor solution. Then, the precursor solution was transferred to a Teflon-lined autoclave for a solvothermal reaction at 200 °C for 12 h. Finally, the product was centrifuged and dried to obtain the precursor powder.

Figure 1.

Schematic diagram of the preparation process of (a) precursor powders, (b) porous HECs.

Figure 1b exhibits the fabrication process of the porous HECs. The precursor powder was mixed with different amounts of SiO2 microspheres to obtain the porous HECs with various porosity. The samples with 0, 5, 10, 15, and 20 wt.% of SiO2 microsphere content are called HEC-1, HEC-2, HEC-3, HEC-4, and HEC-5, respectively, in the forthcoming discussion. The mixed powder was uniaxially pressed into a cylindrical body with a diameter of 30 mm under a pressure of 15 MPa. Then, the prepared green bodies were heat-treated at 800 °C for 2 h in an argon atmosphere. The pre-sintered samples were immersed in hydrogen fluoride (HF) solution (15%) to etch the SiO2 microspheres. Finally, the etched samples were sintered at 2100 °C for 2 h in an argon atmosphere.

2.3. Characterization

The phase compositions of the samples were characterized by X-ray diffraction (XRD, D8ADVANCE-A25, Bruker, MA, USA). The microstructures of the samples were analyzed by aberration-corrected high-resolution transmission electron microscopy (HRTEM, JEM-ARM300F, JEOL, Kyoto, Japan) equipped with electron energy dispersive spectroscopy. The morphologies of the samples were observed by a scanning electron microscope (SEM, Nova Nanosem 430, FEI, OR, USA).

The thermal insulation properties of porous HECs were characterized by the thermal conductivity (k) values, which were calculated according to Equation (1).

where α is the thermal diffusivity, ρ is the density of the material, and Cp is the specific heat capacity. The thermal diffusivity (α) was measured by a laser thermal conductivity testing instrument (LFA 467 HT, NETZSCH, BAV, German) using a sample with a diameter of 12.7 mm and a thickness of 2 mm. Specific heat capacity (Cp) was measured on a differential scanning calorimeter (DSC 250, TA, NETZSCH, BAV, German). Argon was used as the test atmosphere, and the heating rate was set to 10 K/min, with the temperature range from room temperature to 1200 °C. The pore-size distributions and porosity were analyzed by mercury porosimetry (AutoPore IV 9500, Micromeritics, Norcross, GA, USA). The compressive strength of the samples was measured by a universal testing machine (CMT6103, MTS, Eden Prairie, MN, USA). The data for compressive strength represents the average volume of three specimens.

3. Results and Discussion

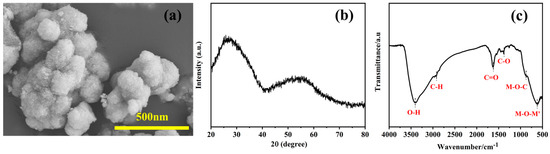

Figure 2a shows the morphology of the submicron precursor particles. The XRD pattern (Figure 2b) shows the precursor was amorphous carbon structure without oxides segregation. The precursor powder was composed of nanospheres with diameters of ~200 nm. These nanospheres were made up of fine particles with a diameter of 2 nm and aggregated to form a loose structure. The fine and loose structures of the nanosphere precursor powder facilitated the plasticity and compressibility in the molding process. The chemical bonding of the precursor powder is shown in Figure 2c. O-H, C-H, C=O, and C-O bonds can be observed, indicating the polymeric state of the precursor’s powder. Furthermore, the M-O-C bonds and M-O-M’ (M’=Ta, Nb, Ti, Zr, and Hf) bonds can be found in the samples, suggesting the occurrences of the condensation reactions during the solvothermal reaction. M-O-C and M-O-M’ (M’=Ta, Nb, Ti, Zr, and Hf) bonds can promote the carbothermal reduction in the precursors in the sintering process [38].

Figure 2.

(a) SEM image, (b) XRD pattern, and (c) infrared spectrum of the precursor powder obtained by the solvothermal method.

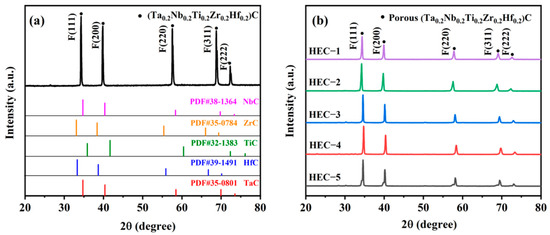

Figure 3a shows the phase structure of the HEC-1 sample. The diffraction positions of the HEC sample were referred to the X-ray diffraction patterns of TiC (PDF: 32–1383), ZrC (PDF: 35–0784), NbC (PDF: 38–1364), HfC (PDF: 39–1491), and TaC (PDF: 35–0801). The HEC exbibits a single cubic phase typical for HEC carbides with a lattice parameter of 4.51 Å in the (111) plane corresponding to those previously reported for this composition. The diffraction peaks of the HEC-1 sample are located around the corresponding diffraction peaks of the five carbides. This further suggests that the five different metal elements form the carbide solid solution. Furthermore, there is no peak for oxide in the XRD pattern. A tiny peak around 26° can be found in the XRD pattern of the HEC-1 sample, which is due to the excess carbon in the precursor powder. Figure 3b presents the XRD patterns of different HEC samples with various amounts of pore-forming agent. There is a slight difference in the diffraction positions among the other samples. The lattice plane values of the HEC samples were calculated as 4.5102 Å (HEC-1), 4.5267 Å (HEC-2), 4.4892 Å (HEC-3), 4.4681 Å (HEC-4), and 4.4827 Å (HEC-5), which are close to the HECs reported values in the reference [32].

Figure 3.

XRD patterns of obtained porous HECs: (a) comparison of HEC-1 sample with various carbides, (b) comparison of different porous HECs with various amount of pore-forming agent.

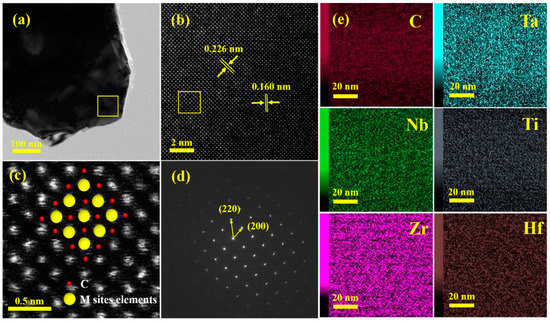

Figure 4a,b show the transmission electron microscopy (TEM) and high-angle annular dark field (HAADF) images of the HEC-1 sample. The HAADF image shows complete and continuous periodic lattice fringes, and the interplanar spacing is measured as 0.226 and 0.160 nm, corresponding to the (200) and (220) planes of the FCC structure. As shown in Figure 4c, since the brightness in the HAADF image is approximately proportional to the square of the atomic number in the periodic table, the bright spot in the image is the location of the transition metal atom with a large atomic number. Moreover, the sample quickly absorbs the light for the C atom with a smaller atomic number, resulting in a black spot at the position of the C atom in the HAADF image. The selected area electron diffraction (SAED) pattern further elaborates the cubic crystal structure of the obtained HEC shown in Figure 4d. Figure 4e is the energy dispersive spectrometry (EDS) map of the yellow border in Figure 4a. The six elements Zr, Hf, Ti, Nb, Ta, and C are uniformly distributed in the material without evident segregation, which further verifies the successful preparation of high-entropy (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C.

Figure 4.

(a) TEM image; (b) HAADF image; (c) schematic diagram of the atom; (d) SAED pattern of HEC-1 sample; (e) EDS mappings for elements C, Ta, Nb, Ti, Zr, and Hf shown in the yellow border in (a).

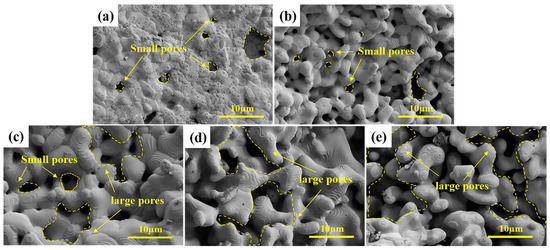

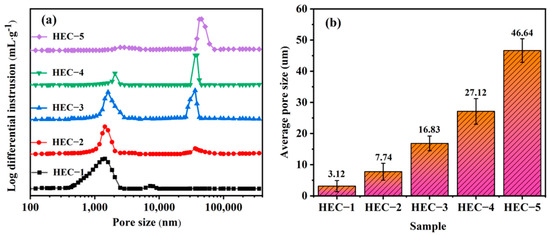

The morphologies of porous HEC samples with different amounts of pore-forming agent are displayed in Figure 5. Most of these pores in the HEC-1 sample are smaller than 2 µm. These small pores were generated from multiple particles sintering and CO gas produced in the carbothermal reaction process. With the addition of pore-forming agent, the morphology of the porous HECs changed significantly. Except for these small pores, spacing can be found among HEC grains. The size of these spacings increases with the increase in the pore-forming agent. The pore-forming agent generates these spacings, forming large pores in the porous HECs. Mercury porosimetry is used further to understand the porosity structure of the porous HEC. The porosities of porous HEC samples are listed in Table 1, and the pore-size distributions are presented in Figure 6a. The porous HECs exhibit a typical dual-porosity structure. The first type of pores is small, ranging from 0.4 to 3 µm. The second kind of pores is the large pores ranging from 20 to 50 µm. The porosity of the porous HECs grows linearly from 23.08% to 59.34% with the increase in the amount of pore-forming agent, while the average pore sizes increase from 3.12 µm to 46.64 µm. Furthermore, the small pores gradually disappeared with the rapid growth of the large pores with the increase in the amount of pore-forming agent. The mercury porosimetry results correspond to the morphology analysis. It suggests that the pore-forming agent controls the porosity volume and tailors the pore structure of the porous HECs.

Figure 5.

SEM images of the porous HECs with various amounts of pore-forming agents (a) HEC-1, (b) HEC-2, (c) HEC-3, (d) HEC-4, and (e) HEC-5.

Table 1.

Porosity, density, and compressive strength of the obtained porous HECs.

Figure 6.

(a) Pore-size distributions and (b) average pore diameters of the porous HECs with the various amounts of pore-forming agent.

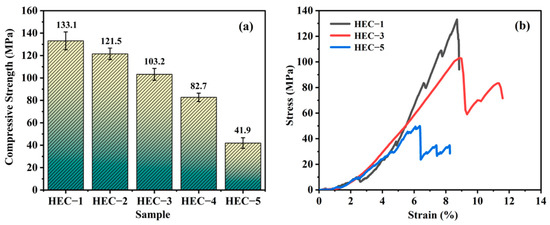

Figure 7a shows the compressive strength of the porous HECs with various porosity values. The compressive strength of the porous HECs decrease with the increase in porosity. Mainly, with the rise of porosity from 23.08% to 59.34%, the compressive strength decreases from 133.1 MPa to 41.9 MPa. Figure 7b shows the typical compressive strain-stress curves of the porous HECs. The HEC-1 sample exhibits a specific brittle fracture characterization, in which the porous ceramic ruptures when the stress surpasses the maximum value. Several zig-zag patterns can be found in the corresponding curve before the rupture, which is attributed to the squashing of the small pores. The rupture of the pores causes cracks that eventually fracture the ceramics. In contrast, the zig-zag pattern occurs after the fracture for both the HEC-3 and HEC-5 samples. The drop in the stress for both the HEC-3 and HEC-5 samples is more significant than that of the HEC-1 sample. The fractures in the HEC-3 and HEC-5 samples mainly respond to the crack propagations among the larger pores. The HEC-5 sample presents a smaller compressive stress, and strain upon fracture. However, the HEC-3 sample shows similar strain and slightly less stress than the HEC-1 sample. The excellent compressive strength is due to the dual-porosity structure of the HEC-3 sample. The small pores can elongate the crack propagation path and enhance the compressive properties.

Figure 7.

(a) Relationship between compressive strength and porosity, and (b) typical stress-strain curves of the porous HECs.

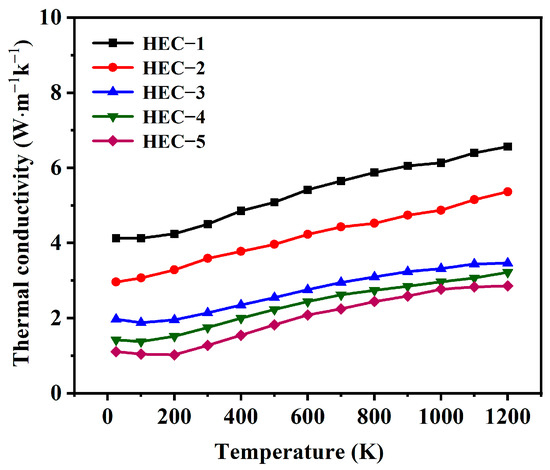

The thermal conductivity of porous HECs with different amounts of the pore-forming agent are shown in Figure 8. It can be seen that porous HECs exhibit low thermal conductivity in the temperature range of 25–1200 °C. The thermal conductivity increases with the increase in temperature. It is known that the heat transfer through lattice vibrations decreases, and convection heat transfer increases with the rise of temperature [20]. The increase in thermal conductivity with temperature indicates that the convection heat transfer is an important heat-transfer mechanism of porous HECs.

Figure 8.

Thermal conductivity of porous HECs with different amounts of the pore-forming agent.

The thermal diffusivity (α), specific heat (Cp), and room temperature thermal conductivity (k) values of these samples are shown in Table 2. The room temperature thermal conductivity ranges from 4.12 W·m−1 k−1 to 1.11 W·m−1 k−1, which is lower than dense HECs (6.45 W·m−1 k−1) due to high porosity. Comparing the thermal conductivity of HEC-1 to HEC-5 at room temperature, the thermal conductivity of porous HECs decreases rapidly when the porosity increases from 23.08% to 36.92%. However, the drop in the thermal conductivity becomes flat when the porosity exceeds 36.92%. The relationship between the thermal conductivity and porosity of the obtained porous HEC is inconsistent with the classical theoretical models of thermal conductivity, such as series [39], parallel [40], Maxwell–Eucken [41], and effective medium theory [42], because these theoretical models are based on only one kind of given porous structure. This discrepancy can also be found in the porous ZrC ceramics prepared using ZrC hollow spheres as the pore-forming agent [20]. This abnormal thermal conductivity behavior was ascribed to the complex pore structure in the porous ceramics. As discussed earlier, the porous HECs possess a dual porosity structure. Besides the large pores (20–50 µm) formed by SiO2 pore-forming agent, several small pores (0.4–3 µm) were also created by the grain overlapping during the sintering process. Wang et al. [41] developed a universal model that is reasonable for estimating the thermal conductivity of heterogeneous materials with multiple continuous phases. According to the universal model, the effective thermal conductivity Ke of the porous HEC can be calculated by Equation (2) with suitable parameters di and k′.

where k is the thermal conductivity of the component, v is the volume fraction of the component, di is the shape factor, and k′ is the effective thermal conductivity of the structure. The obtained porous HECs can be considered spherical dispersed phase structures in this work. The most common approach is to take di = 3. Since HECs are only in the solid phases for porous materials, components 1 and 2 can be regarded as dense HEC and helium, and the thermal conductivities at room temperature are 6.45 and 0.0579 W·m−1 k−1, respectively. The testing data in this work are consistent with the universal model when k′ is chosen as 1.66. This suggests that the universal model can predict the thermal conductivity of porous HECs with a complex pore structure.

Table 2.

Thermal diffusivity (α), specific heat capacity (Cp), and thermal conductivity (k) values for the porous HECs with different amounts of pore-forming agent.

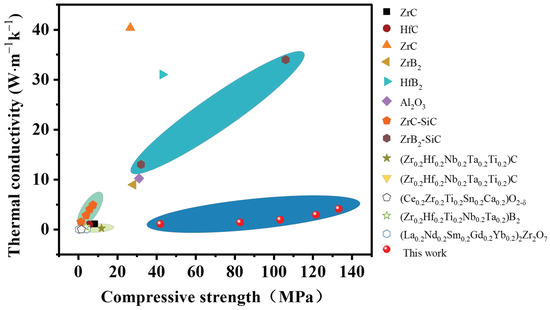

Figure 9 illustrates the properties of compressive strength and thermal conductivity of the porous HECs in this study and UHTCs reported in the literature. Compared with these porous UHTCs, the porous HECs in this study achieved good thermal insulation and excellent compressive strength. Notably, the porous HECs are competitive in thermal insulation while possessing extraordinary compressive strength.

Figure 9.

Comparison of the compressive strength and thermal conductivity of the obtained porous HECs with other porous UHTCs from previous reports [18,30,31,43,44,45,46,47,48,49,50,51].

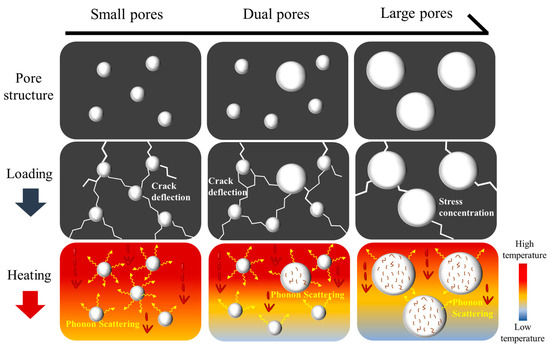

The excellent properties of the porous HECs can be explained by the schematic diagram shown in Figure 10. The good thermal insulation and excellent mechanical properties of the porous HECs come from the synergistic effect of high-entropy and dual-porosity structures. The differences in atomic radii and bond strength of these five metal cations (Ti, Zr, Ta, Hf, and Nb) lead to the atomic-level lattice distortion in the (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C ceramics. The severe lattice distortions reduce the mean free path of phonons and increase phonon scattering, resulting in low intrinsic thermal conductivity in high-entropy ceramics [32,52]. The room temperature thermal conductivity of the densified (Ta0.2Nb0.2Ti0.2Zr0.2Hf0.2)C high-entropy ceramics is only 6.45 W·m−1 k−1, which is much lower than that of the solid ZrC [32]. Moreover, the severe lattice distortion blocks the crack propagation, resulting in a significant increase in compressive strength [53].

Figure 10.

Pressure resistance and thermal conductivity mechanism diagram of dual-porosity high-entropy ceramics.

The number of pores in the ceramics increases the probability of phonon collisions, decreasing the mean free path of gas molecules. Eventually, it reduces the phonon thermal conductivity. Therefore, the thermal conductivity of ceramic can be effectively reduced by introducing pores. It is worth mentioning that introducing small-sized pores is more conducive to heat insulation because they provide more interfaces for phonon scattering and inhibit convection heat transfer of gas molecules. For a given porosity, porous media with a higher proportion of large pores have a weaker reflection and scattering effect on heat transfer [54,55,56]. Even though the HEC-5 sample possesses higher porosity than the HEC-3 sample, the dual-porosity HECs, like the HEC-3 sample, have a thermal conductivity comparable to that of the single-pore HECs such as the HEC-5 sample. Thus, the dual-porosity structure improves the thermal insulation of porous HECs. Except for the high-entropy effect, the excellent compressive strength of the porous HECs is also ascribed to the dual-porosity structure. It is known that the pore sizes greatly influence stress concentrations. As the pore sizes grow larger, the stress concentration becomes more significant. The cracks under the action of the load are more likely to expand, which leads to lower strength [57,58]. For a given porosity, smaller pore sizes increase the number of pores, resulting in more crack deflecting for porous ceramics under load. This suggests that small-sized pores prolong the path of crack propagation and help load transfer, ultimately improving the compressive strength of the porous material [59].

4. Conclusions

The porous HECs have been fabricated by an in situ carbothermal reaction and pressureless sintering method. The pore structures were tuned by adding different amounts of SiO2 microspheres in the precursor powder.

- (1)

- The prepared porous HECs exhibited a dual-porosity structure. The carbothermal reaction and sintering of ceramics precursor led to the formation of small pores of sizes 0.4–3 μm. The SiO2 microspheres resulted in the generation of large pores in the range of 20–50 μm. With the increase in the number of SiO2 microspheres from 0 wt.% to 20 wt.%, the small pores disappeared gradually, and the large pores appeared.

- (2)

- The thermal conductivity of the porous HECs declined from 4.12 W·m−1 k−1 to 1.11 W·m−1 k−1 with the increase in porosity from 23.08% to 59.34%, while the compressive strength decreased from 133.1 MPa to 41.9 MPa. The obtained porous HECs showed competitive thermal insulation and excellent mechanical properties. The porous HECs are a promising family of materials for the TPS.

- (3)

- The unique properties of the porous HECs are ascribed to the high-entropy effects and dual-porosity structures. The severe lattice distortions in the HECs lead to the low intrinsic thermal conductivity by reducing phonons’ mean free path and increasing phonon scattering. Moreover, this results in high compressive strength by inhibiting the crack generations and propagations. The dual-porosity structure possesses several small pores in high-porosity ceramics. These small pores are more efficient in scattering phonon thermal conductivity and inhibiting crack propagations, which are beneficial to improving the thermal insulation and mechanical properties of the porous HECs.

Author Contributions

Conceptualization, H.O. and Q.Y.; methodology, C.L.; software, R.G.; validation, Q.Y. and T.S.; formal analysis, H.O.; investigation, C.L.; resources, J.H.; writing—original draft preparation, Q.Y.; funding acquisition, C.L. and H.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Nature Science Foundation of China (Grant No. 5217130277), the Natural Science Foundation of Shaanxi Province (Grant No. 2021JZ-51), and the Foundation of Education Department of Shaanxi Province (Grant No. 20JC007).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Uyanna, O.; Najafi, H. Thermal protection systems for space vehicles: A review on technology development, current challenges and future prospects. Acta Astronaut. 2020, 176, 341–356. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Z.; Xiang, H.; Dai, F.Z.; Zhang, J.; Wang, S.; Liu, J.; Zhou, Y. Effect of reaction routes on the porosity and permeability of porous high entropy (Y0.2Yb0.2Sm0.2Nd0.2Eu0.2)B6 for transpiration cooling. J. Mater. Sci. Technol. 2020, 38, 80–85. [Google Scholar] [CrossRef]

- Miller, J.E.; Bohl, W.E.; Christiansen, E.L.; Davis, B.A. Ballistic performance of porous ceramic, thermal protection systems. Int. J. Impact. Eng. 2013, 56, 40–46. [Google Scholar] [CrossRef]

- Golla, B.R.; Mukhopadhyay, A.; Basu, B.; Thimmappa, S.K. Review on Ultra High Temperature Boride Ceramics. Prog. Mater. Sci. 2020, 111, 100651. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E. Oxidation of ultra-high temperature transition metal diboride ceramics. Int. Mater. Rev. 2013, 57, 61–72. [Google Scholar] [CrossRef]

- Binner, J.; Porter, M.; Baker, B.; Zou, J.; Venkatachalam, V.; Diaz, V.R.; D’Angio, A.; Ramanujam, P.; Zhang, T.; Murthy, T.S.R.C. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs: A Review. Int. Mater. Rev. 2019, 65, 389–444. [Google Scholar] [CrossRef]

- Ni, D.; Cheng, Y.; Zhang, J.; Liu, J.X.; Zou, J.; Chen, B.; Wu, H.; Li, H.; Dong, S.; Han, J.; et al. Advances in ultra-high temperature ceramics, composites, and coatings. J. Adv. Ceram. 2021, 11, 1–56. [Google Scholar] [CrossRef]

- Tang, S.; Hu, C. Design, Preparation and Properties of Carbon Fibers Reinforced Ultra-high Temperature Ceramic Composites for Aerospace Applications: A Review. J. Mater. Sci. 2017, 33, 117–130. [Google Scholar] [CrossRef]

- Licheri, R.; Musa, C.; Locci, A.M.; Montinaro, S.; Orrù, R.; Cao, G.; Silvestroni, L.; Sciti, D.; Azzali, N.; Mercatelli, L.; et al. Ultra-high temperature porous graded ceramics for solar energy applications. J. Eur. Ceram. Soc. 2019, 39, 72–78. [Google Scholar] [CrossRef]

- Qi, Y.; Jiang, K.; Zhou, C.; Han, W.; Du, Z. Preparation and properties of high-porosity ZrB2-SiC ceramics by water-based freeze casting. J. Eur. Ceram. Soc. 2021, 41, 2239–2246. [Google Scholar] [CrossRef]

- Sani, E.; Mercatelli, L.; Sans, J.L.; Silvestroni, L.; Sciti, D. Porous and dense hafnium and zirconium ultra-high temperature ceramics for solar receivers. Opt. Mater. 2013, 36, 163–168. [Google Scholar] [CrossRef]

- Guo, Q.; Xiang, H.; Sun, X.; Wang, X.; Zhou, Y. Preparation of porous YB4 ceramics using a combination of in-situ borothermal reaction and high temperature partial sintering. J. Eur. Ceram. Soc. 2015, 35, 3411–3418. [Google Scholar] [CrossRef]

- Dollé, M.; Gosset, D.; Bogicevic, C.; Karolak, F.; Simeone, D.; Baldinozzi, G. Synthesis of nanosized zirconium carbide by a sol-gel route. J. Eur. Ceram. Soc. 2007, 27, 2061–2067. [Google Scholar] [CrossRef]

- Li, F.; Kang, Z.; Huang, X.; Wang, X.G.; Zhang, G.J. Preparation of zirconium carbide foam by direct foaming method. J. Eur. Ceram. Soc. 2014, 34, 3513–3520. [Google Scholar] [CrossRef]

- Zhang, D.; Li, L.; Chen, X.; Yang, L.; Hu, X.; Guo, A.; Xie, D.; Wang, W.; Du, H. Fabrication of mullite fiber porous ceramics with even structures by filtration freeze-drying. J. Ceram. Soc. Jpn. 2019, 127, 5–10. [Google Scholar] [CrossRef]

- Schelm, K.; Dammler, K.; Betke, U.; Scheffler, M. Tailoring of the wetting behavior of alumina dispersions on polymer foams by methylcellulose addition: A route toward mechanically stable ceramic replica foams. Adv. Eng. Mater. 2019, 21, 1900635. [Google Scholar] [CrossRef]

- Zhang, M.; Li, X.; Zhang, M.; Xiu, Z.; Li, J.G.; Li, J.; Xie, M.; Chen, J.; Sun, X. High-strength macro-porous alumina ceramics with regularly arranged pores produced by gel-casting and sacrificial template methods. J. Mater. Sci. 2019, 54, 10119–10129. [Google Scholar] [CrossRef]

- Wang, S.; Yin, Y.; Chen, L.; Liu, X.; Jia, Q.; Zhang, S. Controllable preparation of porous ZrB2-SiC ceramics via using KCl space holders. Ceram. Int. 2021, 47, 33978–33987. [Google Scholar] [CrossRef]

- Yan, N.; Fu, Q.; Zhang, Y.; Li, K.; Xie, W.; Zhang, J.; Zhuang, L.; Shi, X. Preparation of pore-controllable zirconium carbide ceramics with tunable mechanical strength, thermal conductivity and sound absorption coefficient. Ceram. Int. 2020, 46, 19609–19616. [Google Scholar] [CrossRef]

- Zhao, K.; Ye, F.; Cheng, L.; Zhou, J.; Wei, Y.; Cui, X. Formation of Ultra-High Temperature Ceramic Hollow Microspheres as Promising Lightweight Thermal Insulation Materials via a Molten Salt-Assisted Template Method. ACS. Appl. Mater. Interface 2021, 13, 37388–37397. [Google Scholar] [CrossRef]

- Dai, F.Z.; Wen, B.; Sun, Y.; Xiang, H.; Zhou, Y. Theoretical prediction on thermal and mechanical properties of high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C by deep learning potential. J. Mater. Sci. Technol. 2020, 43, 168–174. [Google Scholar] [CrossRef]

- Xiang, H.; Xing, Y.; Dai, F.Z.; Wang, H.; Su, L.; Miao, L.; Zhang, G.; Wang, Y.; Qi, X.; Yao, L.; et al. High-entropy ceramics: Present status, challenges, and a look forward. J. Adv. Ceram. 2021, 10, 385–441. [Google Scholar] [CrossRef]

- Ye, B.; Wen, T.; Huang, K.; Wang, C.Z.; Chu, Y.H. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high-entropy ceramics. J. Am. Ceram. Soc. 2019, 102, 4344–4352. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, J.; Zhang, F.; Niu, B.; Lei, L.; Wang, W. High-entropy carbide: A novel class of multicomponent ceramics. Ceram. Int. 2018, 44, 22014–22018. [Google Scholar] [CrossRef]

- Sarkar, A.; Breitung, B.; Hahn, H. High entropy oxides: The role of entropy, enthalpy and synergy. Scr. Mater. 2020, 187, 43–48. [Google Scholar] [CrossRef]

- Liu, D.; Liu, H.; Ning, S.; Ye, B.; Chu, Y.H. Synthesis of high-purity high-entropy metal diboride powders by boro/carbothermal reduction. J. Am. Ceram. Soc. 2019, 102, 7071–7076. [Google Scholar] [CrossRef]

- Feng, L.; Fahrenholtz, W.G.; Brenner, D.W. High-Entropy Ultra-High-Temperature Borides and Carbides: A New Class of Materials for Extreme Environments. Annu. Rev. Mater. Res. 2021, 51, 165–185. [Google Scholar] [CrossRef]

- Gao, M.C.; Miracle, D.B.; Maurice, D.; Yan, X.; Zhang, Y.; Hawk, J.A. High-entropy functional materials. J. Mater. Res. 2018, 33, 3138–3155. [Google Scholar] [CrossRef]

- Ye, B.; Fan, C.; Han, Y.; Ma, M.; Chu, Y.H. Synthesis of high-entropy diboride nanopowders via molten salt-mediated magnesiothermic reduction. J. Am. Ceram. Soc. 2020, 103, 4738–4741. [Google Scholar] [CrossRef]

- Chen, H.; Xiang, H.; Dai, F.Z.; Liu, J.; Lei, Y.; Zhang, J.; Zhou, Y. High porosity and low thermal conductivity high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C. J. Mater. Sci. Technol. 2019, 35, 1700–1705. [Google Scholar] [CrossRef]

- Chen, H.; Xiang, H.; Dai, F.Z.; Liu, J.; Zhou, Y. Porous high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)B2: A novel strategy towards making ultrahigh temperature ceramics thermal insulating. J. Mater. Sci. Technol. 2019, 35, 2404–2408. [Google Scholar] [CrossRef]

- Yan, X.; Constantin, L.; Lu, Y.; Silvain, J.F.; Nastasi, M.; Cui, B. (Hf0.2 Zr0.2Ta0.2Nb0.2Ti0.2)C High-Entropy Ceramics with Low Thermal Conductivity. J. Am. Ceram. Soc. 2018, 101, 4486–4491. [Google Scholar] [CrossRef]

- Gild, J.; Kaufmann, K.; Vecchio, K.; Luo, J. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scr. Mater. 2019, 170, 106–110. [Google Scholar] [CrossRef]

- Backman, L.; Gild, J.; Luo, J.; Opila, E.J. Part II: Experimental Verification of Computationally Predicted Preferential Oxidation in Refractory High Entropy Ultra-high Temperature Ceramics. Acta Mater. 2020, 197, 81–90. [Google Scholar] [CrossRef]

- Castle, E.; Csanádi, T.; Grasso, S.; Dusza, J.; Reece, M. Processing and properties of high-entropy ultra-high temperature carbides. Sci. Rep. 2018, 8, 8609. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Chen, L.; Xu, C.; Zhang, W.; Liu, Z.; Wang, Y. Microstructure and mechanical properties of (TiZrNbTaMo) C high-entropy ceramic. J. Mater. Sci. 2020, 39, 99–105. [Google Scholar]

- Li, R.; Luo, R.Y.; Lin, N.; Li, A.Q.; Zhang, X.C.; Tang, Y. A novel strategy for fabricating (Ti, Ta, Nb, Zr, W)(C, N) high-entropy ceramic reinforced with in situ synthesized W2C particles. Ceram. Int. 2022, 48, 32540–32545. [Google Scholar] [CrossRef]

- Du, B.; Liu, H.; Chu, Y.H. Fabrication and characterization of polymer-derived high-entropy carbide ceramic powders. J. Am. Ceram. Soc. 2020, 103, 4063–4068. [Google Scholar] [CrossRef]

- Wang, J.; Carson, J.K.; North, M.F.; Cleland, D.J. A new approach to modelling the effective thermal conductivity of heterogeneous materials. Int. J. Heat. Mass. Transf. 2006, 49, 3075–3083. [Google Scholar] [CrossRef]

- Zhu, F.; Cui, S.; Gu, B. Fractal analysis for effective thermal conductivity of random fibrous porous materials. Phys. Lett. A 2010, 374, 4411–4414. [Google Scholar] [CrossRef]

- Wang, J.; Carson, J.K.; North, M.F.; Cleland, D.J. A new structural model of effective thermal conductivity for heterogeneous materials with co-continuous phases. Int. J. Heat. Mass. Transf. 2008, 51, 2389–2397. [Google Scholar] [CrossRef]

- Carson, J.K.; Lovatt, S.J.; Tanner, D.J.; Cleland, A.C. Thermal conductivity bounds for isotropic, porous materials. Int. J. Heat. Mass. Transf. 2005, 48, 2150–2158. [Google Scholar] [CrossRef]

- Chen, H.; Xiang, H.; Dai, F.Z.; Liu, J.; Zhou, Y. Low thermal conductivity and high porosity ZrC and HfC ceramics prepared by in-situ reduction reaction/partial sintering method for ultrahigh temperature applications. J. Mater. Sci. Technol. 2019, 35, 2778–2784. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, S.; Li, W.; Chen, Z. Fabrication and characterization of ZrC foam by melt infiltration. J. Alloy. Compd. 2017, 695, 2295–2300. [Google Scholar] [CrossRef]

- Li, F.; Liu, J.X.; Huang, X.; Bao, W.; Zhang, G.J.; Wang, H. Carbothermal Conversion of Self-Supporting Organic/Inorganic Interpenetrating Networks to Porous Metal Boride Monoliths. J. Am. Ceram. Soc. 2019, 102, 5746–5762. [Google Scholar] [CrossRef]

- Tandon, R.; Dumm, H.P.; Corral, E.L.; Loehman, R.E.; Kotula, P.G. Ultra High Temperature Ceramics for Hypersonic Vehicle Applications; Sandia National Laboratories (SNL): Albuquerque, NM, USA, 2006. [Google Scholar]

- Kunhao, X.; Yang, S.; Yong, H.; Jialin, S. Research of (TBA)-Based Gel-Casting Process and (Water)-Based Foaming-Gel Process for Porous Alumina Ceramics Preparation. Rare Metal. Mater. Eng. 2011, 40, 345–348. [Google Scholar]

- Wang, S.; Liu, M.; Liu, X.; Jia, Q.; Zhang, S. Carbothermal reduction synthesis of high porosity and low thermal conductivity ZrC-SiC ceramics via an one-step sintering technique. J. Eur. Ceram. Soc. 2022, 42, 4465–4471. [Google Scholar] [CrossRef]

- Shao, Z.; Wu, Z.; Sun, L.; Liang, X.; Luo, Z.; Chen, H.; Li, J.; Wang, J. High entropy ultra-high temperature ceramic thermal insulator (Zr1/5Hf1/5Nb1/5Ta1/5Ti1/5)C with controlled microstructure and outstanding properties. J. Mater. Sci. Technol. 2022, 119, 190–199. [Google Scholar] [CrossRef]

- Chen, G.; Li, C.; Li, H.; Wang, L.; Chen, K.; An, L. Porous (Ce0.2Zr0.2Ti0.2Sn0.2Ca0.2)O2-δ high-entropy ceramics with both high strength and low thermal conductivity. J. Eur. Ceram. Soc. 2021, 41, 309–314. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, Z.; Wang, Y.; Xu, B. Highly porous (La1/5Nd1/5Sm1/5Gd1/5Yb1/5)2Zr2O7 ceramics with ultra-low thermal conductivity. Ceram. Int. 2022, 48, 26400–26407. [Google Scholar] [CrossRef]

- Rost, C.M.; Borman, T.; Hossain, M.D.; Lim, M.; Quiambao-Tomko, K.F.; Tomko, J.A.; Brenner, D.W.; Maria, J.P.; Hopkins, P.E. Electron and phonon thermal conductivity in high entropy carbides with variable carbon content. Acta Mater. 2020, 196, 231–239. [Google Scholar] [CrossRef]

- Dusza, J.; Csanádi, T.; Medve, D.; Sedlák, R.; Vojtko, M.; Ivor, M.; Ünsal, H.; Tatarko, P.; Tatarková, M.; Šajgalík, P. Nanoindentation and tribology of a (Hf-Ta-Zr-Nb-Ti)C high-entropy carbide. J. Eur. Ceram. Soc. 2021, 41, 5417–5426. [Google Scholar] [CrossRef]

- Pia, G.; Sanna, U. An intermingled fractal units model to evaluate pore size distribution influence on thermal conductivity values in porous materials. Appl. Therm. Eng. 2014, 65, 330–336. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, Y.; Xu, C.; Du, X.; Yang, Y. A thermal conductivity study of double-pore distributed powdered silica aerogels. Int. J. Heat. Mass. Transf. 2017, 108, 1297–1304. [Google Scholar] [CrossRef]

- Ackermann, S.; Scheffe, J.R.; Duss, J. Morphological characterization and effective thermal conductivity of dual-scale reticulated porous structures. Materials 2014, 7, 7173–7195. [Google Scholar] [CrossRef] [PubMed]

- Deo, O.; Neithalath, N. Compressive response of pervious concretes proportioned for desired porosities. Constr. Build. Mater. 2011, 25, 4181–4189. [Google Scholar] [CrossRef]

- Jin, S.; Zhou, J.; Zhao, X. Quantitative relationship between pore size distribution and compressive strength of cementitious materials. Constr. Build. Mater. 2021, 273, 121727. [Google Scholar] [CrossRef]

- Schafföner, S.; Fruhstorfer, J.; Ludwig, S.; Aneziris, C.G. Cyclic cold isostatic pressing and improved particle packing of coarse grained oxide ceramics for refractory applications. Ceram. Int. 2018, 44, 9027–9036. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).