Effects of Melt Hydrogenation on the Microstructure Evolution and Hot Deformation Behavior of TiBw/Ti-6Al-4V Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation

2.2. Characterization

2.3. Testing

3. Results and Discussion

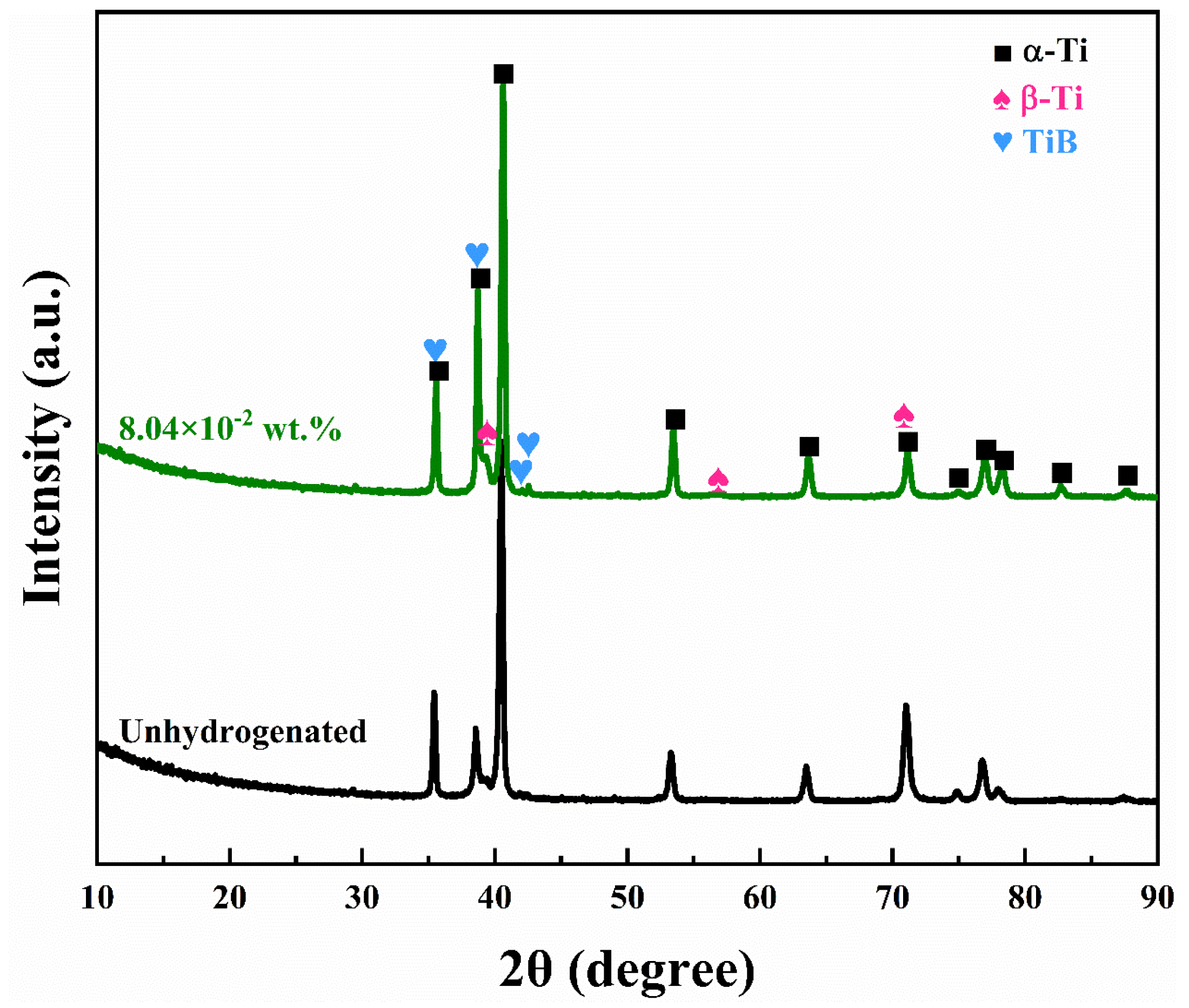

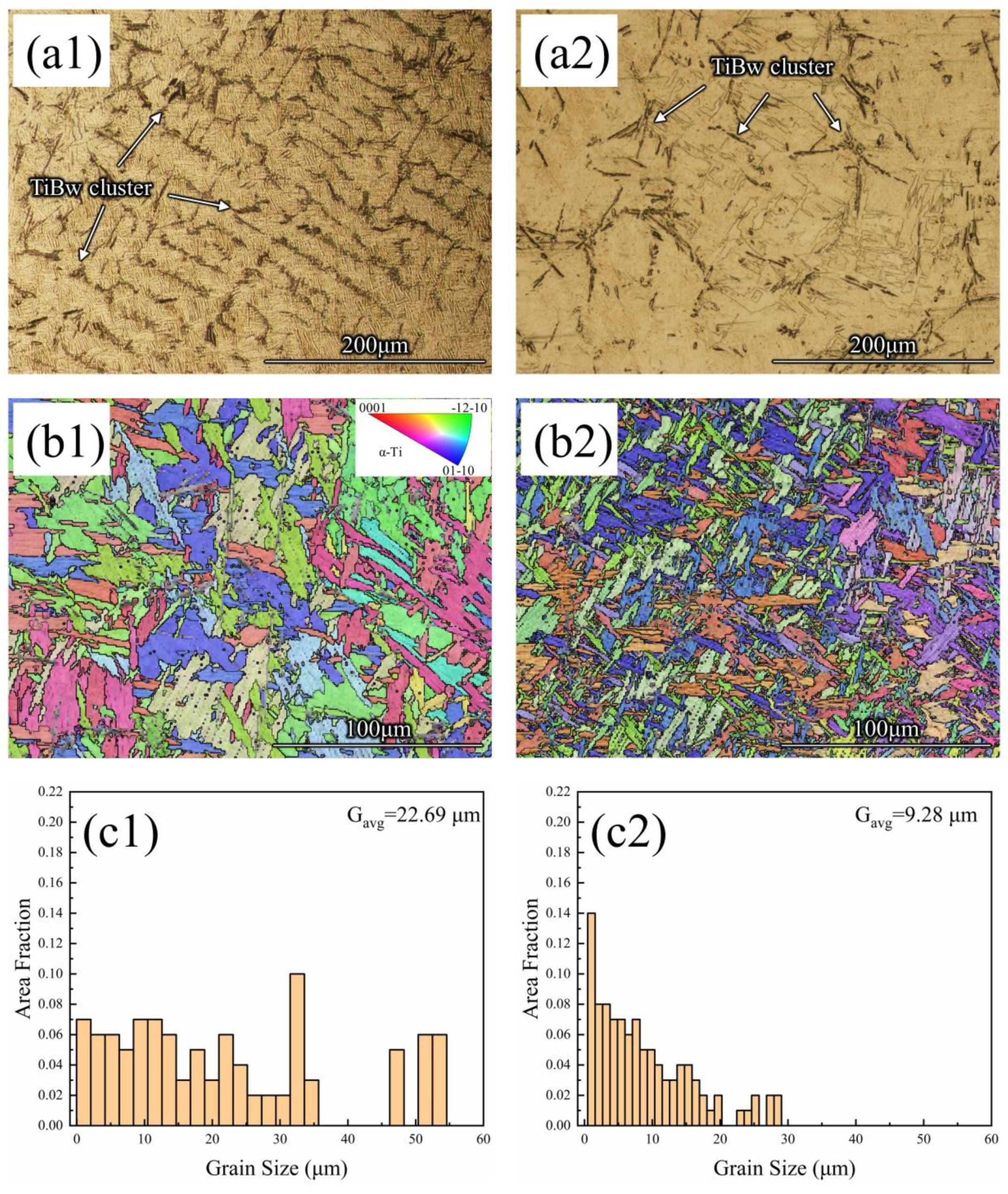

3.1. As-Cast Microstructure Characteristics

3.2. Hot Compression Behavior

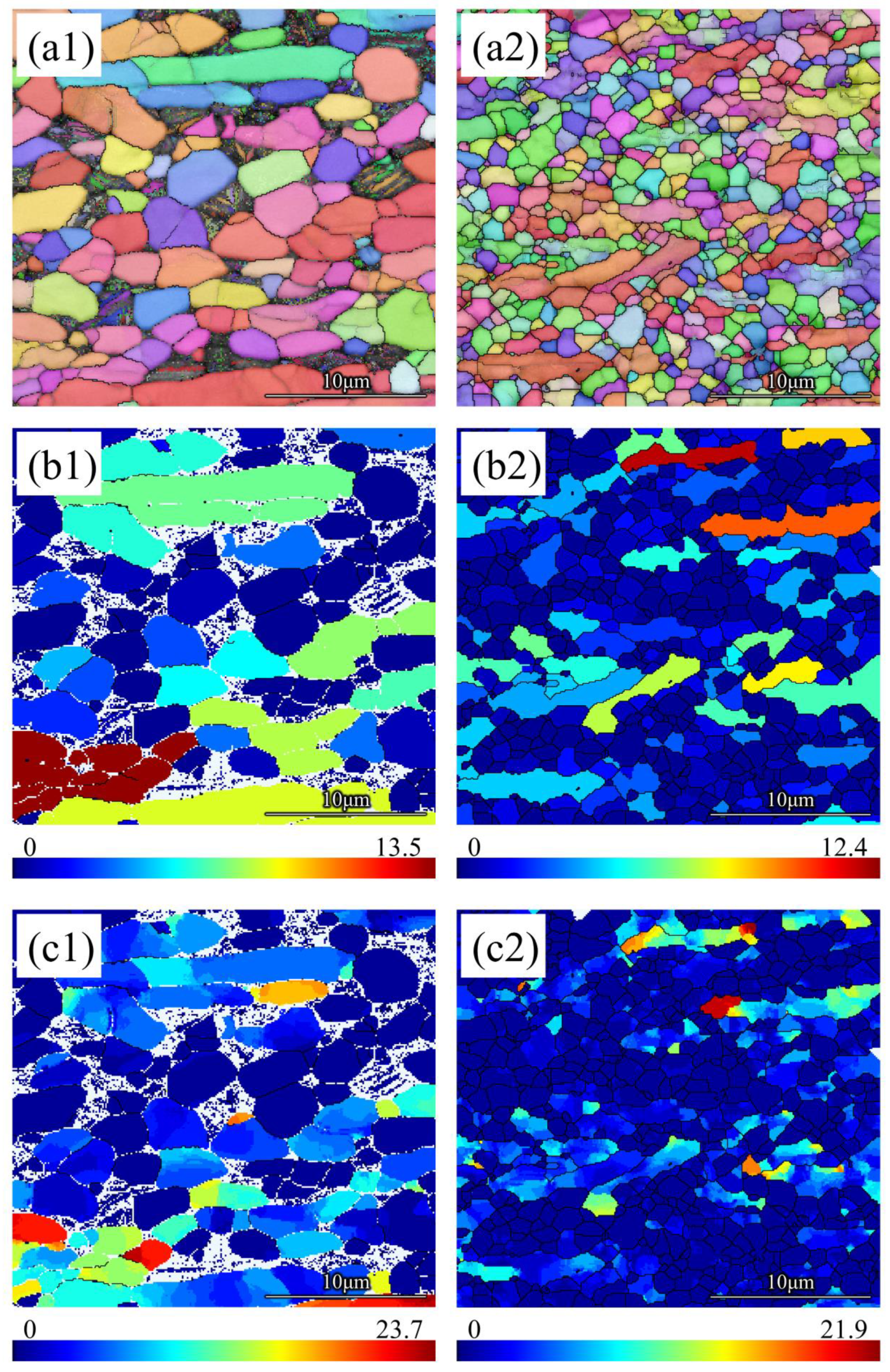

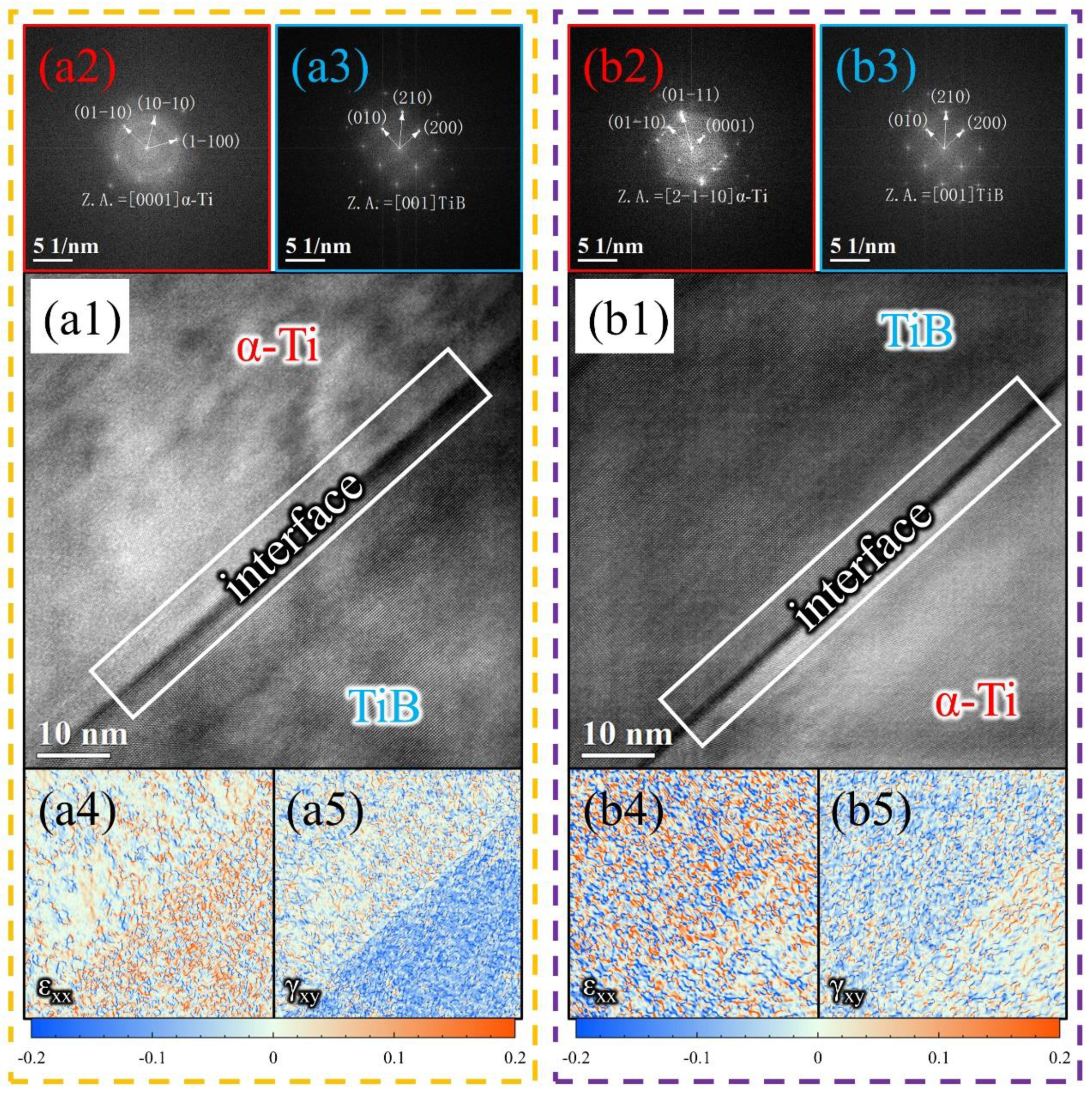

3.3. As-Compressed Microstructure Observation

4. Conclusions

- (1)

- MHT can homogenize the distribution of reinforcements, reduce the grain size of the matrix alloy, and refine the as-cast microstructure of TMC.

- (2)

- MHT can effectively reduce the peak stress during hot compression. At a temperature of 900 °C and a strain rate of 0.01/s, the hydrogen-induced peak stress decreased most significantly, with a reduction of 53.76%.

- (3)

- MHT refinement of the as-cast microstructure can greatly promote DRX grain nucleation, inhibit DRX grain growth, reduce stress concentration at the interface, and thus, improve the hot workability of TMC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Zhang, C.J.; Qu, J.P.; Wu, J.; Zhang, S.Z.; Han, J.C.; Hayat, M.D.; Cao, P. A titanium composite with dual reinforcements of micrometer sized TiB and submicrometer sized Y2O3. Mater. Lett. 2018, 233, 242–245. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Selective Laser Melting of Aluminum and Titanium Matrix Composites: Recent Progress and Potential Applications in the Aerospace Industry. Aerospace 2020, 7, 77. [Google Scholar] [CrossRef]

- Saba, F.; Zhang, F.; Liu, S.; Liu, T. Reinforcement size dependence of mechanical properties and strengthening mechanisms in diamond reinforced titanium metal matrix composites. Compos. Part B Eng. 2019, 167, 7–19. [Google Scholar] [CrossRef]

- Prando, D.; Brenna, A.; Diamanti, M.V.; Beretta, S.; Bolzoni, F.; Ormellese, M.; Pedeferri, M. Corrosion of titanium: Part 1: Aggressive environments and main forms of degradation. J. Appl. Biomater. Funct. Mater. 2017, 15, e291–e302. [Google Scholar] [CrossRef]

- Su, B.; Wang, B.; Luo, L.; Wang, L.; Su, Y.; Wang, F.; Xu, Y.; Han, B.; Huang, H.; Guo, J.; et al. The corrosion behavior of Ti-6Al-3Nb-2Zr-1Mo alloy: Effects of HCl concentration and temperature. J. Mater. Sci. Technol. 2021, 74, 143–154. [Google Scholar] [CrossRef]

- Bai, M.; Namus, R.; Xu, Y.; Guan, D.; Rainforth, M.W.; Inkson, B.J. In-situ Ti-6Al-4V/TiC composites synthesized by reactive spark plasma sintering: Processing, microstructure, and dry sliding wear behaviour. Wear 2019, 432–433, 202944. [Google Scholar] [CrossRef]

- Niu, H.Z.; Yin, B.G.; Zhang, H.R.; Zang, M.C.; Tan, H.; Zhang, D.L. Multiphase polymorphic nanoparticles reinforced titanium matrix composite produced by selective electron beam melting of a prealloyed composite powder. Scr. Mater. 2021, 200, 113916. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, S.; Chen, X.; An, Q.; Huang, L.; Geng, L.; Yang, F. Significantly enhanced superplasticity of TiBw/near-α Ti composite: Microstructure tailoring and deformation mechanisms. Mater. Sci. Eng. A 2022, 853, 143772. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.-W. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Yang, F.Y.; Peng, H.X. In situ TiBw/Ti–6Al–4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 60, 996–999. [Google Scholar] [CrossRef]

- Yang, Z.; Cao, J.; Yu, W.; Hou, S.; Wang, G.; Lang, S.; Ding, P. Effects of microstructure characteristics on the mechanical properties and elastic modulus of a new Ti–6Al–2Nb–2Zr–0.4B alloy. Mater. Sci. Eng. A 2021, 820, 141564. [Google Scholar] [CrossRef]

- Xu, R.; Liu, B.; Liu, Y.; Cao, Y.; Guo, W.; Nie, Y.; Liu, S. High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers. Materials 2018, 11, 1863. [Google Scholar] [CrossRef]

- Izui, H.; Shinohara, T. Mechanical properties of TiB/Ti-6Al-4V alloy composites fabricated by spark plasma sintering. Mech. Eng. J. 2017, 4, 17–00267. [Google Scholar] [CrossRef]

- Yamamoto, T.; Otsuki, A.; Ishihara, K.; Shingu, P.H. Synthesis of near net shape high density TiB/Ti composite. Mater. Sci. Eng. A 1997, 240, 647–651. [Google Scholar] [CrossRef]

- Pan, D.; Zhang, X.; Hou, X.; Han, Y.; Chu, M.; Chen, B.; Jia, L.; Kondoh, K.; Li, S. TiB nano-whiskers reinforced titanium matrix composites with novel nano-reticulated microstructure and high performance via composite powder by selective laser melting. Mater. Sci. Eng. A 2021, 799, 140137. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, C.; Han, J.; Zhang, S.; Yang, F.; Chai, L.; Chen, Z. Effect of Trace B on the Microstructure and Mechanical Properties of a Newly Near α High Temperature Titanium Alloy. Adv. Eng. Mater. 2017, 19, 1700490. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium–titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, J.; Zhang, Z.; Chen, Y.; Lu, W.; Zhang, D. Effect of β heat treatment temperature on microstructure and mechanical properties of in situ titanium matrix composites. Mater. Des. 2010, 31, 4269–4273. [Google Scholar] [CrossRef]

- Li, J.; Han, Y.; Yang, D.; Mao, J. Effect of Heat Treatment on Creep Properties of in situ Synthesized (TiB+La2O3)/Ti Composite. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Senkov, O.N.; Jonas, J.J.; Froes, F.H. Recent advances in the thermohydrogen processing of titanium alloys. Jom-J. Miner. Met. Mater. Soc. 1996, 48, 42–47. [Google Scholar] [CrossRef]

- Il’in, A.A.; Skvortsova, S.V.; Mamonov, A.M. Control of the structure of titanium alloys by the method of thermohydrogen treatment. Mater. Sci. 2008, 44, 336–341. [Google Scholar] [CrossRef]

- Eliaz, N.; Eliezer, D.; Olson, D.L. Hydrogen-assisted processing of materials. Mater. Sci. Eng. A 2000, 289, 41–53. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Li, B.; Chen, N.; Chen, J. Grain refinement mechanism of Ti-55 titanium alloy by hydrogenation and dehydrogenation treatment. Mater. Charact. 2019, 157, 109919. [Google Scholar] [CrossRef]

- Niu, Y.; Li, M. Effect of 0.16 wt% hydrogen addition on high temperature deformation behavior of the Ti600 titanium alloy. Mater. Sci. Eng. A 2009, 513–514, 228–232. [Google Scholar] [CrossRef]

- Ma, T.F.; Chen, R.R.; Guo, J.J.; Ding, H.S.; Su, Y.Q.; Fu, H.Z. Microstructure Evolution and Hot Deformation Behavior of High Nb Contained TiAl Alloys Hydrogenated at High Temperature. Rare Met. Mater. Eng. 2017, 46, 20–24. [Google Scholar]

- Lu, J.; Qin, J.; Lu, W.; Chen, Y.; Zhang, D.; Hou, H. Hot deformation behavior and microstructure evaluation of hydrogenated Ti-6Al-4V matrix composite. Int. J. Hydrogen Energy 2009, 34, 9266–9273. [Google Scholar] [CrossRef]

- Yang, L.; He, L.; Huang, D.; Wang, Y.; Song, Q.; Zhao, L.; Shen, X.; Tian, Z.; Wang, H. Three-dimensional hydrogen distribution and quantitative determination of titanium alloys via neutron tomography. Analyst 2020, 145, 4156–4163. [Google Scholar] [CrossRef]

- Su, Y.; Wang, L.; Luo, L.; Jiang, X.; Guo, J.; Fu, H. Deoxidation of Titanium alloy using hydrogen. Int. J. Hydrogen Energy 2009, 34, 8958–8963. [Google Scholar] [CrossRef]

- Wang, L.; Luo, L.; Wu, S.; Su, Y.; Wang, S.; Wang, G.; Guo, J.; Fu, H. The influence of melt hydrogenation on Ti600 alloy. Int. J. Hydrogen Energy 2014, 39, 6089–6094. [Google Scholar] [CrossRef]

- Su, Y.Q.; Wang, S.J.; Luo, L.S.; Wang, L.; Dong, F.Y.; Guo, J.J.; Fu, H.Z. Gradient microstructure of TC21 alloy induced by hydrogen during hydrogenation. Int. J. Hydrogen Energy 2012, 37, 19210–19218. [Google Scholar] [CrossRef]

- Liu, X.; Su, Y.; Luo, L.; Liu, J.; Guo, J.; Fu, H. Effect of hydrogen on hot deformation behaviors of TiAl alloys. Int. J. Hydrogen Energy 2010, 35, 13322–13328. [Google Scholar] [CrossRef]

- Dong, F.; Liu, Y.; Zhang, Y.; Li, W.; Liaw, P.K.; Shi, M.; Huang, H.; Zuo, X.; Luo, L.; Su, Y.; et al. Thermal deformation behavior of γ-TiAl based alloy by plasma hydrogenation. Int. J. Hydrogen Energy 2020, 45, 34214–34226. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Luo, L.; Xu, Y.; Li, X.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Hydrogen induced softening and hardening for hot workability of (TiB + TiC)/Ti-6Al-4V composites. Int. J. Hydrogen Energy 2017, 42, 3380–3388. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Luo, L.; Wang, B.; Yan, H.; Chen, R.; Su, Y.; Guo, J.; Fu, H. Effect of melt hydrogenation on microstructure evolution and tensile properties of (TiB + TiC)/Ti-6Al-4V composites. J. Mater. Res. Technol. 2020, 9, 6343–6351. [Google Scholar] [CrossRef]

- Wang, X.; Chen, S.; Tan, Y.; Yao, L.; Wang, L.; Su, Y.; Guo, J. Microstructure Evolution and Enhanced Hot Workability of TiC/Ti-6Al-4V Composites Fabricated by Melt Hydrogenation. Materials 2022, 15, 8884. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Wang, L.; Yan, H.; Zhu, G.; Teng, J.; Wang, B.; Luo, L.; Chen, R.; Su, Y.; Guo, J. Hydrogen-induced modification of the interface between matrix and ceramic phase of (TiB + TiC)/Ti–6Al–4V. Compos. Commun. 2023, 37, 101434. [Google Scholar] [CrossRef]

- Decker, B.F.; Kasper, J.S. The crystal structure of TiB. Acta Crystallogr. 1954, 7, 77–80. [Google Scholar] [CrossRef]

- Motyka, M.; Baran-Sadleja, A.; Sieniawski, J.; Wierzbinska, M.; Gancarczyk, K. Decomposition of deformed α′(α″) martensitic phase in Ti-6Al-4V alloy. Mater. Sci. Technol. 2019, 35, 260–272. [Google Scholar] [CrossRef]

- Kapoor, K.; Ravi, P.; Naragani, D.; Park, J.-S.; Almer, J.D.; Sangida, M.D. Strain rate sensitivity, microstructure variations, and stress-assisted β → α′′ phase transformation investigation on the mechanical behavior of dual-phase titanium alloys. Mater. Charact. 2020, 166, 110410. [Google Scholar] [CrossRef]

- Cai, C.; Radoslaw, C.; Zhang, J.; Yan, Q.; Wen, S.; Song, B.; Shi, Y. In-situ preparation and formation of TiB/Ti-6Al-4V nanocomposite via laser additive manufacturing: Microstructure evolution and tribological behavior. Powder Technol. 2019, 342, 73–84. [Google Scholar] [CrossRef]

- Oh, J.-M.; Roh, K.-M.; Lim, J.-W. Brief review of removal effect of hydrogen-plasma arc melting on refining of pure titanium and titanium alloys. Int. J. Hydrogen Energy 2016, 41, 23033–23041. [Google Scholar] [CrossRef]

- Oh, J.-M.; Lee, B.-K.; Suh, C.-Y.; Lim, J.-W. Removal of metallic impurities from Ti binary alloy scraps using hydrogen plasma arc melting. J. Alloys Compd. 2013, 574, 1–5. [Google Scholar] [CrossRef]

- Lalev, G.M.; Lim, J.W.; Munirathnam, N.R.; Choi, G.S.; Uchikoshi, M.; Mimura, K.; Isshiki, M. Concentration Behavior of Non-Metallic Impurities in Cu Rods Refined by Argon and Hydrogen Plasma-Arc Zone Melting. Mater. Trans. 2009, 50, 618–621. [Google Scholar] [CrossRef]

| Element (wt. %) | Al | V | B | H | Ti |

|---|---|---|---|---|---|

| Unhydrogenated TMC | 5.91 | 3.94 | 0.48 | 0 | Balanced |

| Hydrogenated TMC | 5.90 | 3.93 | 0.48 | 0.0804 | Balanced |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Wang, L.; Wang, X.; Jiang, B.; Liu, H.; Wang, B.; Luo, L.; Su, Y.; Guo, J.; Fu, H. Effects of Melt Hydrogenation on the Microstructure Evolution and Hot Deformation Behavior of TiBw/Ti-6Al-4V Composites. Materials 2023, 16, 2496. https://doi.org/10.3390/ma16062496

Yan H, Wang L, Wang X, Jiang B, Liu H, Wang B, Luo L, Su Y, Guo J, Fu H. Effects of Melt Hydrogenation on the Microstructure Evolution and Hot Deformation Behavior of TiBw/Ti-6Al-4V Composites. Materials. 2023; 16(6):2496. https://doi.org/10.3390/ma16062496

Chicago/Turabian StyleYan, Hui, Liang Wang, Xiaoming Wang, Botao Jiang, Hongcan Liu, Binbin Wang, Liangshun Luo, Yanqing Su, Jingjie Guo, and Hengzhi Fu. 2023. "Effects of Melt Hydrogenation on the Microstructure Evolution and Hot Deformation Behavior of TiBw/Ti-6Al-4V Composites" Materials 16, no. 6: 2496. https://doi.org/10.3390/ma16062496

APA StyleYan, H., Wang, L., Wang, X., Jiang, B., Liu, H., Wang, B., Luo, L., Su, Y., Guo, J., & Fu, H. (2023). Effects of Melt Hydrogenation on the Microstructure Evolution and Hot Deformation Behavior of TiBw/Ti-6Al-4V Composites. Materials, 16(6), 2496. https://doi.org/10.3390/ma16062496