Piezoelectricity and Thermophysical Properties of Ba0.90Ca0.10Ti0.96Zr0.04O3 Ceramics Modified with Amphoteric Nd3+ and Y3+ Dopants

Abstract

1. Introduction

2. Experimental Procedure

2.1. Preparation

2.2. Characterisation

3. Results and Discussion

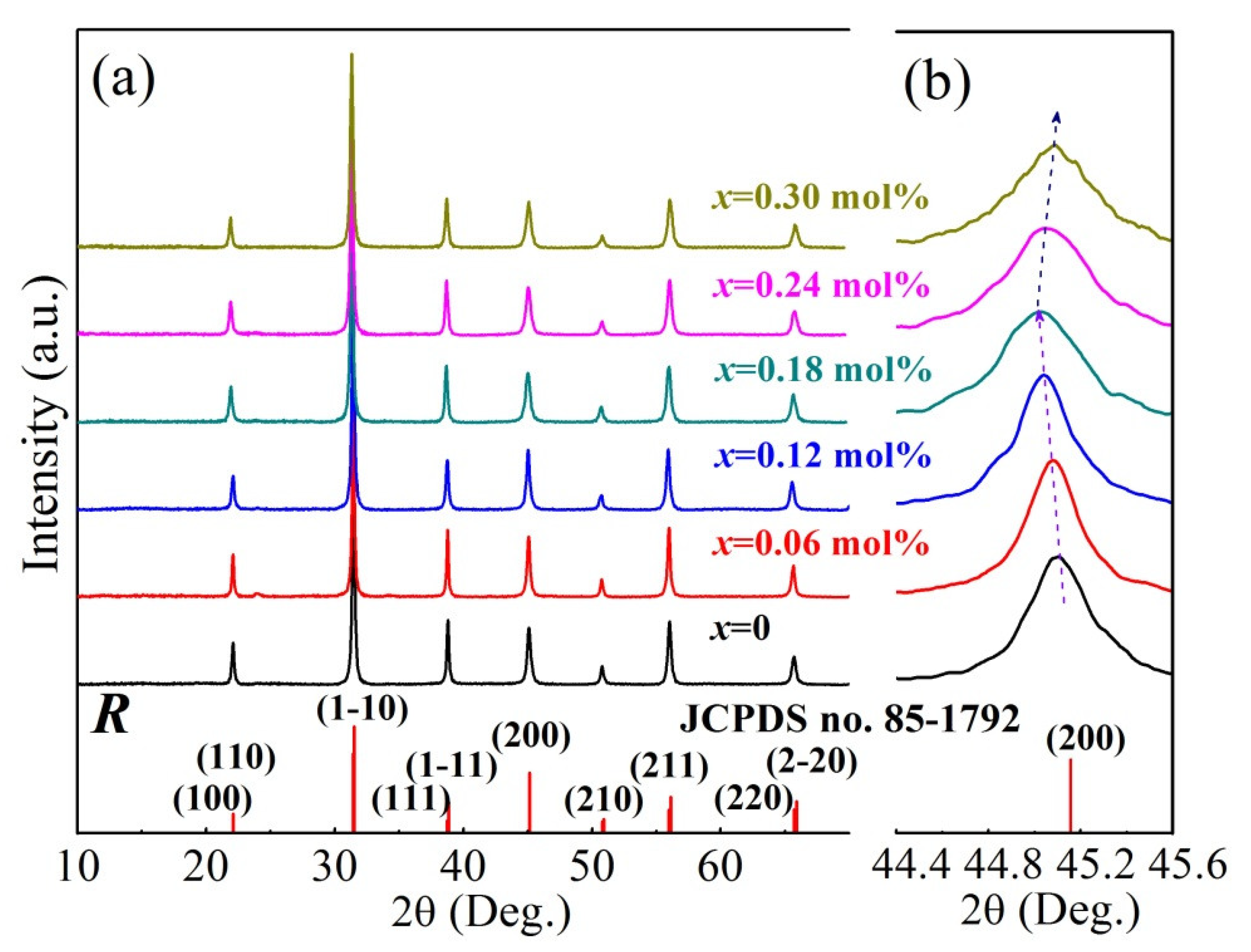

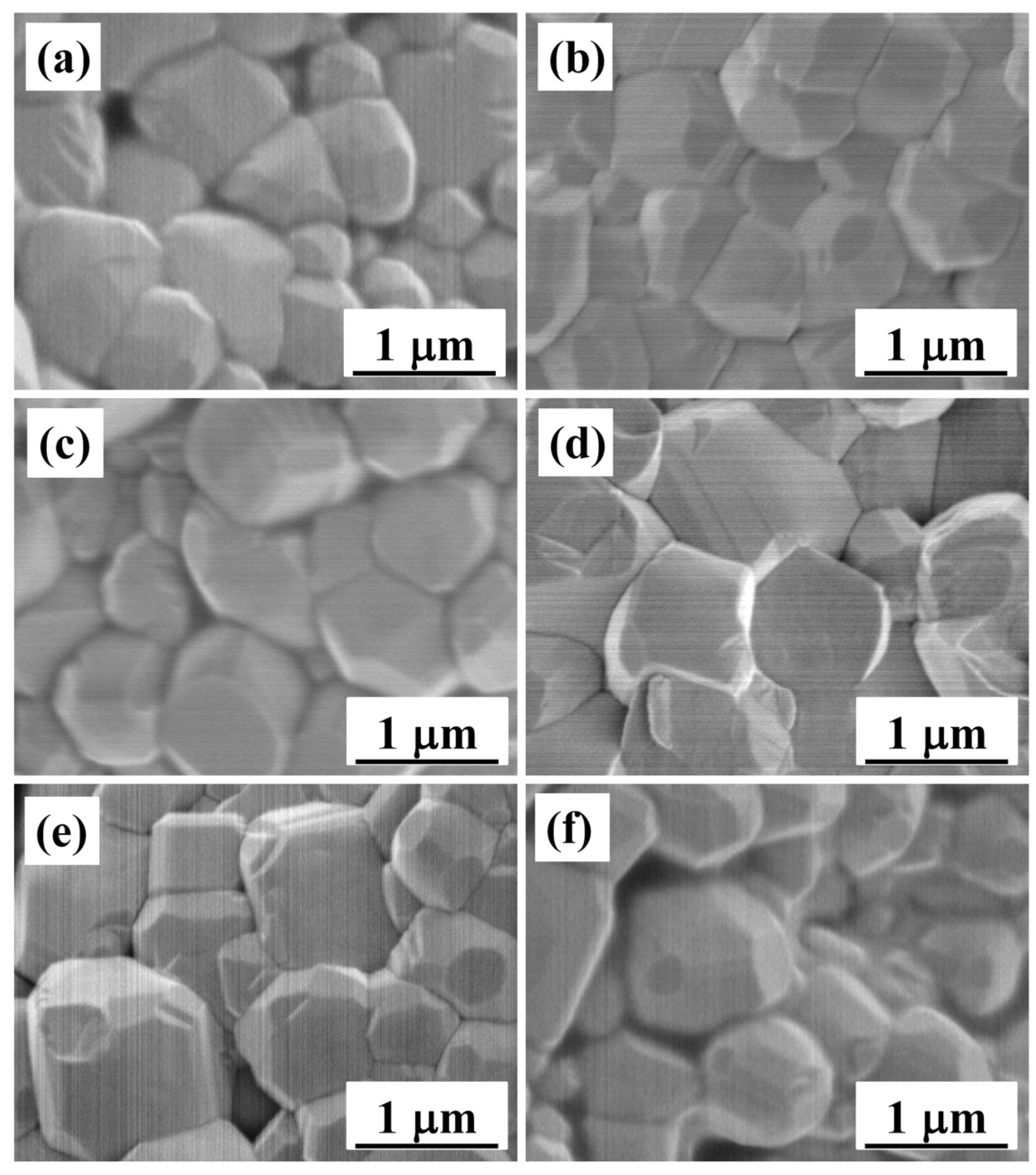

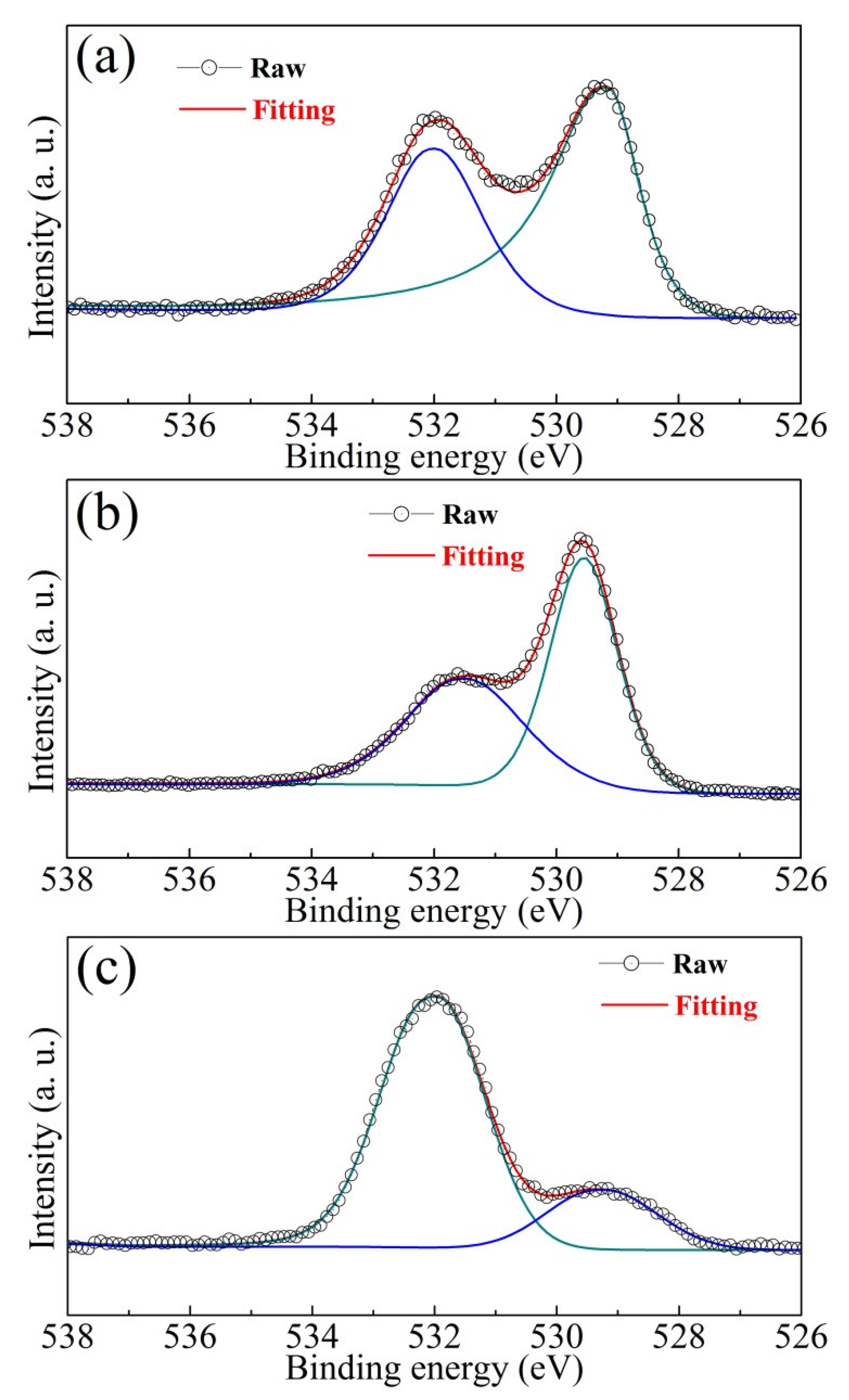

3.1. Phases and Structures

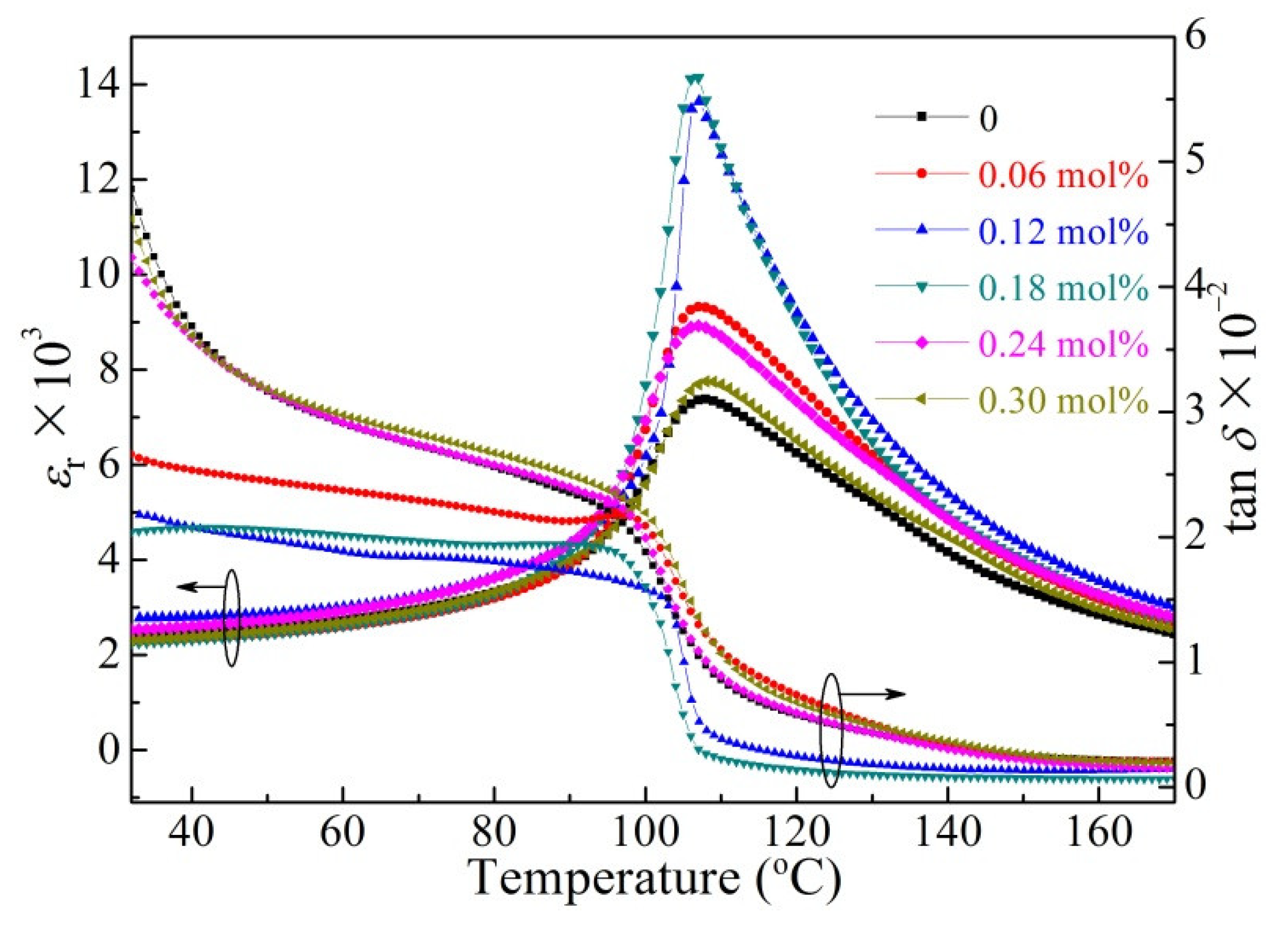

3.2. Dielectric Properties

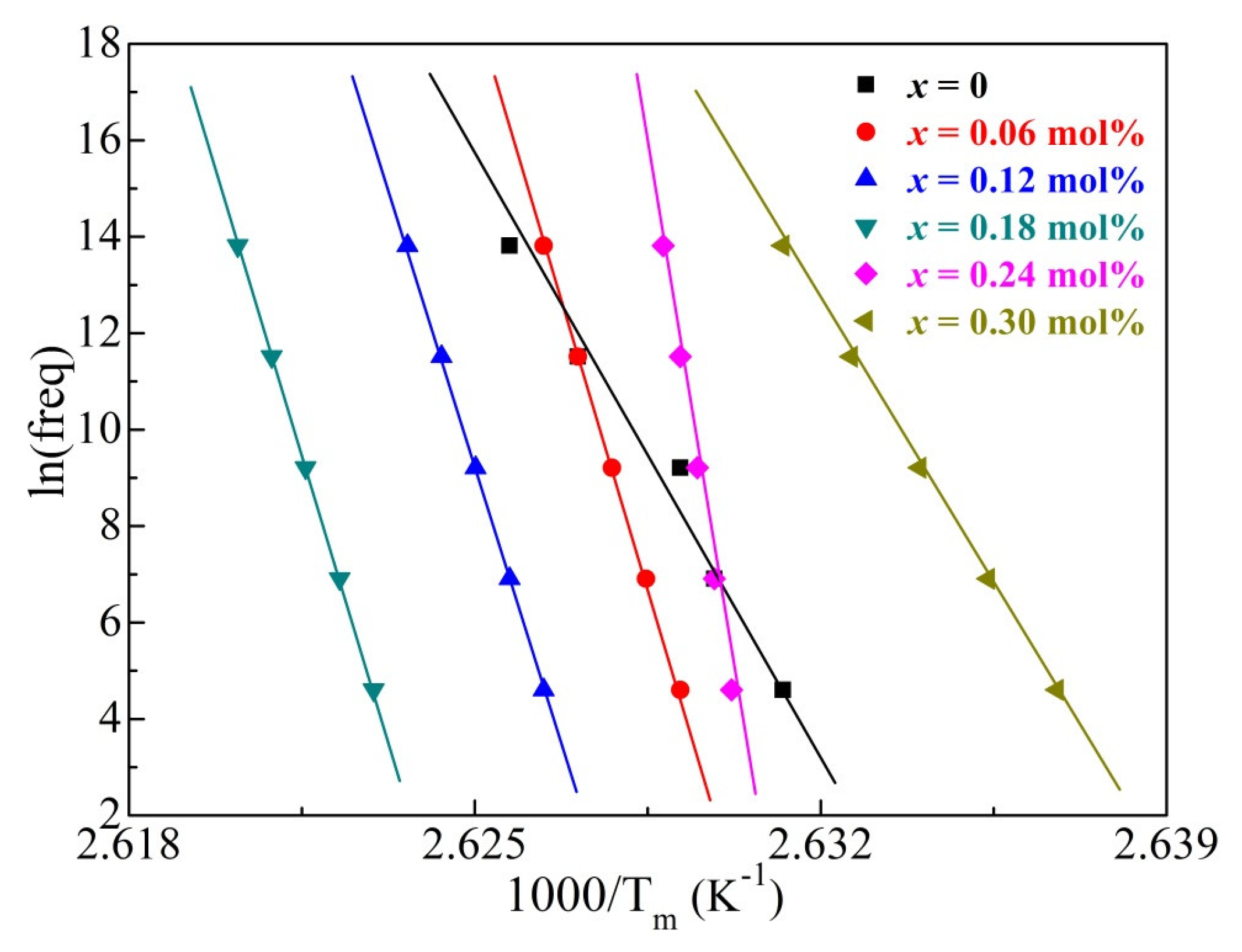

3.3. Activation Energy

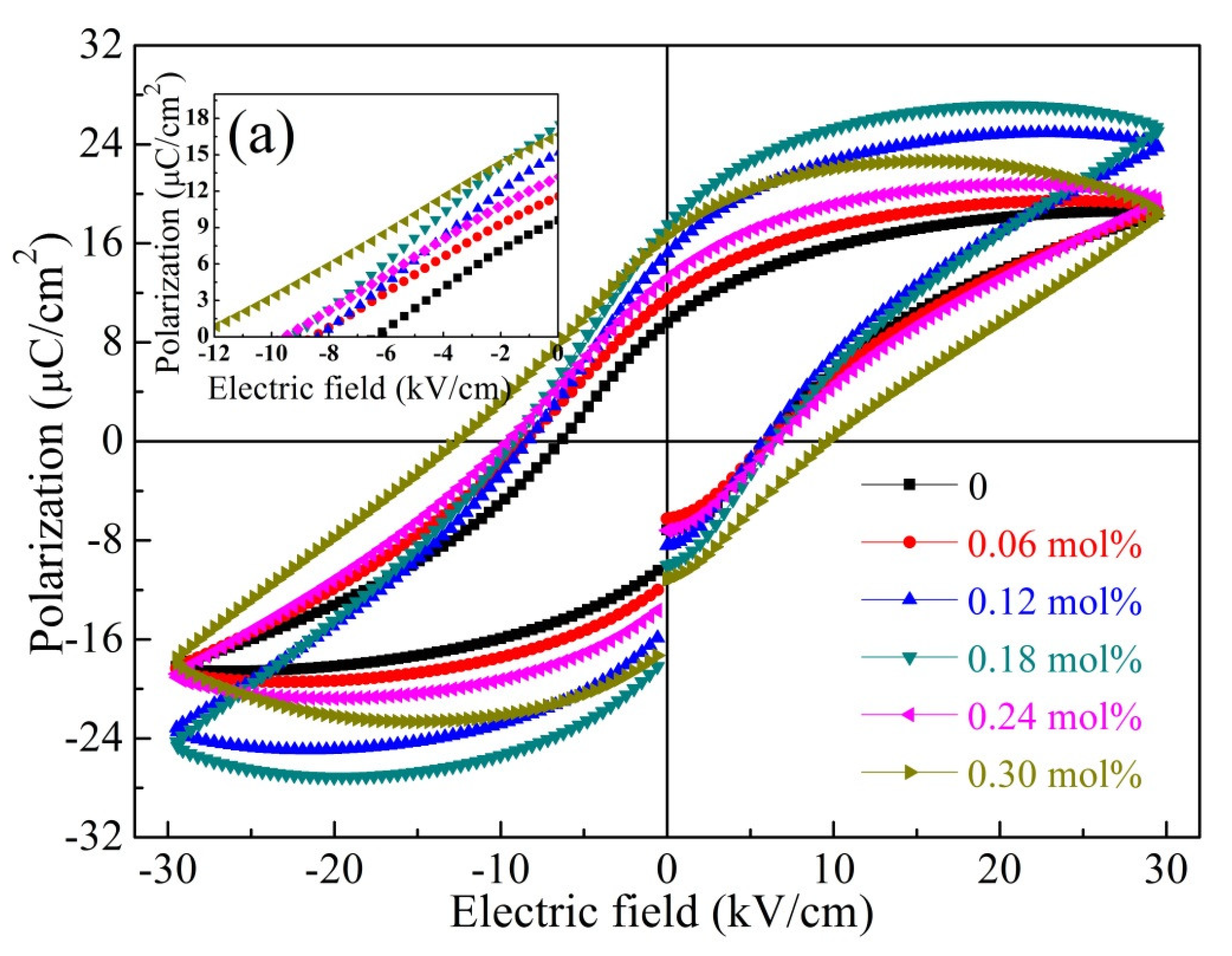

3.4. Ferroelectricity

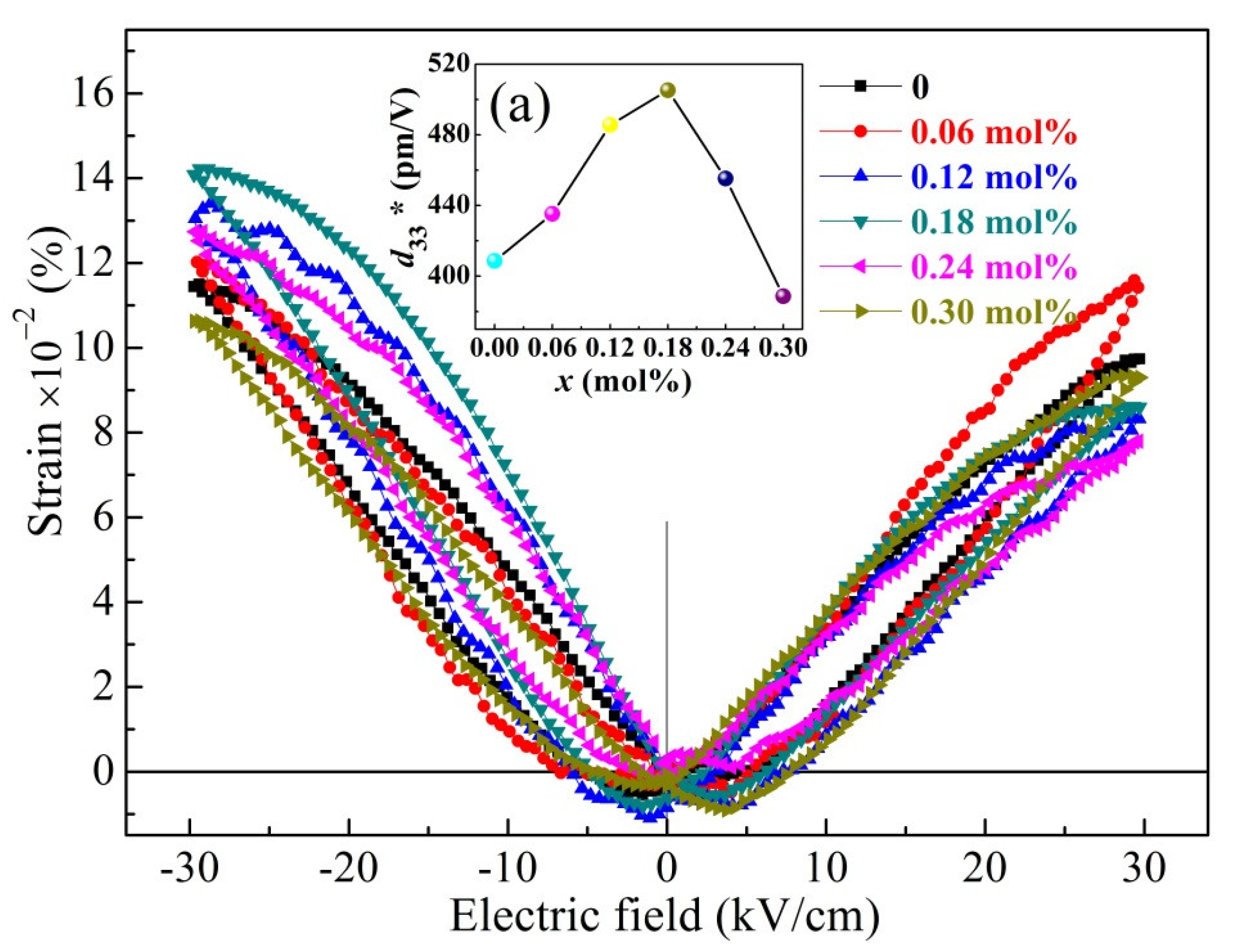

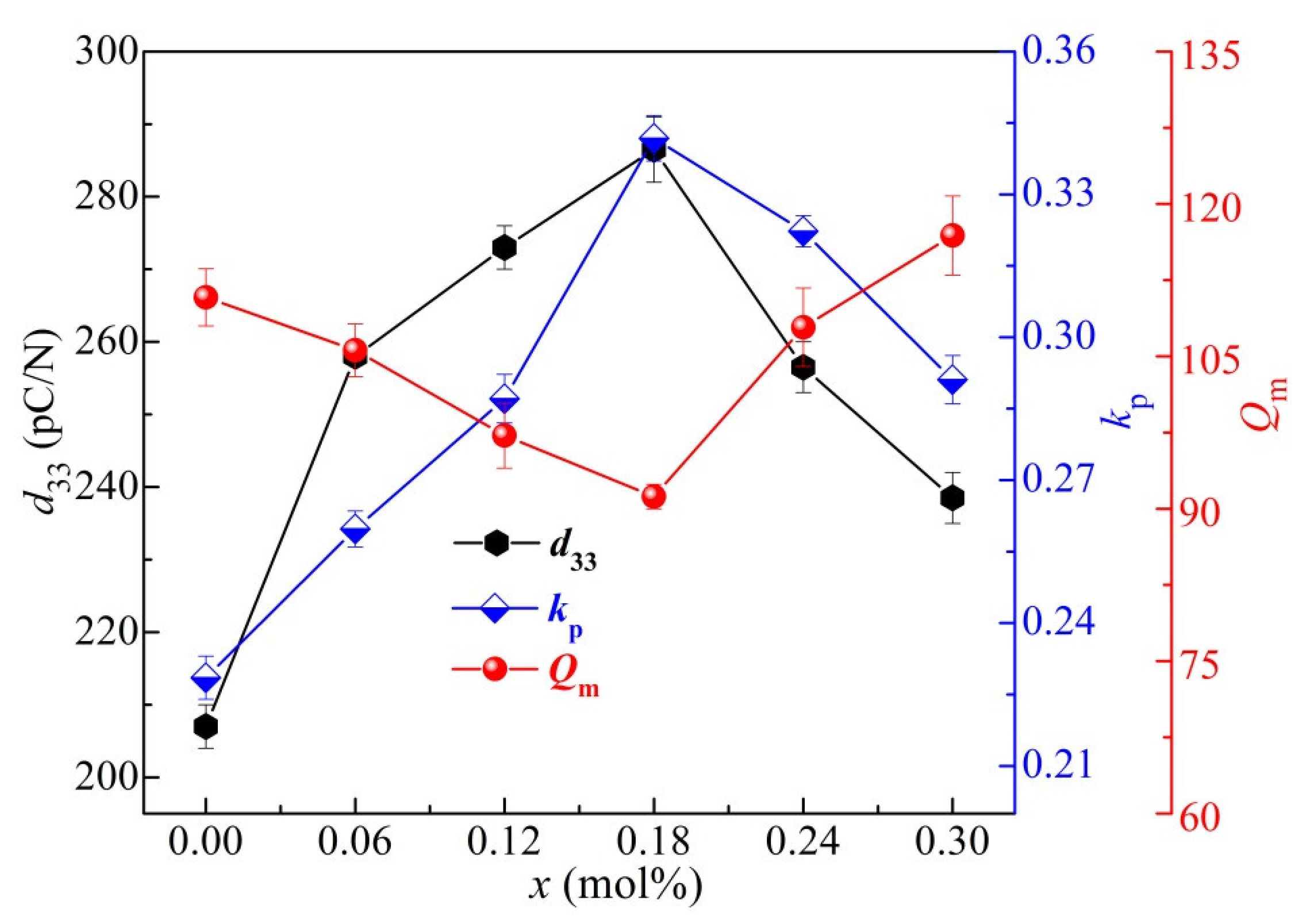

3.5. Piezoelectricity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Recent development in lead-free perovskite piezoelectric bulk materials. Prog. Mater. Sci. 2018, 98, 552–624. [Google Scholar] [CrossRef]

- Rödel, J.; Webber, K.G.; Dittmer, R.; Jo, W.; Kimura, M.; Damjanovic, D. Transferring lead-free piezoelectric ceramics into application. J. Eur. Ceram. Soc. 2015, 35, 1659–1681. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.B.; Chen, Z.B.; Cheng, Z.X.; Wang, J.L.; Li, C.C.; Xu, Z.; Huang, Q.W.; Liao, X.Z.; Chen, L.Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H. Current status and prospects of lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 2005, 25, 2693–2700. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.M.; Granzow, T.; Damjanovic, D. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Li, P.; Zhai, J.W.; Shen, B.; Zhang, S.J.; Li, X.L.; Zhu, F.Y.; Zhang, X.M. Ultrahigh piezoelectric properties in textured (K,Na)NbO3-based lead-free ceramics. Adv. Mater. 2017, 30, 1705171. [Google Scholar] [CrossRef]

- Glaum, J.; Zakhozheva, M.; Acosta, M.; Aksel, E.; Kleebe, H.; Hoffman, M.; Schmitt, L.A. Influence of B-site disorder on the properties of unpoled Bi1/2Na1/2TiO3-0.06Ba(ZrxTi1–x)O3 piezoceramics. J. Am. Ceram. Soc. 2016, 99, 2801–2808. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef]

- Mahmoud, A.; Erba, A.; El-Kelany, K.E.; Rérat, M.; Orlando, R. Low-temperature phase of BaTiO3: Piezoelectric, dielectric, elastic, and photoelastic properties from ab initio simulations. Phys. Rev. B 2014, 89, 045103. [Google Scholar] [CrossRef]

- Hao, J.; Li, W.; Zhai, J.W.; Chen, H. Progress in high-strain perovskite piezoelectric ceramics. Mat. Sci. Eng. R. 2019, 135, 1–57. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Ji, L.; Qi, H.; Wang, J. Phase transformation and dielectric properties in Ba1−xLaxZr0.1Ti0.9O3 ceramics. J. Alloys Compd. 2014, 592, 105–108. [Google Scholar] [CrossRef]

- Damjanovic, D. A morphotropic phase boundary system based on polarization rotation and polarization extension. Appl. Phys. Lett. 2010, 97, 062906. [Google Scholar] [CrossRef]

- Shi, J.; Lu, X.; Shao, J.; Fang, B.; Zhang, S.; Du, Q.; Ding, J.; Zhao, X.; Luo, H. Effects on structure and properties of BCZT lead-free piezoelectric ceramics by rare-earth doping. Ferroelectrics 2017, 507, 186–197. [Google Scholar] [CrossRef]

- Atallah, N.l.; El-Kemary, M.; Pascale, F.; El-Kelany, K.E. Extraordinary piezoelectric induced in two-dimensional rare earth effect monochalcogenides via reducing system dimensionality. J. Mater. 2023, 9, 72–81. [Google Scholar] [CrossRef]

- Tian, Y.; Cao, L.; Qin, P.; Sun, S.; Gong, Y.; Ji, X.; Jing, Q. Piezoelectric and thermophysical performances of La3+ and Ir4+ co-doped Ba0.95Ca0.05Ti0.94Zr0.06O3 ceramics. Ceram. Int. 2019, 45, 12825–12831. [Google Scholar] [CrossRef]

- Zuo, Q.; Luo, L.; Yao, Y. The electrical, upconversion emission, and temperature sensing properties of Er3+/Yb3+-codoped Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3 ferroelectric ceramics. J. Alloys Compd. 2015, 632, 711–716. [Google Scholar] [CrossRef]

- Hamza, A.; Benabdallah, F.; Kallel, I.; Seveyrat, L.; Lebrun, L.; Khemakhem, H. Effect of rare-earth substitution on the electrical properties and Raman spectroscopy of BCTZ ceramics. J. Alloys Compd. 2018, 735, 2523–2531. [Google Scholar] [CrossRef]

- Tian, Y.S.; Cao, L.J.; Zhang, Y.N.; Jing, Y.F.; Ji, X.; Gong, Y.S.; Sun, S.J.; Jing, Q.S. Defect dipole-induced high piezoelectric response and low activation energy of amphoteric Yb3+ and Dy3+ co-doped 0.5BaTi0.8Zr0.2O3-0.5Ba0.7Ca0.3TiO3 lead-free ceramics. Ceram. Int. 2020, 46, 10040–10047. [Google Scholar] [CrossRef]

- Li, C.; Baek, J.S.; Koh, J.H. Ce and Y co-doping effects for (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead-free ceramics. Coatings 2021, 11, 1248. [Google Scholar] [CrossRef]

- Batoo, K.M.; Verma, R.; Chauhan, A.; Kumar, R.; Hadi, M.; Aldossary, O.M.; Al-Douri, Y. Improved room temperature dielectric properties of Gd3+ and Nb5+ co-doped barium titanate ceramics. J. Alloys Compd. 2021, 883, 160836. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, J.; Li, S.; Wang, D. Defect engineering in perovskite oxide thin films. Chem. Commun. 2021, 57, 8402–8420. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Fang, B.; Lu, X.; Zhang, S.; Yuan, N.; Ding, J. Tailoring structure and performance of BCZT ceramics prepared via hydrothermal method. Phys. B 2019, 567, 65–78. [Google Scholar] [CrossRef]

- Li, W.; Hao, J.; Bai, W.; Xu, Z.; Chu, R.; Zhai, J. Enhancement of the temperature stabilities in yttrium doped (Ba0.99Ca0.01)(Ti0.98Zr0.02)O3 ceramics. J. Alloys Compd. 2012, 531, 46–49. [Google Scholar] [CrossRef]

- Messing, G.L.; Poterala, S.; Chang, Y.; Frueh, T.; Kupp, E.R.; Watson, B.B.; Walton, R.L.; Brova, M.J.; Hofer, A.K.; Bermejo, R.; et al. Texture-engineered ceramics—Property enhancements through crystallographic tailoring. J. Mater. Res. 2017, 32, 3219–3241. [Google Scholar] [CrossRef]

- Tian, Y.S.; Li, S.Y.; Li, Y.Y.; Gong, Y.S.; Ji, X.; Sun, S.J.; Jing, Q.S. Diversiform electrical and thermal expansion properties of (1−x)Ba0.95Ca0.05Ti0.94Zr0.06O3–(x)Dy lead-free piezoelectric ceramics influenced by defect complexes. J. Mater. Sci. 2018, 53, 11228–11241. [Google Scholar] [CrossRef]

- Hu, Q.; Tian, Y.; Zhu, Q.; Bian, J.; Jin, L.; Du, H.; Alikin, D.O.; Shur, V.Y.; Feng, Y.; Xu, Z.; et al. Achieve ultrahigh energy storage performance in BaTiO3–Bi(Mg1/2Ti1/2)O3 relaxor ferroelectric ceramics via nano-scale polarization mismatch and reconstruction. Nano Energy 2020, 67, 104264. [Google Scholar] [CrossRef]

- Maneeshya, L.V.; Thomas, P.V.; Joy, K. Effects of site substitutions and concentration on the structural, optical and visible photoluminescence properties of Er doped BaTiO3 thin films prepared by RF magnetron sputtering. Opt. Mater. 2015, 46, 304–309. [Google Scholar] [CrossRef]

- Adhikari, P.; Mazumder, R.; Abhinay, S. Electrical and mechanical properties of MgO added 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3 (BZT–0.5BCT) composite ceramics. J. Electroceram. 2016, 37, 127–136. [Google Scholar] [CrossRef]

- Maraj, M.; Wei, W.; Peng, B.; Sun, W. Dielectric and energy storage properties of Ba(1−x)CaxZryTi(1−y)O3 (BCZT): A review. Materials 2019, 12, 3641. [Google Scholar] [CrossRef]

- Pomyai, P.; Munthala, D.; Sonklin, T.; Supruangnet, R.; Nakajima, H.; Janphuang, P.; Dale, S.M.; Glaum, J.; Pojprapai, S. Electrical fatigue behavior of Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramics under different oxygen concentrations. J. Eur. Ceram. Soc. 2021, 41, 2497–2505. [Google Scholar] [CrossRef]

- Kaddoussi, H.; Gagou, Y.; Lahmar, A.; Belhadi, J.; Allouche, B.; Dellis, J.L.; Courty, M.; Khemakhem, H.; Marssi, M.E. Room temperature electro-caloric effect in lead free Ba(Zr0.1Ti0.9)1-xSnxO3 (x = 0, x = 0.075) ceramics. Solid State Commun. 2015, 201, 64–67. [Google Scholar] [CrossRef]

- Wei, Q.; Zhu, M.; Zheng, M.; Hou, Y. High piezoelectric properties above 150 °C in (Bi0.5Na0.5)TiO3-Based lead-free piezoelectric ceramics. Mater. Chem. Phys. 2020, 249, 122966. [Google Scholar] [CrossRef]

- Xu, Q.; Ding, S.; Peng, Y.; Wu, X. Ferroelectric relaxor behavior in Co-doped BCZT ceramic. Ferroelectrics 2013, 450, 35–41. [Google Scholar] [CrossRef]

- Jo, W.; Schaab, S.; Sapper, E.; Schmitt, L.A.; Kleebe, H.J.; Bell, A.J.; Rödel, J. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2)TiO3-6 mol% BaTiO3. J. Appl. Phys. 2011, 110, 074106. [Google Scholar] [CrossRef]

- Coondoo, I.; Panwar, N.; Amorín, H.; Alguero, M.; Kholkin, A.L. Synthesis and characterization of lead-free 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3 ceramic. J. Appl. Phys. 2013, 113, 214107. [Google Scholar] [CrossRef]

- Chaiyo, N.; Cann, D.P.; Vittayakorn, N. Lead-free (Ba,Ca)(Ti,Zr)O3 ceramics within the polymorphic phase region exhibiting large, fatigue-free piezoelectric strains. Mater. Design. 2017, 133, 109–121. [Google Scholar] [CrossRef]

- Xu, Q.; Ding, S.; Song, T.; Wang, H. Diffuse phase transition of Ba0.92Ca0.08(Ti0.82Zr0.18)O3 based ceramics. Ferroelectrics 2012, 426, 282–289. [Google Scholar] [CrossRef]

- Lv, J.; Lou, X.; Wu, J. Defect dipoles-induced poling characteristics and ferroelectricity of quenched bismuth ferrite-based ceramics. J. Mater. Chem. C 2016, 4, 6140–6151. [Google Scholar] [CrossRef]

- Li, Z.; Wu, J.; Xiao, D.; Zhu, J.; Wu, W. Colossal permittivity in titanium dioxide ceramics modified by tantalum and trivalent elements. Acta Mater. 2016, 103, 243–251. [Google Scholar] [CrossRef]

- Wang, J.L.; Leroy, J.; Niu, G.; Saint-Girons, G.; Gautier, B.; Vilquin, B.; Barrett, N. Chemistry and structure of BaTiO3 ultra-thin films grown by different O2 plasma power. Chem. Phys. Lett. 2014, 592, 206–210. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Z.; Mao, W.J.; Jia, Y.M. The photoluminescence indicating compositional changes of Er3+-doped (Ba1−xCax)(Zr0.1Ti0.9)O3 piezoelectric ceramics. Mater. Lett. 2015, 149, 74–76. [Google Scholar] [CrossRef]

- Jeyaseelan, A.A.; Dutta, S. Improvement in piezoelectric properties of PLZT thin film with large cation doping at A-site. J. Alloys Compd. 2020, 826, 153956. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Dinescu, M.; Scarisoreanu, N.; Galassi, C.; Schranz, W.; Soprunyuk, V. Elastic response of (1−x)Ba(Ti0.8Zr0.2)O3–x(Ba0.7Ca0.3)TiO3 (x = 0.45–0.55) and the role of the intermediate orthorhombic phase in enhancing the piezoelectric coupling. Appl. Phys. Lett. 2014, 105, 232904. [Google Scholar] [CrossRef]

- Xu, K.; Li, L.; Yang, P.; Peng, W. Novel non-stoichiometric (Ba0.91Ca0.09)x(Zr0.18Ti0.82)O3 ferroelectric ceramics with improved diffuse phase transition and dielectric tunable performance. Ceram. Int. 2021, 47, 25901–25909. [Google Scholar] [CrossRef]

- Laha, A.; Krupabidhi, S.B. Normal ferroelectric to relaxor behavior in laser ablated Ca-doped barium titanate thin films. J. Appl. Phys. 2003, 94, 7702. [Google Scholar] [CrossRef]

- Ciomaga, C.E.; Curecheriu, L.P.; Lukacs, V.A.; Horchidan, N.; Doroftei, F.; Valois, R.; Lheureux, M.; Chambrier, M.H.; Mitoseriu, L. Optimization of processing steps for superior functional properties of (Ba,Ca)(Zr,Ti)O3 ceramics. Materials 2022, 15, 8809. [Google Scholar] [CrossRef]

- Babu, V.M.; Praveen, J.P.; Das, D. Synthesis and aging behaviour study of lead-free piezoelectric BCZT ceramics. Chem. Phys. Lett. 2021, 772, 138560. [Google Scholar] [CrossRef]

- Tian, Y.; Cao, L.; Li, S.; Wu, Q.; Jing, Q. The influence mechanism of polarization process on various ferroelectricity and field-induced strain for piezoelectricity and energy storage of Ba0.96Sr0.04TiO3 ceramics. J. Xinyang Norm. Univ. (Nat. Sci. Ed.) 2021, 34, 467–471. [Google Scholar] [CrossRef]

- Li, S.; Tian, Y.; Gao, Y.; Wang, M.; Liu, P. Research on excellent electrical properties of BaTi2O5 ceramics prepared by a modified pechini method. J. Xinyang Norm. Univ. (Nat. Sci. Ed.) 2022, 35, 280–284. [Google Scholar] [CrossRef]

- Bhargavi, G.N.; Badapanda, T.; Khare, A.; Anwar, M.S.; Brahme, N. Investigation of structural and conduction mechanism of europium modified BaZr0.05Ti0.95O3 ceramic prepared by solid-state reaction method. Appl. Phys. A-Mater. 2021, 127, 528. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Yan, F.; He, X.; Huang, K.; Shen, B.; Zhai, J. B-site-doped BiFeO3-based piezoceramics with enhanced ferro/piezoelectric properties and good temperature stability. J. Am. Ceram. Soc. 2020, 103, 6245–6254. [Google Scholar] [CrossRef]

- Xu, Q.; Huang, D.P.; Chen, W.; Zhang, F.; Wang, B.T. Structure, electrical conducting and thermal expansion properties of Ln0.6Sr0.4Co0.2Fe0.8O3 (Ln = La, Pr, Nd, Sm) perovskite-type complex oxides. J. Alloy. Comp. 2007, 429, 34–39. [Google Scholar] [CrossRef]

| x (mol%) | a (Å) | b (Å) | c (Å) | Axial Angle (o) | ρ (g/cm−3) | ρr (%) |

|---|---|---|---|---|---|---|

| 0 | 4.013(3) | 4.013(3) | 4.013(3) | 89.05 | 5.491 | 95.54 |

| 0.06 | 4.015(1) | 4.015(1) | 4.015(1) | 88.96 | 5.517 | 96.00 |

| 0.12 | 4.018(2) | 4.018(2) | 4.018(2) | 88.89 | 5.536 | 96.34 |

| 0.18 | 4.022(0) | 4.022(0) | 4.022(0) | 88.85 | 5.541 | 96.42 |

| 0.24 | 4.017(8) | 4.017(8) | 4.017(8) | 88.97 | 5.533 | 96.27 |

| 0.30 | 4.014(7) | 4.014(7) | 4.014(7) | 89.01 | 5.529 | 96.10 |

| x (mol%) | Ea (eV) | Tf (K) | f0 (×1021 Hz) |

|---|---|---|---|

| 0 | 0.676 | 106.5 | 5.32 |

| 0.06 | 0.584 | 106.9 | 6.75 |

| 0.12 | 0.475 | 107.3 | 7.63 |

| 0.18 | 0.401 | 107.9 | 8.44 |

| 0.24 | 0.527 | 106.9 | 7.69 |

| 0.30 | 0.633 | 105.8 | 5.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Ma, M.; Li, S.; Dong, J.; Ji, X.; Wu, H.; Wang, J.; Jing, Q. Piezoelectricity and Thermophysical Properties of Ba0.90Ca0.10Ti0.96Zr0.04O3 Ceramics Modified with Amphoteric Nd3+ and Y3+ Dopants. Materials 2023, 16, 2369. https://doi.org/10.3390/ma16062369

Tian Y, Ma M, Li S, Dong J, Ji X, Wu H, Wang J, Jing Q. Piezoelectricity and Thermophysical Properties of Ba0.90Ca0.10Ti0.96Zr0.04O3 Ceramics Modified with Amphoteric Nd3+ and Y3+ Dopants. Materials. 2023; 16(6):2369. https://doi.org/10.3390/ma16062369

Chicago/Turabian StyleTian, Yongshang, Mingyang Ma, Shuiyun Li, Junli Dong, Xiang Ji, Haitao Wu, Jinshuang Wang, and Qiangshan Jing. 2023. "Piezoelectricity and Thermophysical Properties of Ba0.90Ca0.10Ti0.96Zr0.04O3 Ceramics Modified with Amphoteric Nd3+ and Y3+ Dopants" Materials 16, no. 6: 2369. https://doi.org/10.3390/ma16062369

APA StyleTian, Y., Ma, M., Li, S., Dong, J., Ji, X., Wu, H., Wang, J., & Jing, Q. (2023). Piezoelectricity and Thermophysical Properties of Ba0.90Ca0.10Ti0.96Zr0.04O3 Ceramics Modified with Amphoteric Nd3+ and Y3+ Dopants. Materials, 16(6), 2369. https://doi.org/10.3390/ma16062369