Effects of an Amphiphilic Micelle of Diblock Copolymer on Water Adsorption of Cement Paste

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.1.1. Materials

2.1.2. Characterization

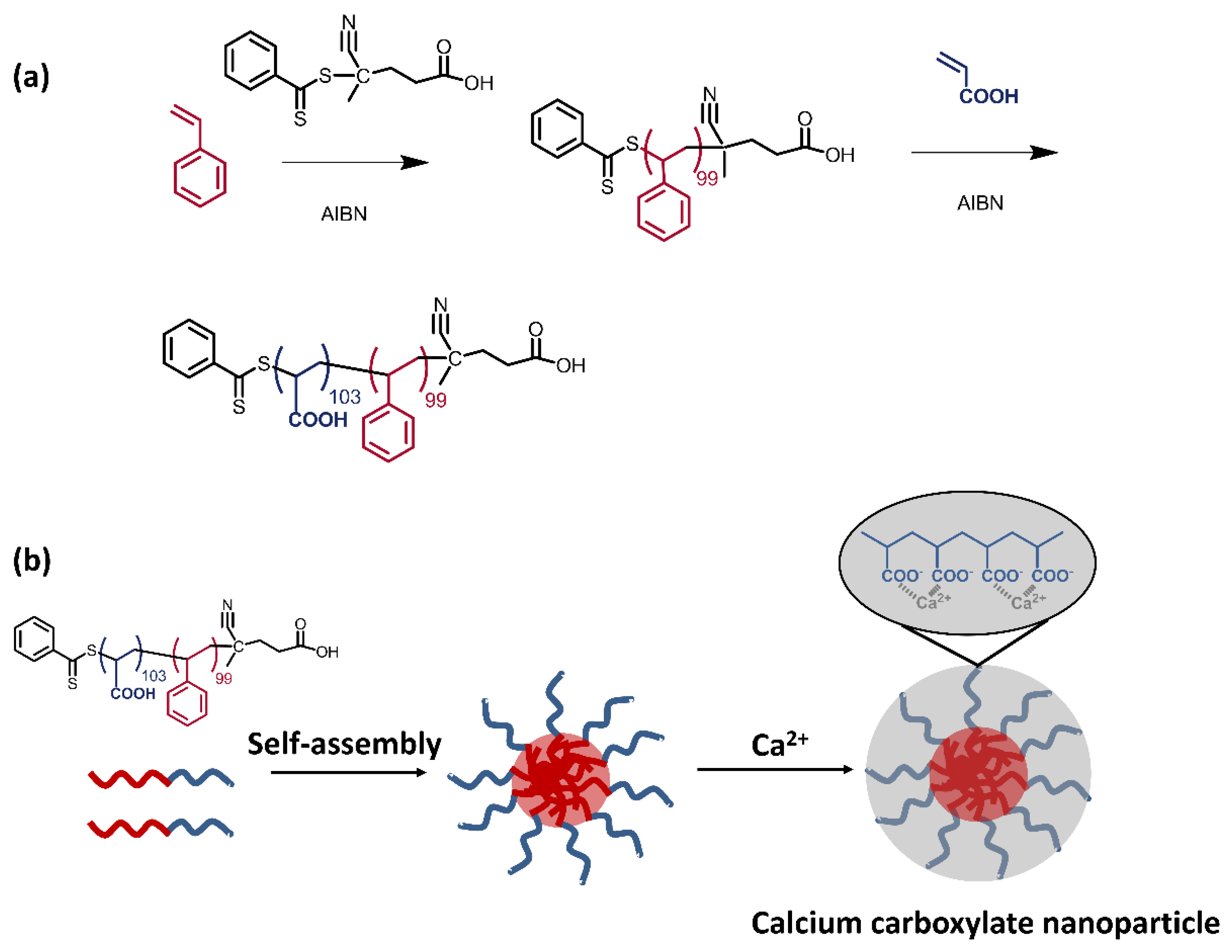

2.2. Preparation of PS-b-PAA Micelle

2.3. Preparation of Cement Pastes

3. Results and Discussion

3.1. Characterization of PS-b-PAA and Micelle

3.1.1. Characterization of PS-b-PAA

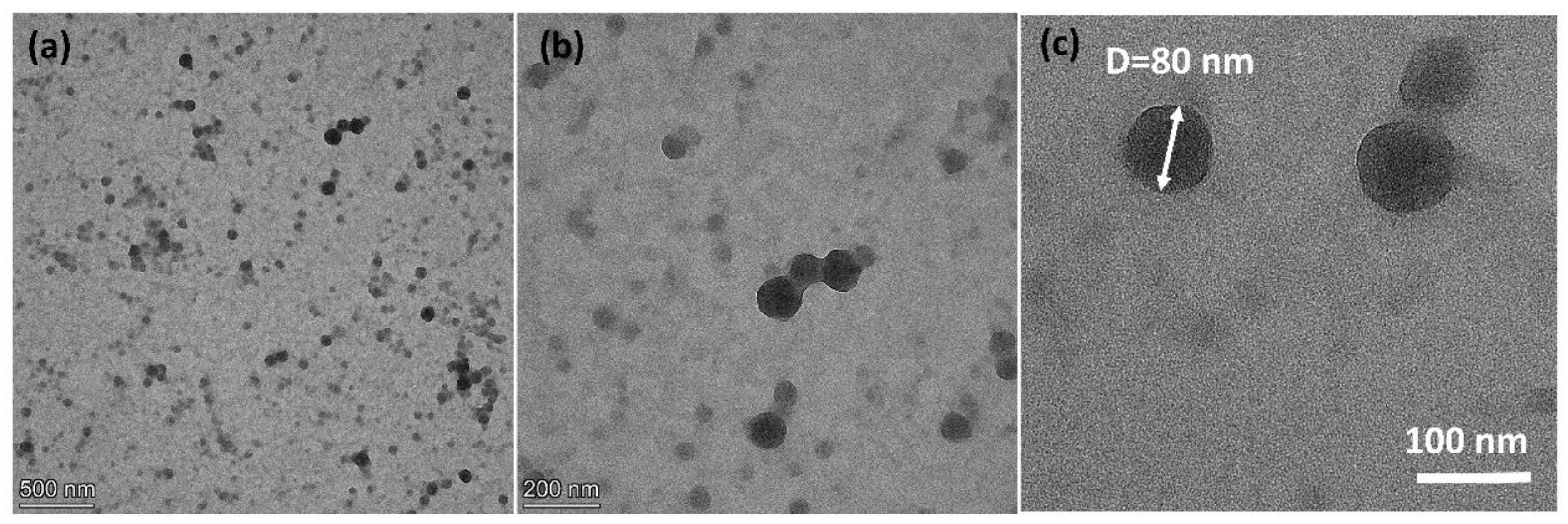

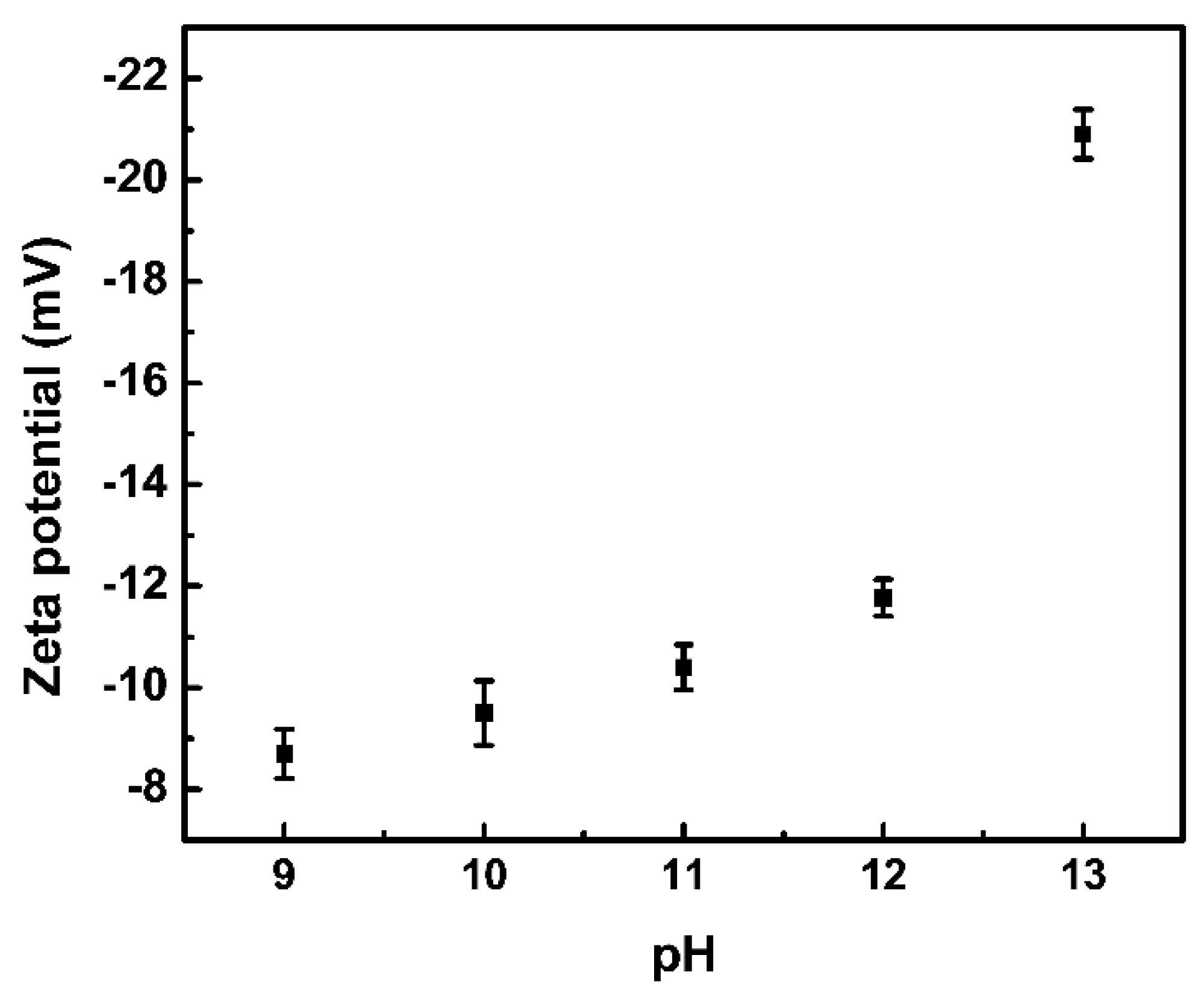

3.1.2. Characterization of Micelle

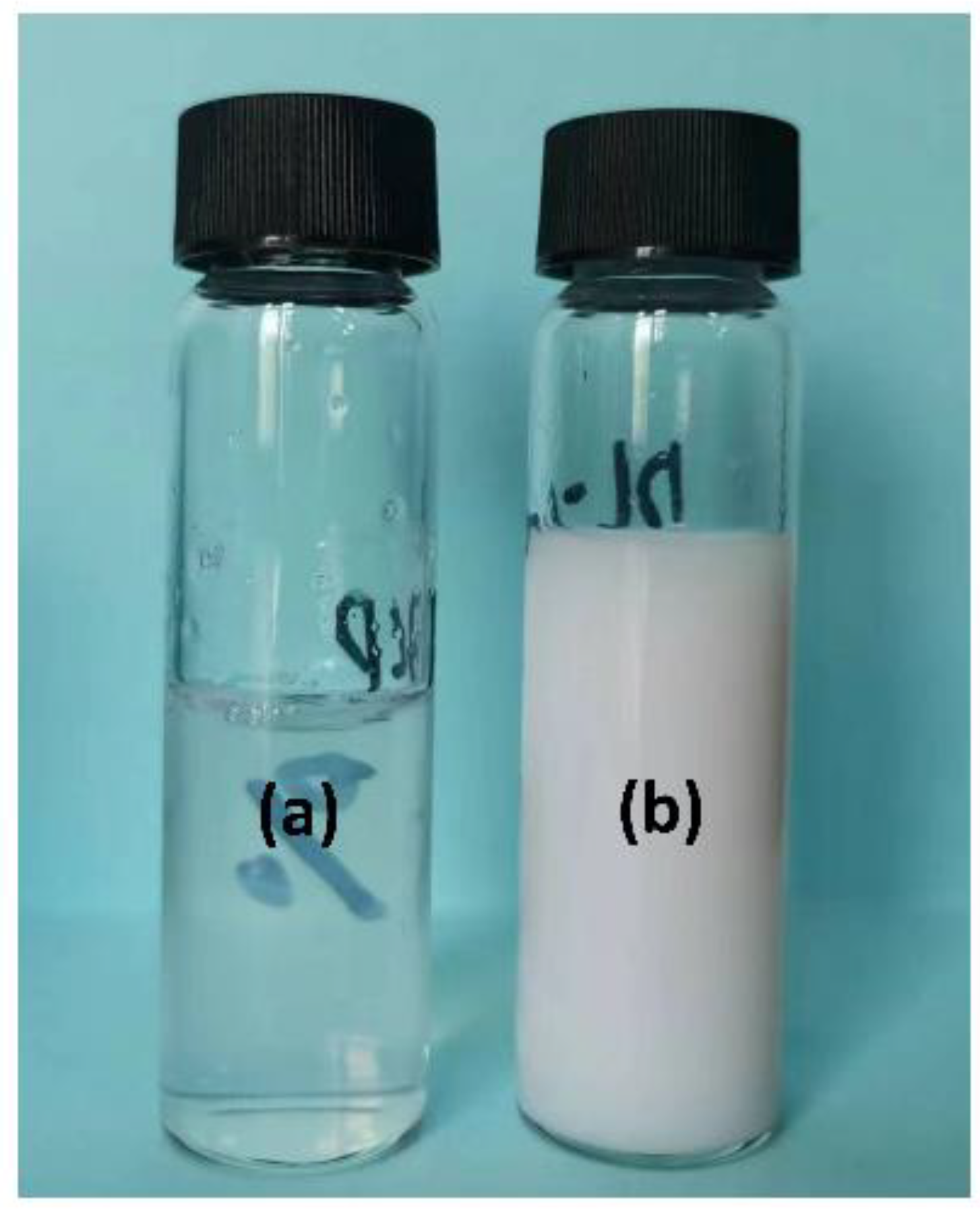

3.1.3. Dispersion Analysis

3.2. Effects of PS-b-PAA Micelle on Rheological Properties, Compressive Strength, and Water Absorption of Cement Paste

3.2.1. Rheological Properties

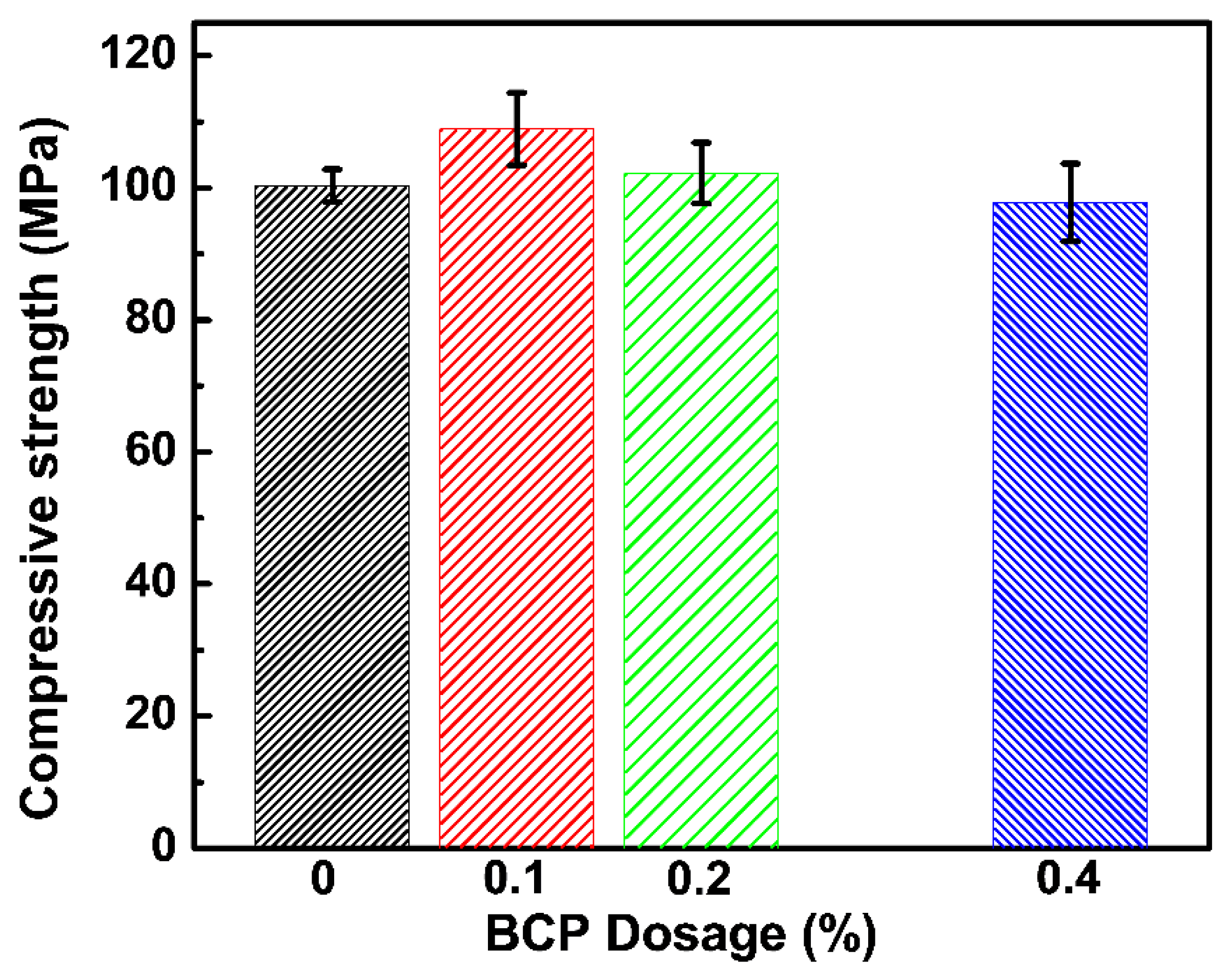

3.2.2. Compressive Strength Test

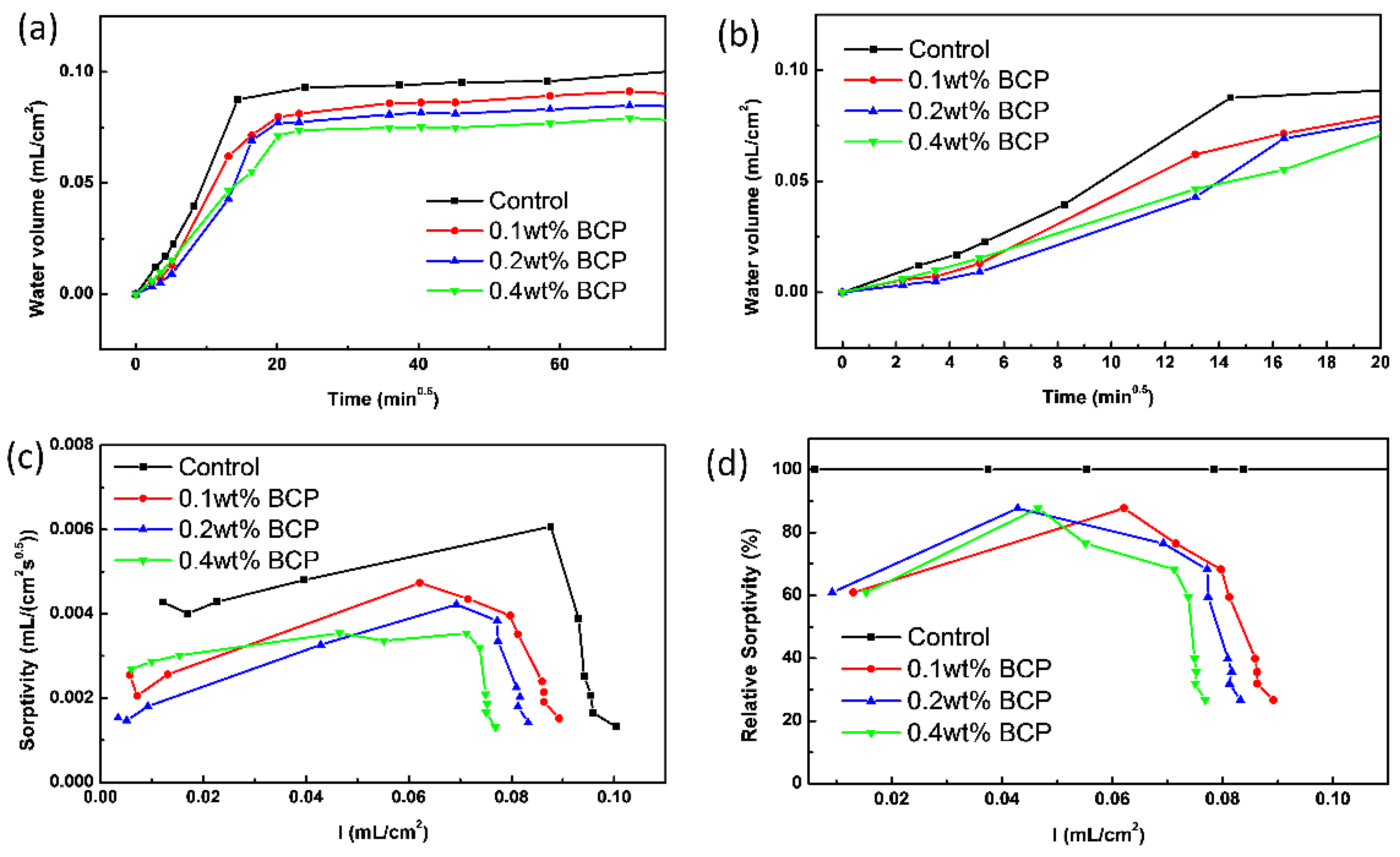

3.2.3. Water Absorption Test

3.3. Effects of PS-b-PAA Micelle on Hydrophobicity, Hydration Process, and Pore Structure of Cement Paste

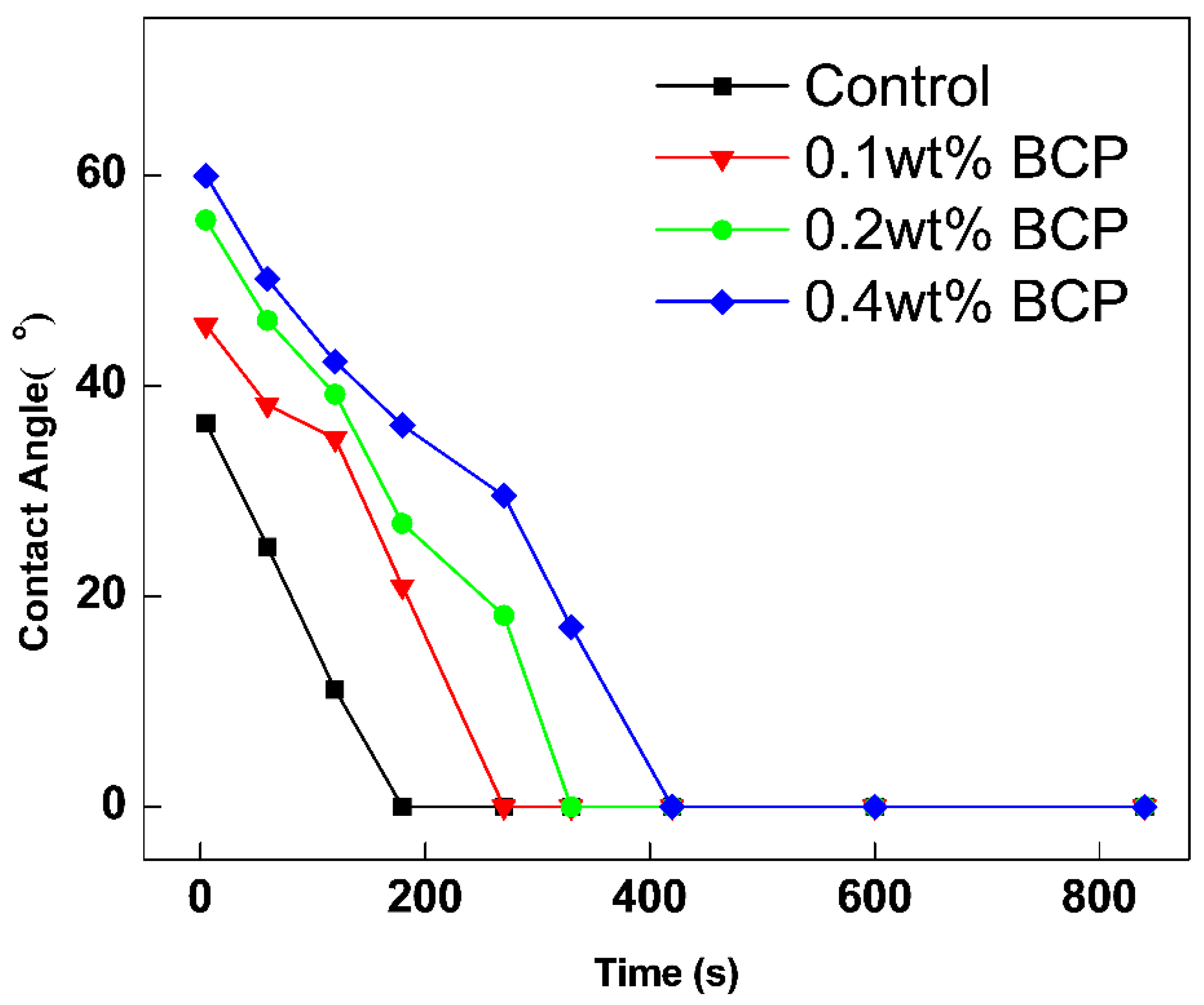

3.3.1. Contact Angle Test

3.3.2. Hydration Process Analysis

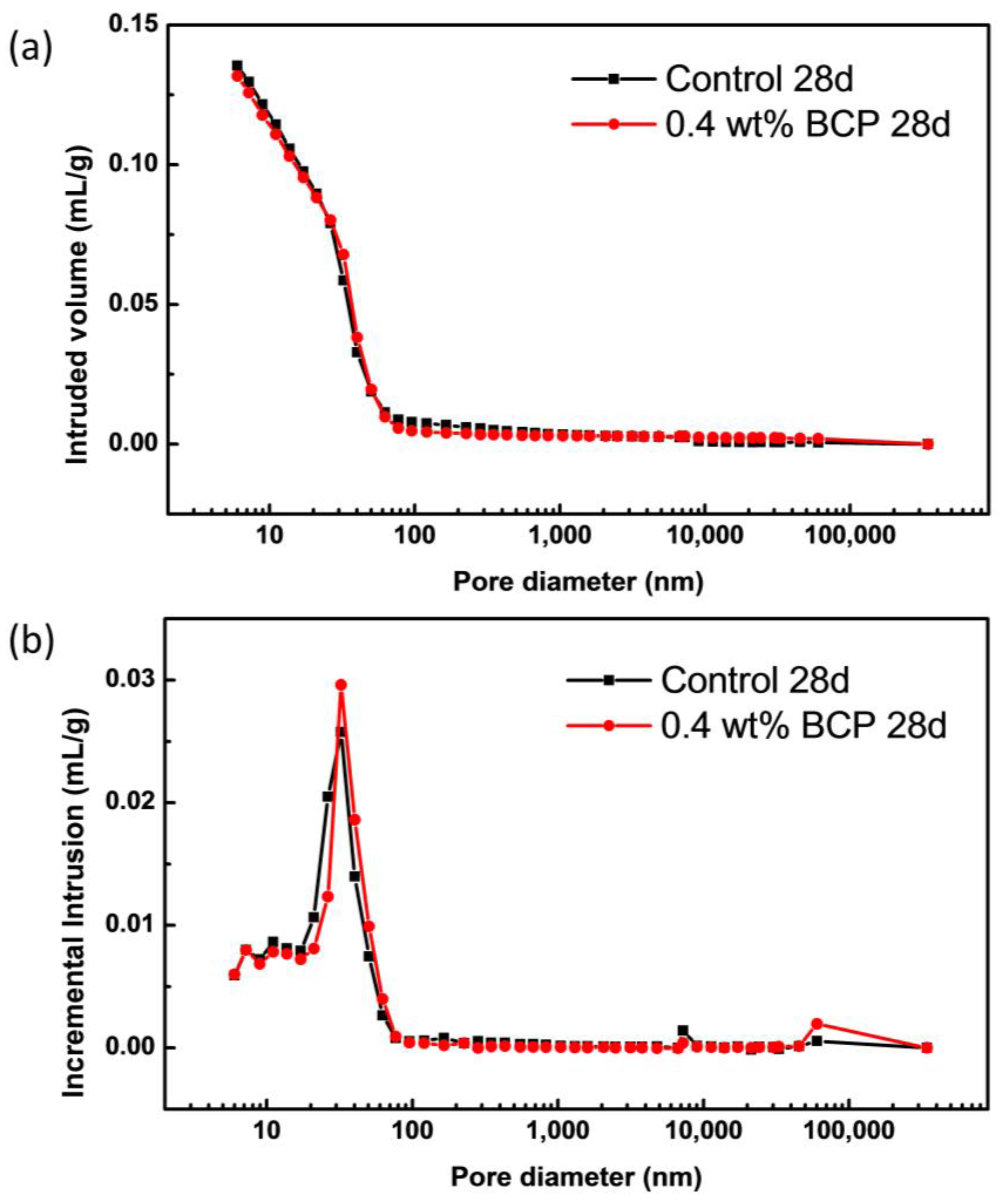

3.3.3. Pore Structure Analysis

- Improved dispersity of hydrophobic polystyrene. When nanometer-sized PS-b-PAA micelles are formed in the aqueous phase, an amphiphilic core-shell structure with hydrophobic PS segments surrounded by hydrophilic PAA is assembled. The surface of well-dispersed nanoparticles with rich charged carboxylic groups may avoid the commonly occurring aggregation of PS nanoparticles via the electrostatic repulsion.

- Hydrophobic modification of the matrix. The added PS-b-PAA micelle significantly improves the hydrophobicity of the cement paste matrix compared with that of the control one. The carboxylic groups on micelle surfaces are possibly complex with the calcium ion from the hydration products, and the inner wall of the pore structure is thus covered by the hydrophobic PS segments. The bulk hydrophobic modification caused by PS segments further leads to the reduced water absorption of the cement paste matrix.

- Unaffected hydration process and pore structure of cement paste. Although PAA segments in micelle may retard and inhibit the hydration process of cement clinker at an early stage, the adverse effects on hydration are considered less than those of polystyrene emulsion. For the control and doped samples, the hydration products and pore structure at late hydration time (7–28 days) are similar, and thus the compressive strength of cement paste is less affected by the added PS-b-PAA micelle.

4. Conclusions

- In the water phase, the hydrophilic core consisted of PS segments surrounded by the hydrophilic shell of PAA segments. The hydrophilic shell surface, along with the negatively charged carboxylic groups on the surface, may improve the dispersity of nanometer-sized PS particles, especially in a highly alkaline environment, compared to that of emulsified PS particles with micrometre size.

- Compared with the control sample, the cement paste exhibited similar rheological behaviours, gradually reducing the water absorption amount and mostly unaffected compressive strength, as the dosage of PS-b-PAA micelle was increased from 0.1 wt% to 0.4 wt%. For a dosage of 0.4 wt%, the water absorption amount of cement paste at 56 h was reduced by 20.1% in comparison with the control sample.

- The main contributor to enhanced water resistance was discovered to be the enhanced hydrophobicity of cement paste caused by the added copolymers, which were indicated by the measurements on initial contact angle and the time of macroscopic water absorption. Besides, the effects of added copolymers on the hydration process and pore structure of cement paste were not obvious, especially after 3–28 days of curing. The less affected hydration degree and pore structure reasonably caused the mostly unchanged 28-day compressive strength of cement paste.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, Z.; Xi, Y.; Gu, X.; Huang, Q.; Zhang, W. Modelling of water vapour sorption hysteresis of cement-based materials based on pore size distribution. Cem. Concr. Res. 2019, 115, 8–19. [Google Scholar] [CrossRef]

- Lyu, K.; She, W.; Miao, C.; Chang, H.; Gu, Y. Quantitative characterization of pore morphology in hardened cement paste via SEM-BSE image analysis. Constr. Build. Mater. 2019, 202, 589–602. [Google Scholar] [CrossRef]

- Khunthongkeaw, J.; Tangtermsirikul, S.; Leelawat, T. A study on carbonation depth prediction for fly ash concrete. Constr. Build. Mater. 2006, 20, 744–753. [Google Scholar] [CrossRef]

- Osborne, G.J. Durability of Portland blast-furnace slag cement concrete. Cem. Concr. Compos. 1999, 21, 11–21. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Chen, H.; Feng, P.; Du, Y.; Jiang, J.; Sun, W. The effect of superhydrophobic nano-silica particles on the transport and mechanical properties of hardened cement pastes. Constr. Build. Mater. 2018, 182, 620–628. [Google Scholar] [CrossRef]

- Kim, B.-J.; Lee, G.-W.; Choi, Y.-C. Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume. Materials 2022, 15, 6599. [Google Scholar] [CrossRef]

- Ma, B.; Li, H.; Mei, J.; Li, X.; Chen, F. Effects of Nano-TiO<sub>2</sub> on the Toughness and Durability of Cement-Based Material. Adv. Mater. Sci. Eng. 2015, 2015, 583106. [Google Scholar]

- Bragança, M.O.; Portella, K.F.; Bonato, M.M.; Alberti, E.; Marino, C.E. Performance of Portland cement concretes with 1% nano-Fe3O4 addition: Electrochemical stability under chloride and sulfate environments. Constr. Build. Mater. 2016, 117, 152–162. [Google Scholar] [CrossRef]

- Zhang, P.; Su, J.; Guo, J.; Hu, S. Influence of carbon nanotube on properties of concrete: A review. Constr. Build. Mater. 2023, 369, 130388. [Google Scholar] [CrossRef]

- Cai, J.; Ran, Q.; Ma, Q.; Zhang, H.; Liu, K.; Zhou, Y.; Mu, S. Influence of a Nano-Hydrophobic Admixture on Concrete Durability and Steel Corrosion. Materials 2022, 15, 6842. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Mu, S.; Liu, J.; Cai, J.; Xie, D.; Liu, G.; Guo, Z. Novel nano-precursor inhibiting material for improving chloride penetration resistance of concrete: Evaluation and mechanism. Materials 2021, 14, 5929. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhang, S.; Yu, J.; Kong, X. Water absorption behavior of hydrophobized concrete using silane emulsion as admixture. Cem. Concr. Res. 2022, 154, 106738. [Google Scholar] [CrossRef]

- Basheer, L.; Cleland, D.J. Durability and water absorption properties of surface treated concretes. Mater. Struct. 2011, 44, 957–967. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhang, W.; Chen, X.; Hou, D.; Zhao, T.; Li, X. Preparation and mechanism of graphene oxide/isobutyltriethoxysilane composite emulsion and its effects on waterproof performance of concrete. Constr. Build. Mater. 2019, 208, 343–349. [Google Scholar] [CrossRef]

- Ramli, M.; Tabassi, A.A.; Hoe, K.W. Porosity, pore structure and water absorption of polymer-modified mortars: An experimental study under different curing conditions. Compos. Part B Eng. 2013, 55, 221–233. [Google Scholar] [CrossRef]

- Schulze, J. Influence of water-cement ratio and cement content on the properties of polymer-modified mortars. Cem. Concr. Res. 1999, 29, 909–915. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, M.; He, Z.; Xu, H.; Tan, J. Mechanical and permeability properties of polymer-modified concrete using hydrophobic agent. J. Build. Eng. 2020, 31, 101337. [Google Scholar] [CrossRef]

- Lanzón, M.; García-Ruiz, P.A. Evaluation of capillary water absorption in rendering mortars made with powdered waterproofing additives. Constr. Build. Mater. 2009, 23, 3287–3291. [Google Scholar] [CrossRef]

- Lagazzo, A.; Vicini, S.; Cattaneo, C.; Botter, R. Effect of fatty acid soap on microstructure of lime-cement mortar. Constr. Build. Mater. 2016, 116, 384–390. [Google Scholar] [CrossRef]

- Liu, P.; Feng, C.; Wang, F.; Gao, Y.; Yang, J.; Zhang, W.; Yang, L. Hydrophobic and water-resisting behavior of Portland cement incorporated by oleic acid modified fly ash. Mater. Struct. 2018, 51, 1–9. [Google Scholar] [CrossRef]

- Zhang, H.; Mu, S.; Cai, J.; Chen, R. The impact of carboxylic acid type hydrophobic agent on compressive strength of cementitious materials. Constr. Build. Mater. 2021, 291, 123315. [Google Scholar] [CrossRef]

- Coates, K.C.; Mohtar, S.A.; Tao, B.Y.; Weiss, J. Can Soy Methyl Esters Reduce Fluid Transport and Improve Durability of Concrete? Transp. Res. Rec. 2009, 2113, 22–30. [Google Scholar] [CrossRef]

- Wittmann, F.; Zhao, T.; Zhan, H.; Zhang, P. Silicon Resins, Functional Polymers in Concrete to Establish a Reliable Chloride Barrier. J. Restor. Build. Monum. 2010, 16, 331–340. [Google Scholar]

- Zhu, Y.-G.; Kou, S.-C.; Poon, C.-S.; Dai, J.-G.; Li, Q.-Y. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Wu, C.; Yin, B.; Hou, D.; Li, S.; Wang, X. A novel strategy of polystyrene acrylate—Polysiloxane core-shell emulsion for surface protection of cementitious materials. Cem. Concr. Compos. 2022, 133, 104720. [Google Scholar] [CrossRef]

- Wu, C.; Hou, D.; Yin, B.; Li, S. Synthesis and application of new core-shell structure via Pickering emulsion polymerization stabilized by graphene oxide. Compos. Part B Eng. 2022, 247, 110285. [Google Scholar] [CrossRef]

- Lu, Y.; Fu, W.; Ren, H.; Wu, S.; Liu, J.; Peng, H. Preparation and application of high-performance composite polymer emulsion cement waterproof coatings. Pigment. Resin Technol. 2022. [Google Scholar] [CrossRef]

- Aggarwal, L.K.; Thapliyal, P.C.; Karade, S.R. Properties of polymer-modified mortars using epoxy and acrylic emulsions. Constr. Build. Mater. 2007, 21, 379–383. [Google Scholar] [CrossRef]

- Folic, R.J.; Radonjanin, V.S. Experimental research on polymer modified concrete. Mater. J. 1998, 95, 463–469. [Google Scholar]

- Chung, D.D.L. Use of polymers for cement-based structural materials. J. Mater. Sci. 2004, 39, 2973–2978. [Google Scholar] [CrossRef]

- Ollitrault-Fichet, R.; Gauthier, C.; Clamen, G.; Boch, P. Microstructural aspects in a polymer-modified cement. Cem. Concr. Res. 1998, 28, 1687–1693. [Google Scholar] [CrossRef]

- Kong, X.; Emmerling, S.; Pakusch, J.; Rueckel, M.; Nieberle, J. Retardation effect of styrene-acrylate copolymer latexes on cement hydration. Cem. Concr. Res. 2015, 75, 23–41. [Google Scholar] [CrossRef]

- Nurain Izzati, M.Y.; Suraya Hani, A.; Shahiron, S.; Sallehuddin Shah, A.; Mohamad Hairi, O.; Zalipah, J.; Noor Azlina, A.H.; Mohamad Nor Akasyah, W.A.; Nurul Amirah, K. Strength and water absorption properties of lightweight concrete brick. IOP Conf. Ser. Mater. Sci. Eng. 2019, 513, 012005. [Google Scholar] [CrossRef]

- Perrier, S. 50th Anniversary Perspective: RAFT Polymerization—A User Guide. Macromolecules 2017, 50, 7433–7447. [Google Scholar] [CrossRef]

- GB 8076–2008; National Standard GB 8076–2008 “Concrete Admixtures” Application Guide. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009.

- Jayalath, A.; San Nicolas, R.; Sofi, M.; Shanks, R.; Ngo, T.; Aye, L.; Mendis, P. Properties of cementitious mortar and concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 2016, 120, 408–417. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Engineering Construction Standardization Association: Beijing, China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2019.

- Alderete, N.M.; Villagrán Zaccardi, Y.A.; De Belie, N. Mechanism of long-term capillary water uptake in cementitious materials. Cem. Concr. Compos. 2020, 106, 103448. [Google Scholar] [CrossRef]

| Sample | Cement (g) | Water (g) | PS-b-PAA Micelle (g) |

|---|---|---|---|

| Control | 200 | 76 | / |

| 0.1 wt% BCP | 200 | 76 | 0.276 |

| 0.2 wt% BCP | 200 | 76 | 0.552 |

| 0.4 wt% BCP | 200 | 76 | 1.104 |

| Sample | Total Intrusion Volume (mL/g) | Total Pore Area (cm3/g) | Median Pore Diameter (nm) | Porosity (%) |

|---|---|---|---|---|

| Control | 0.1355 | 26.44 | 29.85 | 23.49 |

| 0.4 wt% BCP | 0.1318 | 25.32 | 33.00 | 23.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, L.; Meng, F.; Feng, P.; Ran, Q.; Pan, C.; He, J. Effects of an Amphiphilic Micelle of Diblock Copolymer on Water Adsorption of Cement Paste. Materials 2023, 16, 2190. https://doi.org/10.3390/ma16062190

Dong L, Meng F, Feng P, Ran Q, Pan C, He J. Effects of an Amphiphilic Micelle of Diblock Copolymer on Water Adsorption of Cement Paste. Materials. 2023; 16(6):2190. https://doi.org/10.3390/ma16062190

Chicago/Turabian StyleDong, Lei, Fei Meng, Pan Feng, Qianping Ran, Chonggen Pan, and Jianming He. 2023. "Effects of an Amphiphilic Micelle of Diblock Copolymer on Water Adsorption of Cement Paste" Materials 16, no. 6: 2190. https://doi.org/10.3390/ma16062190

APA StyleDong, L., Meng, F., Feng, P., Ran, Q., Pan, C., & He, J. (2023). Effects of an Amphiphilic Micelle of Diblock Copolymer on Water Adsorption of Cement Paste. Materials, 16(6), 2190. https://doi.org/10.3390/ma16062190