Shielding Capability Research on Composite Base Materials in Hybrid Neutron-Gamma Mixed Radiation Fields

Abstract

:1. Introduction

2. Principle and Calculation Method

2.1. Leakage Rate Monitoring Principle of Steam Generator Tube

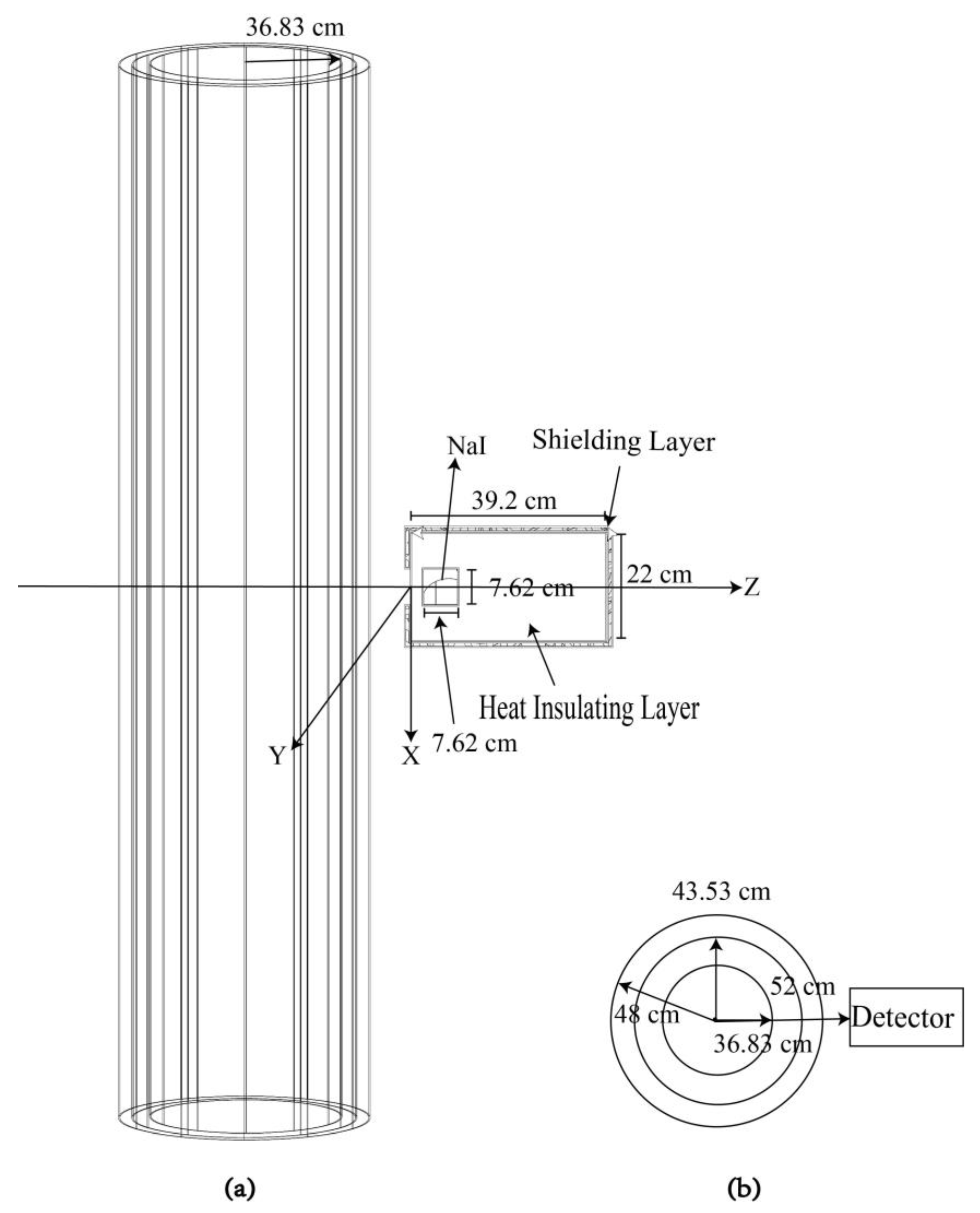

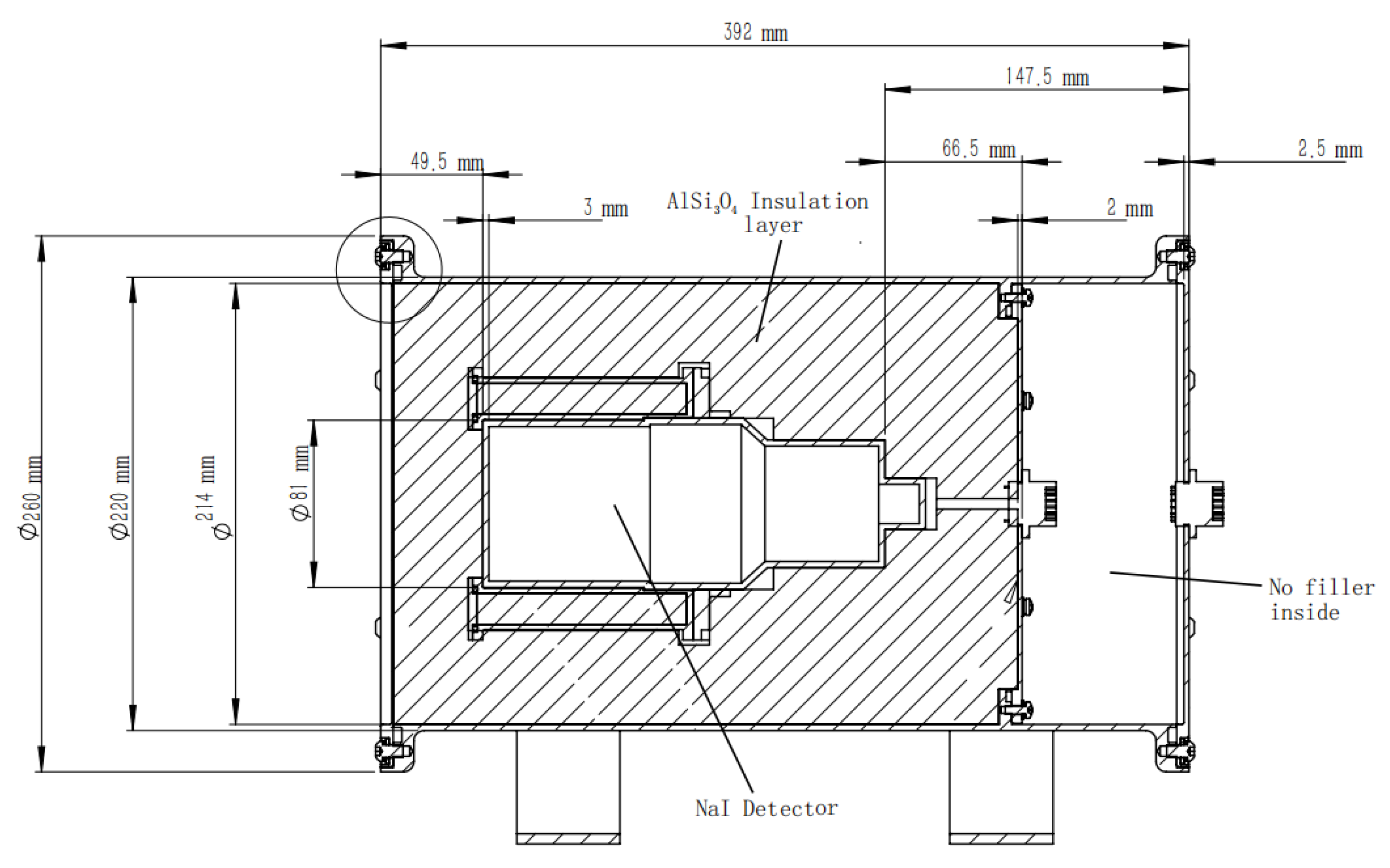

2.2. Model Construction

2.3. Radiation Protection Efficiency

2.4. Mass Attenuation Coefficient

3. Result and Discussion

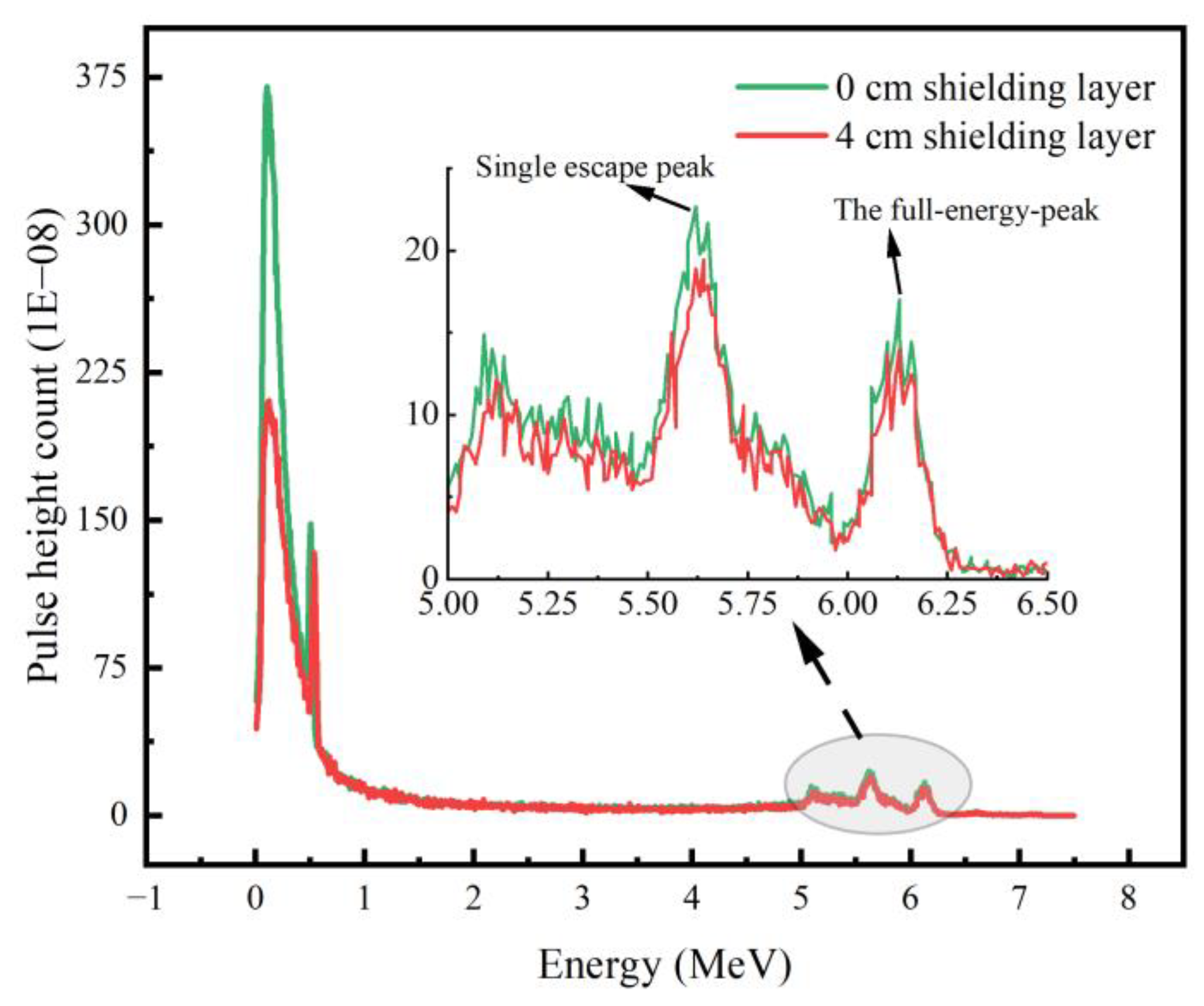

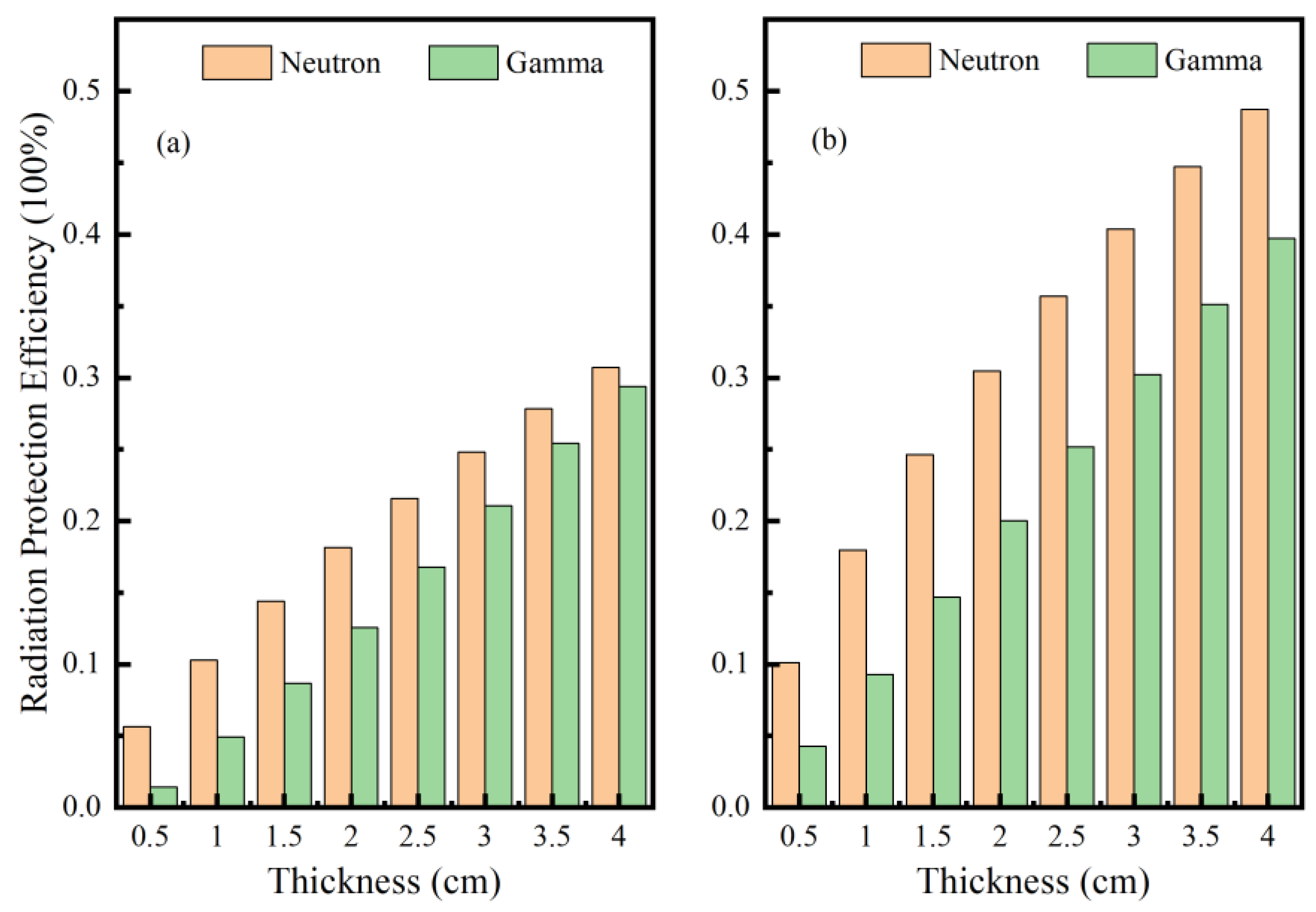

3.1. Shield Thickness

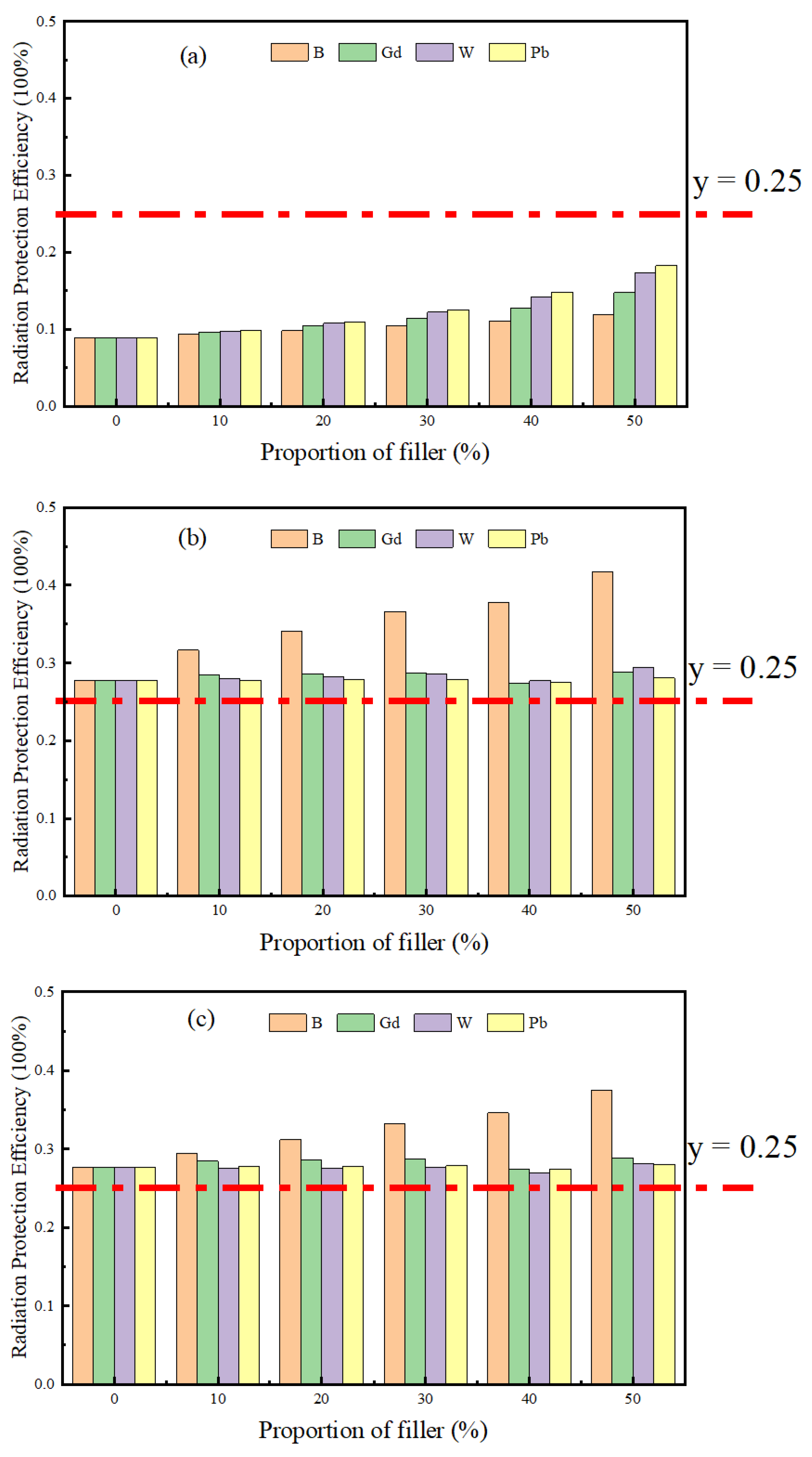

3.2. Shielding of Different Radiation Fields

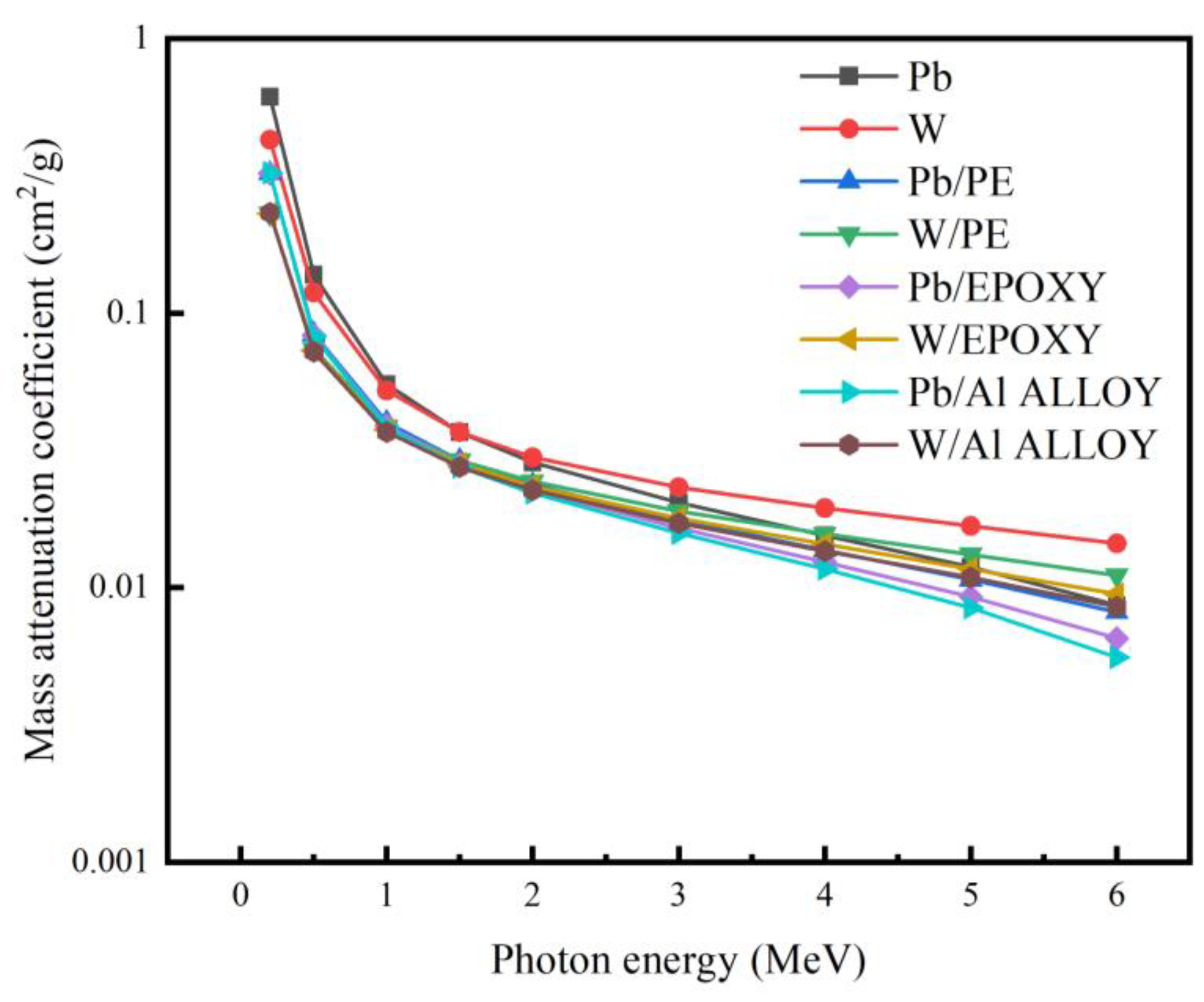

3.3. Mass Attenuation Coefficient of Different Shielding Materials

3.4. The Difference between Single-Layer Shielding and Double-Layer Shielding Materials in a Mixed Radiation Field

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, S.Y.; Xu, K.; Ding, X.X.; Zhang, W.H.; Rao, X.M. Development of 16N γ radiation monitor. Nucl. Stand. Metrol. Qual. 2003, 4, 20–26. [Google Scholar]

- Li, Z.; Tu, C.Q.; Hua, Z.D.; Wang, D.Z.; Chen, J.L.; Shui, J.T. Simulation calculation of detection efficiency of N-16 monitoring system in WWER-1000 nuclear power plant. Nucl. Electron. Detect. Technol. 2011, 31, 3. [Google Scholar]

- Xie, Y.M.; Ji, W.T.; Xie, X.T. Nuclear Power Plant Steam Generator Leakage Monitoring–Nitrogen-16 Radiation Monitor Overview. China Nucl. Power 2010, 3, 6. [Google Scholar]

- Liu, J.J.; Miao, Y.X.; Hou, L.; Tan, E.M. Fault analysis and treatment of 16N monitoring system in nuclear power plant. Nucl. Electron. Detect. Technol. 2019, 39, 141–144. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wu, P.; Luo, P.; Wang, H.J.; Xu, H. Summary of repair experience of steam generator leakage rate monitor. Radiat. Prot. 2022, 42. [Google Scholar]

- Wang, Y.; Yang, J.Y. Retrofit Scheme of Heavy Water Leakage to Secondary Coolant Monitoring System in Heping Reactor. Radiat. Prot. 2016, 36, 4. [Google Scholar]

- Wang, Y.; Wang, G.K.; Hu, T.; Hu, S.; Liu, L. Monte Carlo simulation of γ-ray shielding properties of rare earth lanthanum/rubber matrix composites. China Synth. Rubber Ind. 2020, 43, 216–220. [Google Scholar]

- Wu, J. Composite and application of polymer materials and nuclear radiation shielding functional materials. Technol. Wind. 2018, 339, 66–68. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhang, Y.W.; Du, Z.H.; Cao, K.; Lu, Y.J.; Wang, L.C.; Liu, P.G.; Zhang, X.J.; Ma, H.L. Research progress of epoxy resin-based radiation protection materials. Sci. Technol. Rev. 2022, 40, 115–121. [Google Scholar]

- Abdo, E.S.; El-Sarraf, M.A.; Gaber, F.A. Utilization of ilmenite/epoxy composite for neutrons and gamma rays attenuation. Ann. Nucl. Energy 2003, 30, 175–187. [Google Scholar] [CrossRef]

- Samia, B.; Hotc, D. The multiple characterization of gamma, neutron and proton shielding performances of xPbO-(99-x)B2O3-Sm2O3 glass system. Ceram. Int. 2019, 45, 23561–23571. [Google Scholar]

- Akn, A. Gamma and neutron shielding characterizations of the Ag2O–V2O5–MoO3–TeO2 quaternary tellurite glass system with the Geant4 simulation toolkit and Phy-X software. Ceram. Int. 2020, 46, 6046–6051. [Google Scholar]

- Hua, B.; Zhu, H.G. Review on the research status of strengthening mechanism of particle reinforced aluminum matrix composites. J. Mater. Sci. Eng. 2015, 33, 151–156. [Google Scholar] [CrossRef]

- Wang, A.S.; Liu, C.B.; Meng, Q.B. Development and trend of neutron absorbing materials for spent nuclear fuel storage. Mater. Rep. 2016, 30, 233–236. [Google Scholar]

- Wang, P.; Tang, X.; Chai, H.; Chen, D.; Qiu, Y.L. Design, fabrication, and properties of a continuous carbon-fiber reinforced Sm2O3/polyimide gamma ray/neutron shielding material. Fusion Eng. Des. 2015, 101, 218–225. [Google Scholar] [CrossRef]

- Canel, A.; Korkut, H.; Korkut, T. Improving Neutron and Gamma Flexible Shielding by Adding Medium-Heavy Metal Powder to Epoxy Based Composite Materials. Radiat. Phys. Chem. 2019, 158, 13–16. [Google Scholar] [CrossRef]

- Kurtulus, R.; Kavas, T. Calculations on Linear Attenuation Coefficient and Fast Neutron Removal Cross-section for B2O3-TeO2 Glass System via Phy-X/PSD. J. Turk. Ceram. Soc. 2022, 1, 19–23. [Google Scholar]

- Kurtulus, R.; Kavas, T. The role of B2O3 in lithium-zinc-calcium-silicate glass for improving the radiation shielding competencies: A theoreticalevaluation via Phy-X/PSD. J. Boron 2021, 6, 234–242. [Google Scholar]

- Kurtulus, R.; Kavas, T.; Akkurt, I.; Gunoglu, K. Theoretical and Experimental Gamma-rays Attenuation Characteristics of Waste Soda-lime Glass Doped with La2O3 and Gd2O3. Ceram. Int. 2021, 47, 8432–8440. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Hashim, S.; Hannachi, E.; Slimani, Y.; Elsafi, M. Effect of WO3 Nanoparticles on the Radiative Attenuation Properties of SrTiO3 Perovskite Ceramic. Crystals 2022, 12, 1602. [Google Scholar] [CrossRef]

- Xiang, D.; Guo, L.Y.; Ling, Q. Detection efficiency factor calculation of 16N in steam pipeline by detector. J. Univ. South China 2006, 20, 17–20. [Google Scholar] [CrossRef]

- Jun, Z.; Jie, Y.; Jianhua, W. Research on KRT Monitoring Instrument Alarm Threshold in Main Control Room of Nuclear Power Plant. In Proceedings of the 2019 Chinese Automation Congress (CAC), Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 4022–4025. [Google Scholar] [CrossRef]

- Zheng, J.W.; Xue, F.; Wang, J.Y.; Zhao, Y.P.; Xie, W.M. Research on 16N monitoring of main steam in nuclear power plant for leakage rate measurement of steam generator. China Nucl. Power 2014, 7, 306–310. [Google Scholar]

- Ding, S.Y.; Xu, L.; Huang, X.J.; Wang, P.L.; Nie, J. Development of 16N/19O monitor for steam generator leakage monitoring. In Proceedings of the 13th National Conference on Nuclear Electronics and Nuclear Detection Technology, Xi’an, China, September 2006; pp. 152–160. [Google Scholar]

- Molina Higgins, M.C.; Radcliffe, N.A.; Toro-González, M.; Rojas, J.V. Gamma ray attenuation of hafnium dioxide- and tungsten trioxide-epoxy resin composites. J. Radioanal. Nucl. Chem. Int. J. Deal. All Asp. Appl. Nucl. Chem. 2020, 322, 707–716. [Google Scholar] [CrossRef]

- Norhasri, M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Li, K.F.; Wang, Z.F.; Liu, C.Y.; Fang, K.; Lin, P.; Xu, K. Study on high temperature melting treatment of nuclear shielding material lead boron polyethylene. Bull. Chin. Ceram. 2020, 39, 552–555. [Google Scholar]

- Ouda, A.S.; Abdelgader, H.S. Assessing the physical, mechanical properties, and γ-ray attenuation of heavy density concrete for radiation shielding purposes. Geosystem Eng. 2019, 22, 72–80. [Google Scholar] [CrossRef]

- Korkut, T.; Karabulut, A.; Budak, G.; Aygün, B.; Gencel, O.; Hançerlioğulları, A. Investigation of neutron shielding properties depending on number of boron atoms for colemanite, ulexite and tincal ores by experiments and FLUKA Monte Carlo simulations. Appl. Radiat. Isot. 2012, 70, 341–345. [Google Scholar] [CrossRef]

- Wang, L. Preparation and Properties of Neutron γ-ray Absorption Shielding Material W-Al-B4C. Master’s Thesis, University of South China, Hengyang, China, 2020. [Google Scholar] [CrossRef]

- Huang, B. Radiation safety and protection analysis of nuclear technology application. China Resour. Compr. Util. 2021, 39, 143–145. [Google Scholar]

- Zhang, X.M.; Huang, M.; Chen, J.X. Radiation safety assurance in nuclear technology teaching experiment. Res. Explor. Lab. 2014, 33, 5. [Google Scholar] [CrossRef]

- Mahdi, S.; Mansour, T.; Nahid, C.; Sedigheh, S.; Tayebeh, K. Efficiency of non-lead and lead thyroid shields in radiation protection of CT examinations. Radiat. Phys. Chem. 2021, 180, 109265. [Google Scholar]

- Li, Y.F.; Zhang, F.; Tian, L.L.; Wu, H.; Chen, Q. MC method was used to simulate the X-ray mass attenuation coefficient. Nucl. Electron. Detect. Technol. 2017, 37, 5. [Google Scholar] [CrossRef]

- Wang, L.; Lei, M.; Zhang, W.L.; Ye, Z.F.; ZENG, D.K.; Qu, G.P. MCNP multi-modal calculation of detection efficiency of 16N γ-energy spectral power monitor. Nucl. Electron. Detect. Technol. 2020, 40, 109–114. [Google Scholar]

- Zhao, S.; Huo, Z.P.; Zhong, G.Q.; Zhang, H.; Hu, L.Q. Preparation of modified gadolinium/boron/polyethylene nanocomposites and their shielding properties for neutron and gamma rays. Chem. J. Chin. Univ. 2022, 43, 57–67. [Google Scholar]

- Zhang, Y. Design and Preparation of Nickel-Based Foam Metal Neutron Shielding Composite Material. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Zhang, W.H. Study on the shielding effect of medium materials in neutron radiography system on high energy neutrons. Police Technol. 2010, 122, 65–66. [Google Scholar]

- Li, L.N.; Sun, R.J.; Chen, M.Y.; Tang, Q. Research progress of radiation protection materials. Synth. Fiber China 2019, 48, 21–25. [Google Scholar]

- Zhao, S. Preparation of Modified Gadolinium-Boron Polyethylene Composites and Study of Neutron and Gamma Radiation Shielding Mechanisms. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2021. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Hamad, M.K.; Mhareb, M.H.A.; Kurtulus, R.; Dwaikat, N.; Saleh, M.; Elsafi, M.; Taki, M.M.; Kavas, T.; Zip, K.A.; et al. Assessment of Radiation attenuation properties for novel alloys: An experimental approach. Radiat. Phys. Chem. 2022, 200, 110152. [Google Scholar] [CrossRef]

- Kavas, T.; Sultan, J.; Alrowaili, Z.A.; Tamam, N.; Kurtuluş, R.; Olarinoye, I.O.; Al-Buriahi, M.S. Influence of iron (III) oxide on the optical, mechanical, physical, and radiation shielding properties of sodium-barium-vanadate glass syste. Optik 2022, 257, 168844. [Google Scholar] [CrossRef]

- Ge, F.; Wang, C.G.; Zhang, Y.B. Design of neutron shielding material protective layer. Public Commun. Sci. Technol. 2013, 5, 193–194. [Google Scholar]

- Mu, K.L.; Yang, J.B.; Qiao, Y.J.; Xu, J.; Li, R.; Li, H. Study on energy response function of pumping water injection multi-layer concentric sphere neutron spectrometer under various moderator materials. Nucl. Power Eng. 2020, 41, 174–177. [Google Scholar] [CrossRef]

- Gong, M.; Wang, J.P.; Gao, J.Y.; Wang, R.D. Polyethylene neutron shielding composites for space environment. Manned Spacefl. 2021, 27, 655–662. [Google Scholar] [CrossRef]

- Zhang, P.; Li, J.; Wang, W.X.; Chen, H.S.; Xie, L.; Tan, X.Y. Design and mechanical properties analysis of neutron shielding materials containing gadolinium. At. Energy Sci. Technol. 2019, 53, 434–441. [Google Scholar] [CrossRef]

- He, L.; Cai, Y.J.; Li, Q. Research progress of neutron and gamma ray integrated shielding materials. Mater. Rep. 2018, 32, 7. [Google Scholar] [CrossRef]

- Shen, Z.Q.; Kang, Q. γ-ray shielding properties of tungsten-containing cement-based materials. In Proceedings of the Sixth Symposium on Underground Waste Disposal, Dunhuang, China, August 2016; pp. 208–211. [Google Scholar]

- Dong, M.G.; Xue, X.X.; Yang, H.; Li, Z.F. Shielding analysis and radiation resistance effect of epoxy resin on gamma ray. At. Energy Sci. Technol. 2016, 50, 2101–2106. [Google Scholar] [CrossRef]

- Huo, Z.P.; Zhao, S.; Zhong, G.Q.; Li, Z.F. A neutron and gamma ray composite shielding material and its preparation method. J. Funct. Mater. 2021, 52, 15. [Google Scholar] [CrossRef]

- Jiang, D.W.; Murugadoss, V.; Wang, Y.; Ying, L.; Jing, D.; Tao, W.; Zi, C.S.; Qian, W.; Chao, L.; Hu, L.; et al. Electromagnetic Interference Shielding Polymers and Nanocomposites-A Review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Kumar, P.; Narayan Maiti, U.; Sikdar, A.; Kumar Das, T.; Kumar, A.; Sudarsan, V. Recent Advances in Polymer and Polymer Composites for Electromagnetic Interference Shielding: Review and Future Prospects. Polym. Rev. 2019, 59, 687–738. [Google Scholar] [CrossRef]

- Derradji, M.; Zegaoui, A.; Medjahed, A.; Liu, W.B.; Henniche, A. Hybrid phthalonitrile-based materials with advanced mechanical and nuclear shielding performances. Polym. Compos. 2020, 41, 134–141. [Google Scholar] [CrossRef]

| Double Layer Shielding | Structure Combination | A: 2 cm + 2 cm | B: 3 cm + 1 cm |

| B/EP+W | −8.514% | 11.973% | |

| W+B/EP | −2.895% | 17.534% | |

| B/EP+Pb | 1.796% | 20.245% | |

| Pb+B/EP | −4.686% | 10.355% | |

| B/EP+W/EP | −6.309% | 15.466% | |

| W/EP+B/EP | −14.312% | −1.1347% | |

| B/EP+Pb/EP | −4.839% | 16.523% | |

| Pb/EP+B/EP | −14.997% | 0.707% | |

| Single Layer Shielding | Material components | ||

| 50%B + 50%Epoxy | 44.8% | ||

| 25%B + 25%Pb + 50%Epoxy | 43.570% | ||

| 25%B + 25%W + 50%Epoxy | 43.866% | ||

| 100%B | 52.122% | ||

| 100%W | 48.716% | ||

| 100%Pb | 30.692% | ||

| 100%Epoxy | 39.114% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, M.; Qin, Q.; He, X.; Li, F.; Wang, X. Shielding Capability Research on Composite Base Materials in Hybrid Neutron-Gamma Mixed Radiation Fields. Materials 2023, 16, 2084. https://doi.org/10.3390/ma16052084

Xiao M, Qin Q, He X, Li F, Wang X. Shielding Capability Research on Composite Base Materials in Hybrid Neutron-Gamma Mixed Radiation Fields. Materials. 2023; 16(5):2084. https://doi.org/10.3390/ma16052084

Chicago/Turabian StyleXiao, Ming, Qingao Qin, Xin He, Fei Li, and Xiaobo Wang. 2023. "Shielding Capability Research on Composite Base Materials in Hybrid Neutron-Gamma Mixed Radiation Fields" Materials 16, no. 5: 2084. https://doi.org/10.3390/ma16052084

APA StyleXiao, M., Qin, Q., He, X., Li, F., & Wang, X. (2023). Shielding Capability Research on Composite Base Materials in Hybrid Neutron-Gamma Mixed Radiation Fields. Materials, 16(5), 2084. https://doi.org/10.3390/ma16052084