Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties

Abstract

1. Introduction

2. Experimental Procedure

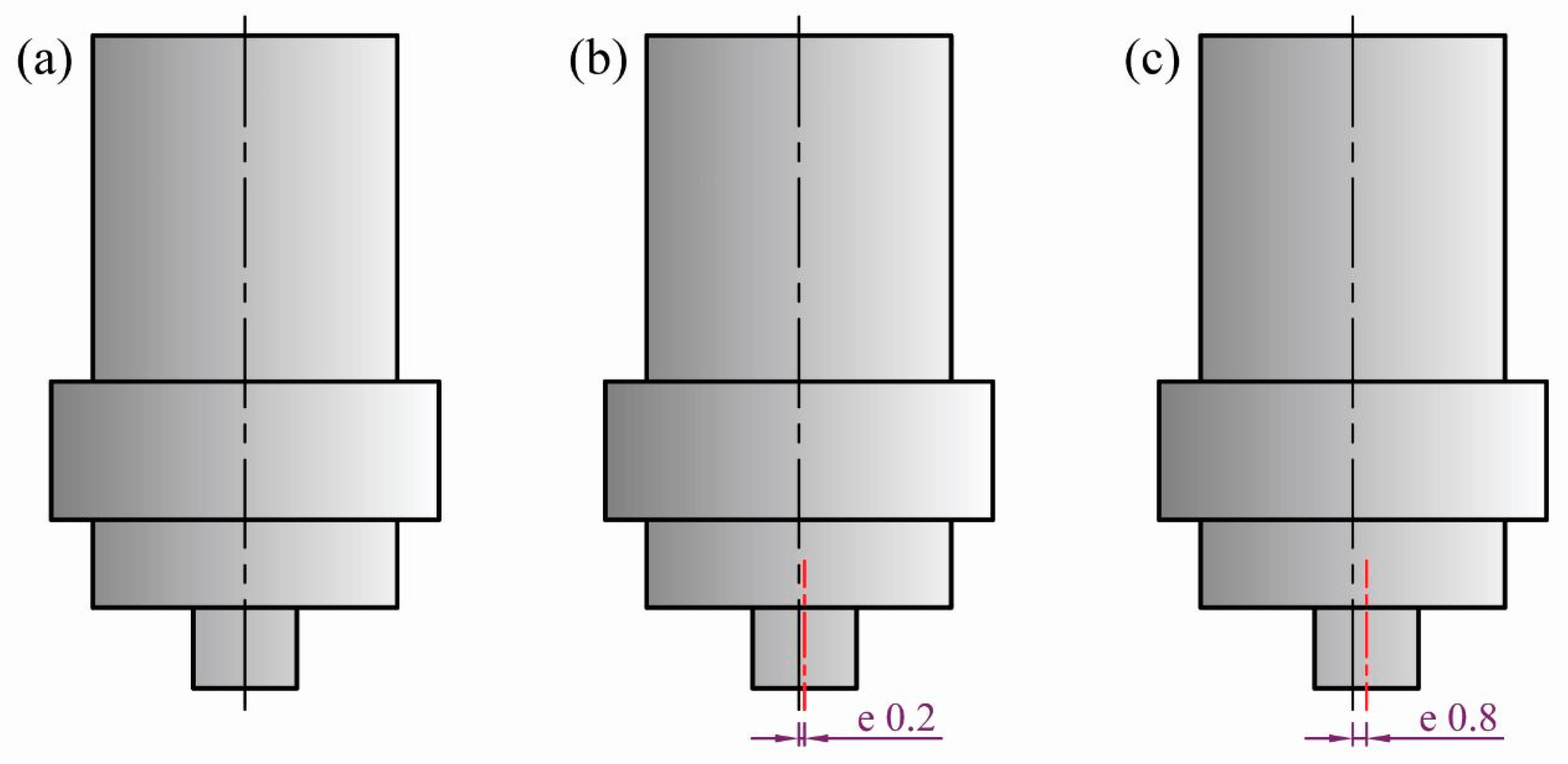

2.1. Friction Stir Welding

2.2. Evaluation of the Welded Joints

3. Results and Discussion

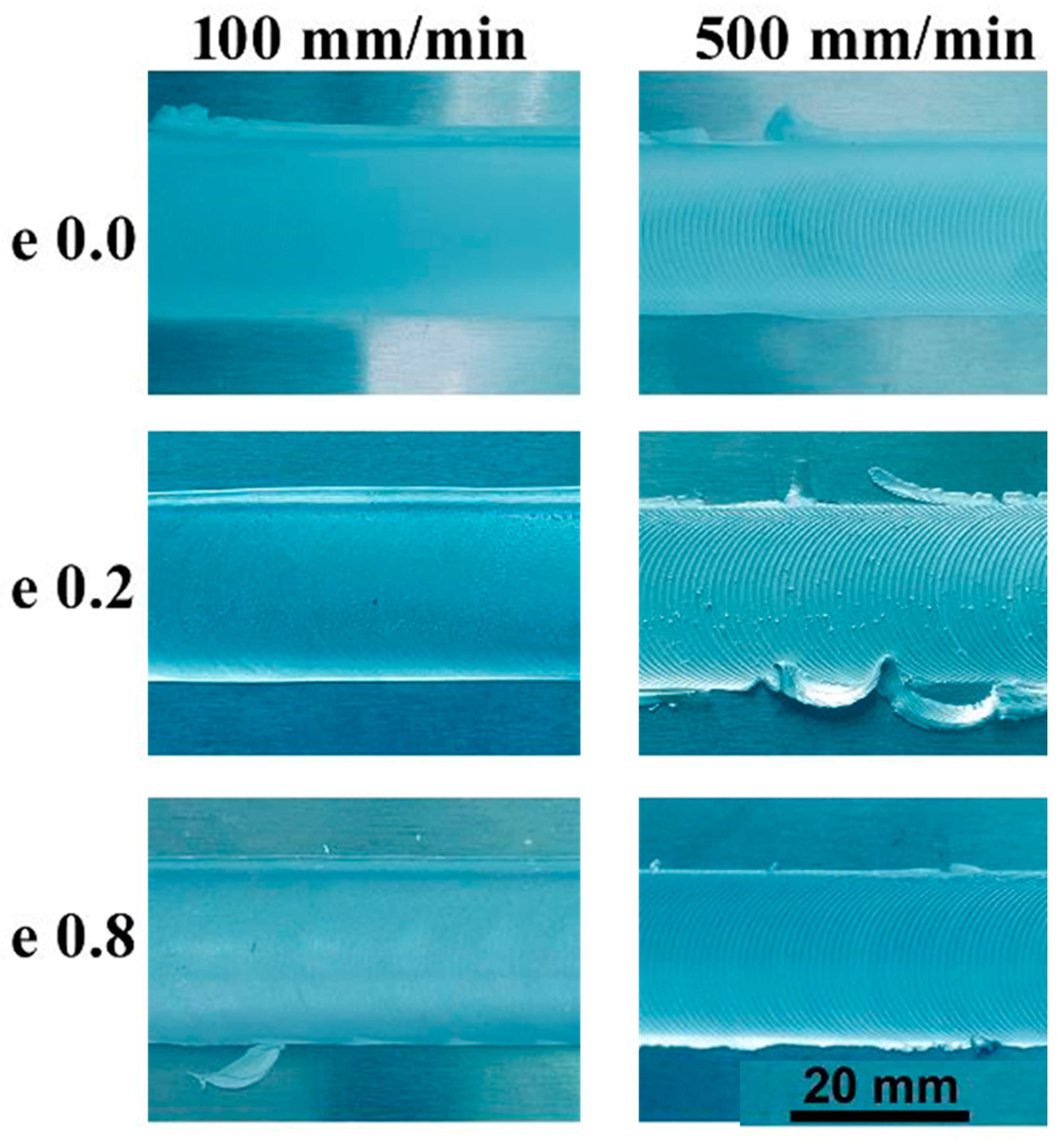

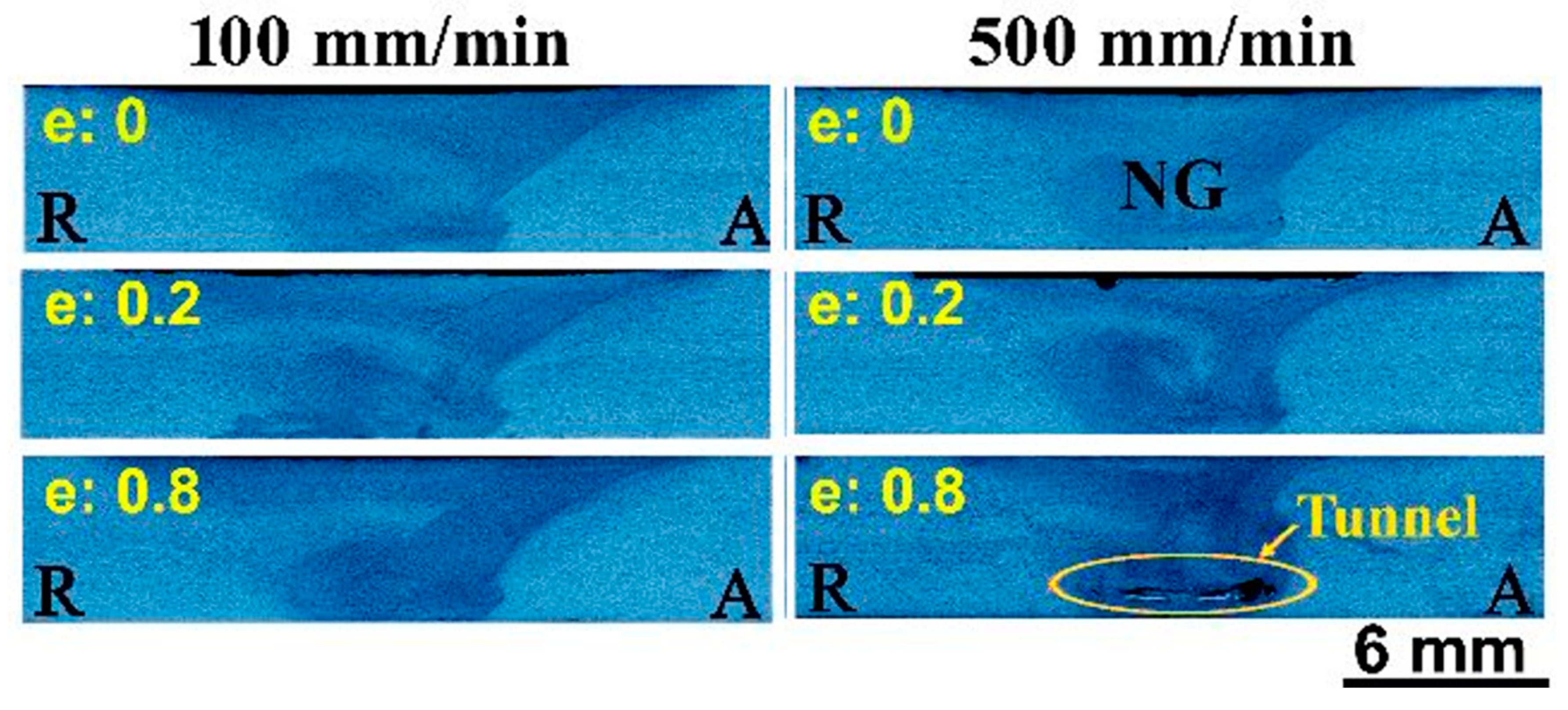

3.1. Joint Top View and Macro Examination of Transverse Cross-Sections

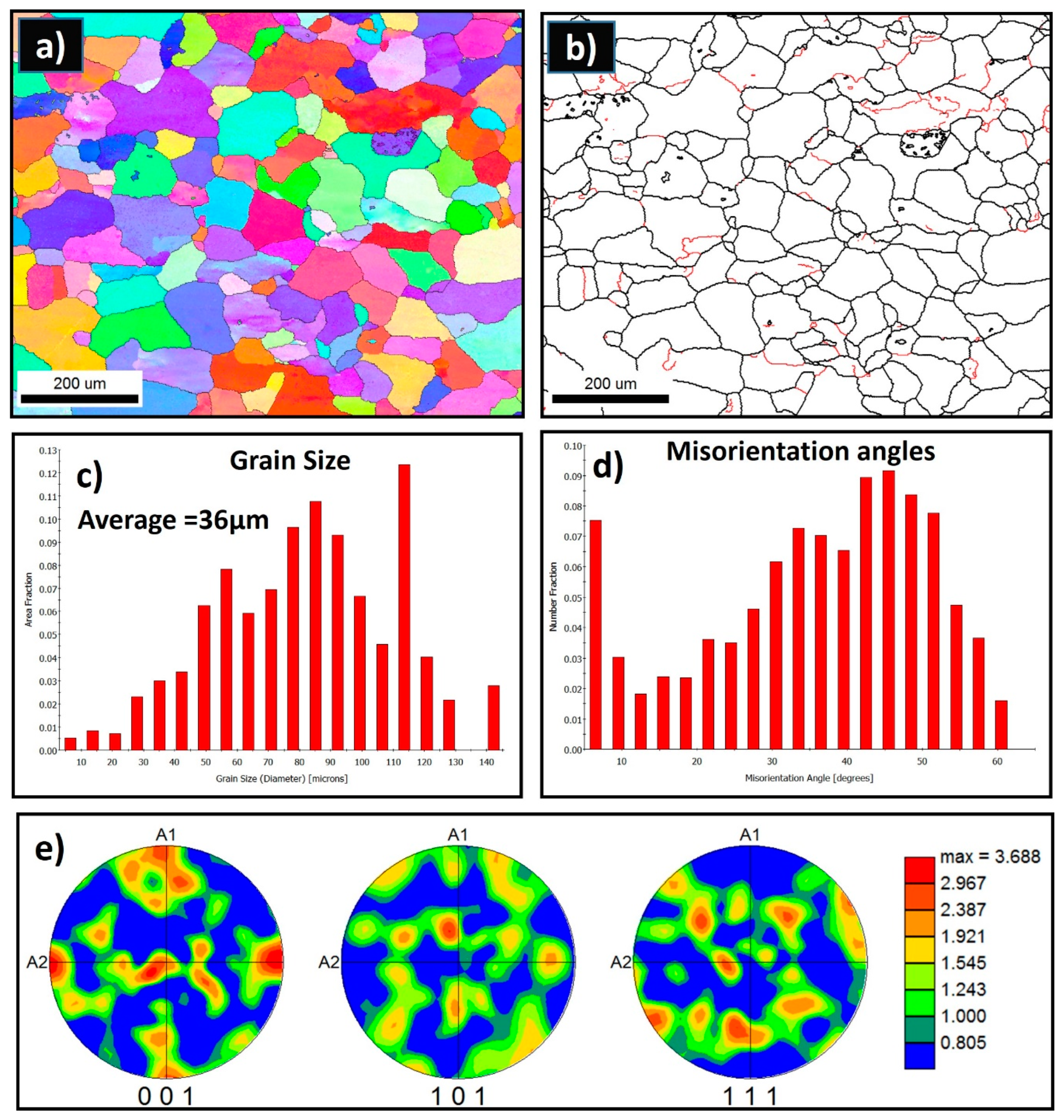

3.2. The Grain Structure and Texture of the As-Received AA5457-H24 Alloy

3.3. Grain Structure and Texture of the FSWed AA5754 Joints

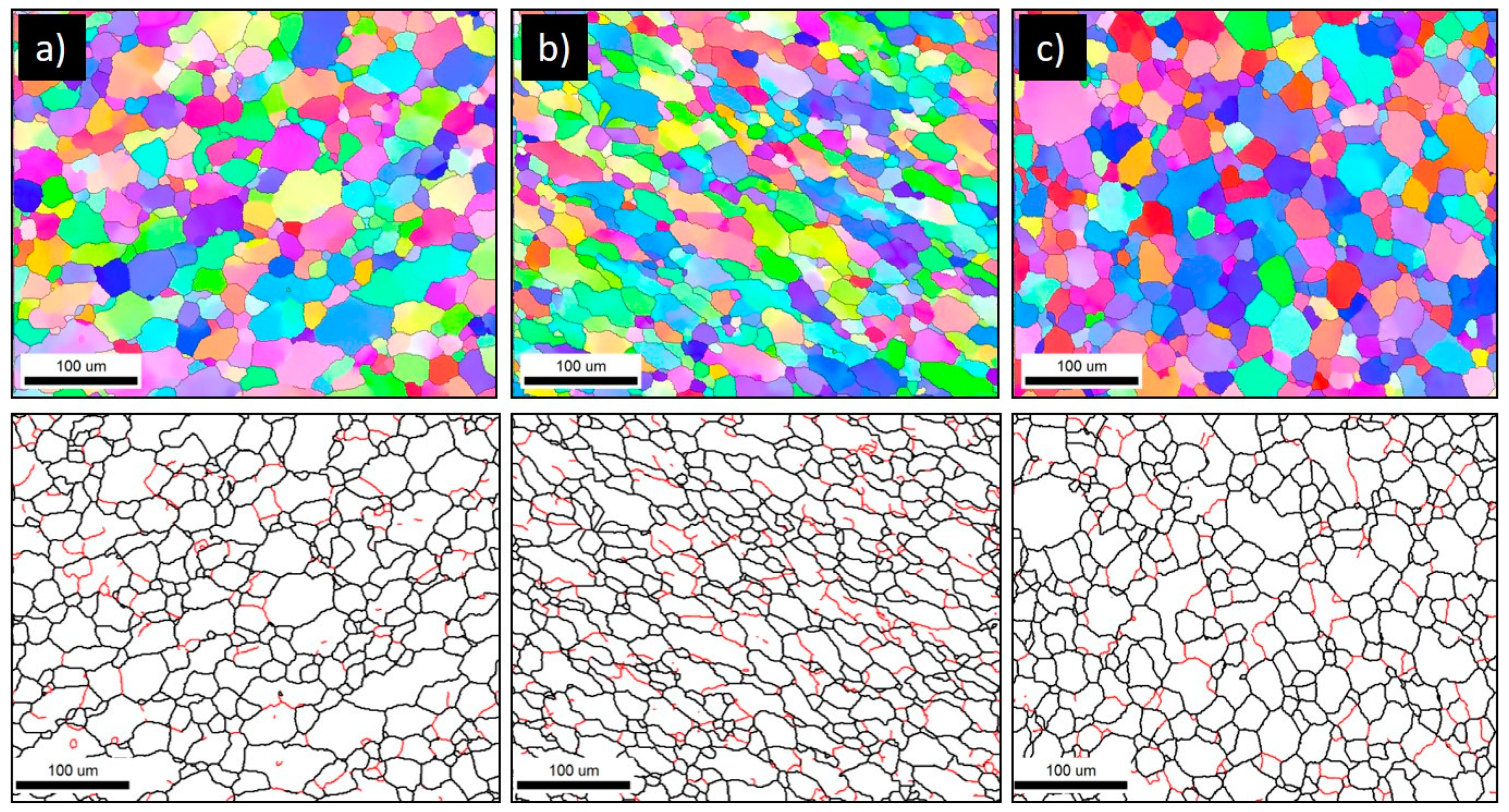

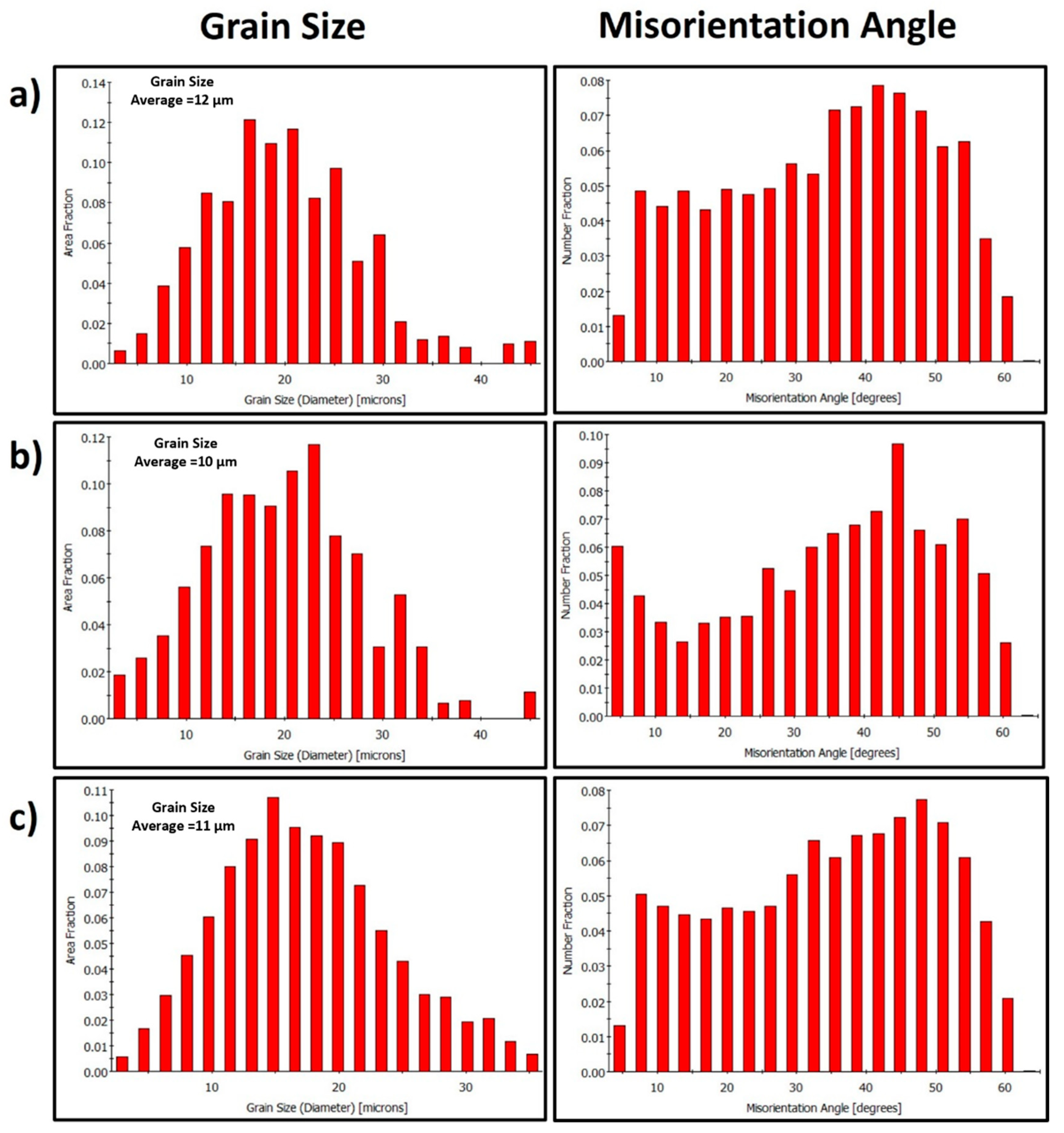

3.3.1. Effect of Tool Pin Eccentricity on Grain Structure

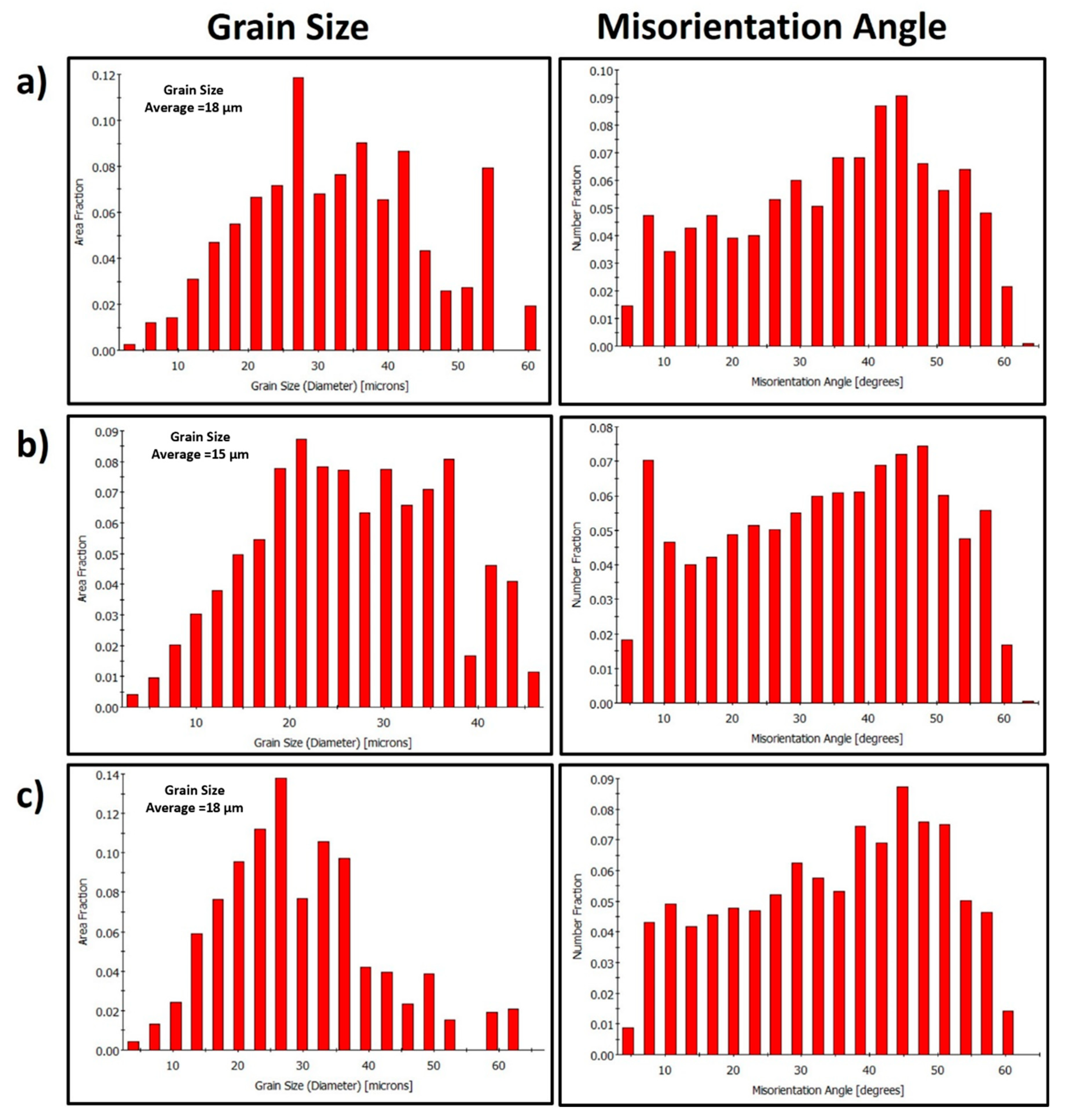

3.3.2. Impact of Tool Welding Speed on the Grain Structure

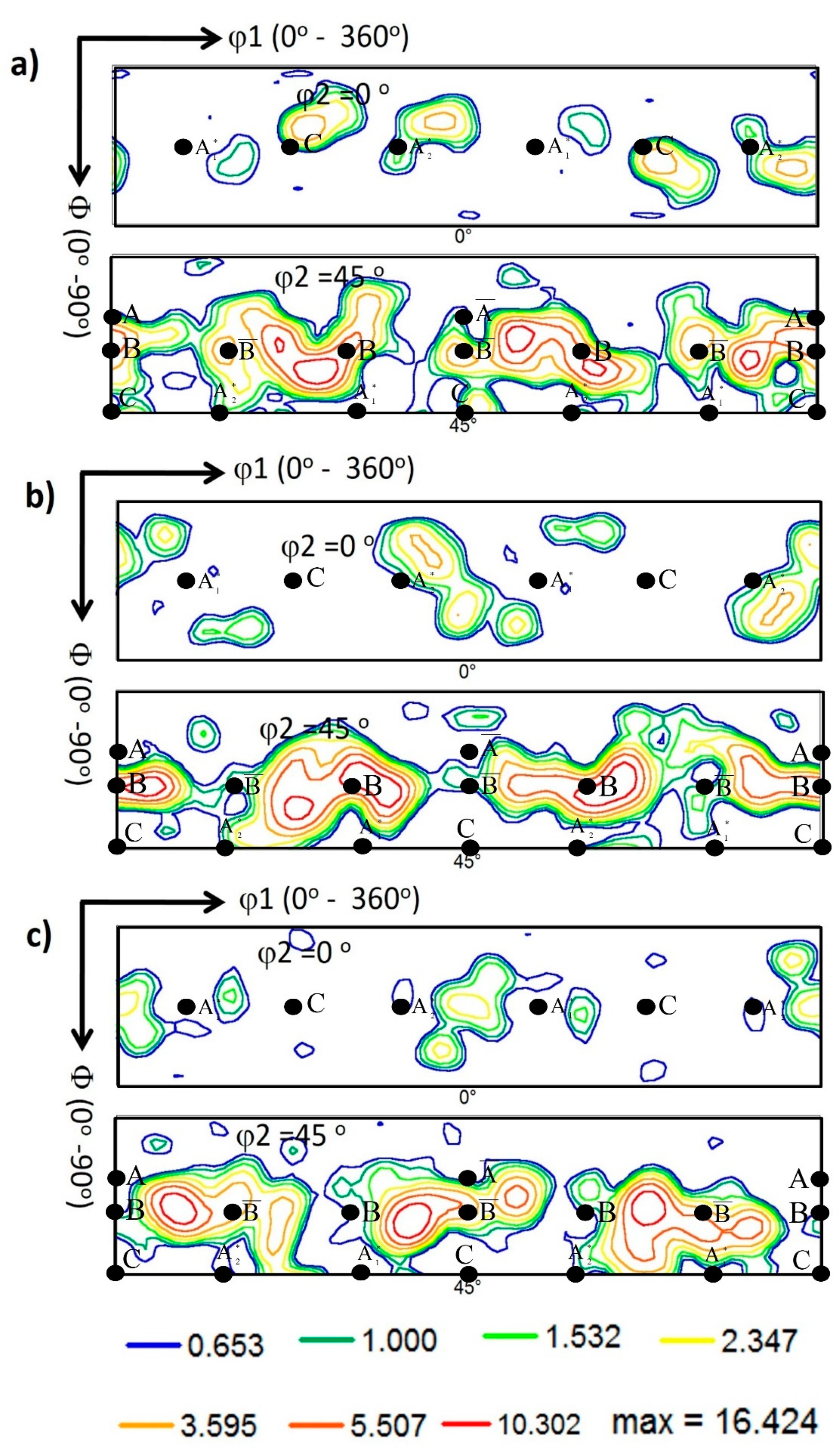

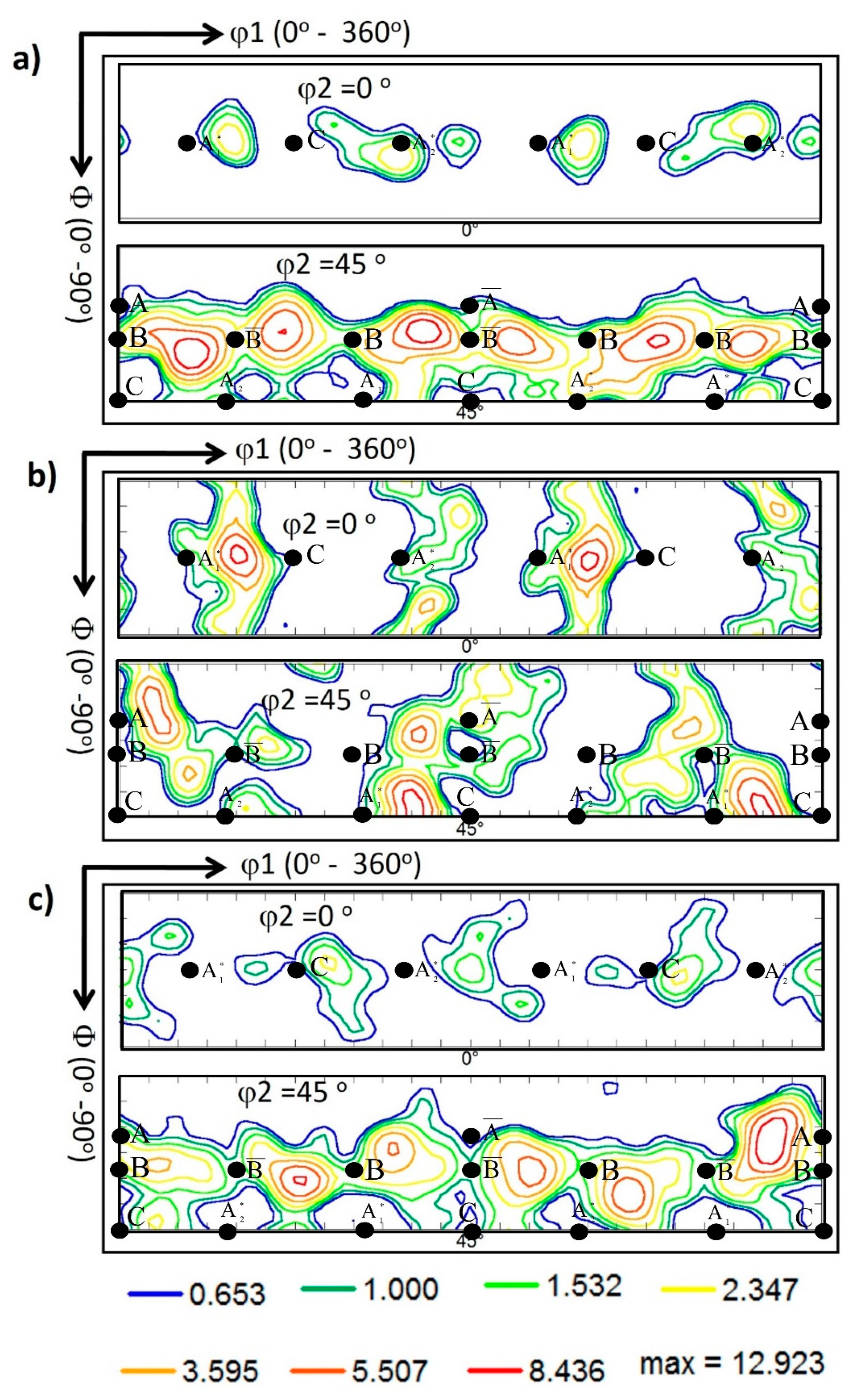

3.3.3. Crystallographic Texture Evolution

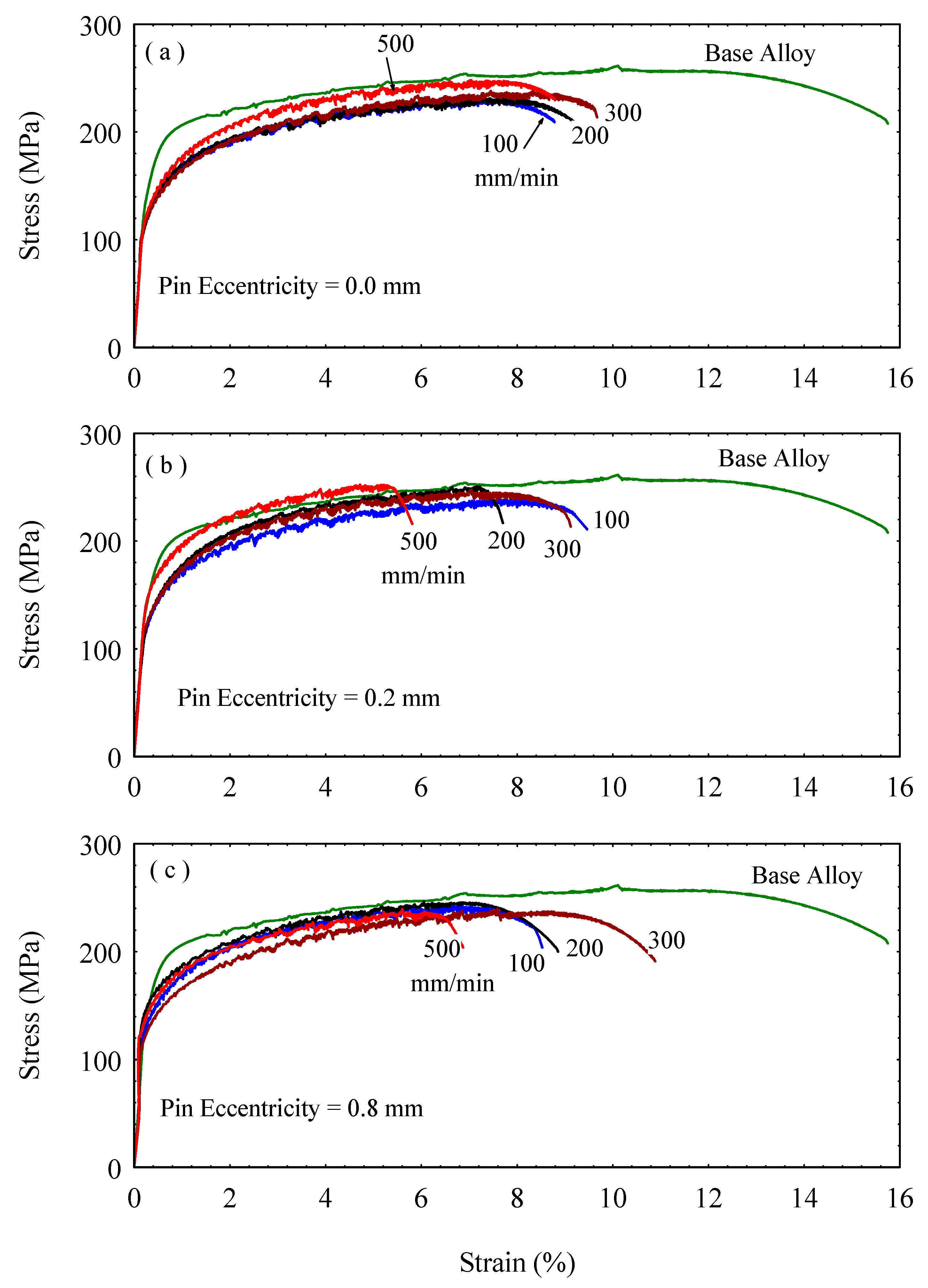

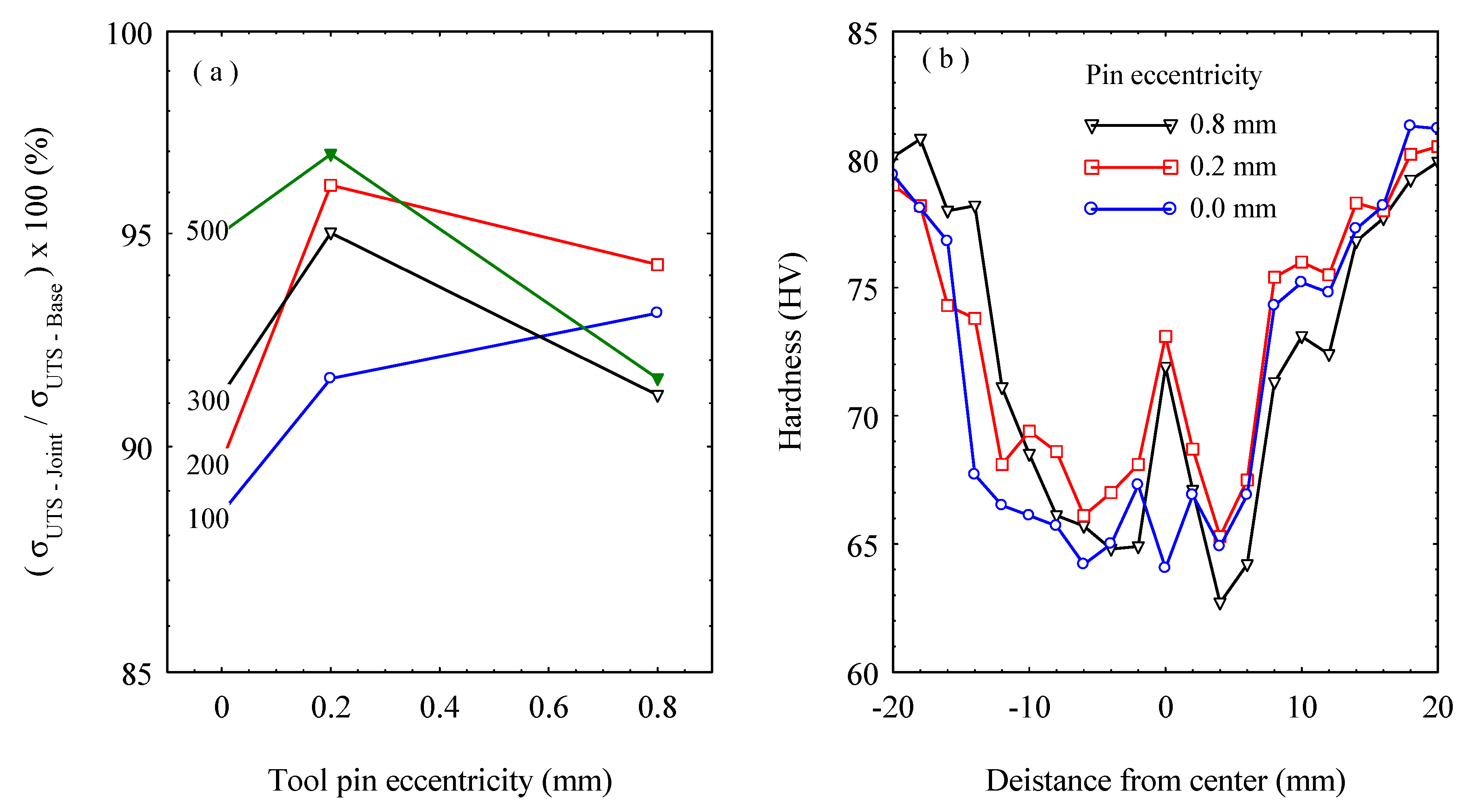

3.4. Tensile Strength and Weld Joint Efficiency

4. Conclusions

- The NG macro investigations showed defect-free joints at pin eccentricities of 0 and 0.2 mm using all welding speeds. In contrast, at the pin eccentricity of 0.8 mm, tunnel defects appear at welding speeds of 300 and 500 mm/min.

- The grain size in the NZ of all the processed specimens at the suggested welding conditions in terms of welding speeds (100–500 mm/min), different pin eccentricities (0, 0.2, and 0.8 mm), and applying a constant tool rotation rate of 600 rpm is lower than that given by the as-received AA5754-H24 alloy.

- Grain structure studied using EBSD for the NG of the joints produced at 100 mm/min, 600 rpm, and different tool pin eccentricities showed significant grain refining due to dynamic recrystallization with an average grain size of 18 µm at e = 0, and 0.8 mm, and 15 µm at e = 0.2 mm. Increasing the welding speed from 100 to 500 mm/min further reduced the average grain size of the NG zone to 12.4, 10, and 11 µm at e = 0, 0.2, and 0.8 mm, respectively.

- The tool pin eccentricity of (e = 0.2 mm) caused the smallest average grain size at 100 and 500 mm/min of 15 and 10 µm, respectively.

- The texture is found to be dominated by the simple shear texture, with both the /B texture component and C component at their ideal positions after rotating the data to align the shear reference frame with the FSW reference frame in both pole figures and ODF sections.

- The tensile properties for the FSWed joints were slightly lower than the as-received alloy due to the hardness reduction in the weld zone. On the other hand, the tensile strength and yield stress for all joints increased by increasing the FSW speed from 100 to 500 mm/min.

- Welding using the pin eccentricity of 0.2 mm resulted in the highest tensile strength; at a welding speed of 500 mm/min, it reached 97% of the strength of the as-received alloy.

- The fracture strains for the whole FSWed samples were much lower than that of the base alloy. Moreover, the FSWed joints produced using a tool with pin eccentricity showed a further decrease in fracture strain, especially at e = 0.2 mm, due to the increased strength.

- The hardness profile showed the typical W shape with a reduction in the hardness of the weld zone and a slight recovery of the hardness in the NG zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gratecap, F.; Girard, M.; Marya, S.; Racineux, G. Exploring Material Flow in Friction Stir Welding: Tool Eccentricity and Formation of Banded Structures. Int. J. Mater. Form. 2011, 5, 99–107. [Google Scholar] [CrossRef]

- Khodaverdizadeh, H.; Heidarzadeh, A.; Saeid, T. Effect of Tool Pin Profile on Microstructure and Mechanical Properties of Friction Stir Welded Pure Copper Joints. Mater. Des. 2013, 45, 265–270. [Google Scholar] [CrossRef]

- Ugender, S. Influence of Tool Pin Profile and Rotational Speed on the Formation of Friction Stir Welding Zone in AZ31 Magnesium Alloy. J. Magnes. Alloys 2018, 6, 205–213. [Google Scholar] [CrossRef]

- Shah, L.H.; Guo, S.; Walbridge, S.; Gerlich, A. Effect of Tool Eccentricity on the Properties of Friction Stir Welded AA6061 Aluminum Alloys. Manuf. Lett. 2018, 15, 14–17. [Google Scholar] [CrossRef]

- Hakim, L.; Shah, A.; Midawi, A.; Walbridge, S.; Gerlich, A. Influence of Tool Eccentricity on the Material Flow and Microstructural Properties of AA6061 Aluminum Alloy Friction Stir Welds. J. Alloys Compd. 2020, 826, 154219. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J.G.B. Friction Stir Butt Welding. Patent Application No. 9125978, 8 December 1991. [Google Scholar]

- Refat, M.; Elashery, A.; Toschi, S.; Ahmed, M.; Morri, A.; El-Mahallawi, I.; Ceschini, L. Microstructure, Hardness and Impact Toughness of Heat-Treated Nanodispersed Surface and Friction Stir-Processed Aluminum Alloy AA7075. J. Mater. Eng. Perform. 2016, 25, 5087–5101. [Google Scholar] [CrossRef]

- Li, Y.; Murr, L.E.; Mcclure, J.C. Flow Visualization and Residual Microstructures Associated with the Friction-Stir Welding of 2024 Aluminum to 6061 Aluminum. Mater. Sci. Eng. A 1999, 271, 213–223. [Google Scholar] [CrossRef]

- Guerra, M.; Schmidt, C.; Mcclure, J.C.; Murr, L.E.; Nunes, A.C. Flow Patterns during Friction Stir Welding. Mater. Charact. 2003, 49, 95–101. [Google Scholar] [CrossRef]

- Li, Y.; Murr, L.; McClure, J. Solid-State Flow Visualization in the Friction-Stir Welding of 2024 Al to 6061 Al. Scr. Mater. 1999, 40, 1041–1046. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Shercliff, H.R. 3-Dimensional CFD Modelling of Flow Round a Threaded Friction Stir Welding Tool Profile. J. Mater. Process. Technol. 2005, 169, 320–327. [Google Scholar] [CrossRef]

- Kumar, K.; Kailas, S.V. The Role of Friction Stir Welding Tool on Material Flow and Weld Formation. Mater. Sci. Eng. A 2008, 485, 367–374. [Google Scholar] [CrossRef]

- Liechty, B.C.; Webb, B.W. Flow Field Characterization of Friction Stir Processing Using a Particle-Grid Method. J. Mater. Process. Technol. 2008, 8, 431–443. [Google Scholar] [CrossRef]

- Schmidt, H.N.B.; Dickerson, T.L.; Hattel, J.H. Material Flow in Butt Friction Stir Welds in AA2024-T3. Acta Mater. 2006, 54, 1199–1209. [Google Scholar] [CrossRef]

- Lorrain, O.; Favier, V.; Zahrouni, H.; Lawrjaniec, D. Understanding the Material Flow Path of Friction Stir Welding Process Using Unthreaded Tools. J. Mater. Process. Technol. 2010, 210, 603–609. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Metall. Mater. Trans. A 2018, 50, 271–284. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Eid, R.G.; Albaijan, I.; Touileb, K. The Influence of Tool Pin Geometry and Speed on the Mechanical Properties of the Bobbin Tool Friction Stir Processed AA1050. Materials 2022, 15, 4684. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of Pin Profile and Rotational Speed of the Tool on the Formation of Friction Stir Processing Zone in AA2219 Aluminium Alloy. Mater. Sci. Eng. A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Thomas, W.M.U.; Nicholas, E.D.; Hall, A.; Cb, C. Friction Stir Welding for the Transportation Industries. Mater. Des. 1998, 18, 269–273. [Google Scholar] [CrossRef]

- Ramadan, A.; Essa, S.; Mohamed, M.; Ahmed, Z.; Ahmed, A.Y.; El-nikhaily, A.E. An Analytical Model of Heat Generation for Eccentric Cylindrical Pin in Friction Stir Welding. J. Mater. Res. Technol. 2016, 5, 234–240. [Google Scholar] [CrossRef]

- Yuqing, M.; Liming, K.; Fencheng, L.; Qiang, L.; Chunping, H.; Li, X. Effect of Tool Pin Eccentricity on Microstructure and Mechanical Properties in Friction Stir Welded 7075 Aluminum Alloy Thick Plate. Mater. Des. 2014, 62, 334–343. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Wang, X.; Ding, H.; Zhao, J.; Zhang, F.; Ren, Z. In Fluence of Tool Pin Eccentricity on Microstructural Evolution and Mechanical Properties of Friction Stir Processed Al-5052 Alloy. Mater. Sci. Eng. A 2019, 739, 272–276. [Google Scholar] [CrossRef]

- Su, H.; Chen, J.; Wu, C. Effect of Tool Eccentricity on the Periodic Material Flow in Friction Stir Welding Process. Int. J. Mech. Sci. 2022, 220, 107164. [Google Scholar] [CrossRef]

- Ahmad Shah, L.H.; Hou, W.; Razmpoosh, M.H.; Walbridge, S.; Gerlich, A. Strain Rate and Microtexture Analysis of Rapid-Quenched AA6061 Friction Stir Welds Produced with Tool Eccentricity. J. Mater. Res. Technol. 2022, 21, 1434–1441. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Elnaml, A.; Shazly, M.; El-Sayed Seleman, M.M. The Effect of Top Surface Lubrication on the Friction Stir Welding of Polycarbonate Sheets. Int. Polym. Process. 2021, 36, 94–102. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded Aa5083/Aa5754 and Aa5083/Aa7020. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Krishnan, K.N. On the Formation of Onion Rings in Friction Stir Welds. Mater. Sci. Eng. A 2002, 327, 246–251. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Habba, M.I.A.; El-Sayed Seleman, M.M.; Hajlaoui, K.; Ataya, S.; Latief, F.H.; EL-Nikhaily, A.E. Bobbin Tool Friction Stir Welding of Aluminum Thick Lap Joints: Effect of Process Parameters on Temperature Distribution and Joints’ Properties. Materials 2021, 14, 4585. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Li, H.; Wang, X.; Ding, H.; Zhao, J.; Zhang, F. Investigation into the Dissimilar Friction Stir Welding of AA5052 and AA6061 Aluminum Alloys Using Pin-Eccentric Stir Tool. Metals 2019, 9, 718. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. Defect Formation and Material Flow in Friction Stir Welding. Eur. J. Mech.-A/Solids 2020, 80, 103912. [Google Scholar] [CrossRef]

- Rasti, J. Study of the Welding Parameters Effect on the Tunnel Void Area during Friction Stir Welding of 1060 Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 2221–2230. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction Stir Welding of Similar and Dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Hamada, A.S.; Järvenpää, A.; Ahmed, M.M.Z.; Jaskari, M.; Wynne, B.P.; Porter, D.A.; Karjalainen, L.P. The Microstructural Evolution of Friction Stir Welded AA6082-T6 Aluminum Alloy during Cyclic Deformation. Mater. Sci. Eng. A 2015, 642, 366–376. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of Friction Stir Welding Speed on Mechanical Properties and Microstructure of Nickel Based Super Alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Kumar, S.; Sethi, D.; Choudhury, S.; Roy, B.S.; Saha, S.C. An Experimental Investigation to the Influence of Traverse Speed on Microstructure and Mechanical Properties of Friction Stir Welded AA2050-T84 Al-Cu-Li Alloy Plates. Mater. Today Proc. 2020, 26, 2062–2068. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Quantifying Crystallographic Texture in the Probe-Dominated Region of Thick-Section Friction-Stir-Welded Aluminium. Scr. Mater. 2008, 59, 507–510. [Google Scholar] [CrossRef]

- Fonda, R.W.; Knipling, K.E. Texture Development in Friction Stir Welds. Sci. Technol. Weld. Join. 2011, 16, 288–294. [Google Scholar] [CrossRef]

- Barnett, M.R.; Montheillet, F. The Generation of New High-Angle Boundaries in Aluminium during Hot Torsion. Acta Mater. 2002, 50, 2285–2296. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.S.; Allam, T.; Alsaleh, N.A.; Ahmed, E. Grain Structure, Crystallographic Texture, and Hardening Behavior of Dissimilar Friction Stir Welded Aa5083-o and Aa5754-H14. Metals 2021, 11, 181. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, R.C.; Lopes, A.B. Effect of Symmetric and Asymmetric Rolling on the Mechanical Properties of AA5182. Mater. Des. 2016, 100, 151–156. [Google Scholar] [CrossRef]

- Gabrielli, F.; Forcellese, A.; El Mehtedi, M.; Simoncini, M. Mechanical Properties and Formability of Cold Rolled Friction Stir Welded Sheets in AA5754 for Automotive Applications. Procedia Eng. 2017, 183, 245–250. [Google Scholar] [CrossRef]

- Hammad, A.S.; Ahmed, M.M.Z.; Lu, H.; El-Shabasy, A.B.; Alzahrani, B.; El-Sayed Seleman, M.M.; Zhang, Y.; El Megharbel, A. An Investigation on Mechanical and Microstructural Evolution of Stationary Shoulder Friction Stir Welded Aluminum Alloy AA7075-T651. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 6665–6676. [Google Scholar] [CrossRef]

- Li, S.; Chen, Y.; Zhou, X.; Kang, J.; Huang, Y.; Deng, H. High-Strength Titanium Alloy/Steel Butt Joint Produced via Friction Stir Welding. Mater. Lett. 2019, 234, 155–158. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

| wt.% | ||||||||

|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.4 | 0.4 | 0.1 | 0.5 | 2.6- | 0.3 | 0.2 | 0.15 | Rest |

| Tensile Strength (MPa) | Proof Stress 0.2% (MPa) | Elongation (%) |

|---|---|---|

| 261 ± 3 | 178 ± 3 | 15.7 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; Essa, A.R.S.; Ataya, S.; El-Sayed Seleman, M.M.; El-Aty, A.A.; Alzahrani, B.; Touileb, K.; Bakkar, A.; Ponnore, J.J.; Mohamed, A.Y.A. Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials 2023, 16, 2031. https://doi.org/10.3390/ma16052031

Ahmed MMZ, Essa ARS, Ataya S, El-Sayed Seleman MM, El-Aty AA, Alzahrani B, Touileb K, Bakkar A, Ponnore JJ, Mohamed AYA. Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials. 2023; 16(5):2031. https://doi.org/10.3390/ma16052031

Chicago/Turabian StyleAhmed, Mohamed M. Z., Ahmed R. S. Essa, Sabbah Ataya, Mohamed M. El-Sayed Seleman, Ali Abd El-Aty, Bandar Alzahrani, Kamel Touileb, Ashraf Bakkar, Joffin J. Ponnore, and Abdelkarim Y. A. Mohamed. 2023. "Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties" Materials 16, no. 5: 2031. https://doi.org/10.3390/ma16052031

APA StyleAhmed, M. M. Z., Essa, A. R. S., Ataya, S., El-Sayed Seleman, M. M., El-Aty, A. A., Alzahrani, B., Touileb, K., Bakkar, A., Ponnore, J. J., & Mohamed, A. Y. A. (2023). Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials, 16(5), 2031. https://doi.org/10.3390/ma16052031