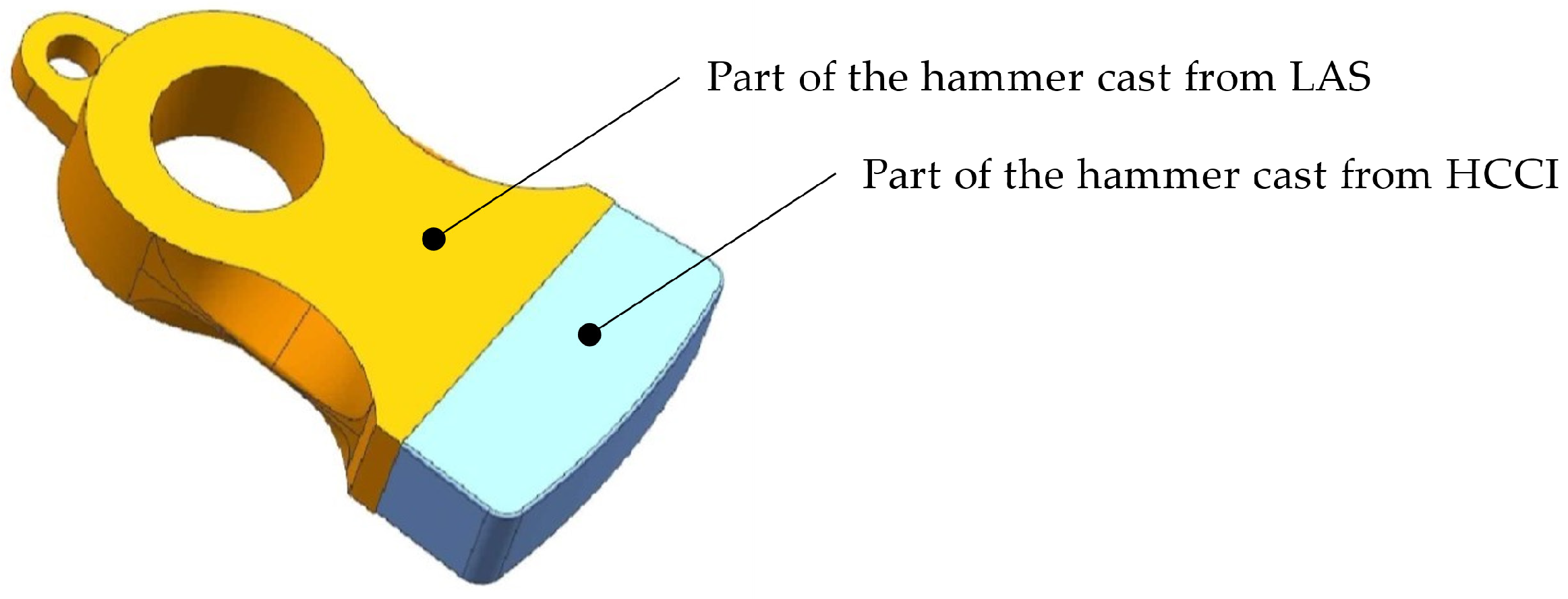

Process Optimization of Dual-Liquid Casting and Interfacial Strength–Toughness of the Produced LAS/HCCI Bimetal

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Simulation Results of Interfacial Solidification for Different Pouring Time Intervals

3.2. Optimum Pouring Time Interval Verified by Experiment

3.2.1. Pouring Time Interval Dependence on Interfacial Width

3.2.2. Pouring Time Interval Dependence on Interfacial Bonding Strength

3.3. Effect of Interfacial Protective Agent on Interfacial Bonding Strength and Toughness

3.4. Microstructure and Properties of the Bimetal Produced by the Optimum Process

4. Conclusions

- (1)

- The interfacial width decreases from 136 μm to 73 μm, and the interfacial bonding strength decreases from 697 MPa to 329 MPa as the pouring time interval increases from 35 s to 50 s. The pouring time interval dependence equations of interfacial width and bonding strength are also established.

- (2)

- Comparing with the specimen produced by the pouring time interval of 40 s without an interfacial protective agent, an increase of 41.5% in interfacial bonding strength and 15.6% in toughness are realized under the positive effect of the interfacial protective agent.

- (3)

- Both theoretical simulation and experiment results indicate that the process with a pouring time interval of 40 s and adding the interfacial protective agent is the optimum dual-liquid casting process to realize metallurgical bonding for the studied LAS/HCCI bimetal.

- (4)

- The interfacial region of the LAS/HCCI bimetal produced by the optimum process is composed of two zones: a fine white precipitation zone and a carbide-free zone. The width of the carbide-free zone and the whole interfacial region is approximately 49.5 and 96.3 μm, respectively. The average toughness and bending strength are, respectively, 17 J/cm2 and 1188 MPa. The excellent interfacial bonding strength causes the tensile fracture occurring on the HCCI side, which has the maximum tensile stress of 515 Mpa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hussain, N.; Kumar, A.; Vijayanand, P.S. Mechanical Property and Microstructural Variation in Semi-Solid Processed High Chromium Cast Iron. Int. J. Eng. Res. Technol. 2014, 3, 1580–1588. [Google Scholar]

- Kvon, S.S.; Kulikov, V.; Filippova, T.S.; Omarova, A. Using high-chromium iron as material for production of the equipping components of mine shafts. Metalurgija 2016, 55, 206–208. [Google Scholar]

- Zumelzu, E.; Goyos, I.; Cabezas, C.; Opitz, O.; Parada, A. Wear and corrosion behaviour of high-chromium (14–30% Cr) cast iron alloys. J. Mater. Process. Technol. 2002, 128, 250–255. [Google Scholar] [CrossRef]

- Li, Y.; Gong, M.; Wang, K.; Li, P.; Yang, X.; Tong, W. Diffusion behavior and mechanical properties of high chromium cast iron/low carbon steel bimetal. Mater. Sci. Eng. A 2018, 718, 260–266. [Google Scholar] [CrossRef]

- Gao, X.; Jiang, Z.; Wei, D.; Jiao, S.; Chen, D.; Xu, J.; Zhang, X.; Gong, D. Effects of temperature and strain rate on microstructure and mechanical properties of high chromium cast iron/low carbon steel bimetal prepared by hot diffusion-compression bonding. Mater. Des. 2014, 63, 650–657. [Google Scholar] [CrossRef]

- Özdemir, Z. Effect of Heat Treatment on the Impact Toughness of ‘High-Chromium Cast Iron—Low Alloy Steel’ Bimetal Components. Met. Sci. Heat Treat. 2017, 58, 738–741. [Google Scholar] [CrossRef]

- Ramadan, M.; Fathy, N.; Abdel-Halim, K.; Alghamdi, A. New trends and advances in bi-metal casting technologies. Int. J. Adv. Appl. Sci. 2019, 6, 75–80. [Google Scholar] [CrossRef]

- Şimşir, M.; Kumruoğlu, L.C.; Özer, A. An investigation into stainless-steel/structural-alloy-steel bimetal produced by shell mould casting. Mater. Des. 2009, 30, 264–270. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S. Interfacial microstructures and properties of hyper-eutectic Al–21Si/hypo-eutectic Al–7.5Si bimetallic material fabricated by liquid–liquid casting route. Mech. Sci. 2020, 11, 371–379. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Sui, Y.; Wang, Q.; Ding, W. An investigation into interface formation and mechanical properties of aluminum–copper bimetal by squeeze casting. Mater. Des. 2016, 89, 1137–1146. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Fan, Z.; Jiang, Z.; Liu, X.; Liu, F. Effects of pouring temperature on microstructure, mechanical properties, and fracture behavior of Al/Mg bimetallic composites produced by lost foam casting process. Int. J. Adv. Manuf. Tech. 2017, 91, 1355–1368. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, F.; Qi, H.; Qi, H.; Meng, Z. Interfacial Bonding Behavior and Mechanical Properties of a Bimetallic Ring Blank Subjected to Centrifugal Casting Process. J. Mater. Eng. Perform. 2022, 31, 3249–3261. [Google Scholar] [CrossRef]

- Jiang, Z.; Fan, Z.; Jiang, W.; Li, G.; Wu, Y.; Guan, F.; Jiang, H. Interfacial microstructures and mechanical properties of Mg/Al bimetal produced by a novel liquid-liquid compound casting process. J. Mater. Process. Technol. 2018, 261, 149–158. [Google Scholar] [CrossRef]

- Zhu, Y.-C.; Wei, Z.-J.; Rong, S.-F.; Wang, H.-W.; Zou, C.-M. Formation mechanism of bimetal composite layer between LCS and HCCI. China Foundry 2016, 13, 396–401. [Google Scholar] [CrossRef]

- Rong, S.F.; Zhao, X.M.; Zhou, H.T.; Wang, J.F.; Yao, J.; Li, C.H. Study on coated–liquid–liquid trimetal composite casting hammer. Mater. Res. Innov. 2014, 18, S2-316–S2-322. [Google Scholar] [CrossRef]

- ASTM A370-22; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Wang, Y.; Qin, F.; Qi, H.; Li, Y.; Yuan, H.; Meng, Z. Centrifugal Casting Technology for Bimetallic Composite Component. Mater. Rep. 2022, 36, 20090287–20090289. [Google Scholar] [CrossRef]

- Guo, M.; Cai, Y.; Sun, H.; Gao, Y. Initial Discussion of Centrifugal Casting Process for Dual-metal Clad Tube in Carbon Steel-High chromium Casting Iron. Steel Pipe 2008, 37, 38–41. [Google Scholar] [CrossRef]

- Xiong, B.; Cai, C.; Lu, B. Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J. Alloys Compd. 2011, 509, 6700–6704. [Google Scholar] [CrossRef]

- Wen, F.; Zhao, J.; Yuan, M.; Wang, J.; Zheng, D.; Zhang, J.; He, K.; Shangguan, J.; Guo, Y. Influence of Ni interlayer on interfacial microstructure and mechanical properties of Ti-6Al-4V/AZ91D bimetals fabricated by a solid–liquid compound casting process. J. Magnes. Alloys 2021, 9, 1382–1395. [Google Scholar] [CrossRef]

- Bina, M.H.; Dehghani, F.; Salimi, M. Effect of heat treatment on bonding interface in explosive welded copper/stainless steel. Mater. Des. 2013, 45, 504–509. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, Y.; Shatrava, O.; Long, J.; Feng, B.; Wang, J.; Chen, W. Effects of Interfacial Additive on Microstructure and Mechanical Properties of Bimetal Composites. Hot Work. Technol. 2022, 51, 88–92. [Google Scholar]

- Li, Y.; Gao, J.; Xu, N.; Li, P.; Gong, M.; Tong, W. Fabrication of a High Chromium Cast Iron/Low Carbon Steel Bimetal: Diffusion Behavior and Bonding Strength. J. Mater. Eng. Perform. 2019, 28, 6904–6911. [Google Scholar] [CrossRef]

- Wang, D.; Rong, S. Study on cast-weld process and composite interface of bimetal composite roll sleeve. J. Mater. Res. Technol. 2021, 12, 848–861. [Google Scholar] [CrossRef]

- Yuan, G.; Han, P.; Zhu, X.; Jiang, Z.; Wang, X. Fabrication of a Composite Material of High-Chromium Cast Iron Dispersed in Low-Carbon Steel by Hot-Rolling Process. Steel Res. Int. 2021, 92, 2100001. [Google Scholar] [CrossRef]

- Xiao, X.-f.; Ye, S.-p.; Yin, W.-x.; Xue, Q. HCWCI/Carbon Steel Bimetal Liner by Liquid-Liquid Compound Lost Foam Casting. J. Iron Steel Res. Int. 2012, 19, 13–19. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; El-Hadad, S.; Mourad, M. Effect of liquid-solid volume ratios on the interfacial microstructure and mechanical properties of high chromium cast iron and low carbon steel bimetal. Mater. Res. Express 2019, 6, 1265c1262. [Google Scholar] [CrossRef]

- Li, W.; Qin, S.; Li, Y.; Wang, Y.; Jiang, P.; Tong, W. Friction resistance and bonding strength of high vanadium alloy steel/low carbon steel bimetal after heat treatments. J. Mater. Res. Technol. 2021, 11, 1678–1687. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Zhou, T. Improvement in microstructure and wear-resistance of high chromium cast iron/medium carbon steel bimetal with high vanadium. Mater. Res. Express 2021, 8, 046512. [Google Scholar] [CrossRef]

- Xiong, B.; Cai, C.; Wan, H.; Lu, B. Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid–solid casting in electromagnetic induction field. Mater. Des. 2011, 32, 2978–2982. [Google Scholar] [CrossRef]

- Ramadan, M. Interface Structure and Elements Diffusion of As-Cast and Annealed Ductile Iron/Stainless Steel Bimetal Castings. Eng. Technol. Appl. Sci. Res. 2018, 8, 2709–2714. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; Ma, X.; Wang, Q.; Dong, J.; Yuan, Z. A strain-dependent ductile damage model and its application in the derivation of fracture toughness by micro-indentation. Mater. Des. 2015, 67, 623–630. [Google Scholar] [CrossRef]

- Moradkhani, A.; Baharvandi, H.; Tajdari, M.; Latifi, H.; Martikainen, J. Determination of fracture toughness using the area of micro-crack tracks left in brittle materials by Vickers indentation test. J. Adv. Ceram. 2013, 2, 87–102. [Google Scholar] [CrossRef]

- Kruzic, J.J.; Kim, D.K.; Koester, K.J.; Ritchie, R.O. Indentation techniques for evaluating the fracture toughness of biomaterials and hard tissues. J. Mech. Behav. Biomed. Mater. 2009, 2, 384–395. [Google Scholar] [CrossRef] [PubMed]

- Sallam, H.E.M.; Abd El-Aziz, K.; Abd El-Raouf, H.; Elbanna, E.M. Failure analysis and flexural behavior of high chromium white cast iron and AISI4140 Steel bimetal beams. Mater. Des. 2013, 52, 974–980. [Google Scholar] [CrossRef]

| Parts | Materials | Normal Chemical Composition, wt.% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni | Fe | ||

| Head | G-X300CrMo153 | 2.73 | 0.48 | 0.65 | 0.035 | 0.026 | 14.66 | 2.11 | 0.101 | Bal. |

| Handle | GS-42CrMo4 | 0.37 | 0.26 | 0.85 | 0.019 | 0.015 | 0.81 | 0.24 | 0 | Bal. |

| Specimens | Intervals, s | Width, μm |

|---|---|---|

| S1 | 35 | 136 ± 12 |

| S2 | 40 | 98 ± 9 |

| S3 | 45 | 84 ± 9 |

| S4 | 50 | 73 ± 8 |

| Sample | Toughness (J/cm2) | |||

|---|---|---|---|---|

| 1 | 2 | 3 | Average | |

| S2* | 14 | 13 | 17 | 14.7 |

| S2 | 17 | 15 | 19 | 17 |

| HCCI | 5 | 4.5 | 5 | 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Z.-G.; He, L.-X.; Liang, S.-X.; Chang, L.-B.; Xiao, Z.-X.; Xing, W.-L.; Shen, H.-B.; Cao, J.-J.; Liu, H.-J. Process Optimization of Dual-Liquid Casting and Interfacial Strength–Toughness of the Produced LAS/HCCI Bimetal. Materials 2023, 16, 2008. https://doi.org/10.3390/ma16052008

Xing Z-G, He L-X, Liang S-X, Chang L-B, Xiao Z-X, Xing W-L, Shen H-B, Cao J-J, Liu H-J. Process Optimization of Dual-Liquid Casting and Interfacial Strength–Toughness of the Produced LAS/HCCI Bimetal. Materials. 2023; 16(5):2008. https://doi.org/10.3390/ma16052008

Chicago/Turabian StyleXing, Zhen-Guo, Li-Xin He, Shun-Xing Liang, Lian-Bo Chang, Zhi-Xia Xiao, Wan-Li Xing, Hai-Bin Shen, Jing-Jing Cao, and Hong-Ji Liu. 2023. "Process Optimization of Dual-Liquid Casting and Interfacial Strength–Toughness of the Produced LAS/HCCI Bimetal" Materials 16, no. 5: 2008. https://doi.org/10.3390/ma16052008

APA StyleXing, Z.-G., He, L.-X., Liang, S.-X., Chang, L.-B., Xiao, Z.-X., Xing, W.-L., Shen, H.-B., Cao, J.-J., & Liu, H.-J. (2023). Process Optimization of Dual-Liquid Casting and Interfacial Strength–Toughness of the Produced LAS/HCCI Bimetal. Materials, 16(5), 2008. https://doi.org/10.3390/ma16052008