Microstructure and Mechanical Properties of Weaving Wire and Arc Additive Manufactured AZ91 Magnesium Alloy Based on Cold Metal Transfer Technique

Abstract

1. Introduction

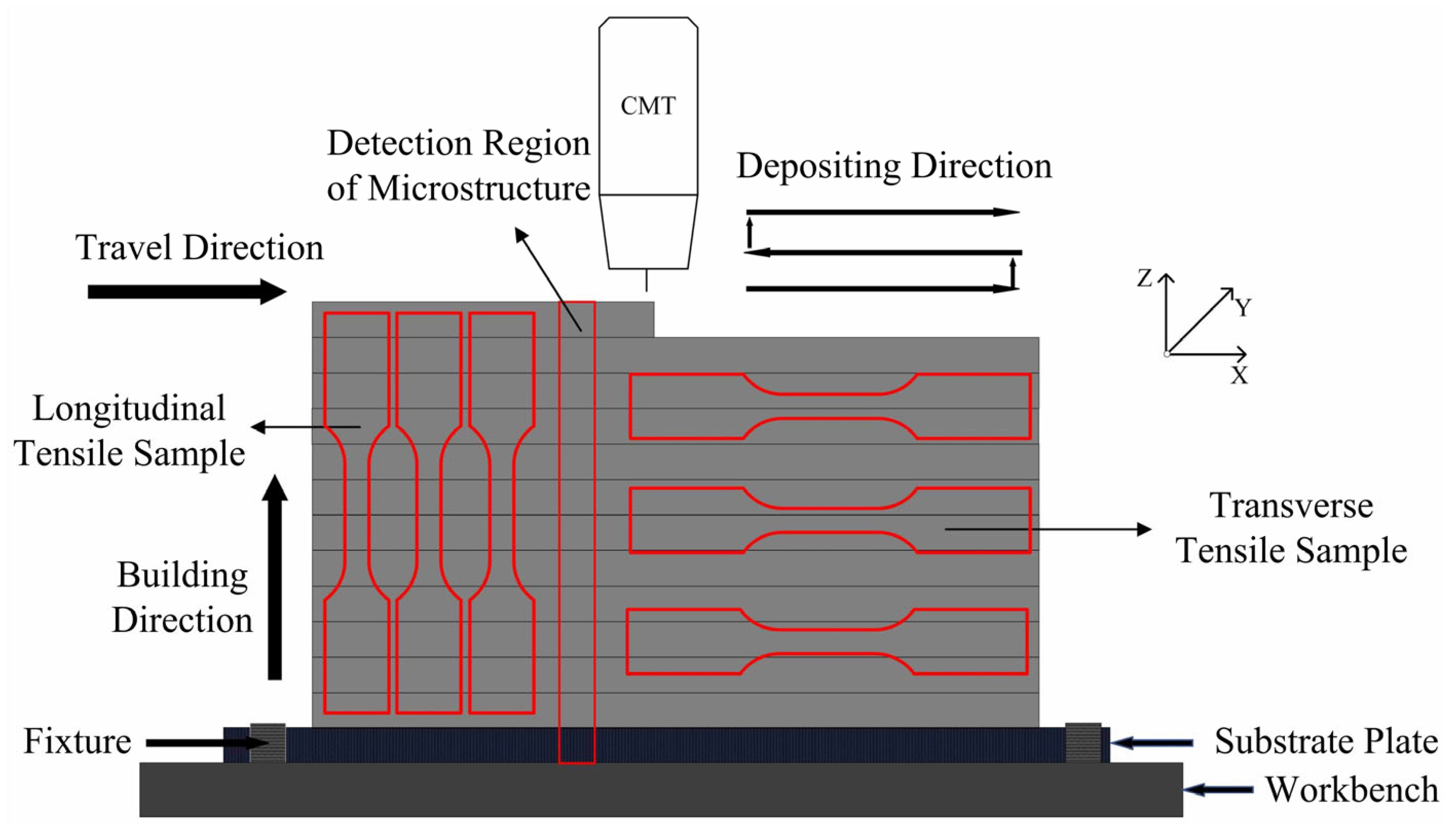

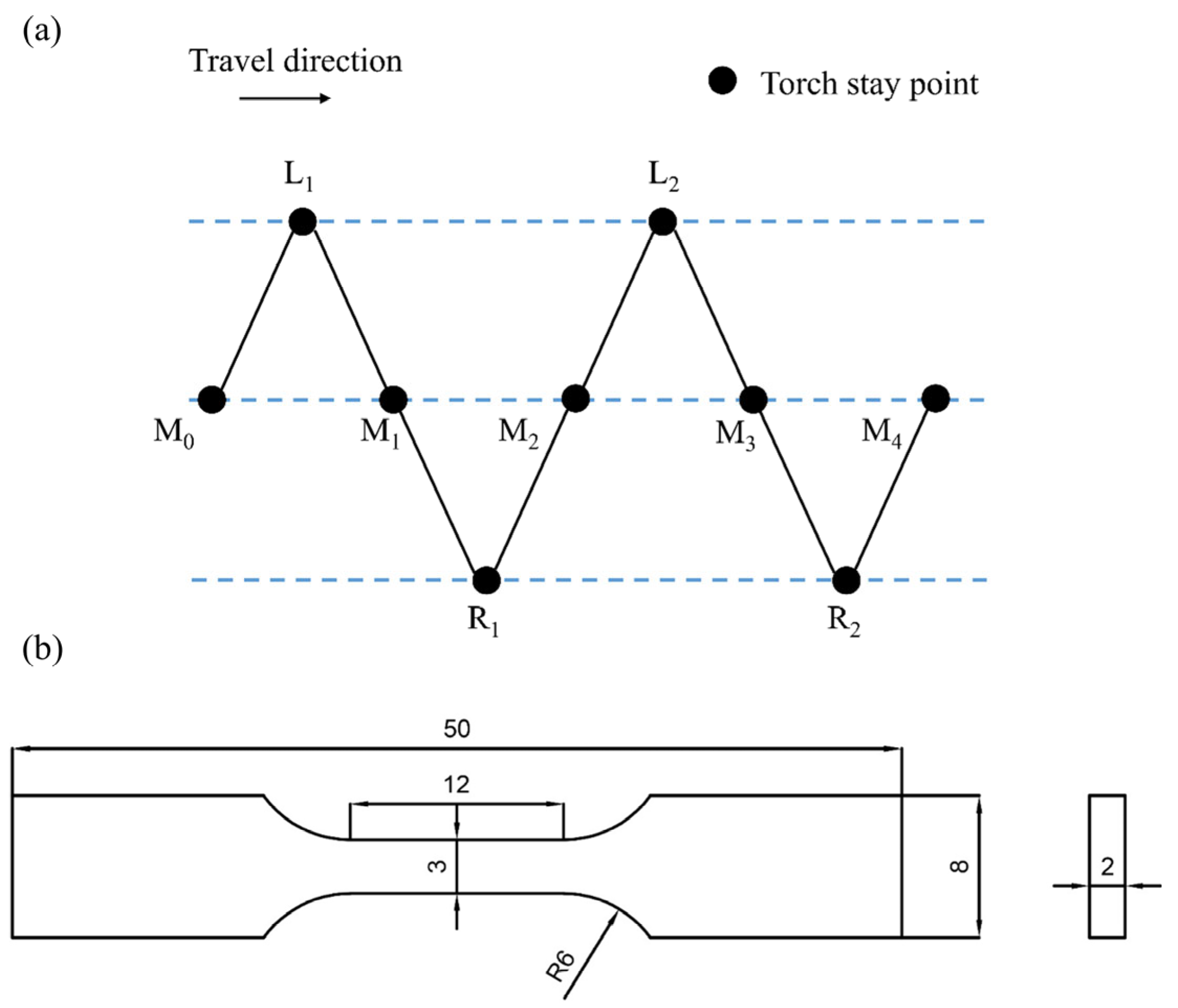

2. Experimental Procedure

3. Results and Discussion

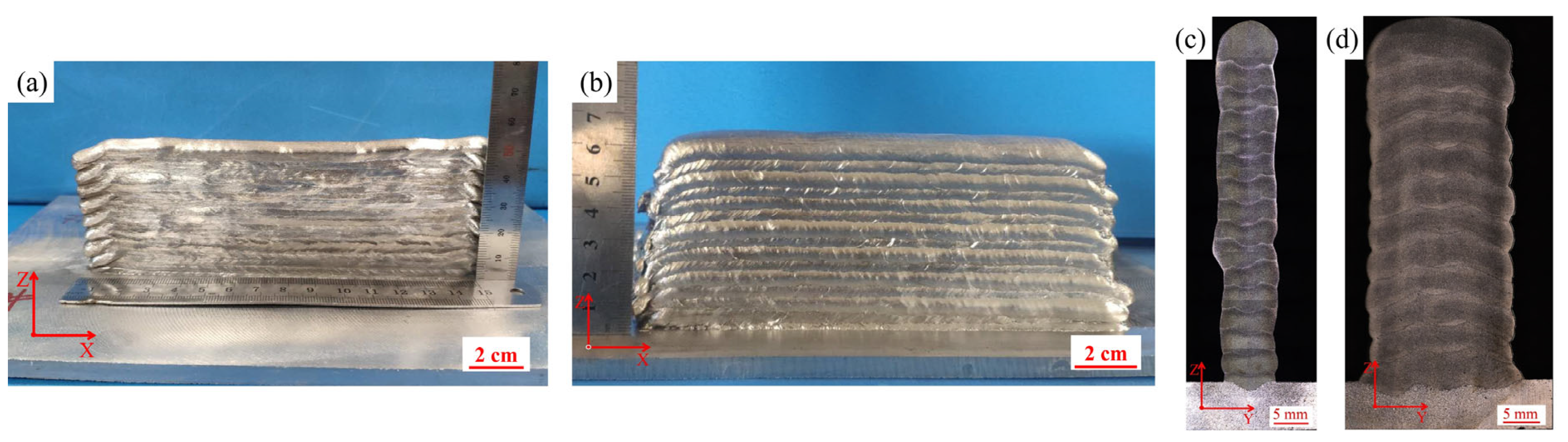

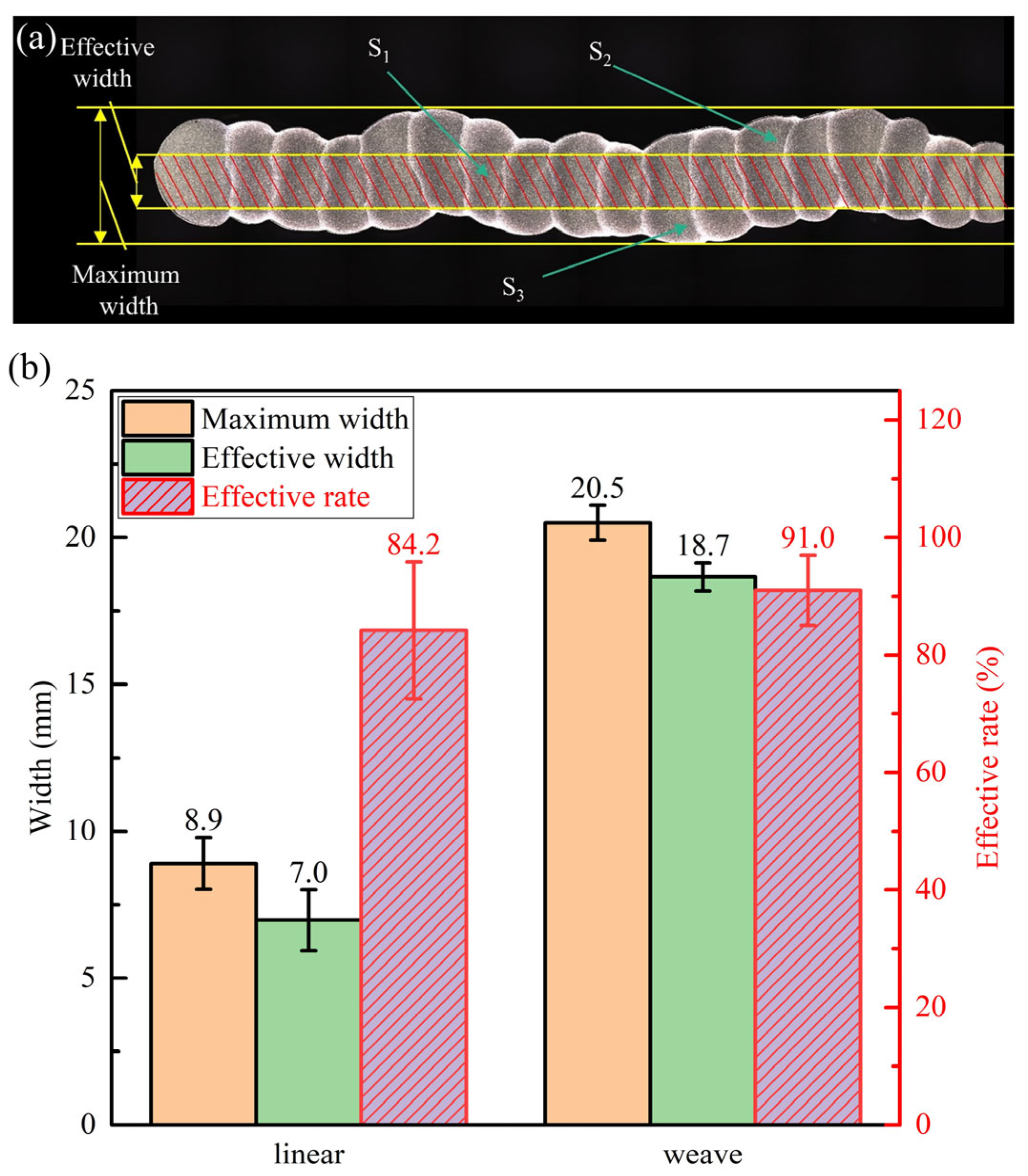

3.1. Macroscopic Morphology

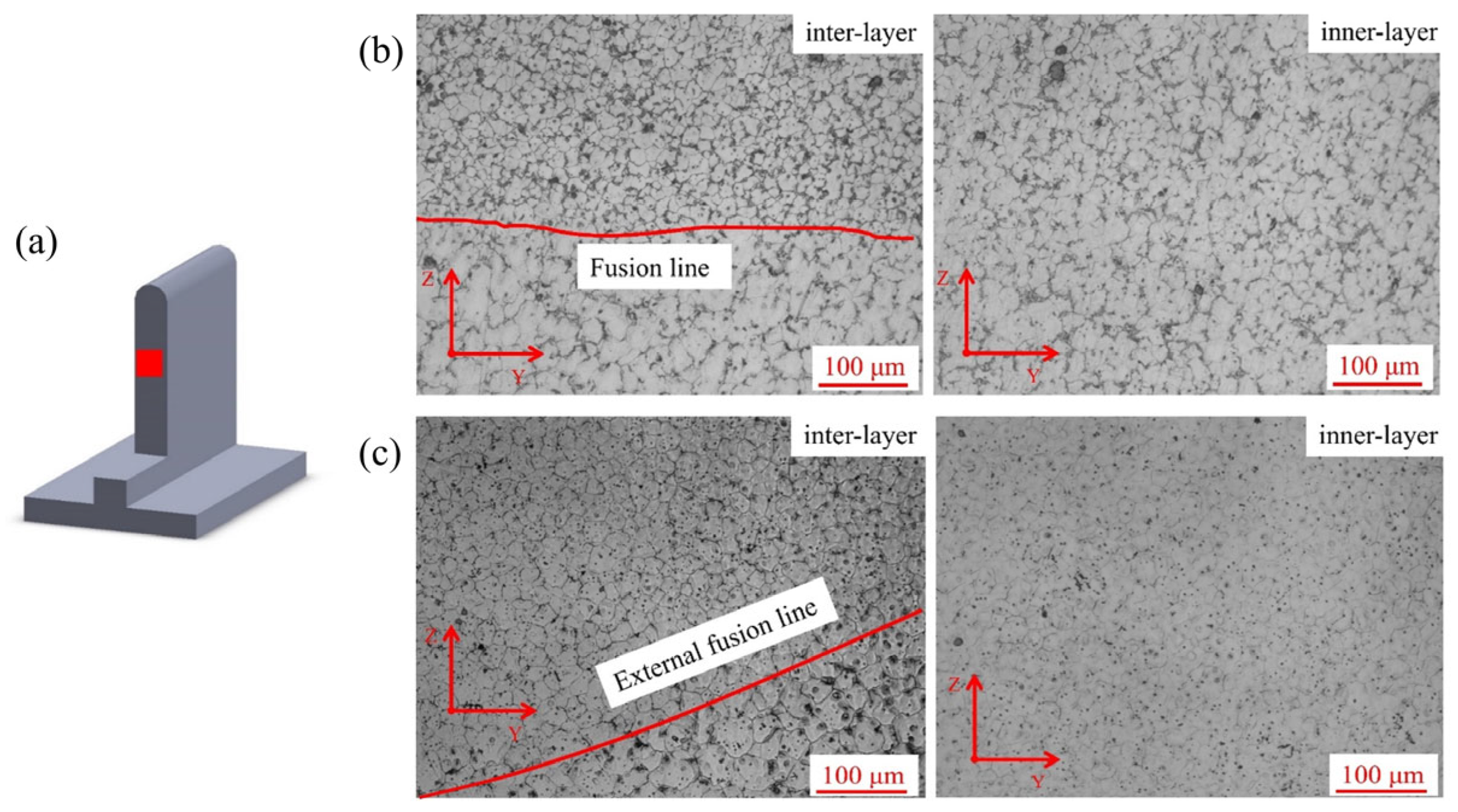

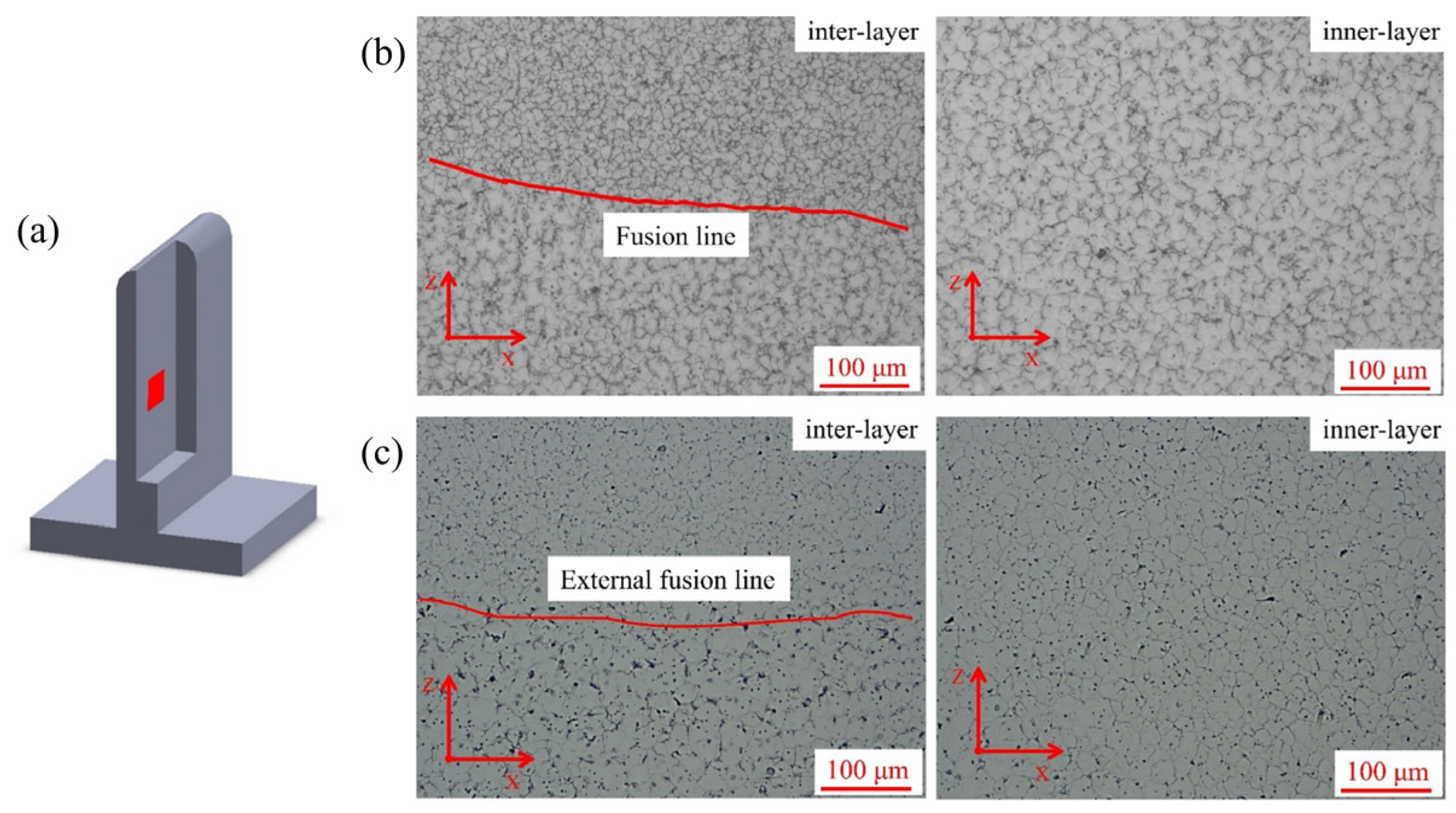

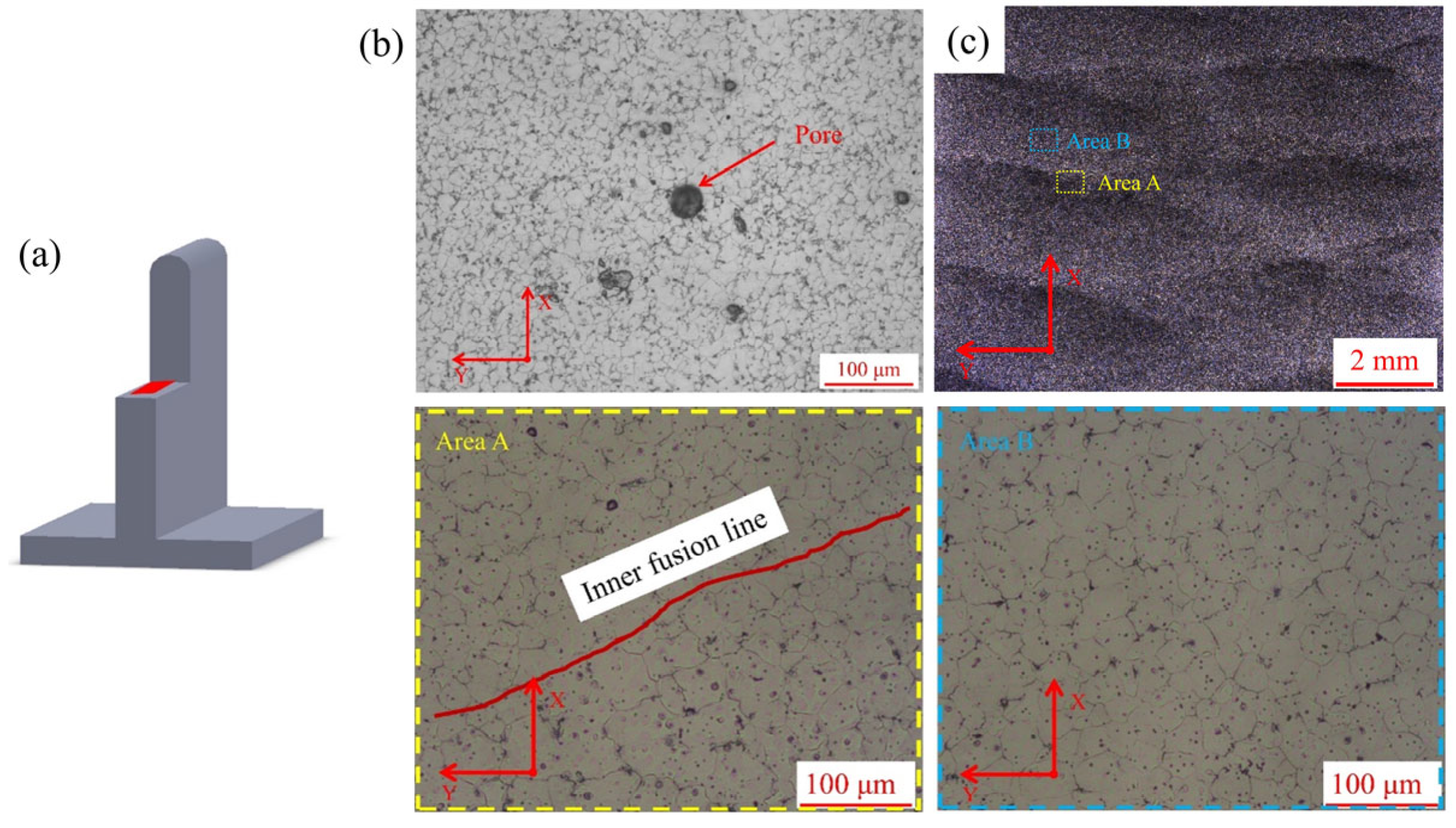

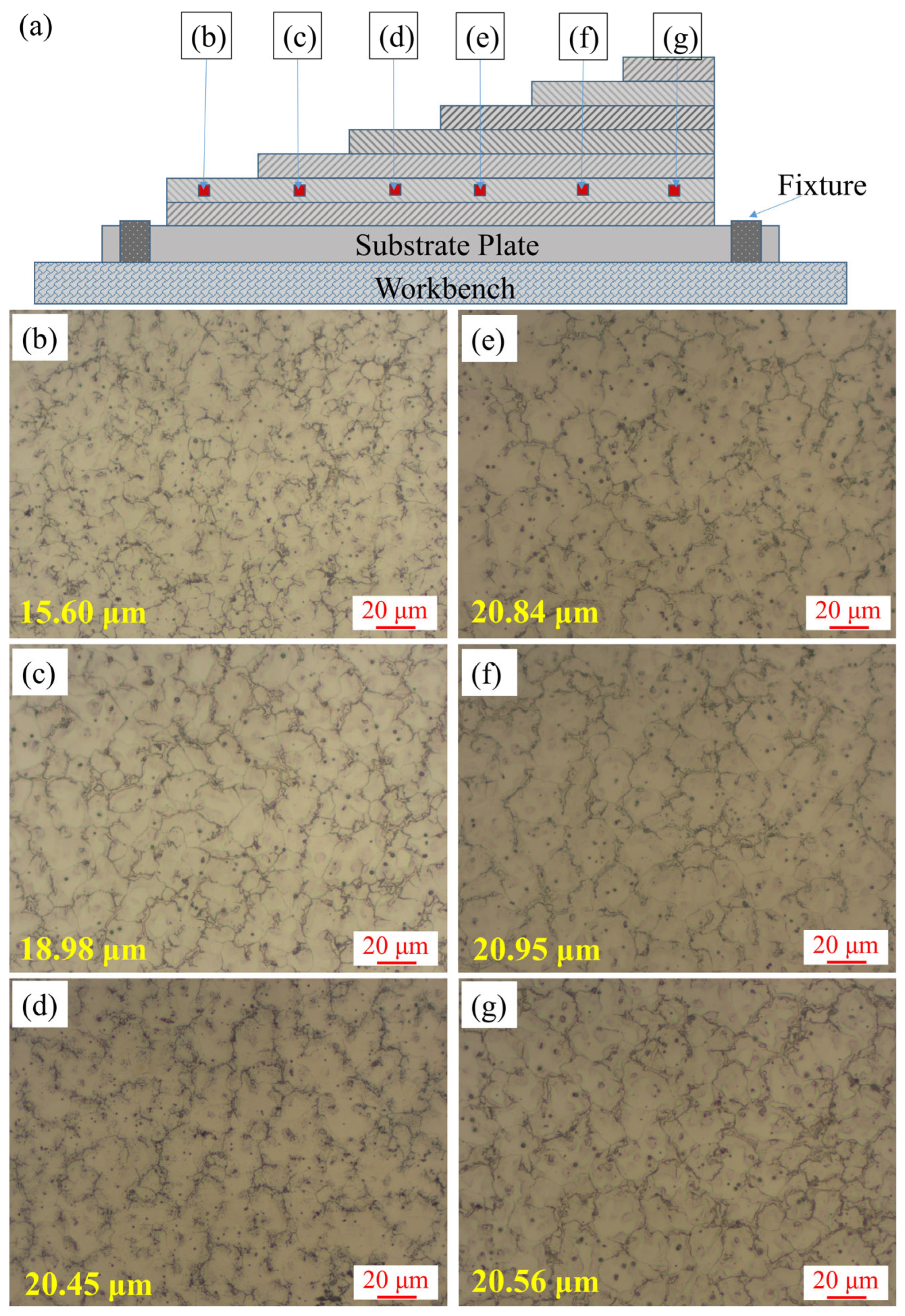

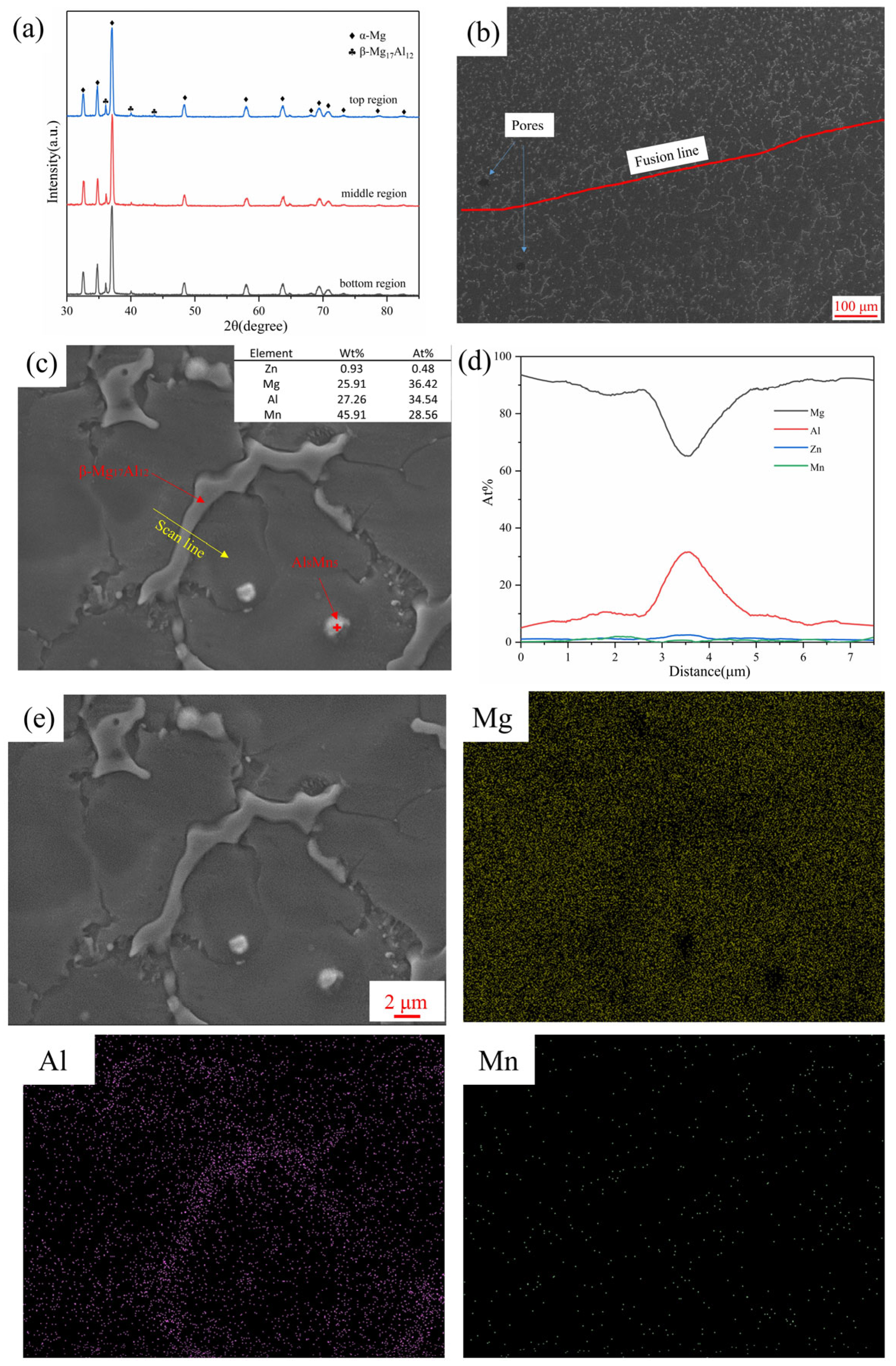

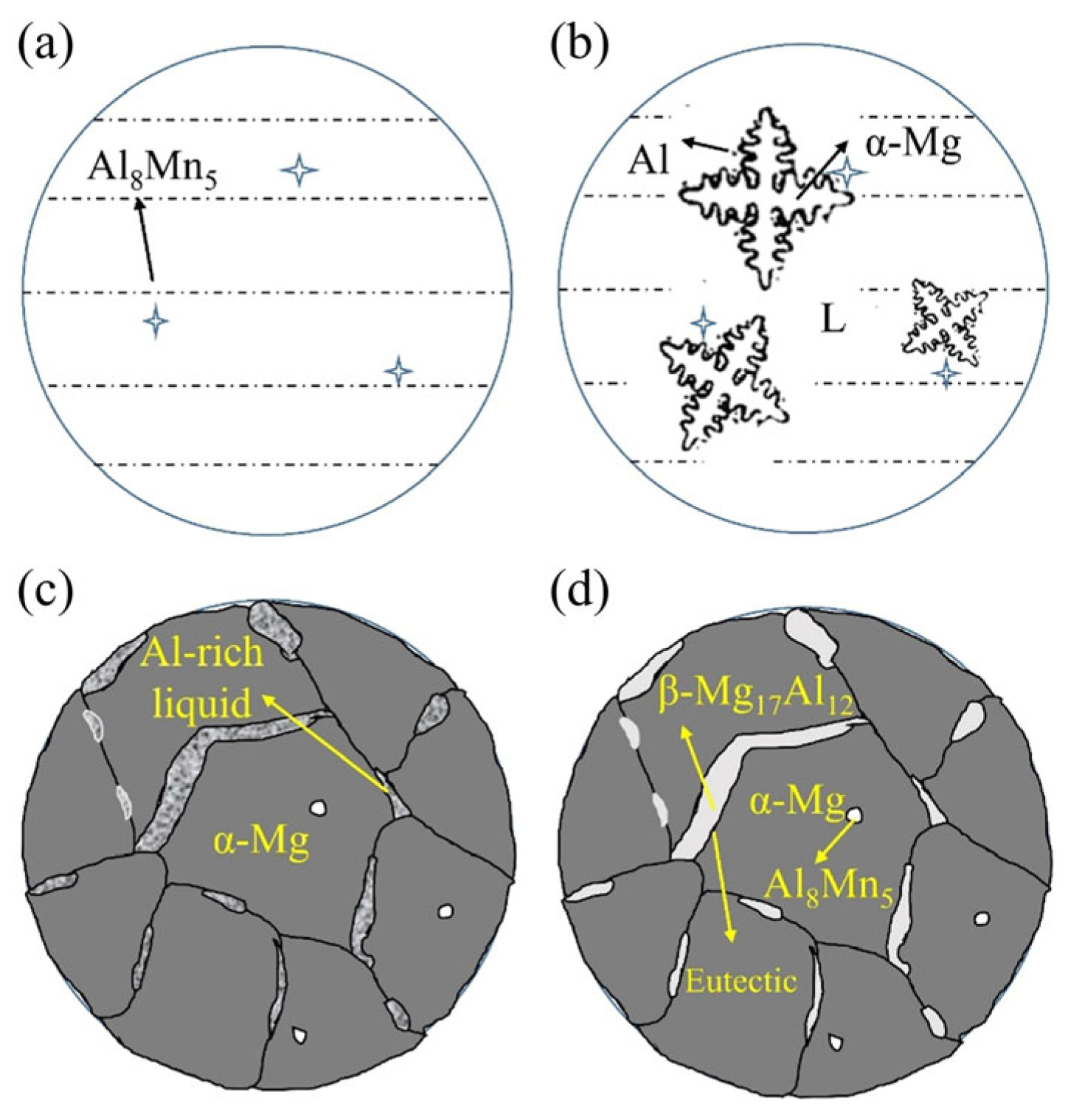

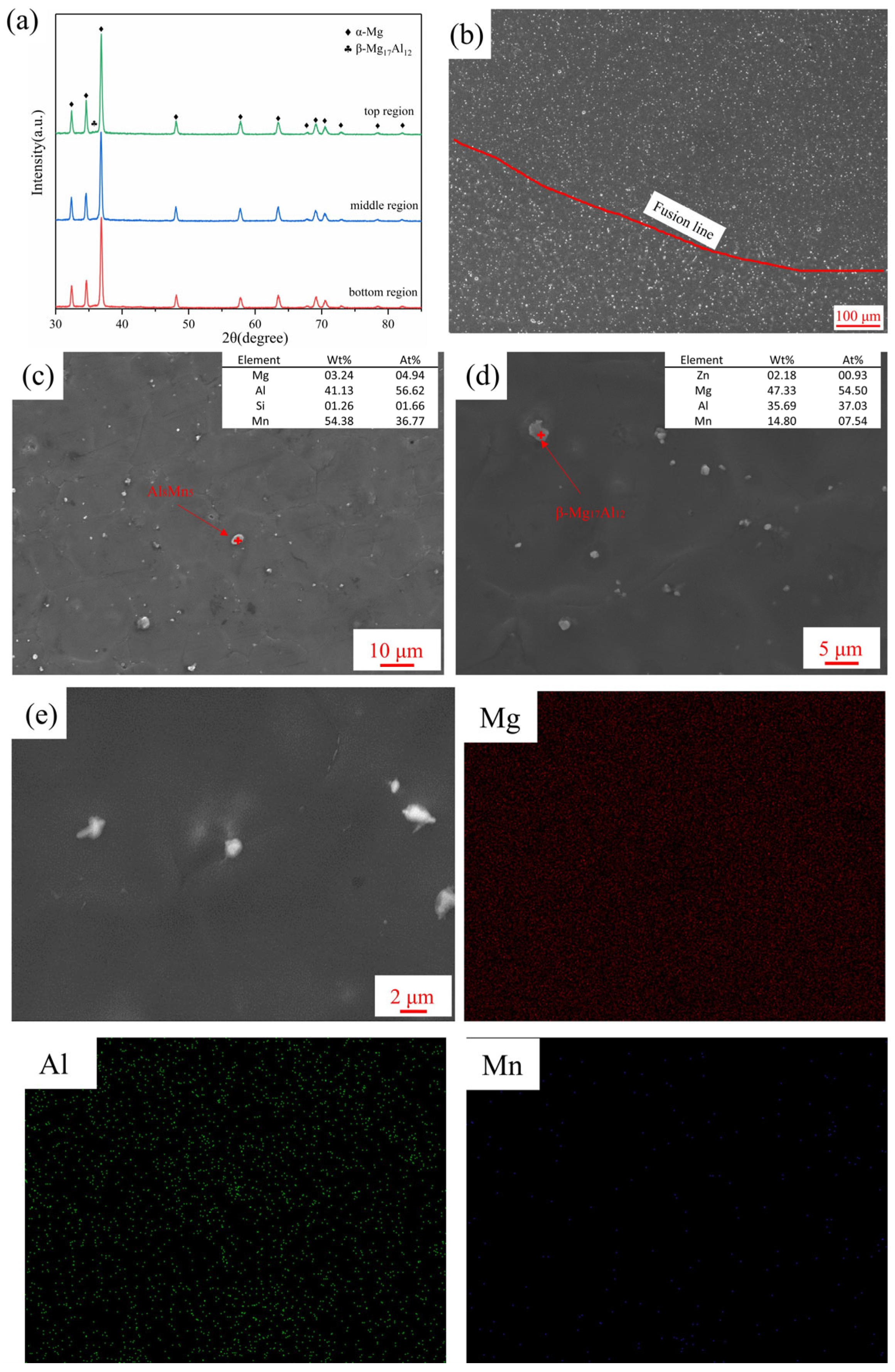

3.2. Microstructure

3.3. Mechanical Properties

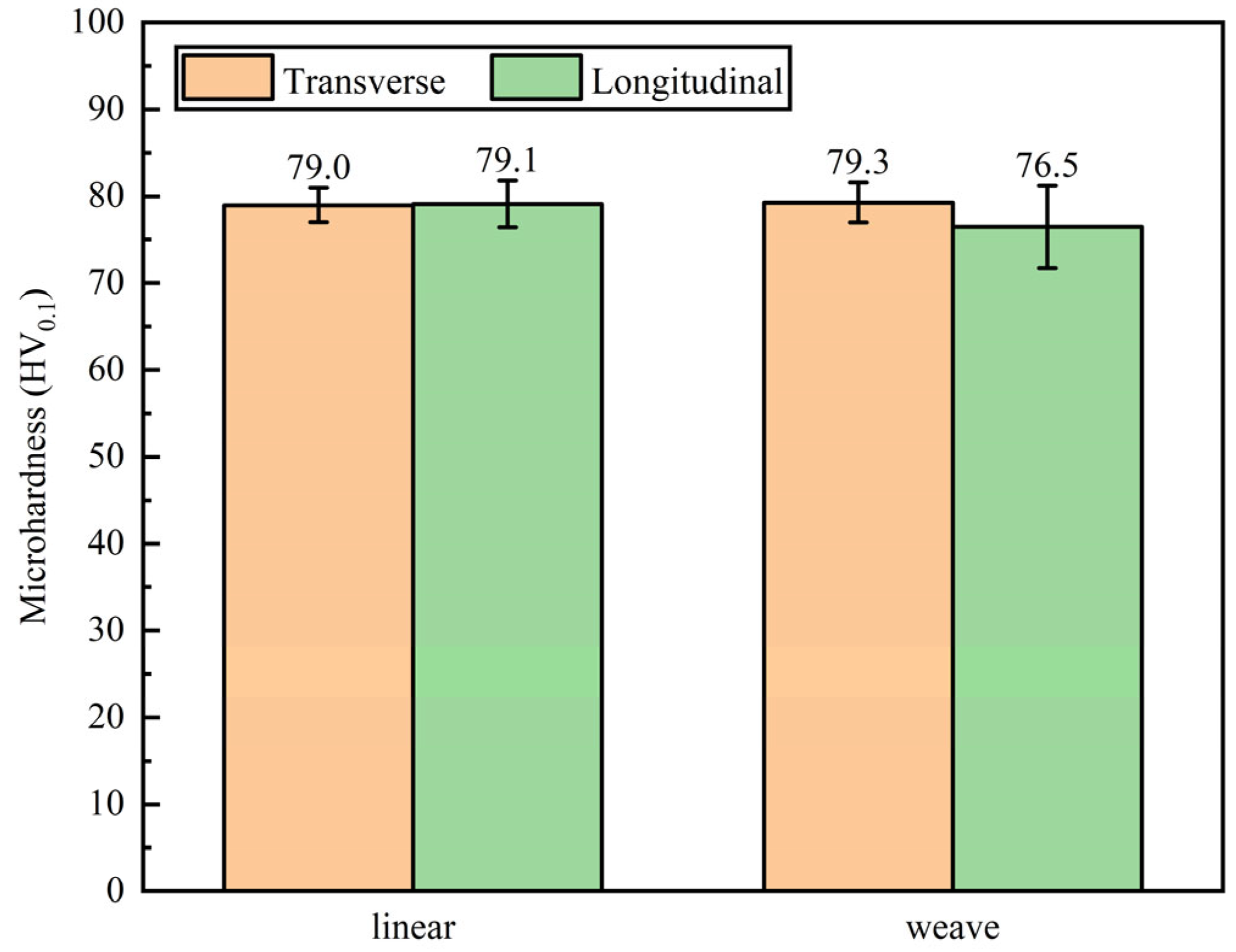

3.3.1. Microhardness

3.3.2. Tensile Properties

4. Conclusions

- (1)

- Compared with the linear arc deposition specimen, the effective width and effective rate was increased from 7.0 mm and 84.2% to 18.7 mm and 91.0%, respectively, by introducing the weaving arc.

- (2)

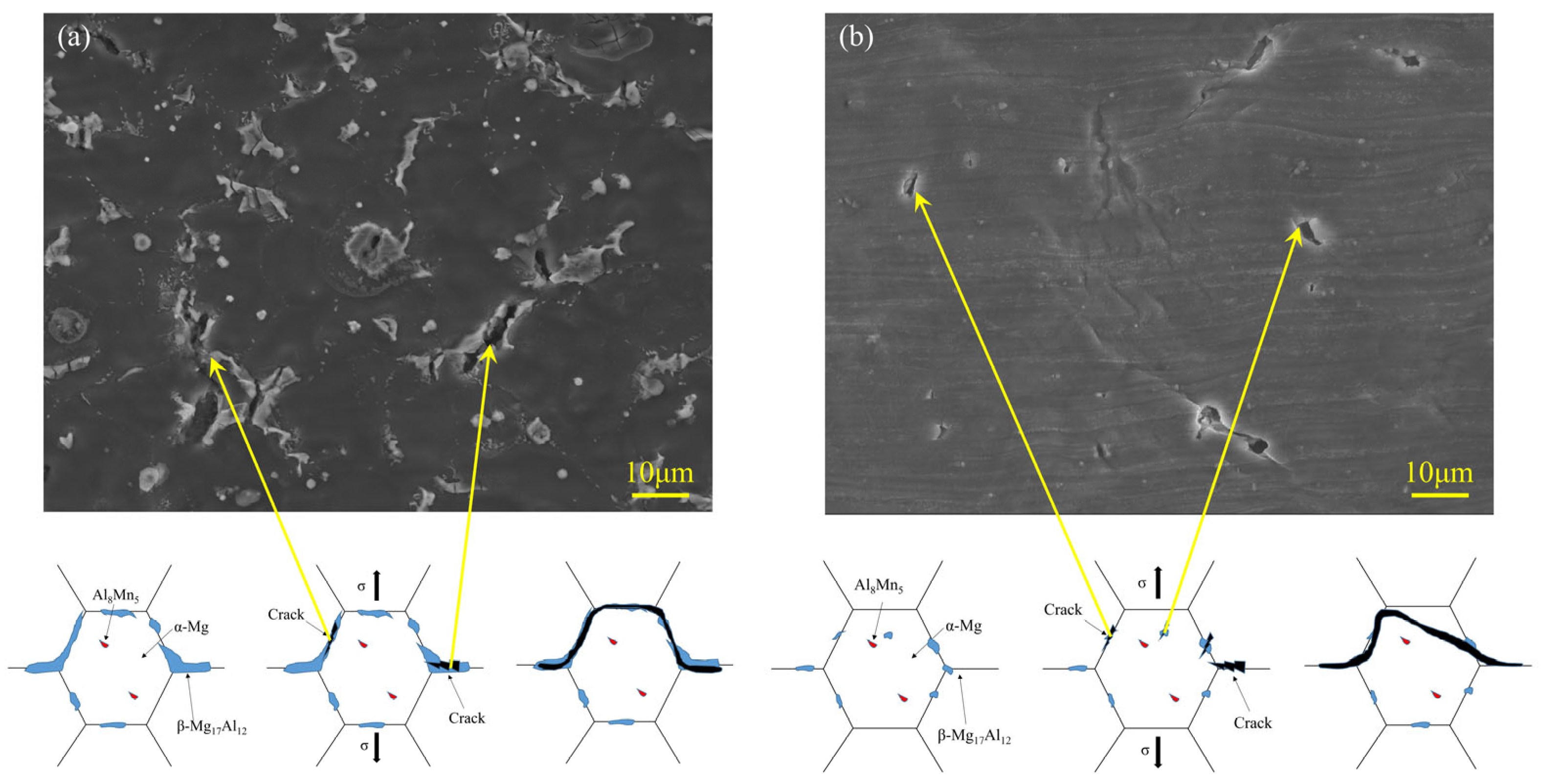

- The weaving arc deposition specimen was mainly composed of α-Mg grains and a fine β-Mg17Al12 phase spread fairly uniformly, as opposed to the linear arc deposition specimen, which included strip-like β-Mg17Al12 phase distributed at grain boundaries. The dendrite remelting caused the α-Mg grains more equiaxial when the weaving arc was introduced, the decrease in the temperature gradient of the molten pool and the increase in the degree of constitutional undercooling caused the β-Mg17Al12 phase to be refined and distributed uniformly.

- (3)

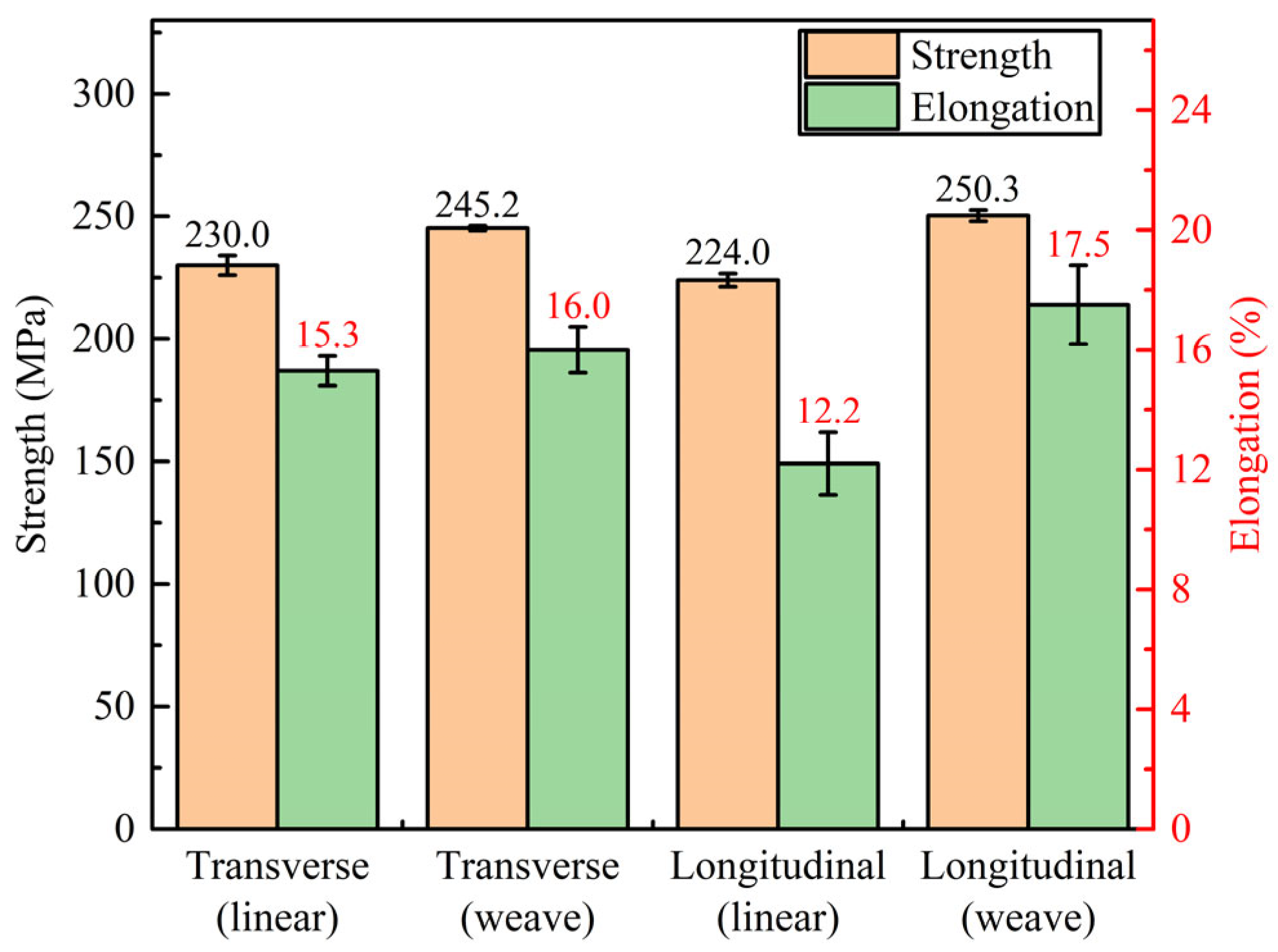

- There was no obvious anisotropy in the mechanical properties of both specimens without and with weaving arc. The tensile properties were similar to those of the diecast AZ91 magnesium alloy and were significantly higher than the as-cast AZ91 magnesium alloy. The ultimate tensile strength and elongation of the weaving arc deposition specimen were 17.0% and 21.7% higher than that of the linear arc deposition specimen. In summary, the weaving arc had a certain increase in the mechanical properties of the deposited wall.

- (4)

- The linear arc deposition specimen showed mixed fractures of ductile and brittle, while the weaving arc deposition specimen exhibited a distinguished ductile fracture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thirumalai, R.; Karthick, S.; Giriraj, M. Microstructural analysis and optimization of welding parameters for AA1100 welded plates. J. Ceram. Process. Res. 2022, 23, 221–227. [Google Scholar]

- Yi, H.; Wang, Q.; Cao, H.J. Wire-arc directed energy deposition of magnesium alloys: Microstructure, properties and quality optimization strategies. J. Mater. Res. Technol. 2022, 20, 627–649. [Google Scholar] [CrossRef]

- Asgari, A.; Delavar, H.; Sedighi, M. Microstructure and surface integrity of machined AZ91 magnesium alloy. J. Mater. Res. Technol. 2023, 22, 735–746. [Google Scholar] [CrossRef]

- Li, J.W.; Qiu, Y.M.; Yang, J.J.; Sheng, Y.Y.; Yi, Y.L.; Zeng, X.; Chen, L.X.; Yin, F.L.; Su, J.Z.; Zhang, T.J.; et al. Effect of grain refinement induced by wire and arc additive manufacture (WAAM) on the corrosion behaviors of AZ31 magnesium alloy in NaCl solution. J. Magnes. Alloy. 2023, 11, 217–229. [Google Scholar] [CrossRef]

- Wang, C.; Liu, T.G.; Zhu, P.; Lu, Y.H.; Shoji, T. Study on microstructure and tensile properties of 316L stainless steel fabricated by CMT wire and arc additive manufacturing. Mater. Sci. Eng. A 2020, 796, 140060. [Google Scholar] [CrossRef]

- Wang, P.; Hu, S.S.; Shen, J.Q.; Liang, Y. Characterization the contribution and limitation of the characteristic processing parameters in cold metal transfer deposition of an Al alloy. J. Mater. Process. Technol. 2017, 245, 122–133. [Google Scholar] [CrossRef]

- Zhao, G.C.; Wang, Z.J.; Hu, S.S.; Duan, S.H.; Chen, Y.Q. Effect of ultrasonic vibration of molten pool on microstructure and mechanical properties of Ti-6Al-4V joints prepared via CMT + P welding. J. Manuf. Process. 2020, 59, 193–202. [Google Scholar] [CrossRef]

- Wagner, D.C.; Yang, Y.K.; Kou, S. Spatter and porosity in gas-metal arc welding of magnesium alloys: Mechanisms and elimination. Weld. J. 2013, 92, 347–362. [Google Scholar]

- Rethmeier, M.; Kleinpeter, B.; Wohlfahrt, H. MIG welding of magnesium alloys metallographic aspects. Weld. World 2004, 48, 28–33. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Salehi, M.; Kopp, A.; Xu, S.W.; Esmaily, M.; Birbilis, N. Recent progress and perspectives in additive manufacturing of magnesium alloys. J. Magnes. Alloy. 2022, 10, 1511–1541. [Google Scholar] [CrossRef]

- Feng, J.C.; Zhang, H.T.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Guo, Y.Y.; Pan, H.H.; Ren, L.B.; Quan, G.F. Microstructure and mechanical properties of wire arc additively manufactured AZ80M magnesium alloy. Mater. Lett. 2019, 247, 4–6. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.R.; Wang, Z.N.; Lin, X.; Liu, F.C.; Huang, W.D.; Liang, E.Q. Microstructure and mechanical properties of wire and arc additive manufactured AZ31 magnesium alloy using cold metal transfer process. Mater. Sci. Eng. A 2020, 774, 138942. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, H.Z.; Zhu, H.; Li, Q.Z.; Feng, M.N. Wire-arc additive manufacturing of AZ31 magnesium alloy fabricated by cold metal transfer heat source: Processing, microstructure, and mechanical behavior. J. Mater. Process. Technol. 2021, 288, 116895. [Google Scholar] [CrossRef]

- Klein, T.; Arnoldt, A.; Schnall, M.; Gneiger, S. Microstructure formation and mechanical properties of a wire-arc additive manufactured magnesium alloy. JOM 2021, 73, 1126–1134. [Google Scholar] [CrossRef]

- Zhu, C.X.; Cheon, J.; Tang, X.H.; Na, S.J.; Lu, F.G.; Cui, H.C. Effect of swing arc on molten pool behaviors in narrow-gap GMAW of 5083 Al-alloy. J. Mater. Process. Technol. 2018, 259, 243–258. [Google Scholar] [CrossRef]

- Mahajan, S.; Biradar, N.S.; Raman, R.; Mishra, S. Effect of mechanical arc oscillation on the grain structure of mild steel weld metal. Trans. Indian Inst. Met. 2012, 65, 171–177. [Google Scholar] [CrossRef]

- Biradar, N.S.; Raman, R. Grain refinement in Al-Mg-Si alloy TIG welds using transverse mechanical arc oscillation. J. Mater. Eng. Perform. 2012, 21, 2495–2502. [Google Scholar] [CrossRef]

- Wei, Y.H.; Liu, F.C.; Liu, F.G.; Yu, D.; You, Q.F.; Huang, C.P.; Wang, Z.T.; Jiang, W.G.; Lin, X.; Hu, X.A. Effect of arc oscillation on porosity and mechanical properties of 2319 aluminum alloy fabricated by CMT-wire arc additive manufacturing. J. Mater. Process. Technol. 2023, 24, 3477–3490. [Google Scholar] [CrossRef]

- Liu, K.; Yan, Z.Y.; Wang, F.D.; Li, K.X.; Lin, S.B.; Chen, S.J. Microstructure, texture and mechanical properties of Inconel GH4169 superalloy fabricated by wire arc additive manufacturing with arc oscillation. J. Alloy. Compd. 2023, 952, 170070. [Google Scholar] [CrossRef]

- Cao, Q.H.; Qi, B.J.; Zeng, C.Y.; Zhang, R.Z.; He, B.C.; Qi, Z.W.; Wang, F.D.; Wang, H.B.; Cong, B.Q. Achieving equiaxed microstructure and isotropic mechanical properties of additively manufactured AZ31 magnesium alloy via ultrasonic frequency pulsed arc. J. Alloy. Compd. 2022, 909, 164742. [Google Scholar] [CrossRef]

- Yuan, T.; Luo, Z.; Kou, S. Grain refining of magnesium welds by arc oscillation. Acta Mater. 2016, 116, 166–176. [Google Scholar] [CrossRef]

- Subravel, V.; Alagappan, N.; Babu, N. Influence of arc oscillation frequency on tensile properties and microstructural characteristics of magnetic arc oscillation welded AZ31B magnesium alloy joints. Mater. Today: Proc. 2020, 22, 606–613. [Google Scholar] [CrossRef]

- Bi, J.; Shen, J.Q.; Hu, S.S.; Zhen, Y.H.; Yin, F.L.; Bu, X.Z. Microstructure and mechanical properties of AZ91 Mg alloy fabricated by cold metal transfer additive manufacturing. Mater. Lett. 2020, 276, 128185. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Chen, Y.W.; Li, P.J.; Male, A.T. Weld deposition-based rapid prototyping: A preliminary study. J. Mater. Process. Technol. 2003, 135, 347–357. [Google Scholar] [CrossRef]

- Zhen, Y.H.; Shen, J.Q.; Hu, S.S.; Yin, C.X.; Yin, F.L.; Bu, X.Z. Effect of rotation rate on microstructure and mechanical properties of CMT cladding layer of AZ91 magnesium alloy fabricated by friction stir processing. J. Manuf. Process. 2022, 79, 553–561. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.F.; Gao, M.; Zeng, X.Y. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Corradi, D.R.; Bracarense, A.Q.; Wu, B.T.; Cuiuri, D.; Pan, Z.X.; Li, H.J. Effect of Magnetic Arc Oscillation on the geometry of single-pass multi-layer walls and the process stability in wire and arc additive manufacturing. J. Mater. Process. Technol. 2020, 283, 116723. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, F.; Chen, S.J.; Lu, Z.Y. Unit block-based process planning strategy of WAAM for complex shell–shaped component. Int. J. Adv. Manuf. Technol. 2019, 104, 3915–3927. [Google Scholar] [CrossRef]

- Bultman, J.; Saldaña, C. Effects of weave path parameters on the geometry of wire arc additive manufactured features. Int. J. Adv. Manuf. Technol. 2023, 124, 2563–2577. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Zhang, W.; Zuback, J.S.; Knapp, G.L.; De, A.; DebRoy, T. Mechanistic models for additive manufacturing of metallic components. Prog. Mater. Sci. 2021, 116, 100703. [Google Scholar] [CrossRef]

- Wei, K.W.; Gao, M.; Wang, Z.M.; Zeng, X.Y. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy. Mater. Sci. Eng. A 2014, 611, 212–222. [Google Scholar] [CrossRef]

- Lee, Y.C.; Dahle, A.K.; StJohn, D.H. The role of solute in grain refinement of magnesium. Metall. Mater. Trans. A 2000, 31, 2895–2906. [Google Scholar] [CrossRef]

- StJohn, D.H.; Qian, M.; Easton, M.A.; Cao, P.; Hildebrand, Z. Grain refinement of magnesium alloys. Metall. Mater. Trans. A 2005, 36, 1669–1679. [Google Scholar] [CrossRef]

- Paliwal, M.; Jung, I.H. Solid/liquid interfacial energy of Mg-Al alloys. Metall. Mater. Trans. A 2013, 44, 1636–1640. [Google Scholar] [CrossRef]

- Koike, J.; Ohyama, R. Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature. Acta Mater. 2005, 53, 1963–1972. [Google Scholar] [CrossRef]

- Zhang, H.J.; Wu, M.H.; Rodrigues, C.M.G.; Ludwig, A.; Kharicha, A.; Rónaföldi, A.; Roósz, A.; Veres, Z.; Svéda, M. Dendrite fragmentation mechanism under forced convection condition by rotating magnetic field during unidirectional solidification of AlSi7 alloy. Acta Mater. 2022, 241, 118391. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Liang, A.Q.; Pey, K.S.; Polcar, T.; Hamilton, A.R. Effects of rescanning parameters on densification and microstructural refinement of 316L stainless steel fabricated by laser powder bed fusion. J. Mater. Process. Technol. 2022, 302, 117493. [Google Scholar] [CrossRef]

- Fisher, C.R.; Bechetti, D.H.; Sinfield, M.F. Comparison of analytical, empirical, and finite-element modeling of weld metal cooling as function of plate orientation, thickness, and heat input. J. Manuf. Process. 2021, 62, 471–482. [Google Scholar] [CrossRef]

- Zhou, B.F.; Lin, W.H.; Liu, Y.; Zheng, T.X.; Zhong, Y.B.; Wang, H.; Wang, Q.L. Effects of high static magnetic field on the microstructure of Zn-Bi monotectic alloys during directional solidification process. J. Alloy. Compd. 2021, 889, 161670. [Google Scholar] [CrossRef]

- Tiller, W.A.; Jackson, K.A.; Rutter, J.W.; Chalmers, B. The redistribution of solute atoms during the solidification of metals. Acta Mater. 1953, 1, 428–437. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X.Y. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Wang, L.W.; Suo, Y.C.; Liang, Z.M.; Wang, D.L.; Wang, Q. Effect of titanium powder on microstructure and mechanical properties of wire + arc additively manufactured Al-Mg alloy. Mater. Lett. 2019, 241, 231–234. [Google Scholar] [CrossRef]

- Cai, X.Y.; Chen, F.K.; Dong, B.L.; Lin, S.B.; Yang, C.L. Microstructure and mechanical properties of GTA-based wire arc additive manufactured AZ91D magnesium alloy. J. Magnes. Alloy. 2022; in press. [Google Scholar] [CrossRef]

| Material | Al | Zn | Mn | Si | Fe | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| Substrate | 8.70 | 0.58 | 0.24 | 0.02 | 0.002 | 0.005 | 0.001 | Bal. |

| Wire | 8.99 | 0.65 | 0.26 | 0.037 | 0.0018 | 0.0025 | 0.00043 | Bal. |

| Material | Ultimate Tensile Strength (MPa) | Elongation (%) | Anisotropy (%) | ||

|---|---|---|---|---|---|

| Transverse | Longitudinal | Transverse | Longitudinal | ||

| GTAW-WAAM [45] | 243.7 | 243.5 | 11.7 | 11.5 | 0.08 |

| CMT-WAAM | 230.0 | 224.0 | 15.3 | 12.2 | 2.68 |

| CMT-WAAM by weaving arc | 245.2 | 250.3 | 16.0 | 17.5 | 2.08 |

| As-Cast (Substrate) | 124.0 | 1.0 | - | ||

| Die-Cast (Standard ASTM B94-18) | 230.0 | 3.0 | - | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Shen, J.; Bi, J.; Hu, S.; Zhen, Y.; Bu, X. Microstructure and Mechanical Properties of Weaving Wire and Arc Additive Manufactured AZ91 Magnesium Alloy Based on Cold Metal Transfer Technique. Materials 2023, 16, 4047. https://doi.org/10.3390/ma16114047

Zhang Z, Shen J, Bi J, Hu S, Zhen Y, Bu X. Microstructure and Mechanical Properties of Weaving Wire and Arc Additive Manufactured AZ91 Magnesium Alloy Based on Cold Metal Transfer Technique. Materials. 2023; 16(11):4047. https://doi.org/10.3390/ma16114047

Chicago/Turabian StyleZhang, Zhongrui, Junqi Shen, Ji Bi, Shengsun Hu, Yahui Zhen, and Xianzheng Bu. 2023. "Microstructure and Mechanical Properties of Weaving Wire and Arc Additive Manufactured AZ91 Magnesium Alloy Based on Cold Metal Transfer Technique" Materials 16, no. 11: 4047. https://doi.org/10.3390/ma16114047

APA StyleZhang, Z., Shen, J., Bi, J., Hu, S., Zhen, Y., & Bu, X. (2023). Microstructure and Mechanical Properties of Weaving Wire and Arc Additive Manufactured AZ91 Magnesium Alloy Based on Cold Metal Transfer Technique. Materials, 16(11), 4047. https://doi.org/10.3390/ma16114047