A Temperature-Dependent Viscoplasticity Model for the Hot Work Steel X38CrMoV5-3, Including Thermal and Cyclic Softening under Thermomechanical Fatigue Loading

Abstract

1. Introduction

1.1. Softening Mechanisms in Martensitic Steels

1.2. Plasticity Models for Martensitic Steels Including Softening

1.3. Aims and Structure of the Paper

2. Materials and Methods

2.1. Material

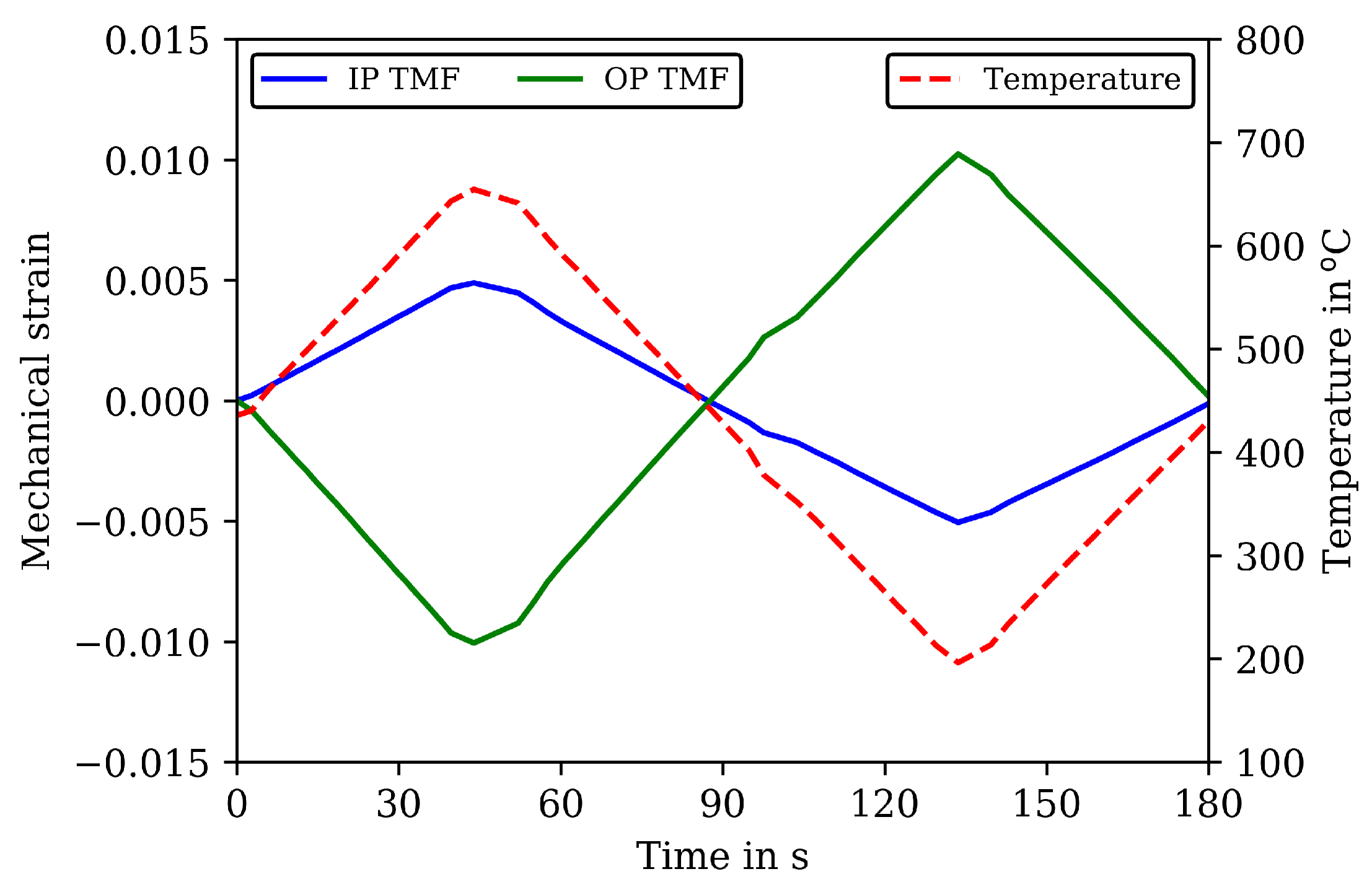

2.2. Isothermal and Thermomechanical Low-Cycle Fatigue Tests

3. The Viscoplasticity Model Including Thermal and Cyclic Softening

3.1. The Base Model

3.2. The New Cyclic Softening Model

3.3. The Kinetic Model Describing Thermal Softening

4. Results

- Step 1:

- Determination of individual material properties on the basis of the complex part of the CLCF tests neglecting thermal and cyclic softening.The initial loading cycles of the CLCF tests are considered, assuming that cyclic softening is not significant during the initial cycles. From that data, the temperature-dependent material properties are determined for HT0, HT1, and HT2 individually.

- Step 2:

- Determination of functional dependencies of the material properties from thermal and cyclic softening on the basis of the full CLCF and TMF tests.The material properties for the cyclic-softening model (Section 3.2) are determined from all cycles of the CLCF and TMF tests and the functional dependencies of the material properties on normalized carbide size z are derived. All cycles of the CLCF and TMF tests are computed with the viscoplasticity model including thermal and cyclic softening.

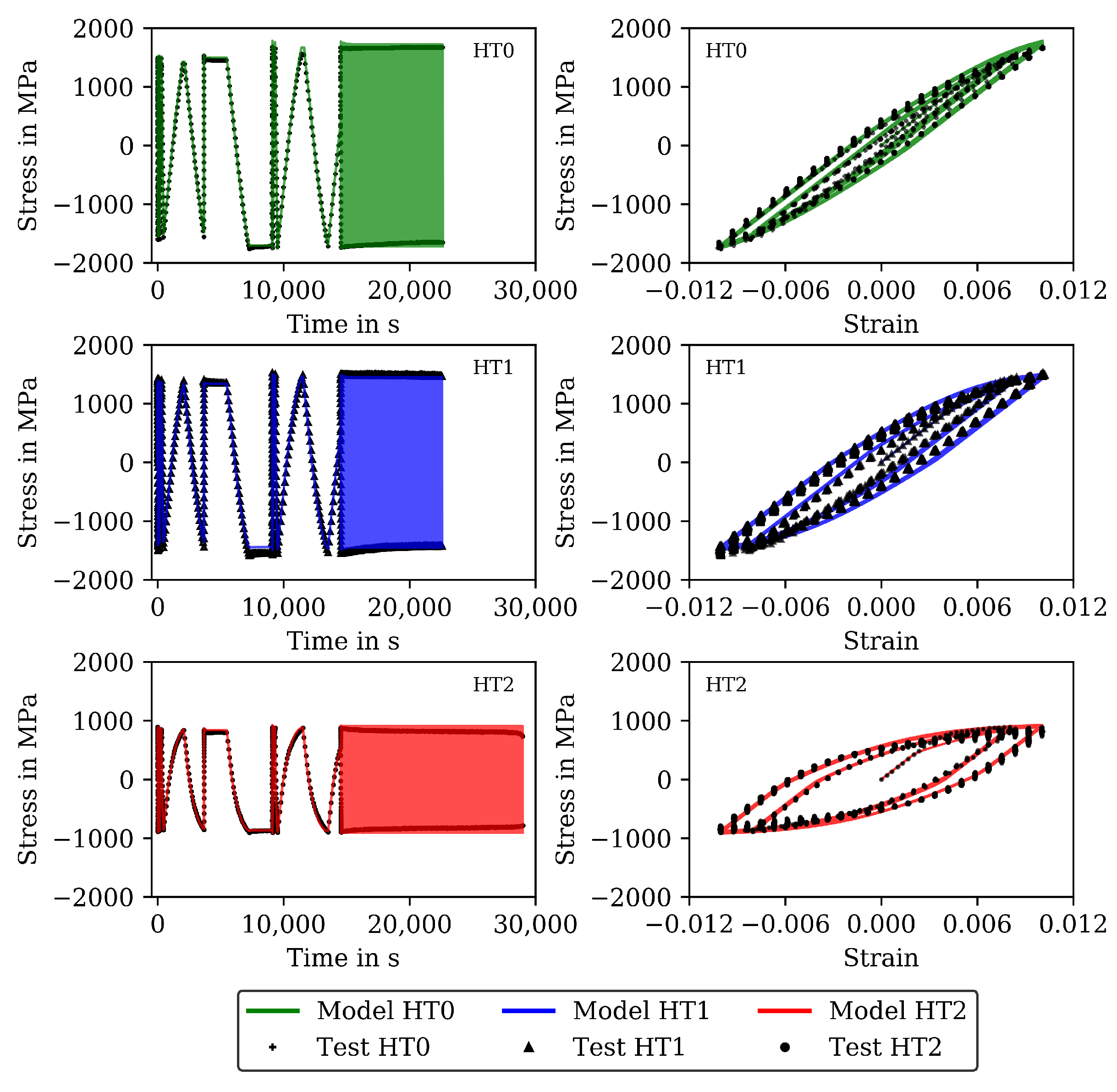

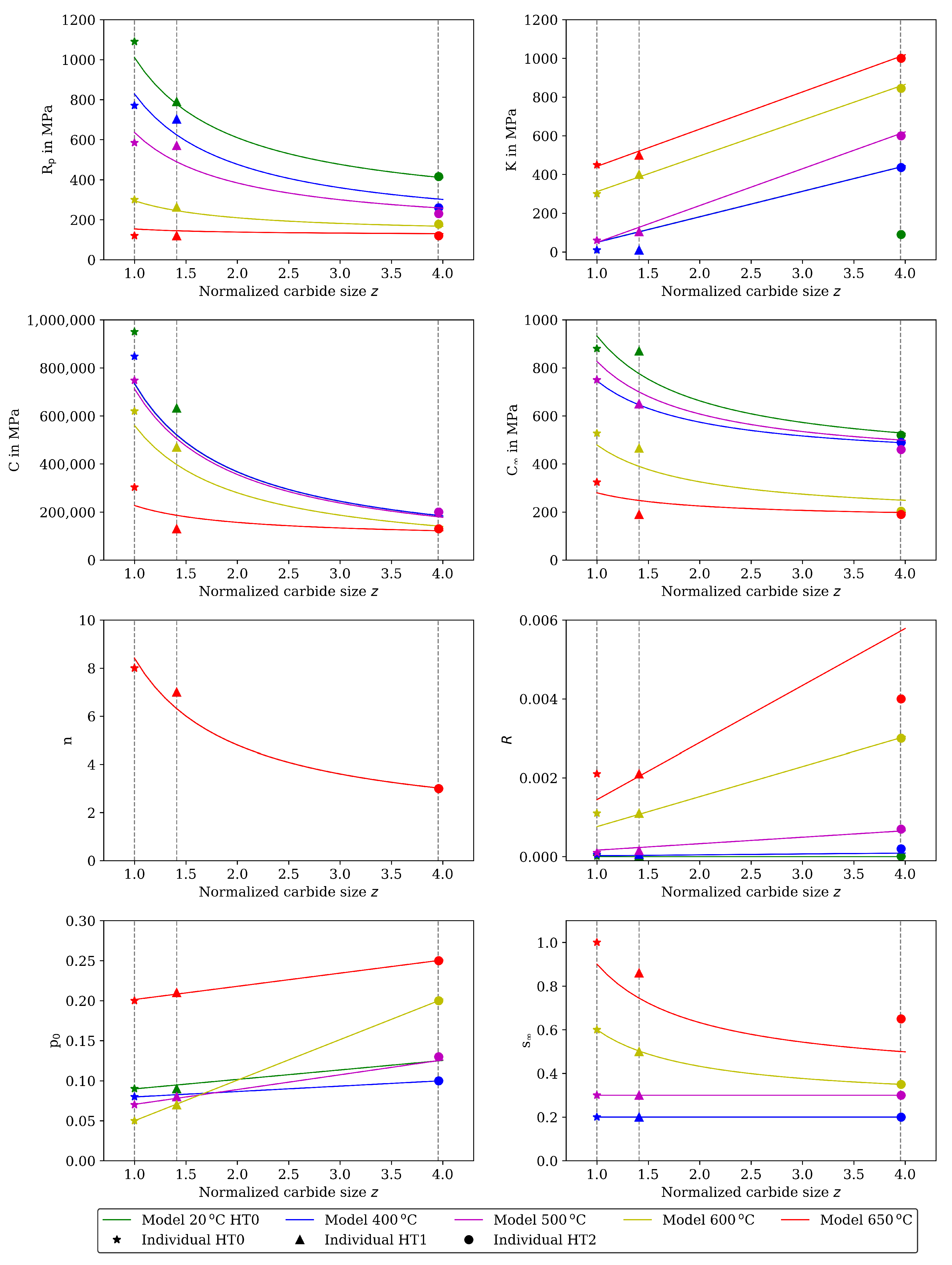

4.1. Step 1: Material Properties for the Initial Behavior Neglecting Thermal and Cyclic Softening

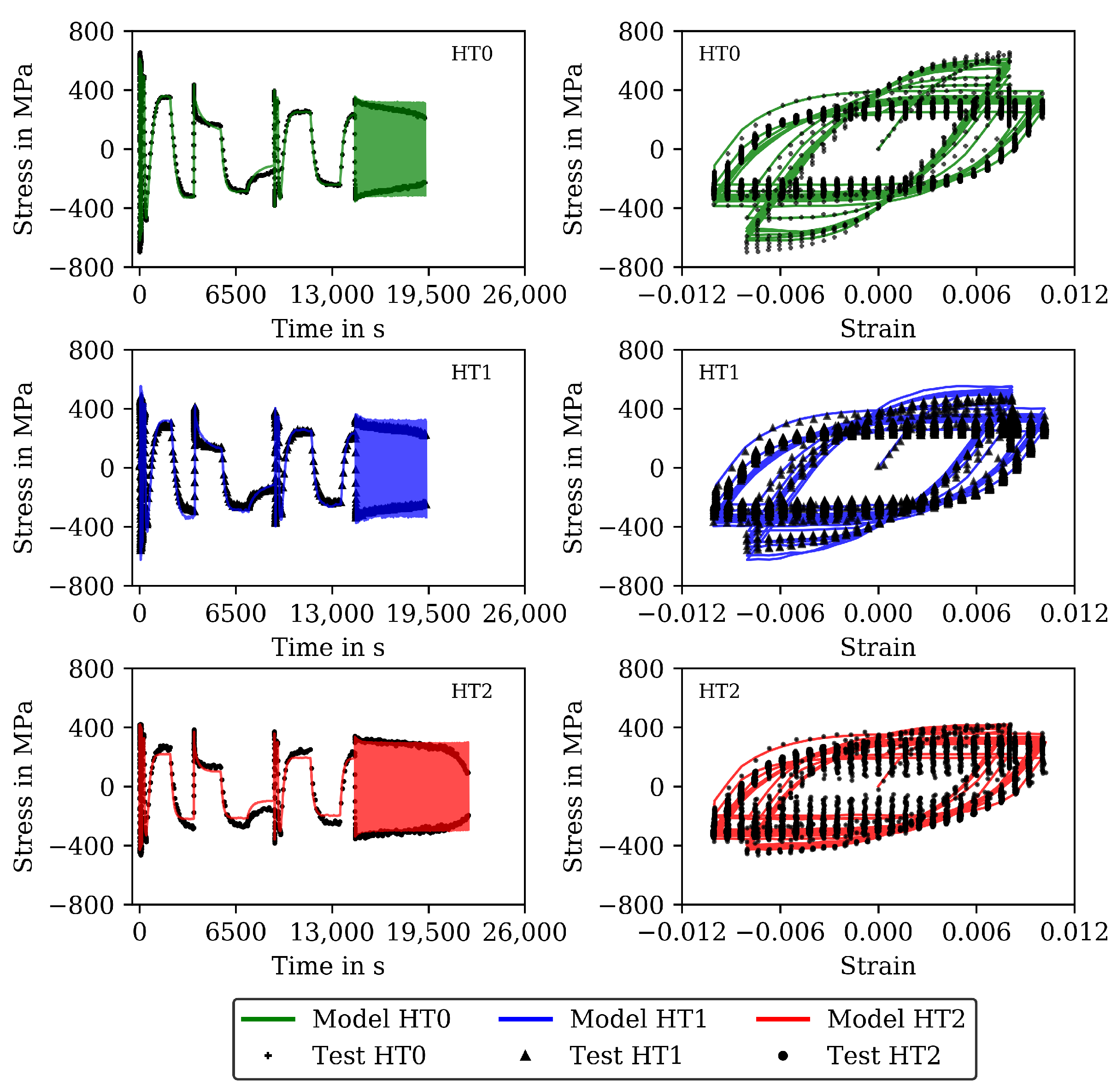

4.2. Step 2: Material Properties for the Full Behavior Including Thermal and Cyclic Softening

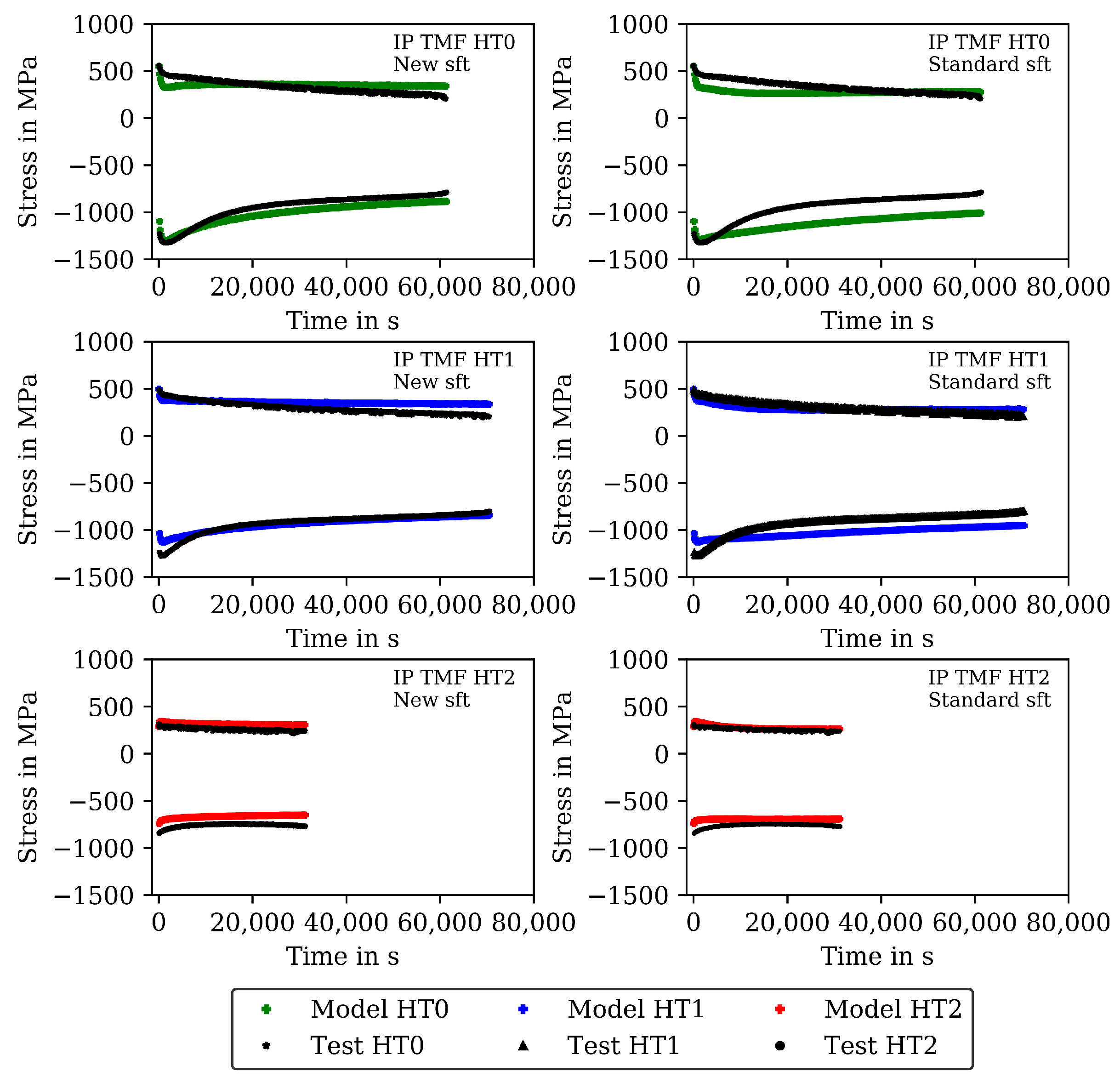

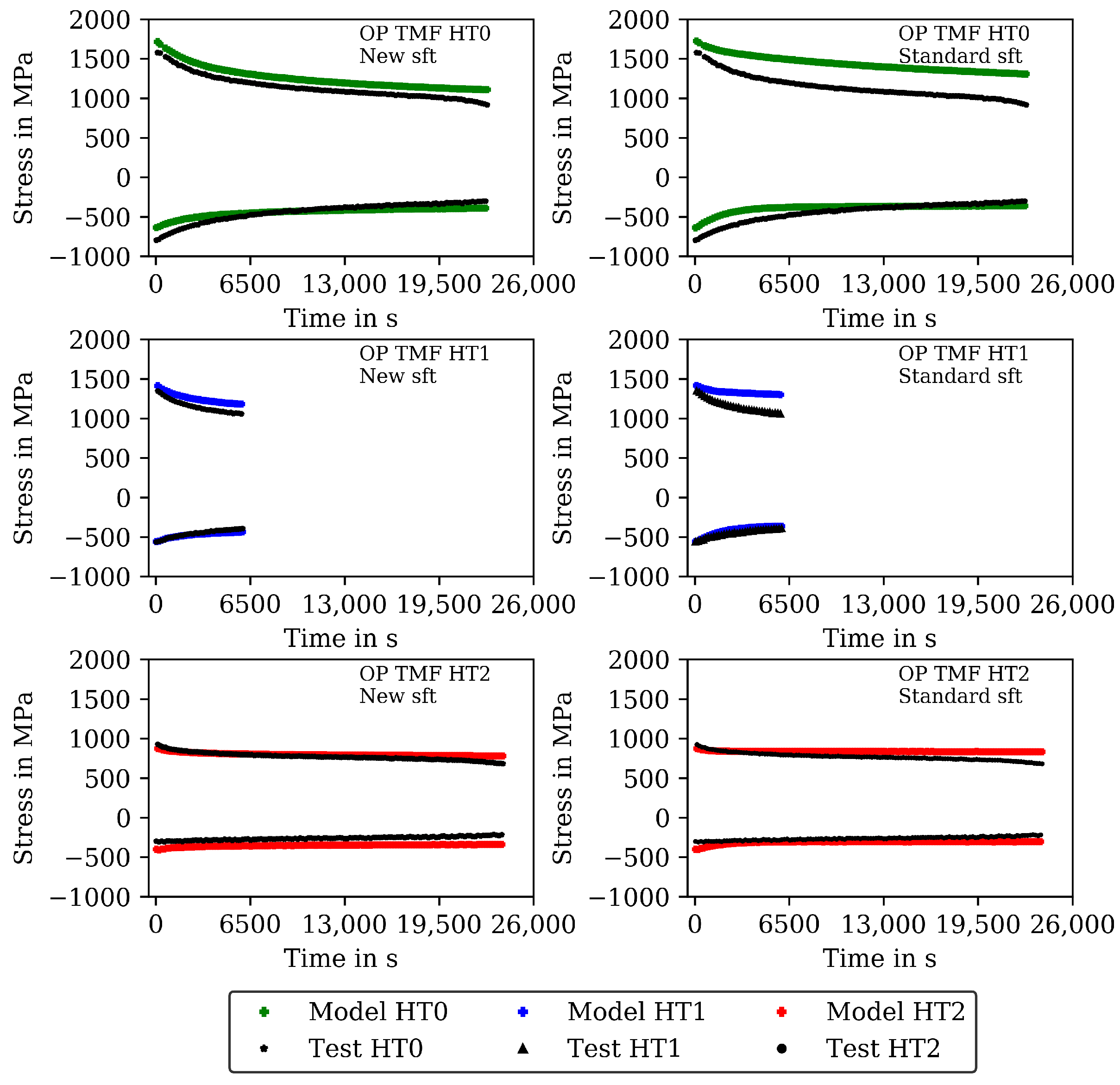

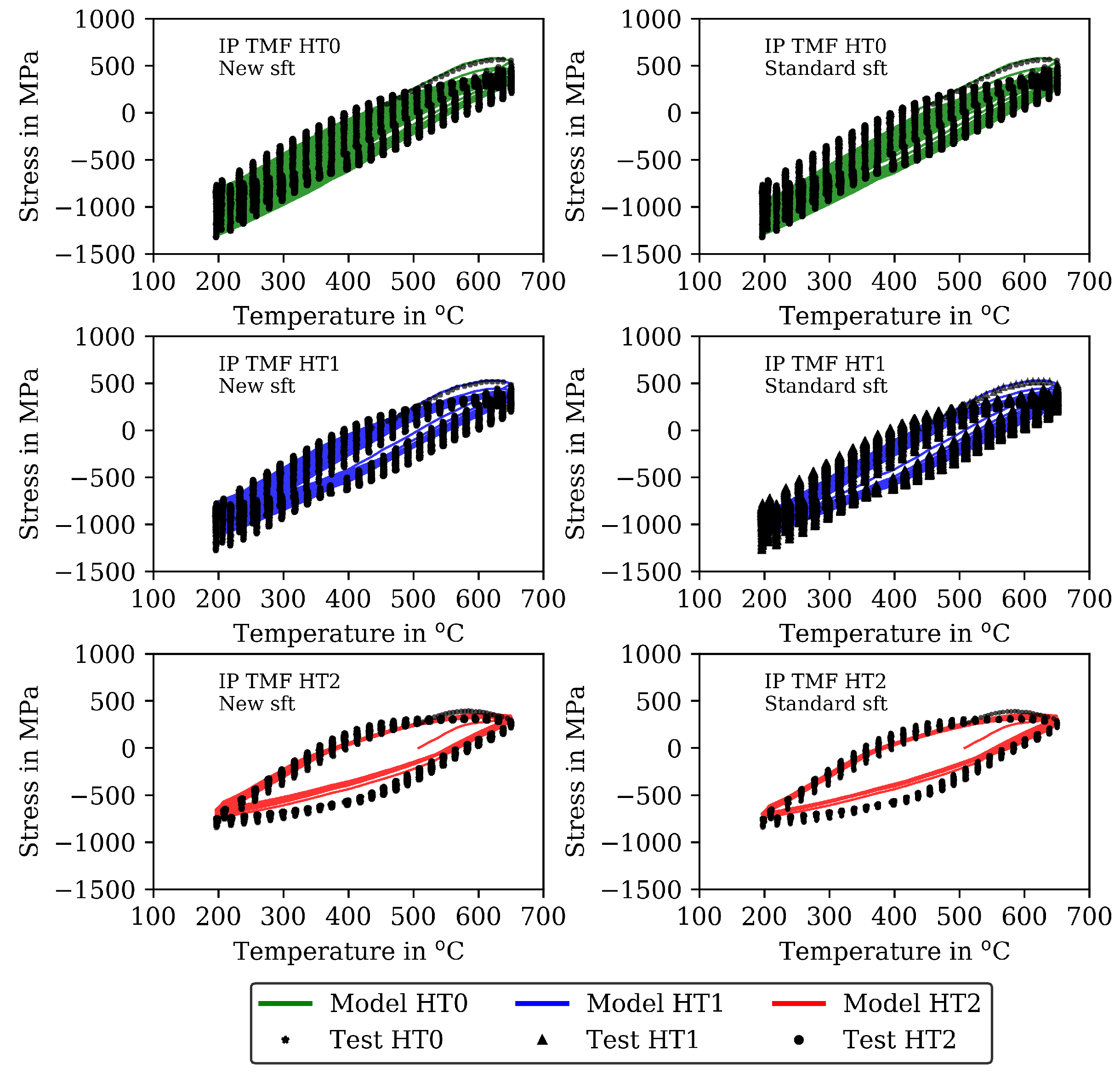

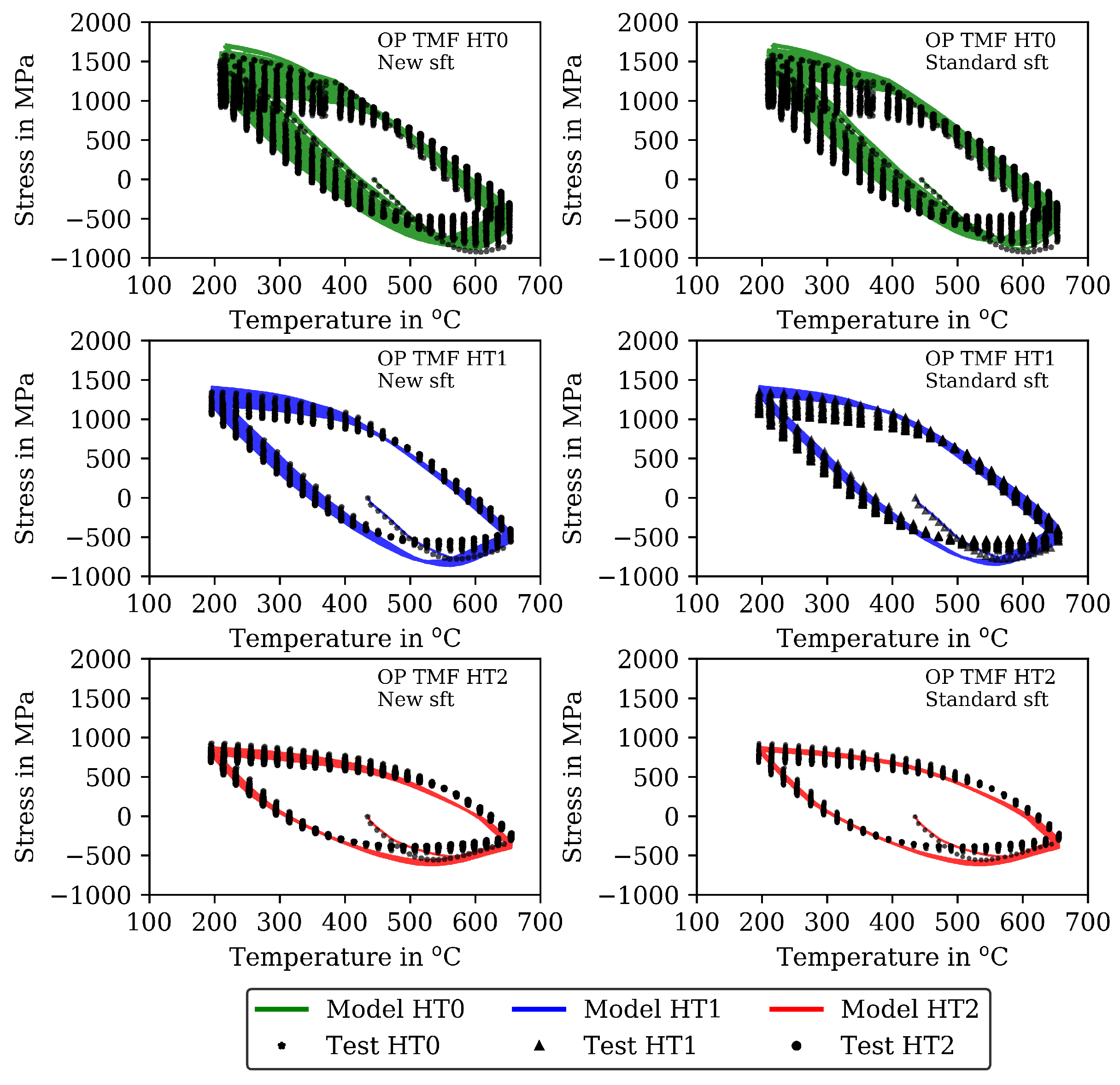

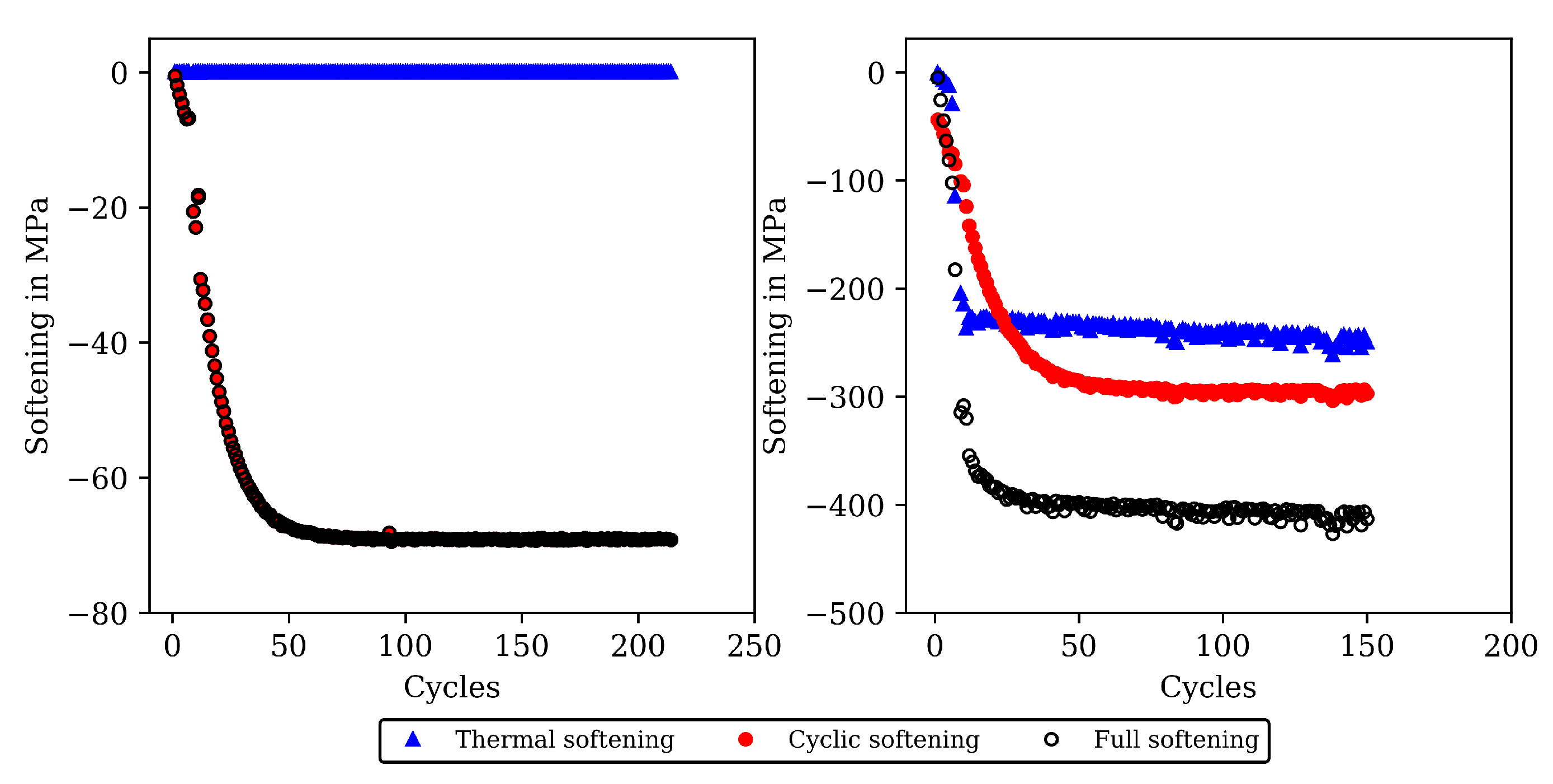

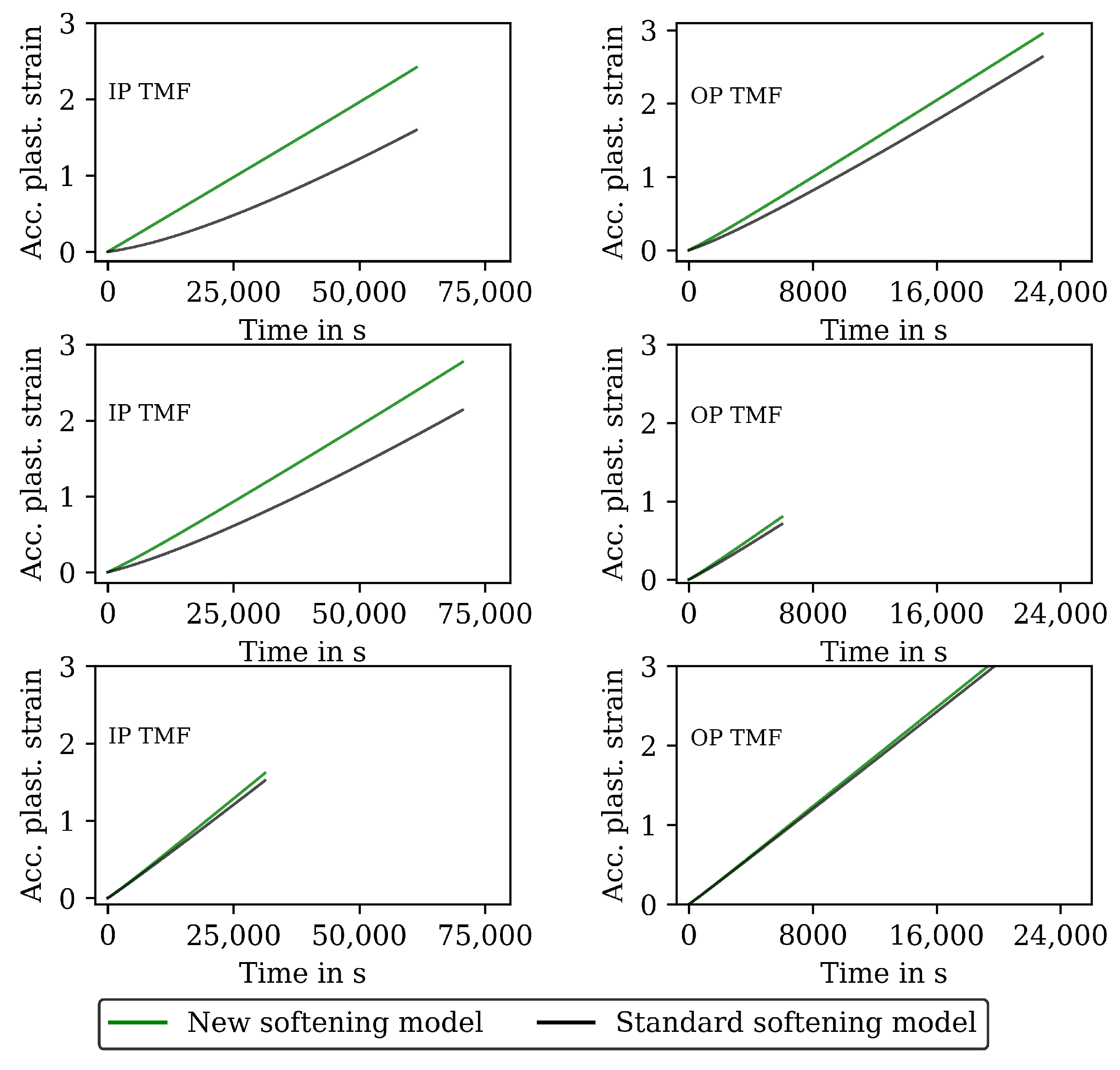

4.3. Comparison of TMF Results with Standard- and New Cyclic-Softening Model

5. Discussion

5.1. Experimental Data and Material Properties

5.2. Thermal-Softening and Cyclic-Softening Model

5.3. Microstructure-Related Aspects

5.4. Future Works

6. Conclusions

- The experimental results of the CLCF and TMF tests show a significant effect of heat treatment, i.e., thermal softening, as well as cyclic softening during the test on the mechanical properties, especially in the CLCF tests at higher temperatures and the TMF tests. The designed test program has proven to be efficient for the determination of the material properties of the proposed viscoplasticity model.

- The investigated steel has wide application in processes where heat resistance, hardness, and heat toughness are required. The model can be transferred to materials that show the same phenomena under TMF, e.g., steels in power-generation applications. An efficient determination of the material properties on basis of experimental results is possible due to the phenomenological modelling approach.

- A new cyclic-softening model is derived that describes history effects found during thermomechanical loading. The cyclic-softening model describes the evolution of a softening variable s for isothermal and thermomechancial conditions.

- A stepwise, experience-based approach is presented to determine the material properties and their functional dependency on the size of secondary carbides controlling thermal softening based on the isothermal CLCF tests. For the determination of the material properties of the new cyclic-softening model, the results of the TMF tests showing the history effect needs to be employed. A calibration of the model without TMF tests is, hence, not possible.

- The viscoplasticity models and the determined temperature-dependent material properties give a good overall description of the complete data from CLCF and TMF tests with different heat treatments.

- A three-dimensional formulation of the viscoplasticity model can be obtained by using the von Mises yield criterion with kinematic hardening and is well suited for finite-element implementation to assess the thermomechanical behavior and fatigue life of hot work tools.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Doege, E.; Behrens, B.A. Handbuch Umformtechnik: Grundlagen, Technologien, Maschinen, 3. aufl. 2016 ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Behrens, B.A.; Bouguecha, A.; Vucetic, M.; Bonhage, M.; Malik, I. Numerical Investigation for the Design of a Hot Forging Die with Integrated Cooling Channels. Procedia Technol. 2016, 26, 51–58. [Google Scholar] [CrossRef]

- Behrens, B.A.; Rosenbusch, D.; Wester, H.; Siring, J. Numerical investigations on stresses and temperature development of tool dies during hot forging. Key Eng. Mater. 2022, 926, 559–568. [Google Scholar] [CrossRef]

- Ebara, R. Fatigue crack initiation and propagation behavior of forging die steels. Int. J. Fatigue 2010, 32, 830–840. [Google Scholar] [CrossRef]

- Behrens, B.A.; Huskic, A.; Rosenbusch, D.; Peddinghaus, J.; Wester, H.; Siegmund, M.; Giedenbacher, J.; Siring, J. Design, Characterisation and Numerical Investigations of Additively Manufactured H10 Hybrid-Forging Dies with Conformal Cooling Channels. Metals 2022, 12, 1063. [Google Scholar] [CrossRef]

- Behrens, B.A.; Schäfer, F. Service Life Predictions for Hot Bulk Forming Tools. In Steel Research International; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Vlasov, A.V. Thermomechanical fatigue of dies for hot stamping. Steel Transl. 2016, 46, 356–360. [Google Scholar] [CrossRef]

- Aktaa, J.; Petersen, C. Challenges in the constitutive modeling of the thermo-mechanical deformation and damage behavior of EUROFER 97. Eng. Fract. Mech. 2009, 76, 1474–1484. [Google Scholar] [CrossRef]

- Seifert, T.; Schweizer, C.; Schlesinger, M.; Möser, M.; Eibl, M. Thermomechanical fatigue of 1.4849 cast steel—Experiments and life prediction using a fracture mechanics approach. Int. J. Mater. Res. 2010, 101, 942–950. [Google Scholar] [CrossRef]

- Ohmenhäuser, F.; Schwarz, C.; Thalmair, S.; Evirgen, H.S. Constitutive modeling of the thermo-mechanical fatigue and lifetime behavior of the cast steel 1.4849. Mater. Des. 2014, 64, 631–639. [Google Scholar] [CrossRef]

- Wagner, M.; Decker, M. Simulation of Thermo-mechanical Deformation Behavior and Lifetime of a Nickel-base Alloy. Procedia Eng. 2015, 133, 272–281. [Google Scholar] [CrossRef]

- Mao, J.; Engler-Pinto, C.C.; Li, T.; Hsieh, J.; Su, X. Effect of Constitutive Model on Thermomechanical Fatigue Life Prediction. Procedia Eng. 2015, 133, 655–668. [Google Scholar] [CrossRef]

- Bartošák, M. Constitutive modelling for isothermal low-cycle fatigue and fatigue-creep of a martensitic steel. Mech. Mater. 2021, 162, 104032. [Google Scholar] [CrossRef]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Chaboche, J.L. Cyclic Viscoplastic Constitutive Equations, Part I: A Thermodynamically Consistent Formulation. J. Appl. Mech. 1993, 60, 813–821. [Google Scholar] [CrossRef]

- Chaboche, J.L. Thermodynamic formulation of constitutive equations and application to the viscoplasticity and viscoelasticity of metals and polymers. Int. J. Solids Struct. 1997, 34, 2239–2254. [Google Scholar] [CrossRef]

- Ghalehbandi, S.M.; Biglari, F. Predicting damage and failure under thermomechanical fatigue in hot forging tools. Eng. Fail. Anal. 2020, 113, 104545. [Google Scholar] [CrossRef]

- Brnic, J.; Turkalj, G.; Canadija, M.; Lanc, D.; Krscanski, S. Martensitic stainless steel AISI 420—Mechanical properties, creep and fracture toughness. Mech. Time-Depend. Mater. 2011, 15, 341–352. [Google Scholar] [CrossRef]

- Alimi, A.; Fajoui, J.; Kchaou, M.; Branchu, S.; Elleuch, R.; Jacquemin, F. Multi-scale hot working tool damage (X40CrMoV5-1) analysis in relation to the forging process. Eng. Fail. Anal. 2016, 62, 142–155. [Google Scholar] [CrossRef]

- Zuo, P.; Wu, X.; Zeng, Y.; He, X. In-phase and out-of-phase thermomechanical fatigue behavior of 4Cr5MoSiV1 hot work die steel cycling from 400 °C to 700 °C. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 159–169. [Google Scholar] [CrossRef]

- Caliskanoglu, D.; Stiller, I.; Ebner, R.; Leitner, H.; Jeglitsch, F. Thermal fatigue and softening behavior of hot work tool steels. In The Use of Tool Steels: Experience and Research; Bergström, J., Ed.; Karlstad Univerity: Karlstad, Sweden, 2002; pp. 707–719. [Google Scholar]

- Bischof, M.; Staron, P.; Caliskanoglu, D.; Leitner, H.; Scheu, C.; Clemens, H. On the overaging behaviour of tool steel X38 CrMoV 5-3. Mater. Sci. Eng. A 2008, 472, 148–156. [Google Scholar] [CrossRef]

- Medvedeva, A.; Bergström, J.; Gunnarsson, S.; Andersson, J. High-temperature properties and microstructural stability of hot-work tool steels. Mater. Sci. Eng. A 2009, 523, 39–46. [Google Scholar] [CrossRef]

- Grüning, A.; Lebsanft, M.; Scholtes, B. Cyclic stress–strain behavior and damage of tool steel AISI H11 under isothermal and thermal fatigue conditions. Mater. Sci. Eng. A 2010, 527, 1979–1985. [Google Scholar] [CrossRef]

- Jilg, A.; Seifert, T.; Bouguecha, A. Ermüdungslebensdauerbewertung von Warmumformwerkzeugen - Ein Überblick über den Stand der Forschung und Anwendung. Mater. Und Werkst. 2017, 48, 1057–1069. [Google Scholar] [CrossRef]

- Hu, X.; Li, L.; Wu, X.; Mei, Z. Coarsening behavior of M23C6 carbides after ageing or thermal fatigue in AISI H13 steel with niobium. Int. J. Fatigue 2006, 28, 175–182. [Google Scholar] [CrossRef]

- Ning, A.; Liu, Y.; Gao, R.; Yue, S.; Wang, M.; Guo, H. Effect of Tempering Condition on Microstructure, Mechanical Properties and Precipitates in AISI H13 Steel. JOM 2020, 73, 2194–2202. [Google Scholar] [CrossRef]

- Zhang, Z.; Delagnes, D.; Bernhart, G. Ageing effect on cyclic plasticity of a tempered martensitic steel. Int. J. Fatigue 2007, 29, 336–346. [Google Scholar] [CrossRef]

- Hofinger, M.; Seisenbacher, B.; Landefeld, A.; Ognianov, M.; Turk, C.; Leitner, H.; Schnitzer, R. Influence of thermomechanical fatigue loading conditions on the nanostructure of secondary hardening steels. Mater. Sci. Eng. A 2021, 802, 140672. [Google Scholar] [CrossRef]

- Jilg, A.; Seifert, T. Temperature dependent cyclic mechanical properties of a hot work steel after time and temperature dependent softening. Mater. Sci. Eng. A 2018, 721, 96–102. [Google Scholar] [CrossRef]

- Markežič, R.; Mole, N.; Naglič, I.; Šturm, R. Time and temperature dependent softening of H11 hot-work tool steel and definition of an anisothermal tempering kinetic model. Mater. Today Commun. 2020, 22, 100744. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Oriani, R. Ostwald ripening of precipitates in solid matrices. Acta Metall. 1964, 12, 1399–1409. [Google Scholar] [CrossRef]

- Zhang, Z.; Delagnes, D.; Bernhart, G. Microstructure evolution of hot-work tool steels during tempering and definition of a kinetic law based on hardness measurements. Mater. Sci. Eng. A 2004, 380, 222–230. [Google Scholar] [CrossRef]

- Zhang, Z.; Bernhart, G.; Delagnes, D. Cyclic behaviour constitutive modelling of a tempered martensitic steel including ageing effect. Int. J. Fatigue 2008, 30, 706–716. [Google Scholar] [CrossRef]

- Jilg, A.; Seifert, T. A temperature dependent cyclic plasticity model for hot work tool steel including particle coarsening. In Proceedings of the 21st International ESAFORM Conference on Material Forming, Palermo, Italy, 23–25 April 2018; Fratini, L., Di Lorenzo, R., Buffa, G., Ingarao, G., Eds.; Conference Collection. AIP Publishing: Melville, NY, USA, 2018; p. 170007. [Google Scholar] [CrossRef]

- Bernhart, G.; Moulinier, G.; Brucelle, O.; Delagnes, D. High temperature low cycle fatigue behaviour of a martensitic forging tool steel. Int. J. Fatigue 1999, 21, 179–186. [Google Scholar] [CrossRef]

- Zhang, Z.; Delagnes, D.; Bernhart, G. Anisothermal cyclic plasticity modelling of martensitic steels. Int. J. Fatigue 2002, 24, 635–648. [Google Scholar] [CrossRef]

- Egner, W.; Sulich, P.; Mroziński, S.; Egner, H. Modelling thermo-mechanical cyclic behavior of P91 steel. Int. J. Plast. 2020, 135, 102820. [Google Scholar] [CrossRef]

- Song, K.; Wang, K.; Zhao, L.; Xu, L.; Han, Y.; Hao, K. A combined elastic–plastic framework unifying the various cyclic softening/hardening behaviors for heat resistant steels: Experiment and modeling. Int. J. Fatigue 2022, 158, 106736. [Google Scholar] [CrossRef]

- Velay, V.; Bernhart, G.; Penazzi, L. Cyclic behavior modeling of a tempered martensitic hot work tool steel. Int. J. Plast. 2006, 22, 459–496. [Google Scholar] [CrossRef]

- Egner, H.; Egner, W. Modeling of a tempered martensitic hot work tool steel behavior in the presence of thermo-viscoplastic coupling. Int. J. Plast. 2014, 57, 77–91. [Google Scholar] [CrossRef]

- DIN EN ISO 4957:2018-11; Werkzeugstähle (ISO_4957:2018). Deutsche Fassung EN_ISO_4957:2018; Beuth Verlag GmbH: Berlin, Germany, 2018. [CrossRef]

- Virgamet Home Page. Alloy Tool Steel for Hot-Working X38CrMoV5-3. Available online: https://virgamet.com/x38crmov53-1-2367-z38cdv53-4ch5m3f-4h5m3f-tool-steel (accessed on 18 January 2023).

- Erbacher Härtetechnik Home Page. Härten Martensitisch. Available online: https://www.erbacher-haertetechnik.de/waermebehandlungsverfahren/haerten-martensitisch/index.html (accessed on 18 January 2023).

- von Hartrott, P.; Seifert, T.; Dropps, S. TMF Life Prediction of High Temperature Components Made of Cast Iron HiSiMo: Part I: Uniaxial Tests and Fatigue Life Model. SAE Int. J. Mater. Manuf. 2014, 7, 439–445. [Google Scholar] [CrossRef]

- Frederick, C.O.; Armstrong, P.J. A mathematical representation of the multiaxial Bauschinger effect. Mater. High Temp. 2007, 24, 1–26. [Google Scholar] [CrossRef]

- Chaboche, J.L. A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Cailletaud, G.; Depoid, C.; Massinon, D.; Nicouleau-Bourles, E. Elastoviscoplasticity with aging in aluminium alloys. In Continuum Thermomechanics; Solid Mechanics and Its Applications; Maugin, G.A., Drouot, R., Sidoroff, F., Eds.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; Voluem 76, pp. 75–86. [Google Scholar] [CrossRef]

- Mayer, S.; Scheu, C.; Leitner, H.; Clemens, H.; Siller, I. Influence of the Cooling Rate on the Mechanical Properties of a Hot-work Tool Steel. BHM Berg- Und Hüttenmännische Monatshefte 2007, 152, 132–136. [Google Scholar] [CrossRef]

- Rekun, I.; Seifert, T.; Roland, J. Determination of stable and robust material properties for the assessment of thermomechanically loaded components of rocket engines with viscoplastic constitutive equations. In Proceedings of the European Conference on Spacecraft Structures, Materials and Environmental Testing (ECSSMET), Toulouse, France, 27–30 September 2016. [Google Scholar]

- Sonderegger, B.; Kozeschnik, E.; Leitner, H.; Clemens, H.; Svoboda, J.; Fischer, F.D.; Staron, P. Kinetics of Precipitation in a Complex Hot-work Tool Steel. Steel Res. Int. 2010, 81, 64–73. [Google Scholar] [CrossRef]

- Yu, X.S.; Wu, C.; Shi, R.X.; Yuan, Y.S. Microstructural evolution and mechanical properties of 55NiCrMoV7 hot-work die steel during quenching and tempering treatments. Adv. Manuf. 2021, 9, 520–537. [Google Scholar] [CrossRef]

- Eser, A.; Broeckmann, C.; Simsir, C. Multiscale modeling of tempering of AISI H13 hot-work tool steel—Part 1: Prediction of microstructure evolution and coupling with mechanical properties. Comput. Mater. Sci. 2016, 113, 280–291. [Google Scholar] [CrossRef]

- Lerchbacher, C.; Zinner, S.; Leitner, H. Atom probe study of the carbon distribution in a hardened martensitic hot-work tool steel X38CrMoV5-1. Micron 2012, 43, 818–826. [Google Scholar] [CrossRef]

- Sun, J.; Sun, T.; Sha, S.; Ji, K.; Qi, T.Y.; Chen, C. A Study of Thermal Cyclic Softening Behavior of Hot-Deformed Die Steel. Met. Sci. Heat Treat. 2021, 63, 18–25. [Google Scholar] [CrossRef]

- Carasi, G.; Yu, B.; Hutten, E.; Zurob, H.; Casati, R.; Vedani, M. Effect of Heat Treatment on Microstructure Evolution of X38CrMoV5-1 Hot-Work Tool Steel Produced by L-PBF. Metall. Mater. Trans. A 2021, 52, 2564–2575. [Google Scholar] [CrossRef]

- Kunz, J.; Herzog, S.; Kaletsch, A.; Broeckmann, C. Influence of initial defect density on mechanical properties of AISI H13 hot-work tool steel produced by laser powder bed fusion and hot isostatic pressing. Powder Metall. 2021, 65, 1–12. [Google Scholar] [CrossRef]

- Pellizzari, M.; AlMangour, B.; Benedetti, M.; Furlani, S.; Grzesiak, D.; Deirmina, F. Effects of building direction and defect sensitivity on the fatigue behavior of additively manufactured H13 tool steel. Theor. Appl. Fract. Mech. 2020, 108, 102634. [Google Scholar] [CrossRef]

- Son, J.; Shin, G.; Lee, K.; Choi, C.h.; Shim, D. High-temperature Properties of Hot-Work Tool Steel (AISI H13) Deposited via Direct Energy Deposition. In Forming the Future; The Minerals, Metals & Materials Series; Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1665–1676. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Wei, Q.; Shi, Y. Thermal Fatigue Properties of H13 Hot-Work Tool Steels Processed by Selective Laser Melting. Metals 2020, 10, 116. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo | V | |

|---|---|---|---|---|---|---|---|---|

| Measured | 0.388 | 0.49 | 0.40 | 0.021 | 0.004 | 5.15 | 2.60 | 0.504 |

| Min. | 0.35 | 0.3 | 0.3 | - | - | 4.8 | 2.7 | 0.4 |

| Max. | 0.4 | 0.5 | 0.5 | 0.03 | 0.02 | 5.2 | 3.2 | 0.6 |

| Notation | Heat Treatment |

|---|---|

| HT0 | initial state |

| HT1 | 300 min. at 600 C |

| HT2 | 1000 min. at 650 C |

| Temperature | 20 C | 400 C | 500 C | 600 C | 650 C |

|---|---|---|---|---|---|

| Number of cycles to failure HT0 | 215 | 153 | 133 | 69 | 130 |

| Number of cycles to failure HT1 | 213 | 197 | 275 | 141 | 150 |

| Number of cycles to failure HT2 | 373 | 237 | 250 | 251 | 203 |

| Type | In-Phase TMF | Out-of-Phase TMF |

|---|---|---|

| Number of cycles to failure HT0 | 341 | 127 |

| Number of cycles to failure HT1 | 392 | 155 |

| Number of cycles to failure HT2 | 174 | 133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schlayer, M.; Warwas, M.; Seifert, T. A Temperature-Dependent Viscoplasticity Model for the Hot Work Steel X38CrMoV5-3, Including Thermal and Cyclic Softening under Thermomechanical Fatigue Loading. Materials 2023, 16, 994. https://doi.org/10.3390/ma16030994

Schlayer M, Warwas M, Seifert T. A Temperature-Dependent Viscoplasticity Model for the Hot Work Steel X38CrMoV5-3, Including Thermal and Cyclic Softening under Thermomechanical Fatigue Loading. Materials. 2023; 16(3):994. https://doi.org/10.3390/ma16030994

Chicago/Turabian StyleSchlayer, Markus, Marc Warwas, and Thomas Seifert. 2023. "A Temperature-Dependent Viscoplasticity Model for the Hot Work Steel X38CrMoV5-3, Including Thermal and Cyclic Softening under Thermomechanical Fatigue Loading" Materials 16, no. 3: 994. https://doi.org/10.3390/ma16030994

APA StyleSchlayer, M., Warwas, M., & Seifert, T. (2023). A Temperature-Dependent Viscoplasticity Model for the Hot Work Steel X38CrMoV5-3, Including Thermal and Cyclic Softening under Thermomechanical Fatigue Loading. Materials, 16(3), 994. https://doi.org/10.3390/ma16030994