Influence of Cryogenic Treatment on the Corrosion Properties of 42CrMo Low Alloy Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

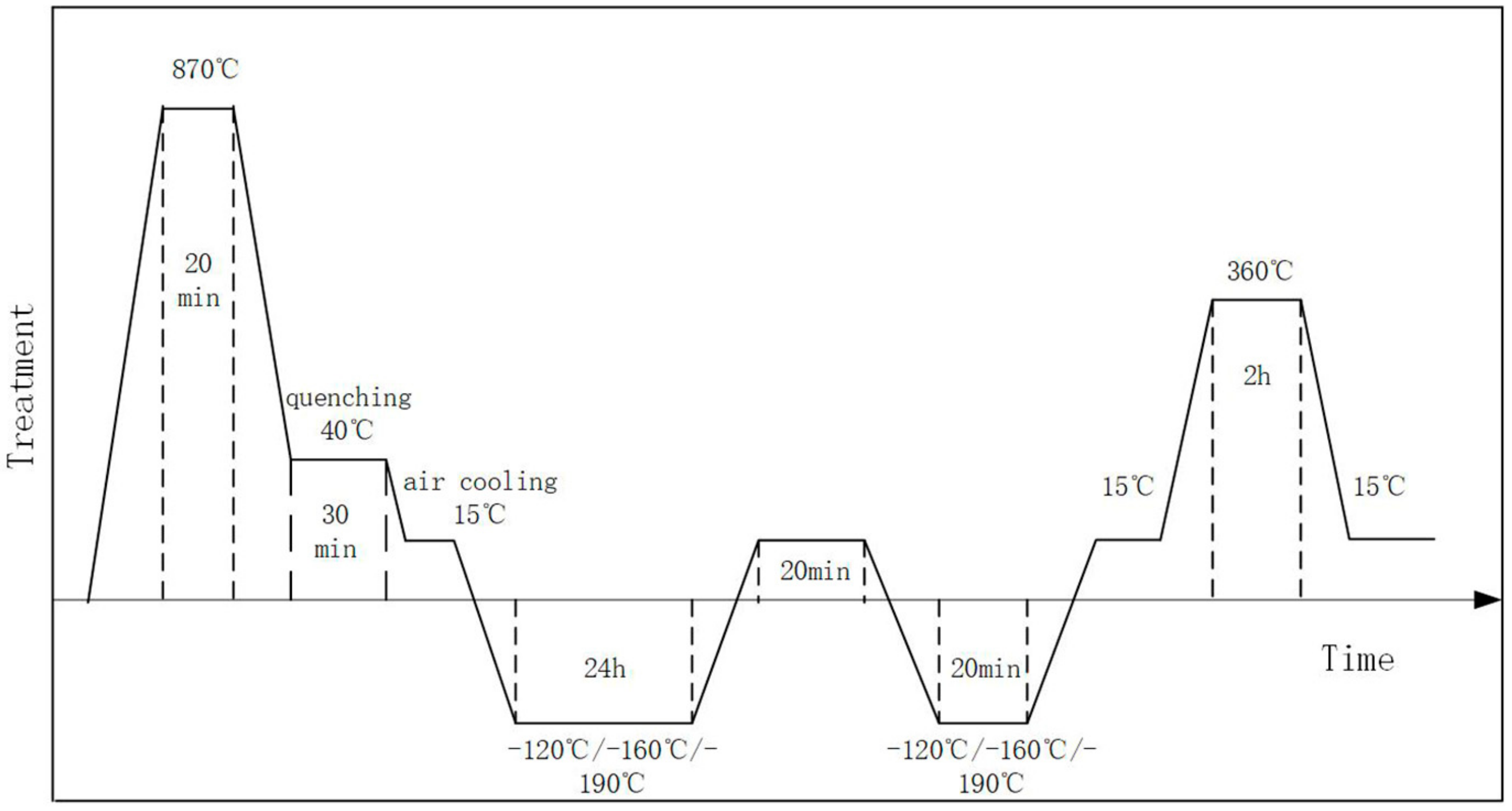

2.2. Methods

2.2.1. Electrochemical Corrosion Test

2.2.2. Microstructure Observation

2.2.3. Hydrogen Sulphide Stress Corrosion Test

3. Results and Discussion

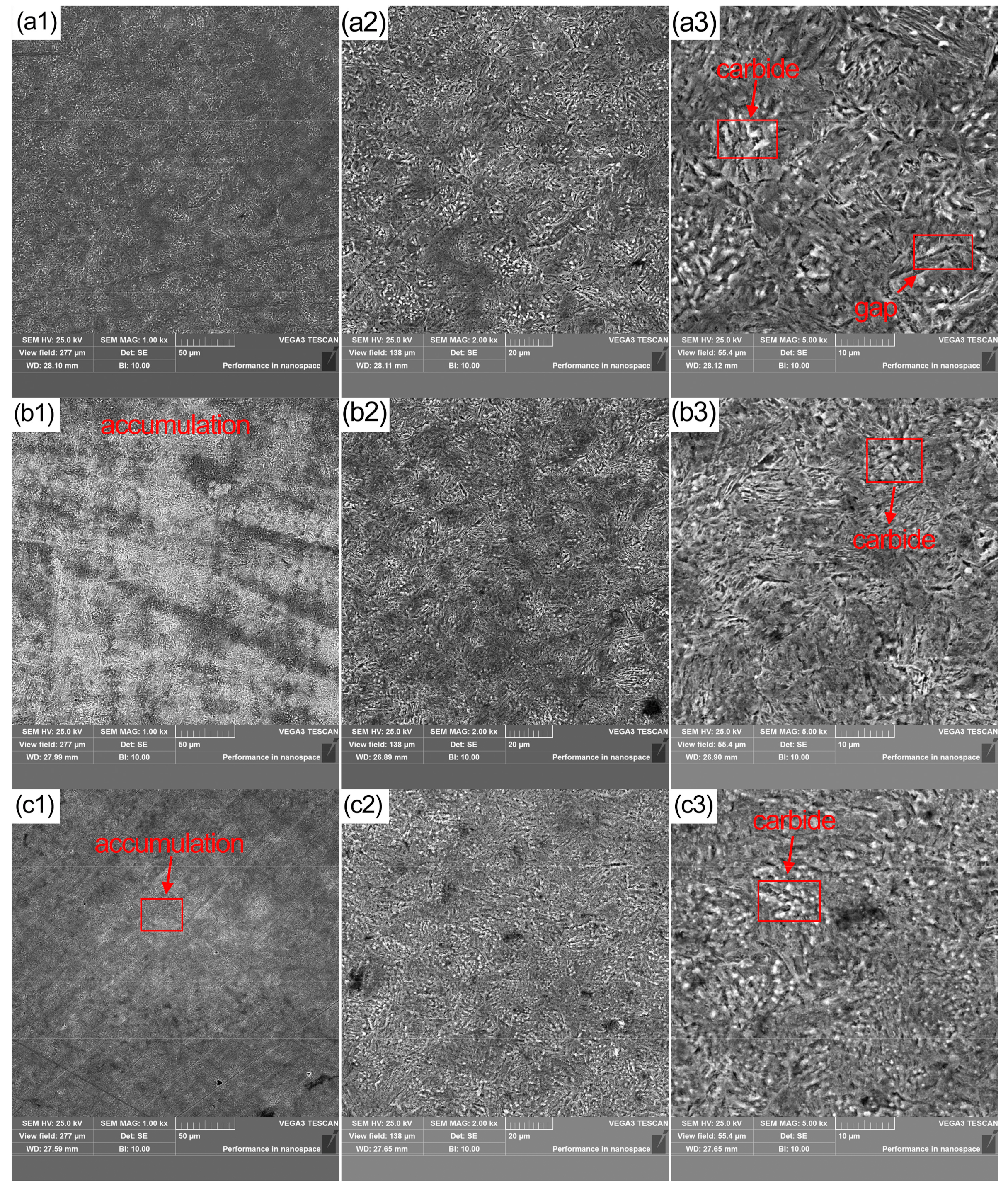

3.1. Effect of Cryogenic Treatment on Microstructure

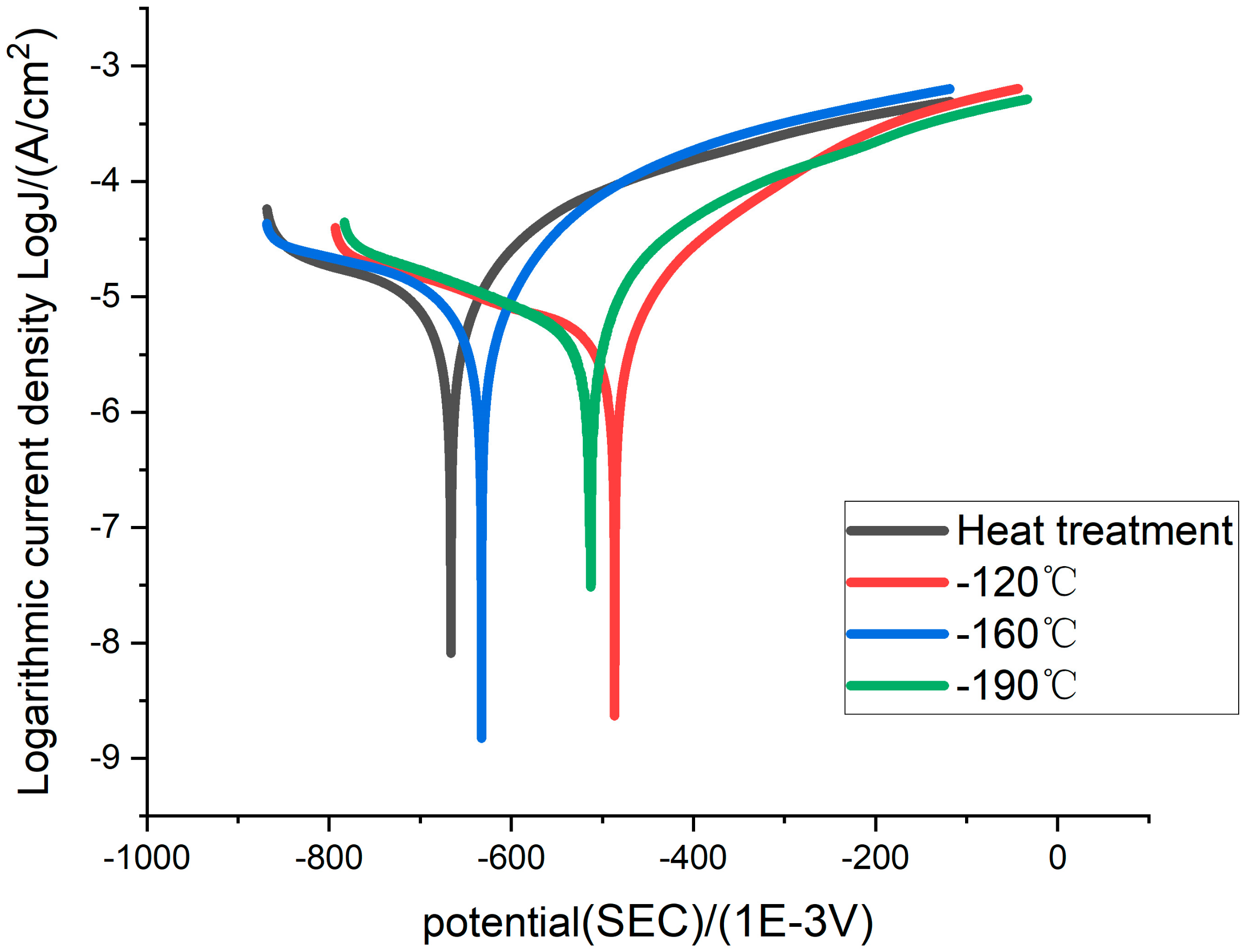

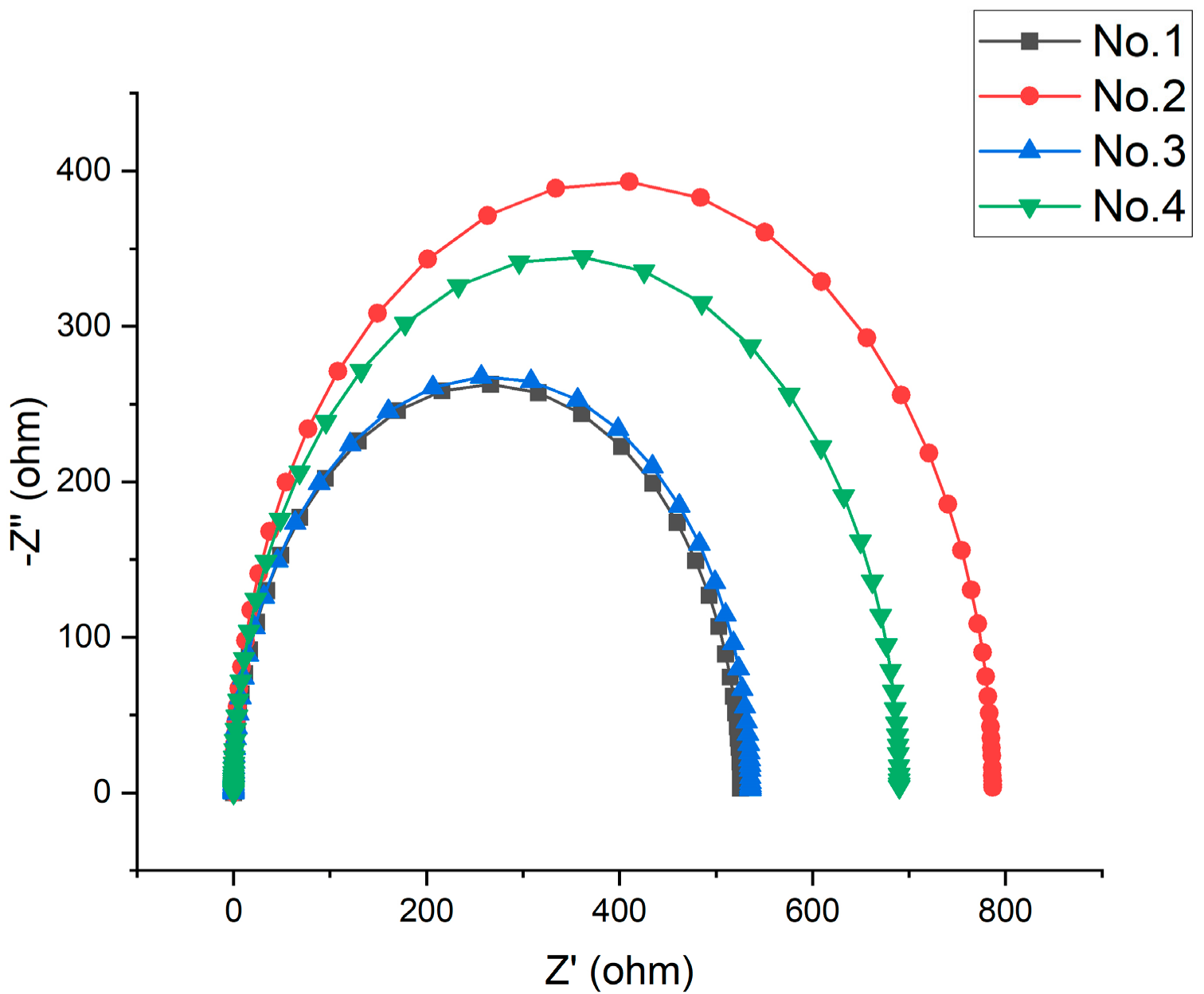

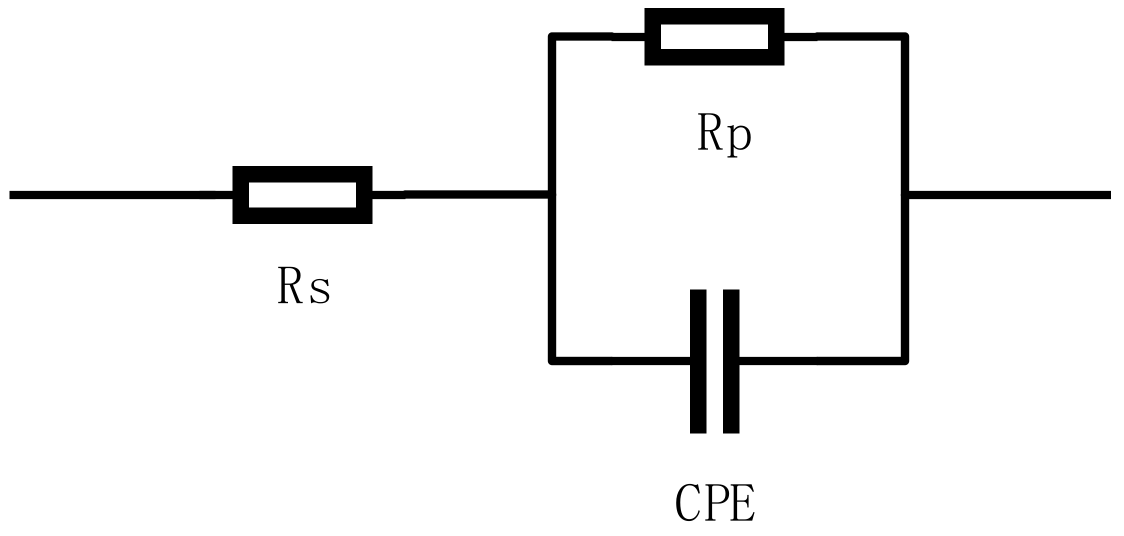

3.2. Electrochemical Corrosion Test

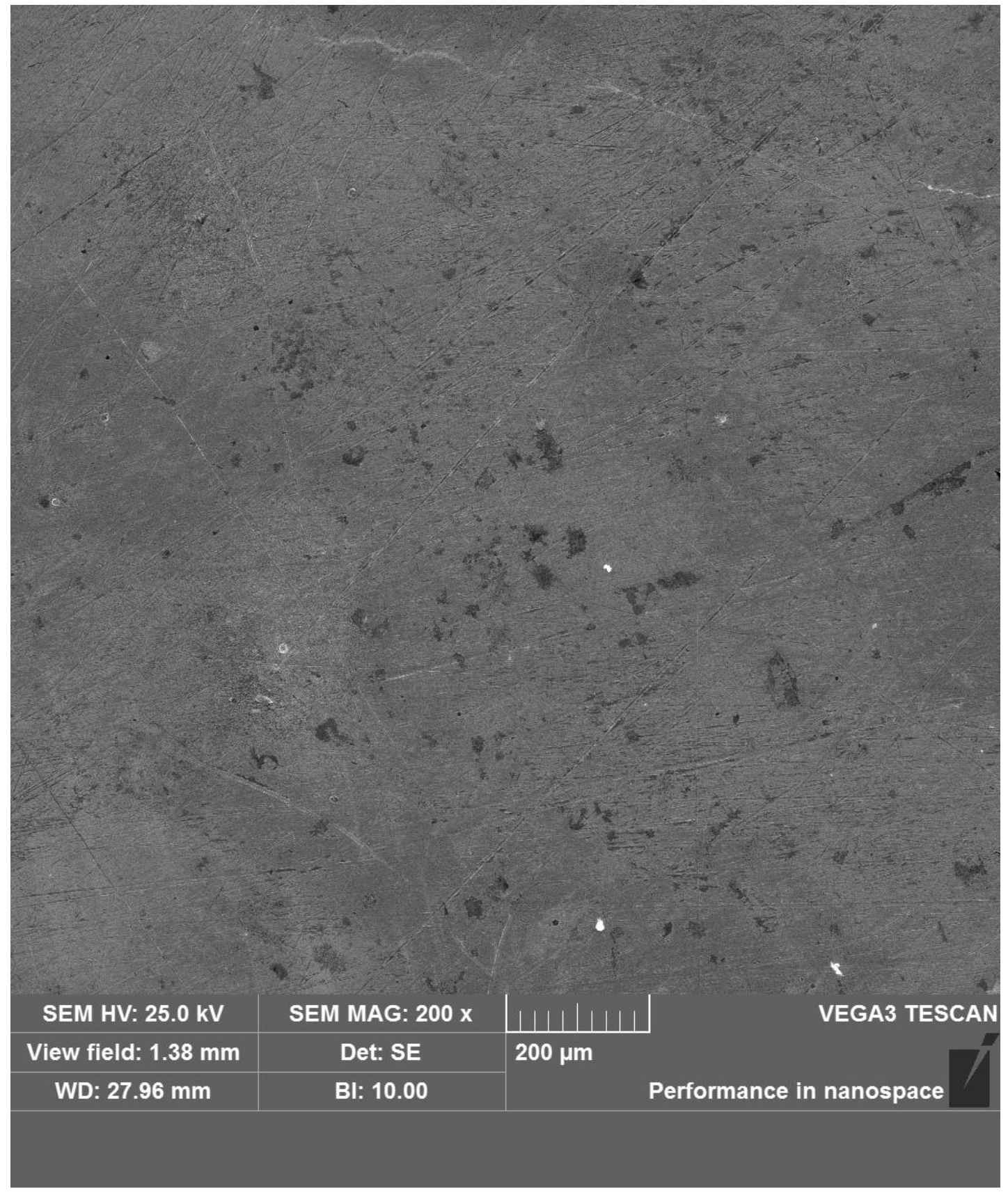

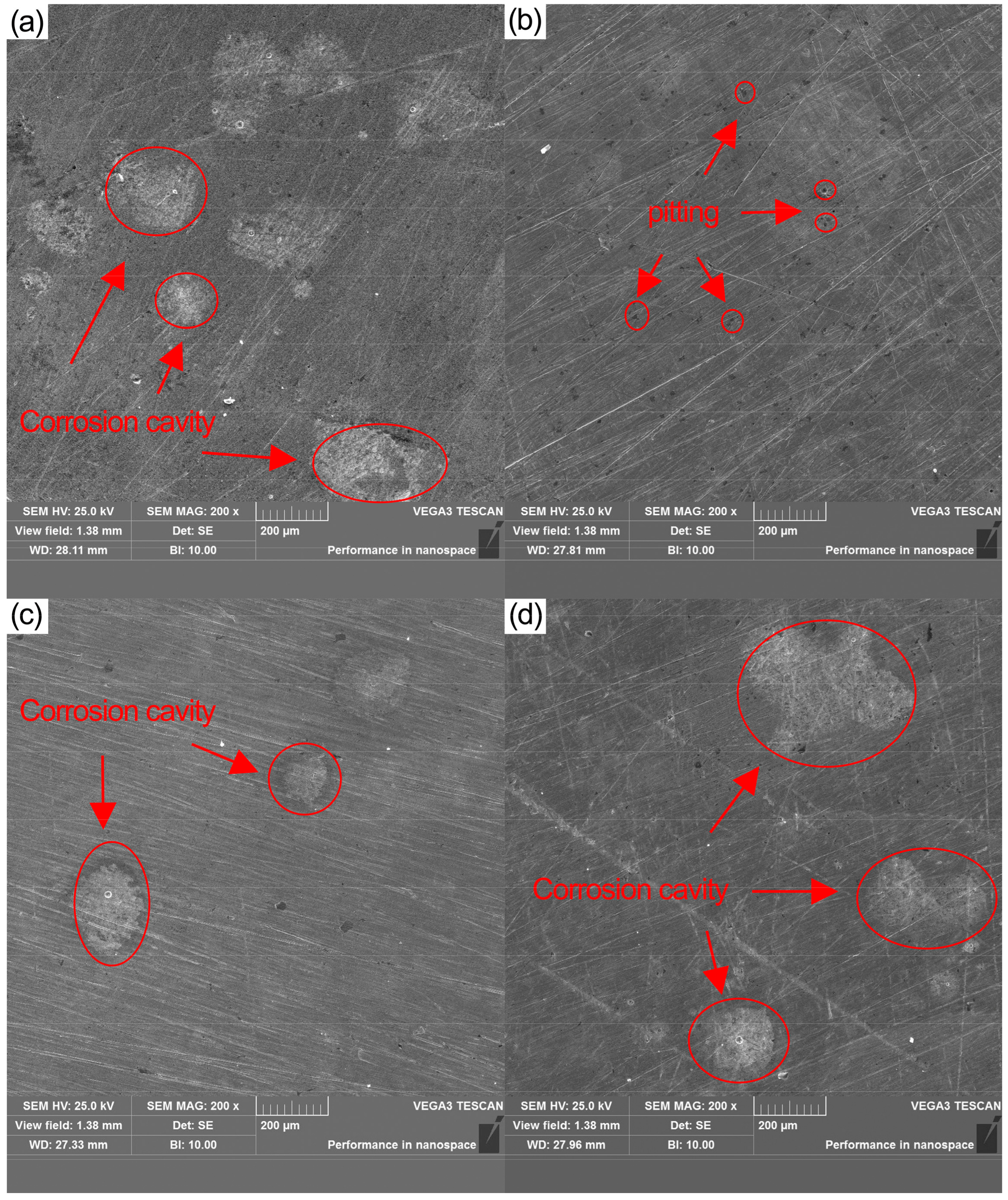

3.3. Micro Corrosion Morphology

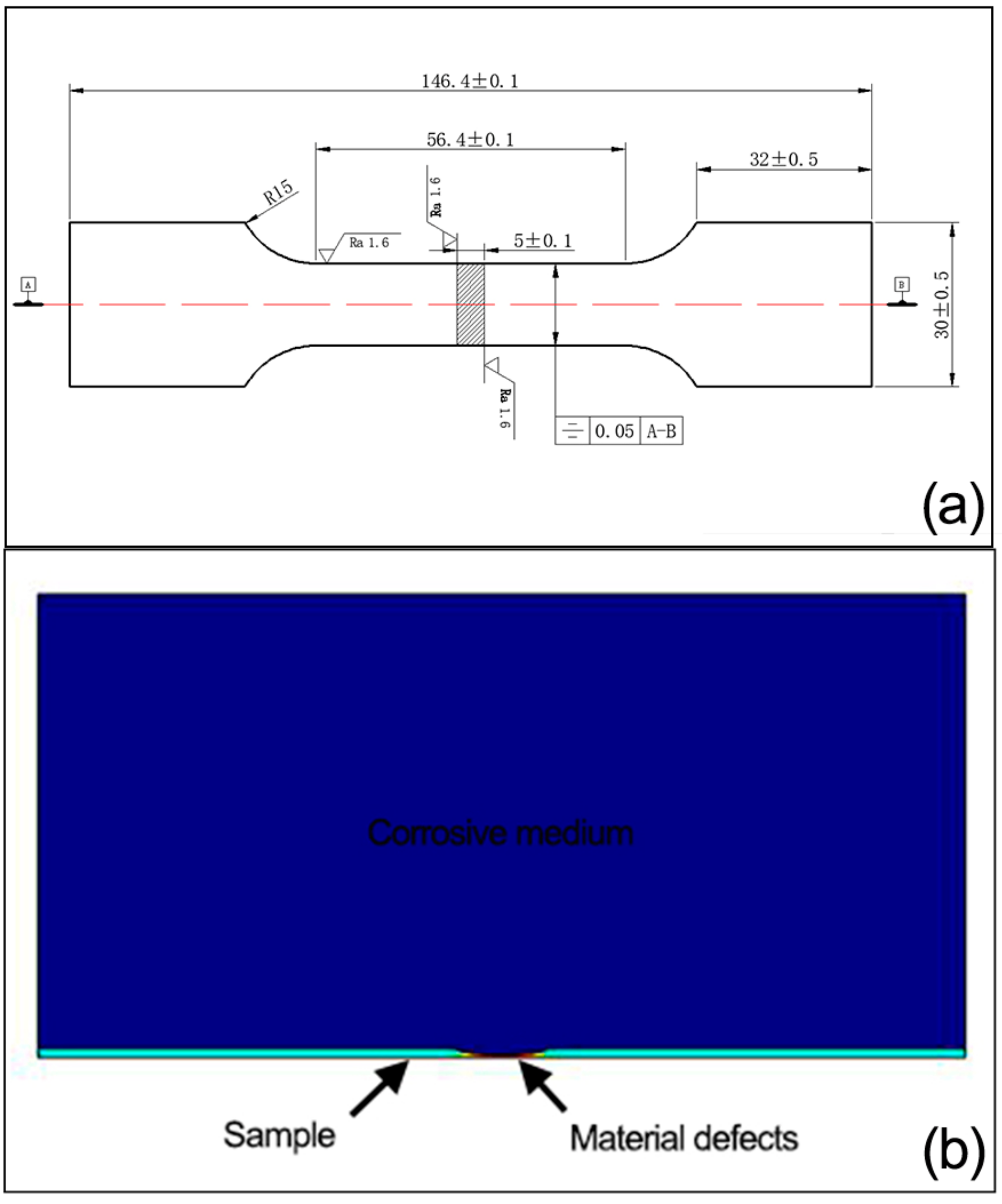

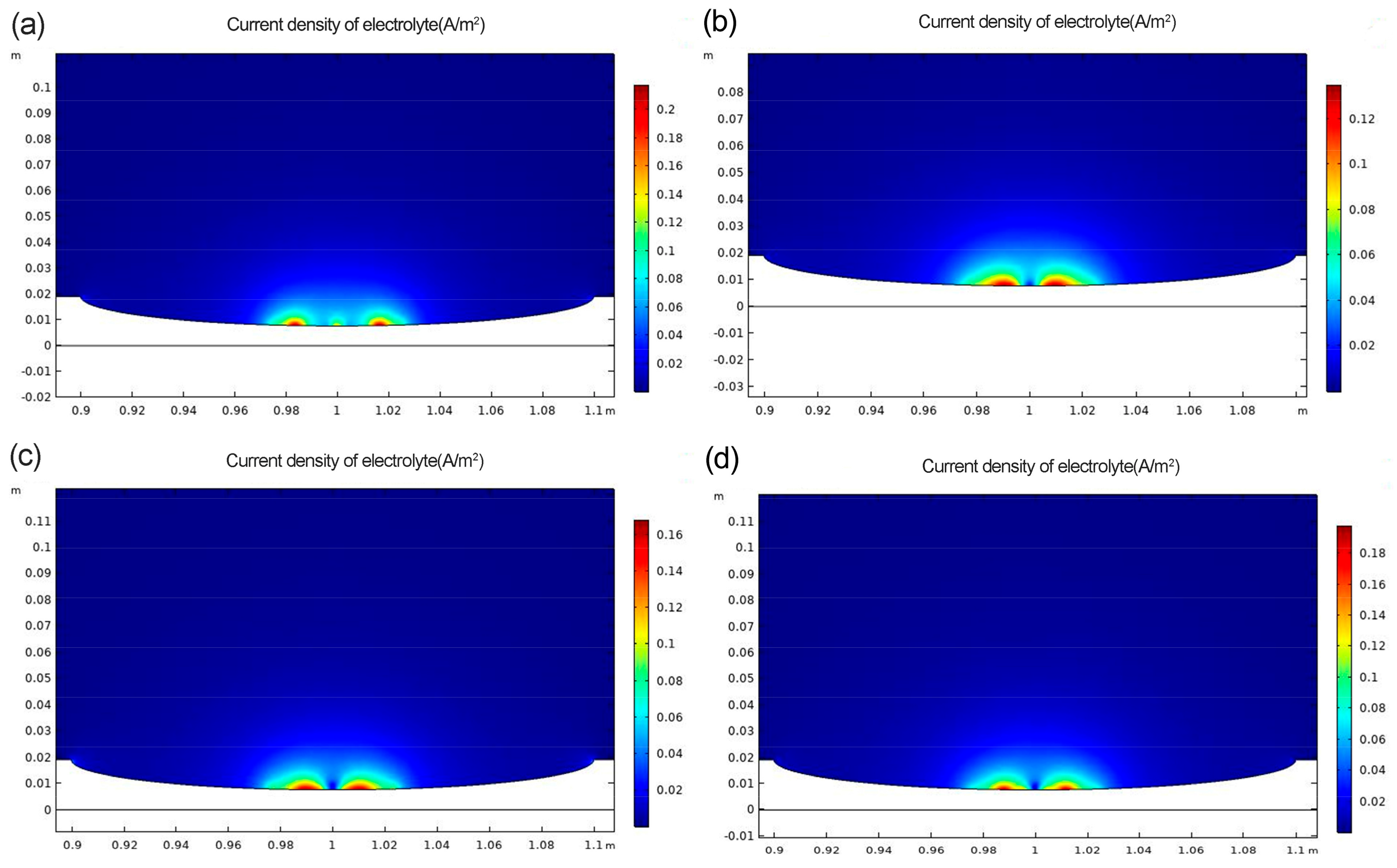

4. Simulation

5. Conclusions

- The cryogenic treatment promotes the precipitation and fill of carbides in the 42CrMo alloy steel matrix to grain gaps and defects. With the decrease in cryogenic temperature, surface carbides gradually accumulate and affect the corrosion resistance of materials. After the −120 °C process group, the SEM image displays that the carbide is fine and uniform. The −190 °C process group also improves corrosion resistance, but there is carbide aggregation. After processing at−160 °C, a large number of carbides accumulated, which was not conducive to improving the corrosion resistance of materials.

- Electrochemical polarization test fitting results show that after the deep cooling process the corrosion current is reduced by 40%, 20% and 30% respectively. The electrochemical impedance spectroscopy results show that 42CrMo alloy steel has the highest impedance value at −120 °C deep cold temperature with the lowest corrosion tendency.

- In the simulation of stress corrosion with defects, the simulation results also show the most robust corrosion resistance at −120 °C which has a reference value.

- In this test, the best process group was explored as follows: Quenching at 870 °C for 20 min, oil quenching at 40 °C for 30 min, cryogenic treatment at −120 °C for 24 h, and tempering at 360 °C for 2 h.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sunaba, T.; Ito, T.; Miyata, Y.; Asakura, S.; Shinohara, T.; Yakou, T.; Tomoe, Y.; Honda, H. Influence of Chloride Ions on Corrosion of Modified Martensitic Stainless Steels at High Temperatures Under a CO2 Environment. Corros. Sci. 2014, 70, 988–999. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.B.; Zhang, G.A.; Liu, W.; Lu, M.X. The formation mechanism of corrosion scale and electrochemical characteristic of low alloy steel in carbon dioxide-saturated solution. Corros. Sci. 2012, 57, 131–138. [Google Scholar] [CrossRef]

- Ma, H.Y.; Cheng, X.L.; Li, G.Q.; Chen, S.H.; Quan, Z.L.; Zhao, S.Y.; Lin, N. The influence of hydrogen sulfide on corrosion of iron under different conditions. Corros. Sci. 2000, 42, 1669–1683. [Google Scholar] [CrossRef]

- Huang, B.S.; Wen, X.; Li, G.W.; Li, T.N. Research on impact toughness of 105SS drill pipe in wet H2S environment. Mater. Res. Express 2019, 6, 065508. [Google Scholar] [CrossRef]

- Marchi, C.S. Hydrogen embrittlement of stainless steels and their welds. Mater. Sci. 2012, 2, 592–623. [Google Scholar] [CrossRef]

- Brooks, J.A.; West, A.J. Hydrogen induced ductility losses in austenitic stainless steel welds. Met. Mater. Trans. A 1981, 12A, 213–223. [Google Scholar] [CrossRef]

- Jovičević-Klug, P.; Podgornik, B. Review on the Effect of Deep Cryogenic Treatment of Metallic Materials in Automotive Applications. Metals 2020, 10, 434. [Google Scholar] [CrossRef]

- Li, S.H.; Guo, H.; Li, Z.M.; Li, J. Carbides precipitation and kinetics of H13 steel subjected to deep cryogenic treatment. Mater. Sci. Technol. 2022, 38, 1376–1389. [Google Scholar] [CrossRef]

- Ridvan, G. Combined effects of cryogenic treatment and tempering on microstructural and tribological features of AISI H13 steel. Mater. Chem. Phys. 2022, 292, 126802. [Google Scholar] [CrossRef]

- Qian, Y.H.; Ma, C.H.; Niu, D.; Xu, J.J.; Li, M.S. Influence of alloyed chromium on the atmospheric corrosion resistance of weathering steels. Corros. Sci. 2013, 74, 424–429. [Google Scholar] [CrossRef]

- Matic, J.K.; Patricia, J.K.; Tjaša, K.; Bojan, P. Cross-effect of Surface Finishing and Deep Cryogenic Treatment on Corrosion Resistance of AISI M35 steel. J. Mater. Res. Technol. 2021, 14, 2365–2381. [Google Scholar] [CrossRef]

- Huang, Z.H.; Li, Y.; Xie, Z.X.; Xu, Z.H. Corrosion resistance behavior of 304LN steel with welds under different cryogenic treatments. Mater. Res. Express 2019, 6, 126535. [Google Scholar] [CrossRef]

- Ramesh, S.; Bhuvaneshwari, B.; Palani, G.S.; Mohan Lal, D.; Mondal, K.; Raju, K.G. Enhancing the corrosion resistance performance of structural steel via a novel deep cryogenic treatment process. Vacuum 2019, 159, 468–475. [Google Scholar] [CrossRef]

- Wach, P.; Ciski, A.; Babul, T.; Kapuścińska, A.; Oleszak, D. The application of deep cryogenic treatment to improve the properties of nitrided layers formed on X153CrMoV12 steel. Arch. Metall. Mater. 2019, 64, 303–309. [Google Scholar] [CrossRef]

- Zhang, H.D.; Yan, X.G.; Chen, Z.; Zhao, M.N.; Tang, L.; Gao, Y.; Li, J.J. Effect of Cryogenic Treatment on Wear Resistance and Microstructure of 42CrMo Steel. Arch. Metall. Mater. 2022, 67, 127–135. [Google Scholar] [CrossRef]

- Zhou, G.H.; Deng, S.; Wei, W.T.; Liu, Q.L. Effect of multiple deep cryo-treating and tempering on microstructure and property evolution of high carbon bearing steel. Mater. Res. Express 2020, 7, 066529. [Google Scholar] [CrossRef]

- Singla, A.K.; Singh, J.; Sharma, V.S. Processing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1042–6914. [Google Scholar] [CrossRef]

- Tamil Moli, L.; Wahab, N.; Gopinathan, M.; Karmegam, K.; Maniyarasi, M. Effects of gaseous nitriding AISI4140 alloy steel on corrosion and hardness properties. Mater. Sci. Eng. 2016, 152, 012059. [Google Scholar] [CrossRef]

- Medina-Flores, A.; Arganis, C.; Santiago, P.; Oseguera, J. Electrochemicals corrosion tests of an AISI-SAE 4140 steel nitrided by post-discharge microwave plasma. Surf. Coat. Technol. 2004, 188, 140–145. [Google Scholar] [CrossRef]

- Kovacı, H.; Baran, Ö.; Bayrak, Ö.; Yetim, A.F.; Çelik, A. Influence of plasma nitriding treatment on the adhesion of DLC films deposited on AISI 4140 steel by PVD magnetron sputtering. J. Adhes. Sci. Technol. 2017, 31, 2015–2027. [Google Scholar] [CrossRef]

| Element | Mass Percentage | GB/T 3077 |

|---|---|---|

| C | 0.41 | 0.38–0.45 |

| Cr | 0.99 | 0.90–1.20 |

| Mo | 0.18 | 0.15–0.25 |

| Si | 0.21 | 0.17–0.37 |

| Mn | 0.63 | 0.50–0.80 |

| S | 0.0045 | <0.0046 |

| P | 0.018 | <0.035 |

| Fe | balance | - |

| Treatment Process | Cryogenic Treatment (°C) | Cryogenic Time (h) | Sample Number |

|---|---|---|---|

| Annealed-Air cooled | - | - | No. 1 |

| Annealed-Air cooled +cryogenic | −120 | 24 | No. 2 |

| Annealed-Air cooled +cryogenic | −160 | 24 | No. 3 |

| Annealed-Air cooled +cryogenic | −190 | 24 | No. 4 |

| Specimen | Corrosive Potential (SEC) (mV) | Self-Corrosive Current Density (A/cm2) | Cathode Tafel Slope (V/dec) | Anode Tafel Slope (V/dec) | Corrosion Rate (g/m2h) | Corrosion Depth (mm/year) |

|---|---|---|---|---|---|---|

| No. 1 | −666.4 | 3.16 × 10−6 | −0.08 | 0.06 | 3.22 × 10−2 | 3.61 × 10−2 |

| No. 2 | −486.5 | 1.99 × 10−6 | −0.12 | 0.06 | 2.73 × 10−2 | 3.06 × 10−2 |

| No. 3 | −632.8 | 2.51 × 10−6 | −0.08 | 0.06 | 4.09 × 10−2 | 4.50 × 10−2 |

| No. 4 | −513.7 | 2.24 × 10−6 | −0.09 | 0.06 | 2.87 × 10−2 | 3.21 × 10−2 |

| Treatment Process | Rs (Ω·cm2) | Rp (Ω·cm2) |

|---|---|---|

| Annealed-Air cooled | 2.7 | 525.4 |

| Annealed-Air cooled +cryogenic treatment (−120 °C) | 3 | 815.6 |

| Annealed-Air cooled +cryogenic treatment (−160 °C) | 2.8 | 525.7 |

| Annealed-Air cooled +cryogenic treatment (−190 °C) | 2.9 | 625.6 |

| Displacements | 3.75 mm | 4 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| Cryogenic treatment | - | −120 °C | −160 °C | −190 °C | - | −120 °C | −160 °C | −190 °C |

| Current density (A/m2) | 0.20 | 0.11 | 0.20 | 0.21 | 0.21 | 0.13 | 0.20 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Li, C.; Su, H.; Huang, Y.; Yan, X. Influence of Cryogenic Treatment on the Corrosion Properties of 42CrMo Low Alloy Steel. Materials 2023, 16, 899. https://doi.org/10.3390/ma16030899

Chen Z, Li C, Su H, Huang Y, Yan X. Influence of Cryogenic Treatment on the Corrosion Properties of 42CrMo Low Alloy Steel. Materials. 2023; 16(3):899. https://doi.org/10.3390/ma16030899

Chicago/Turabian StyleChen, Zhi, Chao Li, Hang Su, Yao Huang, and Xianguo Yan. 2023. "Influence of Cryogenic Treatment on the Corrosion Properties of 42CrMo Low Alloy Steel" Materials 16, no. 3: 899. https://doi.org/10.3390/ma16030899

APA StyleChen, Z., Li, C., Su, H., Huang, Y., & Yan, X. (2023). Influence of Cryogenic Treatment on the Corrosion Properties of 42CrMo Low Alloy Steel. Materials, 16(3), 899. https://doi.org/10.3390/ma16030899