Advanced Photocatalysts for CO2 Conversion by Severe Plastic Deformation (SPD)

Abstract

1. Introduction

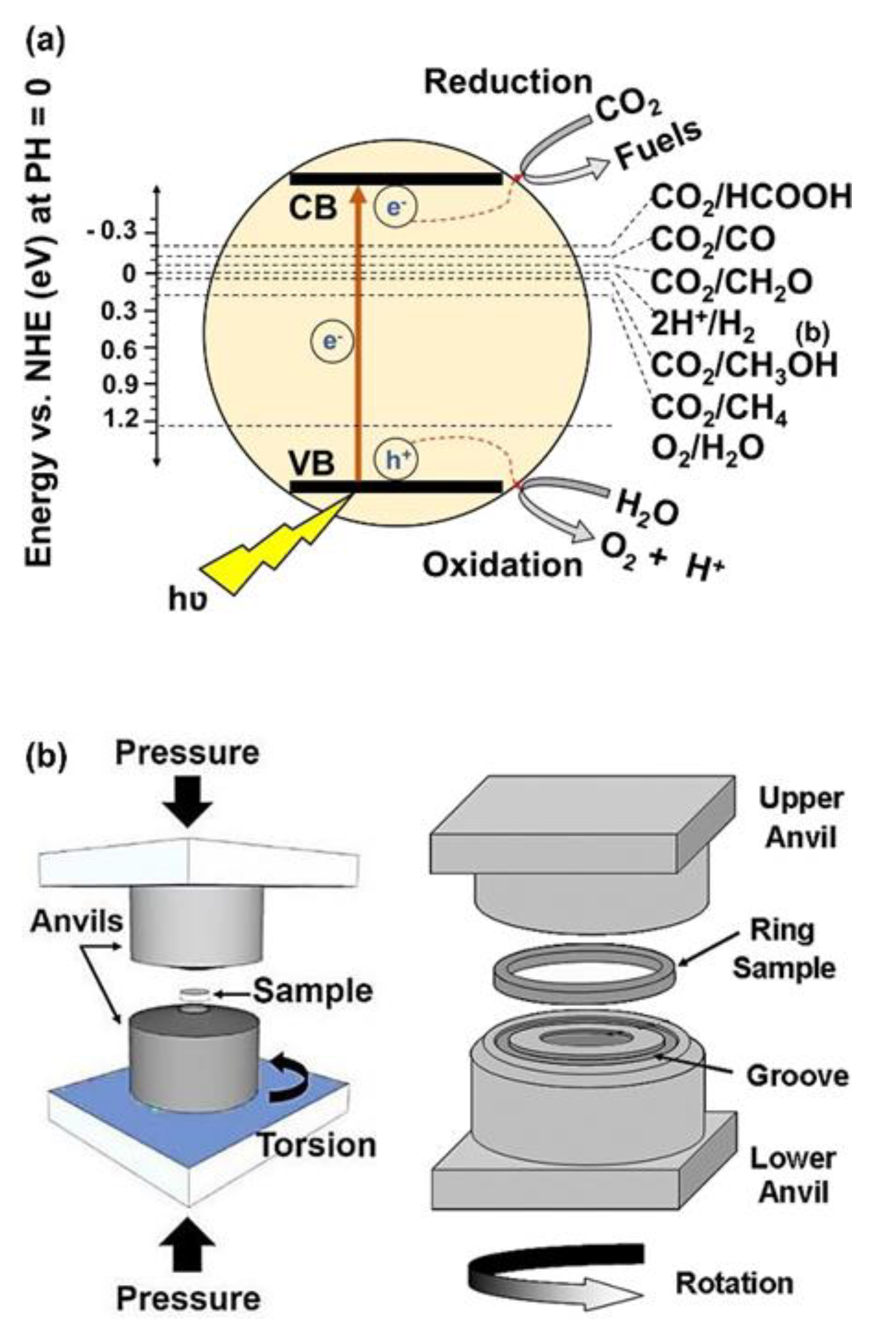

2. Influence of HPT on Photocatalytic CO2 Conversion

2.1. Simultaneous Strain and Oxygen Vacancy Engineering

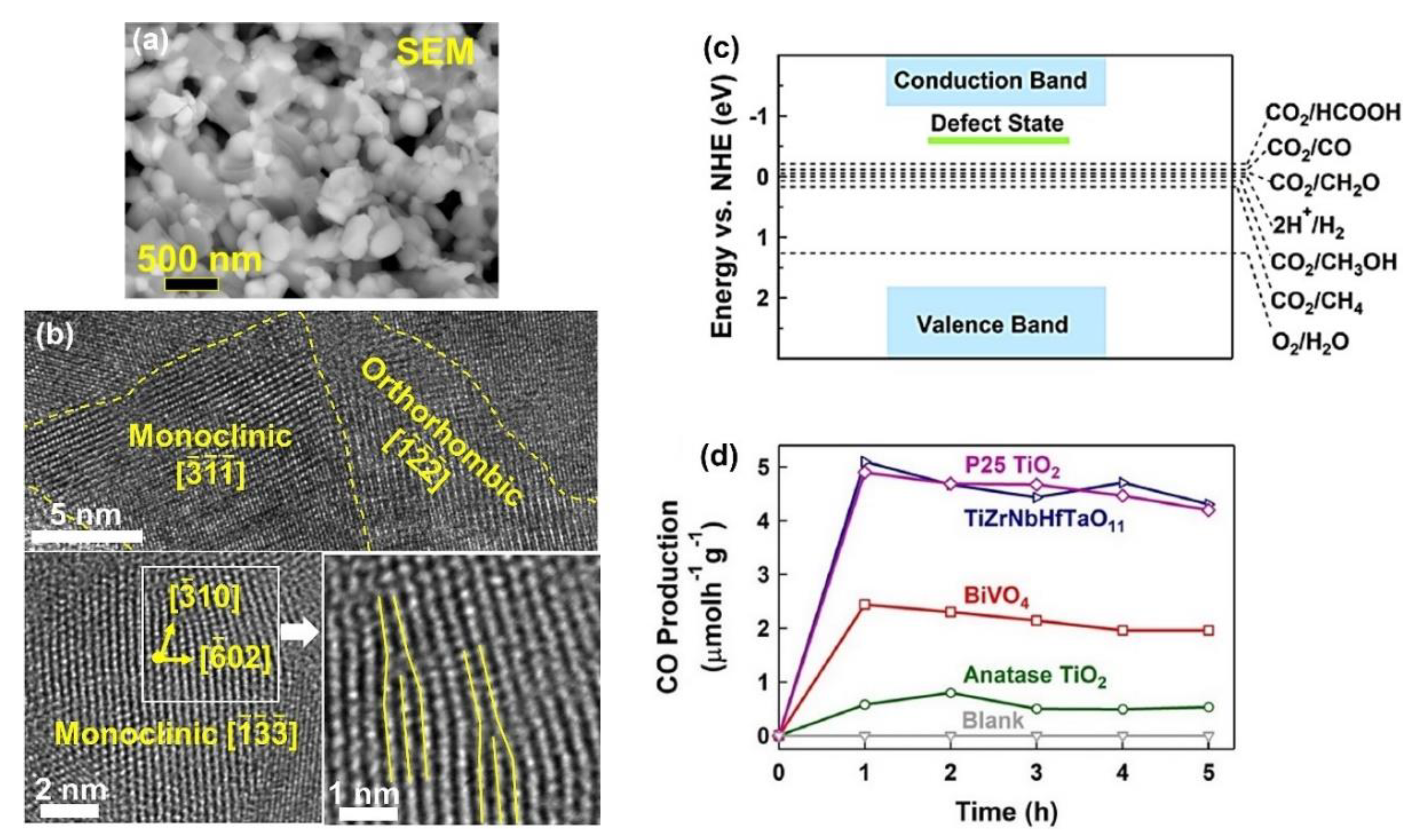

2.2. Introducing High-Pressure Phases

2.3. Formation of Defective High-Entropy Phases

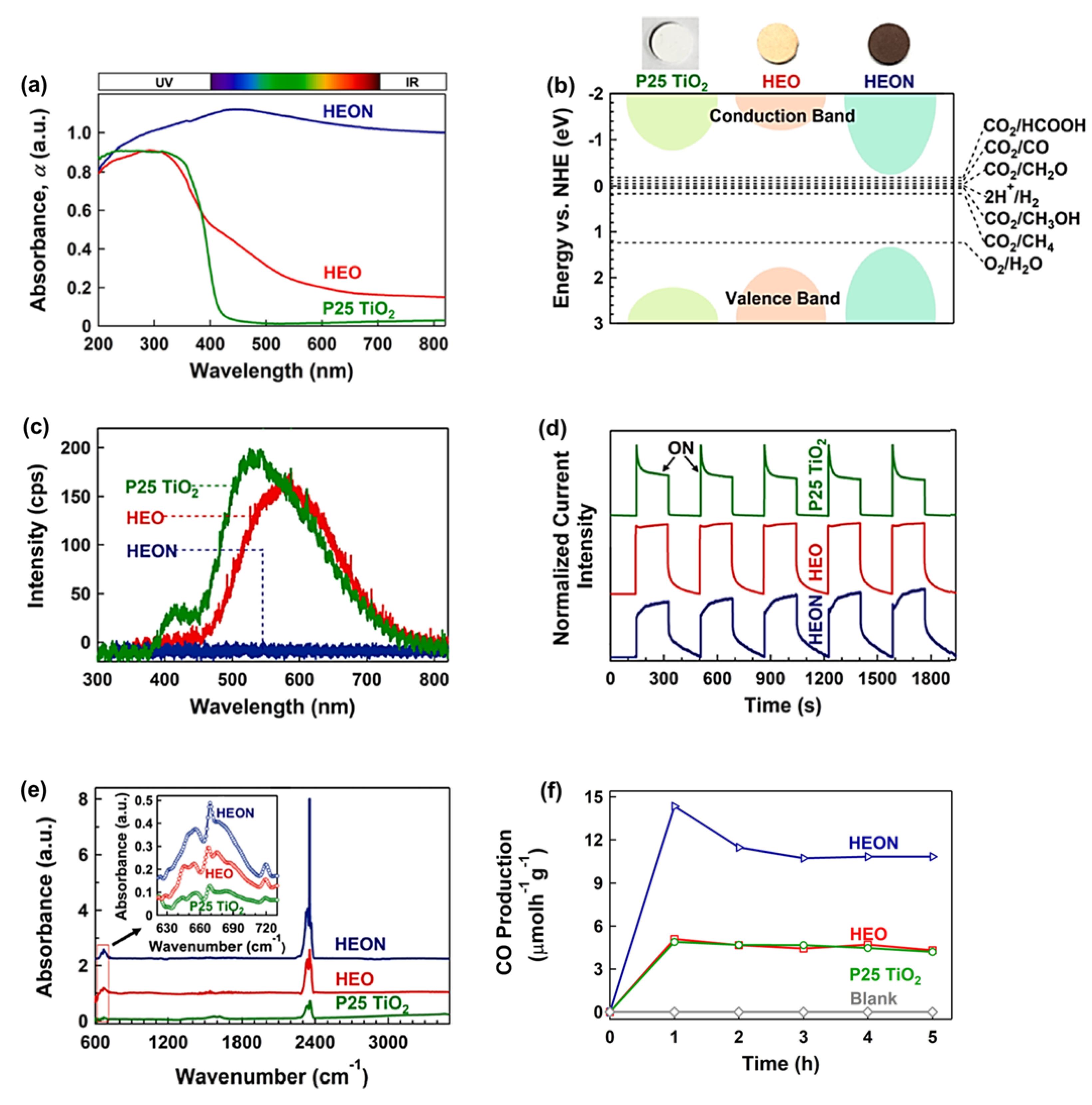

2.4. Synthesis of Low-Bandgap High-Entropy Oxynitrides

3. Discussion on Future Outlook

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forkel, M.; Carvalhais, N.; Rodenbeck, C.; Keeling, R.; Heimann, M.; Thonicke, K.; Zaehle, S.; Reichstein, M. Enhanced seasonal CO2 exchange caused by amplified plant productivity in northern ecosystems. Science 2016, 351, 696–699. [Google Scholar] [CrossRef] [PubMed]

- Morris, A.J.; Meyer, G.J.; Fujita, E. Molecular approaches to the photocatalytic reduction of carbon dioxide for solar fuels. Acc. Chem. Res. 2009, 42, 1983–1994. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Ouyang, S.; Bi, Y.; Umezawa, N.; Oshikiri, M.; Ye, J. Nano-photocatalytic materials: Possibilities and challenges. Adv. Mater. 2012, 24, 229–251. [Google Scholar] [CrossRef]

- Li, X.; Yu, J.; Jiang, C. Chapter 1—Principle and surface science of photocatalysis. Interface Sci. Technol. 2020, 31, 1–38. [Google Scholar]

- Ola, O.; Maroto-Valer, M.M. Synthesis, characterization and visible light photocatalytic activity of metal based TiO2 monoliths for CO2 reduction. Chem. Eng. J. 2016, 283, 1244–1253. [Google Scholar] [CrossRef]

- Neatu, S.; Macia-Agullo, J.A.; Concepcion, P.; Garcia, H. Gold-copper nanoalloys supported on TiO2 as photocatalysts for CO2 reduction by water. J. Am. Chem. Soc. 2014, 136, 15969–15976. [Google Scholar] [CrossRef]

- Kocí, K.; Mateju, K.; Obalova, L.; Krejcikova, S.; Lacny, Z.; Placha, D.; Capek, L.; Hospodkova, A.; Solcova, O. Effect of silver doping on the TiO2 for photocatalytic reduction of CO2. Appl. Catal. B 2010, 96, 239–244. [Google Scholar] [CrossRef]

- Akhundi, A.; Habibi-Yangjeh, A.; Abitorabi, M.; Pouran, S.R. Review on photocatalytic conversion of carbon dioxide to value-added compounds and renewable fuels by graphitic carbon nitride-based photocatalysts. Catal. Rev. Sci. Eng. 2019, 61, 595–628. [Google Scholar] [CrossRef]

- Xia, P.; Antonietti, M.; Zhu, B.; Heil, T.; Yu, J.; Cao, S. Designing defective crystalline carbon nitride to enable selective CO2 photoreduction in the gas phase. Adv. Funct. Mater. 2019, 29, 1900093. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, L.; Su, Y.; Sun, S.; Wang, Q.; Wang, H.; Wang, W. Boosted CO2 photoreduction to methane via Co doping in bismuth vanadate atomic layers. Catal. Sci. Technol. 2018, 8, 3115–3122. [Google Scholar] [CrossRef]

- Huang, L.; Duan, Z.; Song, Y.; Li, Q.; Chen, L. BiVO4 microplates with oxygen vacancies decorated with metallic Cu and Bi nanoparticles for CO2 photoreduction. ACS Appl. Nano Mater. 2021, 4, 3576–3585. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, C.X.; Hwang, Y.T.; Lin, Y.C.; Wu, R.J. Fuel generation through photoreduction of CO2 on novel Cu/BiVO4. Mater. Res. Bull. 2020, 130, 110955. [Google Scholar] [CrossRef]

- Lee, G.J.; Anandan, S.; Masten, S.J.; Wu, J.J. Photocatalytic hydrogen evolution from water splitting using Cu doped ZnS microspheres under visible light irradiation. Renew. Energy 2016, 89, 18–26. [Google Scholar] [CrossRef]

- Liu, B.; Ye, L.; Wang, R.; Yang, J.; Zhang, Y.; Guan, R.; Tian, L.; Chen, X. Phosphorus-doped graphitic carbon nitride nanotubes with amino-rich surface for efficient CO2 capture, enhanced photocatalytic activity, and product selectivity. ACS Appl. Mater. Interfaces 2018, 10, 4001–4009. [Google Scholar] [CrossRef]

- Kuvarega, A.T.; Krause, R.W.M.; Mamba, B.B. Nitrogen/palladium-codoped TiO2 for efficient visible light photocatalytic dye degradation. J. Phys. Chem. C 2011, 115, 22110–22120. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, N.; Gao, C.; Xiong, Y. Defect engineering in photocatalytic materials. Nano Energy 2018, 53, 293–336. [Google Scholar] [CrossRef]

- Di, J.; Zhu, C.; Ji, M.; Duan, M.; Long, R.; Yan, C.; Gu, K.; Xiong, J.; She, Y.; Xia, J.; et al. Defect-rich Bi12O17Cl2 nanotubes self-accelerating charge separation for boosting photocatalytic CO2 reduction. Angew. Chem. 2018, 57, 14847–14851. [Google Scholar] [CrossRef]

- Cai, X.; Wang, F.; Wang, R.; Xi, Y.; Wang, A.; Wang, J.; Teng, B.; Baiy, S. Synergism of surface strain and interfacial polarization on Pd@Au core-shell cocatalysts for highly efficient photocatalytic CO2 reduction over TiO2. J. Mater. Chem. A 2020, 8, 7350–7359. [Google Scholar] [CrossRef]

- Liu, Z.; Menendez, C.; Shenoy, J.; Hart, J.N.; Sorrell, C.C.; Cazorl, C. Strain engineering of oxide thin films for photocatalytic applications. Nano Energy 2020, 72, 104732. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.N.; Zhan, Z.; Woo, M.H.; Wu, C.Y.; Biswas, P. Photocatalytic reduction of CO2 with H2O on mesoporous silica supported Cu/TiO2 catalysts. Appl. Catal. B 2010, 100, 386–392. [Google Scholar] [CrossRef]

- Cao, S.; Shen, B.; Tong, T.; Fu, J.; Yu, J. 2D/2D heterojunction of ultrathin MXene/ Bi2WO6 nanosheets for improved photocatalytic CO2 reduction. Adv. Funct. Mater. 2018, 28, 1800136. [Google Scholar] [CrossRef]

- Li, J.; Shao, W.; Geng, M.; Wan, S.; Ou, M.; Chen, Y. Combined Schottky junction and doping effect in CdxZn1-xS@Au/BiVO4 Z-Scheme photocatalyst with boosted carriers charge separation for CO2 reduction by H2O. J. Colloid Interface Sci. 2022, 606, 1469–1476. [Google Scholar] [CrossRef] [PubMed]

- Razavi-Khosroshahi, H.; Edalati, K.; Hirayama, M.; Emami, H.; Arita, M.; Yamauchi, M.; Hagiwara, H.; Ida, S.; Ishihara, T.; Akiba, E.; et al. Visible- light-driven photocatalytic hydrogen generation on nanosized TiO2-II stabilized by high-pressure torsion. ACS Catal. 2016, 6, 5103–5107. [Google Scholar] [CrossRef]

- Edalati, K.; Fujiwara, K.; Takechi, S.; Wang, Q.; Arita, M.; Watanabe, M.; Sauvage, X.; Ishihara, T.; Horita, Z. Improved photocatalytic hydrogen evolution on tantalate perovskites CsTaO3 and LiTaO3 by strain-induced vacancies. ACS Appl. Energy Mater. 2020, 3, 1710–1718. [Google Scholar] [CrossRef]

- Edalati, K.; Uehiro, R.; Takechi, S.; Wang, Q.; Arita, M.; Watanabe, M.; Ishihara, T.; Horita, Z. Enhanced photocatalytic hydrogen production on GaN-ZnO oxynitride by introduction of strain-induced nitrogen vacancy complexes. Acta Mater. 2020, 185, 149–156. [Google Scholar] [CrossRef]

- Wang, Q.; Edalati, K.; Koganemaru, Y.; Nakamura, S.; Watanabe, M.; Ishihara, T.; Horita, Z. Photocatalytic hydrogen generation on low-bandgap black zirconia (ZrO2) produced by high-pressure torsion. J. Mater. Chem. A 2020, 8, 3643–3650. [Google Scholar] [CrossRef]

- Edalati, P.; Wang, Q.; Razavi-Khosroshahi, H.; Fuji, M.; Ishihara, T.; Edalati, K. Photocatalytic hydrogen evolution on a high entropy oxide. J. Mater. Chem. A 2020, 8, 3814–3821. [Google Scholar] [CrossRef]

- Hidalgo-Jimeneza, J.; Wang, Q.; Edalatib, K.; Cubero-Sesína, J.M.; Razavi-Khosroshahid, H.; Ikomac, Y.; Gutiérrez-Fallase, D.; Dittel-Mezaa, F.A.; Rodríguez-Rufinoa, J.C.; Fujid, M.; et al. Phase transformations, vacancy formation and variations of optical and photocatalytic properties in TiO2-ZnO composites by high pressure torsion. Int. J. Plast. 2020, 124, 170–185. [Google Scholar] [CrossRef]

- Edalati, P.; Shen, X.F.; Watanabe, M.; Ishihara, T.; Arita, M.; Fuji, M.; Edalati, K. High-entropy oxynitride as a low-bandgap and stable photocatalyst for hydrogen production. J. Mater. Chem. A 2021, 9, 15076–15086. [Google Scholar] [CrossRef]

- Edalati, P.; Itagoe, Y.; Ishihara, H.; Ishihara, T.; Emami, H.; Arita, M.; Fuji, M.; Edalati, K. Visible-light photocatalytic oxygen production on a high-entropy oxide by multiple-heterojunction introduction. J. Photochem. Photobiol. A 2022, 433, 114167. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Edalati, K.; Wu, J.; Nakashima, Y.; Arita, M.; Ikoma, Y.; Sadakiyo, M.; Inagaki, Y.; Staykov, A.; Yamauchi, M.; et al. High-pressure zinc oxide phase as visible-light-active photocatalyst with narrow band gap. J. Mater. Chem. A 2017, 5, 20298–20303. [Google Scholar] [CrossRef]

- Edalati, K.; Fujita, I.; Takechi, S.; Nakashima, Y.; Kumano, K.; Razavi-Khosroshahi, H.; Arita, M.; Watanabe, M.; Sauvage, X.; Akbay, T.; et al. Photocatalytic activity of aluminum oxide by oxygen vacancy generation using high-pressure torsion straining. Scr. Mater. 2019, 173, 120–124. [Google Scholar] [CrossRef]

- Fujita, I.; Edalati, K.; Wang, Q.; Arita, M.; Watanabe, M.; Munetoh, S.; Ishihara, T.; Horita, Z. High-pressure torsion to induce oxygen vacancies in nanocrystals of magnesium oxide: Enhanced light absorbance, photocatalysis and significance in geology. Materialia 2020, 11, 100670. [Google Scholar] [CrossRef]

- Wang, Q.; Edalati, K.; Fujita, I.; Watanabe, M.; Ishihara, T.; Horita, Z. High-pressure torsion of SiO2 quartz sand: Phase transformation, optical properties, and significance in geology. J. Am. Ceram. Soc. 2020, 103, 6594–6602. [Google Scholar] [CrossRef]

- Akrami, S.; Murakami, Y.; Watanabe, M.; Ishihara, T.; Arita, M.; Guo, Q.; Fuji, M.; Edalati, K. Enhanced CO2 conversion on highly-strained and oxygen-deficient BiVO4 photocatalyst. Chem. Eng. J. 2022, 442, 136209. [Google Scholar] [CrossRef]

- Akrami, S.; Watanabe, M.; Ling, T.H.; Ishihara, T.; Arita, M.; Fuji, M.; Edalati, K. High pressure TiO2-II polymorph as an active photocatalyst for CO2 to CO conversion. Appl. Catal. B 2021, 298, 120566. [Google Scholar] [CrossRef]

- Akrami, S.; Murakami, Y.; Watanabe, M.; Ishihara, T.; Arita, M.; Fuji, M.; Edalati, K. Defective high-entropy oxide photocatalyst with high activity for CO2 conversion. Appl. Catal. B 2022, 303, 120896. [Google Scholar] [CrossRef]

- Akrami, S.; Edalati, P.; Shundo, Y.; Watanabe, M.; Ishihara, T.; Fuji, M.; Edalati, K. Significant CO2 photoreduction on a high-entropy oxynitride. Chem. Eng. J. 2022, 449, 137800. [Google Scholar]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A.; et al. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. A review on high-pressure torsion (HPT) from 1935 to 1988. Mater. Sci. Eng. A 2016, 652, 325–352. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Scaling-up of high pressure torsion using ring shape. Mater. Trans. 2009, 50, 92–95. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z.; Mine, Y. High-pressure torsion of hafnium. Mater. Sci. Eng. A 2010, 527, 2136–2141. [Google Scholar] [CrossRef]

- Lee, S.; Edalati, K.; Horita, Z. Microstructures and mechanical properties of pure V and Mo processed by high-pressure torsion. Mater. Trans. 2010, 51, 1072–1079. [Google Scholar] [CrossRef]

- Chen, L.; Ping, L.; Ye, T.; Lingfeng, L.; Kemin, X.; Meng, Z. Observations on the ductility and thermostability of tungsten processed from micropowder by improved high-pressure torsion. Rare Met. Mater. Eng. 2016, 45, 3089–3094. [Google Scholar] [CrossRef]

- Edalati, K.; Yokoyama, Y.; Horita, Z. High-pressure torsion of machining chips and bulk discs of amorphous Zr50Cu30Al10Ni10. Mater. Trans. 2010, 51, 23–26. [Google Scholar] [CrossRef]

- Wang, Y.B.; Qu, D.D.; Wang, X.H.; Cao, Y.; Liao, X.Z.; Kawasaki, M.; Ringer, S.P.; Shan, Z.W.; Langdon, T.G.; Shen, J. Introducing a strain-hardening capability to improve the ductility of bulk metallic glasses via severe plastic deformation. Acta Mater. 2012, 60, 253–260. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Correlations between hardness and atomic bond parameters of pure metals and semi-metals after processing by high-pressure torsion. Scr. Mater. 2011, 64, 161–164. [Google Scholar] [CrossRef]

- Ikoma, Y.; Hayano, K.; Edalati, K.; Saito, K.; Guo, Q.; Horita, Z. Phase transformation and nanograin refinement of silicon by processing through high-pressure torsion. Appl. Phys. Lett. 2012, 101, 121908. [Google Scholar] [CrossRef]

- Blank, V.D.; Churkin, V.D.; Kulnitskiy, B.A.; Perezhogin, I.A.; Kirichenko, A.N.; Erohin, S.V.; Sorokin, P.B.; Popov, M.Y. Pressure-induced transformation of graphite and diamond to onions. Crystals 2018, 8, 68. [Google Scholar] [CrossRef]

- Gao, Y.; Ma, Y.; An, Q.; Levitas, V.I.; Zhang, Y.; Feng, B.; Chaudhuri, J.; Goddard, W.A. III: Shear driven formation of nano-diamonds at sub-gigapascals and 300 K. Carbon 2019, 146, 364–368. [Google Scholar] [CrossRef]

- Edalati, K.; Uehiro, R.; Fujiwara, K.; Ikeda, Y.; Li, H.W.; Sauvage, X.; Valiev, R.Z.; Akiba, E.; Tanaka, I.; Horita, Z. Ultra-severe plastic deformation: Evolution of microstructure, phase transformation and hardness in immiscible magnesium-based systems. Mater. Sci. Eng. A 2017, 701, 158–166. [Google Scholar] [CrossRef]

- Oberdorfer, B.; Lorenzoni, B.; Unger, K.; Sprengel, W.; Zehetbauer, M.; Pippan, R.; Wurschum, R. Absolute concentration of free volume-type defects in ultrafine-grained Fe prepared by high-pressure torsion. Scr. Mater. 2010, 63, 452–455. [Google Scholar] [CrossRef] [PubMed]

- Straumal, B.B.; Mazilkin, A.A.; Baretzky, B.; Schütz, G.; Rabkin, E.; Valiev, R.Z. Accelerated diffusion and phase transformations in Co-Cu alloys driven by the severe plastic deformation. Mater. Trans. 2012, 53, 63–71. [Google Scholar] [CrossRef]

- Edalati, K.; Emami, H.; Staykov, A.; Smith, D.J.; Akiba, E.; Horita, Z. Formation of metastable phases in magnesium-titanium system by high-pressure torsion and their hydrogen storage performance. Acta Mater. 2015, 50, 150–156. [Google Scholar] [CrossRef]

- Kormout, K.S.; Pippan, R.; Bachmaier, A. Deformation-induced supersaturation in immiscible material systems during high-pressure torsion. Adv. Eng. Mater. 2017, 19, 1600675. [Google Scholar] [CrossRef]

- Bridgman, P.W. Effects of high shearing stress combined with high hydrostatic pressure. Phys. Rev. 1935, 48, 825–847. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Application of high-pressure torsion for consolidation of ceramic Powders. Scr. Mater. 2010, 63, 174–177. [Google Scholar] [CrossRef]

- Edalati, K.; Toh, S.; Ikomaa, Y.; Horita, Z. Plastic deformation and allotropic phase transformations in zirconia ceramics during high-pressure torsion. Scr. Mater. 2011, 65, 974–977. [Google Scholar] [CrossRef]

- Makhnev, A.A.; Nomerovannaya, L.V.; Gizhevskii, B.A.; Naumov, S.V.; Kostromitin, N.V. Effect of redistribution of the optical spectral weight in CuO nanostructured ceramics. Solid State Phenom. 2011, 168–169, 285–288. [Google Scholar] [CrossRef]

- Gizhevskii, B.A.; Sukhorukov, Y.P.; Nomerovannaya, L.V.; Makhnev, A.A.; Ponosov, Y.S.; Telegin, A.V.; Mostovshchikov, E.V. Features of optical properties and the electronic structure of nanostructured oxides of 3D-Metals. Solid State Phenom. 2011, 168–169, 317–320. [Google Scholar] [CrossRef]

- Delogu, F. Are processing conditions similar in ball milling and high-pressure torsion? The case of the tetragonal-to-monoclinic phase transition in ZrO2 powders. Scr. Mater. 2012, 67, 340–343. [Google Scholar] [CrossRef]

- Mostovshchikova, E.V.; Gizhevskii, B.A.; Loshkareva, N.N.; Galakhov, V.R.; Naumov, S.V.; Ponosov, Y.S.; Ovechkina, N.A.; Kostromitina, N.V.; Buling, A.; Neumann, M. Infrared and X-ray absorption spectra of Cu2O and CuO nanoceramics. Solid State Phenom. 2012, 190, 683–686. [Google Scholar] [CrossRef]

- Telegin, A.V.; Gizhevskii, B.A.; Nomerovannaya, L.V.; Makhnev, A.A. The optical and magneto-optical properties of nanostructured oxides of 3d-metals. J. Supercond. Nov. Magn. 2012, 25, 2683–2686. [Google Scholar] [CrossRef]

- Edalati, K.; Arimura, M.; Ikoma, Y.; Daio, T.; Miyata, M.; Smith, D.J.; Horita, Z. Plastic deformation of BaTiO3 ceramics by high-pressure torsion and changes in phase transformations, optical and dielectric properties. Mater. Res. Lett. 2015, 3, 216–221. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Edalati, K.; Arita, M.; Horita, Z.; Fuji, M. Plastic strain and grain size effect on high-pressure phase transformations in nanostructured TiO2 ceramics. Scr. Mater. 2016, 124, 59–62. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Edalati, K.; Emami, H.; Akiba, E.; Horita, Z.; Fuji, M. Optical properties of nanocrystalline monoclinic Y2O3 stabilized by grain size and plastic strain effects via high-pressure torsion. Inorg. Chem. 2017, 56, 2576–2580. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsova, E.I.; Degtyarev, M.V.; Zyuzeva, N.A.; Bobylev, I.B.; Pilyugin, V.P. Microstructure of YBa2Cu3Oy subjected to severe plastic deformation by high pressure torsion. Phys. Met. Metallogr. 2017, 118, 815–823. [Google Scholar] [CrossRef]

- Feng, B.; Levitas, V.I. Coupled elastoplasticity and plastic strain-induced phase transformation under high pressure and large strains: Formulation and application to BN sample compressed in a diamond anvil cell. Int. J. Plast. 2017, 96, 156–181. [Google Scholar] [CrossRef]

- Qian, C.; He, Z.; Liang, C.; Ji, W. New in situ synthesis method for Fe3O4/flake graphite nanosheet composite structure and its application in anode materials of lithium-ion batteries. J. Nanomater. 2018, 2018, 2417949. [Google Scholar] [CrossRef]

- Qi, Y.; Kosinova, A.; Kilmametov, A.R.; Straumal, B.B.; Rabkin, E. Plastic flow and microstructural instabilities during high-pressure torsion of Cu/ZnO composites. Mater. Charact. 2018, 145, 389–401. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Makarov, A.V.; Kozlov, K.A.; Sagaradze, V.V.; Zamatovskii, A.E.; Volkova, E.G.; Luchko, S.N. Deformation-induced dissolution and precipitation of nitrides in austenite and ferrite of a high-nitrogen stainless steel. Phys. Met. Metallogr. 2018, 119, 193–204. [Google Scholar] [CrossRef]

- Feng, B.; Levitas, V.I.; Li, W. FEM modeling of plastic flow and strain-induced phase transformation in BN under high pressure and large shear in a rotational diamond anvil cell. Int. J. Plast. 2019, 113, 236–254. [Google Scholar] [CrossRef]

- Edalati, K.; Wang, Q.; Eguchi, H.; Razavi-Khosroshahi, H.; Emami, H.; Yamauchi, M.; Fuji, M.; Horita, Z. Impact of TiO2-II phase stabilized in anatase matrix by high-pressure torsion on electrocatalytic hydrogen production. Mater. Res. Lett. 2019, 7, 334–339. [Google Scholar] [CrossRef]

- Edalati, K. Review on recent advancements in severe plastic deformation of oxides by high-pressure torsion (HPT). Adv. Eng. Mater. 2019, 21, 1800272. [Google Scholar] [CrossRef]

- Permyakova, I.; Glezer, A. Amorphous-nanocrystalline composites prepared by high-pressure torsion. Metals 2020, 10, 511. [Google Scholar] [CrossRef]

- Fujita, I.; Edalati, P.; Wang, Q.; Watanabe, M.; Arita, M.; Munetoh, S.; Ishihara, T.; Edalati, K. Novel black bismuth oxide (Bi2O3) with enhanced photocurrent generation, produced by high-pressure torsion straining. Scr. Mater. 2020, 187, 366–370. [Google Scholar] [CrossRef]

- Wang, Q.; Watanabe, M.; Edalati, K. Visible-light photocurrent in nanostructured high-pressure TiO2-II (Columbite) phase. J. Phys. Chem. C 2020, 124, 13930–13935. [Google Scholar] [CrossRef]

- Edalati, K.; Fujita, I.; Sauvage, X.; Arita, M.; Horita, Z. Microstructure and phase transformations of silica glass and vanadium oxide by severe plastic deformation via high-pressure torsion straining. J. Alloys Compd. 2019, 779, 394–398. [Google Scholar] [CrossRef]

- Edalati, K.; Wang, Q.; Razavi-Khosroshahi, H.; Emami, H.; Fuji, M.; Horita, Z. Low-temperature anatase-to-rutile phase transformation and unusual grain coarsening in titanium oxide nanopowders by high-pressure torsion straining. Scr. Mater. 2019, 162, 341–344. [Google Scholar] [CrossRef]

- Qi, Y.; Kauffmann, Y.; Kosinova, A.; Kilmametov, A.R.; Straumal, B.B.; Rabkin, E. Gradient bandgap narrowing in severely deformed ZnO nanoparticles. Matter. Res. Lett. 2021, 9, 58–64. [Google Scholar] [CrossRef]

- Akrami, S.; Edalati, P.; Edalati, K.; Fuji, M. High-entropy ceramics: A review of principles, production and applications. Mater. Sci. Eng. R 2021, 146, 100644. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Sarkar, A.; Velasco, L.; Wang, D.; Wang, Q.; Talasila, G.; de Biasi, L.; Kübel, C.; Brezesinski, T.; Bhattacharya, S.S.; Hahn, H.; et al. High entropy oxides for reversible energy storage. Nat. Commun. 2018, 9, 3400. [Google Scholar] [CrossRef]

- Chen, H.; Lin, W.; Zhang, Z.; Jie, K.; Mullins, D.R.; Sang, X.; Yang, S.Z.; Jafta, C.J.; Bridges, C.A.; Hu, X. Mechanochemical synthesis of high entropy oxide materials under ambient conditions: Dispersion of catalysts via entropy maximization. ACS, Mater. Lett. 2019, 1, 83–88. [Google Scholar] [CrossRef]

- Radon, A.; Hawełek, D.; Łukowiec, J.; Kubacki, P.; Włodarczyk, P. Dielectric and electromagnetic interference shielding properties of high entropy (Zn, Fe, Ni, Mg, Cd)Fe2O4 ferrite. Sci. Rep. 2019, 9, 20078. [Google Scholar] [CrossRef]

- Witte, R.; Sarkar, A.; Kruk, R.; Eggert, B.; Brand, R.A.; Wende, H.; Hahn, H. High entropy oxides: An emerging prospect for magnetic rare-earth transition metal perovskites. Phys. Rev. Mater. 2019, 3, 034406. [Google Scholar] [CrossRef]

- Wright, A.J.; Huang, C.; Walock, M.J.; Ghoshal, A.; Murugan, M.; Luo, J. Sand corrosion, thermal expansion, and ablation of medium-and high-entropy compositionally complex fluorite oxides. J. Am. Ceram. Soc. 2021, 104, 448–462. [Google Scholar] [CrossRef]

- Takata, T.; Pan, C.; Domen, K. Recent progress in oxynitride photocatalysts for visible-light-driven water splitting. Sci. Technol. Adv. Mater. 2015, 16, 033506. [Google Scholar] [CrossRef]

- Wang, K.; Lu, J.; Lu, y.; Lau, C.H.; Zheng, Y.; Fan, X. Unravelling the C-C coupling in CO2 photocatalytic reduction with H2O on Au/TiO2-x: Combination of plasmonic excitation and oxygen vacancy. Appl. Catal. B 2021, 292, 120147. [Google Scholar] [CrossRef]

- Lu, H.; Tournet, J.; Dastafkan, K.; Liu, Y.; Ng, Y.H.; Karuturi, S.K.; Zhao, C.; Yin, Z. No-blemetal- free multicomponent nanointegration for sustainable energy conversion. Chem. Rev. 2021, 121, 10271–10366. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Zuo, Y.; Wang, F.; Yao, J.; Li, B.; Kang, S.; Li, X.; Cui, L. Hierarchically mesostructured TiO2/graphitic carbon composite as a new efficient photocatalyst for the reduction of CO2 under simulated solar irradiation. Catal. Sci. Technol. 2013, 3, 3286–3291. [Google Scholar] [CrossRef]

- Liu, L.J.; Pitts, D.T.; Zhao, H.L.; Zhao, C.Y.; Li, Y. Silver-incorporated bicrystalline (anatase/brookite) TiO2 microspheres for CO2 photoreduction with water in the presence of methanol. Appl. Catal. A 2013, 467, 474–482. [Google Scholar] [CrossRef]

- Sekizawa, K.; Maeda, K.; Domen, K.; Koike, K.; Ishitani, O. Artificial Z-scheme constructed with a supramolecular metal complex and semiconductor for the photocatalytic reduction of CO2. J. Am. Chem. Soc. 2013, 135, 4596–4599. [Google Scholar] [CrossRef] [PubMed]

- Tahir, M.; Amin, N.S. Photocatalytic reduction of carbon dioxide with water vapors over montmorillonite modified TiO2 nanocomposites. Appl. Catal. B 2013, 142–143, 512–522. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wang, Z.; Cao, S.W.; Xue, C. Au/Pt nanoparticle-decorated TiO2 nanofibers with plasmon-enhanced photocatalytic activities for solar-to-fuel conversion. J. Phys. Chem. C 2013, 117, 25939–25947. [Google Scholar] [CrossRef]

- He, Z.; Wen, L.; Wang, D.; Xue, Y.; Lu, Q.; Wu, C.; Chen, J.; Song, S. Photocatalytic reduction of CO2 in aqueous solution on surface-fuorinated anatase TiO2 nanosheets with exposed {001} fcets. Energy Fuels 2014, 28, 3982–3993. [Google Scholar] [CrossRef]

- Fang, B.Z.; Bonakdarpour, A.; Reilly, K.; Xing, Y.L.; Taghipour, F.; Wilkinson, D.P. Large-scale synthesis of TiO2 microspheres with hierarchical nanostructure for highly efficient photodriven reduction of CO2 to CH4. ACS Appl. Mater. Interfaces 2014, 6, 15488–15498. [Google Scholar] [CrossRef]

- Li, K.; Lin, L.; Peng, T.; Guo, Y.; Li, R.; Zhang, J. Asymmetric zinc porphyrin-sensitized nanosized TiO2 for efficient visible-light-driven CO2 photoreduction to CO/CH4. J. Chem. Commun. 2015, 51, 12443–12446. [Google Scholar] [CrossRef]

- Fang, B.Z.; Xing, Y.L.; Bonakdarpour, A.; Zhang, S.C.; Wilkinson, D.P. Hierarchical CuO-TiO2 hollow microspheres for highly efficient photodriven reduction of CO2 to CH4. ACS Sustain. Chem. Eng. 2015, 3, 2381–2388. [Google Scholar] [CrossRef]

- Tahir, M.; Amin, N.S. Indium-doped TiO2 nanoparticles for photocatalytic CO2 reduction with H2O vapors to CH4. Appl. Catal. B 2015, 162, 98–109. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, H.B.; Xu, N.Y.; Li, H.L.; Fang, B.Z.; Zhao, Y.C.; Zhang, J.Y.; Zheng, C.G. Photocatalytic reduction of CO2 on Pt2+–Pt0/TiO2 nanoparticles under UV/Vis light irradiation: A combination of Pt2+ doping and Pt nanoparticles deposition. Int. J. Hydrog. Energy 2015, 40, 10049–10062. [Google Scholar] [CrossRef]

- Ye, L.; Wang, H.; Jin, X.; Su, Y.; Wang, D.; Xie, H.; Liu, X.; Liu, X. Synthesis of olive- green few-layered BiOI for efficient photoreduction of CO2 into solar fuels under visible/near-infrared light. Sol. Energy Mater. Sol. Cells 2016, 144, 732–739. [Google Scholar] [CrossRef]

- Nakada, A.; Nakashima, T.; Sekizawa, K.; Maeda, K.; Ishitani, O. Visible-light-driven CO2 reduction on a hybrid photocatalyst consisting of a Ru(II) binuclear complex and a Ag-loaded TaON in aqueous solutions. Chem. Sci. 2016, 7, 4364–4371. [Google Scholar] [CrossRef] [PubMed]

- Ye, T.; Huang, W.; Zeng, L.; Li, M.; Shi, J. CeO2-x platelet from monometallic cerium layered double hydroxides and its photocatalytic reduction of CO2. Appl. Catal. B 2017, 210, 141–148. [Google Scholar] [CrossRef]

- Pastor, E.; Pesci, F.; Reynal, A.; Handoko, A.; Guo, M.; An, X.; Cowan, A.; Klug, D.; Durrant, J.; Tang, J. Interfacial charge separation in Cu2O/RuOx as a visible light driven CO2 reduction catalyst. Phys. Chem. Chem. Phys. 2014, 16, 5922–5926. [Google Scholar] [CrossRef]

- Jiao, J.; Wei, Y.; Zhao, Y.; Zhao, Z.; Duan, A.; Liu, J.; Pang, Y.; Li, J.; Jiang, G.; Wang, Y. AuPd/3DOM-TiO2 catalysts for photocatalytic reduction of CO2: High efficient separation of photogenerated charge carriers. Appl. Catal. B 2017, 209, 228–239. [Google Scholar] [CrossRef]

- Kim, C.; Cho, K.M.; Al-Saggaf, A.; Gereige, I.; Jung, H.T. Z-scheme photocatalytic CO2 conversion on three-dimensional BiVO4/carbon-coated Cu2O nanowire arrays under visible light. ACS Catal. 2018, 8, 4170–4177. [Google Scholar] [CrossRef]

- Wang, J.; Qin, C.; Wang, H.; Chu, M.; Zada, A.; Zhang, X.; Li, J.; Raziq, F.; Qu, Y.; Jing, L. Exceptional photocatalytic activities for CO2 conversion on AlO bridged g-C3N4/α-Fe2O3 z-scheme nanocomposites and mechanism insight with isotopes Z. Appl. Catal. B 2018, 224, 459–466. [Google Scholar] [CrossRef]

- Jiang, H.; Katsumata, K.; Hong, J.; Yamaguchi, A.; Nakata, K.; Terashima, C.; Matsushita, N.; Miyauchi, M.; Fujishima, A. Photocatalytic reduction of CO2 on Cu2O-loaded Zn-Cr layered double hydroxides. Appl. Catal. B 2018, 224, 783–790. [Google Scholar] [CrossRef]

- Crake, A.; Christoforidis, K.C.; Godin, R.; Moss, B.; Kafizas, A.; Zafeiratos, S.; Durrant, J.R.; Petit, C. Titanium dioxide/carbon nitride nanosheet nanocomposites for gas phase CO2 photoreduction under UV-visible irradiation. Appl. Catal. B 2019, 242, 369–378. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Song, M.; Li, D.; Zhang, X.; Liu, Y. TiO2-x/CoOx Photocatalyst sparkles in photothermocatalytic reduction of CO2 with H2O steam. Appl. Catal. B 2019, 243, 760–770. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, P.; Wang, L.; Yang, B.; Xie, H.; Zhou, Y.; Ye, L. Ultrathin Bi4O5Br2 nanosheets for selective photocatalytic CO2 conversion into CO. Chem. Eng. J. 2019, 360, 473–482. [Google Scholar] [CrossRef]

- Maiti, D.; Meier, A.J.; Cairns, J.; Ramani, S.; Martinet, K.; Kuhn, J.N.; Bhethanabotla, V.R. Intrinsically strained noble metal-free oxynitrides for solar photoreduction of CO2. Dalton Trans. 2019, 48, 12738–12748. [Google Scholar] [CrossRef] [PubMed]

- Kozlova, E.A.; Lyulyukin, M.N.; Markovskaya, D.V.; Selishchev, D.S.; Cherepanova, S.V.; Kozlov, D.V. Synthesis of Cd1-xZnxS photocatalysts for gas-phase CO2 reduction under visible light. Photochem. Photobiol. Sci. 2019, 18, 871–877. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Lv, C.; Zhou, X.; Ye, L.; Xie, H.; Liu, Y.; Su, H.; Zhang, B.; Chen, G. Oxygen vacancies engineering Bi24O31Cl10 photocatalyst for boosted CO2 conversion. ChemSusChem 2019, 12, 2740–2747. [Google Scholar] [CrossRef]

- Guo, S.; Di, J.; Chen, C.; Zhu, C.; Duan, M.; Lian, C.; Ji, M.; Zhou, W.; Xu, M.; Song, P.; et al. Oxygen vacancy mediated bismuth stannate ultra-small nanoparticle towards photocatalytic CO2-to-CO conversion. Appl. Catal. B 2020, 276, 119156. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Wei, C.; Chen, L. Ag-Bi/BiVO4 chain-like hollow microstructures with enhanced photocatalytic activity for CO2 conversion. Appl. Catal. A 2020, 594, 117459. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Cao, Y.; Zhang, F.; Zou, Y.; Huang, Z.; Ye, L.; Zhou, Y. Interfacial oxygen vacancy engineered two-dimensional g-C3N4/BiOCl heterostructures with boosted photocatalytic conversion of CO2. ACS Appl. Energy Mater. 2020, 3, 4610–4618. [Google Scholar] [CrossRef]

- Dao, X.Y.; Xie, X.F.; Guo, J.H.; Zhang, X.Y.; Kang, Y.S.; Sun, W.Y. Boosting photocatalytic CO2 reduction efficiency by heterostructues of NH2-MIL-101 (Fe)/g-C3N4. ACS Appl. Energy Mater. 2020, 3, 3946–3954. [Google Scholar] [CrossRef]

- Zhang, X.; Ren, G.; Zhang, C.; Li, R.; Zhao, Q.; Fan, C. Photocatalytic reduction of CO2 to CO over 3D Bi2MoO6 microspheres: Simple synthesis, high efficiency and selectivity, reaction mechanism. Catal. Lett. 2020, 150, 2510–2516. [Google Scholar] [CrossRef]

- Xie, Y.; Zhuo, Y.; Liu, S.; Lin, Y.; Zuo, D.; Wu, X.; Li, C.; Wong, P.K. Ternary g-C3N4/ZnNCN@ZIF-8 hybrid photocatalysts with robust interfacial interactions and enhanced CO2 reduction. Solar RRL 2020, 4, 1900440. [Google Scholar] [CrossRef]

- Lin, N.; Lin, Y.; Qian, X.; Wang, X.; Su, W. Construction of a 2D/2D WO3/LaTiO2N direct Z-scheme photocatalyst for enhanced CO2 reduction performance under visible light. ACS Sustain. Chem. Eng. 2021, 9, 13686–13694. [Google Scholar] [CrossRef]

- Song, J.; Lu, Y.; Lin, Y.; Liu, Q.; Wang, X.; Su, W. A direct Z-scheme α-Fe2O3/LaTiO2N visible-light photocatalyst for enhanced CO2 reduction activity. Appl. Catal. B 2021, 292, 120185. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CRIP Ann. Mauuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Segal, V. Review: Modes and processes of severe plastic deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef] [PubMed]

- Zehetbauer, M.; Grossinger, R.; Krenn, H.; Krystian, M.; Pippan, R.; Rogl, P.; Waitz, T.; Wurschum, R. Bulk nanostructured functional ‘materials by severe plastic deformation. Adv. Eng. Mater. 2010, 12, 692–700. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Special issue on severe plastic deformation for nanomaterials with advanced functionality. Mater. Trans. 2019, 60, 1103. [Google Scholar] [CrossRef]

- Bryła, K.; Edalati, K. Historical studies by polish scientist on ultrafine-grained materials by severe plastic deformation. Mater. Trans. 2019, 60, 1553–1560. [Google Scholar] [CrossRef]

- Horita, Z.; Edalati, K. Severe plastic deformation for nanostructure controls. Mater. Trans. 2020, 61, 2241–2247. [Google Scholar] [CrossRef]

- Pereira, P.H.R.; Figueiredo, R.B. Finite element modelling of high-pressure torsion: An overview. Mater. Trans. 2019, 60, 1139–1150. [Google Scholar] [CrossRef]

- Levitas, V.I. High-pressure phase transformations under severe plastic deformation by torsion in rotational anvils. Mater. Trans. 2019, 60, 1294–1301. [Google Scholar] [CrossRef]

- Tsuji, N.; Gholizadeh, R.; Ueji, R.; Kamikawa, N.; Zhao, L.; Tian, Y.; Bai, Y.; Shibata, A. Formation mechanism of ultrafine grained microstructures: Various possibilities for fabricating bulk nanostructured metals and alloys. Mater. Trans. 2019, 60, 1518–1532. [Google Scholar] [CrossRef]

- Renk, O.; Pippan, R. Saturation of grain refinement during severe plastic deformation of single phase materials: Reconsiderations, current status and open questions. Mater. Trans. 2019, 60, 1270–1282. [Google Scholar] [CrossRef]

- Popov, V.V.; Popova, E.N. Behavior of Nb and Cu¬Nb composites under severe plastic deformation and annealing. Mater. Trans. 2019, 60, 1209–1220. [Google Scholar] [CrossRef]

- Skrotzki, W. Deformation heterogeneities in equal channel angular pressing. Mater. Trans. 2019, 60, 1331–1343. [Google Scholar] [CrossRef]

- Miura, H.; Iwama, Y.; Kobayashi, M. Comparisons of microstructures and mechanical properties of heterogeneous nano-structure induced by heavy cold rolling and ultrafine-grained structure by multi-directional forging of Cu¬Al alloy. Mater. Trans. 2019, 60, 1111–1115. [Google Scholar] [CrossRef]

- Faraji, G.; Torabzadeh, H. An overview on the continuous severe plastic deformation methods. Mater. Trans. 2019, 60, 1316–1330. [Google Scholar] [CrossRef]

- Toth, L.S.; Chen, C.; Pougis, A.; Arzaghi, M.; Fundenberger, J.J.; Massion, R.; Suwas, S. High pressure tube twisting for producing ultra fine grained materials: A review. Mater. Trans. 2019, 60, 1177–1191. [Google Scholar] [CrossRef]

- Masuda, T.; Horita, Z. Grain refinement of AZ31 and AZ61 Mg alloys through room temperature processing by up-scaled high-pressure torsion. Mater. Trans. 2019, 60, 1104–1110. [Google Scholar] [CrossRef]

- Yang, X.; Pan, H.; Zhang, J.; Gao, H.; Shu, B.; Gong, Y.; Zhu, X. Progress in mechanical properties of gradient structured metallic materials induced by surface mechanical attrition treatment. Mater. Trans. 2019, 60, 1543–1552. [Google Scholar] [CrossRef]

- Grosdidier, T.; Novelli, M. Recent developments in the application of surface mechanical attrition treatments for improved gradient structures: Processing parameters and surface reactivity. Mater. Trans. 2019, 60, 1344–1355. [Google Scholar] [CrossRef]

- Suwas, S.; Mondal, S. Texture evolution in severe plastic deformation processes. Mater. Trans. 2019, 60, 1457–1471. [Google Scholar] [CrossRef]

- Sauvage, X.; Duchaussoy, A.; Zaher, G. Strain induced segregations in severely deformed materials. Mater. Trans. 2019, 60, 1151–1158. [Google Scholar] [CrossRef]

- Wilde, G.; Divinski, S. Grain boundaries and diffusion phenomena in severely deformed materials. Mater. Trans. 2019, 60, 1302–1315. [Google Scholar] [CrossRef]

- Gubicza, J. Lattice defects and their influence on the mechanical properties of bulk materials processed by severe plastic deformation. Mater. Trans. 2019, 60, 1230–1242. [Google Scholar] [CrossRef]

- Čížek, J.; Janeček, M.; Vlasák, T.; Smola, B.; Melikhova, O.; Islamgaliev, R.K.; Dobatkin, S.V. The development of vacancies during severe plastic deformation. Mater. Trans. 2019, 60, 1533–1542. [Google Scholar] [CrossRef]

- Kunimine, T.; Watanabe, M. A comparative study of hardness in nanostructured Cu-Zn, Cu-Si and Cu-Ni solid-solution alloys processed by severe plastic deformation. Mater. Trans. 2019, 60, 1484–1488. [Google Scholar] [CrossRef]

- Kuramoto, S.; Furuta, T. Severe plastic deformation to achieve high strength and high ductility in Fe¬Ni based alloys with lattice softening. Mater. Trans. 2019, 60, 1116–1122. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. The contribution of severe plastic deformation to research on superplasticity. Mater. Trans. 2019, 60, 1123–1130. [Google Scholar] [CrossRef]

- Demirtas, M.; Purcek, G. Room temperature superplaticity in fine/ultrafine grained materials subjected to severe plastic deformation. Mater. Trans. 2019, 60, 1159–1167. [Google Scholar] [CrossRef]

- Moreno-Valle, E.C.; Pachla, W.; Kulczyk, M.; Sabirov, I.; Hohenwarter, A. Anisotropy of tensile and fracture behavior of pure titanium after hydrostatic extrusion. Mater. Trans. 2019, 60, 2160–2167. [Google Scholar] [CrossRef]

- Kral, P.; Dvorak, J.; Sklenicka, V.; Langdon, T.G. The characteristics of creep in metallic materials processed by severe plastic deformation. Mater. Trans. 2019, 60, 1506–1517. [Google Scholar] [CrossRef]

- Razavi-Khosroshahi, H.; Fuji, M. Development of metal oxide high-pressure phases for photocatalytic properties by severe plastic deformation. Mater. Trans. 2019, 60, 1203–1208. [Google Scholar] [CrossRef]

- Ikoma, Y. Severe plastic deformation of semiconductor materials using high-pressure torsion. Mater. Trans. 2019, 60, 1168–1176. [Google Scholar] [CrossRef]

- Blank, V.D.; Popov, M.Y.; Kulnitskiy, B.A. The effect of severe plastic deformations on phase transitions and structure of solids. Mater. Trans. 2019, 60, 1500–1505. [Google Scholar] [CrossRef]

- Révész, Á.; Kovács, Z. Severe plastic deformation of amorphous alloys. Mater. Trans. 2019, 60, 1283–1293. [Google Scholar] [CrossRef]

- Beloshenko, V.; Vozniak, I.; Beygelzimer, Y.; Estrin, Y.; Kulagin, R. Severe plastic deformation of polymers. Mater. Trans. 2019, 60, 1192–1202. [Google Scholar] [CrossRef]

- Mazilkin, A.; Straumal, B.; Kilmametov, A.; Straumal, P.; Baretzky, B. Phase transformations induced by severe plastic deformation. Mater. Trans. 2019, 60, 1489–1499. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. High-pressure torsion deformation induced phase transformations and formations: New material combinations and advanced properties. Mater. Trans. 2019, 60, 1256–1269. [Google Scholar] [CrossRef]

- Han, J.K.; Jang, J.I.; Langdon, T.G.; Kawasaki, M. Bulk-state reactions and improving the mechanical properties of metals through high-pressure torsion. Mater. Trans. 2019, 60, 1131–1138. [Google Scholar] [CrossRef]

- Edalati, K. Metallurgical alchemy by ultra-severe plastic deformation via high-pressure torsion process. Mater. Trans. 2019, 60, 1221–1229. [Google Scholar] [CrossRef]

- Mito, M.; Shigeoka, S.; Kondo, H.; Noumi, N.; Kitamura, Y.; Irie, K.; Nakamura, K.; Takagi, S.; Deguchi, H.; Tajiri, T.; et al. Hydrostatic compression effects on fifth-group element superconductors V, Nb, and Ta subjected to high-pressure torsion. Mater. Trans. 2019, 60, 1472–1483. [Google Scholar] [CrossRef]

- Nishizaki, T.; Edalati, K.; Lee, S.; Horita, Z.; Akune, T.; Nojima, T.; Iguchi, S.; Sasaki, T. Critical temperature in bulk ultrafine-grained superconductors of Nb, V, and Ta processed by high-pressure torsion. Mater. Trans. 2019, 60, 1367–1376. [Google Scholar] [CrossRef]

- Rogl, G.; Zehetbauer, M.J.; Rogl, P.F. The effect of severe plastic deformation on thermoelectric performance of skutterudites, half-Heuslers and Bi-tellurides. Mater. Trans. 2019, 60, 2071–2085. [Google Scholar] [CrossRef]

- Enikeev, N.A.; Shamardin, V.K.; Radiguet, B. Radiation tolerance of ultrafine-grained materials fabricated by severe plastic deformation. Mater. Trans. 2019, 60, 1723–1731. [Google Scholar] [CrossRef]

- Leiva, D.R.; Jorge, A.M.; Ishikawa, T.T., Jr.; Botta, W.J. Hydrogen storage in Mg and Mg-based alloys and composites processed by severe plastic deformation. Mater. Trans. 2019, 60, 1561–1570. [Google Scholar] [CrossRef]

- Huot, J.; Tousignant, M. Effect of cold rolling on metal hydrides. Mater. Trans. 2019, 60, 1571–1576. [Google Scholar] [CrossRef]

- Miyamoto, H.; Yuasa, M.; Rifai, M.; Fujiwara, H. Corrosion behavior of severely deformed pure and single-phase materials. Mater. Trans. 2019, 60, 1243–1255. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Parfenov, E.V.; Parfenova, L.V. Developing nanostructured metals for manufacturing of medical implants with improved design and biofunctionality. Mater. Trans. 2019, 60, 1356–1366. [Google Scholar] [CrossRef]

- Lowe, T.C.; Valiev, R.Z.; Li, X.; Ewing, B.R. Commercialization of bulk nanostructured metals and alloys. MRS Bull. 2021, 46, 265–272. [Google Scholar] [CrossRef]

| Materials | Investigated Properties and Applications | Reference |

|---|---|---|

| Various Materials | Impact of pressure and strain on allotropy | Bridgman (1935) [56] |

| α-Al2O3 | Microstructure and mechanical properties | Edalati et al. (2010) [57] |

| ZrO2 | Allotropic phase transformations | Edalati et al. (2011) [58] |

| CuO | Dielectric properties | Makhnev et al. (2011) [59] |

| CuO, Y3Fe5O12, FeBO3 | Optical properties and electronic structure | Gizhevskii et al. (2011) [60] |

| ZrO2 | Phase transformation | Delogu et al. (2012) [61] |

| Cu2O, CuO | Middle infrared absorption and X-ray absorption | Mostovshchikova et al. (2012) [62] |

| CuO, Y3Fe5O12, FeBO3 | Optical properties | Telegin et al. (2012) [63] |

| BaTiO3 | Optical and dielectric properties | Edalati et al. (2015) [64] |

| TiO2-II | Photocatalytic activity for hydrogen production | Razavi-Khosroshahi et al. (2016) [23] |

| Various Materials | Review on HPT | Edalati et al. (2016) [40] |

| TiO2 | Plastic strain and phase transformation | Razavi-Khosroshahi et al. (2016) [65] |

| Y2O3 | Optical properties | Razavi-Khosroshahi et al. (2016) [66] |

| YBa2Cu3Oy | Microstructural investigation | Kuznetsova et al. (2017) [67] |

| BN | Coupled elastoplasticity and plastic strain-induced phase transformation | Feng et al. (2017) [68] |

| ZnO | Photocatalytic activity for dye degradation | Razavi-Khosroshahi et al. (2017) [26] |

| Fe3O4 | Lithium-ion batteries | Qian et al. (2018) [69] |

| ZnO | Plastic flow and microstructural instabilities | Qi et al. (2018) [70] |

| Fe71.2Cr22.7Mn1.3N4.8 | Microstructural features | Shabashov et al. (2018) [71] |

| BN | Modeling of plastic flow and strain-induced phase transformation | Feng et al. (2019) [72] |

| TiO2-II | Electrocatalysis for hydrogen generation | Edalati et al. (2019) [73] |

| γ-Al2O3 | Photocatalytic activity for dye degradation | Edalati et al. (2019) [27] |

| Various Oxides | Review on HPT of oxides | Edalati et al. (2019) [74] |

| MgO | Photocatalytic activity for dye degradation | Fujita et al. (2020) [28] |

| ZrO2 | Photocatalytic activity for hydrogen production | Wang et al. (2020) [26] |

| SiO2 | Photocatalytic activity for dye degradation | Wang et al. (2020) [34] |

| CsTaO3, LiTaO3 | Photocatalytic activity for hydrogen production | Edalati et al. (2020) [24] |

| GaN-ZnO | Photocatalytic activity for hydrogen production | Edalati et al. (2020) [25] |

| Fe53.3Ni26.5B20.2, Co28.2Fe38.9Cr15.4Si0.3B17.2 | Microstructure and mechanical properties | Permyakova et al. (2020) [75] |

| TiHfZrNbTaO11 | Photocatalytic activity for hydrogen production | Edalati et al. (2020) [27] |

| TiO2-ZnO | Photocatalytic activity for hydrogen production | Hidalgo-Jimeneza et al. (2020) [28] |

| Bi2O3 | Enhanced photocurrent generation | Fujita et al. (2020) [76] |

| TiO2-II | Visible-light photocurrent generation | Wang et al. (2020) [77] |

| TiO2-II | Photocatalytic activity for CO2 conversion | Akrami et al. (2021) [30] |

| TiZrHfNbTaO6N3 | Photocatalytic activity for hydrogen production | Edalati et al. (2021) [29] |

| SiO2, VO2 | Phase transformation | Edalati et al. (2021) [78] |

| TiO2 | Grain coarsening and phase transformation | Edalati et al. (2021) [79] |

| ZnO | Bandgap narrowing | Qi et al. (2021) [80] |

| BiVO4 | Photocatalytic activity for CO2 conversion | Akrami et al. (2022) [29] |

| TiHfZrNbTaO11 | Photocatalytic activity for CO2 conversion | Akrami et al. (2022) [31] |

| TiZrNbTaWO12 | Photocatalytic activity for oxygen production | Edalati et al. (2022) [30] |

| TiZrHfNbTaO6N3 | Photocatalytic activity for CO2 conversion | Akrami et al. (2022) [32] |

| Photocatalyst | Catalyst Concentration | Light Source | CO Production Rate (µmolh−1g−1) | CO Production Rate (µmolh−1m−1) | Ref. |

|---|---|---|---|---|---|

| TiO2/Graphitic Carbon | 100 mg (Gas System) | 300 W Xenon | 10.16 | 0.04 | Wang et al. (2013) [91] |

| Bicrystalline Anatase/Brookite TiO2 Microspheres | 30 mg (Gas System) | 150 W Solar Simulator | 145 | 0.95 | Liu et al. (2013) [92] |

| Ag/TaON/RuBLRu′ | 2 gL−1 (Liquid System) | 500 W High-Pressure Mercury | 0.056 | ---- | Sekizawa et al. (2013) [93] |

| 10 wt % Montmorillonite-Loaded TiO2 | 50 mg (Gas System) | 500 W Mercury | 103 | 1.25 | Tahir et al. (2013) [94] |

| Anatase TiO2 Nanofibers | 50 gL−1 (Liquid System) | 500 W Mercury Flash | 40 | ----- | Zhang et al. (2013) [95] |

| TiO2 Nanosheets Exposed {001} Facet | 1 gL−1 (Liquid System) | Two 18 W Low-Pressure Mercury | 0.12 | 0.00095 | He et al. (2014) [96] |

| Anatase TiO2 Hierarchical Microspheres | 200 mg (Gas System) | 40 W Mercury UV | 18.5 | 0.37 | Fang et al. (2014) [97] |

| TiO2 and Zn(II) Porphyrin Mixed Phases | 60 mg (Gas System) | 300 W Xenon | 8 | 0.062 | Li et al. (2015) [98] |

| Anatase TiO2 Hollow Sphere | 100 mg (Gas System) | 40 W Mercury UV | 14 | 0.16 | Fang et al. (2015) [99] |

| 10 wt % In-Doped Anatase TiO2 | 250 mg (Gas System) | 500 W Mercury Flash | 81 | 1.33 | Tahir et al. (2015) [100] |

| Pt2+–Pt0/TiO2 | 100 mg (Gas System) | 300 W Xenon | ~12.14 | 0.7 | Xiong et al. (2015) [101] |

| BiOI | 150 mg (Gas System) | 300 W High-Pressure Xenon | 4.1 | 0.03 | Ye et al. (2016) [102] |

| RuRu/Ag/TaON | 1 gL−1 (Liquid System) | High-Pressure Mercury | 5 | ---- | Nakada et al. (2016) [103] |

| RuRu/TaON | 1 gL−1 (Liquid System) | High-Pressure Mercury | 3.33 | ---- | Nakada et al. (2016) [103] |

| CeO2-x | 50 mg (Gas System) | 300 W Xenon | 1.65 | 0.08 | Ye et al. (2017) [104] |

| Cu2O/RuOx | 500 mg (Gas System) | 150 W Xenon | 0.88 | --- | Pastor et al. (2017) [105] |

| TiO2 3D Ordered Microporous/Pd | 100 mg (Gas System) | 300 W Xenon | 3.9 | 0.066 | Jiao et al. (2017) [106] |

| BiVO4/C/Cu2O | --- | 300 W Xenon | 3.01 | ---- | Kim et al. (2018) [107] |

| g-C3N4/α-Fe2O3 | 200 mg (Gas System) | 300 W Xenon | 5.7 | ----- | Wang et al. (2018) [108] |

| xCu2O/Zn2-2xCr | 4 gL−1 (Liquid System) | 200 W Mercury-Xenon | 2.5 | 0.018 | Jiang et al. (2018) [109] |

| TiO2/Carbon Nitride Nanosheet | 25 mg (Gas System) | 150 W Xenon | 2.04 | ---- | Crake et al. (2019) [110] |

| TiO2/CoOx Hydrogenated | 50 mg (Gas System) | 150 W UV | 1.24 | 0.0045 | Li et al. (2019) [111] |

| Bi4O5Br2 | 20 mg (Gas System) | 300 W High-Pressure Xenon | 63.13 | 0.58 | Bai et al. (2019) [112] |

| ZnGaON | --- | 1600 W Xenon | 1.05 | --- | Maiti et al. (2019) [113] |

| C3N4 by Thermal Condensation | 100 mg (Gas System) | 350 W Mercury | 4.83 | ------ | Xia et al. (2019) [9] |

| Cd1-xZnxS | 45 mg (Gas System) | UV-LED Irradiation | 2.9 | 0.015 | Kozlova et al. (2019) [114] |

| Bi24O31Cl10 | 50 mg (Gas System) | 300 W High-Pressure Xenon | 0.9 | --- | Jin et al. (2019) [115] |

| Bi2Sn2O7 | 0.4 gL−1 (Liquid System) | 300 W Xenon | 14.88 | 0.24 | Guo et al. (2020) [116] |

| Ag/Bi/BiVO4 | 10 mg (Gas System) | 300 W Xenon Illuminator | 5.19 | 0.42 | Duan et al. (2020) [117] |

| g-C3N4/BiOCl | 20 mg (Gas System) | 300 W High-Pressure Xenon | 4.73 | --- | Chen et al. (2020) [118] |

| Fe/g-C3N4 | 1 gL−1 (Liquid System) | 300 W Xenon | ~22.5 | 0.06 | Dao et al. (2020) [119] |

| Bi2MoO6 | 0.7 gL−1 (Liquid System) | 300 W Xenon | 41.5 | 1.26 | Zhang et al. (2020) [120] |

| g-C3N4/Zinc Carbodiimide/Zeolitic Imidazolate Framework | 100 mg (Gas System) | 300 W Xenon | ~0.45 | 0.014 | Xie et al. (2020) [121] |

| WO3/LaTiO2N | 10 mg (Gas System) | 300 W Xenon | 2.21 | 0.4 | Lin et al. (2021) [122] |

| α-Fe2O3/LaTiO2N | 20 mg (Gas System) | 300 W Xenon | 9.7 | 0.65 | Song et al. (2021) [123] |

| TiZrHfNbTaO6N3 | 0.2 gL−1 (Liquid System) | 400 W High-Pressure Mercury | 10.72 ± 1.77 | 4.66 ± 0.3 | Akrami et al. (2022) [32] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akrami, S.; Ishihara, T.; Fuji, M.; Edalati, K. Advanced Photocatalysts for CO2 Conversion by Severe Plastic Deformation (SPD). Materials 2023, 16, 1081. https://doi.org/10.3390/ma16031081

Akrami S, Ishihara T, Fuji M, Edalati K. Advanced Photocatalysts for CO2 Conversion by Severe Plastic Deformation (SPD). Materials. 2023; 16(3):1081. https://doi.org/10.3390/ma16031081

Chicago/Turabian StyleAkrami, Saeid, Tatsumi Ishihara, Masayoshi Fuji, and Kaveh Edalati. 2023. "Advanced Photocatalysts for CO2 Conversion by Severe Plastic Deformation (SPD)" Materials 16, no. 3: 1081. https://doi.org/10.3390/ma16031081

APA StyleAkrami, S., Ishihara, T., Fuji, M., & Edalati, K. (2023). Advanced Photocatalysts for CO2 Conversion by Severe Plastic Deformation (SPD). Materials, 16(3), 1081. https://doi.org/10.3390/ma16031081