Investigation of the Dislocation Density of NiCr Coatings Prepared Using PVD–LMM Technology

Abstract

:1. Introduction

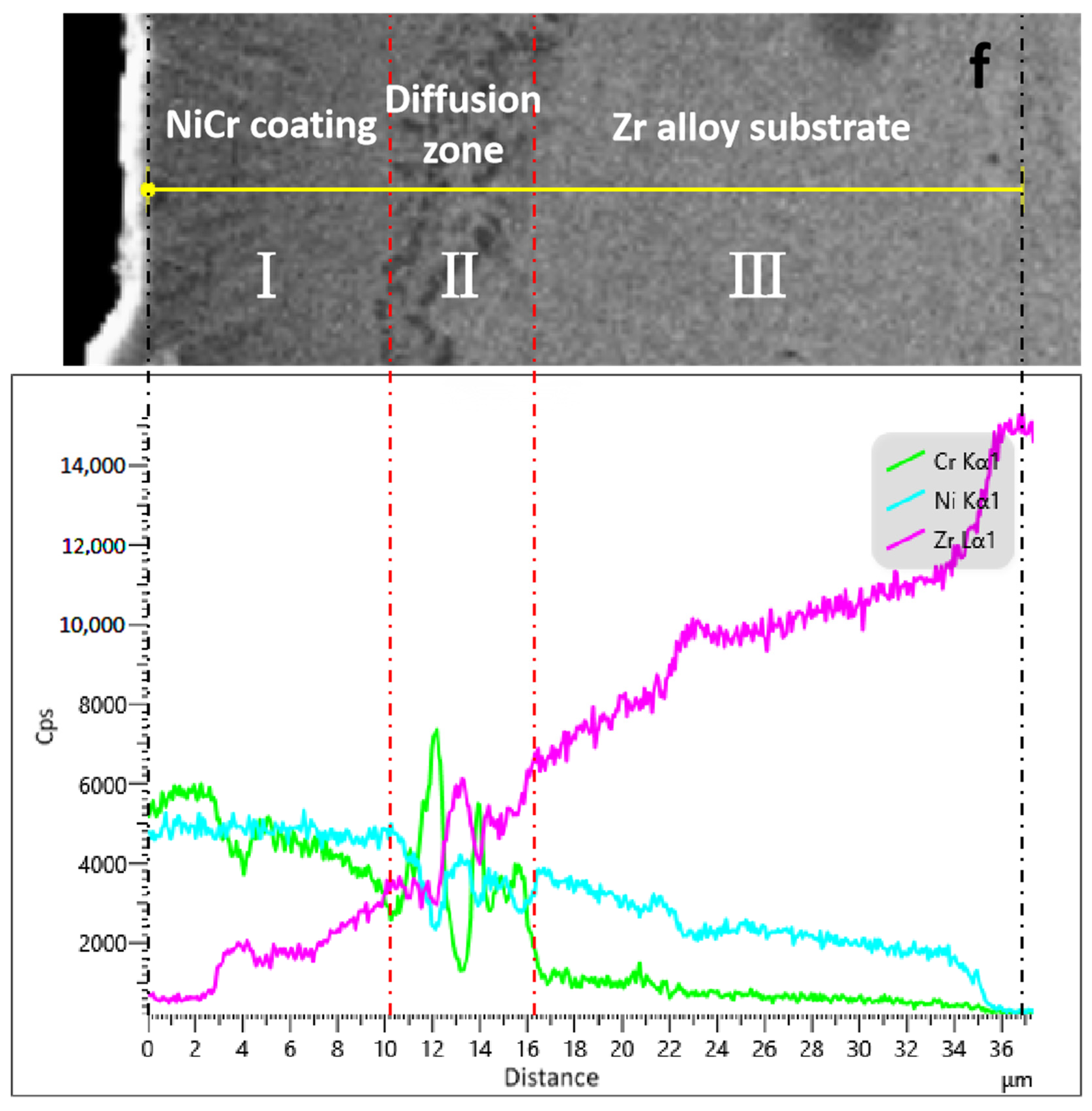

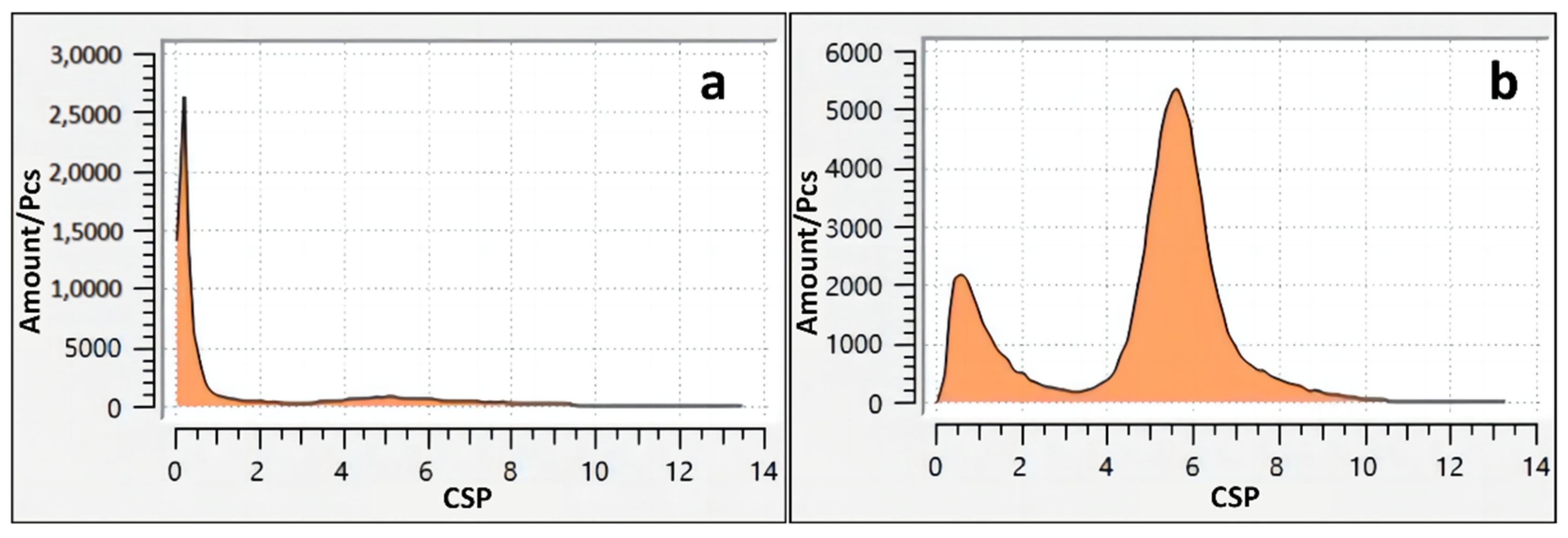

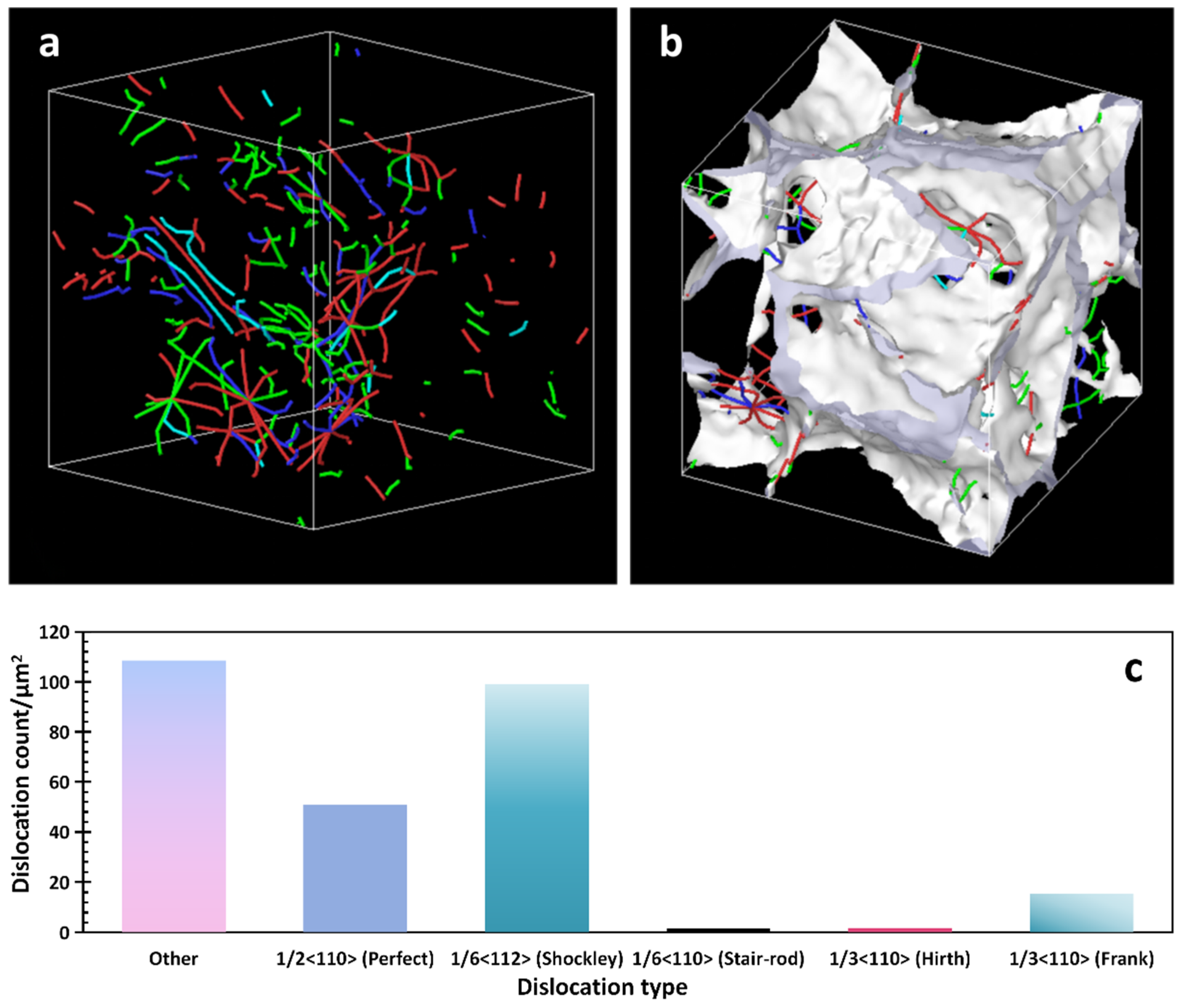

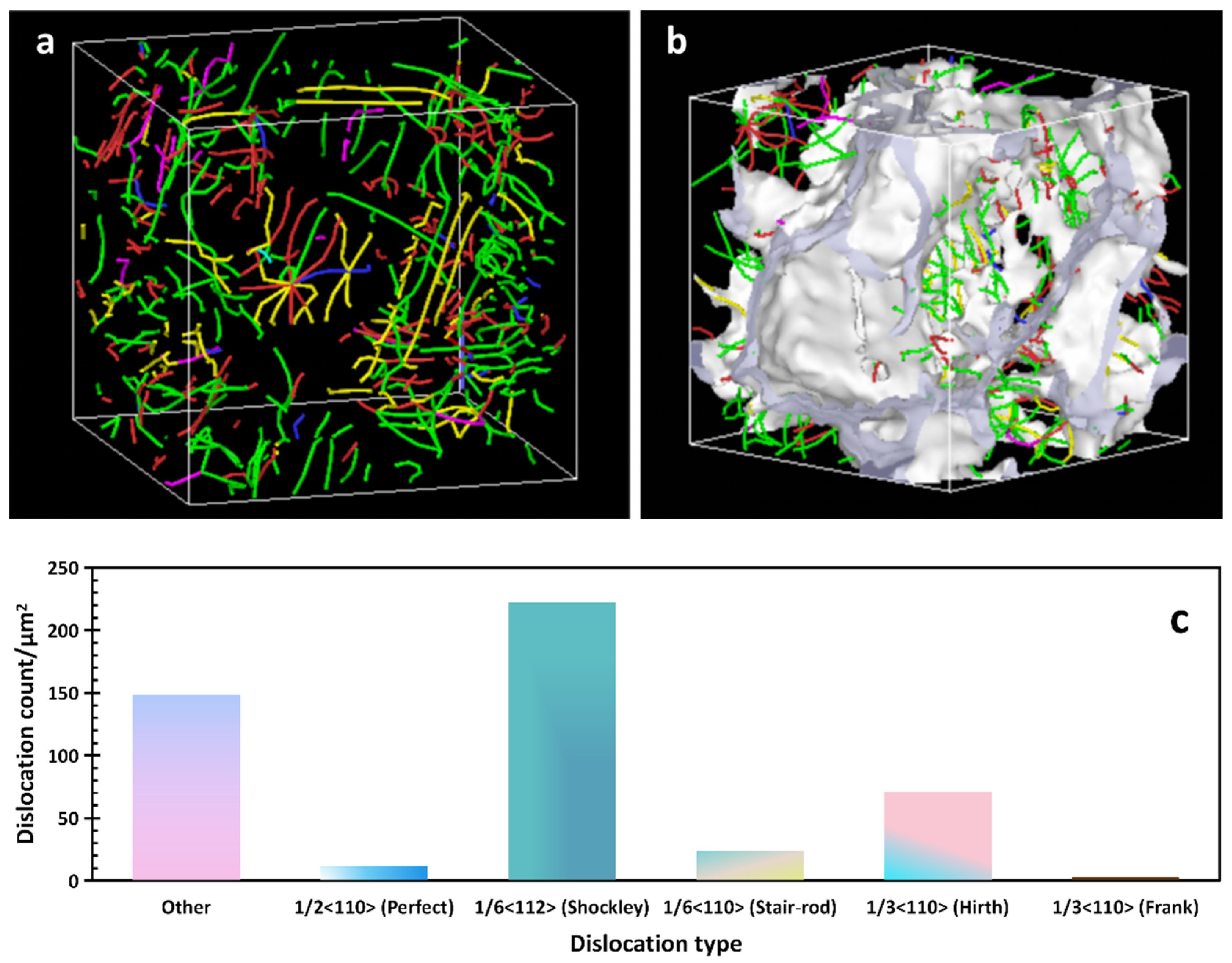

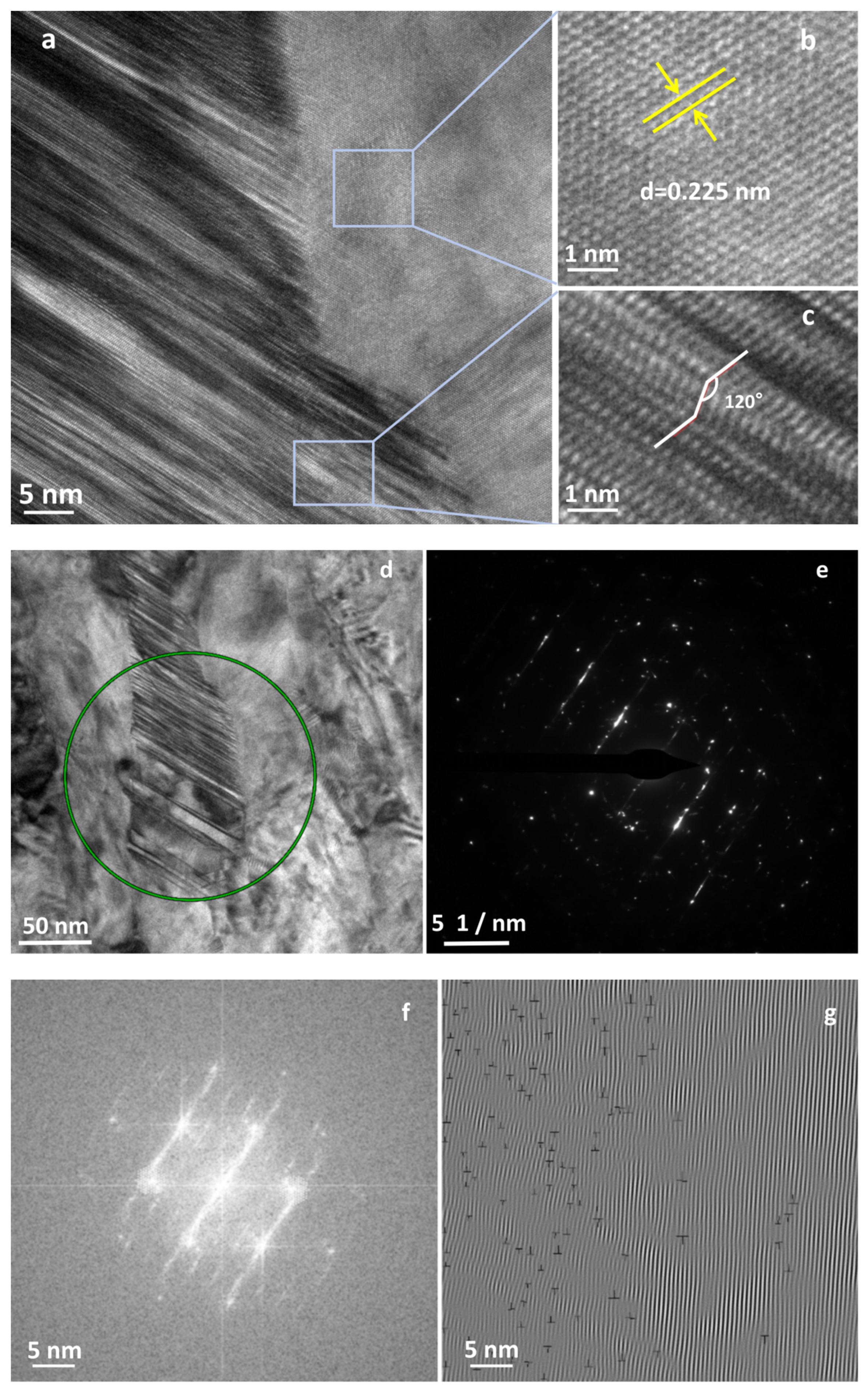

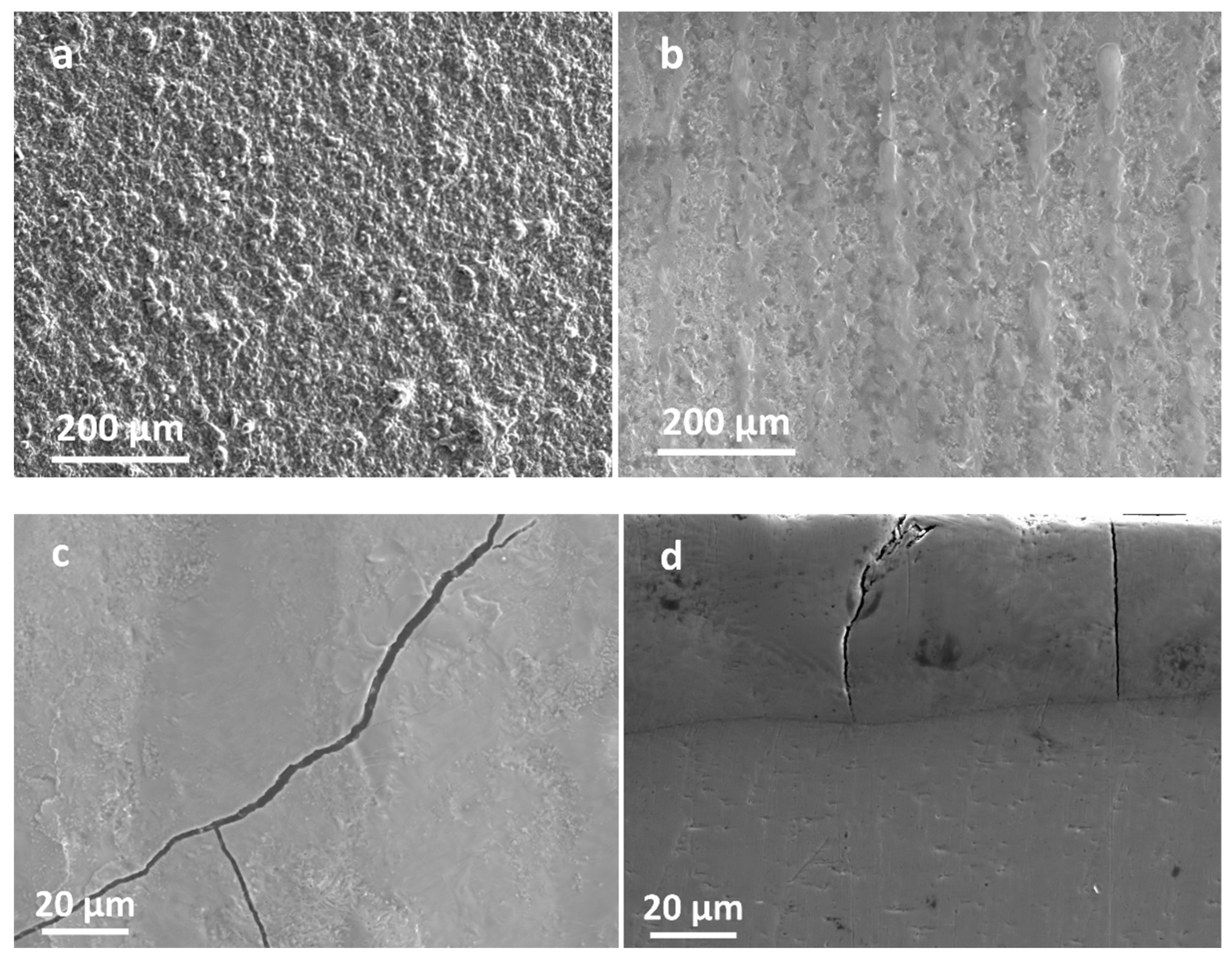

2. Experiment

2.1. Materials and Methods

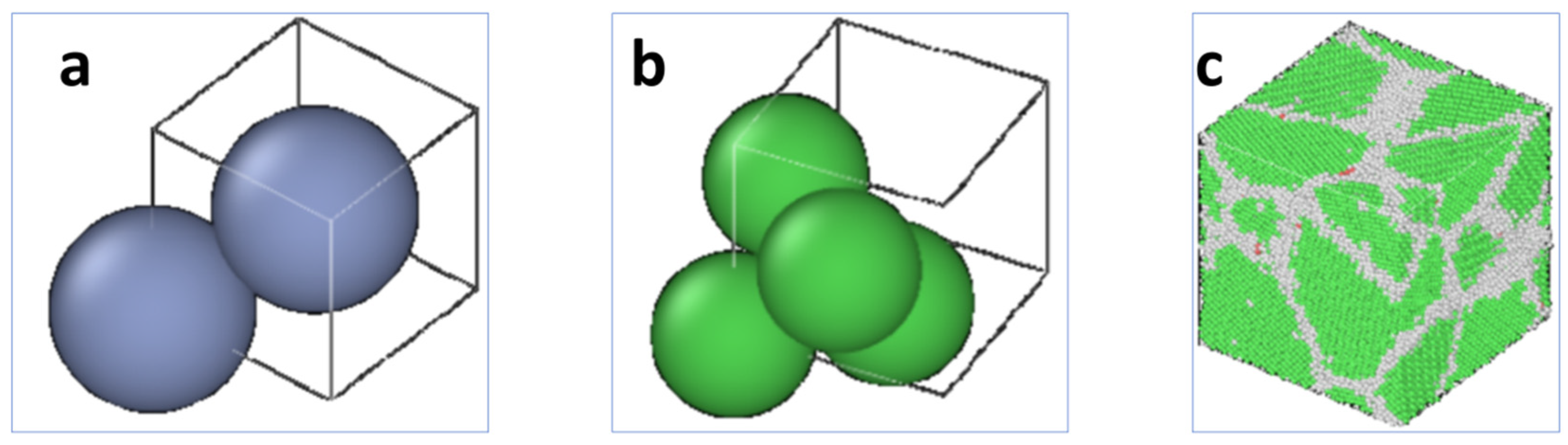

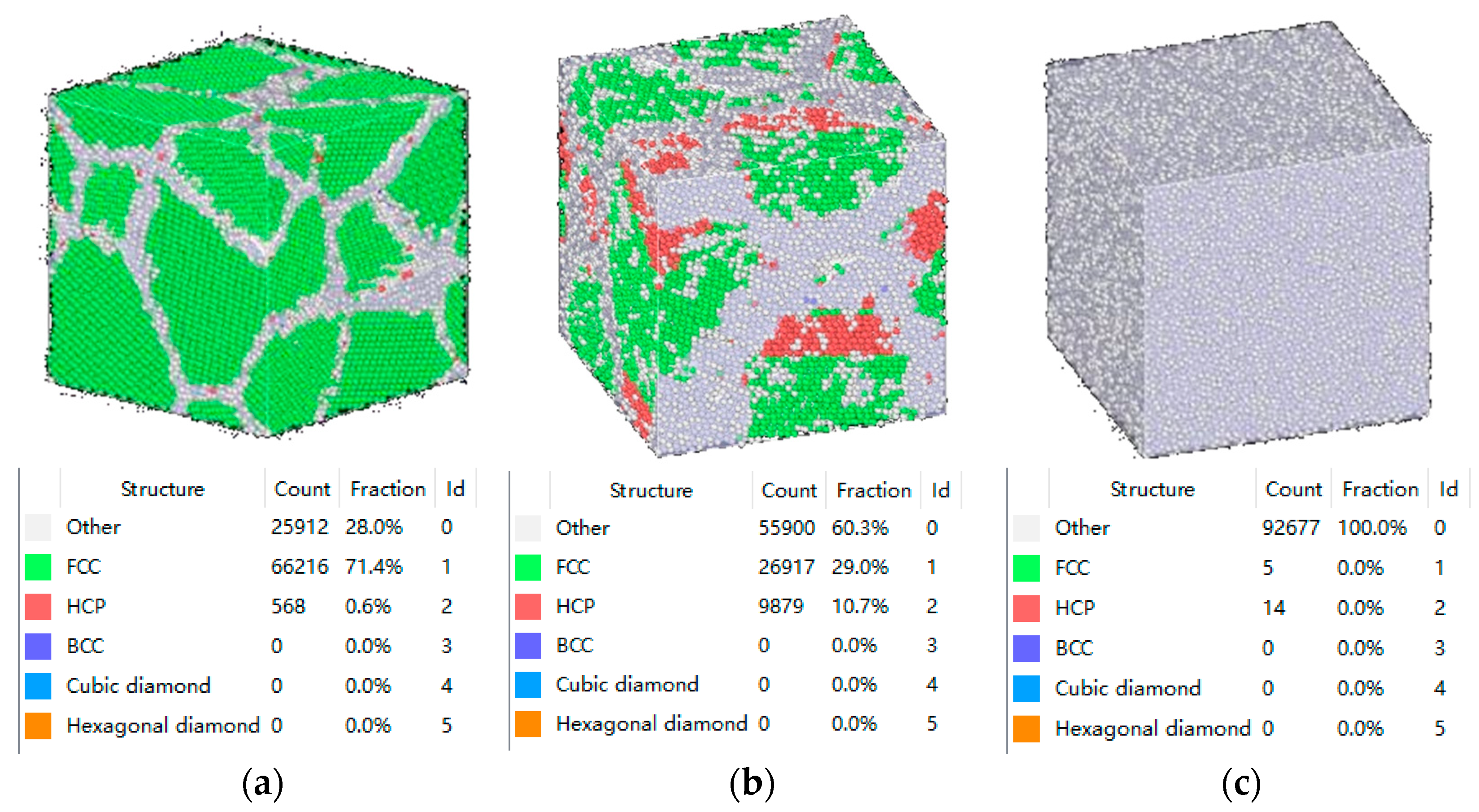

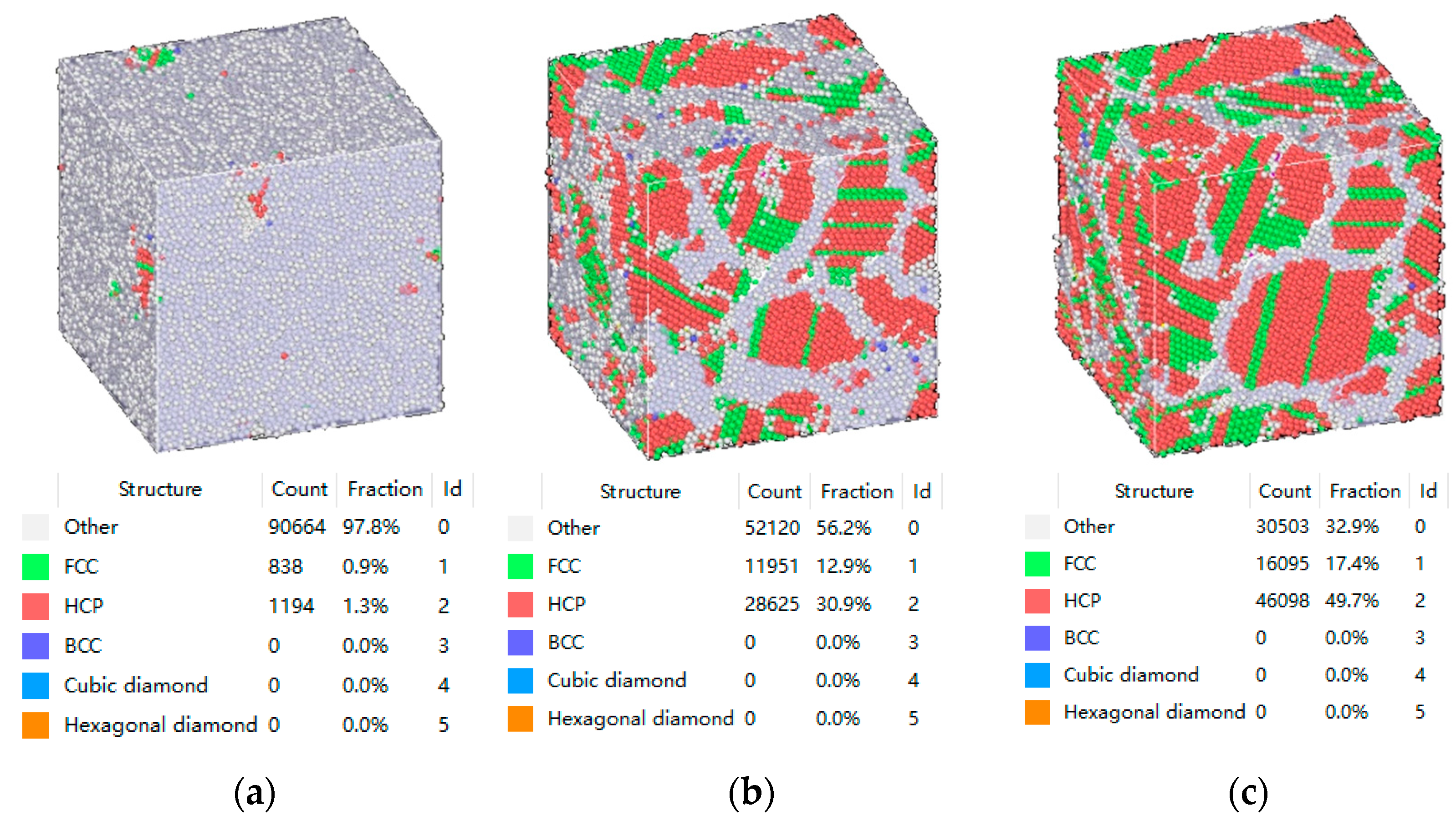

2.2. Simulation and Calculation

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Lei, Y.; Li, W.; Zhang, J.; Wang, J. Thermal stability and performance of optimized ZrCx diffusion barriers in ceramic coating systems for ATF applications. J. Am. Ceram. Soc. 2021, 104, 5424–5431. [Google Scholar] [CrossRef]

- Lee, D.; Elward, B.; Brooks, P.; Umretiya, R.; Rojas, J.; Bucci, M.; Rebak, R.B.; Anderson, M. Enhanced flow boiling heat transfer on chromium coated zircaloy-4 using cold spray technique for accident tolerant fuel (ATF) materials. Appl. Therm. Eng. 2021, 185, 116347. [Google Scholar] [CrossRef]

- Tang, C.; Stueber, M.; Seifert, H.J.; Steinbrueck, M. Protective coatings on zirconium-based alloys as accident-tolerant fuel (ATF) claddings. Corros. Rev. 2017, 35, 141–165. [Google Scholar] [CrossRef]

- Jin, D.; Yang, F.; Zou, Z.; Gu, L.; Zhao, X.; Guo, F.; Xiao, P. A study of the zirconium alloy protection by Cr3C2-NiCr coating for nuclear reactor application. Surf. Coat. Technol. 2016, 287, 55–60. [Google Scholar] [CrossRef]

- Duan, Z.; Yang, H.; Satoh, Y.; Murakami, K.; Kano, S.; Zhao, Z.; Shen, J.; Abe, H. Current status of materials development of nuclear fuel cladding tubes for light water reactors. Nucl. Eng. Des. 2017, 316, 131–150. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Zha, X.; Jiang, F.; Xu, X. Investigating the high frequency fatigue failure mechanisms of mono and multilayer PVD coatings by the cyclic impact tests. Surf. Coat. Technol. 2018, 344, 689–701. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Zhu, J.; Zhong, Z.; Gu, J. Cohesive failure and film adhesion of PVD coating: Cemented carbide substrate phase effect and its micro-mechanism. Int. J. Refract. Met. Hard Mater. 2023, 111, 106066. [Google Scholar] [CrossRef]

- Blinkov, I.V.; Volkhonsky, A.O.; Belov, D.S.; Blinkov, V.I.; Skryleva, E.A.; Shvyndina, N.V. Nanostructuring and property modification of arc PVD TiN coatings by nickel. Inorg. Mater. 2015, 51, 122–128. [Google Scholar] [CrossRef]

- An, Y.; Zheng, S.; Pang, X.; Pu, J. Effect of laser remelting on copper-nickel alloy coating prepared by extreme high-speed laser cladding. J. Manuf. Process. 2023, 95, 497–507. [Google Scholar] [CrossRef]

- Erica, L.; Alessandro, A.; Alessandro, F. Multilayered WC–Co coatings by Direct Energy Deposition-based cladding: Effect of laser remelting on interface defects. Surf. Coat. Technol. 2023, 464, 129556. [Google Scholar]

- Yu, Z.; Zheng, Y.; Chen, J.; Wu, C.; Xu, J.; Lu, H.; Yu, C. Effect of laser remelting processing on microstructure and mechanical properties of 17-4 PH stainless steel during laser direct metal deposition. J. Mater. Process. Tech. 2020, 284, 116738. [Google Scholar] [CrossRef]

- Tao, Y.; Li, J.; Lv, Y.; Hu, L. Residual stress distribution in different depths of TiNi/Ti 2 Ni-based laser clad coating prepared at different environmental temperatures. Trans. Nonferrous Met. Soc. China 2017, 27, 2043–2054. [Google Scholar] [CrossRef]

- Bo, X.; Xianxin, Z.; Guang, C.; Jun, Y.; Yadong, G. Microstructure and mechanical properties of thin-wall structure by hybrid laser metal deposition and laser remelting process. Opt. Laser Technol. 2020, 127, 106087. [Google Scholar]

- Liu, W.; Cheng, Y.; Sui, H.; Fu, J.; Duan, H. Microstructure-based intergranular fatigue crack nucleation model: Dislocation transmission versus grain boundary cracking. J. Mech. Phys. Solids 2023, 173, 105233. [Google Scholar] [CrossRef]

- Arias, D.F.; Gómez, A.; Souza, R.M.; Vélez, J.M. Residual stress gradient of Cr and CrN thin films. Mater. Chem. Phys. 2018, 204, 269–276. [Google Scholar] [CrossRef]

- Liu, H.; Qian, D. Evaluation of residual stress and corrosion behaviour of electroless plated NiP/NiMoP coatings. Trans. Nonferrous Met. Soc. China 2018, 28, 2499–2510. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, H.; Zhang, P.; Wang, Z.; Wang, M.; Sha, G.; Lin, H.; Ma, J.; Zhang, Z.; Song, Y.; et al. An exceptionally strong, ductile and impurity-tolerant austenitic stainless steel prepared by laser additive manufacturing. Acta Mater. 2023, 250, 118868. [Google Scholar] [CrossRef]

- Massimo, Z.; Andrey, S.; Corrado, B.; Anna, M.; Viviana, S.; Cristiano, C.; Leo, M.; Francesco, L.V. Extended defects in 3C-SiC: Stacking faults, threading partial dislocations, and inverted domain boundaries. Acta Mater. 2021, 213, 116915. [Google Scholar]

- Alejandro, P.; Francisco, S.P.; Mathieu, B.G.; Eduardo, B.; José, C.M.; Manuel, P.J.; Jorge, K.; Ovidio, P.R.; Antonio, R. Molecular dynamics simulation of surface phenomena due to high electronic excitation ion irradiation in amorphous silica. Eur. Phys. J. D 2023, 77, 18. [Google Scholar]

- Fang, Y.; Jiachun, L. Molecular dynamics study on the effects of nanorolling processes on the properties of nickel-based superalloy GH4169. Mater. Res. Express 2023, 10, 025002. [Google Scholar]

- Chen, S.; Xu, N. Detecting Microstructural Criticality/Degeneracy through Hybrid Learning Strategies Trained by Molecular Dynamics Simulations. ACS Appl. Mater. Interfaces 2023, 15, 10193–10202. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Li, Y.; Daniel, Ş.; Jürgen, E.; Wenping, W. Molecular dynamics study of shock-induced deformation phenomena and spallation failure in Ni-based single crystal superalloys. Int. J. Plast. 2023, 162, 103539. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, W. Simulation of bulk and grain boundary diffusion phenomena in a high entropy CoCrFeMnNi alloy by molecular dynamics. Phys. Scr. 2023, 98, 035006. [Google Scholar]

- Susumu, I.; Bin, F.; Naoya, S.; Yuichi, I. Ion diffusion across/along symmetric tilt grain boundaries in yttria-stabilized zirconia investigated by molecular dynamics simulations. Solid State Ion. 2023, 392, 116163. [Google Scholar]

- Sangjun, L.; Heon, K.; Donghyun, B. Molecular Dynamics Study on Crack Propagation in Al Containing Mg-Si Clusters Formed during Natural Aging. Materials 2023, 16, 883. [Google Scholar]

- Feng, K.; Wang, J.; Hao, S.; Xie, J. Molecular Dynamics Study of Interfacial Micromechanical Behaviors of 6H-SiC/Al Composites under Uniaxial Tensile Deformation. Nanomaterials 2023, 13, 404. [Google Scholar] [CrossRef]

- Poletaev, G.M.; Karakulova, I.V.; Rakitin, R.Y. Crystallization Front Motion Velocity in Nickel Depending on Orientation and Supercooling Temperature: Molecular Dynamics Simulation. Russ. Phys. J. 2023, 65, 1323–1327. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B Condens. Matter 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Chen, H.; Xu, L. Comparative studies of thermal conductivity for bilayer graphene with different potential functions in molecular dynamic simulations. Results Phys. 2021, 22, 103894. [Google Scholar] [CrossRef]

- Yuan, X.; Guo, X.; Guan, N.; Wang, X.; Zhan, J.; Sun, L. Molecular dynamics simulation of NiCr alloy fabricated by micro-plasma additive manufacturing. Trans. China Weld. Inst. 2021, 42, 25–32. [Google Scholar]

- Byol, J.G.; Son, J.H.; Pom, S. Structure stabilities and mono-vacancy properties of BCC transition metals by MAEAM potentials. Appl. Phys. A 2020, 126, 1–8. [Google Scholar]

- Budi, S.A.; Erfan, H.; Setyo, B.A.; Hadi, N. Thermodynamic and structure properties of aluminum nanoparticle due to heat treatment: A molecular dynamics study. J. Phys. Conf. Ser. 2022, 2193, 012029. [Google Scholar]

- Yeom, H.; Hauch, B.; Cao, G.; Garcia Diaz, B.; Martinez Rodriguez, M.; Colon Mercado, H.; Olson, L.; Sridharan, K. Laser surface annealing and characterization of Ti2AlC plasma vapor deposition coating on zirconium-alloy substrate. Thin Solid Film. 2016, 615, 202–209. [Google Scholar] [CrossRef]

- Woo, W.; Naeem, M.; Jeong, J.; Lee, C.; Harjo, S.; Kawasaki, T.; He, H.; Wang, X. Comparison of dislocation density, twin fault probability, and stacking fault energy between CrCoNi and CrCoNiFe medium entropy alloys deformed at 293 and 140 K. Mater. Sci. Eng. 2020, 781, 139224. [Google Scholar] [CrossRef]

- Guan, X.; Yu, B. Cellular Automaton Simulation for the Effects of Uneven Distribution of Dislocation Density and Small-Sized Precipitated Particles on Dynamic Recrystallization. IOP Conf. Ser. Mater. Sci. Eng. 2017, 230, 012025. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Liu, C.; Zhao, J.; Wang, B.; Li, Z.; Luo, L.; Chen, R.; Su, Y.; Guo, J. Hall-Petch Strengthening by Grain Boundaries and Annealing Twin Boundaries in Non-Equiatomic Ni2FeCr Medium-Entropy Alloy. Metals 2023, 13, 134. [Google Scholar] [CrossRef]

- Ye, F.; Yu, Y.; Zhang, B.; Rong, J.; He, D.; Han, B.; Ma, X.; Zeng, Y.; Xu, Y.; Wu, S. Influence of pre-stretching at ambient and cryogenic temperatures on dislocation configuration, precipitation behaviour, and mechanical properties of 2195 Al-Cu-Li alloy. J. Mater. Res. Technol. 2023, 22, 2983–2995. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, Z.; Ning, J.; Feng, C. Dynamic impact constitutive relation of 6008-T6 aluminum alloy based on dislocation density and second-phase particle strengthening effects. J. Alloys Compd. 2023, 932, 167718. [Google Scholar] [CrossRef]

- Sun, J.; Han, J.; Yang, Z.; Liu, H.; Song, D.; Ma, A.; Fang, L. Rebuilding the Strain Hardening at a Large Strain in Twinned Au Nanowires. Nanomaterials 2018, 8, 848. [Google Scholar] [CrossRef]

- Sankar, N.; Cheng, G.; Zeng, Z.; Zhu, Y.; Zhu, T. Strain Hardening and Size Effect in Five-fold Twinned Ag Nanowires. Nano Lett. 2015, 15, 37–44. [Google Scholar]

- Shu, X.; Lu, Y.; Xin, T.; Li, Z.; Chen, Y.; Zhou, H.; Mao, S.; Liao, X. In-situ investigation of dislocation tangle-untangle processes in small-sized body-centered cubic Nb single crystals. Mater. Lett. 2017, 198, 16–18. [Google Scholar] [CrossRef]

- Lu, S.; Xiong, J.; Wei, D.; Ding, Y.; Zhang, B.; Wu, R.; Zhang, X. Effect of Dislocation Mechanism on Elastoplastic Behavior of Crystals with Heterogeneous Dislocation Distribution. Acta Mech. Solida Sin. 2020, 33, 487–495. [Google Scholar] [CrossRef]

- Yang, W.; Gong, M.; Yao, J.; Wang, J.; Zheng, S.; Ma, X. Hardening induced by dislocation core spreading at disordered interface in Cu/Nb multilayers. Scr. Mater. 2021, 200, 113917. [Google Scholar] [CrossRef]

- Bu, L.; Cheng, Z.; Zhang, Y.; Wu, H.; Zhu, T.; Lu, L. Trans-twin dislocations in nanotwinned metals. Scr. Mater. 2023, 229, 115348. [Google Scholar] [CrossRef]

| Element | Co | Si | Mg | Cu | Ti | Fe | Overall Amount |

|---|---|---|---|---|---|---|---|

| Content. (ppm) | 90 | 48 | 45 | 52 | 32 | 220 | ≤0.1 |

| Substrate Bias Voltage | Target Current | Deposition Time | Ar Gas Flow Rate | Duty Cycle | Target Base Distance | Substrate Temperature |

|---|---|---|---|---|---|---|

| −200 V | 65 A | 90 min | 110 mL/min | 50% | 160 mm | 300 °C |

| Laser Power | Scanning Speed | Defocusing Amount | Offset | Ar Gas Flow Rate |

|---|---|---|---|---|

| 30 W | 1500 mm/min | 10 mm | 0.045 mm | 10 L/min |

| Sample | Hardness Value/HV | Average Value/HV | RMSE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PVD–LMM | 504.9 | 454.1 | 462.1 | 509.7 | 507.5 | 441.0 | 483.6 | 431.2 | 466.3 | 498.2 | 475.9 | 27.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, G.; Wei, W.; Shuai, B.; Liu, B.; Chen, Y. Investigation of the Dislocation Density of NiCr Coatings Prepared Using PVD–LMM Technology. Materials 2023, 16, 7234. https://doi.org/10.3390/ma16227234

Song G, Wei W, Shuai B, Liu B, Chen Y. Investigation of the Dislocation Density of NiCr Coatings Prepared Using PVD–LMM Technology. Materials. 2023; 16(22):7234. https://doi.org/10.3390/ma16227234

Chicago/Turabian StyleSong, Guoqing, Wentian Wei, Bincai Shuai, Botao Liu, and Yong Chen. 2023. "Investigation of the Dislocation Density of NiCr Coatings Prepared Using PVD–LMM Technology" Materials 16, no. 22: 7234. https://doi.org/10.3390/ma16227234

APA StyleSong, G., Wei, W., Shuai, B., Liu, B., & Chen, Y. (2023). Investigation of the Dislocation Density of NiCr Coatings Prepared Using PVD–LMM Technology. Materials, 16(22), 7234. https://doi.org/10.3390/ma16227234