Properties, Applications and Recent Developments of Cellular Solid Materials: A Review

Abstract

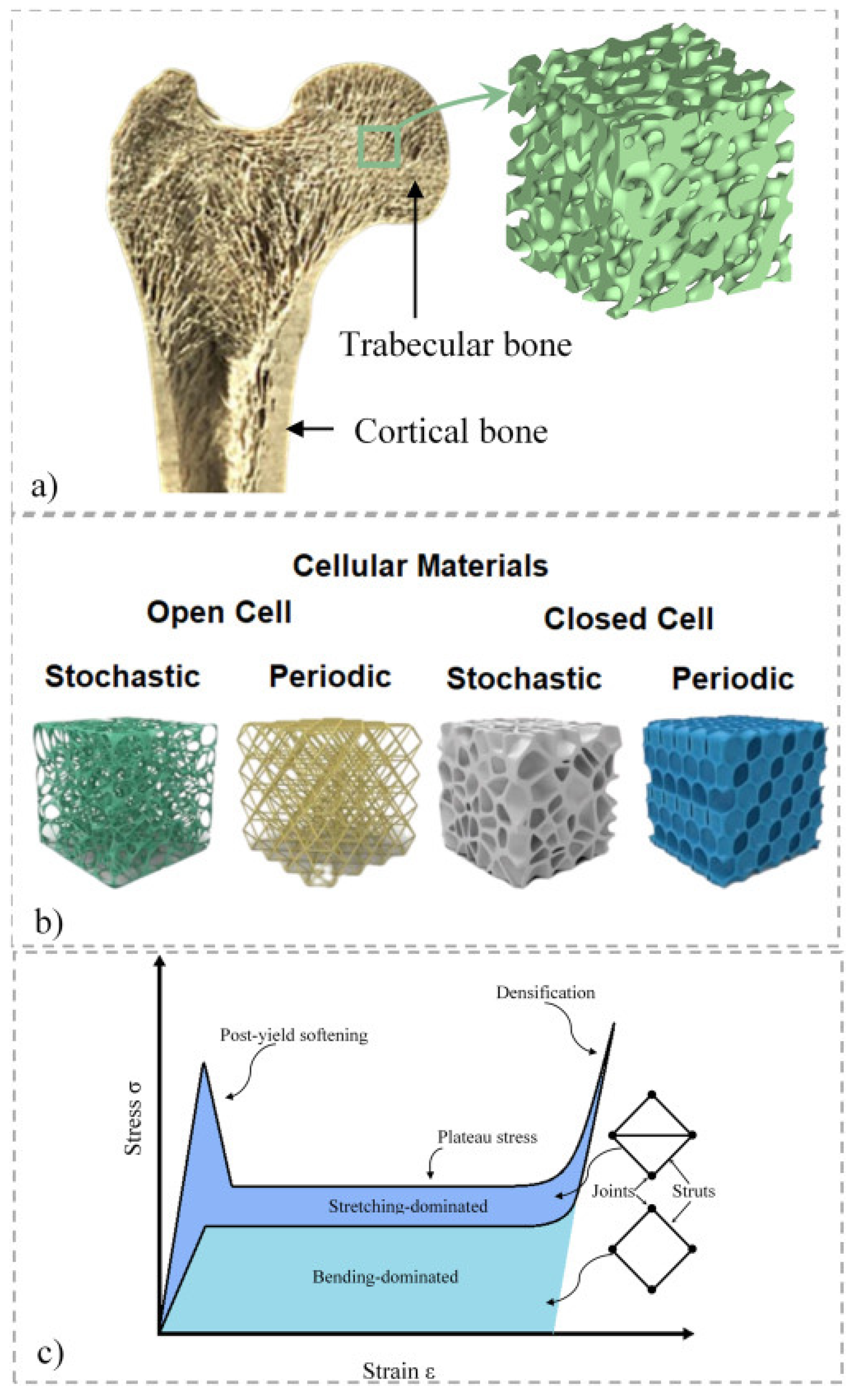

1. Introduction

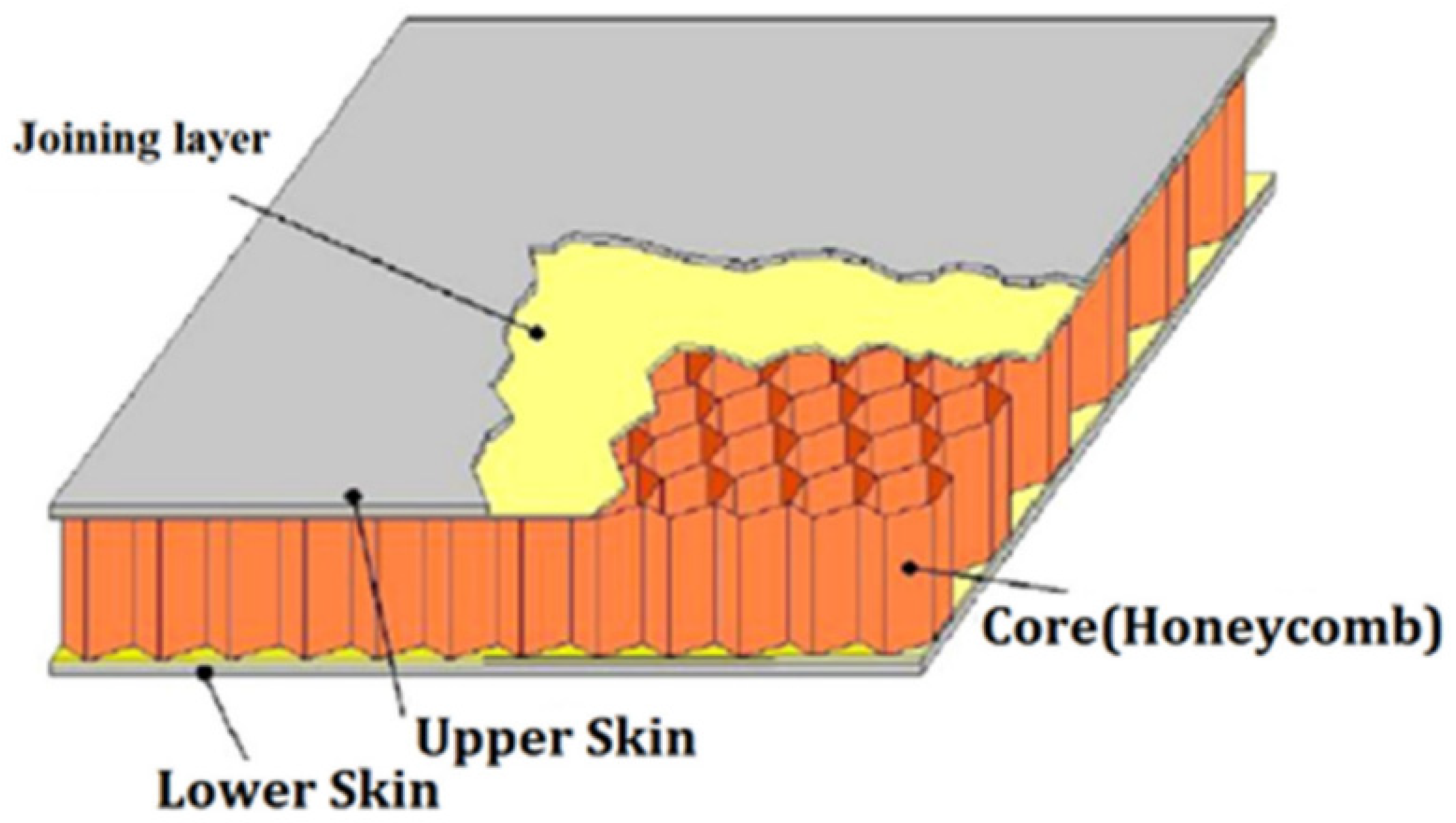

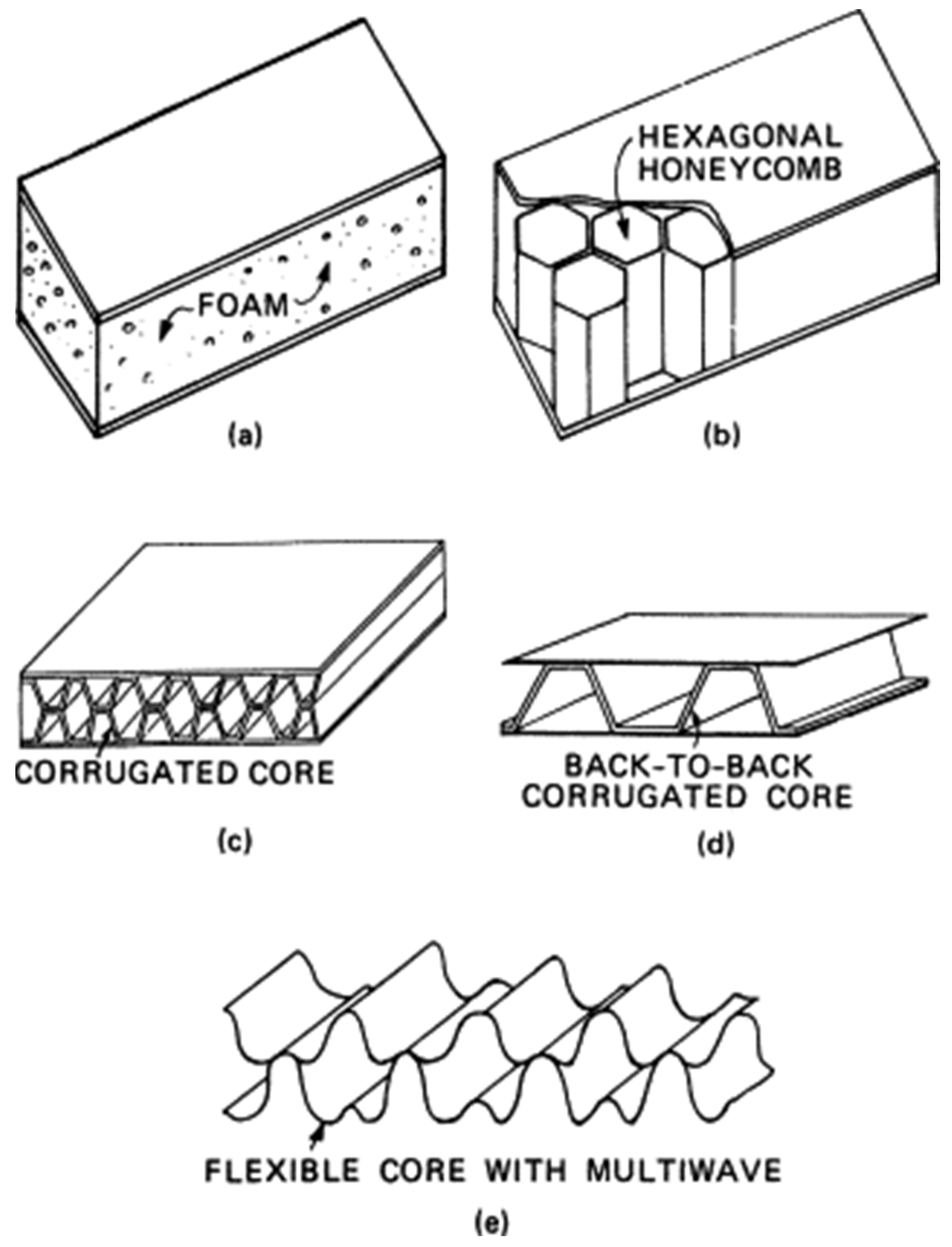

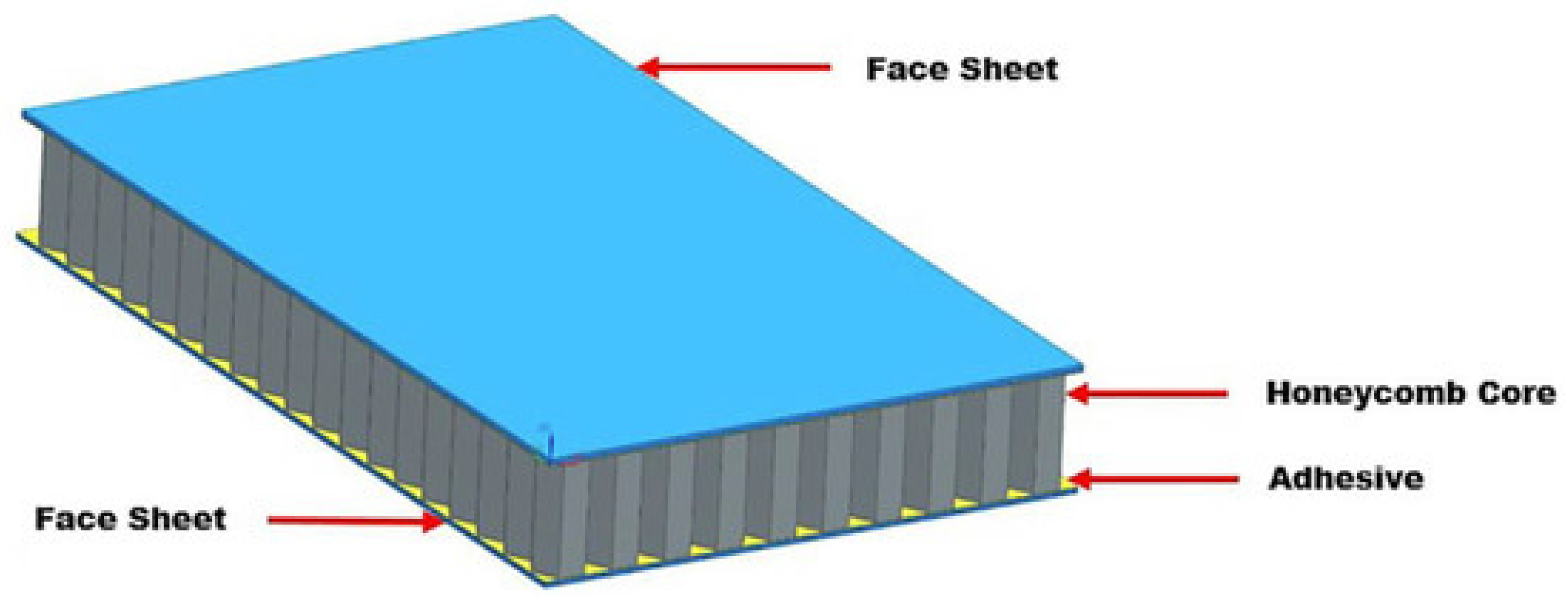

2. Sandwich Composite Cellular Materials

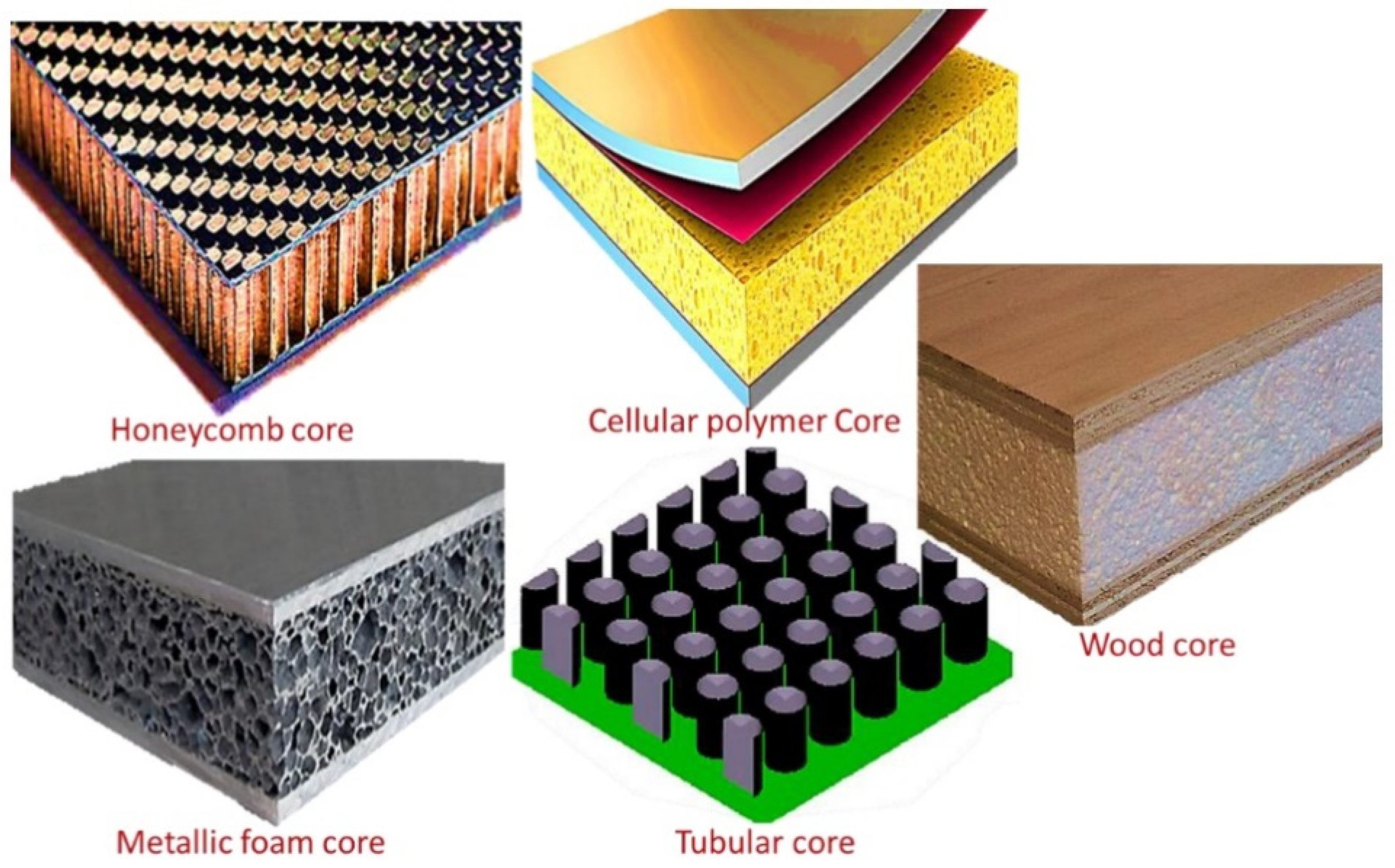

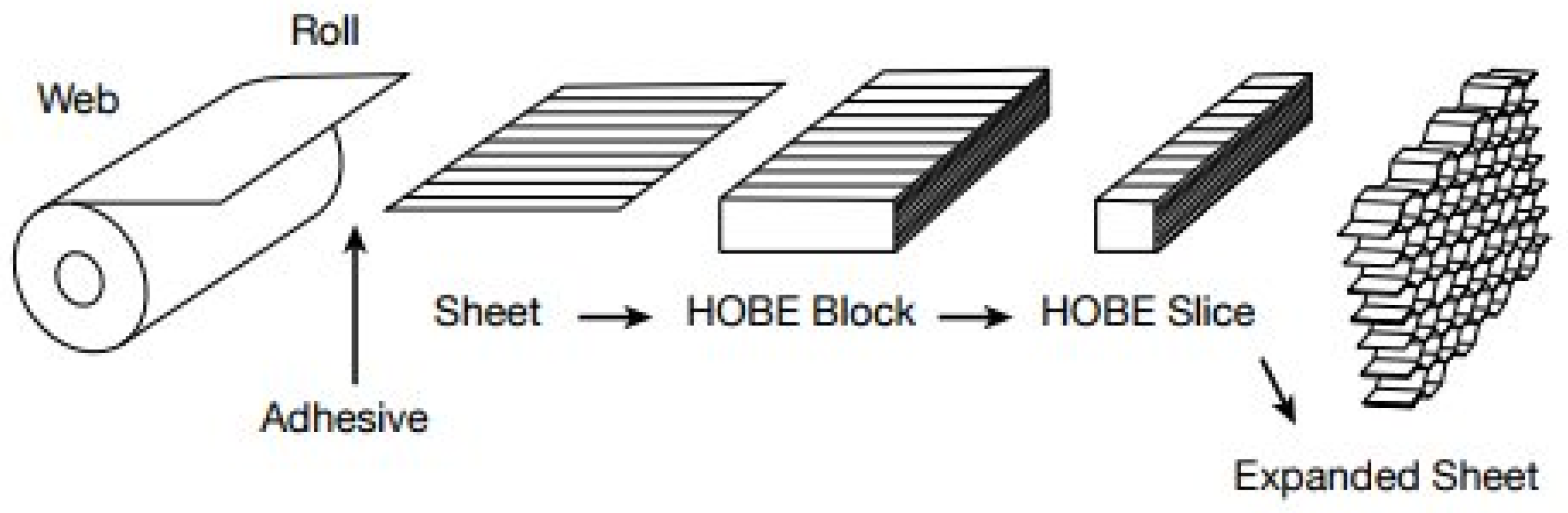

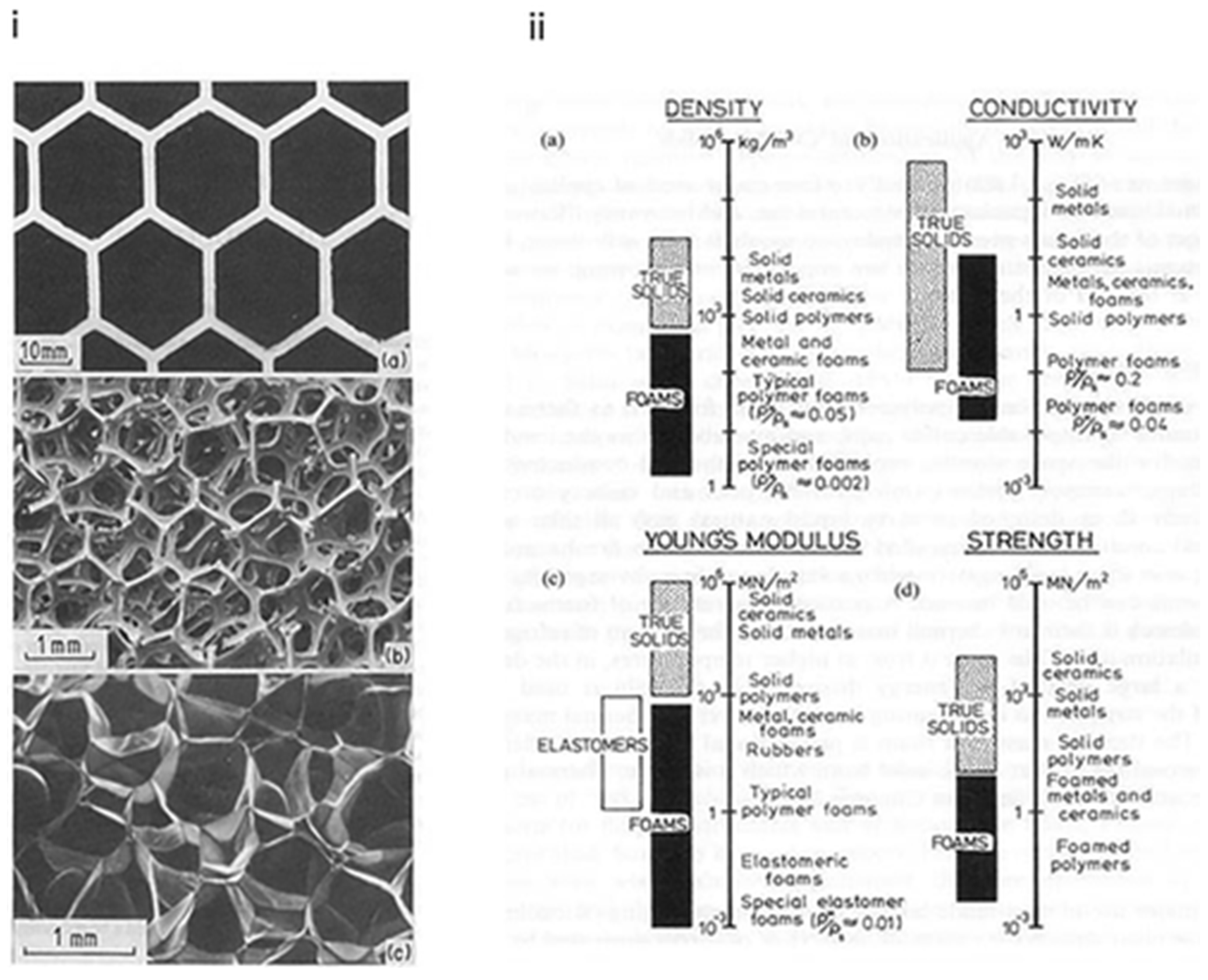

2.1. Honeycomb Core

2.2. Cellular Polymer Core

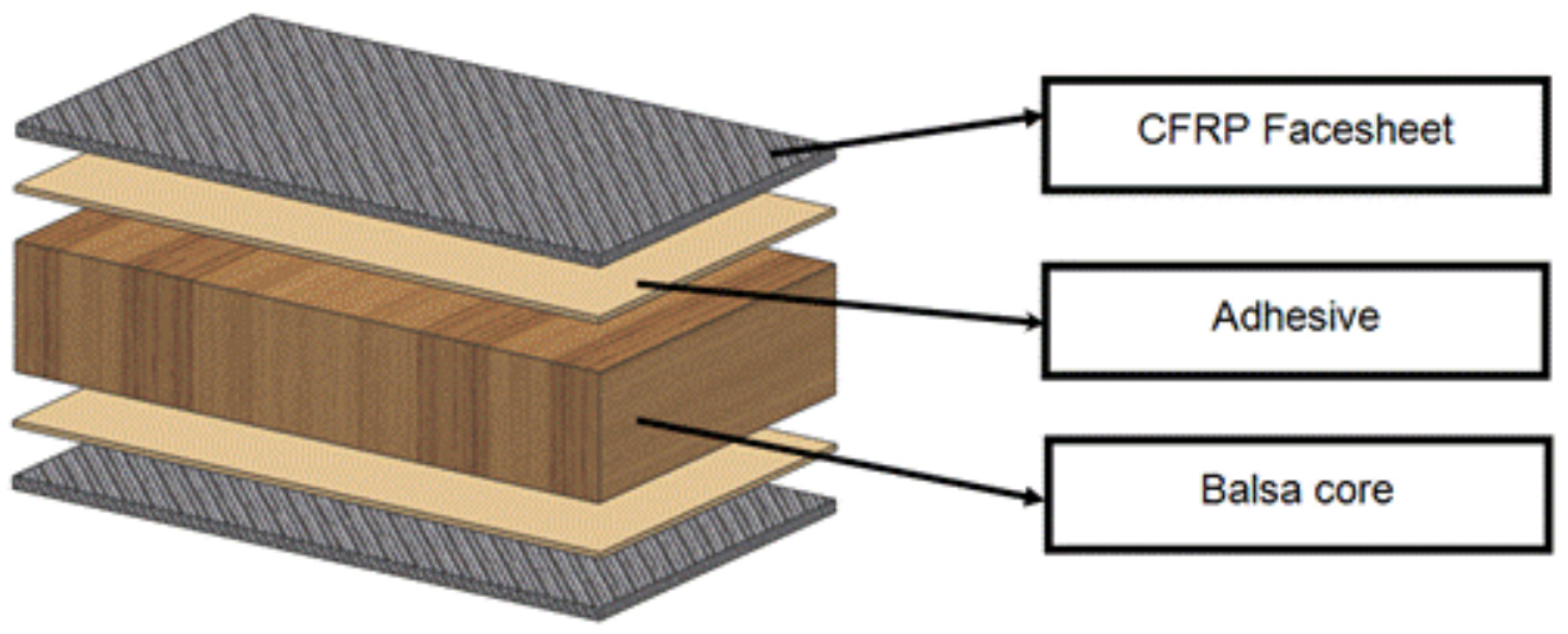

2.3. Wood Core

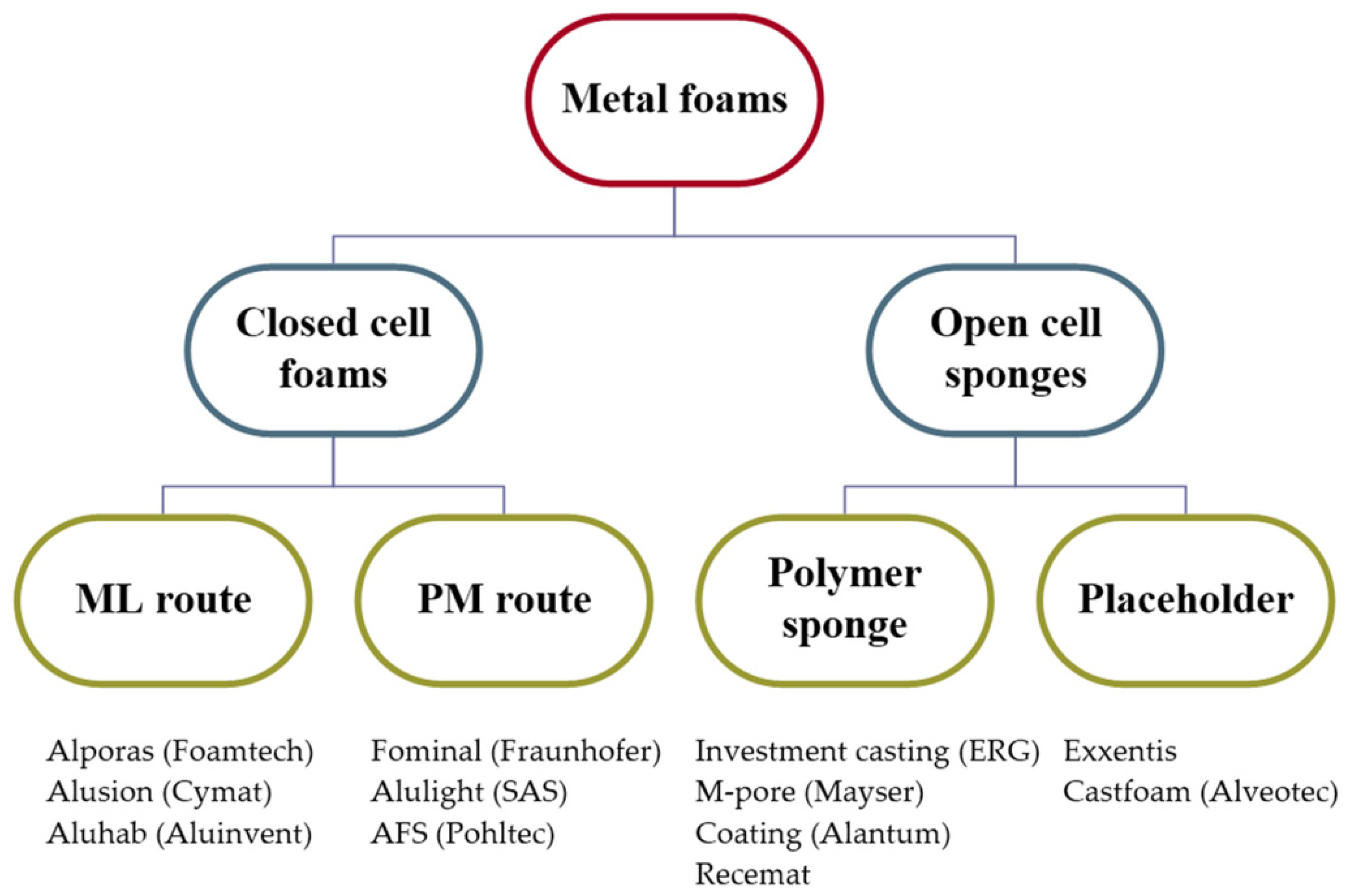

2.4. Metallic Foam Core

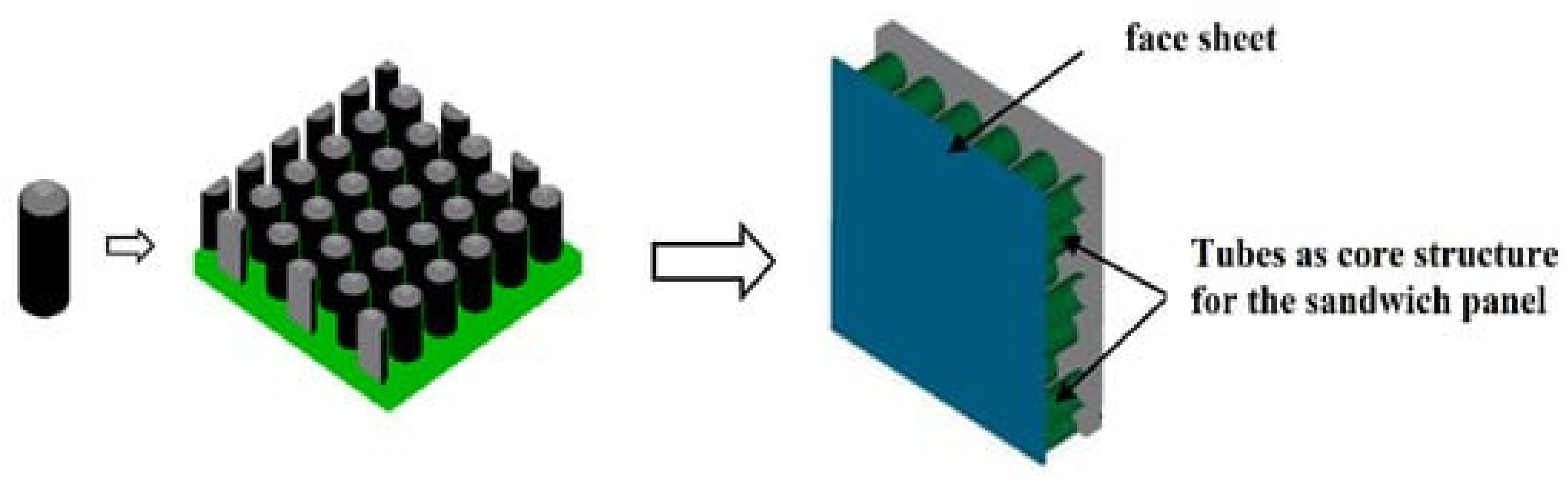

2.5. Tubular Core

3. Manufacturing Process of Cellular Solids Sandwich Structures

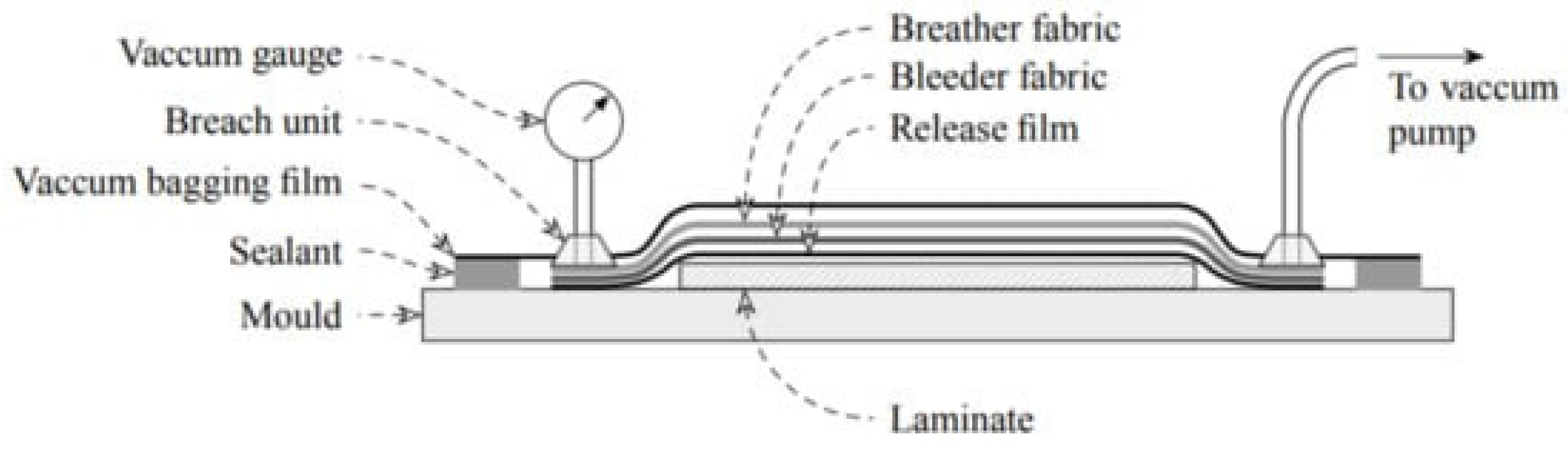

3.1. Prepreg Lay-Up Process

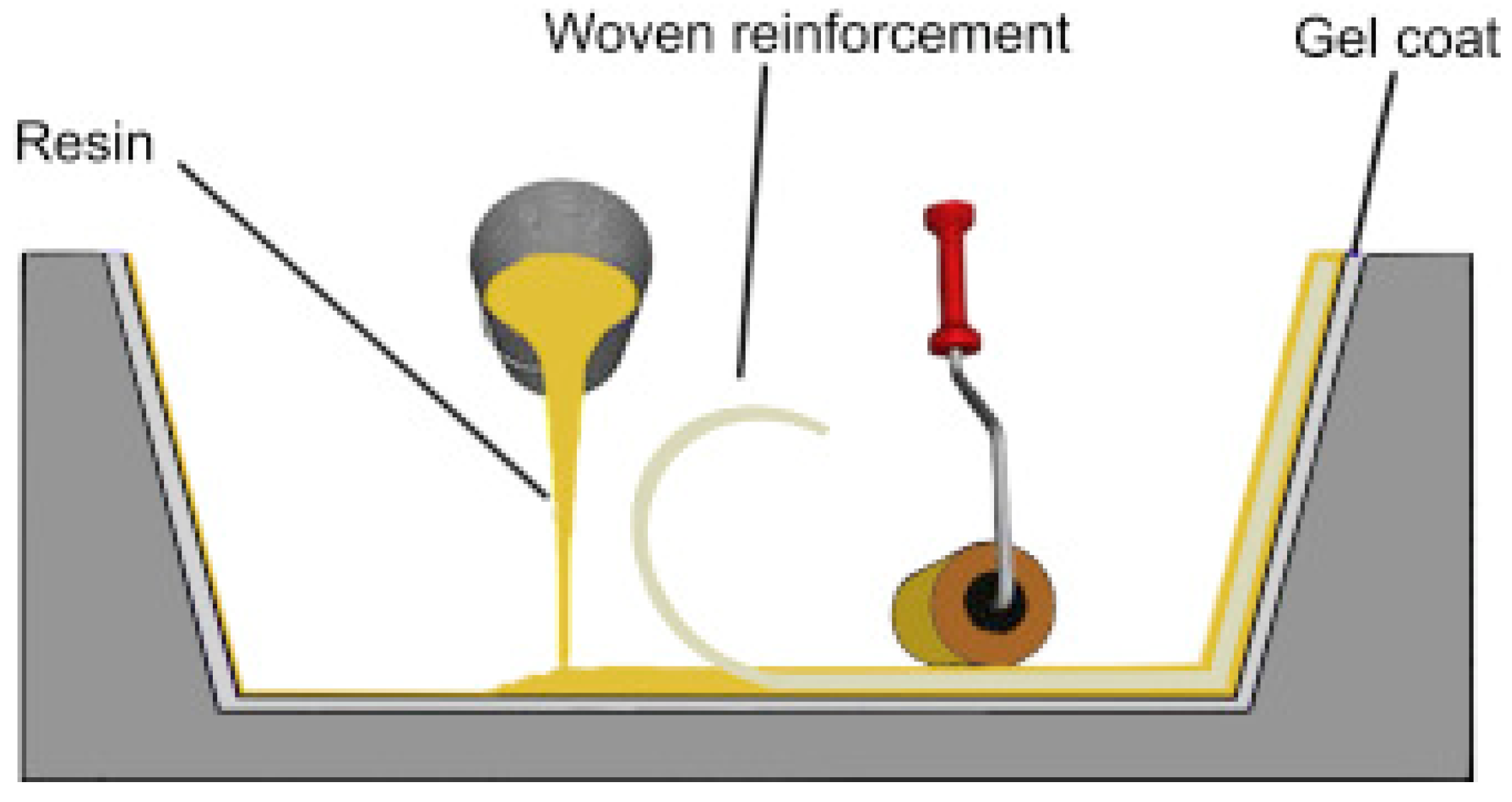

3.2. Hand Lay-Up Process

3.3. Liquid Bonding

3.4. Continuous Lamination

3.5. Adhesive Bonding

4. Applications of Cellular Solid Structures

5. Properties of Cellular Structures

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Benedetti, M.; du Plessis, A.; Ritchie, R.O.; Dallago, M.; Razavi, N.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R 2021, 144, 100606. [Google Scholar] [CrossRef]

- Bobbert, F.S.L.; Lietaert, K.; Eftekhari, A.A.; Pouran, B.; Ahmadi, S.M.; Weinans, H.; Zadpoor, A.A. Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical and mass transport properties. Acta Biomat. 2017, 53, 572–584. [Google Scholar] [CrossRef] [PubMed]

- Clarke, D.J.; Imediegwu, C.; Moat, R.; Jowers, I. A systematic numerical and experimental study into the mechanical properties of five honeycombs. Compos. Part B Eng. 2023, 264, 110895. [Google Scholar] [CrossRef]

- Choi, B.H.; Chudnovsky, A.; Sehanobish, K. Modeling of failure mechanisms using the true stress-strain response of polymeric foam materials. Proc. Eng. 2011, 10, 1609–1614. [Google Scholar] [CrossRef][Green Version]

- Peyrton, J.; Averous, L. Structure-properties relationship of cellular materials from bio-based polyurethane foams. Mater. Sci. Eng. R 2021, 145, 100608. [Google Scholar] [CrossRef]

- Sahu, S.K.; Rama Sreekanth, P.S.; Reddy, S.V.K. A brief review on advanced sandwich structures with customized design core and composite face sheet. Polymers 2022, 14, 4267. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Rahka, S.A.; Heisa, M.H.; Diallo, A. State of the art of sandwich composite structures: Manufacturing to high performance applications. J. Compos. Sci. 2023, 7, 102. [Google Scholar] [CrossRef]

- Ueng, C.E.S. Sandwich structures. In Encyclopedia of Physical Sciences and Technology, 3rd ed.; Meyers, R.A., Ed.; Academic Press: New York, NY, USA, 2001; pp. 407–412. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Jose, A.J.; Alagar, M. Preparation and characterization of polysulfone-based nanocomposites. In Manufacturing of Nanocomposites with Engineering Plastics; Mittals, V., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 31–59. [Google Scholar] [CrossRef]

- Lopez Garcia, J. Wettability Analysis and Water Absorption Studies of Plasma Activated Polymeric Materials. In Non-Thermal Plasma Technology for Polymeric Materials; Thomas, S., Mozetič, M., Cvelbar, U., Špatenka, P., Praveen, K.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 261–285. [Google Scholar] [CrossRef]

- Zaharia, S.; Morariu, C.; Nedelcu, A.; Pop, M.A. Experimental Study of Static and Fatigue Behavior of CFRP-Balsa Sandwiches under Three-point Flexural Loading. Bioresources 2017, 12, 2673–2689. [Google Scholar] [CrossRef]

- Wu, C.; Vahedi, N.; Vassipoulos, A.P.; Keller, T. Mechanical properties of a balsa wood veneer structural sandwich core material. Constr. Build. Mater. 2020, 265, 120193. [Google Scholar] [CrossRef]

- Clyne, T.W. Composites interfaces. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 1382–1391. [Google Scholar] [CrossRef]

- Neikov, O.D. Porous Powders and Metallic Foams. In Handbook of Non-Ferrous Metal Powders, 2nd ed.; Neikov, O.D., Naboychenko, S.S., Yefimov, N.A., Eds.; Elsevier: Oxford, UK, 2019; pp. 329–349. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, R.; Chu, X.; Liu, H. Multiscale design of graded stochastic cellular structures for the heat transfer problem. Appl. Sci. 2023, 13, 4409. [Google Scholar] [CrossRef]

- Garcia Moreno, F. Commercial applications of metal foams: Their properties and production. Materials 2016, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Chung Kim Yuen, S.; Nurick, G. The Use of Tubular Structures as Cores for Sandwich Panels Subjected to Dynamic and Blast Loading: A Current ‘State of the Art’. In Blast Mitigation: Experimental and Numerical Studies; Shukla, A., Rajakapse, Y., Hynes, M., Eds.; Springer: New York, NY, USA, 2014; pp. 229–248. [Google Scholar] [CrossRef]

- Tarlochan, F. Sandwich structures for energy absorption applications: A review. Materials 2021, 14, 4731. [Google Scholar] [CrossRef] [PubMed]

- Clarke, G. Characterization of Low Velocity Impact Damage in Metallic Honeycomb Sandwich Aircraft Panels Using Finite Element Analysis. Master’s Thesis, Mechanical Engineering, Royal Military College of Canada, Kingston, ON, Canada, 2017. [Google Scholar]

- Kenny, J.M.; Nicolais, L.; Maffezoli, A.; Torre, L.; Trivisano, A.; Akovali, G. (Eds.) Nato Asi Series, Vol. 230; Springer: Dordrecht, The Netherlands, 1993. [Google Scholar] [CrossRef]

- Ekuase, O.A.; Anjum, N.; Eze, V.O.; Okoli, O.I. A reviw on the out-of-autoclave process for composite manufacturing. J. Compos. Sci. 2022, 6, 172. [Google Scholar] [CrossRef]

- Raji, M.; Abdellaoui, H.; Essabir, H.; Kakou, C.A.; Bouhfid, R.; El Kacem Qaiss, A. Prediction of the cyclic durability of wovem-hybrid composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Sultan, T.H.; Rajeswari, N. Manufacturing techniques of composites for aerospace applications. In Sustainable Composites for Aerospace Applications; Jawaid, M., Thariq, M., Eds.; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Kratz, J.; Hubert, P. Vacuum bag only co-bonding prepreg skins to aramid honeycomb core. Part I. Model and material properties for core pressure during processing. Compos. Part A Appl. Sci. Manuf. 2015, 72, 228–238. [Google Scholar] [CrossRef]

- Bae, J.; Lee, K.; Seo, S.; Park, J.G.; Zhou, Z.; Kim, T. Controlled open-cell two-dimensional liquid foam generation for micro- and nanoscale patterning of materials. Nat. Commun. 2019, 10, 3209. [Google Scholar] [CrossRef] [PubMed]

- Campbell, F.C. Introduction to composite materials and processes: Unique materials that require unique processes. In Manufacturing Processes for Advanced Composites; Campbell, F.C., Ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 1–37. [Google Scholar] [CrossRef]

- Davies, P. Review of standard procedures for delamination resistance testing. In Delamination Behaviour of Composites; Sridharan, S., Ed.; In Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2008; pp. 65–86. [Google Scholar] [CrossRef]

- Szabelski, J.; Karpinnski, R.; Jonak, J.; Frigione, M. Adhesive Joint Degradation Due to Hardener-to-Epoxy Ratio Inaccuracy under Varying Curing and Thermal Operating Conditions. Materials 2022, 15, 7765. [Google Scholar] [CrossRef]

- Srinivasan, D.V.; Idapalapati, S. Review of debonding techniques in adhesively bonded composite structures for sustainability. Sustain. Mater. Technol. 2021, 30, e00345. [Google Scholar] [CrossRef]

- Prabhu, S.; Raja, V.; Nikhil, R. Applications of Cellular Materials—An Overview. Appl. Mech. Mater. 2015, 766–767, 511–517. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowsan, R.; Alami, A.H. Biomimetic Materials for Engineering Applications. In Encyclopedia of Smart Material; Olabi, A.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 25–34. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.M. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int. J. Impact. Eng. 2018, 112, 74–115. [Google Scholar] [CrossRef]

- Wahrhaftig, A.; Ribeiro, H.; Nogueria, A.A.; Ribeiro, H.; Nogueria, A. A structural composite for marine boat constructions. In Marine Composites; Pemberton, R., Summerscales, J., Graham-Jones, J., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 301–314. [Google Scholar] [CrossRef]

- Munsch, M. Laser additive manufacturing of customized prosthetics and implants for biomedical applications. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 399–420. [Google Scholar] [CrossRef]

- Zheng, Y.; Gao, T.; Chen, S.; Ferguson, C.T.; Zhang, K.A.; Fang, F.; Shen, Y.; Khan, N.A.; Wang, L.; Ye, L.; et al. CsPbBr3 quantum dots-decorated porous covalent triazine frameworks nanocomposites for enhanced solar-driven H2O2 production. Comp. Commun. 2022, 36, 101390. [Google Scholar] [CrossRef]

- Zheng, Y.; Khan, N.A.; Ni, X.; Zhang, K.A.I.; Shen, Y.; Huang, N.; Kong, X.Y.; Ye, L. Emerging covalent triazine framework-based nanomaterials for electrochemical energy storage and conversion. Chem. Commun. 2023, 59, 6314–6334. [Google Scholar] [CrossRef] [PubMed]

- Babaie, E.; Bhaduri, S. Fabrication Aspects of Porous Biomaterials in Orthopedic Applications: A Review. ACS Biomater. Sci. Eng. 2017, 4, 1–39. [Google Scholar] [CrossRef]

- Zheng, Y. Biological design of materials. In Bioinspired Design of Materials Surfaces; Zheng, Y., Ed.; Materials Today; Elsevier: Amsterdam, The Netherlands, 2019; pp. 27–97. [Google Scholar] [CrossRef]

- Luo, G.; Zhu, Y.; Zhang, R.; Cao, P.; Liu, Q.; Zhang, J.; Sun, Y.; Yuan, H.; Guo, W.; Shen, Q.; et al. A Review on Mechanical Models for Cellular Media: Investigation on Material Characterization and Numerical Simulation. Polymers 2021, 13, 3283. [Google Scholar] [CrossRef] [PubMed]

- Ongaro, F. Estimation of the effective properties of two-dimensional cellular materials: A review. Theoret. Appl. Mech. Lett. 2018, 8, 209–230. [Google Scholar] [CrossRef]

- Gardner, D.J. Wood: Surface Properties and Adhesion. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 9745–9748. [Google Scholar] [CrossRef]

- Ulm, F.J. Construction: Cellular Materials. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 1570–1574. [Google Scholar] [CrossRef]

- Zhang, H. The Basic Properties of Building Materials. In Building Materials in Civil Engineering; Woodhead Publishing: Cambridge, UK, 2011; pp. 7–423. [Google Scholar] [CrossRef]

- Pugno, N.M.; Chen, Q. In-plane elastic properties of hierarchical cellular solids. Eng. Proc. 2011, 10, 3026–3031. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costanza, G.; Solaiyappan, D.; Tata, M.E. Properties, Applications and Recent Developments of Cellular Solid Materials: A Review. Materials 2023, 16, 7076. https://doi.org/10.3390/ma16227076

Costanza G, Solaiyappan D, Tata ME. Properties, Applications and Recent Developments of Cellular Solid Materials: A Review. Materials. 2023; 16(22):7076. https://doi.org/10.3390/ma16227076

Chicago/Turabian StyleCostanza, Girolamo, Dinesh Solaiyappan, and Maria Elisa Tata. 2023. "Properties, Applications and Recent Developments of Cellular Solid Materials: A Review" Materials 16, no. 22: 7076. https://doi.org/10.3390/ma16227076

APA StyleCostanza, G., Solaiyappan, D., & Tata, M. E. (2023). Properties, Applications and Recent Developments of Cellular Solid Materials: A Review. Materials, 16(22), 7076. https://doi.org/10.3390/ma16227076