Thermal and Mechanical Properties of Biocomposites Based on Polylactide and Tall Wheatgrass

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.3. Methods

2.3.1. Thermogravimetric Analysis

2.3.2. Differential Scanning Calorimetry (DSC)

- ΔHm—enthalpy change in the melting process;

- ΔHcc—enthalpy change in the cold crystallization process;

- ΔHm100%—enthalpy change value of 100% crystalline PLA;

- x—filler content.

2.3.3. Mechanical Testing

2.4. Statistical Analysis

3. Results

Mechanical Properties

4. Conclusions

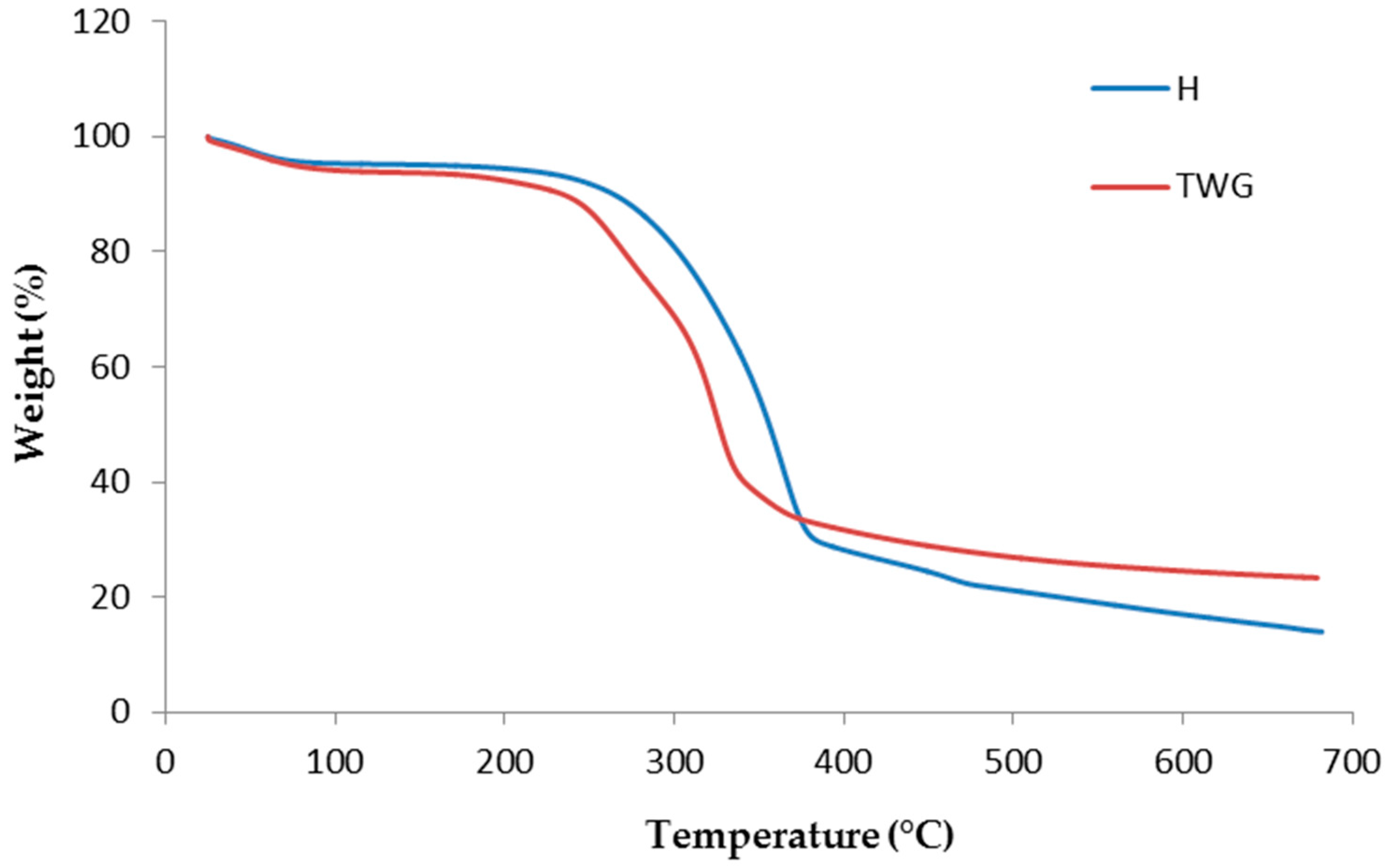

- The introduction of a plant filler into the polylactide matrix reduced the thermal resistance of the resulting composites. The decrease in thermal resistance was greater in the case of the composite containing couch grass. Additionally, it was observed that increasing the content of plant fillers resulted in a further decrease in the degradation temperature of the composites.

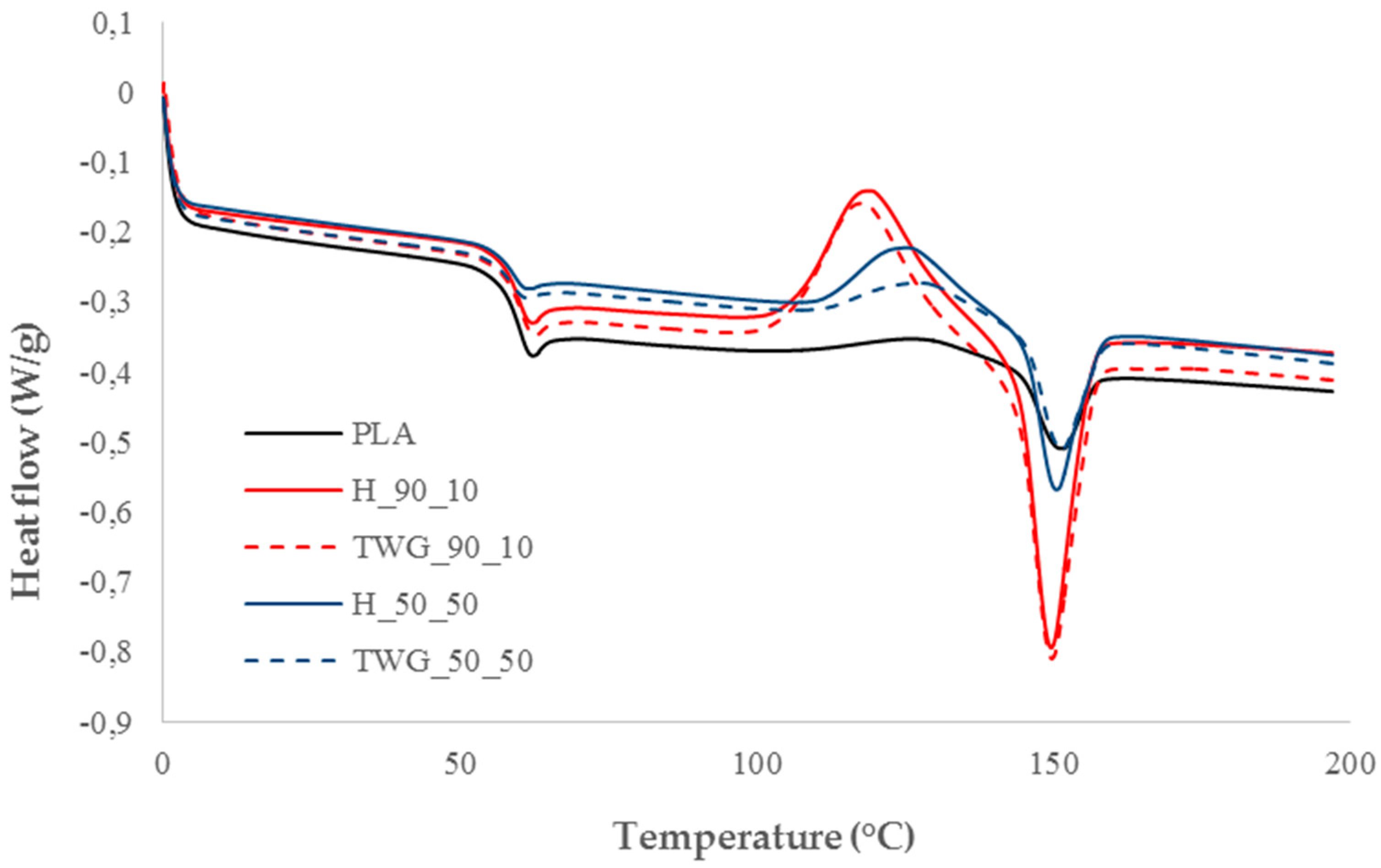

- Plant fillers influenced primarily the cold crystallization process, probably due to their nucleating properties. After the introduction of plant filler particles, a significant increase in the intensity of the cold crystallization process was observed, along with a simultaneous decrease in the temperature of this process.

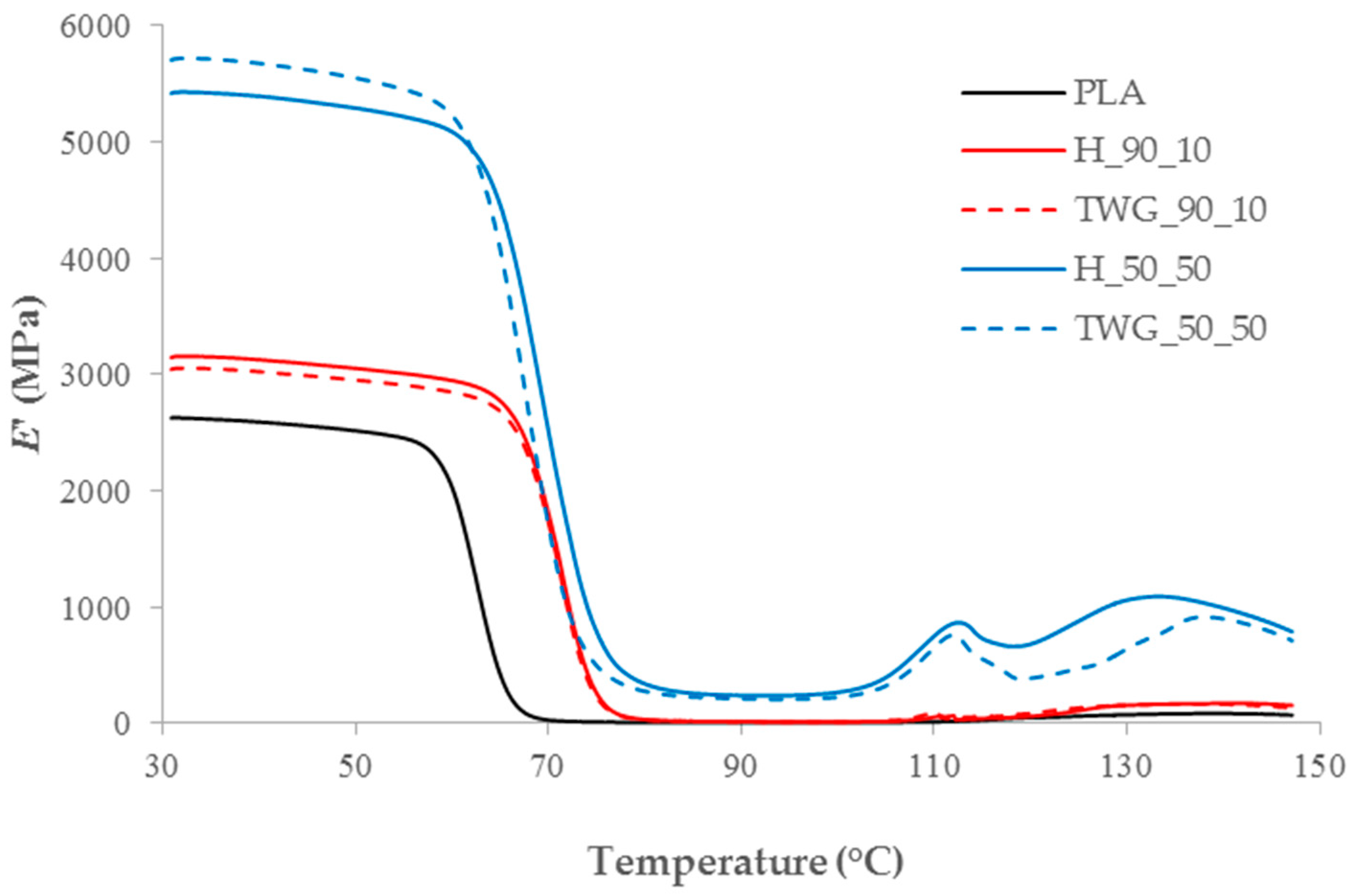

- Plant fillers change the thermomechanical characteristics of composites. The introduction of fillers into the matrix caused an increase in the storage modulus in the entire tested temperature range compared to pure PLA.

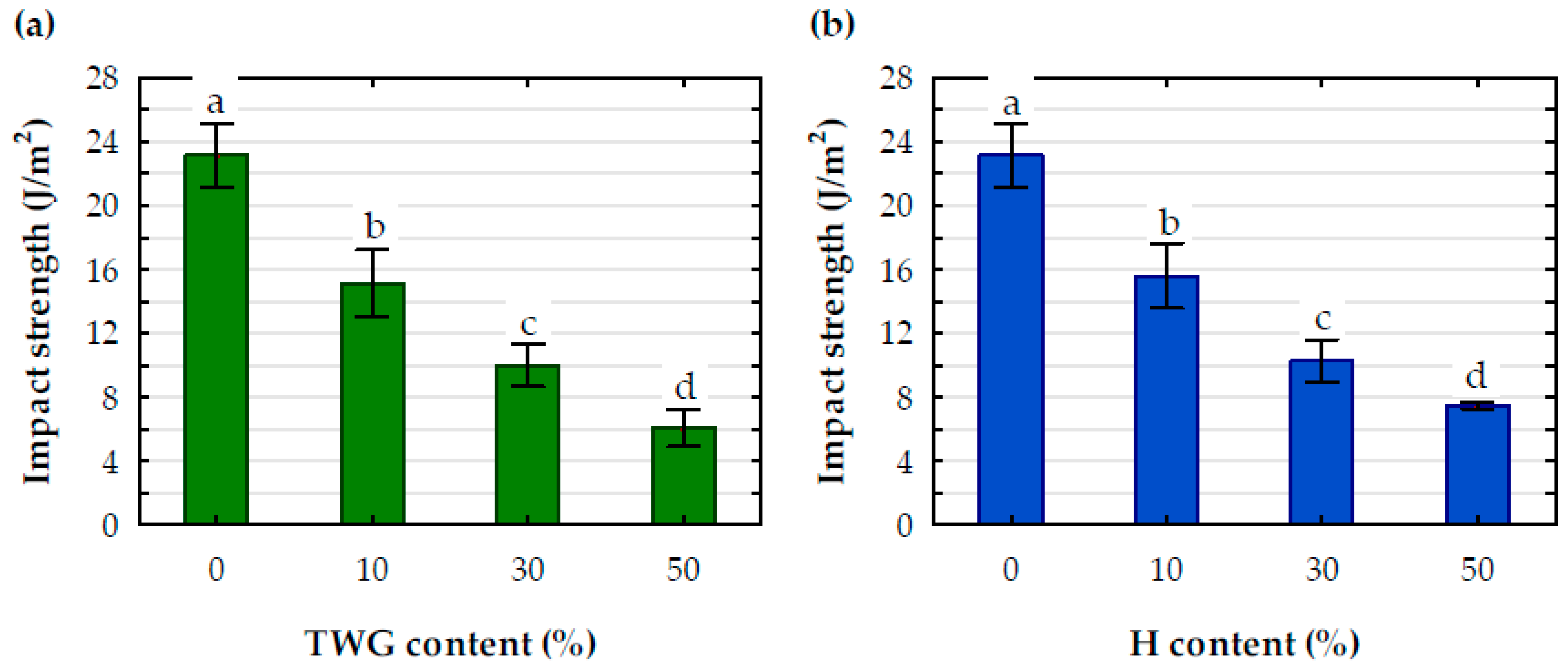

- Filling PLA with plant particles allows one to obtain a composite with increased stiffness and reduced strength and impact resistance.

- The mechanical properties of the tested composites depended significantly on the amount of plant filler used. Increasing the amount of filler resulted in an increase in the elastic modulus and a decrease in the elastic modulus as well as a decrease in tensile strength and impact strength.

- The mechanical properties of composites depended only slightly on the type of plant particles used to produce them. Composites containing TWG particles had a slightly higher elastic modulus and slightly lower strength and impact strength than composites containing H.

Author Contributions

Funding

Conflicts of Interest

References

- Bakas, I.; Fernández, R.; Reichel, A.; Trier, X.; Zeiger, B.; European Environment Agency. Plastics, the Circular Economy and Europe’s Environment: A Priority for Action; European Environmental Agency: Copenhagen, Denmark, 2021; p. 75.

- Landrigan, P.J.; Raps, H.; Symeonides, C.; Chiles, T.; Cropper, M.; Enck, J.; Hahn, M.E.; Hixson, R.; Kumar, P.; Mustapha, A.; et al. Announcing the Minderoo–Monaco Commission on Plastics and Human Health. Ann. Glob. Health 2022, 88, 73–74. [Google Scholar] [CrossRef] [PubMed]

- Le Duigou, A.; Requile, S.; Beaugrand, J.; Scarpa, F.; Castro, M. Natural Fibres Actuators for Smart Bio-Inspired Hygromorph Biocomposites. Smart Mater. Struct. 2017, 26, 125009. [Google Scholar] [CrossRef]

- Shen, M.; Song, B.; Zeng, G.; Zhang, Y.; Huang, W.; Wen, X.; Tang, W. Are Biodegradable Plastics a Promising Solution to Solve the Global Plastic Pollution? Environ. Pollut. 2020, 263, 114469. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of Natural Filler Materials on Fiber Reinforced Hybrid Polymer Composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Fowler, P.A.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, Environmental Credentials and Market Forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Arifur Rahman, M.; Parvin, F.; Hasan, M.; Hoque, M.E. Introduction to Manufacturing of Natural Fibre-Reinforced Polymer Composites. In Introduction to Manufacturing of Natural Fibre-Reinforced Polymer Composites; Springer International Publishing: New York, NY, USA, 2015; pp. 17–43. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant Fibre Based Bio-Composites: Sustainable and Renewable Green Materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymer 2020, 12, 2373. [Google Scholar] [CrossRef]

- Gavrilescu, D.; Tofǎnicǎ, B.M.; Puiţel, A.C.; Petrea, P. Sustainable Use of Vegetal Fibers in Composite Materials. Sources of Vegetal Fibers. Environ. Eng. Manag. J. 2009, 8, 429–438. [Google Scholar] [CrossRef]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 1–698. [Google Scholar] [CrossRef]

- Kajaks, J.; Zagorska, A.; Mežinskis, A. Some Exploitation Properties of Wood Plastic Composites (WPC), Based on High Density Polyethylene and Timber Industry Waste. Medziagotyra 2015, 21, 396–399. [Google Scholar] [CrossRef]

- Bodîrlău, R.; Spiridon, I.; Teacă, C.-A. Influence of Components Ratio Upon Mechanical Properties of Wood/Thermoplastic Polymer Composites. Cellul. Chem. Technol. Cellul. Chem. Technol. 2009, 43, 205–209. [Google Scholar]

- Bhaskar, K.; Jayabalakrishnan, D.; Vinoth Kumar, M.; Sendilvelan, S.; Prabhahar, M. Analysis on Mechanical Properties of Wood Plastic Composite. Mater. Today Proc. 2021, 45, 5886–5891. [Google Scholar] [CrossRef]

- Bhaskar, J.; Haq, S.; Yadaw, S.B. Evaluation and Testing of Mechanical Properties of Wood Plastic Composite. J. Thermoplast. Compos. Mater. 2011, 25, 391–401. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K.; Mandal, M. Study on Properties of Nanocomposites Based on HDPE, LDPE, PP, PVC, Wood and Clay. Polym. Bull. 2011, 67, 1875–1892. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Skórczewska, K.; Mirowski, J.; Zajchowski, S.; Wilczewski, S. Rheological Properties of Wood Polymer Composites at High Shear Rates–Evaluation of Additional Pressure Losses as a Result of Inlet Effects. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106804. [Google Scholar] [CrossRef]

- Cheng, R.X.; Zhang, L.; Li, Y. Study on Bonding Properties of PVC-Based WPC Bonded with Acrylic Adhesive. J. Adhes. Sci. Technol. 2012, 26, 2729–2735. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Wilczyński, A.; Zajchowski, S. Mechanical Properties of Wood-Polymer Composites with Different Polymers. Ann. Warsaw Univ. Life Sci. For. Wood 2011, 74, 82–85. [Google Scholar]

- Li, J.; Huo, R.; Liu, W.; Fang, H.; Jiang, L.; Zhou, D.; Li, J.; Huo, R.; Liu, W.; Fang, H.; et al. Mechanical Properties of PVC-Based Wood-Plastic Composites Effected by Temperature. FrMat 2022, 9, 1018902. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Zajchowski, S. Thermal and Structural Effects of Poly(Vinyl Chloride)/(Wood Flour) Compound Gelation in the Brabender Mixer. J. Vinyl Addit. Technol. 2011, 17, 239–244. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and New Opportunities on Barrier Performance of Biodegradable Polymers for Sustainable Packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Kolybaba, M.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J.; Powell, T.; Wang, B. Biodegradable Polymers: Past, Present, and Future; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006; p. 1. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymer 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Kandemir, N.; Yemeniciogwlu, A.; Mecitogwlu, Ç.; Elmaci, Z.S.; Arslanogwlu, A.; Göksungur, Y.; Baysal, T. Production of Antimicrobial Films by Incorporation of Partially Purified Lysozyme into Biodegradable Films of Crude Exopolysaccharides Obtained from Aureobasidium Pullulans Fermentation. Food Technol. Biotechnol. 2005, 43, 343–350. [Google Scholar]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Fibrous Biocomposites from Nettle (Girardinia Diversifolia) and Poly(Lactic Acid) Fibers for Automotive Dashboard Panel Application. Compos. Part B Eng. 2017, 130, 54–63. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J.S.; Lee, S.Y.; Mahajan, R.L.; Kim, Y.T. Exploration of Hybrid Nanocarbon Composite with Polylactic Acid for Packaging Applications. Int. J. Biol. Macromol. 2020, 144, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lin, Y.; Liu, M.; Meng, L.; Li, C. A Review of Research and Application of Polylactic Acid Composites. J. Appl. Polym. Sci. 2023, 140, e53477. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczynski, A. Effect of Wood Flour Type on Tensile Properties of Wood-Polymer Composites. Ann. Warsaw Univ. Life Sci. For. Wood 2015, 91, 65–69. [Google Scholar]

- Kumar, V.; Tyagi, L.; Sinha, S. Wood Flour-Reinforced Plastic Composites: A Review. Rev. Chem. Eng. 2011, 27, 253–264. [Google Scholar] [CrossRef]

- Kokta, B.V.; Raj, R.G.; Daneault, C. Use of Wood Flour as Filler in Polypropylene: Studies on Mechanical Properties. Polym. Plast. Technol. Eng. 1989, 28, 247–259. [Google Scholar] [CrossRef]

- Gozdecki, C.; Zajchowski, S.; Kociszewski, M.; Wilczyński, A.D.; Mirowski, J. Effect of Wood Particle Size on Mechanical Properties of Industrial Wood Particle-Polyethylene Composites. Polimery 2011, 56, 375–380. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyński, A.; Kociszewski, M.; Zajchowski, S. Properties of Wood–Plastic Composites Made of Milled Particleboard and Polypropylene. Eur. J. Wood Wood Prod. 2015, 73, 87–95. [Google Scholar] [CrossRef]

- Kociszewski, M.; Gozdecki, C.; Wilczyński, A.; Zajchowski, S.; Mirowski, J. Effect of Industrial Wood Particle Size on Mechanical Properties of Wood-Polyvinyl Chloride Composites. Eur. J. Wood Wood Prod. 2012, 70, 113–118. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.M.; MohdIshak, Z.A. Pultruded Kenaf Fibre Reinforced Composites: Effect of Different Kenaf Fibre Yarn Tex. Procedia Chem. 2016, 19, 577–585. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-Polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef] [PubMed]

- Tavares, T.D.; Antunes, J.C.; Ferreira, F.; Felgueiras, H.P. Biofunctionalization of Natural Fiber-Reinforced Biocomposites for Biomedical Applications. Biomolecules 2020, 10, 148. [Google Scholar] [CrossRef]

- Dhawan, V.; Singh, S.; Singh, I. Effect of Natural Fillers on Mechanical Properties of GFRP Composites. J. Compos. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Jabbar, M. Bio-Composites: Eco-Friendly Substitute of Glass Fiber Composites. Handb. Nanomater. Nanocomposites Energy Environ. Appl. 2021, 1, 151–176. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on Mechanical Properties of Natural Fiber Composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef] [PubMed]

- Atikah, M.S.N.; Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Ibrahim, R.; Atiqah, A.; Ansari, M.N.M.; Jumaidin, R. Degradation and Physical Properties of Sugar Palm Starch/Sugar Palm Nanofibrillated Cellulose Bionanocomposite. Polimery/Polymers 2019, 64, 680–689. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Rafiqah, S.A.; Aisyah, H.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Effect of Hydrolysis Time on the Morphological, Physical, Chemical, and Thermal Behavior of Sugar Palm Nanocrystalline Cellulose (Arenga Pinnata (Wurmb.) Merr). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N.; Mohd Nurazzi, N.; Atiqah, A.; Ansari, M.N.M.; et al. Effect of Sugar Palm Nanofibrillated Cellulose Concentrations on Morphological, Mechanical and Physical Properties of Biodegradable Films Based on Agro-Waste Sugar Palm (Arenga Pinnata (Wurmb.) Merr) Starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar Palm (Arenga Pinnata (Wurmb.) Merr) Cellulosic Fibre Hierarchy: A Comprehensive Approach from Macro to Nano Scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and Man-Made Cellulose Fibre-Reinforced Poly(Lactic Acid) (PLA) Composites: An Overview about Mechanical Characteristics and Application Areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Singh, I. PLA/Banana Fiber Based Sustainable Biocomposites: A Manufacturing Perspective. Compos. Part B Eng. 2020, 180, 107535. [Google Scholar] [CrossRef]

- Salasinska, K.; Polka, M.; Gloc, M.; Ryszkowska, J. Natural Fiber Composites: The Effect of the Kind and Content of Filler on the Dimensional and Fire Stability of Polyolefin-Based Composites. Polimery 2016, 61, 255–265. [Google Scholar] [CrossRef]

- Obasi, H.C. Peanut Husk Filled Polyethylene Composites: Effects of Filler Content and Compatibilizer on Properties. J. Polym. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Masirek, R.; Kulinski, Z.; Chionna, D.; Piorkowska, E.; Pracella, M. Composites of Poly(L-Lactide) with Hemp Fibers: Morphology and Thermal and Mechanical Properties. J. Appl. Polym. Sci. 2007, 105, 255–268. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of Accelerated Ageing on the Physico-Mechanical Properties of Alkali-Treated Industrial Hemp Fibre Reinforced Poly(Lactic Acid) (PLA) Composites. Polym. Degrad. Stab. 2010, 95, 59–65. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Chen, S.; Zheng, Y.; Ruan, S.; Bin, Y. Mechanical Properties of Poly (Lactic Acid)/Hemp Fiber Composites Prepared with a Novel Method. J. Polym. Environ. 2013, 21, 1117–1127. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Manufacture and Characterisation of Thermoplastic Composites Made from PLA/Hemp Co-Wrapped Hybrid Yarn Prepregs. Compos. Part A Appl. Sci. Manuf. 2013, 50, 93–101. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of Mechanical Performance of Industrial Hemp Fibre Reinforced Polylactide Biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319. [Google Scholar] [CrossRef]

- Gupta, A.; Lolic, L.; Mekonnen, T.H. Reactive Extrusion of Highly Filled, Compatibilized, and Sustainable PHBV/PBAT–Hemp Residue Biocomposite. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106885. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing Mechanisms of Natural Fibers in Green Composites: Role of Fibers Morphology in a PLA/Hemp Model System. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of Fibre Treatments on Interfacial Shear Strength of Hemp Fibre Reinforced Polylactide and Unsaturated Polyester Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of Fiber Surface-Treatments on the Properties of Laminated Biocomposites from Poly(Lactic Acid) (PLA) and Kenaf Fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Oza, S.; Ning, H.; Ferguson, I.; Lu, N. Effect of Surface Treatment on Thermal Stability of the Hemp-PLA Composites: Correlation of Activation Energy with Thermal Degradation. Compos. Part B Eng. 2014, 67, 227–232. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, Z.; Zhang, R.; Jenkins, B.M.; Blunk, S. Particleboard Quality Characteristics of Saline Jose Tall Wheatgrass and Chemical Treatment Effect. Bioresour. Technol. 2007, 98, 1304–1310. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, Z.; Zhang, R.; Jenkins, B.M.; Blunk, S. Medium-Density Particleboard from Saline Jose Tall Wheatgrass. In 2005 ASAE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005; p. 1. [Google Scholar] [CrossRef]

- Janiszewska, D.; Żurek, G.; Martyniak, D.; Bałęczny, W. Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture. Materials 2022, 15, 6384. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 527-2:2012; Plastics: Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- Ray, S.S.; Yamada, K.; Okamoto, M.; Fujimoto, Y.; Ogami, A.; Ueda, K. New Polylactide/Layered Silicate Nanocomposites. 5. Designing of Materials with Desired Properties. Polymer 2003, 44, 6633–6646. [Google Scholar] [CrossRef]

- EN ISO 179-1:2010; Plastics — Determination of Charpy Impact Properties — Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2010.

- Krishnaiah, P.; Ratnam, C.T.; Manickam, S. Enhancements in Crystallinity, Thermal Stability, Tensile Modulus and Strength of Sisal Fibres and Their PP Composites Induced by the Synergistic Effects of Alkali and High Intensity Ultrasound (HIU) Treatments. Ultrason. Sonochem. 2017, 34, 729–742. [Google Scholar] [CrossRef]

- Singamneni, S.; Smith, D.; LeGuen, M.J.; Truong, D. Extrusion 3D Printing of Polybutyrate-Adipate-Terephthalate-Polymer Composites in the Pellet Form. Polymer 2018, 10, 922. [Google Scholar] [CrossRef] [PubMed]

| Composite Code | Filler Content (%) | Filler |

|---|---|---|

| PLA | 0 | - |

| H_90_10 | 10 | H |

| TWG_90_10 | 10 | TWG |

| H_70_30 | 30 | H |

| TWG_70_30 | 30 | TWG |

| H_50_50 | 50 | H |

| TWG_50_50 | 50 | TWG |

| Sample | T5% (°C) | M (%) | R (%) |

|---|---|---|---|

| PLA | 310.2 | 0.0 | 0.0 |

| H_90_10 | 299.5 | 0.5 | 3.0 |

| TWG_P_90_10 | 289.7 | 0.5 | 2.7 |

| H_70_30 | 286.9 | 0.8 | 8.0 |

| TWG_70_30 | 259.2 | 1.0 | 8.4 |

| H_50_50 | 274.1 | 2.0 | 12.6 |

| TWG_50_50 | 243.9 | 1.6 | 15.7 |

| Sample | T5% (°C) | M (%) | R (%) |

|---|---|---|---|

| H | 285.9 | 4.5 | 14.0 |

| TWG | 240.5 | 6.1 | 23.3 |

| Sample | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHcc (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA | 60.1 | 127.5 | 4.7 | 151.1 | 5.1 | 0.4 |

| H_90_10 | 59.9 | 119.3 | 20.0 | 149.3 | 21.3 | 1.6 |

| TWG_90_10 | 60.5 | 118.3 | 20.9 | 149.4 | 21.9 | 1.2 |

| H_70_30 | 59.8 | 121.8 | 15.7 | 149.9 | 15.8 | 0.2 |

| TWG_70_30 | 59.6 | 121.7 | 14.9 | 149.9 | 15.5 | 0.9 |

| H_50_50 | 59.0 | 126.0 | 10.4 | 150.3 | 10.8 | 0.9 |

| TWG_50_50 | 58.8 | 128.5 | 7.0 | 151.3 | 7.5 | 1.1 |

| Sample | E’30 (MPa) | E’50 (MPa) | E’70 (MPa) | E’90 (MPa) | E’130 (MPa) | Tg (°C) |

|---|---|---|---|---|---|---|

| PLA | 2625 | 2515 | 28 | 7 | 73 | 69.1 |

| H_90_10 | 3149 | 3005 | 138 | 17 | 166 | 71.2 |

| TWG_90_10 | 3047 | 2906 | 127 | 21 | 161 | 71.2 |

| H_70_30 | 4243 | 4111 | 358 | 94 | 508 | 71.0 |

| TWG_70_30 | 3984 | 3837 | 398 | 78 | 470 | 71.9 |

| H_50_50 | 5427 | 5267 | 1384 | 309 | 1088 | 72.6 |

| TWG_50_50 | 5716 | 5520 | 888 | 253 | 733 | 71.0 |

| Property | Filler Content (%) | ||

|---|---|---|---|

| 10 | 30 | 50 | |

| Tensile modulus | 0.026138 * | 0.042118 * | 0.004789 ** |

| Tensile strength | 0.000033 ** | 0.071074 ns | 0.007733 ** |

| Impact strength | 0.690906 ns | 0.743999 ns | 0.016076 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gozdecki, C.; Moraczewski, K.; Kociszewski, M. Thermal and Mechanical Properties of Biocomposites Based on Polylactide and Tall Wheatgrass. Materials 2023, 16, 6923. https://doi.org/10.3390/ma16216923

Gozdecki C, Moraczewski K, Kociszewski M. Thermal and Mechanical Properties of Biocomposites Based on Polylactide and Tall Wheatgrass. Materials. 2023; 16(21):6923. https://doi.org/10.3390/ma16216923

Chicago/Turabian StyleGozdecki, Cezary, Krzysztof Moraczewski, and Marek Kociszewski. 2023. "Thermal and Mechanical Properties of Biocomposites Based on Polylactide and Tall Wheatgrass" Materials 16, no. 21: 6923. https://doi.org/10.3390/ma16216923

APA StyleGozdecki, C., Moraczewski, K., & Kociszewski, M. (2023). Thermal and Mechanical Properties of Biocomposites Based on Polylactide and Tall Wheatgrass. Materials, 16(21), 6923. https://doi.org/10.3390/ma16216923