1. Introduction

Piezoelectric sensors have long been the most efficient devices for generating and measuring dynamic forces, below or slightly above room temperature. For example, conventional ultrasonic echography measurements of the wall thickness of pipes and tanks offer advantages over other non-destructive testing methods, such as low cost, ease of operation, and the ability to conduct in operando measurements [

1]. Piezoelectric sensors are already well established for this type of application but are limited to operating temperatures of up to 260 °C [

2] due to most devices relying on the ubiquitous piezoelectric ceramic lead zirconate titanate or PZT. Therefore, considerable efforts are now aimed at developing materials that can satisfy the growing demand for piezoelectric elements with operating temperatures within the range of 350–600 °C.

One such material is BiFeO

3 (BFO), which has an exceptionally high Curie temperature, TC, of 825 °C [

3] and the additional benefit of being lead-free in composition. This high TC makes BFO an ideal candidate for use as a high-temperature lead-free piezoceramic [

1]. Unfortunately, research on bulk BFO ceramics has not been as successful, as it has not demonstrated high piezoelectric coefficients and has had serious temperature issues. This is largely due to its high electrical conductivity at temperatures >200 °C, which limits the use of this material in real devices.

For high-temperature applications in actuators, transducers, sensors, etc., solid-state solutions of BiMeO

3-PbTiO

3 with a perovskite structure have been proposed as more sensitive prospective compositions due to their high Curie temperatures (TCs), especially those systems near morphotropic phase boundaries (MPBs). For example, the BiScO

3-PbTiO

3 (BS-PT) system was once expected to be a substitute for PZT for high-temperature applications due to its excellent performance near its MPB. However, the high cost of the raw material Sc

2O

3 made it unsuitable for commercial applications [

4]. Also widely studied is the BiFeO

3–PbTiO

3 (BFO-PT) system, which has the highest TC (TC at MPB, approximately 630 °C) in the family of binary piezoceramics based on PT. However, it is difficult to obtain mechanically strong BFO-PT ceramics due to their negative temperature coefficient of expansion and high tetragonality, as in the case of pure PT ceramics [

5]. In addition, the large tetragonal distortion (c/a ratio 1.18) for BFO-PT solid solutions results in a large coercive field of Ec > 100 kV/cm, making it difficult to have them fully poled [

6].

It has been reported that a reduction in Ec and c/a of BFO-PT ceramics could be achieved through the substitution of large cations [

7] to weaken the hybridization [

8] between Pb

2+/Bi

3+ and O

2– ions as well as to strengthen the ferroelectric activity of B-site cations.

Popular strategies for improving piezoelectric responses reported in the literature include chemical modification (doping of elements, substitution or formation of new solid solutions) to reduce tetragonality, which can be achieved by replacing large cations to expand the a-axis and weakly ferroactive cations to shorten the c-axis [

9,

10]. For example, the introduction of La, Ca, Ba, or Sr into the A site, Ga, Al, Ta, or Nb into the B site, or a combination of PbZrO

3, BaZrO

3, or BaTiO

3 with BFO-PT will lead to a significant decrease in the c/a ratio and a significant improvement in piezoelectric properties and in particular the mechanical stability. Most recently, BFO-PT-based ternary solid solutions, such as BFO-PT-BT, BFO-PT-BZ, and BFO-PT-BZT, have attracted great attention [

11,

12,

13]. Preliminary experiments have shown high piezoelectric properties up to 300–400 pC/N (at room temperature), with a Curie temperature of approximately 300–400 °C. However, these piezoceramics generally have a high coercive field, up to 60–100 kV/cm, which creates difficulties in fully activating the piezoelectric properties upon poling.

The current study adopted the method of site engineering, introducing SrTiO

3 (ST) into the BFO-PT system to form a ternary system. Despite the fact that ST itself does not possess piezoelectric properties at room temperature, it can still stabilize BFO-PT structures and decrease conductivity at RT and elevated temperatures. Furthermore, solutions of BFO-ST have been reported to have different structures at varying BiFeO

3 contents, e.g., rhombohedral structures between 100 and 65 mol%, pseudocubic structures between 67 and 20 mol%, and cubic structures below 20 mol% of BFO [

14]. The introduction of Sr

2+ in the A site greatly influences the Pb/Bi–O bonding interaction and thus provides additional flexibility to tailor the dielectric, piezoelectric, and mechanical properties of BFO-PT-based solid solutions.

It is well known that BFO-PT and BFO-ST both can form solid solutions near the morphotropic phase boundary (MPB) region [

14,

15,

16,

17]. It is widely known that all functional properties of piezo materials with compositions near the MPB region increase due to the coexistence of two phases. For BFO-PT, the two phases in equilibrium are tetragonal and rhombohedral, and for BFO-ST, they are rhombohedral and cubic. For BFO-PT, a continuous solid solution across its entire composition range has been reported, with a rhombohedral–tetragonal MPB at 0.7–0.8 BFO.

The formation of ternary solid solutions provides additional degrees of freedom in the material design to improve the comprehensive properties and to meet various materials requirements.

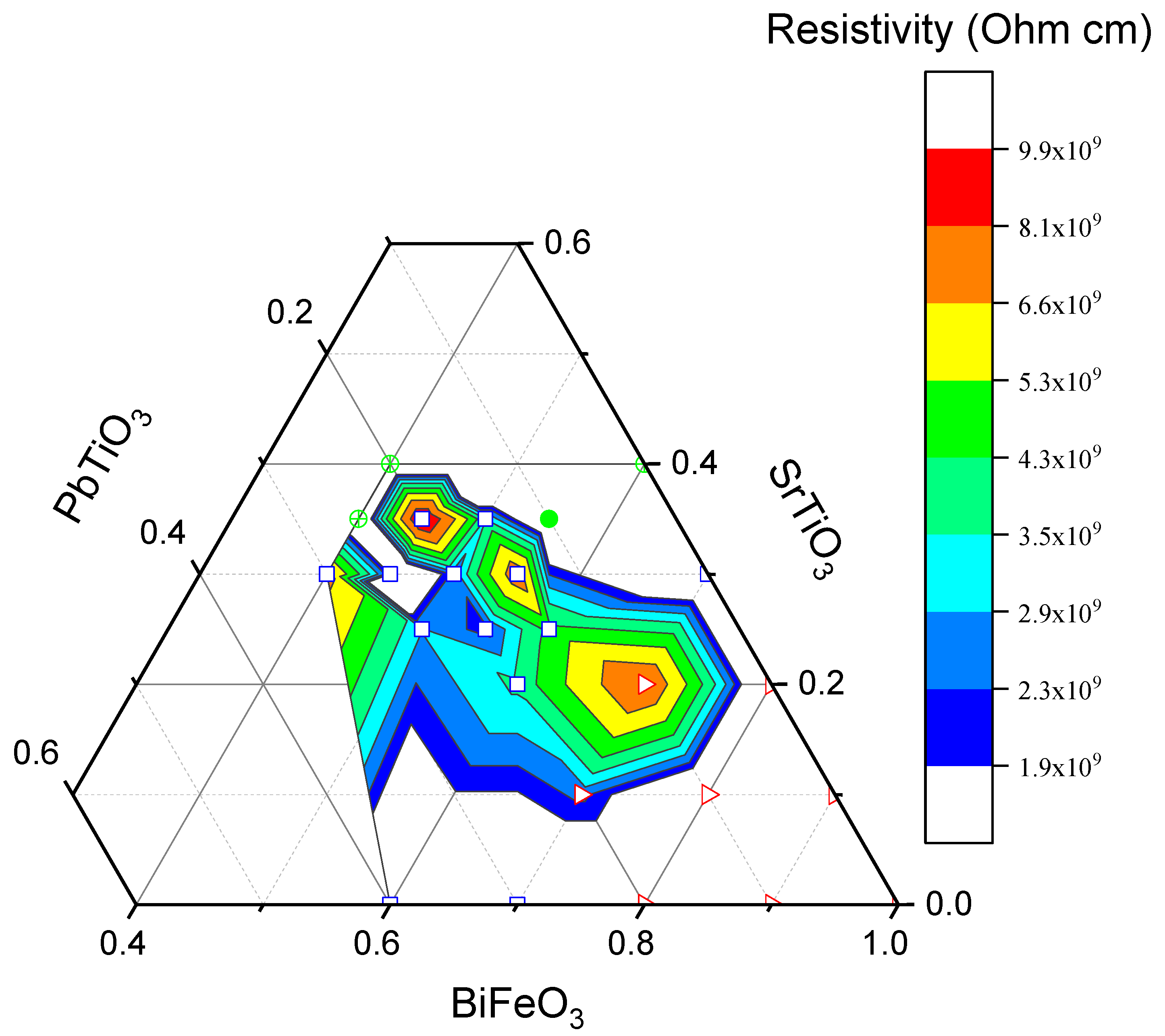

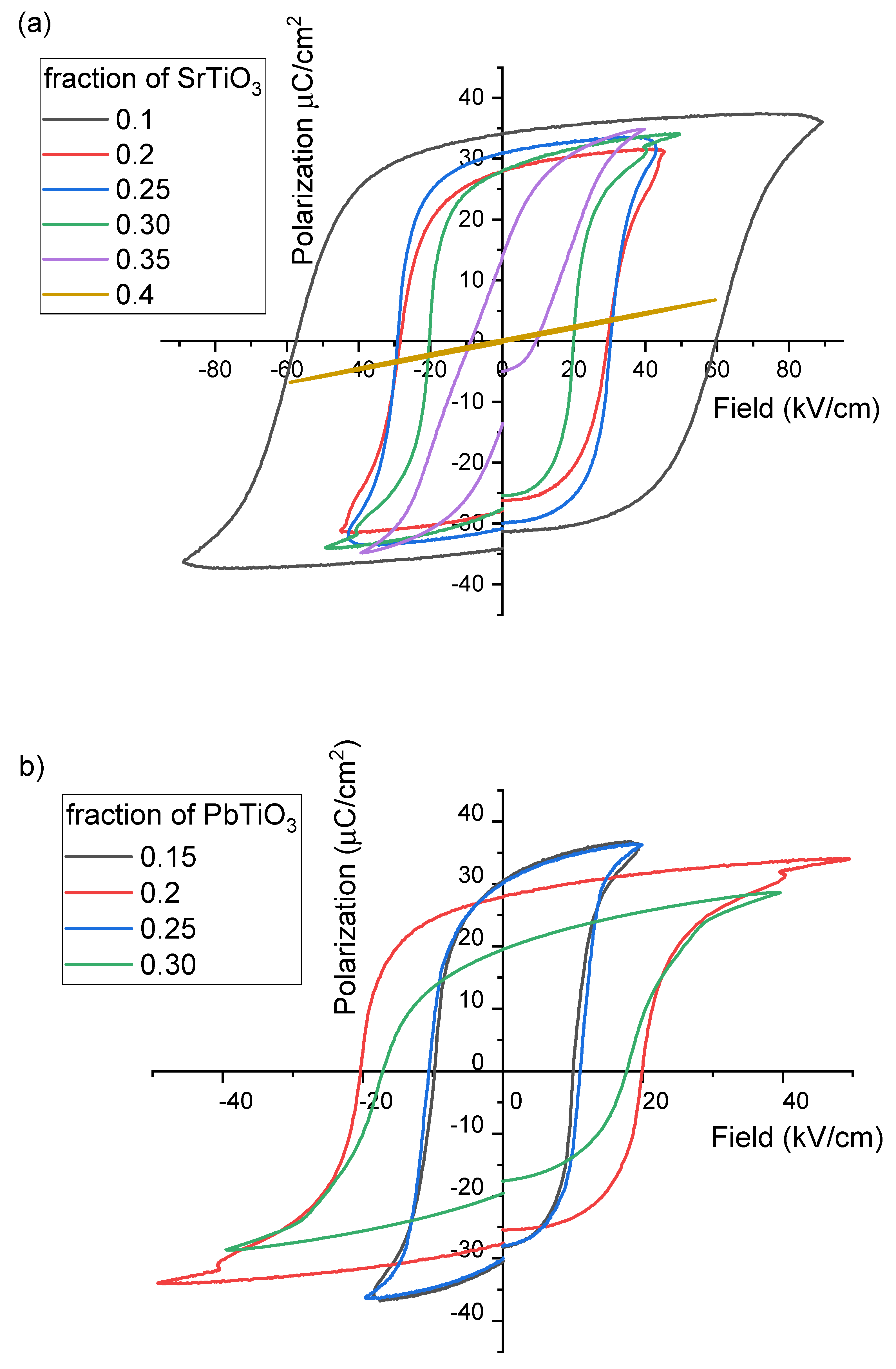

In the present study, bulk ceramics with pseudoternary compositions of (1 − (y + x)) BFO–y·PT–x·ST (0.1 ≤ x≤ 0.35; 0.1 ≤ y ≤ 0.3) were explored to obtain a combination of a high TC and good piezo properties at elevated temperatures. The ceramics were prepared by a conventional powder sintering method. The objectives of this study were: (1) to obtain high-strength piezoceramics with a low electrical conductivity at room temperature and a suitable coercive field for complete polarization, (2) to study the softening effect of ST on BFO-PT ceramics and determine the position of the phase boundary, and (3) to study the temperature dependence of the piezoelectric and electrical properties for the most promising systems.

2. Experimental Procedure

BiFeO3-PbTiO3-SrTiO3 (BFO-PT-ST) samples were prepared by a conventional solid-state reaction process using analytical-grade powders as raw materials: Bi2O3, Fe2O3, PbO, TiO2, and SrCO3. All powders were individually ground before weighing and mixing. Grinding and mixing were performed using yttria-stabilized ZrO2 balls in an isopropanol medium in polypropylene containers. The powders were subsequently dried and calcined at 775 °C for 1 h with a heating rate of 600 °C/h. After a slow cooling process, the calcined powders were reground, granulated by mixing with 2 wt% QPAC 40 binder, and then uniaxially pressed into disks (13 mm in diameter and approximately 1 mm in thickness) using a compaction pressure of 200–250 MPa. The final synthesis and sintering were performed at 1025, 1050, or 1075 °C for 1 h, depending on the system’s composition. Sintering parameters were optimized to achieve the highest density. In total, 15 different compositions were explored.

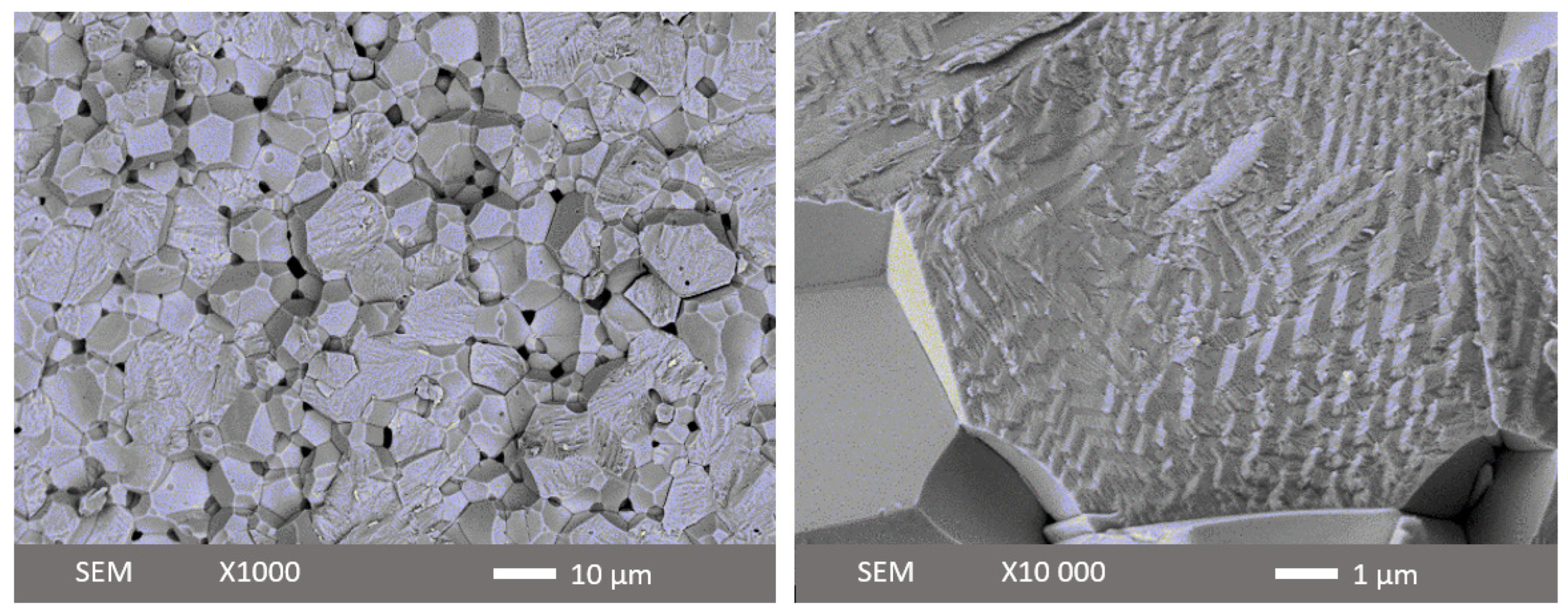

Scanning electron microscope (SEM) images were taken using a Jeol JSM 7500F field emission scanning electron microscope, Tokyo, Japan. Prior to SEM measurements, a thin (15 nm) layer of gold was deposited on the sample. To determine the phase purity, X-ray diffraction studies with Cu Kα radiation were conducted using a Rigaku MiniFlex tabletop XRD analyzer, Tokyo, Japan. X-ray diffraction studies with Cu Kα radiation were also performed using a Bruker D8 Discover diffractometer at elevated temperatures, Billerica, MA, USA. Scans were recorded at set temperatures: RT, 200 to 700 °C in 25 °C increments for selected systems. The density was determined by Archimedes’ method in an aqueous medium.

For electrical characterization, the samples were polished, coated with silver paste (DuPont 5220), and fired at 150 °C for 20 min. Polarization–electric field hysteresis loops were measured at room temperature using a Radiant precision ferroelectric analyzer. The samples were poled under a DC electric field of 20–80 kV/cm for 20 min in silicone oil at room temperature. After aging for 24 h, the piezoelectric constant d33 was measured with a quasi-static piezoelectric d33 meter. The Curie temperature was determined indirectly by determining the depolarization temperature. The electrical properties of samples at room temperature were measured using an Agilent 4263B LCR meter at 1 kHz and 1 V, Santa Clara, CA, USA.

Measurements of the high-temperature piezoelectric constant were carried out by a direct method using a laboratory setup from Kistler Instrumente AG at their lab in Winterthur. To this aim, samples were clamped between two Al2O3 disks with static preload of 1 MPa (100 N). To measure the piezoelectric response, a dynamic load of 0.1 MPa (10 N) with a frequency of 1, 2, 5, 10, 20, 50, 100 Hz was applied. Such measurements were performed at 22, 50, 100, 150, 200, 250, 300, 350 °C. When changing the temperature either during heating or cooling, the preload was removed. Up to 5 temperature cycles up to the maximum temperature have been performed to check the stability of the temperature dependency of the properties.

4. Discussion

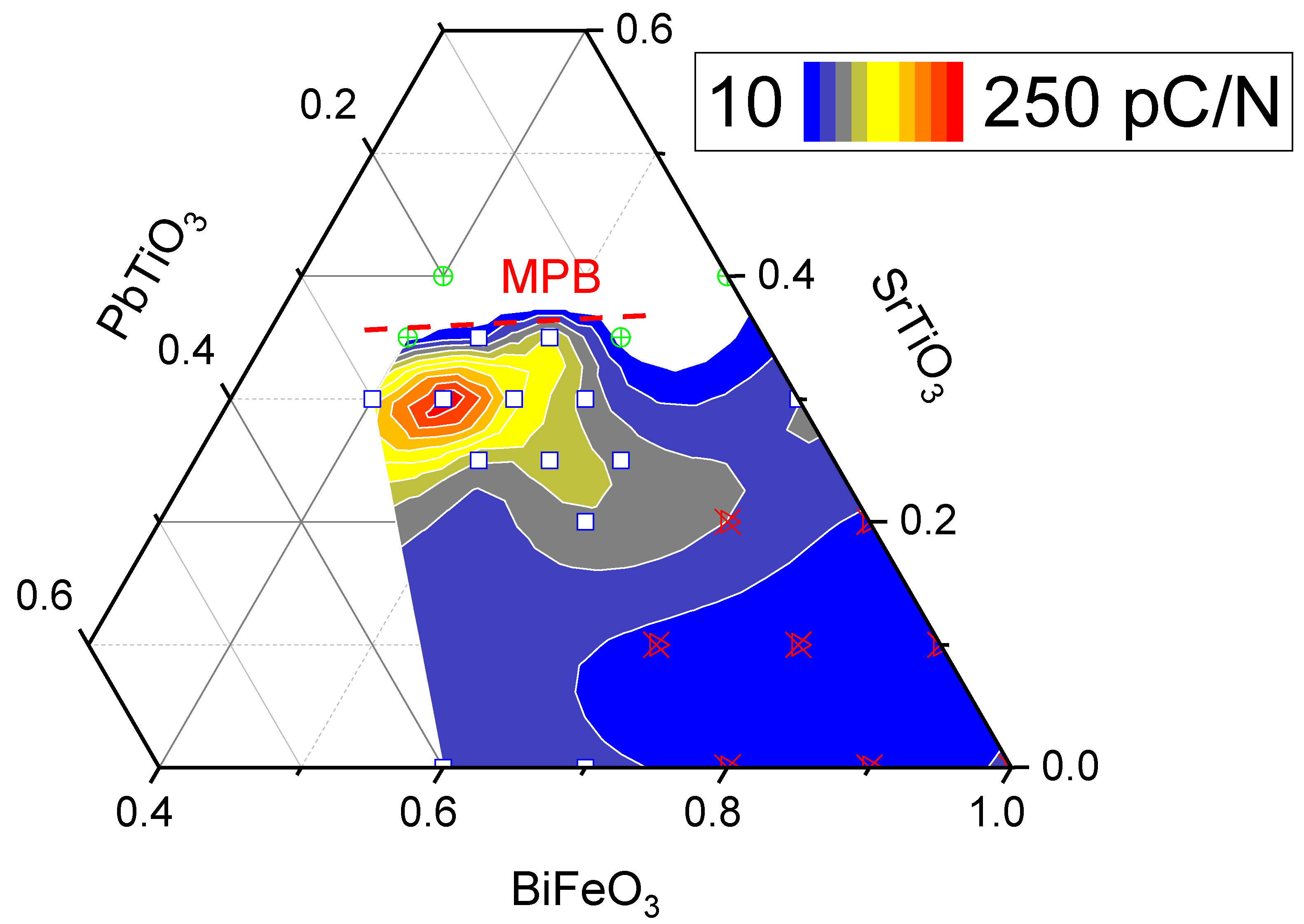

BFO-PT-ST was fabricated across the compositional space with the intention of replicating the MPB observed in PZT. The perovskite structure was formed across the entire compositional space with the absence of secondary phases. As indicated in

Table 1, the BiFeO

3-rich end of the phase diagram belonging to the rhombohedral phase was indexed to the R3c space group. The phase changed from pseudocubic to cubic as the concentration of BFO in the solution decreased. Similar to PZT [

17], the piezoelectric properties significantly increase upon transitioning from the pseudocubic phase to the cubic phase, as opposed to the transition from the pseudocubic phase to the rhombohedral phase. As expected, this also reduces the giant tetragonality of 1.18 [

5] and the electric coercive field of the system near the MPB, which hinders its use in applications. A possible explanation is an increase in poling efficiency due to a decrease in the coercive field with a decreasing amount of BFO in the system.

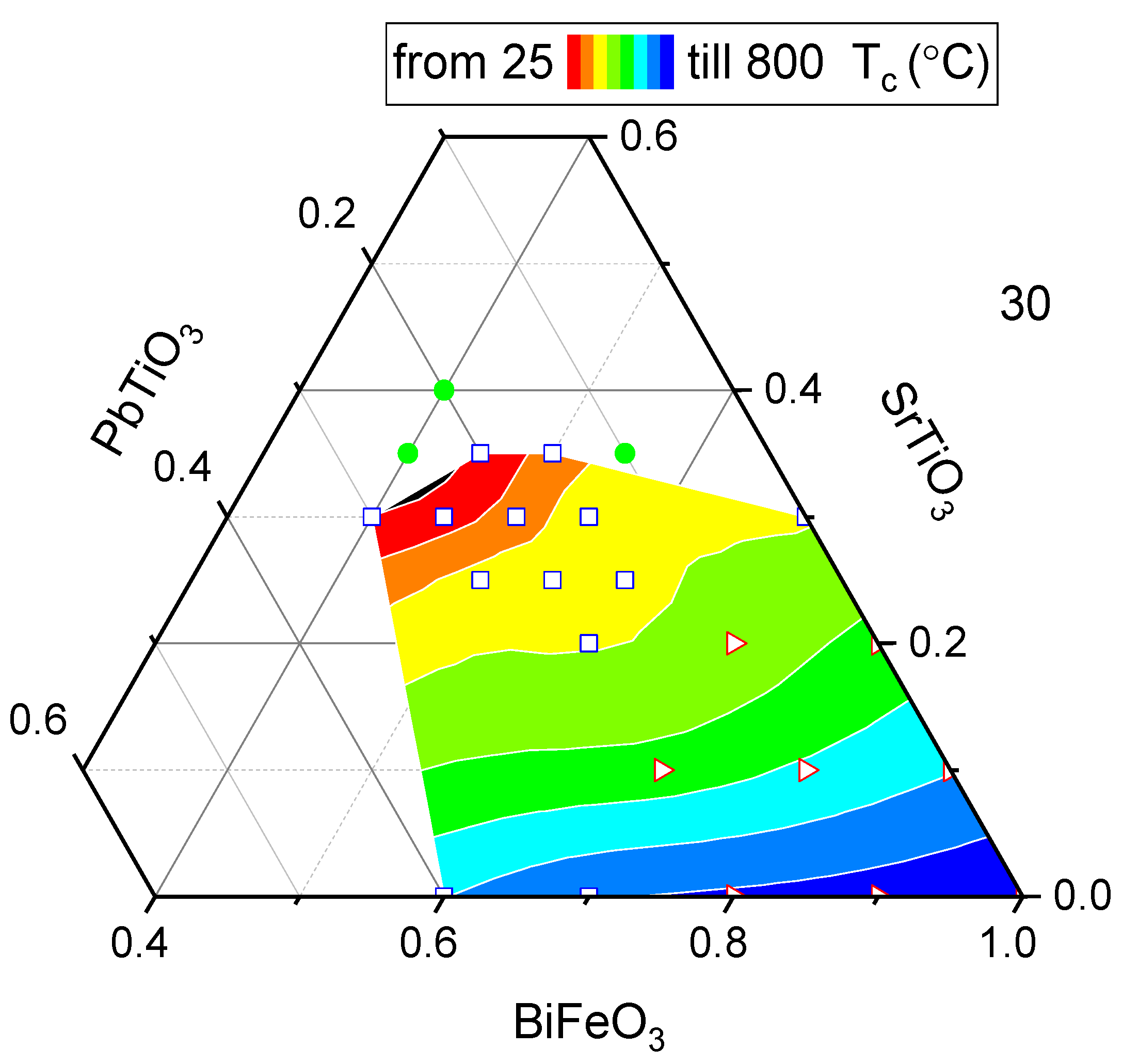

The ferroelectric Curie temperature was in wide range of 30–650 °C across the entire phase diagram and, as can be seen in

Figure 3, the depolarization temperature was also largely commensurate with the Curie temperature. High-temperature stability was maintained for d

33 until 20–50 °C below the TC.

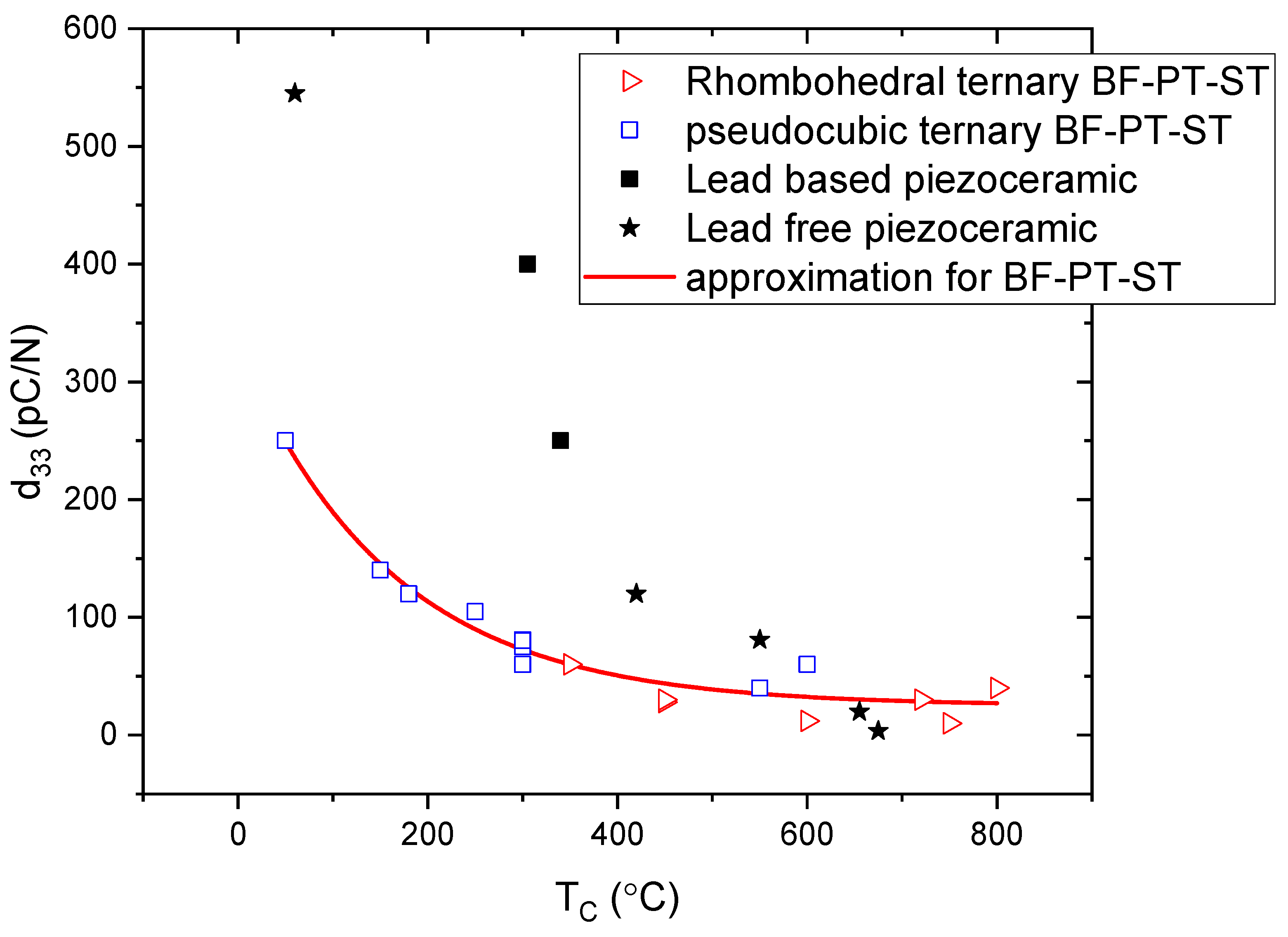

Figure 4 shows that all compositions fit a simple and unique relationship between the piezoelectric properties (at room temperature) and the Curie temperature very well. It should be noted that, according to the Landau theory [

6], if the system experiences a second-order phase transition, all secondary parameters (dielectric permittivity, piezoelectric coefficient) increase a lot. This also explains the absence of a jump during the transition from the rhombohedral phase to the pseudocubic one, since this is a first-order phase transition.

Based upon this preliminary research into the BFO-PT system [

1,

16,

17], it was hypothesized that the partial substitution of ST may reduce long-range non-centrosymmetric structural order and enhance piezoelectric performance. This could provide an explanation for the potential relationship between the increase in properties with similar ST and PT contents. Moreover, the influence of the relative concentrations of ST and PT on the crystal structure and the resultant piezoelectric properties merits further investigation.

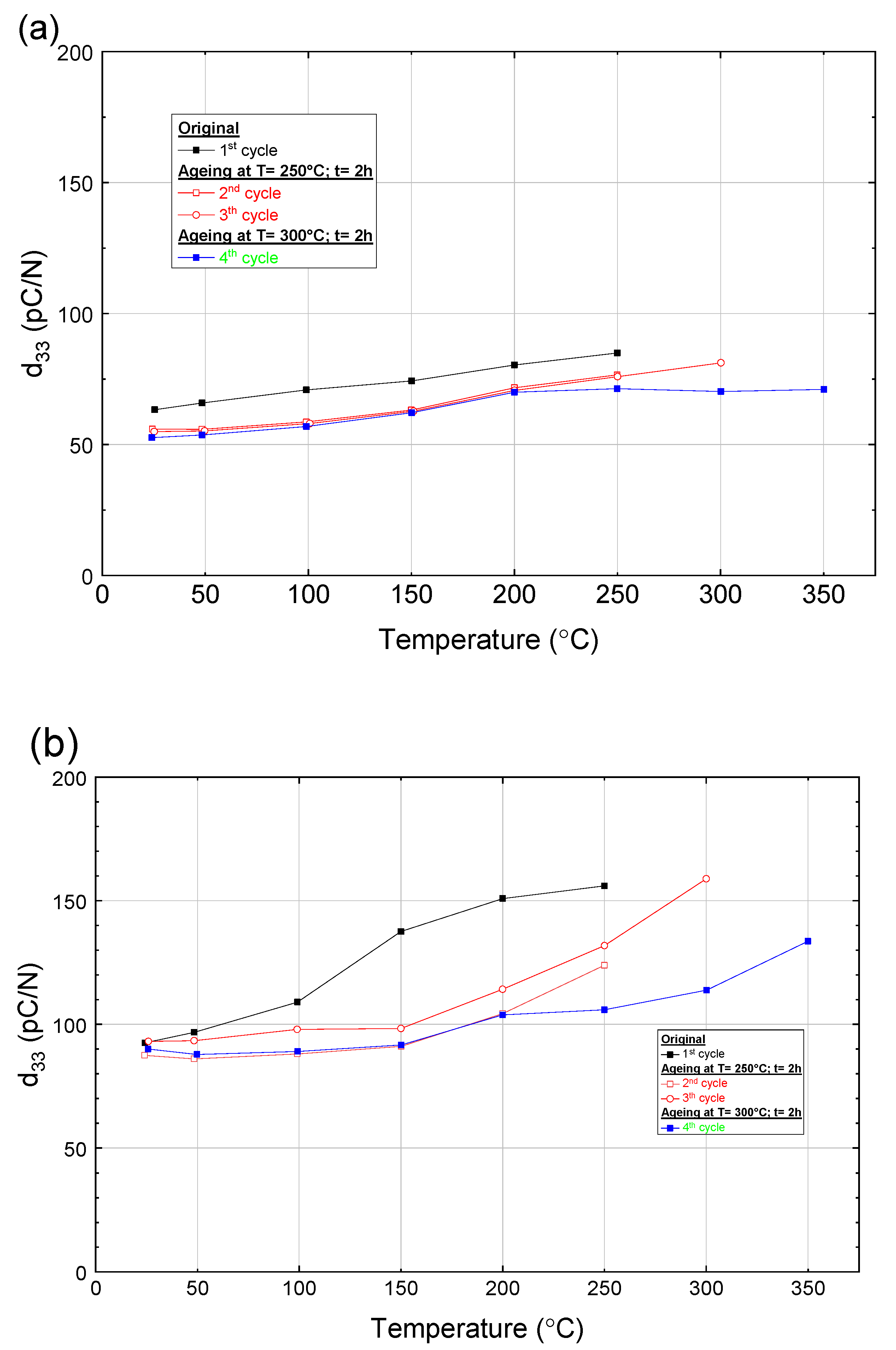

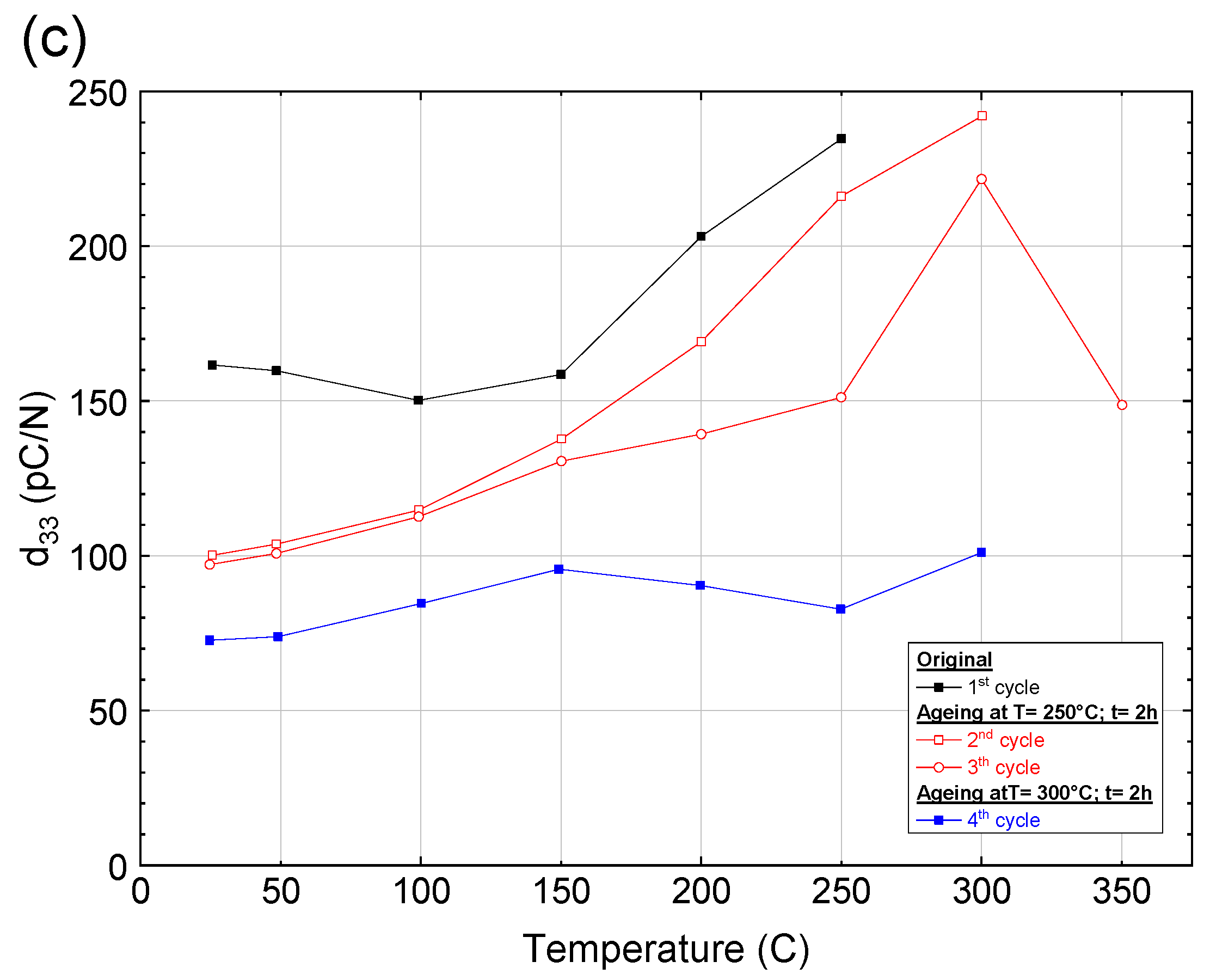

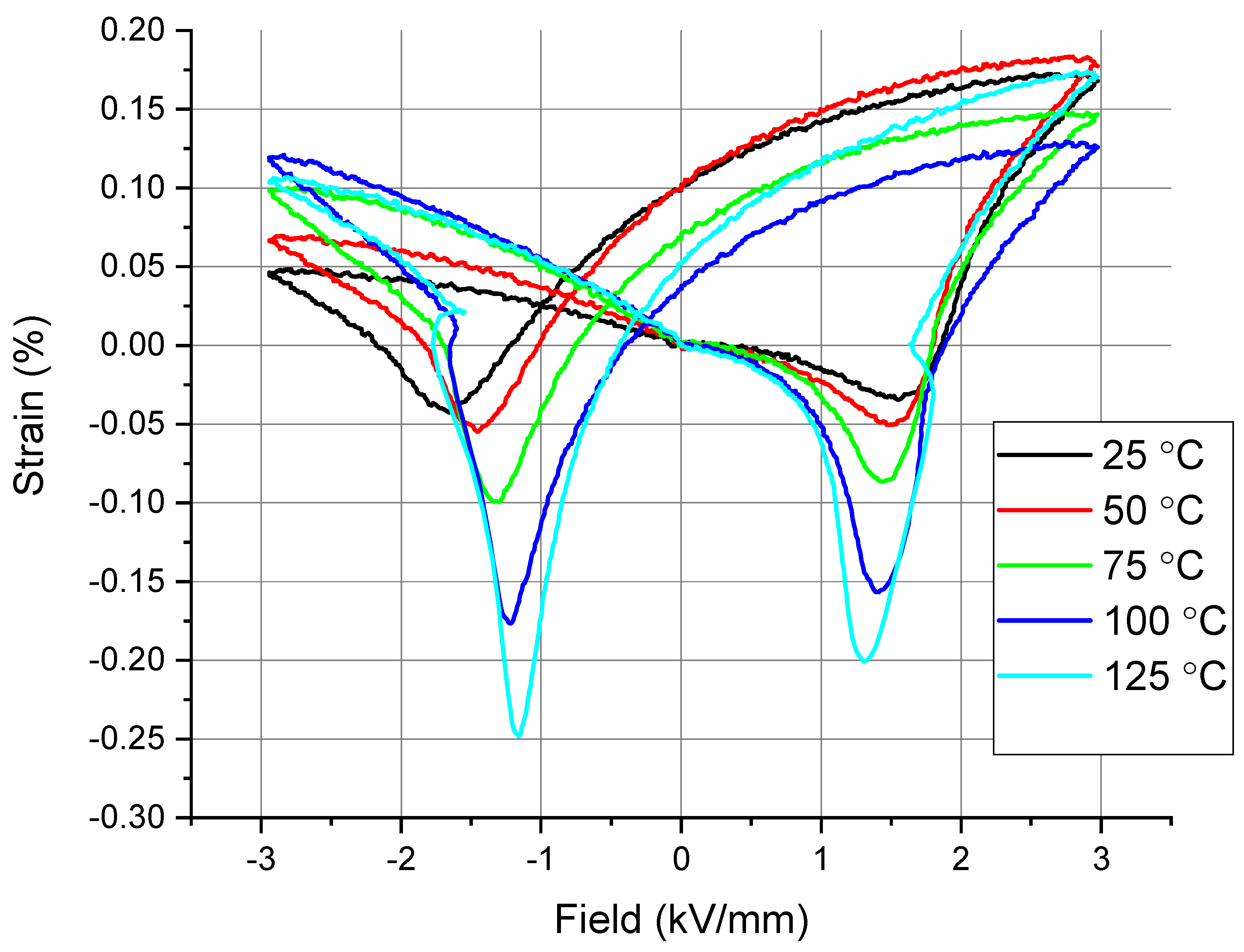

The selected compositions for the d

33 test at elevated temperatures demonstrated an increase in the magnitude of the d

33 coefficient as the temperature increases, consistent with the Landau theory [

6]. The d

33 coefficient exhibited strong temperature dependence, as depicted in

Figure 7 for compositions in the vicinity of the MPB. The increase in the piezoelectric charge coefficients d

33 with increasing temperature is observed in many ferroelectrics including barium titanate and PZT [

15,

16]. Such an increase has also been reported in the binary BiScO

3-PbTiO

3 solid solutions [

17]. The correlation between the d

33 coefficient’s temperature behavior and the crystal structure is evident. Changes in the crystallographic phases with temperature modulate the piezoelectric properties, enhancing them close to phase transition temperatures.

In the ternary system with the highest ST content, a significant peak (i.e., the d33 coefficient increased by two times compared to room temperature) was observed in piezoelectric properties at 300 °C. This observation was attributed to a phase transition, as the Curie temperature for this sample was determined to be in the region of 350 °C.

Based on the obtained data, it can be concluded that the sample 0.7BFO-0.2PT-0.1ST can be utilized up to a temperature of 350 °C, 0.6BFO-0.2PT-0.2ST up to 150–200 °C, and 0.5BFO-0.2PT-0.3ST only at room temperature. At these maximum use temperatures, the d33 coefficient remains stable, with variations of no more than 10%. But, in contrast to PZT, the depolarization temperature is relatively high and approaches the phase transition temperature. The unusual enhancement of the d33 which we observe at 250–300 °C in the 0.5BFO-0.2PT-0.3ST ceramics can be practically useful. These findings provide important insights for the selection of appropriate compositions for piezoelectric applications under varying temperature conditions. However, the risk of depolarization in the vicinity of a phase transition can be a strong obstacle for practical applications at such high temperatures.

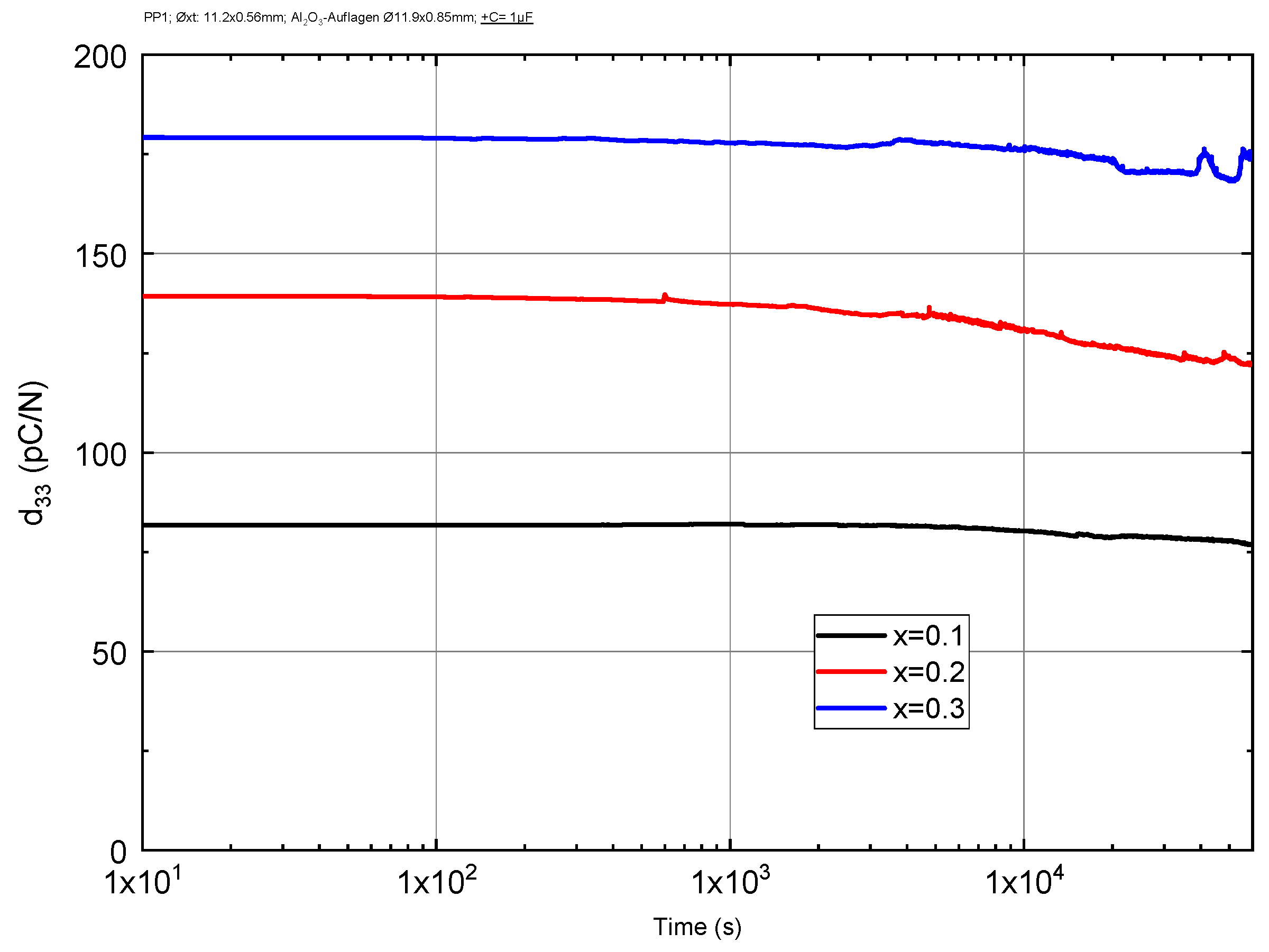

In practical applications, the repeatability of the material’s d

33 during thermal cycling is maybe even more significant than the magnitude of its change. After several annealing cycles, as shown on

Figure 7, not only did d

33 at room temperature decrease but the temperature dependence also became weaker. As, for example, for the sample 0.6BFO-0.2PT-0.2ST: in the first annealing cycle, noticeable changes in d

33 occur upon reaching a temperature of 150 °C, while during the second or third cycle this occurs already in the region of 200–250 °C. And, for the 0.5BFO-0.2PT-0.3ST sample: during annealing up to 300 °C, the d

33 curves did not change, apart from after the 3rd cycle, when the temperature exceeded 350 °C (which is presumably higher than the Curie temperature). Hence, in the fourth cycle the piezoelectric response was significantly reduced. However, once this treatment was received the sample became more stable and showed no peaks in d

33 at 300 °C. Similar results are seen when analyzing the bipolar strain curve; as the sample is heated, the stress asymmetry vanishes. This effect can presumably be explained by the domain pinning by oxygen defects similar to what occurs in hard-PZT ceramics [

1,

20,

21]. This is when, at elevated temperatures, oxygen defects become more mobile and start concentrating on domain walls, thereby reducing the dipole moment (as a consequence of d

33) but also preventing reorientation of domains (domain pinning) at lower temperatures, which leads to stabilization of d

33. As shown in

Figure 8, it is interesting that the decrease in piezoelectric properties at elevated temperatures does not occur immediately but after some time. It is possible that defects need time to diffuse to the domain walls and accumulate before a noticeable effect appears.

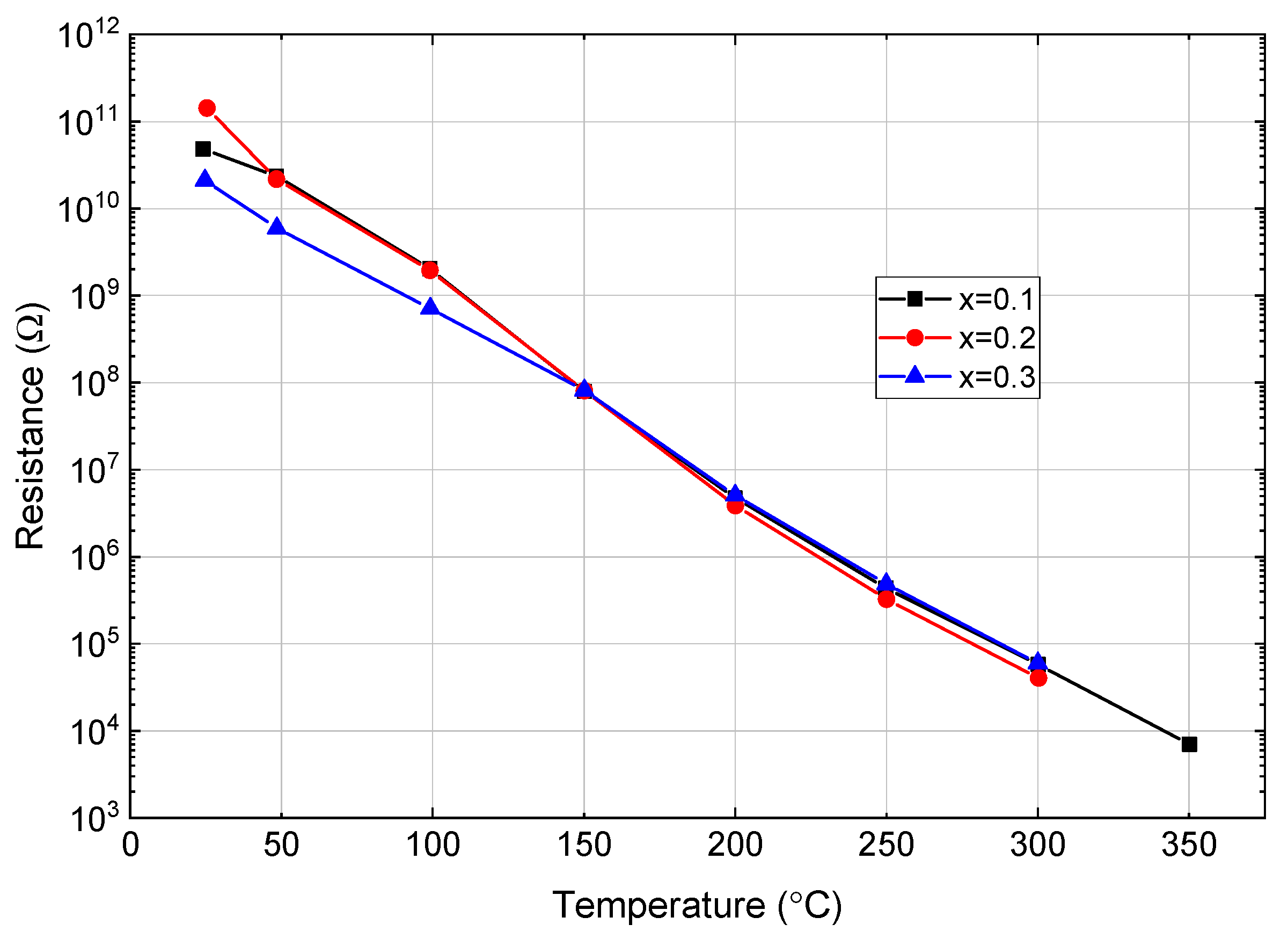

Although for all materials synthesized the electrical conductivity was high and adequate for use in sensors, the observed high electrical conductivity of the studied material at elevated temperatures, as shown in

Figure 9, remains problematic. Varying the ST level had no noticeable effect on the temperature dependence of conductivity. Consequently, this makes the material unsuitable for high-temperature applications where stability and low electric conductivity are key factors. The high electrical conductivity may have originated from intrinsic defects or impurities present in the material. Further studies may be conducted to elucidate the origin of the high electrical conductivity and potentially mitigate this undesired effect in the material.