Thermodynamic Irreversibility Analysis of Thermal Radiation in Coal-Fired Furnace: Effect of Coal Ash Deposits

Abstract

1. Introduction

2. Numerical Models and Formulation

2.1. Formula for REG Rate

2.2. Solution of Radiative Heat Transfer

3. Numerical Procedure

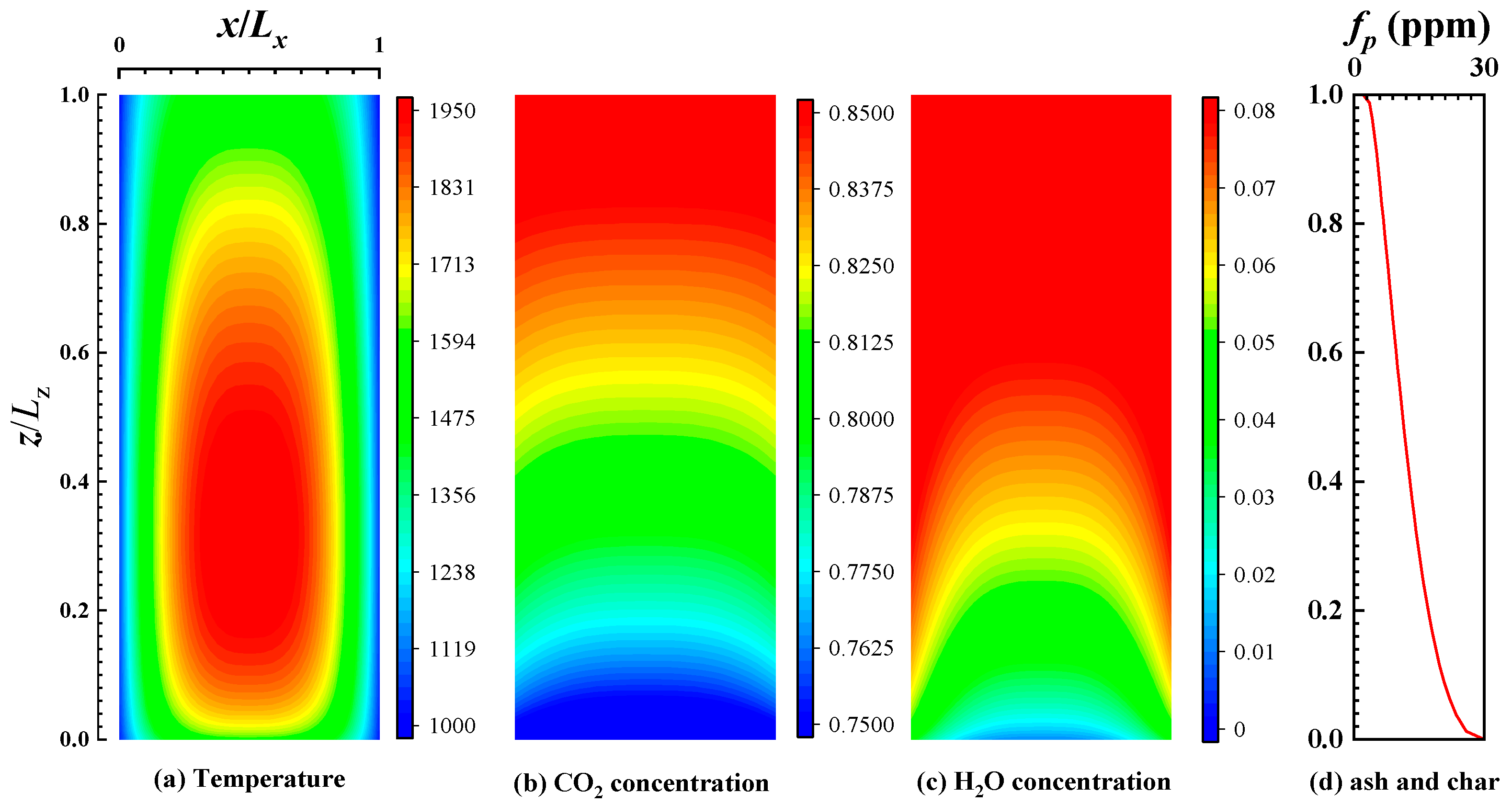

3.1. Simplified Combustion Model

3.2. Spectral Emittance of Deposits

4. Results

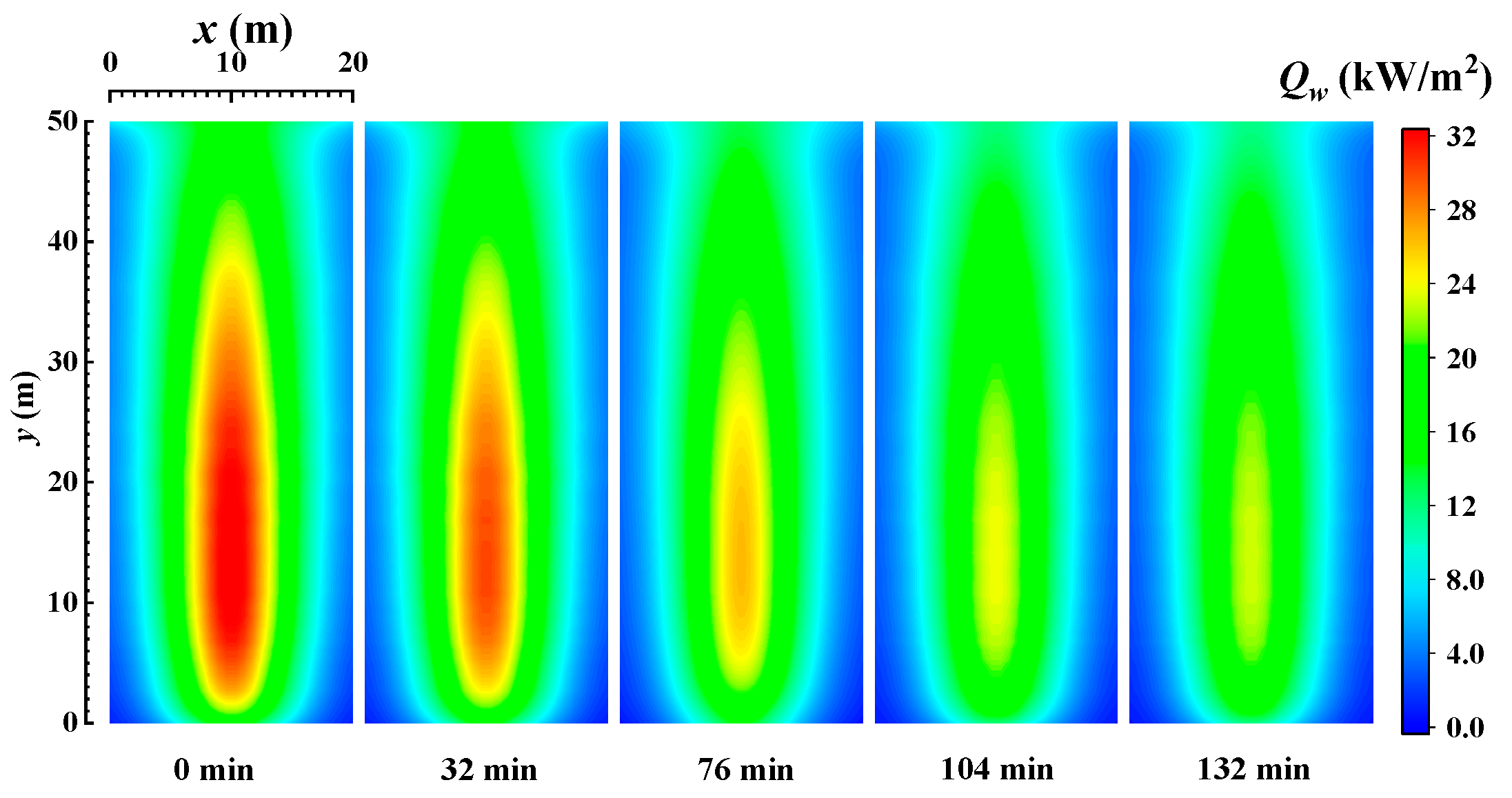

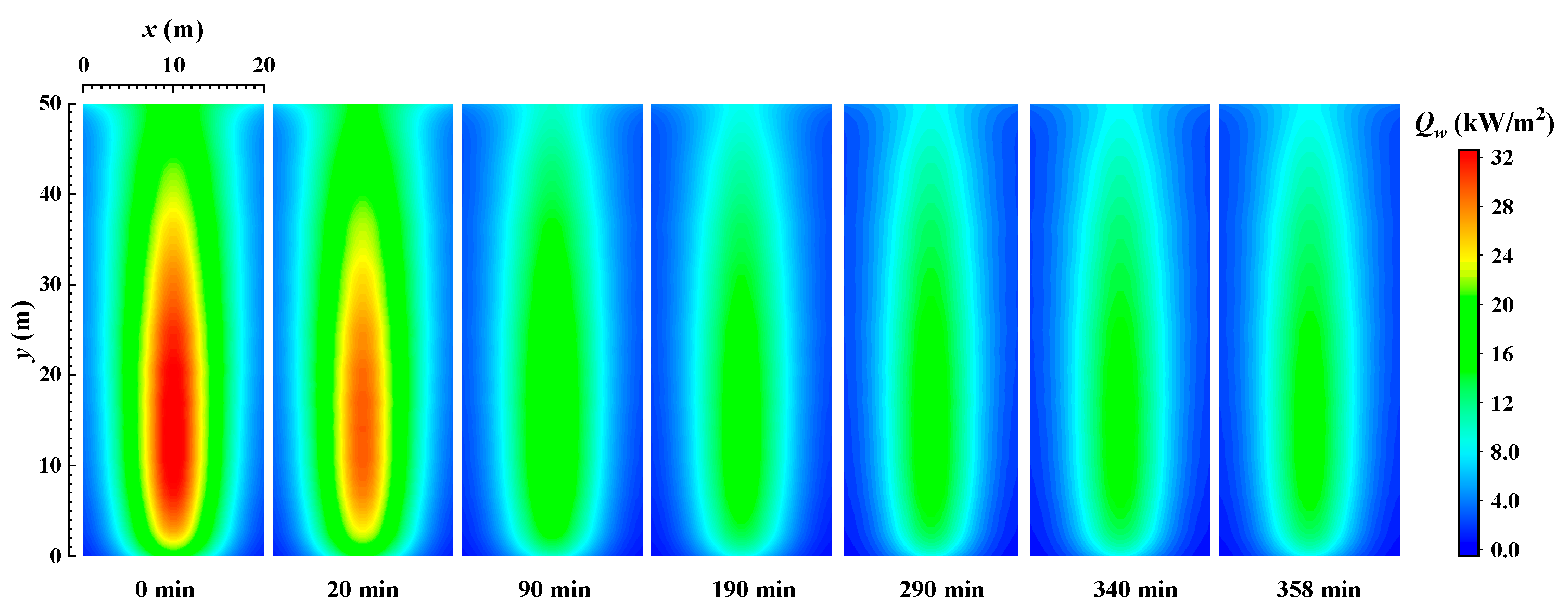

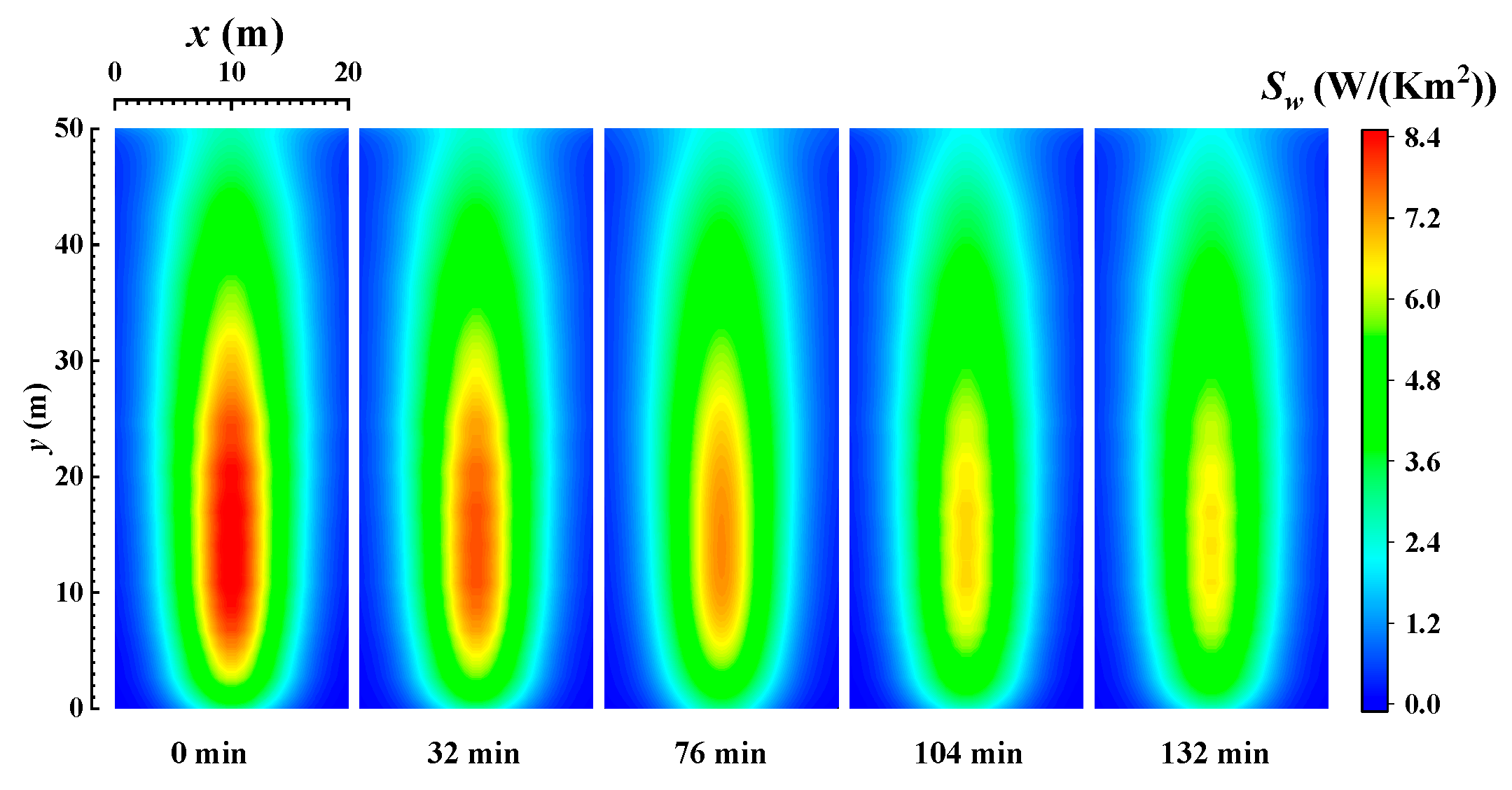

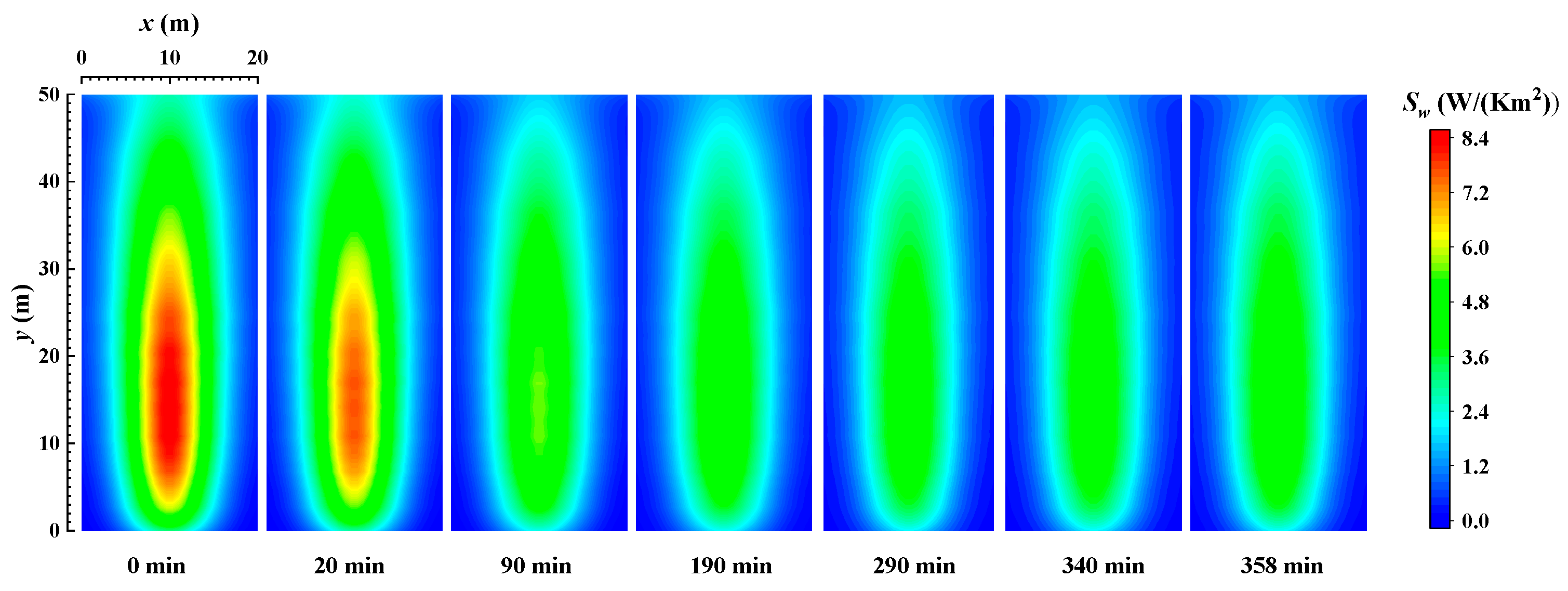

4.1. Distributions of the Local Heat Flux Density and the Local REG Rate on the Wall

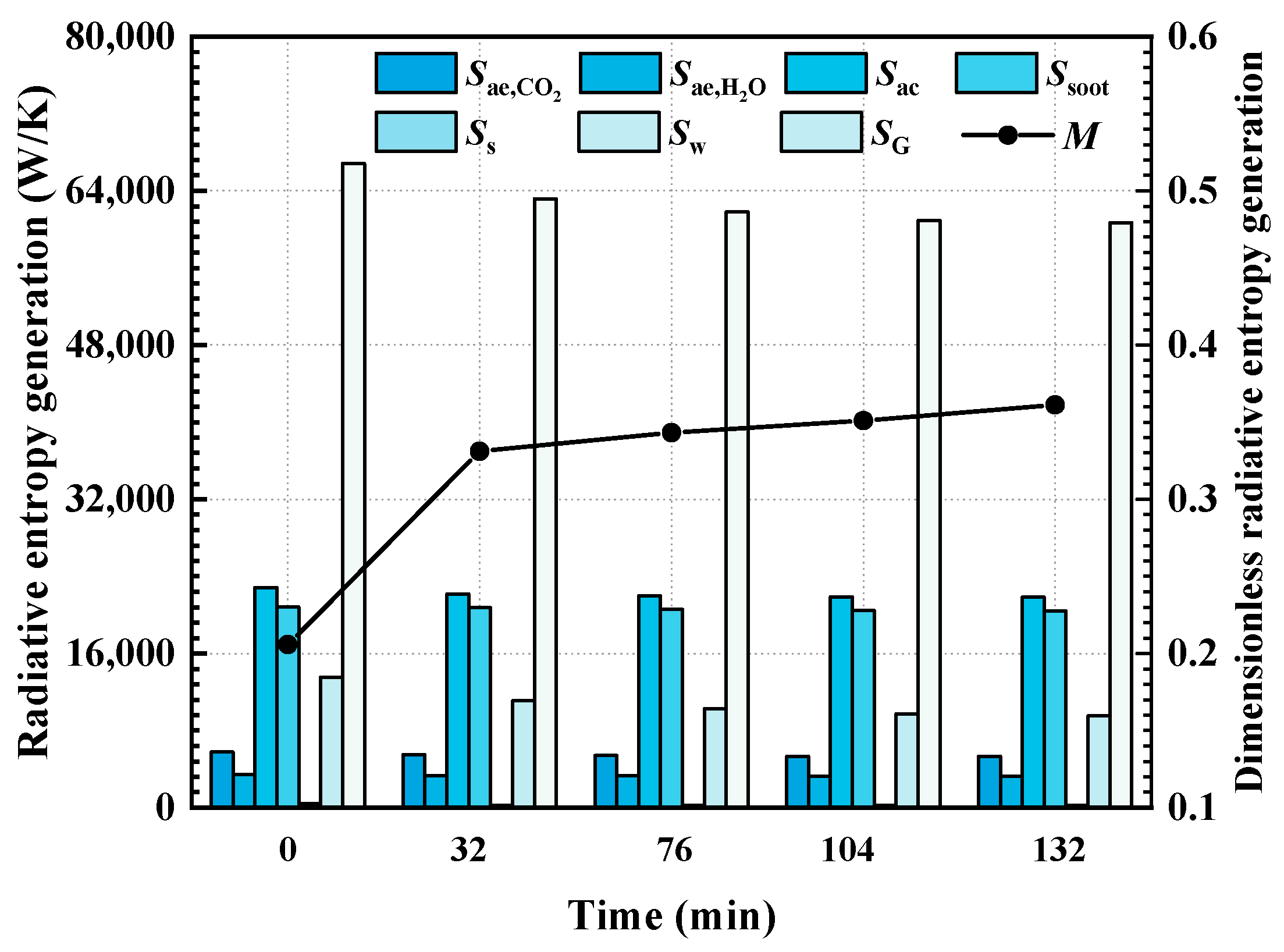

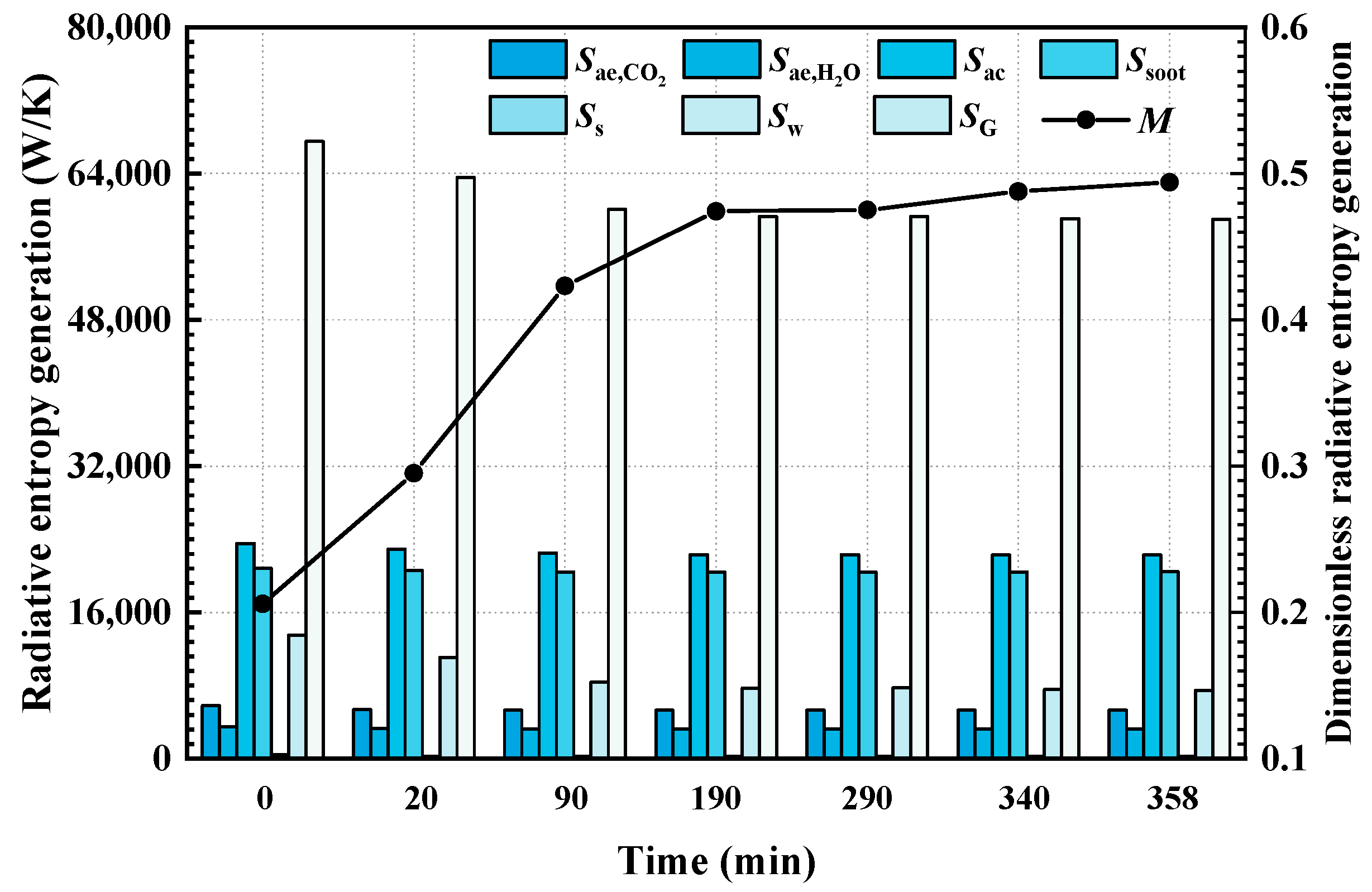

4.2. Total REG Rate

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, J.; Zheng, H.; Vardanyan, M. Achieving carbon neutrality through green technological progress: Evidence from China. Energe Policy 2023, 173, 113397. [Google Scholar] [CrossRef]

- Cartelle Barros, J.J.; Paz, F.L.; Coira, L.M.; de la Cruz López, M.P.; del Caño Gochi, A.; Soares, A. New approach for assessing and optimizing the environmental performance of multinational electricity sectors: A European case study. Energe Conver. Manag. 2022, 268, 116023. [Google Scholar] [CrossRef]

- Jia, Z.; Lin, B. How to achieve the first step of the carbon-neutrality 2060 target in China: The coal substitution perspective. Energy 2021, 233, 121179. [Google Scholar] [CrossRef]

- Som, S.K.; Datta, A. Thermodynamic irreversibilities and exergy balance in combustion processes. Prog. Energe Combust. 2008, 34, 351–376. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Agudelo, A.; Cortés, C. Thermal radiation and the second law. Energy 2010, 35, 679–691. [Google Scholar] [CrossRef]

- Caldas, M.; Semião, V. Entropy generation through radiative transfer in participating media. J. Quant. Spectrosc. Radiat. Transf. 2005, 96, 427–437. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Basu, S. Entropy flow and generation in radiative transfer between surfaces. Int. J. Heat Mass Transf. 2007, 50, 702–712. [Google Scholar] [CrossRef]

- Liu, L.H.; Chu, S.X. Verification of numerical simulation method for entropy generation of radiation heat transfer in semitransparent medium. J. Quant. Spectrosc. Radiat. Transf. 2007, 103, 43–56. [Google Scholar] [CrossRef]

- Sadeghi, P.; Safavinejad, A. Radiative entropy generation in a gray absorbing, emitting, and scattering planar medium at radiative equilibrium. J. Quant. Spectrosc. Radiat. Transf. 2017, 201, 17–29. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Lou, C. Numerical analysis of radiative entropy generation in a parallel plate system with non-uniform temperature distribution participation medium. J. Quant. Spectros. Radiat. Transf. 2019, 225, 319–326. [Google Scholar] [CrossRef]

- Shan, S.Q.; Zhou, Z.J. Second Law Analysis of spectral radiative transfer and calculation in one-dimensional furnace cases. Entropy 2019, 21, 461. [Google Scholar] [CrossRef] [PubMed]

- Makhanlall, D. Thermodynamic second-law analysis of radiative heat transfer in two-phase (particulate) media. J. Thermophys. Heat Transf. 2013, 27, 360–363. [Google Scholar] [CrossRef]

- Bahrami, A.; Safavinejad, A.; Amiri, H. Spectral radiative entropy generation in a non-gray planar participating medium including H2O and CO2. J. Quant. Spectrosc. Radiat. Transf. 2019, 227, 32–46. [Google Scholar] [CrossRef]

- Zhang, Z.; Lou, C.; Li, Z.; Long, Y. Evaluation of radiative entropy generation in a high temperature system including H2O, CO2 and soot with non-gray wall. J. Quant. Spectros. Radiat. Transf. 2020, 253, 107175. [Google Scholar] [CrossRef]

- Zhang, Z.N.; Lou, C.; Long, Y.; Benjamin, M.K. Thermodynamics second-law analysis of hydrocarbon diffusion flames: Effects of soot and temperature. Combust. Flame 2021, 234, 111618. [Google Scholar] [CrossRef]

- Yan, H.; Tang, G.; Wang, C.; Li, L.; Zhou, Y.; Zhang, Z.; Lou, C. Thermodynamics irreversibilities analysis of oxy-fuel diffusion flames: Effect of oxygen concentration. Entropy 2022, 24, 205. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, Z.; Sun, H.; Yao, B.; Lou, C. Numerical investigation of exergy loss of ammonia addition in hydrocarbon diffusion flames. Entropy 2022, 24, 922. [Google Scholar] [CrossRef]

- Makhanlall, D.; Munda, J.L.; Jiang, P. Radiation energy devaluation in diffusion combusting flow of natural gas. Energy 2013, 61, 657–663. [Google Scholar] [CrossRef]

- Rajabi, V.; Amani, E. A computational study of swirl number effects on entropy generation in gas turbine combustors. Heat Transf. Eng. 2019, 40, 346–361. [Google Scholar] [CrossRef]

- Lou, C.; Zhang, Z. Experimental and numerical analysis of radiative entropy generation in industrial and boiler furnaces. J. Quant. Spectros. Radiat. Transf. 2019, 232, 27–34. [Google Scholar] [CrossRef]

- Helble, J.J.; Srinivasachar, S.; Boni, A.A. Factors influencing the transformation of minerals during pulverized coal combustion. Prog. Energy Combust. Sci. 1990, 16, 267–279. [Google Scholar] [CrossRef]

- Richter, W.; Payne, R.; Heap, M.P. Influence of Thermal Properties of Wall Deposits on Performance of Pulverized Fuel Fired Boiler Combustion Chambers. Mineral Matter and Ash in Coal ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1986. [Google Scholar]

- Wall, T.F.; Bhattacharya, S.P.; Zhang, D.K.; Gupta, R.P.; He, X. The properties and thermal effects of ash deposits in coal-fired furnaces. Prog. Energy Combust. Sci. 1993, 19, 487–504. [Google Scholar] [CrossRef]

- Syrodoy, S.V.; Kuznetsov, G.V.; Gutareva, N.Y.; Salomato, V.V. The efficiency of heat transfer through the ash deposits on the heat exchange surfaces by burning coal and coal-water fuels. J. Energy Inst. 2018, 91, 1091–1101. [Google Scholar] [CrossRef]

- Melanie, G.; Elmar, P.; Primpuna, H.S.; David, D. Impact of Solid Body Emissivity on Radiative Heat Transfer Efficiency in Furnaces—A Numerical Study. Energy Procedia 2017, 120, 628–634. [Google Scholar]

- Vangaever, S.; Van Thielen, J.; Hood, J.; Olver, J.; Honnerovà, P.; Heynderickx, G.J.; Van Geem, K.M. The effect of refractory wall emissivity on the energy efficiency of a gas-fired steam cracking pilot unit. Materials 2021, 14, 880. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Lou, C. Effect of wall spectral emissivity on heat flux and radiative entropy generation in three-dimensional enclosures. In Proceedings of the 15th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Virtual Conference, 26–28 July 2021. [Google Scholar]

- Markham, J.R.; Best, P.E.; Solomon, P.R.; Yu, Z.Z. Measurement of radiative properties of ash and slag by FT-IR emission and reflection spectroscopy. J. Heat Transfer. ASME 1992, 114, 458–464. [Google Scholar] [CrossRef]

- BaxterL, L.; Richards, G.H.; Ottesen, D.K.; Harb, J.N. In situ, real-time characterization of coal ash deposits using Fourier transform infrared emission spectroscopy. Energy Fuels 1993, 7, 755–760. [Google Scholar] [CrossRef]

- Moore, J.T.; Cundick, D.P.; Jones, M.R.; Tree, D.R.; Maynes, R.D.; Baxter, L.L. In situ measurements of the spectral emittance of coal ash deposits. J. Quant. Spectrosc. Radiat. Transf. 2011, 112, 1978–1986. [Google Scholar] [CrossRef]

- El-Kolaly, M.A.; El-Agramy, A.M.; Hafez, H.S. Effect of different activators on thermoluminescence properties of gamma irradiated cement clinker and its ferrite phase. Radiat. Eff. Defects Solids 1996, 139, 221–227. [Google Scholar] [CrossRef]

- Mirković, M.; Kljajević, K.; Nenadović, S. Fly ash as a raw material for low-carbon cement clinkers and its radiological properties. J. Radioanal. Nucl. Chem. 2021, 328, 1391–1398. [Google Scholar] [CrossRef]

- El-Hosiny, F.I.; El-Faramawy, N.A. Shielding of gamma radiation by hydrated Portland cement lead pastes. Radiat. Meas. 2000, 32, 93–99. [Google Scholar] [CrossRef]

- Modest, M.F.; Mazumder, S. Radiative Heat Transfer; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Liu, F.; Smallwood, G.J.; Gulder, O.L. Application of the statistical narrow-band correlated-k method to low-resolution spectral intensity and radiative heat transfer calculations-effects of the quadrature scheme. Int. J. Heat Mass Transf. 2000, 43, 3119–3135. [Google Scholar] [CrossRef]

- Kez, V.; Consalvi, J.L.; Liu, F.; Strohle, J.; Epple, B. Assessment of several gas radiation models for radiative heat transfer calculations in a three-dimensional oxy-fuel furnace under coal-fired conditions. Int. J. Therm. Sci. 2017, 120, 289–302. [Google Scholar] [CrossRef]

- Guo, J.; Hu, F.; Luo, W.; Li, P.; Liu, Z. A full spectrum k-distribution based non-gray radiative property model for unburnt char. Proc. Combust. Inst. 2019, 37, 3081–3089. [Google Scholar] [CrossRef]

- Bohnes, S.; Scherer, V.; Linka, S. Spectral emissivity measurements of single mineral phases and ash deposits. Heat Transfer. 2005, 4, 175–182. [Google Scholar]

- Baxter, L.L.; Fletcher, T.H.; Ottesen, D.K. Spectral emittance measurements of coal particles. Energy Fuels 1988, 2, 423–430. [Google Scholar] [CrossRef]

- Liu, L.H.; Chu, S.X. On the entropy generation formula of radiation heat transfer processes. J. Heat Transfer. 2006, 128, 504–506. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhang, Z.; Lou, C. Thermodynamic Irreversibility Analysis of Thermal Radiation in Coal-Fired Furnace: Effect of Coal Ash Deposits. Materials 2023, 16, 799. https://doi.org/10.3390/ma16020799

Zhang C, Zhang Z, Lou C. Thermodynamic Irreversibility Analysis of Thermal Radiation in Coal-Fired Furnace: Effect of Coal Ash Deposits. Materials. 2023; 16(2):799. https://doi.org/10.3390/ma16020799

Chicago/Turabian StyleZhang, Chong, Zhongnong Zhang, and Chun Lou. 2023. "Thermodynamic Irreversibility Analysis of Thermal Radiation in Coal-Fired Furnace: Effect of Coal Ash Deposits" Materials 16, no. 2: 799. https://doi.org/10.3390/ma16020799

APA StyleZhang, C., Zhang, Z., & Lou, C. (2023). Thermodynamic Irreversibility Analysis of Thermal Radiation in Coal-Fired Furnace: Effect of Coal Ash Deposits. Materials, 16(2), 799. https://doi.org/10.3390/ma16020799