CeO2-rGO Composites for Photocatalytic H2 Evolution by Glycerol Photoreforming

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Photocatalytic Tests

2.3. Characterization Techniques

3. Results

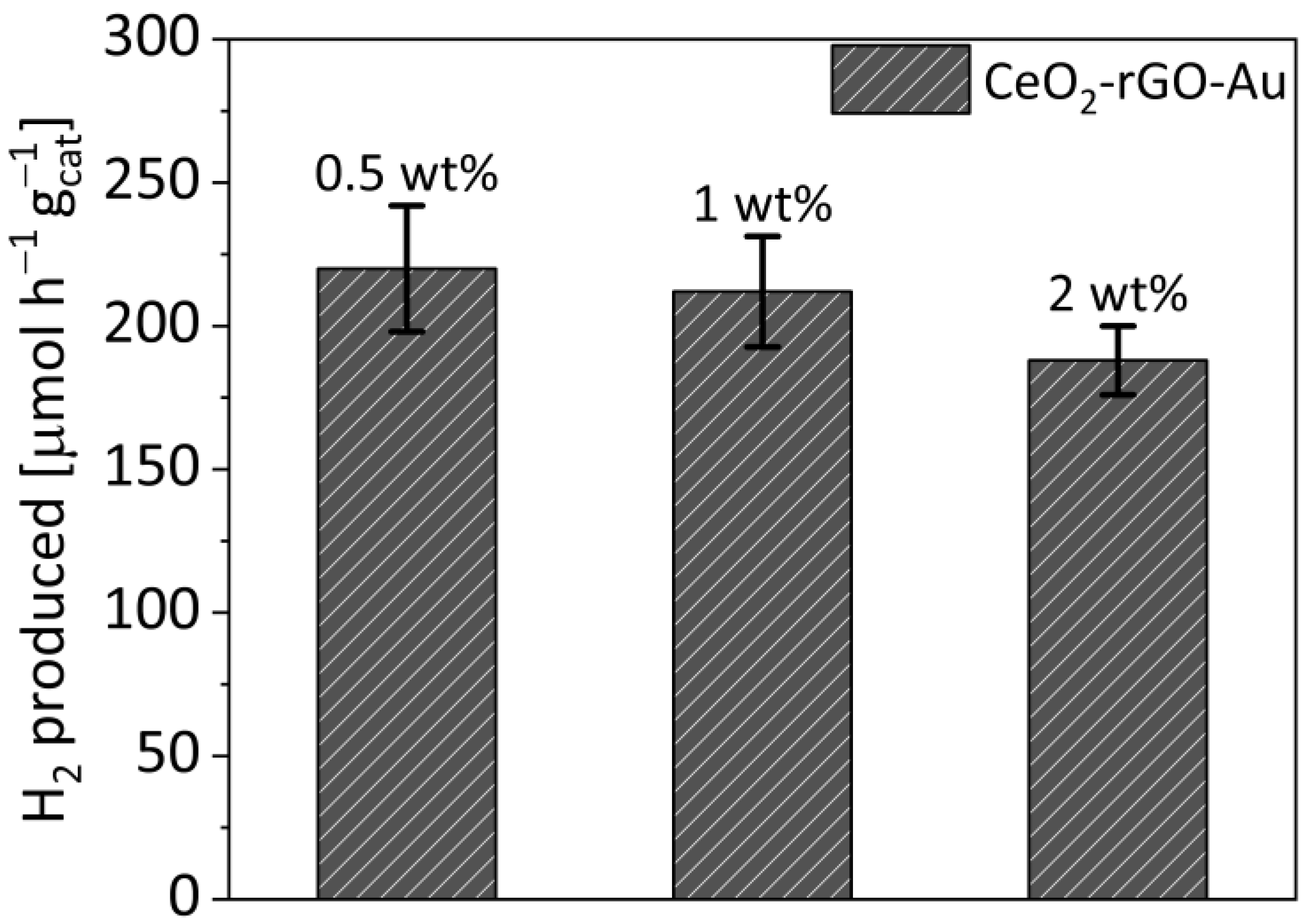

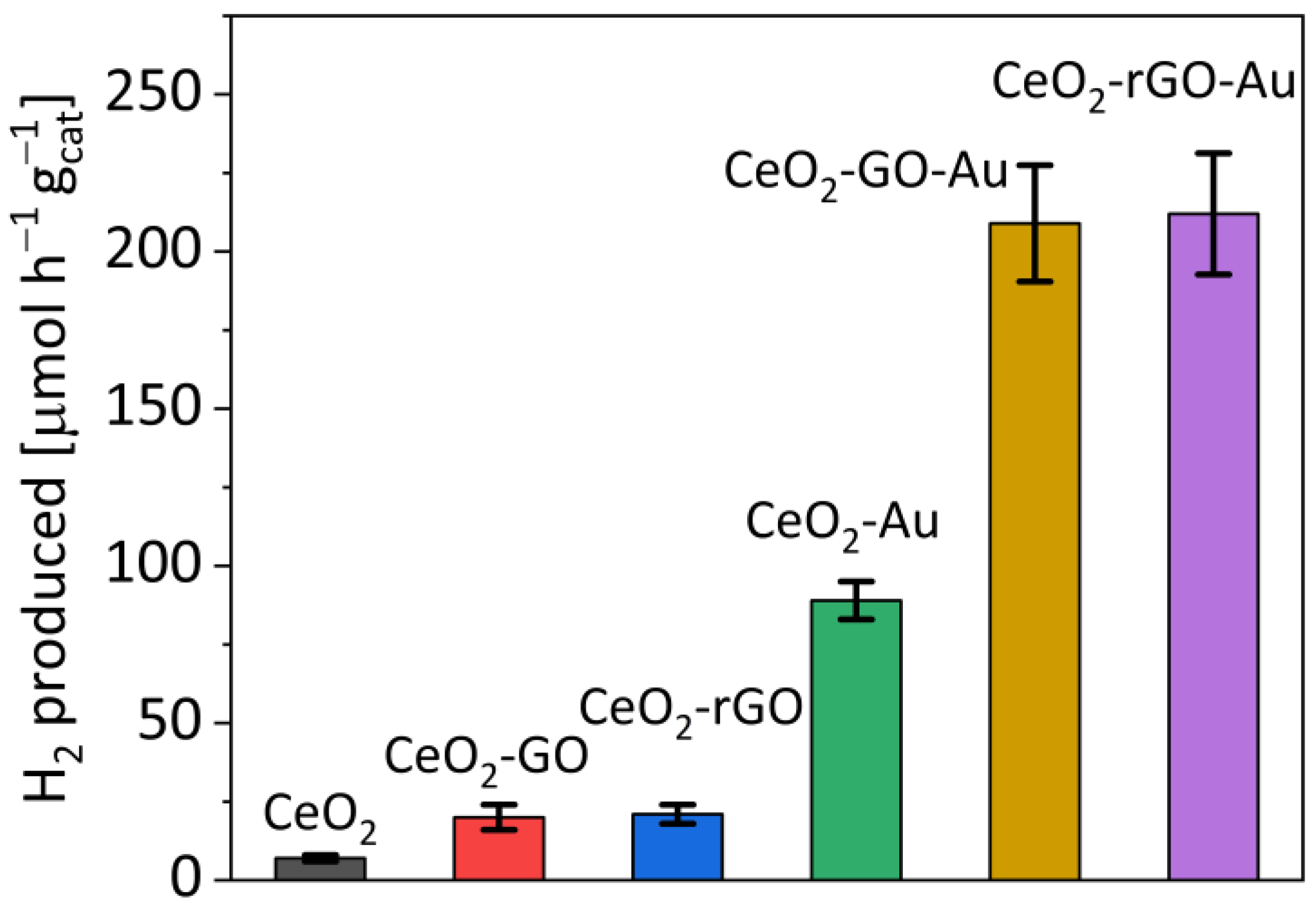

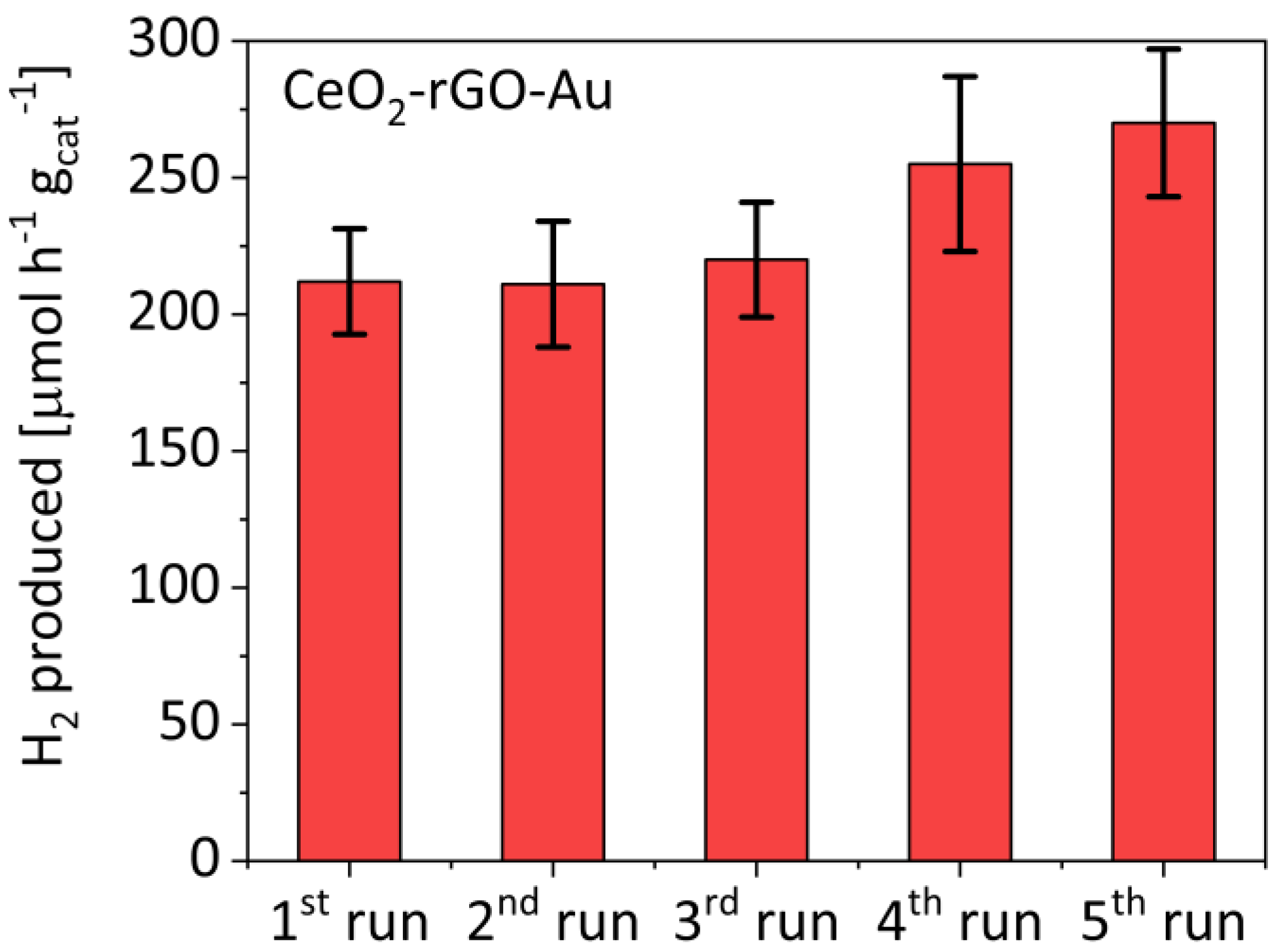

3.1. Photocatalytic Hydrogen Evolution

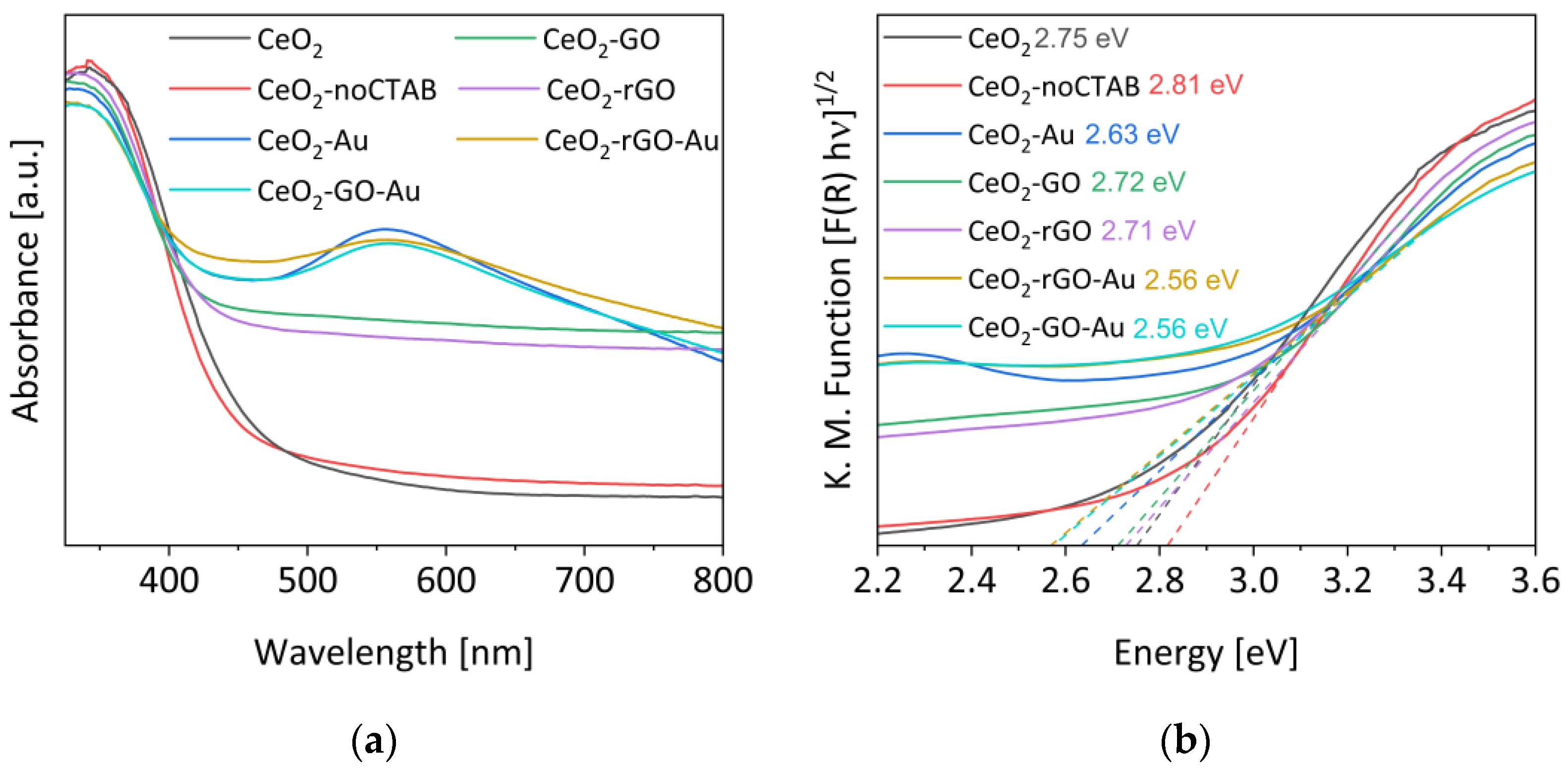

3.2. Photocatalyst Characterizations

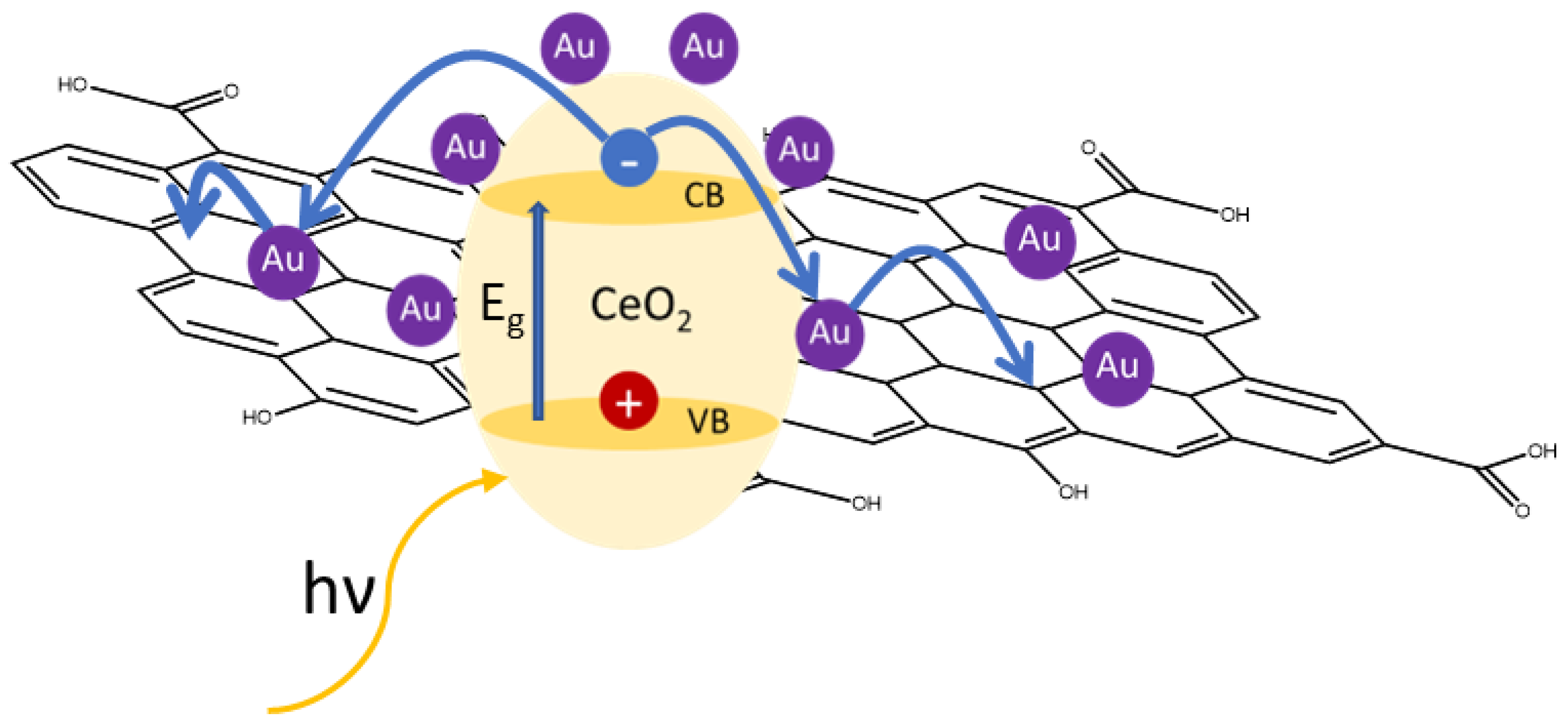

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pruvost, F.; Cloete, S.; Arnaiz del Pozo, C.; Zaabout, A. Blue, Green, and Turquoise Pathways for Minimizing Hydrogen Production Costs from Steam Methane Reforming with CO2 Capture. Energy Convers. Manag. 2022, 274, 116458. [Google Scholar] [CrossRef]

- Banerjee, D.; Kushwaha, N.; Shetti, N.P.; Aminabhavi, T.M.; Ahmad, E. Green Hydrogen Production via Photo-Reforming of Bio-Renewable Resources. Renew. Sustain. Energy Rev. 2022, 167, 112827. [Google Scholar] [CrossRef]

- Bhakta, A.K.; Fiorenza, R.; Jlassi, K.; Mekhalif, Z.; Ali, A.M.A.; Chehimi, M.M. The Emerging Role of Biochar in the Carbon Materials Family for Hydrogen Production. Chem. Eng. Res. Des. 2022, 188, 209–228. [Google Scholar] [CrossRef]

- Christoforidis, K.C.; Fornasiero, P. Photocatalytic Hydrogen Production: A Rift into the Future Energy Supply. ChemCatChem 2017, 9, 1523–1544. [Google Scholar] [CrossRef]

- Chiarello, G.L.; Dozzi, M.V.; Selli, E. TiO2-Based Materials for Photocatalytic Hydrogen Production. J. Energy Chem. 2017, 26, 250–258. [Google Scholar] [CrossRef]

- Lewicka, E.; Guzik, K.; Galos, K. On the Possibilities of Critical Raw Materials Production from the EU’s Primary Sources. Resources 2021, 10, 50. [Google Scholar] [CrossRef]

- Fiorenza, R.; Balsamo, S.A.; Condorelli, M.; D’Urso, L.; Compagnini, G.; Scirè, S. Solar Photocatalytic H2 Production over CeO2-Based Catalysts: Influence of Chemical and Structural Modifications. Catal. Today 2021, 380, 187–198. [Google Scholar] [CrossRef]

- Sujay, S.G.C.; Alkanad, K.; Alnaggar, G.; Al-Zaqri, N.; Bajiri, M.A.; Thejaswini, B.; Dhileepan, M.D.; Neppolian, B.; Lokanath, N.K. Surface Defect-Engineered CeO2−x by Ultrasound Treatment for Superior Photocatalytic H2 Production and Water Treatment. Catal. Sci. Technol. 2022, 12, 2071–2083. [Google Scholar] [CrossRef]

- Hou, H.; Yamada, H.; Nitta, A.; Murakami, Y.; Saito, N. Efficient Separation of Photoexcited Charge at Interface between Pure CeO2 and Y3+-Doped CeO2 with Heterogonous Doping Structure for Photocatalytic Overall Water Splitting. Materials 2021, 14, 350. [Google Scholar] [CrossRef]

- Liu, X.; Liu, R.; Li, T.; Liu, Y.; Liu, L.; Lyu, K.; Shah, S.P. Research on the Anticorrosion Properties of CeO2-GO/EP Nanocomposite Coating in Simulated Sea Water. Polymers 2021, 13, 2072. [Google Scholar] [CrossRef]

- Liu, F.; Wang, X.; Zhang, L.; Persson, K.M.; Chen, B.-Y.; Hsu, Y.; Chang, C.T. Near-Visible-Light-Driven Noble Metal-Free of Reduced Graphene Oxide Nanosheets over CeO2 Nanowires for Hydrogen Production. J. Taiwan Inst. Chem. Eng. 2020, 107, 139–151. [Google Scholar] [CrossRef]

- Balsamo, S.A.; Fiorenza, R.; Condorelli, M.; Pecoraro, R.; Brundo, M.V.; Presti, F.L.; Sciré, S. One-Pot Synthesis of TiO2-RGO Photocatalysts for the Degradation of Groundwater Pollutants. Materials 2021, 14, 5938. [Google Scholar] [CrossRef] [PubMed]

- Nemati, F.; Rezaie, M.; Tabesh, H.; Eid, K.; Xu, G.; Ganjali, M.R.; Hosseini, M.; Karaman, C.; Erk, N.; Show, P.-L.; et al. Cerium Functionalized Graphene Nano-Structures and Their Applications; A Review. Environ. Res. 2022, 208, 112685. [Google Scholar] [CrossRef] [PubMed]

- Ganguly, S.; Mondal, S.; Das, P.; Bhawal, P.; Das, T.K.; Ghosh, S.; Remanan, S.; Das, N.C. An Insight Into the Physico-Mechanical Signatures of Silylated Graphene Oxide in Poly(Ethylene Methyl Acrylate) Copolymeric Thermoplastic Matrix. Macromol. Res. 2019, 27, 268–281. [Google Scholar] [CrossRef]

- Rumayor, M.; Corredor, J.; Rivero, M.J.; Ortiz, I. Prospective Life Cycle Assessment of Hydrogen Production by Waste Photoreforming. J. Clean. Prod. 2022, 336, 130430. [Google Scholar] [CrossRef]

- Balsamo, S.A.; Sciré, S.; Condorelli, M.; Fiorenza, R. Photocatalytic H2 Production on Au/TiO2: Effect of Au Photodeposition on Different TiO2 Crystalline Phases. J 2022, 5, 92–104. [Google Scholar] [CrossRef]

- Rueda-Navarro, C.M.; Ferrer, B.; Baldoví, H.G.; Navalón, S. Photocatalytic Hydrogen Production from Glycerol Aqueous Solutions as Sustainable Feedstocks Using Zr-Based UiO-66 Materials under Simulated Sunlight Irradiation. Nanomaterials 2022, 12, 3808. [Google Scholar] [CrossRef]

- Corredor, J.; Rivero, M.J.; Rangel, C.M.; Gloaguen, F.; Ortiz, I. Comprehensive Review and Future Perspectives on the Photocatalytic Hydrogen Production. J. Chem. Technol. Biotechnol. 2019, 94, 3049–3063. [Google Scholar] [CrossRef]

- Wang, G.; Mu, Q.; Chen, T.; Wang, Y. Synthesis, Characterization and Photoluminescence of CeO2 Nanoparticles by a Facile Method at Room Temperature. J. Alloy. Compd. 2010, 493, 202–207. [Google Scholar] [CrossRef]

- Ahmad, T.; Shahazad, M.; Ubaidullah, M.; Ahmed, J. Synthesis, Characterization and Dielectric Properties of TiO2-CeO2 Ceramic Nanocomposites at Low Titania Concentration. Bull. Mater. Sci. 2018, 41, 99. [Google Scholar] [CrossRef]

- Mahmoud, M.A.; Chamanzar, M.; Adibi, A.; El-Sayed, M.A. Effect of the Dielectric Constant of the Surrounding Medium and the Substrate on the Surface Plasmon Resonance Spectrum and Sensitivity Factors of Highly Symmetric Systems: Silver Nanocubes. J. Am. Chem. Soc. 2012, 134, 6434–6442. [Google Scholar] [CrossRef] [PubMed]

- García-López, E.I.; Abbasi, Z.; Parrino, F.; La Parola, V.; Liotta, L.F.; Marcì, G. Au/CeO2 Photocatalyst for the Selective Oxidation of Aromatic Alcohols in Water under Uv, Visible and Solar Irradiation. Catalysts 2021, 11, 1467. [Google Scholar] [CrossRef]

- Ma, L.; Wang, D.; Li, J.; Bai, B.; Fu, L.; Li, Y. Ag/CeO2 Nanospheres: Efficient Catalysts for Formaldehyde Oxidation. Appl. Catal. B Environ. 2014, 148–149, 36–43. [Google Scholar] [CrossRef]

- Ramesh, K.; Gnanavel, B.; Shkir, M. Enhanced Visible Light Photocatalytic Degradation of Bisphenol A (BPA) by Reduced Graphene Oxide (RGO)–Metal Oxide (TiO2, ZnO and WO3) Based Nanocomposites. Diam. Relat. Mater. 2021, 118, 108514. [Google Scholar] [CrossRef]

- Qian, J.; Chen, Z.; Sun, H.; Chen, F.; Xu, X.; Wu, Z.; Li, P.; Ge, W. Enhanced Photocatalytic H2 Production on Three-Dimensional Porous CeO2/Carbon Nanostructure. ACS Sustain. Chem. Eng. 2018, 6, 9691–9698. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Jorio, A.; Ferreira, E.H.M.; Moutinho, M.V.O.; Stavale, F.; Achete, C.A.; Capaz, R.B. Measuring Disorder in Graphene with the G and D Bands. Phys. Status Solidi (B) Basic Res. 2010, 247, 2980–2982. [Google Scholar] [CrossRef]

- Sotomayor, F.; Quantatec, A.P.; Sotomayor, F.J.; Cychosz, K.A.; Thommes, M. Characterization of Micro/Mesoporous Materials by Physisorption: Concepts and Case Studies. Acc. Mater. Surf. Res 2018, 3, 34–50. [Google Scholar]

- Fiorenza, R.; Balsamo, S.A.; D’urso, L.; Sciré, S.; Brundo, M.V.; Pecoraro, R.; Scalisi, E.M.; Privitera, V.; Impellizzeri, G. CeO2 for Water Remediation: Comparison of Various Advanced Oxidation Processes. Catalysts 2020, 10, 446. [Google Scholar] [CrossRef]

- Aslam, M.; Qamar, M.T.; Soomro, M.T.; Ismail, I.M.I.; Salah, N.; Almeelbi, T.; Gondal, M.A.; Hameed, A. The Effect of Sunlight Induced Surface Defects on the Photocatalytic Activity of Nanosized CeO2 for the Degradation of Phenol and Its Derivatives. Appl. Catal. B Environ. 2016, 180, 391–402. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Holgado, J.P.; Alvarez, R.; Munuera, G. Study of CeO2 XPS Spectra by Factor Analysis: Reduction of CeO2. Appl. Surf. Sci. 2000, 161, 301–315. [Google Scholar] [CrossRef]

- Natile, M.M.; Glisenti, A. Nanostructured CeO2 Powders by XPS. Surf. Sci. Spectra 2006, 13, 17–30. [Google Scholar] [CrossRef]

- Chang, A.; Peng, W.-S.; Tsai, I.-T.; Chiang, L.-F.; Yang, C.-M. Efficient Hydrogen Production by Selective Alcohol Photoreforming on Plasmonic Photocatalyst Comprising Sandwiched Au Nanodisks and TiO2. Appl. Catal. B Environ. 2019, 255, 117773. [Google Scholar] [CrossRef]

- Morales, M.V.; Asedegbega-Nieto, E.; Castillejos-López, E.; Bachiller-Baeza, B.; Guerrero-Ruiz, A. Difference in the Deactivation of Au Catalysts during Ethanol Transformation When Supported on ZnO and on TiO2. RSC Adv. 2018, 8, 7473–7485. [Google Scholar] [CrossRef]

- Nath, M.P.; Biswas, S.; Nath, P.; Choudhury, B. Synergy of Adsorption and Plasmonic Photocatalysis in the Au–CeO2 Nanosystem: Experimental Validation and Plasmonic Modeling. Langmuir 2022, 38, 7628–7638. [Google Scholar] [CrossRef]

- Fiorenza, R.; Bellardita, M.; D’Urso, L.; Compagnini, G.; Palmisano, L.; Scirè, S. Au/TiO2-CeO2 Catalysts for Photocatalytic Water Splitting and VOCs Oxidation Reactions. Catalysts 2016, 6, 121. [Google Scholar] [CrossRef]

- Sundaram, I.M.; Kalimuthu, S.; Priya, P.G.; Sekar, K.; Rajendran, S. Hierarchical TiO2 Spheroids Decorated g-C3N4 Nanocomposite for Solar Driven Hydrogen Production and Water Depollution. Int. J. Hydrogen Energy 2022, 47, 3709–3721. [Google Scholar] [CrossRef]

- Corredor, J.; Rivero, M.J.; Ortiz, I. New Insights in the Performance and Reuse of RGO/TiO2 Composites for the Photocatalytic Hydrogen Production. Int. J. Hydrogen Energy 2021, 46, 17500–17506. [Google Scholar] [CrossRef]

- Tian, B.; Yang, B.; Li, J.; Li, Z.; Zhen, W.; Wu, Y.; Lu, G. Water Splitting by CdS/Pt/WO3-CeOx Photocatalysts with Assisting of Artificial Blood Perfluorodecalin. J. Catal. 2017, 350, 189–196. [Google Scholar] [CrossRef]

- Yadav, A.A.; Hunge, Y.M.; Kang, S.-W. Visible Light-Responsive CeO2/MoS2 Composite for Photocatalytic Hydrogen Production. Catalysts 2022, 12, 1185. [Google Scholar] [CrossRef]

- Tong, R.; Sun, Z.; Zhong, X.; Wang, X.; Xu, J.; Yang, Y.; Xu, B.; Wang, S.; Pan, H. Enhancement of Visible-Light Photocatalytic Hydrogen Production by CeCO3OH in g-C3N4/CeO2 System. ChemCatChem 2019, 11, 1069–1075. [Google Scholar] [CrossRef]

- Dong, B.; Li, L.; Dong, Z.; Xu, R.; Wu, Y. Fabrication of CeO2 Nanorods for Enhanced Solar Photocatalysts. Int. J. Hydrogen Energy 2018, 43, 5275–5282. [Google Scholar] [CrossRef]

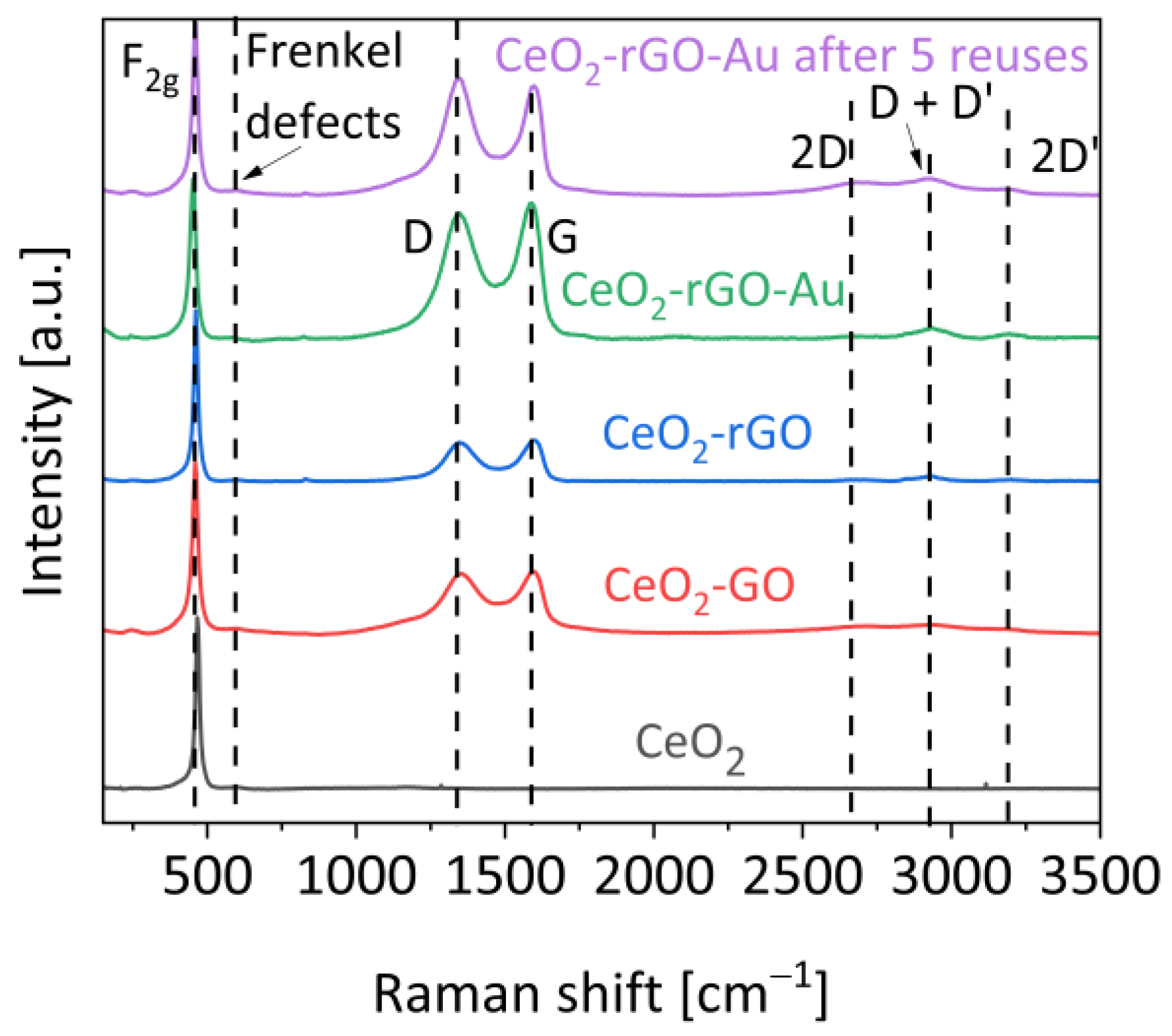

| Sample | ID/IG | FWHM (cm−1) |

|---|---|---|

| GO | 0.88 | 166D, 83G |

| CeO2-GO | 0.99 | 188D, 90G |

| CeO2-rGO | 0.99 | 136D, 76G |

| CeO2-rGO-Au | 0.99 | 159D, 84G |

| CeO2-rGO-Au after 5 runs | 1.02 | 130D, 70G |

| Sample | Isotherm | SBET (m2 g−1) | dP (nm) |

|---|---|---|---|

| CeO2 | IV; H2 | 81 ± 2 | 24 |

| CeO2-Au | IV; H2 | 72 ± 2 | 8 |

| CeO2-GO-Au | IV; H2 | 69 ± 2 | 17 |

| CeO2-rGO-Au | IV; H2 | 70 ± 2 | 18 |

| Sample | Synthesis | Photoreforming Conditions | Irradiation Source | H2 Evolution (μmol/gcat h) | Ref. |

|---|---|---|---|---|---|

| CeO2-rGO-Au (after 5 runs) | Photoreduction | 10% (v/v) solution of glycerol in MilliQ water G | 150 W Xe lamp solar simulator | 270 | this work |

| CdS/Pt/WO3-CeOx | Precipitation | In situ material synthesis and H2 evolution | 300 W Xe lamp, with a 420 nm cutoff filter | 50 | [40] |

| CeO2/C quantum dots | Bio-template strategy | 100 mL of water containing 10 vol% methanol | 300 W, 50 mW/cm2 Xe lamp | 60 | [25] |

| CeO2/MoS2 | Hydrothermal | 100 mL aqueous solution containing 0.3 M Na2SO3/Na2S | 150 W xenon arc lamp (>400 nm) | 125 | [41] |

| C3N4/CeCO3OH/CeO2 | Hydrothermal | 80 mL water including 10 vol% TEOA | AM 1.5G solar light | 40 | [42] |

| CeO2 nanorods | Hydrothermal | 100 mL of an aqueous solution containing 0.43 M Na2S mixed with 0.50 M Na2SO3 | 300 W Xe lamp | 5 | [43] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balsamo, S.A.; La Greca, E.; Calà Pizzapilo, M.; Sciré, S.; Fiorenza, R. CeO2-rGO Composites for Photocatalytic H2 Evolution by Glycerol Photoreforming. Materials 2023, 16, 747. https://doi.org/10.3390/ma16020747

Balsamo SA, La Greca E, Calà Pizzapilo M, Sciré S, Fiorenza R. CeO2-rGO Composites for Photocatalytic H2 Evolution by Glycerol Photoreforming. Materials. 2023; 16(2):747. https://doi.org/10.3390/ma16020747

Chicago/Turabian StyleBalsamo, Stefano Andrea, Eleonora La Greca, Marta Calà Pizzapilo, Salvatore Sciré, and Roberto Fiorenza. 2023. "CeO2-rGO Composites for Photocatalytic H2 Evolution by Glycerol Photoreforming" Materials 16, no. 2: 747. https://doi.org/10.3390/ma16020747

APA StyleBalsamo, S. A., La Greca, E., Calà Pizzapilo, M., Sciré, S., & Fiorenza, R. (2023). CeO2-rGO Composites for Photocatalytic H2 Evolution by Glycerol Photoreforming. Materials, 16(2), 747. https://doi.org/10.3390/ma16020747