Evaluation of Fillers for Magnesium Potassium Phosphate Cement (MKPC) for the Encapsulation of Low and Intermediate Level Metallic Radioactive Wastes

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of MKPC Mortars and Pastes

3. Results and Discussion

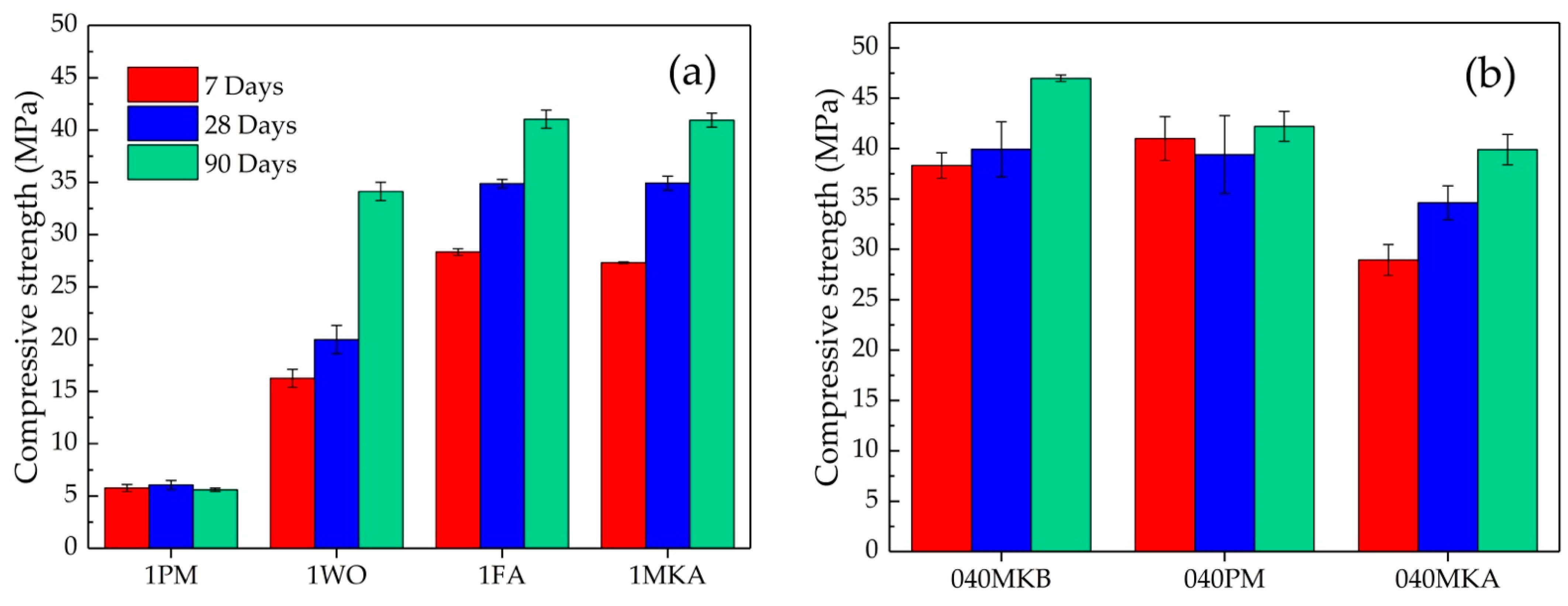

3.1. Mechanical Characterization

3.1.1. Fresh Paste Properties: Workability and Setting Time

3.1.2. Compressive Strength

3.1.3. Dimensional Stability

3.2. Chemical Characterization

3.2.1. pH Measurement

3.2.2. Mineralogical and Microstructural Analysis (XRD and SEM-EDX)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanter, B.; Vikman, A.; Brückner, T.; Schamel, M.; Gbureck, U.; Ignatius, A. Bone Regeneration Capacity of Magnesium Phosphate Cements in a Large Animal Model. Acta Biomater. 2018, 69, 352–361. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Wang, B.; Ren, B.; Liu, Y.; Zhang, N.; Wang, Z.; Liu, J.; Mao, K. Characterization and Biomechanical Study of a Novel Magnesium Potassium Phosphate Cement. Life 2022, 12, 997. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, W.; Cao, Y. Laboratory Evaluation of Magnesium Phosphate Cement Paste and Mortar for Rapid Repair of Cement Concrete Pavement. Constr. Build. Mater. 2014, 58, 122–128. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property Evaluation of Magnesium Phosphate Cement Mortar as Patch Repair Material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, J.; Wang, R. Assessment of Magnesium Potassium Phosphate Cement for Waste Sludge Solidification: Macro- and Micro-Analysis. J. Clean. Prod. 2021, 294, 126365. [Google Scholar] [CrossRef]

- Buj, I.; Torras, J.; Casellas, D.; Rovira, M.; de Pablo, J. Effect of Heavy Metals and Water Content on the Strength of Magnesium Phosphate Cements. J. Hazard. Mater. 2009, 170, 345–350. [Google Scholar] [CrossRef]

- Iyengar, S.R.; Al-Tabbaa, A. Developmental Study of a Low-PH Magnesium Phosphate Cement for Environmental Applications. Environ. Technol. 2007, 28, 1387–1401. [Google Scholar] [CrossRef]

- Fu, Y.C.; Cao, X.P.; Li, Z.J. Printability of Magnesium Potassium Phosphate Cement with Different Mixing Proportion for Repairing Concrete Structures in Severe Environment. Key Eng. Mater. 2016, 711, 989–995. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, M.; Xu, J.; Li, L.; Huang, Y.; Yang, L.; Zhao, P.; Lu, L. Mix Design and Rheological Properties of Magnesium Potassium Phosphate Cement Composites Based on the 3D Printing Extrusion System. Constr. Build. Mater. 2021, 284, 122797. [Google Scholar] [CrossRef]

- Weng, Y.; Ruan, S.; Li, M.; Mo, L.; Unluer, C.; Tan, M.J.; Qian, S. Feasibility Study on Sustainable Magnesium Potassium Phosphate Cement Paste for 3D Printing. Constr. Build. Mater. 2019, 221, 595–603. [Google Scholar] [CrossRef]

- Covill, A.; Hyatt, N.C.; Hill, J.; Collier, N.C. Development of Magnesium Phosphate Cements for Encapsulation of Radioactive Waste. Adv. Appl. Ceram. 2011, 110, 151–156. [Google Scholar] [CrossRef]

- Gardner, L.J.; Corkhill, C.L.; Walling, S.A.; Vigor, J.E.; Murray, C.A.; Tang, C.C.; Provis, J.L.; Hyatt, N.C. Early Age Hydration and Application of Blended Magnesium Potassium Phosphate Cements for Reduced Corrosion of Reactive Metals. Cem. Concr. Res. 2021, 143, 106375. [Google Scholar] [CrossRef]

- Pyo, J.-Y.; Um, W.; Heo, J. Magnesium Potassium Phosphate Cements to Immobilize Radioactive Concrete Wastes Generated by Decommissioning of Nuclear Power Plants. Nucl. Eng. Technol. 2021, 53, 2261–2267. [Google Scholar] [CrossRef]

- IAEA. Management of Problematic Waste and Material Generated during the Decommissioning of Nuclear Facilities; International Atomic Energy Agency: Vienna, Austria, 2006; p. 71. [Google Scholar]

- Vargel, C. Chapter B.1—The Corrosion of Aluminium. In Corrosion of Aluminium, 2nd ed.; Vargel, C., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 41–61. ISBN 978-0-08-099925-8. [Google Scholar]

- Haque, M.A.; Chen, B. Research Progresses on Magnesium Phosphate Cement: A Review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Zheng, D.-D.; Ji, T.; Wang, C.-Q.; Sun, C.-J.; Lin, X.-J.; Hossain, K.M.A. Effect of the Combination of Fly Ash and Silica Fume on Water Resistance of Magnesium–Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Lu, X.; Chen, B. Experimental Study of Magnesium Phosphate Cements Modified by Metakaolin. Constr. Build. Mater. 2016, 123, 719–726. [Google Scholar] [CrossRef]

- Lahalle, H.; Cau Dit Coumes, C.; Mercier, C.; Lambertin, D.; Cannes, C.; Delpech, S.; Gauffinet, S. Influence of the w/c Ratio on the Hydration Process of a Magnesium Phosphate Cement and on Its Retardation by Boric Acid. Cem. Concr. Res. 2018, 109, 159–174. [Google Scholar] [CrossRef]

- Ma, C.; Wang, F.; Zhou, H.; Jiang, Z.; Ren, W.; Du, Y. Effect of Early-Hydration Behavior on Rheological Properties of Borax-Admixed Magnesium Phosphate Cement. Constr. Build. Mater. 2021, 283, 122701. [Google Scholar] [CrossRef]

- Liu, R.; Fang, B.; Zhang, G.; Guo, J.; Yang, Y. Investigation of Sodium Alginate as a Candidate Retarder of Magnesium Phosphate Cement: Hydration Properties and Its Retarding Mechanism. Ceram. Int. 2022, 48, 30846–30852. [Google Scholar] [CrossRef]

- Li, Y.; Sun, J.; Chen, B. Experimental Study of Magnesia and M/P Ratio Influencing Properties of Magnesium Phosphate Cement. Constr. Build. Mater. 2014, 65, 177–183. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Winnefeld, F. Influence of Wollastonite on Hydration and Properties of Magnesium Potassium Phosphate Cements. Cem. Concr. Res. 2020, 131, 106012. [Google Scholar] [CrossRef]

- Le Rouzic, M.; Chaussadent, T.; Stefan, L.; Saillio, M. On the Influence of Mg/P Ratio on the Properties and Durability of Magnesium Potassium Phosphate Cement Pastes. Cem. Concr. Res. 2017, 96, 27–41. [Google Scholar] [CrossRef]

- Walling, S.A.; Provis, J.L. Magnesia-Based Cements: A Journey of 150 Years, and Cements for the Future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef] [PubMed]

- Qin, Z.; Ma, C.; Zheng, Z.; Long, G.; Chen, B. Effects of Metakaolin on Properties and Microstructure of Magnesium Phosphate Cement. Constr. Build. Mater. 2020, 234, 117353. [Google Scholar] [CrossRef]

- Mo, L.; Lv, L.; Deng, M.; Qian, J. Influence of Fly Ash and Metakaolin on the Microstructure and Compressive Strength of Magnesium Potassium Phosphate Cement Paste. Cem. Concr. Res. 2018, 111, 116–129. [Google Scholar] [CrossRef]

- Alqarni, A.S. A Comprehensive Review on Properties of Sustainable Concrete Using Volcanic Pumice Powder Ash as a Supplementary Cementitious Material. Constr. Build. Mater. 2022, 323, 126533. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Blended Cement Using Volcanic Ash and Pumice. Cem. Concr. Res. 2003, 33, 1601–1605. [Google Scholar] [CrossRef]

- Anwar Hossain, K.M. Properties of Volcanic Pumice Based Cement and Lightweight Concrete. Cem. Concr. Res. 2004, 34, 283–291. [Google Scholar] [CrossRef]

- Pınarcı, İ.; Kocak, Y. Hydration Mechanisms and Mechanical Properties of Pumice Substituted Cementitious Binder. Constr. Build. Mater. 2022, 335, 127528. [Google Scholar] [CrossRef]

- Nuclear Decommissioning Authority. Geological Disposal. Guidance on the Application of the Waste Package Specifications for Unshielded Waste Packages; Radioactive Waste Management Limited: Didcot, UK, 2014; p. 84.

- Nirex. WPS/903: Guidance on the Immobilisation of Radionuclides in Wasteforms; United Kingdom Nirex Limited: Harwell, UK, 2007; p. 39. [Google Scholar]

- EN 196-1; Methods of Testing Cement. Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- Tan, Z.; Bernal, S.A.; Provis, J.L. Reproducible Mini-Slump Test Procedure for Measuring the Yield Stress of Cementitious Pastes. Mater. Struct. 2017, 50, 235. [Google Scholar] [CrossRef]

- ASTM C191-08; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2008.

- Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. The HighScore Suite. Powder Diffr. 2014, 29, S13–S18. [Google Scholar] [CrossRef]

- Alonso, M.C.; Garcia, J.; Walker, C.; Naito, M.; Pettersson, S.; Puigdomenech, I.; Cuñado, M.A.; Vuorio, M.; Weber, H.; Ueda, H.; et al. Development of an Accurate PH Measurement Methodology for the Pore Fluids of Low PH Cementitious Materials; Svensk Kärnbränslehantering AB: Stockholm, Sweden, 2012. [Google Scholar]

- Alonso, M.C.; Calvo, J.L.G.; Pettersson, S.; Puigdomenech, I.; Cuñado, M.A.; Vuorio, M.; Weber, H.; Ueda, H.; Naito, M.; Walker, C.; et al. Round Robin Test for Defining an Accurate Protocol to Measure the Pore Fluid PH of Low-PH Cementitious Materials. In Cement-Based Materials for Nuclear Waste Storage; Bart, F., Cau-di-Coumes, C., Frizon, F., Lorente, S., Eds.; Springer: New York, NY, USA, 2013; pp. 251–259. ISBN 978-1-4614-3445-0. [Google Scholar]

- Soudée, E.; Péra, J. Influence of Magnesia Surface on the Setting Time of Magnesia–Phosphate Cement. Cem. Concr. Res. 2002, 32, 153–157. [Google Scholar] [CrossRef]

- Ding, Z.; Li, Z. Effect of Aggregates and Water Contents on the Properties of Magnesium Phospho-Silicate Cement. Cem. Concr. Compos. 2005, 27, 11–18. [Google Scholar] [CrossRef]

- Xu, B.; Winnefeld, F.; Kaufmann, J.; Lothenbach, B. Influence of Magnesium-to-Phosphate Ratio and Water-to-Cement Ratio on Hydration and Properties of Magnesium Potassium Phosphate Cements. Cem. Concr. Res. 2019, 123, 105781. [Google Scholar] [CrossRef]

- Gardner, L.J.; Bernal, S.A.; Walling, S.A.; Corkhill, C.L.; Provis, J.L.; Hyatt, N.C. Characterisation of Magnesium Potassium Phosphate Cements Blended with Fly Ash and Ground Granulated Blast Furnace Slag. Cem. Concr. Res. 2015, 74, 78–87. [Google Scholar] [CrossRef]

- De Campos, M.; Davy, C.A.; Djelal, N.; Rivenet, M.; Garcia, J. Development of a Stoichiometric Magnesium Potassium Phosphate Cement (MKPC) for the Immobilization of Powdered Minerals. Cem. Concr. Res. 2021, 142, 106346. [Google Scholar] [CrossRef]

- Li, Y.; Chen, B. Factors That Affect the Properties of Magnesium Phosphate Cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Deltombe, E.; Pourbaix, M. The Electrochemical Behavior of Aluminum—Potential PH Diagram of the System AI-H2O at 25 C. Corrosion 1958, 14, 16–20. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Setting and Strength Development of Magnesium Phosphate Cement Paste. Adv. Cem. Res. 2009, 21, 175–180. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Leemann, A.; Winnefeld, F. Reaction Mechanism of Magnesium Potassium Phosphate Cement with High Magnesium-to-Phosphate Ratio. Cem. Concr. Res. 2018, 108, 140–151. [Google Scholar] [CrossRef]

| wt.% | Fly Ash | Wollastonite | Pumice | Metakaolin A | Metakaolin B |

|---|---|---|---|---|---|

| SiO2 | 52.9 | 41.21 | 55.4 | 57.31 | 52.94 |

| Al2O3 | 21.85 | 4.98 | 17.65 | 37.01 | 43.18 |

| CaO | 3.79 | 43.31 | 1.23 | 0.11 | 0.02 |

| Fe2O3 | 10.55 | 3.68 | 3.26 | 1.62 | 0.54 |

| MgO | 1.55 | 2.45 | - | 0.32 | - |

| K2O | 1.77 | 1.64 | 9.7 | 0.73 | 0.19 |

| Na2O | 1.24 | 1.26 | 10.24 | - | 0.31 |

| TiO2 | 0.97 | 0.54 | 0.32 | 2.37 | 2.47 |

| P2O5 | 0.15 | - | 0.04 | - | 0.11 |

| - | - | 0.53 | - | - | |

| - | - | 0.36 | - | - | |

| ∑ others | 0.81 | 0.94 | 1.29 | 0.54 | 0.25 |

| SSA* (m2/g) | 11.68 | 6.54 | 2.69 | 21.28 | 12.61 |

| Filler | MgO/KH2PO4(Molar) | H2O/Cement (Mass) | Filler/Cement (Mass) | Sand/Cement (Mass) | H3BO3/Cement (Mass) |

|---|---|---|---|---|---|

| Mortars | |||||

| 1FA | 1.00 | 0.51 | 1.00 | 1.00 | 0.02 |

| 1WO | 0.51 | 1.00 | |||

| 1PM | 0.75 | 1.00 | |||

| 040PM | 0.51 | 0.40 | |||

| 1MKA | 0.65 | 1.00 | |||

| 040MKA | 0.51 | 0.40 | |||

| 040MKB | 0.51 | 0.40 | |||

| Pastes | |||||

| FA | 1.00 | 0.4 | 1.00 | 0.00 | 0.02 |

| WO | 1.00 | ||||

| PM | 0.40 | ||||

| MKA | 0.40 | ||||

| MKB | 0.40 | ||||

| Formulation | Initial Setting Time (h) | Final Setting Time (h) | Flow Area (cm2) |

|---|---|---|---|

| 1FA | 2.0 | 4.0 | 34.3 ± 4.5 |

| 1WO | 3.2 | 6.2 | 40.9 ± 2.4 |

| 040PM | 2.2 | 2.6 | 39.0 ± 3.2 |

| 040MKA | 2.0 | 2.4 | 41.9 ± 1.6 |

| 040MKB | 1.7 | 2.1 | 36.9 ± 1.1 |

| No Filler | 5.2 | 5.8 | 81.3 ± 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dieguez, M.; Ruiz, A.I.; Cuevas, J.; Alonso, M.C.; García-Lodeiro, I.; Fernández, R. Evaluation of Fillers for Magnesium Potassium Phosphate Cement (MKPC) for the Encapsulation of Low and Intermediate Level Metallic Radioactive Wastes. Materials 2023, 16, 679. https://doi.org/10.3390/ma16020679

Dieguez M, Ruiz AI, Cuevas J, Alonso MC, García-Lodeiro I, Fernández R. Evaluation of Fillers for Magnesium Potassium Phosphate Cement (MKPC) for the Encapsulation of Low and Intermediate Level Metallic Radioactive Wastes. Materials. 2023; 16(2):679. https://doi.org/10.3390/ma16020679

Chicago/Turabian StyleDieguez, Mikel, Ana Isabel Ruiz, Jaime Cuevas, María Cruz Alonso, Inés García-Lodeiro, and Raúl Fernández. 2023. "Evaluation of Fillers for Magnesium Potassium Phosphate Cement (MKPC) for the Encapsulation of Low and Intermediate Level Metallic Radioactive Wastes" Materials 16, no. 2: 679. https://doi.org/10.3390/ma16020679

APA StyleDieguez, M., Ruiz, A. I., Cuevas, J., Alonso, M. C., García-Lodeiro, I., & Fernández, R. (2023). Evaluation of Fillers for Magnesium Potassium Phosphate Cement (MKPC) for the Encapsulation of Low and Intermediate Level Metallic Radioactive Wastes. Materials, 16(2), 679. https://doi.org/10.3390/ma16020679