Abstract

The most frequently used construction material in buildings is concrete exhibiting a brittle behaviour. Adding fibers to concrete can improve its ductility and mechanical properties. To this end, a laboratory study was conducted to present an experimental model for the specimens’ size effect of on macro-synthetic fiber-reinforced concrete using variations in fracture energy. Composite concrete beams with different thicknesses and widths were made and tested under mode I to obtain (1) fracture toughness, (2) fracture energy, and (3) critical stress intensity factor values. Results indicated that by increasing the thickness and the width, fracture toughness and fracture energy were enhanced. Moreover, increasing the thickness and width of the beam led to critical stress intensity factors enhancement respectively by 35.01–41.43% and 7.77–8.09%.

1. Introduction

Fiber-reinforced concrete is a type of composite material made of concrete mixed with fibers of various types and sizes, which can additionally include glass, polymer, carbon, and steel [1].

Studies have been conducted to investigate the effect of fibers on concrete, such as its mechanical properties, fatigue life, and durability, which indicate the positive effect of fibers on concrete performance [2,3,4,5]. Ahmad ([6]) indicated that polypropylene fiber improves the mechanical strength and durability of concrete (particularly tensile capacity) but decreases the flowability of concrete. The optimum dose is important, as a higher dose adversely affects strength and durability due to a lack of flowability. Scanning electronic microscopy results indicate that polypropylene fibers restrict the propagation of cracks, which improves the strength and durability of concrete [6]. Wang et al. reported that with the increase in the steel fiber volume fraction, some fracture parameters increase gradually and maintain a certain linear growth [7].

Pakravan et al. focused on the use of hybrid fibers in concrete and reported that combining various types of fibers would yield better results in terms of concrete toughness and energy absorption [8]. Bordelon and Roesler studied fiber-reinforced concrete pavements using steel, synthetic, and steel mesh fibers. They reported that the use of fibers leads to increased bearing capacity and reduces the thickness of the concrete pavement [9]. Chari et al. investigated the mode I fracture behavior of high-strength steel-fiber-reinforced concrete, the results of which indicated that increased beam size leads to enhanced fracture energy [10]. The shear stress of three beams with different sizes was analyzed by Gustafsson et al. [11]. Their results showed that a concrete mixture containing steel fibers yields better strength. Kreiger [12] conducted a study on a model to explain the mode I rupture of high-performance steel-fiber-reinforced concrete and concluded that increasing the fiber percentage leads to higher fracture energy. In addition, by increasing the span-length-to-depth ratio of the beam, the maximum rupture force significantly reduced. Rao and Rao conducted a study on the toughness change in steel-fiber-reinforced concrete, estimated by mode II loading. Adding fibers to the concrete significantly influenced the concrete’s toughness and shear strength [13]. Different methods were used to rank the toughness of fiber-reinforced concrete, toughness optimization, and the properties of the reinforced concrete.

A summary of recent studies on the effects of different types of fibers on concrete’s mechanical properties is presented in Table 1.

Table 1.

A summary of fibers’ effects on mechanical properties, as reported in the literature (increase ↑, decrease ↓, not significant, N.S.).

There are numerous studies on the mechanical properties of fiber-reinforced concrete and the size effect of concrete specimens. However, most of the studies related to the size effect increased the thickness and span of the beam specimens. This approach does not describe the effect of thickness or width variations independently.

In this study, we evaluated the effect of the size of a macro-synthetic-fiber-reinforced concrete specimen on the variations in fracture energy. The studied parameters were the fracture energy of notched concrete beams and the stress intensity factor. We used twisted fibers, which were added to the concrete mix with a volume fraction of 0.4%. Three samples were developed for each specimen, and the results were averaged and recorded in tables.

This research was conducted to achieve the following goals:

- The experimental model of variations in concrete fracture energy considers thickness, width, and macro-synthetic fiber content.

- The effect of specimen size on the fracture energy of concrete specimens is explained.

- The effect of fibers on the stress intensity factor of concrete specimens with three different thicknesses and widths is described.

2. Materials and Methods

2.1. Test Variables

To evaluate the fracture energy and stress intensity factor of notched concrete beams, a concrete mixture was designed based on the ACI 211 standard [29]. All the concrete samples were developed with the same mix design and 0, 0.4, and 0.6 volume percentages of twisted fibers. In this research, concrete mix designs were coarse aggregate 880 (kg/m3), fine aggregate 789 (kg/m3), cement 442 (kg/m3), water 199 (kg/m3), superplasticizer 2.2 (kg/m3) m3), and fibers with two doses of 3.6 and 5.4 (kg/m3). The fibers used in this research were selected according to the specifications of ASTM D7508/D7508M-10, with a length of 3.8 cm [30]. Figure 1 shows the fibers used in this research.

Figure 1.

Twisted fibers used in the manufacturing of fiber-reinforced concrete.

2.2. Specimen Preparation

To evaluate the fracture energy and critical stress intensity factor (KIc) of fiber-reinforced concrete, concrete beam samples were fabricated based on the JCI-S-001-2003 standard [31]. First, cement was mixed with sand, gravel, and fibers; then water was mixed with a superplasticizer accordingly; and finally, several rectangular beam specimens with and without twisted fibers were manufactured. Table 2 shows the geometrical properties of the prepared specimens.

Table 2.

Specifications of tested specimens.

2.3. Fracture Energy Tests

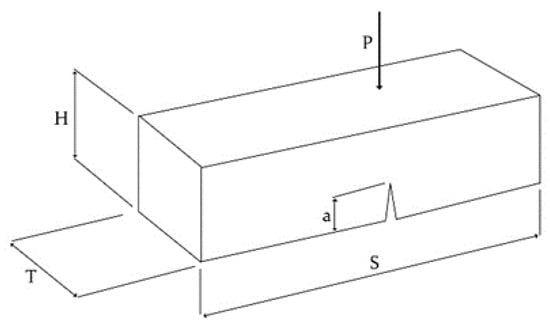

Fracture energy is defined as the amount of energy required for crack growth per unit area along the ligament. The fracture energy of the manufactured concrete specimens was measured based on the Japan Concrete Institute’s standard [31]. In this research, the geometry of specimens was as shown in Figure 2. Next, using a three-point bend test, the diagram of load–crack mouth opening displacement (CMOD) was obtained. The area under the curve was measured, and fracture energy GF was calculated using Equations (1) and (2).

where

Figure 2.

The geometry of the tested specimen [28].

- GF—the fracture energy (N/mm2),

- W0—the area below the CMOD curve up to rupture of the specimen (Nmm),

- W1—the work done by the deadweight of the specimen and loading jig (a piece between the testing machine and the specimen; Nmm),

- Alig—the area of the broken ligament (b × h; mm2),

- m1—the mass of the specimen (kg),

- S—the loading span (mm),

- L—the total length of the specimen (mm),

- m2—the mass of the jig not attached to the testing machine but placed on the specimen.

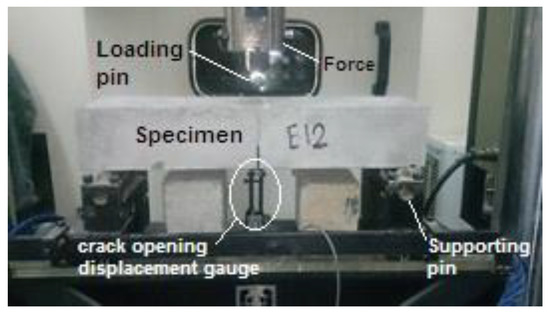

The adjustment of the device and specimen is presented in Figure 3.

Figure 3.

Adjustment of the device and specimen to measure the load–CMOD.

2.4. Critical Stress Intensity Factor

As an important parameter in fracture mechanics, the critical value of the stress intensity factor shows the resistance of a material to crack growth. When a cracked specimen is exposed to remote load, high-stress intensity occurs around the tip of the crack, and when this stress reaches its critical value, the fracture process is initiated in the specimen. The value of the stress intensity coefficient, which is calculated based on this critical stress, is known as the critical stress intensity factor (KIc) [31,32]. The stress intensity factor for a notched beam subjected to three-point bend loading is obtained from Equation (3).

where P, H, T, and S are shown in Figure 2.

3. Results and Discussion

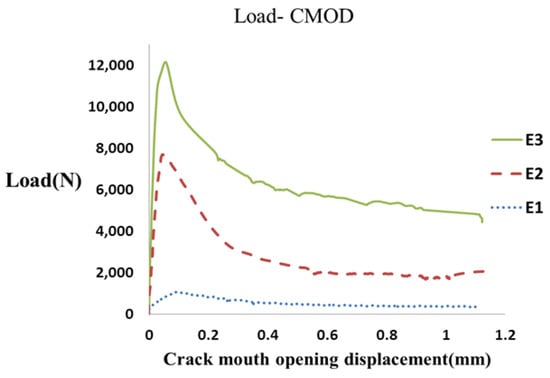

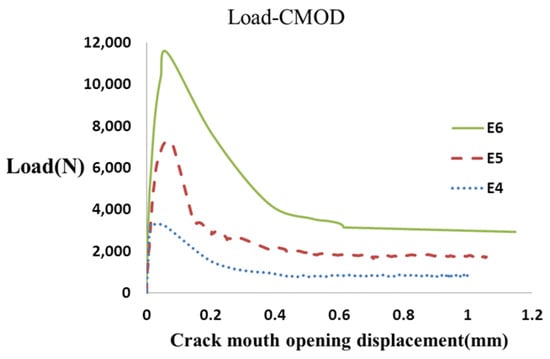

3.1. Fracture Energy

To calculate the fracture energy of fiber-reinforced concrete specimens, notched specimens with three different thicknesses (8, 10, and 15 cm) and widths (5, 10, and 15 cm) were manufactured based on the JCI-S-001-2003 standard [31] and loaded by three-point bend loading. The P-CMOD diagrams were obtained from the experiments, and the fracture energy of each concrete specimen was calculated by measuring the area under the curve using Equations (1) and (2). Figure 4 depicts an example of load–CMOD curves of the tested notched fiber-reinforced concrete specimens with a 0.4% fiber volume fraction with different thicknesses.

Figure 4.

The load–CMOD curve obtained for fiber-reinforced concrete specimens with different thicknesses.

To study the effect of independent variables, including the thickness of concrete specimens, and fiber dosage on fracture energy, multiple linear regressions were used. The initial equation considered for analysis is shown in Equation (4).

where:

- GF—fracture energy (N/mm2)

- H—thickness of concrete specimens (CM)

- Fiberdosage—fiber volume fraction (%) are regression coefficients.

After fitting, coefficients of their significance values were less than the present significance level and were eliminated by the stepwise regression and backward elimination method, and the final model was obtained according to Table 3 and Table 4. Following Table 4, the quadratic term for thickness (H) and the linear term for fiber dosage was meaningful if the p-values were less than 0.05 with 95% reliability. In the final model, the interactive term was eliminated due to insignificance, which means that the thickness (H) and percentage of the fibers do not interact with each other. According to Table 3, the high value of F indicates the overall significance of the model at a high confidence level. However, the adjusted R2 value of 0.98 indicates that two variables, thickness (H) and fiber dosage, explain about 98% of the fracture energy variations; hence, the model is suitable to predict fracture energy.

Table 3.

ANOVA table.

Table 4.

Values of regression coefficients of GF.

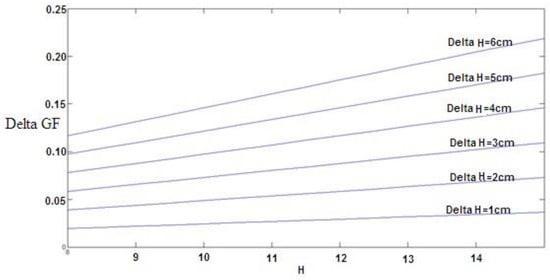

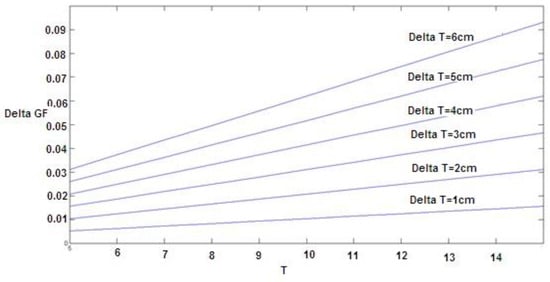

As shown in Table 4, the coefficient H2 was equal to 0.00122. Therefore, if the change in fracture energy for thickness (H), holding other factors fixed, is considered, the equation would show the fracture energy change value by thickness change (which is plotted for changes from 1 to 6 cm in Figure 5). These diagrams can be used for optimal design and economic evaluation. However, considering fiber dosage coefficients, each 1% increase in the amount of fiber increases the fracture energy by 0.09. To investigate the effect of two variables, thickness and fiber dosage, on fracture energy, considering that the units of these two variables are not the same, the effects of these variables cannot be compared with each other according to their coefficients. For this purpose, the coefficients must first be standardized so that it is possible to compare. The values of these standard coefficients are presented in the last column of Table 4. As can be seen, the higher the value of the coefficient H2, the greater the effect of the thickness variable (H) relative to the fiber dosage on the fracture energy.

Figure 5.

The effect of thickness H change on fracture energy GF.

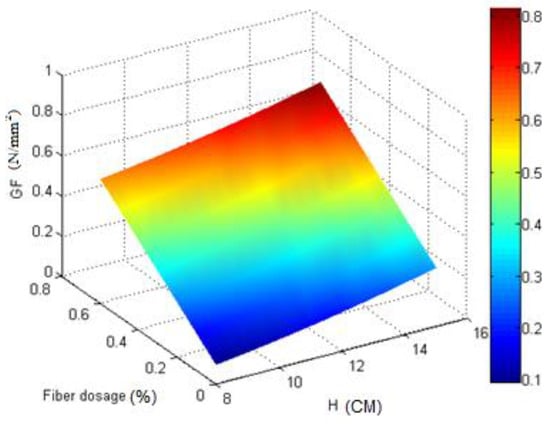

According to the model, the relationship between the three mentioned variables is graphically plotted in Figure 6, which is parabolic. As shown in Figure 6, the thickness and fiber dosage had a positive effect on the fracture energy, and by increasing each, the fracture energy increased, and the highest fracture energy occurred at the highest values of thickness and fiber dosage.

Figure 6.

The relationship between GF, H, and Fiberdosage.

Figure 7 shows an example of the load–CMOD curve of the notched fiber-reinforced concrete specimens with different widths and a 0.4% volume fraction.

Figure 7.

The load–CMOD curve of fiber-reinforced concrete specimens with different widths T.

To study the effect of independent variables, including the width of concrete specimens and fiber dosage, on fracture energy, multiple linear regressions were used. The initial equation considered for analysis is shown in Equation (4) by replacing T with H.

Similar to the method used for thickness variations, a width change was also made and the final model was obtained according to Table 5 and Table 6. According to Table 5, the high value of F indicates the overall significance of the model at a high confidence level. However, the adjusted R2 value of 0.98 indicates that two variables, width (T) and Fiberdosage, explain about 96% of the fracture energy variations; hence, the model is suitable to predict fracture energy.

Table 5.

ANOVA table.

Table 6.

Values of regression coefficients of GF.

As shown in Table 6, the coefficient T2 was equal to 0.00051. Therefore, if the change in fracture energy for width (T), holding other factors fixed, is considered, the equation would show the fracture energy change value by width change (which is plotted for changes from 1 to 6 cm in Figure 8). These diagrams can be used for optimal design and economic evaluation. However, considering fiber dosage coefficients, each 1% increase in the amount of fiber increases the fracture energy by 0.26. To investigate the effect of two variables, width and fiber dosage, on fracture energy, considering that the units of these two variables are not the same, the effects of these variables cannot be compared with each other according to their coefficients. For this purpose, the coefficients must first be standardized so that it is possible to compare. The values of these standard coefficients are presented in the last column of Table 6. As can be seen, the higher the value of the fiber dosage coefficient, the greater effect of the fiber dosage relative to the width variable (T) on the fracture energy.

Figure 8.

The effect of width change on fracture energy.

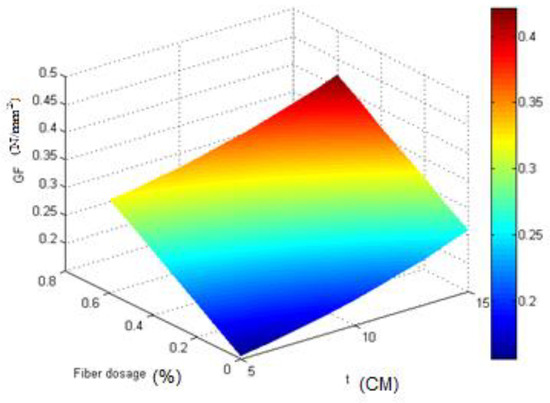

According to the model, the relationship between the three mentioned variables is graphically plotted in Figure 9, which is parabolic. The width and fiber dosage had a positive effect on the fracture energy, and by increasing each, the fracture energy increased, and the highest fracture energy occurred at the highest values of width and fiber dosage.

Figure 9.

The relationship between GF, T, and Fiberdosage.

3.2. Critical Stress Intensity Factor

The critical stress intensity factors of different notched macro-synthetic fiber-reinforced concrete specimens were calculated based on Equation (3) and are presented in Table 7 and Table 8.

Table 7.

Critical stress intensity factor for different thicknesses H.

Table 8.

Critical stress intensity factor for different widths T.

As seen from these results, generally, the value of KIc increases by increasing the thickness H and width T of concrete beams.

3.3. Assessment of Ruptured Cross Section and Fibers

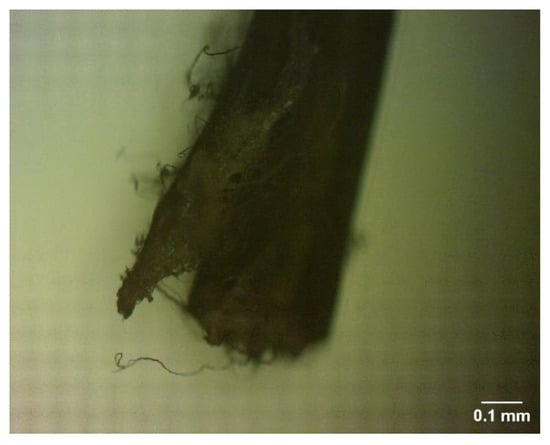

After the tests, the cross-sectional area of the sample was broken and the tip of the fiber was examined.

Figure 10 shows the number of broken sections of the fiber. A cross-sectional analysis of the broken sample showed that most of the sample failure was from aggregates and the mixture design was suitable. In addition, according to the figure, the tip of the fiber shows that the fibers did not rupture due to elongation and were not pulled out, which indicates good performance of the fibers.

Figure 10.

The cross-sectional area of a fiber.

4. Conclusions

In this study, we calculated the fracture energy for macro-synthetic fiber-reinforced concrete specimens with different thicknesses and widths tested using notched beam specimens. The main concluding remarks are:

- The experimental model of the effect of specimen size was presented by testing specimens with three different thicknesses and widths for normal and fiber-reinforced concrete.

- The results in Table 7 indicate that adding fibers and increasing the thickness will increase the critical stress intensity factor up to 52.14%.

- The results in Table 8 indicate that adding fibers and increasing the width will increase the critical stress intensity factor up to 13.05%.

Author Contributions

Conceptualization, M.D., A.H. and M.R.M.A.; Methodology, M.D., A.H., M.R.M.A. and T.S.; Validation, M.R.M.A. and T.S.; Formal analysis, A.H.; Investigation, M.D.; Writing—original draft, M.D.; Writing—review & editing, A.H., M.R.M.A. and T.S.; Supervision, A.H., M.R.M.A. and T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Ministry of Education and Science of the Republic of Poland within the statutory research numbers: FD-20/IL-4/018.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zongjin, L.J.H. Advanced Concrete Technology; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lee, M.G.; Wang, W.C.; Wang, Y.C.; Hsieh, Y.C.; Lin, Y.C. Mechanical Properties of High-Strength Pervious Concrete with Steel Fiber or Glass Fiber. Buildings 2022, 12, 620. [Google Scholar] [CrossRef]

- Abd Elmoaty, A.E.M.; Morsy, A.M.; Harraz, A.B. Effect of Fiber Type and Volume Fraction on Fiber Reinforced Concrete and Engineered Cementitious Composite Mechanical Properties. Buildings 2022, 12, 2108. [Google Scholar] [CrossRef]

- Li, L.; Li, B.; Wang, Z.; Zhang, Z.; Alselwi, O. Effects of Hybrid PVA–Steel Fibers on the Mechanical Performance of High-Ductility Cementitious Composites. Buildings 2022, 12, 1934. [Google Scholar] [CrossRef]

- Daneshfar, M.; Hassani, A.; Aliha, M.R.; Berto, F. Investigating Flexural Performance of Fiber-Reinforced Concrete with Different Contents and Types of Macrosynthetic Fiber. Strength Mater. 2022, 54, 650–661. [Google Scholar] [CrossRef]

- Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; Alogla, S.M.; Majdi, A.; Deifalla, A.F.J.B. A Review on Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced Concrete. Buildings 2022, 12, 1951. [Google Scholar] [CrossRef]

- Wang, Z.; Gou, J.; Gao, D. Experimental study on the fracture parameters of concrete. Materials 2020, 14, 129. [Google Scholar] [CrossRef]

- Pakravan, H.; Latifi, M.; Jamshidi, M.J.C. Hybrid short fiber reinforcement system in concrete: A review. Constr. Build. Mater. 2017, 142, 280–294. [Google Scholar] [CrossRef]

- Bordelon, A.; Roesler, J.R. Fiber-reinforced concrete pavement design and material requirements. In Proceedings of the 8th International Conference on the Bearing Capacity of Roads, Railways and Airfields (BCR2A’09), Urbana, IL, USA, 29 June–2 July 2009; pp. 717–727. [Google Scholar]

- Chari, K.B.; Research, I. Investigation on Mode–I Fracture Parameters Using Steel Fibers in High Strength Concrete. Int. J. Sci. Eng. Res. 2015, 3, 2347–3878. [Google Scholar]

- Gustafsson, J.; Noghabai, K. Steel fibers as shear reinforcement in high strength concrete beams. Nord. Concr. Res. Publ. 1999, 22, 35–52. [Google Scholar]

- Kreiger, E.L. A Model to Describe the Mode I Fracture of Steel Fiber Reinforced Ultra-High Performance Concrete. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2012. [Google Scholar]

- Rao, G.A.; Rao, A.S. Toughness indices of fiber reinforced concrete subjected to mode II loading. Proc. Fract. Mech. Concr. Struct. 2010, 112–117. [Google Scholar]

- Valdez Aguilar, J.; Juárez-Alvarado, C.A.; Mendoza-Rangel, J.M.; Terán-Torres, B.T.J.M. Effect of the notch-to-depth ratio on the post-cracking behavior of steel-fiber-reinforced concrete. Materials 2021, 14, 445. [Google Scholar] [CrossRef]

- Blazy, J.; Drobiec, Ł.; Wolka, P.J.M. Flexural tensile strength of concrete with synthetic fibers. Materials 2021, 14, 4428. [Google Scholar] [CrossRef]

- Daneshfar, M.; Hassani, A.; Aliha, M.R.M.; Berto, F. Evaluating mechanical properties of macro-synthetic fiber-reinforced concrete with various types and contents. Strength Mater. 2017, 49, 618–626. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Lee, J.-H.; Cho, B.; Choi, E.J.C. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. Fibre reinforced concrete with a combination of polyolefin and steel-hooked fibres. Compos. Struct. 2017, 171, 317–325. [Google Scholar] [CrossRef]

- Hesami, S.; Hikouei, I.S.; Emadi, S.A.A. Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 2016, 133, 228–234. [Google Scholar] [CrossRef]

- Saidani, M.; Saraireh, D.; Gerges, M.J.E.S. Behaviour of different types of fibre reinforced concrete without admixture. Eng. Struct. 2016, 113, 328–334. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T.J.C. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Yew, M.K.; Mahmud, H.B.; Ang, B.C.; Yew, M.C.J.C. Influence of different types of polypropylene fibre on the mechanical properties of high-strength oil palm shell lightweight concrete. Constr. Build. Mater. 2015, 90, 36–43. [Google Scholar] [CrossRef]

- Karadelis, J.N.; Lin, Y. Flexural strengths and fibre efficiency of steel-fibre-reinforced, roller-compacted, polymer modified concrete. Constr. Build. Mater. 2015, 93, 498–505. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M.J.C. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar] [CrossRef]

- Pająk, M.; Ponikiewski, T.J.C. Flexural behavior of self-compacting concrete reinforced with different types of steel fibers. Constr. Build. Mater. 2013, 47, 397–408. [Google Scholar] [CrossRef]

- Singh, S.; Singh, A.; Bajaj, V. Strength and flexural toughness of concrete reinforced with steel-polypropylene hybrid fibres. Asian J. Civ. Eng. 2010, 11, 495–507. [Google Scholar]

- Silva, F.J.; Thaumaturgo, C. Fibre reinforcement and fracture response in geopolymeric mortars. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 167–172. [Google Scholar] [CrossRef]

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal. Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2009.

- D7508/D7508M-10; Standard Specification for Polyolefin Chopped Strands for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- JCI-S-001e2003; Japan Concrete Institute Standard. Method of Test for Fracture Energy of Concrete by Use of Notched Beam. Japan Concrete Institute: Tokyo, Japan, 2003.

- Zhu, X.K.; Joyce, J.A. Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Eng. Fract. Mech. 2012, 85, 1–46. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).