Evolution of Statistical Strength during the Contact of Amorphous Polymer Specimens below the Glass Transition Temperature: Influence of Chain Length

Abstract

1. Introduction

2. Materials and Methods

2.1. Polymers and Samples

2.2. Self-Bonding of PS–PS Interfaces

2.3. Fracture Tests

2.4. Statistical Analysis

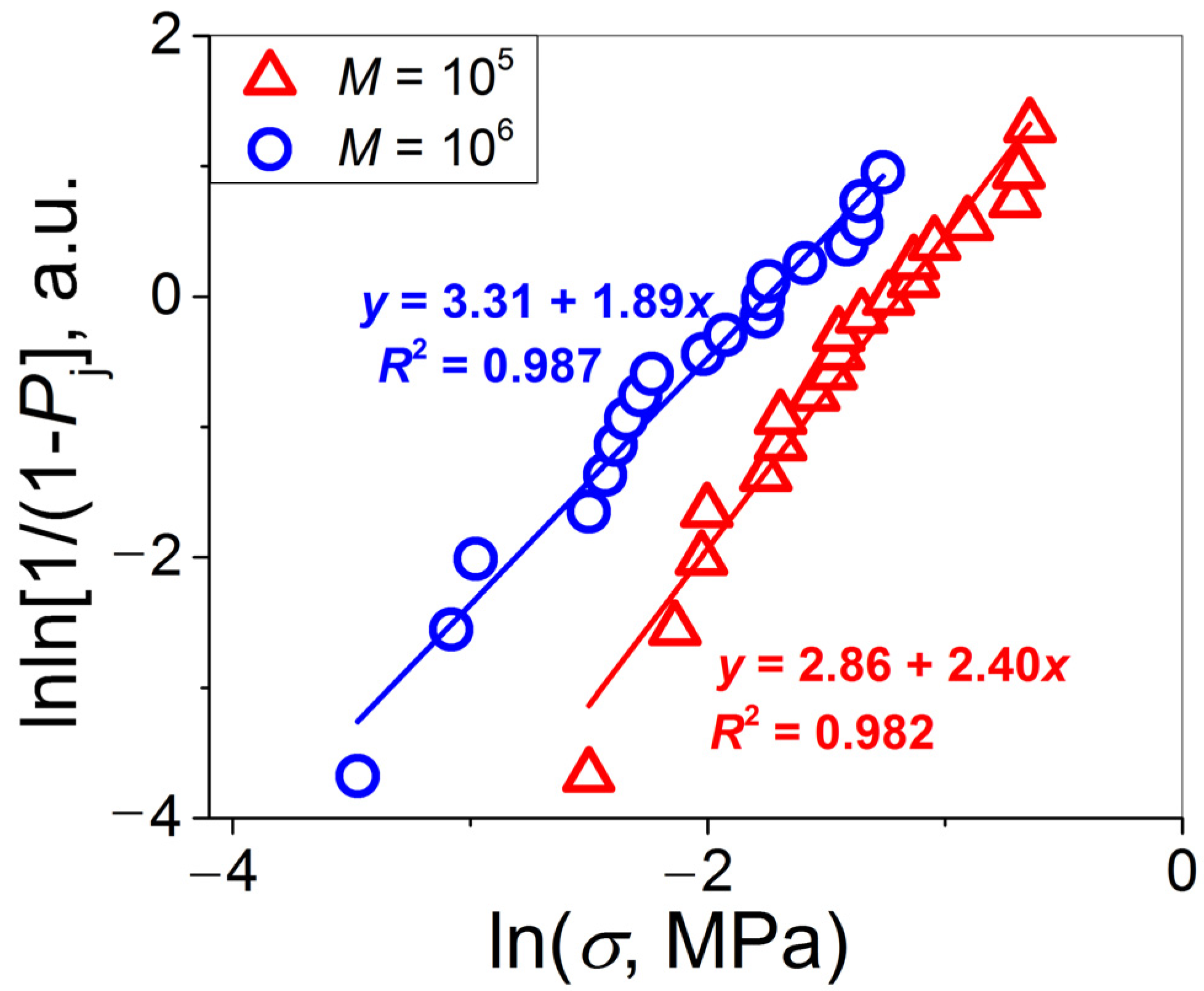

2.4.1. Weibull’s Statistics

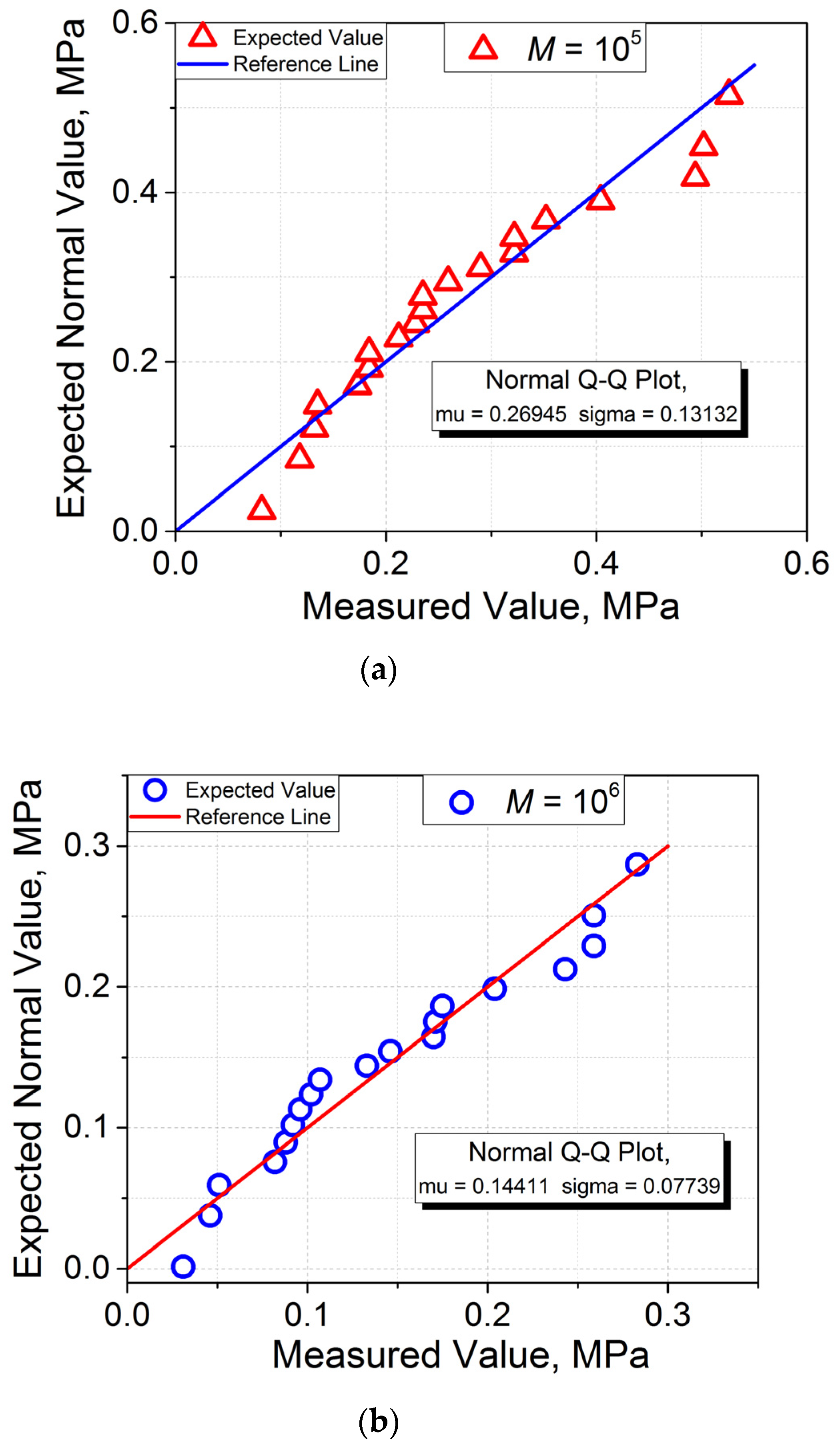

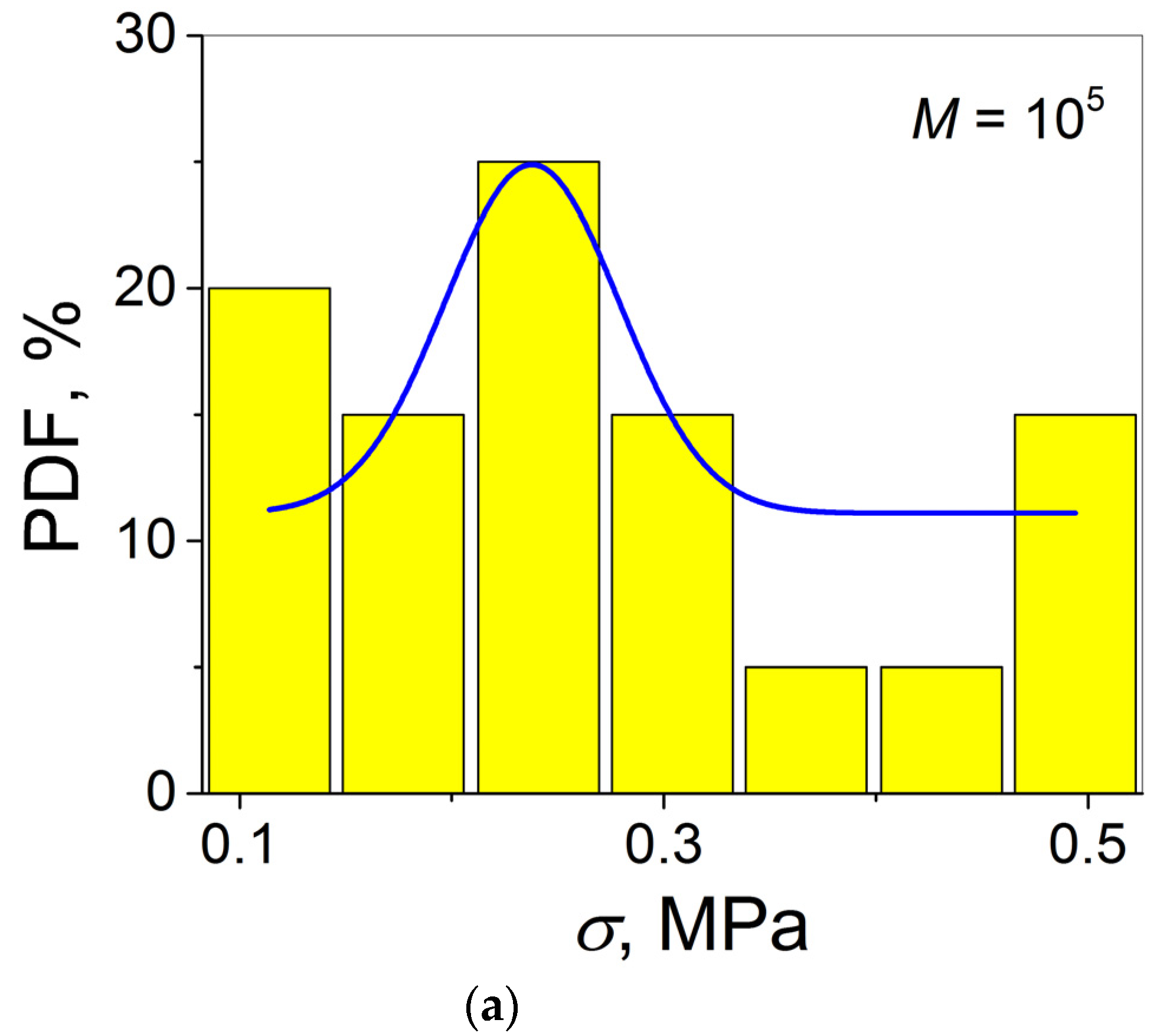

2.4.2. Normality Tests

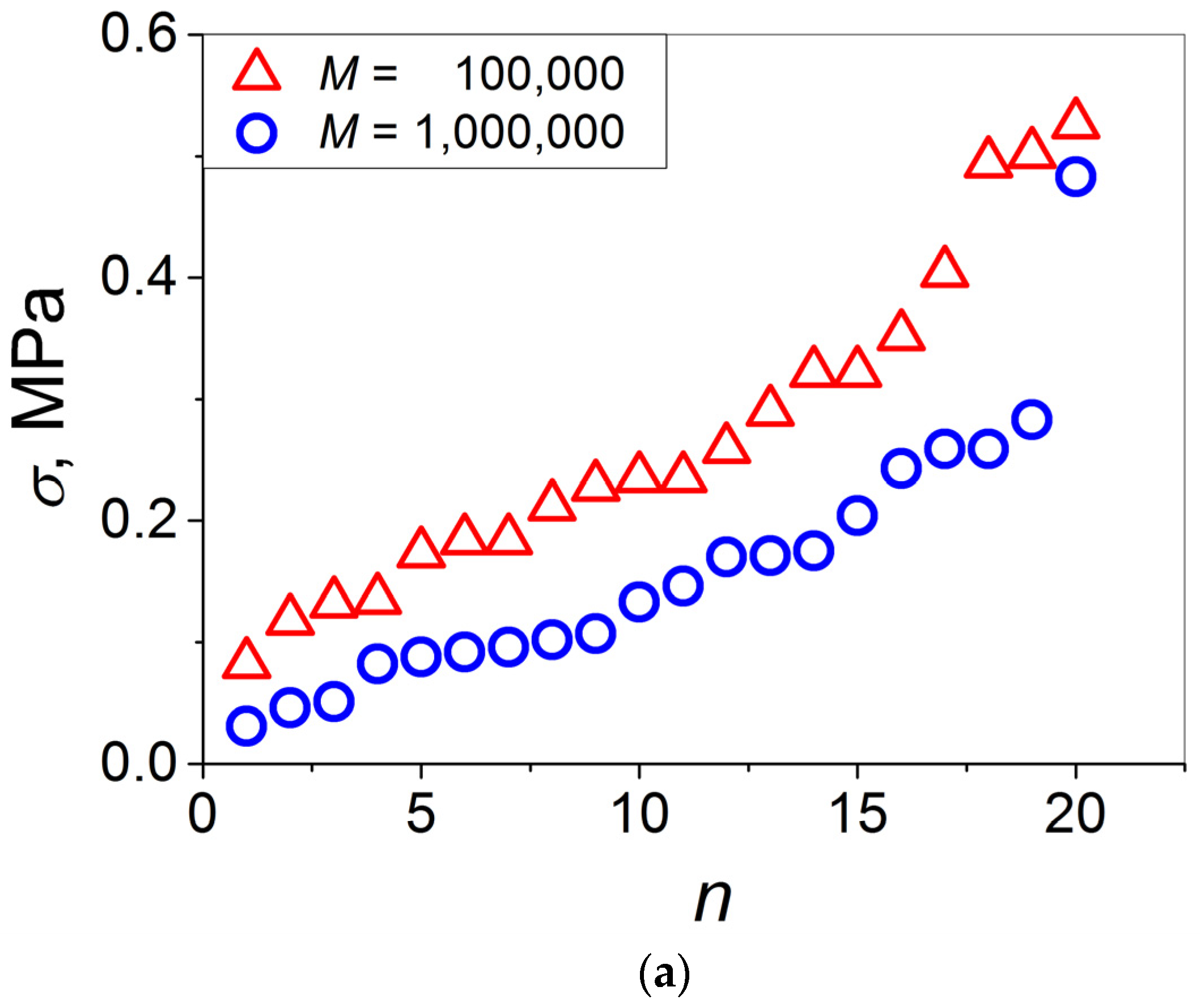

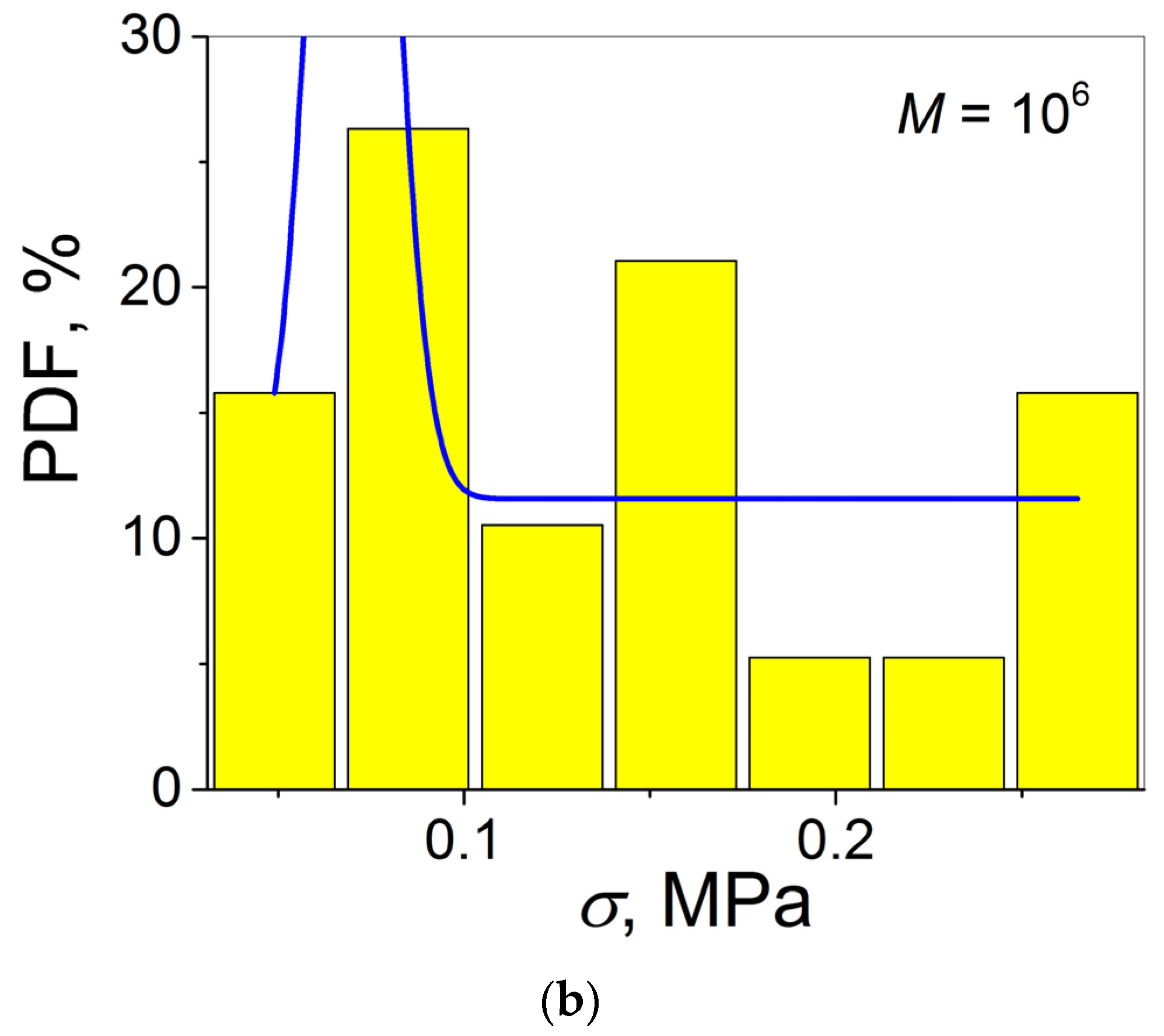

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ward, I.; Sweeney, J. Mechanical Properties of Solid Polymers, 3rd ed.; Wiley: Chichester, UK, 2013; p. 461. [Google Scholar]

- Callister, W.; Rethwisch, D. Characteristics, applications, and processing of polymers. In Materials Science and Engineering, 10th ed.; Wiley: Chichester, UK, 2020; pp. 523–576. [Google Scholar]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly (lactic acid)—Biochar biocomposites: Effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Stanciu, M.D.; Draghicescu, H.T.; Rosca, I.C. Mechanical properties of GFRPs exposed to tensile, compression and tensile-tensile cyclic tests. Polymers 2021, 13, 898. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, F.; Okabe, T.; Okuda, H.; Kinloch, I.A.; Young, R.J. Factors controlling the strength of carbon fibers in tension. Compos. Part A 2014, 57, 88–94. [Google Scholar] [CrossRef]

- Boiko, Y.M.; Marikhin, V.A.; Myasnikova, L.P.; Moskalyuk, O.A.; Radovanova, E.I. Weibull statistics of tensile strength distribution of gel-cast ultra-oriented film threads of ultra-high-molecular-weight polyethylene. J. Mater. Sci. 2017, 52, 1727–1735. [Google Scholar] [CrossRef]

- Guo, K.; Zhang, X.; Dong, Z.; Ni, Y.; Chen, Y.; Zhang, Y.; Li, H.; Xia, Q.; Zhao, P. Ultra-fine and high-strength silk fibers secreted by bimolter silkworms. Polymers 2020, 12, 2537. [Google Scholar] [CrossRef]

- Boiko, Y.M. Impact of crystallization on the development of statistical self-bonding strength at initially amorphous polymer–polymer interfaces. Polymers 2022, 14, 4519. [Google Scholar] [CrossRef]

- Boiko, Y.M. Statistical adhesion strength of an amorphous polymer—Its miscible blend interface self-healed at a temperature below the bulk glass transition temperature. J. Adhes. 2020, 96, 760–775. [Google Scholar] [CrossRef]

- Boiko, Y.M. Statistics of strength distribution upon the start of adhesion between glassy polymers. Colloid Polym. Sci. 2016, 294, 1727–1732. [Google Scholar] [CrossRef]

- Boiko, Y.M. Weibull statistics of the lap-shear strength developed at early stages of self-healing of the interfaces of glassy and semi-crystalline poly(ethylene terephthalate). J. Non-Cryst. Solids 2020, 532, 119874. [Google Scholar] [CrossRef]

- Weibull, W.J. A statistical distribution function of wide applicability. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Zok, F.W. On weakest link theory and Weibull statistics. J. Am. Ceram. Soc. 2017, 100, 1265–1268. [Google Scholar] [CrossRef]

- Yang, C.-W.; Jiang, S.-J. Weibull statistical analysis of strength fluctuation for failure prediction and structural durability of friction stir welded Al-Cu dissimilar joints correlated to metallurgical bonded characteristics. Materials 2019, 12, 205. [Google Scholar] [CrossRef]

- Bazant, Z.P. Design of quasibrittle materials and structures to optimize strength and scaling at probability tail: An apercu. Proc. R. Soc. 2019, A475, 20180617. [Google Scholar] [CrossRef]

- Zakaria, M.N.; Crosky, A.; Beehag, A. Weibull probability model for tensile properties of kenaf technical fibers. AIP Conf. Proc. 2018, 2030, 020015. [Google Scholar]

- Nitta, K.-H.; Li, C.-Y. A stohastic equation for predicting tensile fractures in ductile polymer solids. Physica A 2018, 490, 1076–1086. [Google Scholar] [CrossRef]

- Baikova, L.G.; Pesina, T.I.; Kireenko, M.F.; Tikhonova, L.V.; Kurkjian, C.R. Strength of optical silica fibers measured in liquid nitrogen. Technol. Phys. 2015, 60, 869–872. [Google Scholar] [CrossRef]

- Baikova, L.G.; Pesina, T.I.; Mansyrev, E.I.; Kireenko, M.F.; Tikhonova, L.V. Deformation and strength of silica fibers in three-point bending in consideration of non-linear elasticity of glass. Technol. Phys. 2017, 62, 47–52. [Google Scholar] [CrossRef]

- Boiko, Y.M. Statistical elastic and fracture mechanical properties of quasi-brittle and ductile amorphous polymers. Polym. Bull. 2023. [Google Scholar] [CrossRef]

- Thomopoulos, N.T. Statistical Distributions: Applications and Parameter Estimates; Springer International Publishing AG: Berlin/Heidelberg, Germany, 2017; p. 189. [Google Scholar]

- Yap, B.W.; Sim, C.H. Comparisons of various types of normality tests. J. Stat. Comput. Simul. 2011, 81, 2141–2155. [Google Scholar] [CrossRef]

- Yue, H.; Yu, J.-Y. Quantile-quantile plot compared with stabilized probability plot. Am. J. Appl. Math. 2016, 4, 110–113. [Google Scholar] [CrossRef]

- Boiko, Y.M.; Prud’homme, R.E. Bonding at symmetric polymer/polymer interfaces below the glass transition temperature. Macromolecules 1997, 30, 3708–3710. [Google Scholar] [CrossRef]

- Boiko, Y.M. Surface glass transition of amorphous miscible polymers blends. Colloid Polym. Sci. 2010, 288, 1757–1761. [Google Scholar] [CrossRef]

- Wool, R.P. Polymer Interfaces: Structure and Strength; Hanser Press: New York, NY, USA, 1995. [Google Scholar]

- Boiko, Y.M.; Bach, A.; Lyngaae-Jørgensen, J. Self-bonding in an amorphous polymer below the glass transition: A T-peel test investigation. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 1861–1867. [Google Scholar] [CrossRef]

- Boiko, Y.M. On the molecular mechanism of self-healing of glassy polymers. Colloid Polym. Sci. 2016, 294, 1237–1242. [Google Scholar] [CrossRef]

| Molecular Weight, g/mol | Test Type | Statistic | p-Value | Decision at Level 5% * |

|---|---|---|---|---|

| 105 | Shapiro–Wilk | 0.92935 | 0.15004 | + |

| 106 | 0.93979 | 0.2614 | + | |

| 105 | Lilliefors | 0.15347 | 0.2 | + |

| 106 | 0.15788 | 0.2 | + | |

| 105 | Kolmogorov–Smirnov | 0.15347 | 0.70769 | + |

| 106 | 0.15788 | 0.70223 | + | |

| 105 | Anderson–Darling | 0.49761 | 0.18727 | + |

| 106 | 0.41675 | 0.29844 | + | |

| D’Agostino–K squared: | ||||

| 105 | Omnibus | 1.95367 | 0.3765 | + |

| Skewness | 1.36904 | 0.17099 | + | |

| Kurtosis | −0.28178 | 0.77811 | + | |

| 106 | Omnibus | 1.94532 | 0.37808 | + |

| Skewness | 0.79625 | 0.42589 | + | |

| Kurtosis | −1.14512 | 0.25216 | + |

| Molecular Weight, g/mol | Statistic | 10% Critical Value | 5% Critical Value | Decision at Level 5% * |

|---|---|---|---|---|

| 105 | −0.00868 | 0.01371 | 0.05109 | + |

| 106 | −0.03627 | 0.01427 | 0.05232 | + |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boiko, Y.M. Evolution of Statistical Strength during the Contact of Amorphous Polymer Specimens below the Glass Transition Temperature: Influence of Chain Length. Materials 2023, 16, 491. https://doi.org/10.3390/ma16020491

Boiko YM. Evolution of Statistical Strength during the Contact of Amorphous Polymer Specimens below the Glass Transition Temperature: Influence of Chain Length. Materials. 2023; 16(2):491. https://doi.org/10.3390/ma16020491

Chicago/Turabian StyleBoiko, Yuri M. 2023. "Evolution of Statistical Strength during the Contact of Amorphous Polymer Specimens below the Glass Transition Temperature: Influence of Chain Length" Materials 16, no. 2: 491. https://doi.org/10.3390/ma16020491

APA StyleBoiko, Y. M. (2023). Evolution of Statistical Strength during the Contact of Amorphous Polymer Specimens below the Glass Transition Temperature: Influence of Chain Length. Materials, 16(2), 491. https://doi.org/10.3390/ma16020491