Microstructure and Corrosion Behavior of Laser-Welded Al–Mn–Zr Alloy for Heat Exchanger

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Laser Welding Process

2.2. Surface Analysis

2.3. Corrosion Testing

3. Results and Discussion

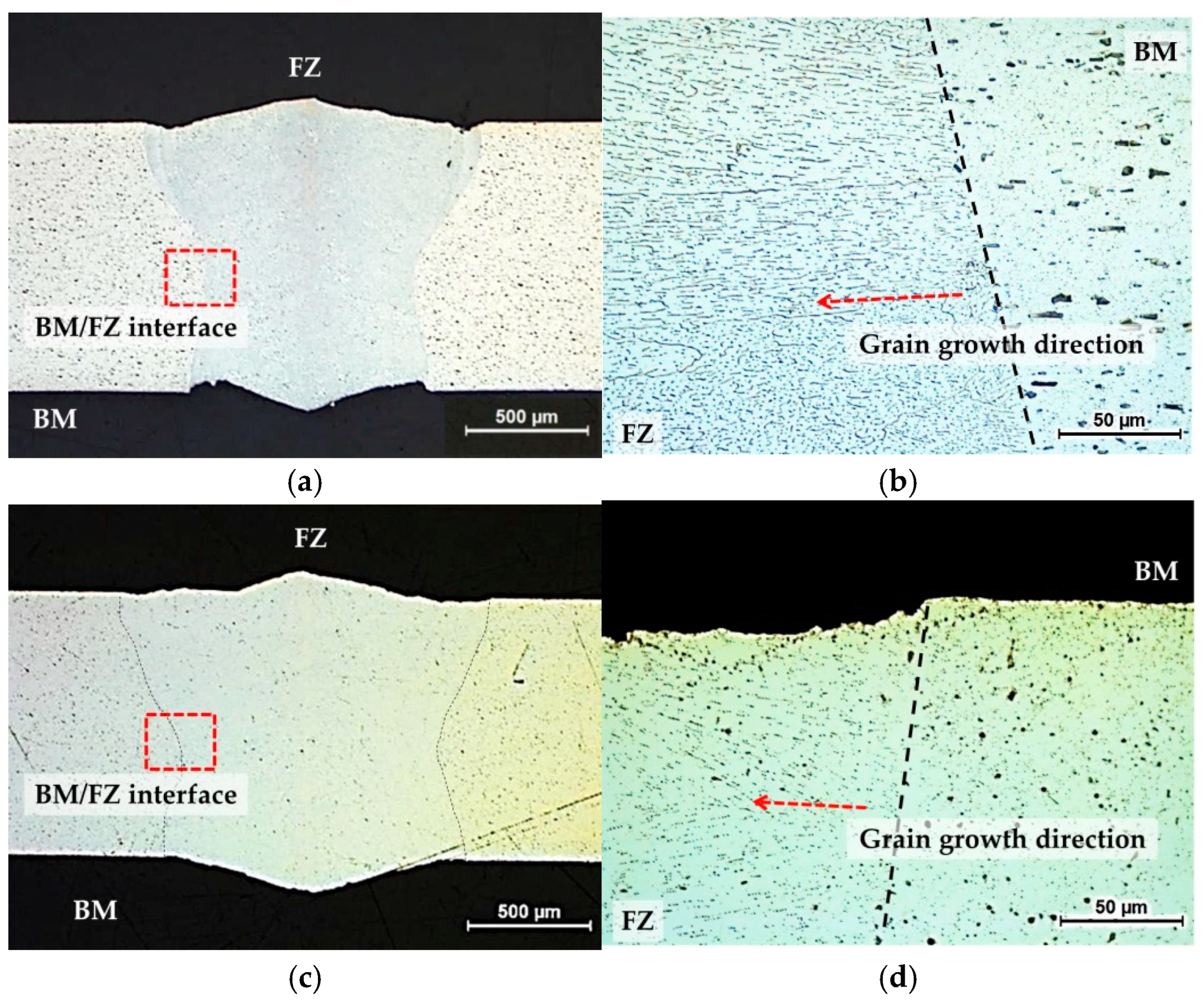

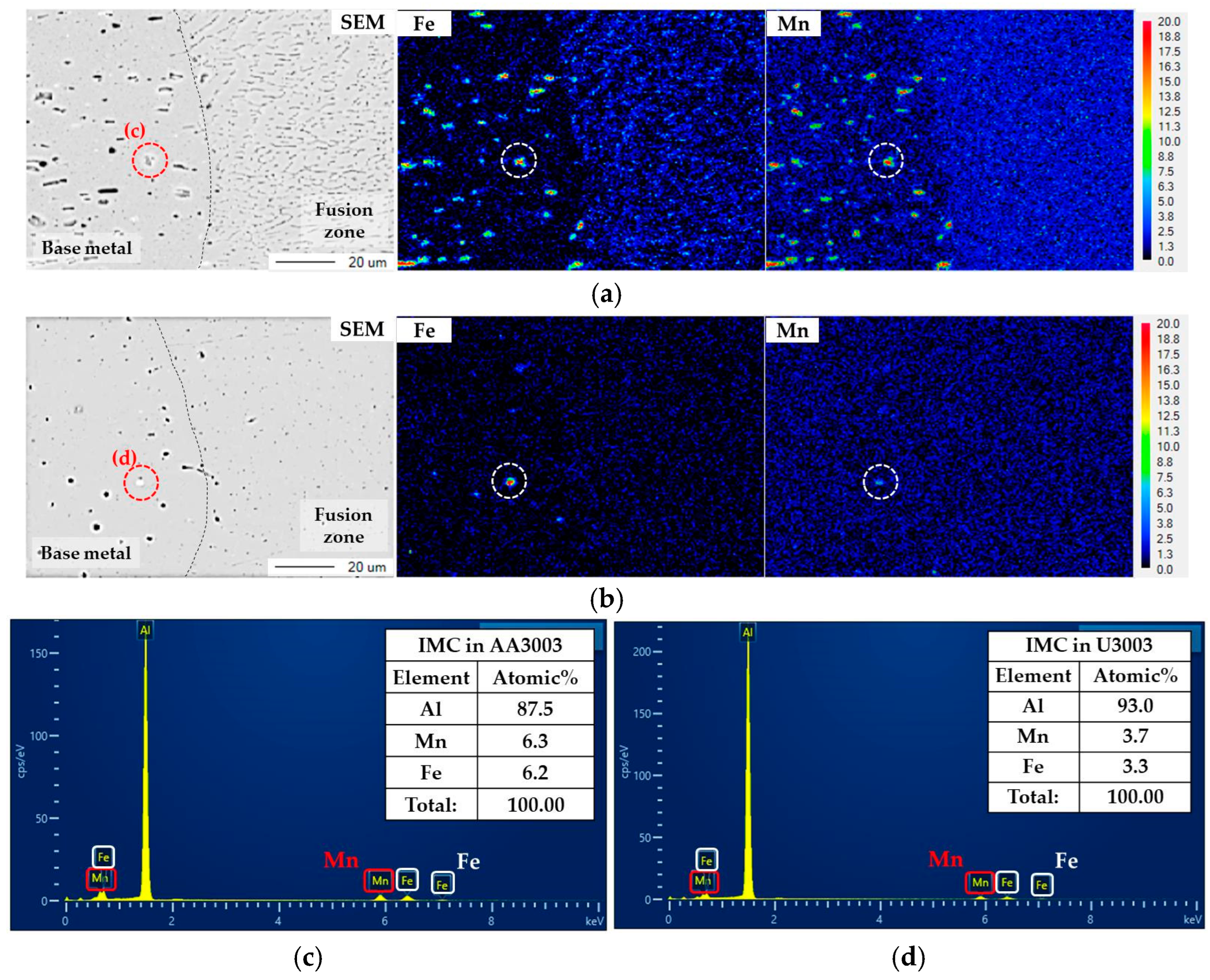

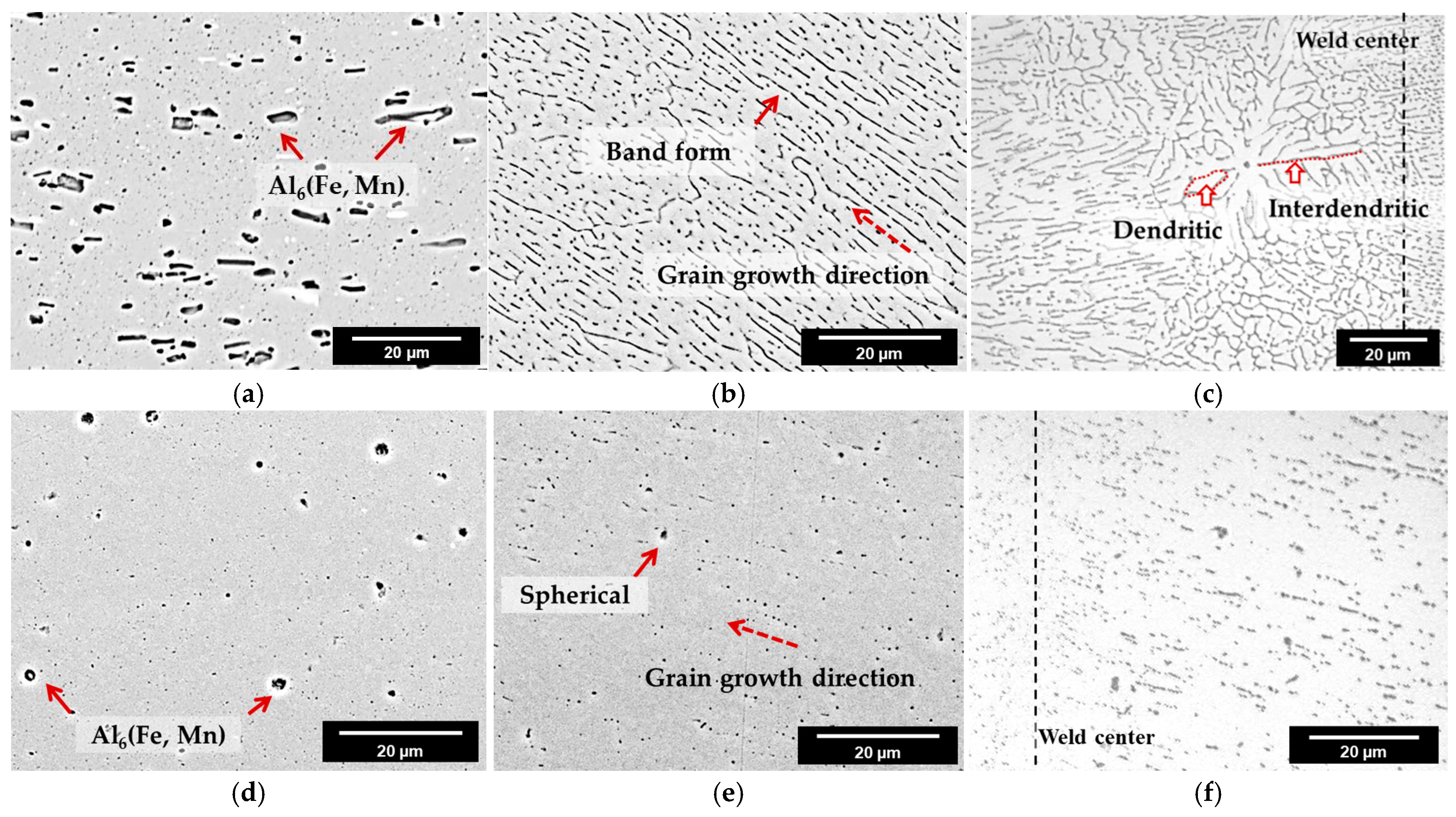

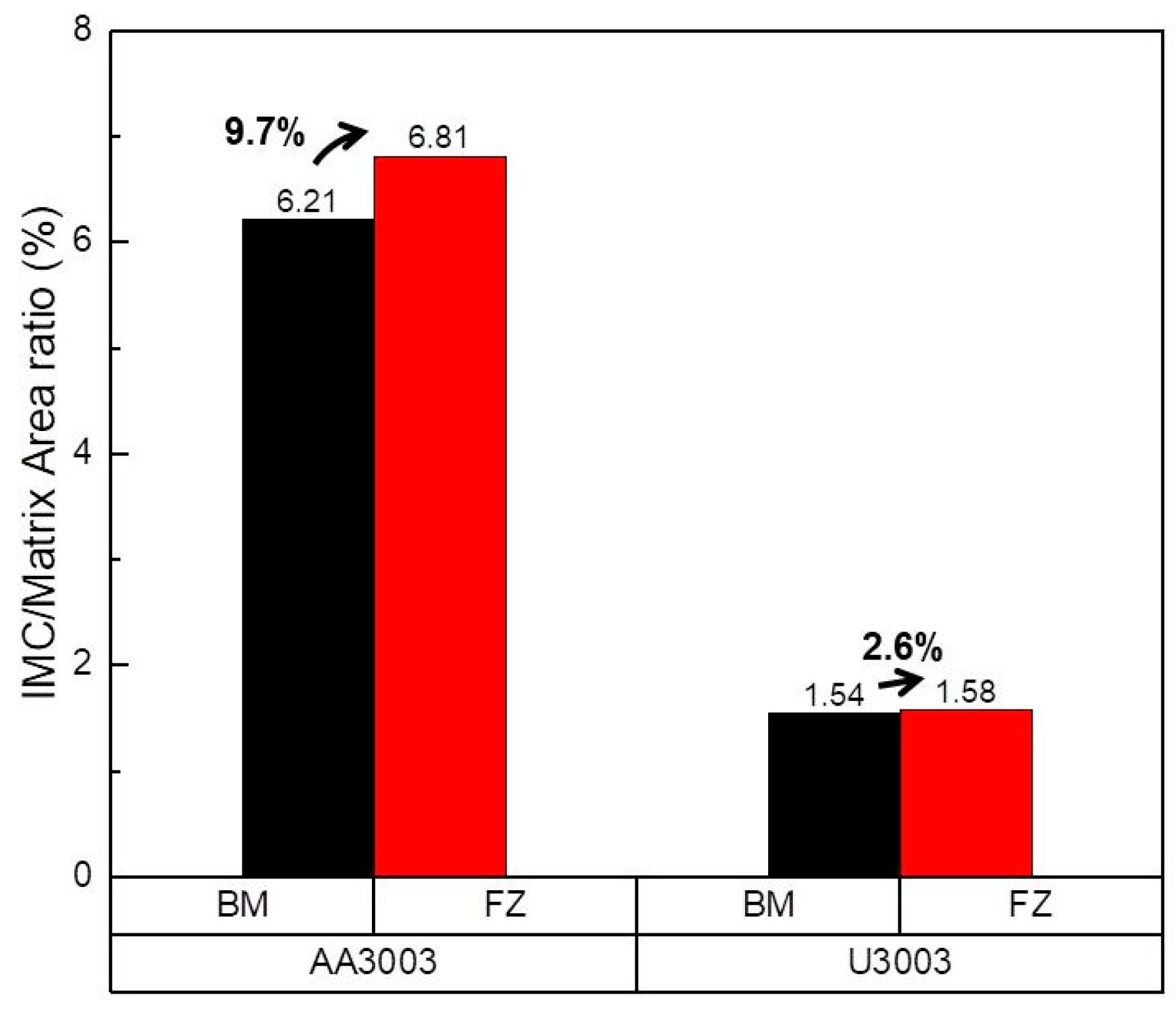

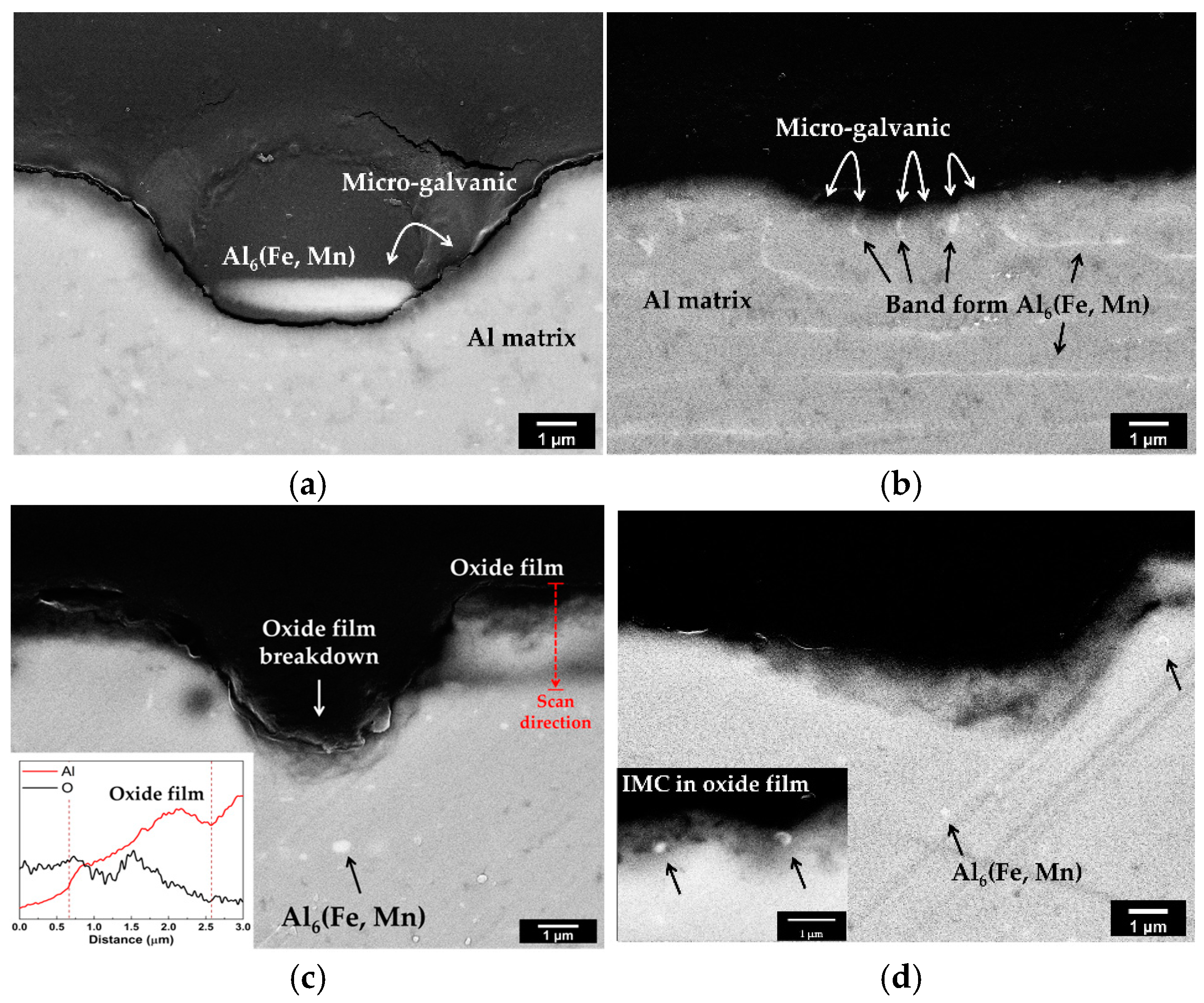

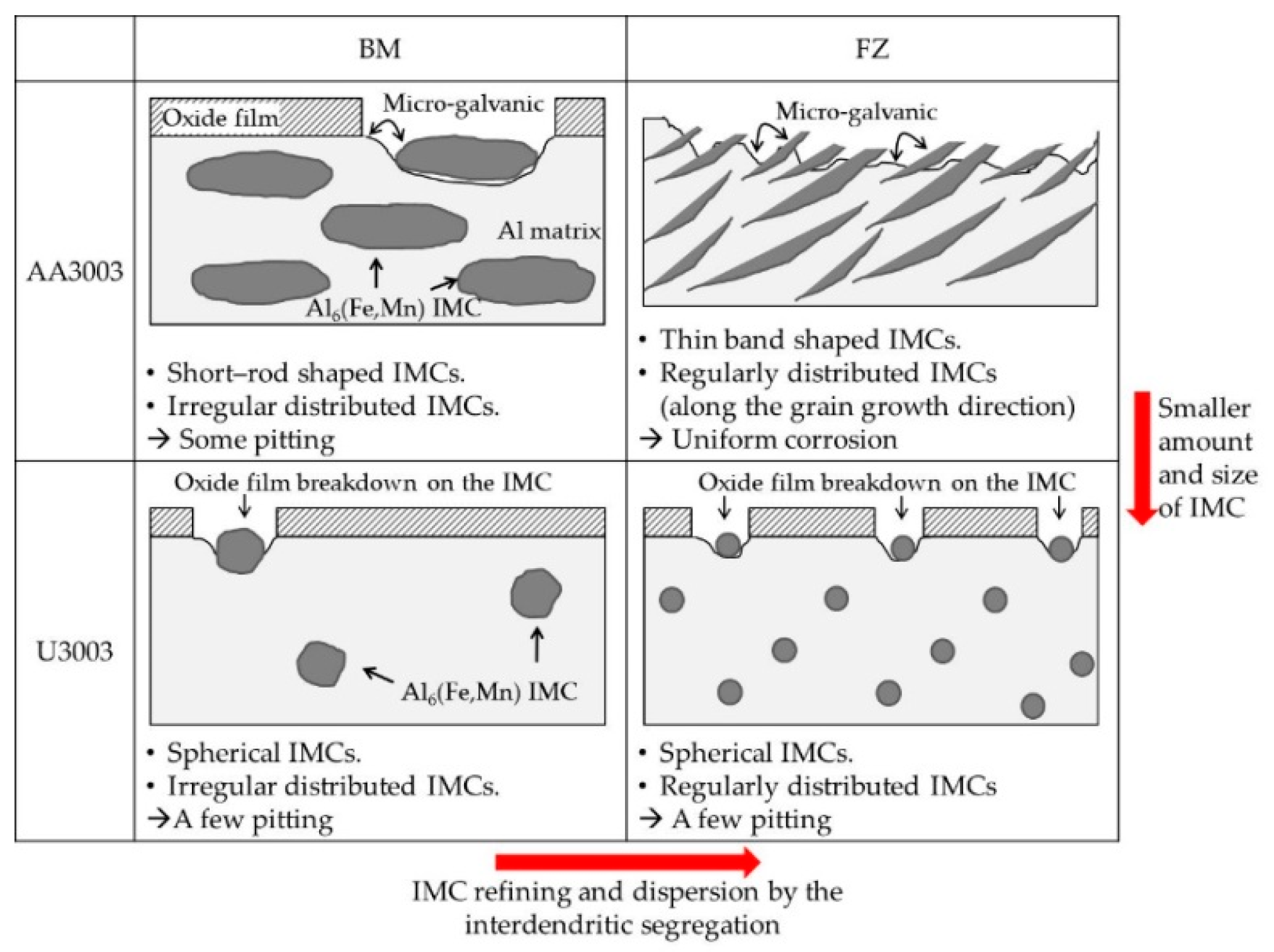

3.1. Microstructure of Laser-Weld Beads

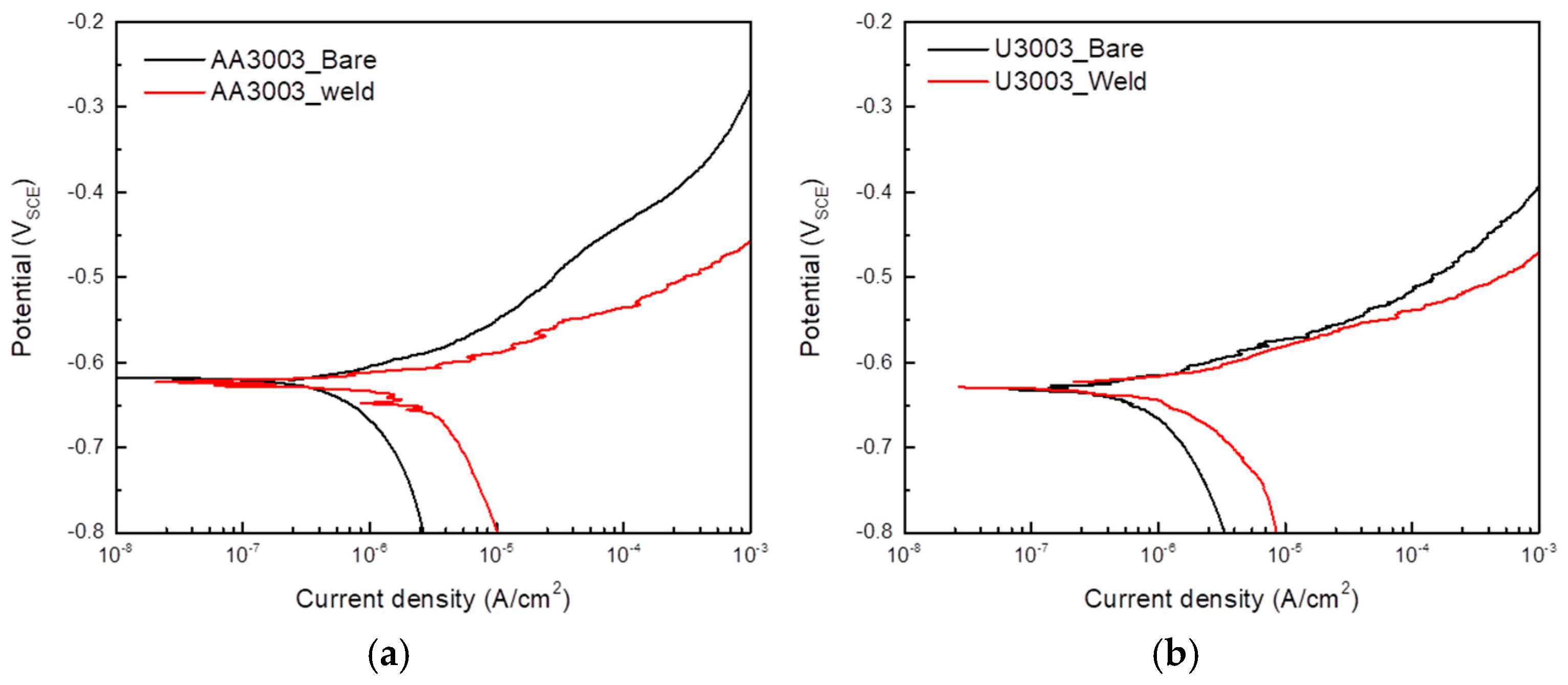

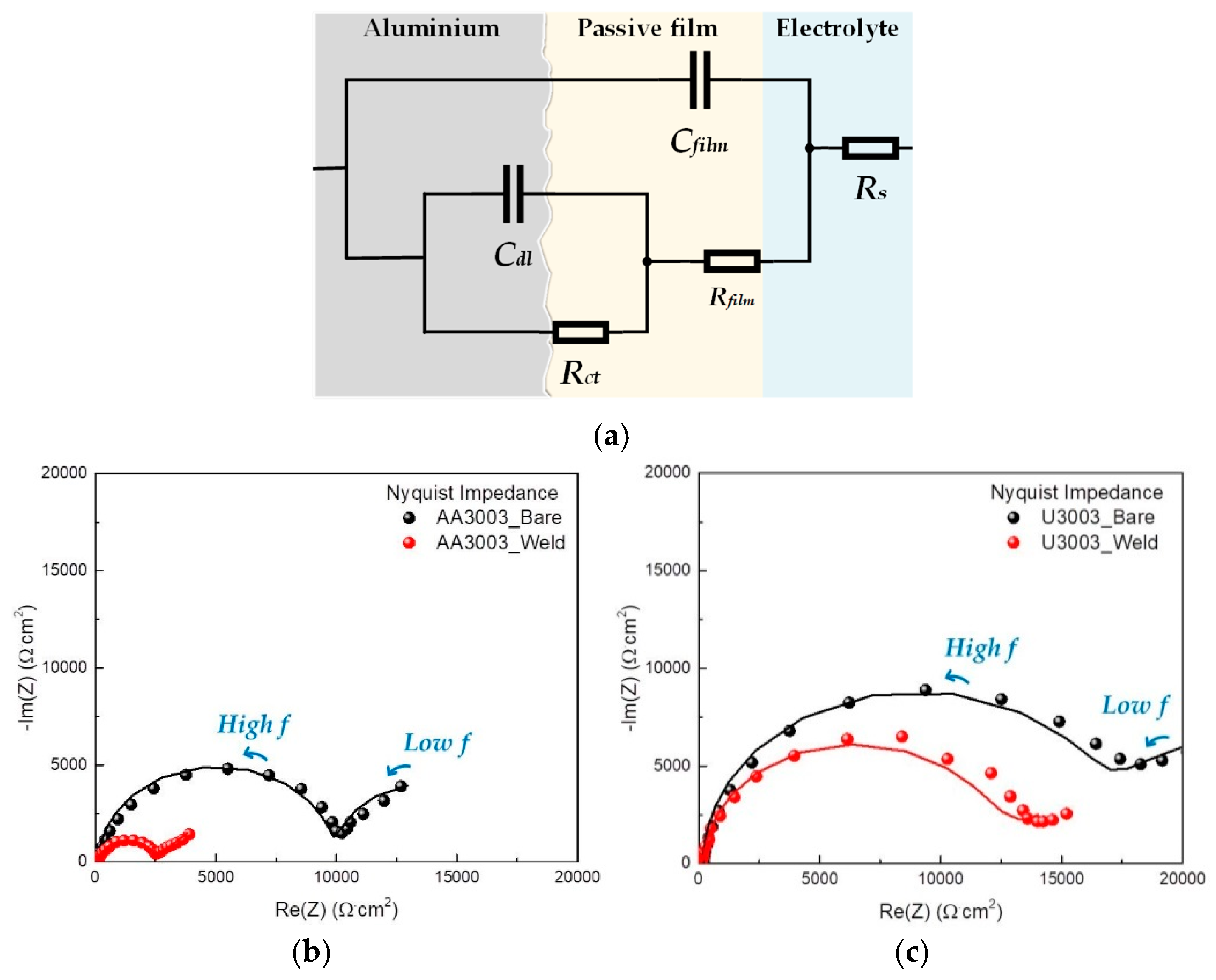

3.2. Corrosion Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sinha, A.; Chattopadhyay, H.; Iyengar, A.K.; Biswas, G. Enhancement of heat transfer in a fin-tube heat exchanger using rectangular winglet type vortex generators. Int. J. Heat Mass Transf. 2016, 101, 667–681. [Google Scholar] [CrossRef]

- Jaradeh, M.M.R.; Carlberg, T. Solidification studies of 3003 aluminium alloys with Cu and Zr additions. J. Mater. Sci. Technol. 2011, 27, 615–627. [Google Scholar] [CrossRef]

- Zaffaroni, G.G.B.; Gudla, V.C.; Ambat, R.; Mangelsdorf, A. Microstructural and corrosion issues of embossed and welded aluminium heat exchanger tubes. In Proceedings of the EUROCORR 2017, European Corrosion Congress, Prague, Czech Republic, 3–7 September 2017. [Google Scholar]

- Gagliardi, A.; Lanzutti, A.; Simonato, M.; Furlanetto, R.; Magnan, M.; Andreatta, F.; Fedrizzi, L. Failure analysis of a plate heat exchanger used in a blast chiller. Eng. Fail. Anal. 2018, 92, 289–300. [Google Scholar] [CrossRef]

- Hagiwara, M.; Baba, Y.; Tanabe, Z.; Miura, T.; Hasegawa, Y.; Iijima, K. Development of corrosion resistant aluminum heat exchanger, Part 1: Development of new aluminum alloy sheets for sacrificial anode. SAE Trans. 1986, 95, 477–481. [Google Scholar]

- Humpston, G.; Sangha, S.; Jacobson, D. New filler metals and process for fluxless brazing of aluminium engineering alloys. Mater. Sci. Technol. 1995, 11, 1161–1168. [Google Scholar] [CrossRef]

- Mathers, G. The Welding of Aluminium and Its Alloys; Elsevier: Cambridge, UK, 2002; pp. 150–155. [Google Scholar]

- Zhao, H.; White, D.R.; DebRoy, T. Current issues and problems in laser welding of automotive aluminium alloys. Int. Mater. Rev. 1999, 44, 238–266. [Google Scholar] [CrossRef]

- Coelho, B.N.; Lima, M.S.F.D.; Carvalho, S.M.D.; Costa, A.R.D. A comparative study of the heat input during laser welding of aeronautical aluminum alloy AA6013-T4. J. Aerosp. Technol. Manag. 2018, 10, e2918. [Google Scholar] [CrossRef]

- Haboudou, A.; Peyre, P.; Vannes, A.; Peix, G. Reduction of porosity content generated during Nd: YAG laser welding of A356 and AA5083 aluminium alloys. Mater. Sci. Eng. A 2003, 363, 40–52. [Google Scholar] [CrossRef]

- Cao, X.; Wallace, W.; Immarigeon, J.-P.; Poon, C. Research and progress in laser welding of wrought aluminum alloys II. Metallurgical microstructures, defects, and mechanical properties. Mater. Manuf. Process. 2003, 18, 23–49. [Google Scholar] [CrossRef]

- Sheikhi, M.; Ghaini, F.M.; Torkamany, M.; Sabbaghzadeh, J. Characterisation of solidification cracking in pulsed Nd: YAG laser welding of 2024 aluminium alloy. Sci. Technol. Weld. Join. 2009, 14, 161–165. [Google Scholar] [CrossRef]

- Watkins, K.G.; McMahon, M.A.; Steen, W.M. Microstructure and corrosion properties of laser surface processed aluminium alloys: A review. Mater. Sci. Eng. A 1997, 231, 55–61. [Google Scholar] [CrossRef]

- Padovani, C.; Fratini, L.; Squillace, A.; Bellucci, F. Electrochemical analysis on friction stir welded and laser welded 6XXX aluminium alloys T-joints. Corros. Rev. 2007, 25, 475–489. [Google Scholar] [CrossRef]

- Miyagi, M.; Kawahito, Y.; Wang, H.; Kawakami, H.; Shoubu, T.; Tsukamoto, M. X-ray phase contrast observation of solidification and hot crack propagation in laser spot welding of aluminum alloy. Opt. Express 2018, 26, 22626–22636. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, B.; Zhou, X.; Wang, J.; Hashimoto, T.; Luo, C.; Sun, Z.; Tang, Z.; Lu, F. Laser welding introduced segregation and its influence on the corrosion behaviour of Al-Cu-Li alloy. Corros. Sci. 2018, 135, 177–191. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Li, J.; Joo, H.G.; Lee, K.Y. Corrosion properties of Nd: YAG laser–GMA hybrid welded AA6061 Al alloy and its microstructure. Corros. Sci. 2009, 51, 1399–1404. [Google Scholar] [CrossRef]

- Anderson, W.; Stumpf, H. Effects of manganese on the electrode or free corrosion potentials of aluminum. Corrosion 1980, 36, 212–213. [Google Scholar] [CrossRef]

- Zamin, M. The role of Mn in the corrosion behavior of Al-Mn alloys. Corrosion 1981, 37, 627–632. [Google Scholar] [CrossRef]

- Kim, Y.S.; Park, I.J.; An, B.S.; Park, J.G.; Yang, C.W.; Lee, Y.H.; Kim, J.G. Improvement of corrosion penetration resistance for aluminum heat exchanger by alloying zirconium. Mater. Chem. Phys. 2020, 241, 122275. [Google Scholar] [CrossRef]

- Jia, Z.; Hu, G.; Forbord, B.; Solberg, J.K. Effect of homogenization and alloying elements on recrystallization resistance of Al–Zr–Mn alloys. Mater. Sci. Eng. A 2007, 444, 284–290. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.; Portnoy, V.; Mochugovskiy, A.; Zadorozhnyy, M.Y.; Tabachkova, N.Y.; Golovin, I. Effect of homogenisation treatment on precipitation, recrystallisation and properties of Al–3% Mg–TM alloys (TM = Mn, Cr, Zr). Mater. Des. 2016, 109, 197–208. [Google Scholar] [CrossRef]

- Kutsuna, M.; Kitamura, S.; Shibata, K.; Sakamoto, H.; Tsushima, K. Improvement of the joint performance in laser welding of aluminium alloys. Weld. World 2006, 50, 22–27. [Google Scholar] [CrossRef]

- Dongxia, Y.; Xiaoyan, L.; Dingyong, H.; Hui, H. Effect of minor Er and Zr on microstructure and mechanical properties of Al–Mg–Mn alloy (5083) welded joints. Mater. Sci. Eng. A 2013, 561, 226–231. [Google Scholar] [CrossRef]

- Ramkumar, K.R.; Natarajan, S. Investigations on microstructure and mechanical properties of TiO2 nanoparticles addition in Al 3003 alloy joints by gas tungsten arc welding. Mater. Sci. Eng. A 2018, 727, 51–60. [Google Scholar] [CrossRef]

- ASTM E407; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2016.

- Hong, M.S.; Park, I.J.; Kim, J.G. Alloying effect of copper concentration on the localized corrosion of aluminum alloy for heat exchanger tube. Met. Mater. Int. 2017, 23, 708–714. [Google Scholar] [CrossRef]

- ASTM G5; Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements. ASTM International: West Conshohocken, PA, USA, 2021.

- Cao, X.; Wallace, W.; Poon, C.; Immarigeon, J.-P. Research and progress in laser welding of wrought aluminum alloys I. Laser welding processes. Mater. Manuf. Process. 2003, 18, 1–22. [Google Scholar] [CrossRef]

- Ion, J.C. Laser beam welding of wrought aluminium alloys. Sci. Technol. Weld. Join. 2000, 5, 265–276. [Google Scholar] [CrossRef]

- Denholm, W.; Esdaile, J.; Siviour, N.; Wilson, B. The nature of the FeAl3 liquid-(FeMn) Al6 reaction in the Al-Fe-Mn system. Metall. Trans. A 1987, 18, 393–397. [Google Scholar] [CrossRef]

- Yan, F.; Kumar, S.; Mckay, B.; O’Reilly, K. Effect of Mn on Fe containing phase formation in high purity aluminium. Int. J. Cast Met. Res. 2014, 27, 202–206. [Google Scholar] [CrossRef]

- Homonnay, Z.; Vértes, A.; Cziráki, Á.; Oszkó, A.; Menczel, G.; Murgás, L. Mössbauer study of Al6(Fe, Mn) formation in Al-rich Al−Fe−Mn alloys. J. Radioanal. Nucl. Chem. 1990, 139, 127–134. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.; Marthinsen, K. Precipitation crystallography of plate-shaped Al6 (Mn, Fe) dispersoids in AA5182 alloy. Acta Mater. 2012, 60, 5963–5974. [Google Scholar] [CrossRef]

- Li, J.; Dang, J. A summary of corrosion properties of Al-rich solid solution and secondary phase particles in Al alloys. Metals 2017, 7, 84. [Google Scholar] [CrossRef]

- Pakdil, M.; Çam, G.; Koçak, M.; Erim, S. Microstructural and mechanical characterization of laser beam welded AA6056 Al-alloy. Mater. Sci. Eng. A 2011, 528, 7350–7356. [Google Scholar] [CrossRef]

- Almenara, M.D.; Capace, M.C. Microstructure and mechanical properties of GTAW welded joints of AA6105 aluminum alloy. Rev. Fac. Ing. 2016, 25, 7–19. [Google Scholar] [CrossRef]

- Haghdadi, N.; Phillion, A.B.; Maijer, D.M. Microstructure characterization and thermal analysis of aluminum alloy B206 during solidification. Metall. Mater. Trans. A 2015, 46, 2073–2081. [Google Scholar] [CrossRef]

- Kim, Y.S.; Park, J.G.; An, B.S.; Lee, Y.H.; Yang, C.W.; Kim, J.-G. Investigation of zirconium effect on the corrosion resistance of aluminum alloy using electrochemical methods and numerical simulation in an acidified synthetic sea salt solution. Materials 2018, 11, 1982. [Google Scholar] [CrossRef] [PubMed]

- Aidun, D.; Dean, J. Effect of enhanced convection on the microstructure of Al-Cu-Li welds. Weld. J. 1999, 78, 349–354. [Google Scholar]

- Lu, B.; Li, Y.; Wang, H.; Wang, Y.; Yu, W.; Wang, Z.; Xu, G. Effects of cooling rates on the solidification behavior, microstructural evolution and mechanical properties of Al–Zn–Mg–Cu alloys. J. Mater. Res. Technol. 2023, 22, 2532–2548. [Google Scholar] [CrossRef]

- Deshpande, K.B. Numerical modeling of micro-galvanic corrosion. Electrochim. Acta 2011, 56, 1737–1745. [Google Scholar] [CrossRef]

- Mansfeld, F.; Kenkel, J. Galvanic corrosion of Al alloys—III. The effect of area ratio. Corros. Sci. 1975, 15, 239–250. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, B.; Wu, B.; Wang, Y.; Tian, X.; Yang, L.; Oguzie, E.; Ma, X. Enhanced corrosion resistance by engineering crystallography on metals. Nat. Commun. 2022, 13, 726. [Google Scholar] [CrossRef]

- Terachi, T.; Fujii, K.; Arioka, K. Microstructural characterization of SCC crack tip and oxide film for SUS 316 stainless steel in simulated PWR primary water at 320 °C. J. Nucl. Sci. Technol. 2005, 42, 225–232. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, G.; Cheng, Y. Electronic structure and pitting behavior of 3003 aluminum alloy passivated under various conditions. Electrochim. Acta 2009, 54, 4155–4163. [Google Scholar] [CrossRef]

- Yu, M.; Zhao, X.; Xiong, L.; Xue, B.; Kong, X.; Liu, J.; Li, S. Improvement of corrosion protection of coating system via inhibitor response order. Coatings 2018, 8, 365. [Google Scholar] [CrossRef]

- Hirschorn, B.; Orazem, M.E.; Tribollet, B.; Vivier, V.; Frateur, I.; Musiani, M. Determination of effective capacitance and film thickness from constant-phase-element parameters. Electrochim. Acta 2010, 55, 6218–6227. [Google Scholar] [CrossRef]

- Benoit, M.; Bataillon, C.; Gwinner, B.; Miserque, F.; Orazem, M.E.; Sánchez-Sánchez, C.M.; Tribollet, B.; Vivier, V. Comparison of different methods for measuring the passive film thickness on metals. Electrochim. Acta 2016, 201, 340–347. [Google Scholar] [CrossRef]

- Hernández, H.H.; Reynoso, A.M.R.; González, J.C.T.; Morán, C.O.G.; Hernández, J.G.M.; Ruiz, A.M.; Hernández, J.M.; Cruz, R.O. Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels; IntechOpen: London, UK, 2020. [Google Scholar]

- Wang, L.; Snihirova, D.; Deng, M.; Vaghefinazari, B.; Höche, D.; Lamaka, S.V.; Zheludkevich, M.L. Revealing physical interpretation of time constants in electrochemical impedance spectra of Mg via Tribo-EIS measurements. Electrochim. Acta 2022, 404, 139582. [Google Scholar] [CrossRef]

- Choi, W.; Shin, H.C.; Kim, J.M.; Choi, J.Y.; Yoon, W.S. Modeling and applications of electrochemical impedance spectroscopy (EIS) for lithium-ion batteries. J. Electrochem. Sci. Technol. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Saitou, M. Determination of a dimensionless fluctuation coefficient using electrochemical impedance spectroscopy. Int. J. Electrochem. Sci. 2019, 14, 8028–8038. [Google Scholar] [CrossRef]

- Le, D.; Yoo, Y.; Kim, J.; Cho, S.; Son, Y. Corrosion characteristics of polyaniline-coated 316L stainless steel in sulphuric acid containing fluoride. Corros. Sci. 2009, 51, 330–338. [Google Scholar] [CrossRef]

- Ma, M.; Liu, H.; Chen, L. Effect of cerium on the initiation of pitting corrosion of 444-type heat-resistant ferritic stainless steel. High Temp. Mater. Process. 2020, 39, 576–587. [Google Scholar] [CrossRef]

- Cramer, S.D.; Covino, B.S., Jr.; Moosbrugger, C.; Sanders, B.R.; Anton, G.J.; Hrivnak, N.; Kinson, J.; Polakowski, C.; Muldoon, K.; Henry, S.D. ASM Handbook; ASM International Materials Park: Geauga County, OH, USA, 2003; pp. 491–492. [Google Scholar]

- Mohammadi, F.; Nickchi, T.; Attar, M.; Alfantazi, A. EIS study of potentiostatically formed passive film on 304 stainless steel. Electrochim. Acta 2011, 56, 8727–8733. [Google Scholar] [CrossRef]

- McCafferty, E.; Shafrin, E.G.; McKay, J.A. Microstructural and surface modification of an aluminum alloy by rapid solidification with a pulsed laser. Surf. Technol. 1981, 14, 219–223. [Google Scholar] [CrossRef]

- Fares, C.; Belouchrani, M.; Bellayer, S.; Boukharouba, T.; Britah, A. Influence of intermetallic compounds and metallurgical state of the 2017A aluminum alloy on the morphology of alumina films developed by anodic oxidation. J. Tribol. Surf. Eng. 2011, 2, 239–251. [Google Scholar]

- Cirik, E.; Genel, K. Effect of anodic oxidation on fatigue performance of 7075-T6 alloy. Surf. Coat. Technol. 2008, 202, 5190–5201. [Google Scholar] [CrossRef]

| Alloys | Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| Mn | Fe | Zr | Si | Cu | Mg | Al | |

| AA3003 | 1.126 | 0.357 | - | 0.100 | 0.120 | 0.017 | Bal. |

| U3003 | 0.485 | 0.086 | 0.164 | 0.032 | - | 0.002 | Bal. |

| Power Mode | Speed (m/min) | Beam Power (kW) | Beam Size (μm) | Wavelength (μm) | Incident Angle (°) | Defocusing (mm) |

|---|---|---|---|---|---|---|

| Continuous | 10 | Main 3.0 Ring 0.5 | Main 210 Ring 540 | 1070 | 0 | 0 |

| pH | SO42− (mg/L) | NO3− (mg/L) | Cl− (mg/L) |

|---|---|---|---|

| 4 | 2.212 | 1.545 | 400 |

| Alloy | AA3003-Bare | AA3003-Weld | U3003-Bare | U3003-Weld |

|---|---|---|---|---|

| Corrosion potential (mVSCE) | 623.7 | 621.7 | 631.2 | 631.2 |

| Corrosion current density (μA/cm2) | 0.78 | 3.15 | 0.46 | 0.69 |

| Alloy | Rs (Ω·cm2) | Cfilm (F/cm2) | Rfilm (Ω·cm2) | Cdl (F/cm2) | Rct (Ω·cm2) | icorr (µA/cm2) | |

|---|---|---|---|---|---|---|---|

| AA3003 | BM | 144.12 | 7.39 × 10−6 | 9840 | 1.7 × 10−3 | 7908 | 0.48 |

| FZ | 86.2 | 10.3 × 10−6 | 404 | 0.01 × 10−3 | 1846 | 3.80 | |

| U3003 | BM | 181.62 | 6.6 × 10−6 | 17,622 | 0.3 × 10−3 | 11,070 | 0.30 |

| FZ | 117.42 | 11.2 × 10−6 | 993 | 0.6 × 10−3 | 11,000 | 0.71 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, J.-M.; So, Y.-S.; Kim, J.-G. Microstructure and Corrosion Behavior of Laser-Welded Al–Mn–Zr Alloy for Heat Exchanger. Materials 2023, 16, 6009. https://doi.org/10.3390/ma16176009

Lim J-M, So Y-S, Kim J-G. Microstructure and Corrosion Behavior of Laser-Welded Al–Mn–Zr Alloy for Heat Exchanger. Materials. 2023; 16(17):6009. https://doi.org/10.3390/ma16176009

Chicago/Turabian StyleLim, Jeong-Min, Yoon-Sik So, and Jung-Gu Kim. 2023. "Microstructure and Corrosion Behavior of Laser-Welded Al–Mn–Zr Alloy for Heat Exchanger" Materials 16, no. 17: 6009. https://doi.org/10.3390/ma16176009

APA StyleLim, J.-M., So, Y.-S., & Kim, J.-G. (2023). Microstructure and Corrosion Behavior of Laser-Welded Al–Mn–Zr Alloy for Heat Exchanger. Materials, 16(17), 6009. https://doi.org/10.3390/ma16176009