Investigating the Effects of Recycled Plastic as Fibers on Bending Behavior of Green Concrete Beams Exposed to Marine Environment

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Cement

2.1.2. Metakaolin

2.1.3. Zeolite

2.1.4. Aggregates

2.1.5. Water

2.1.6. Superplasticizers

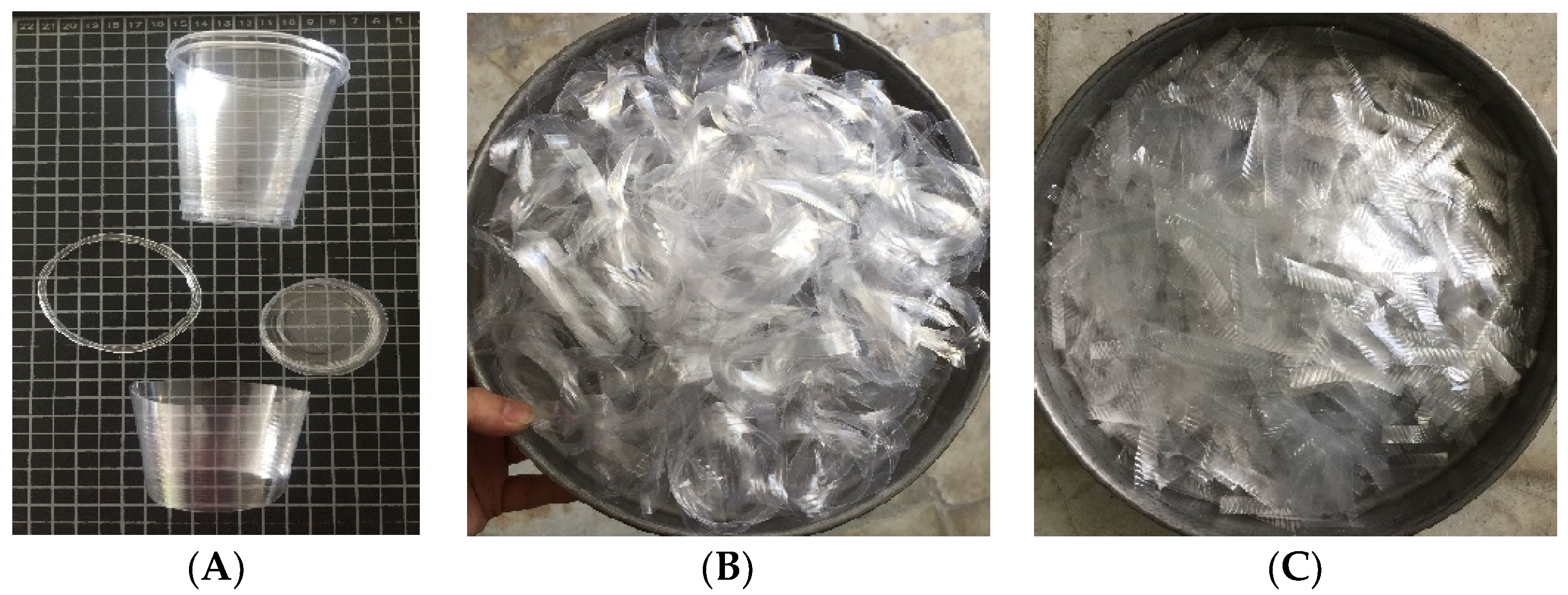

2.1.7. Recycled Fibers

Disposable Glass RF

Disposable Glass SF

2.2. Mixture Properties

2.3. Specimen Preparation

3. Exposure Conditions

4. Testing Methods

Flexural Behavior

5. Results and Discussion

5.1. Flexural Behavior

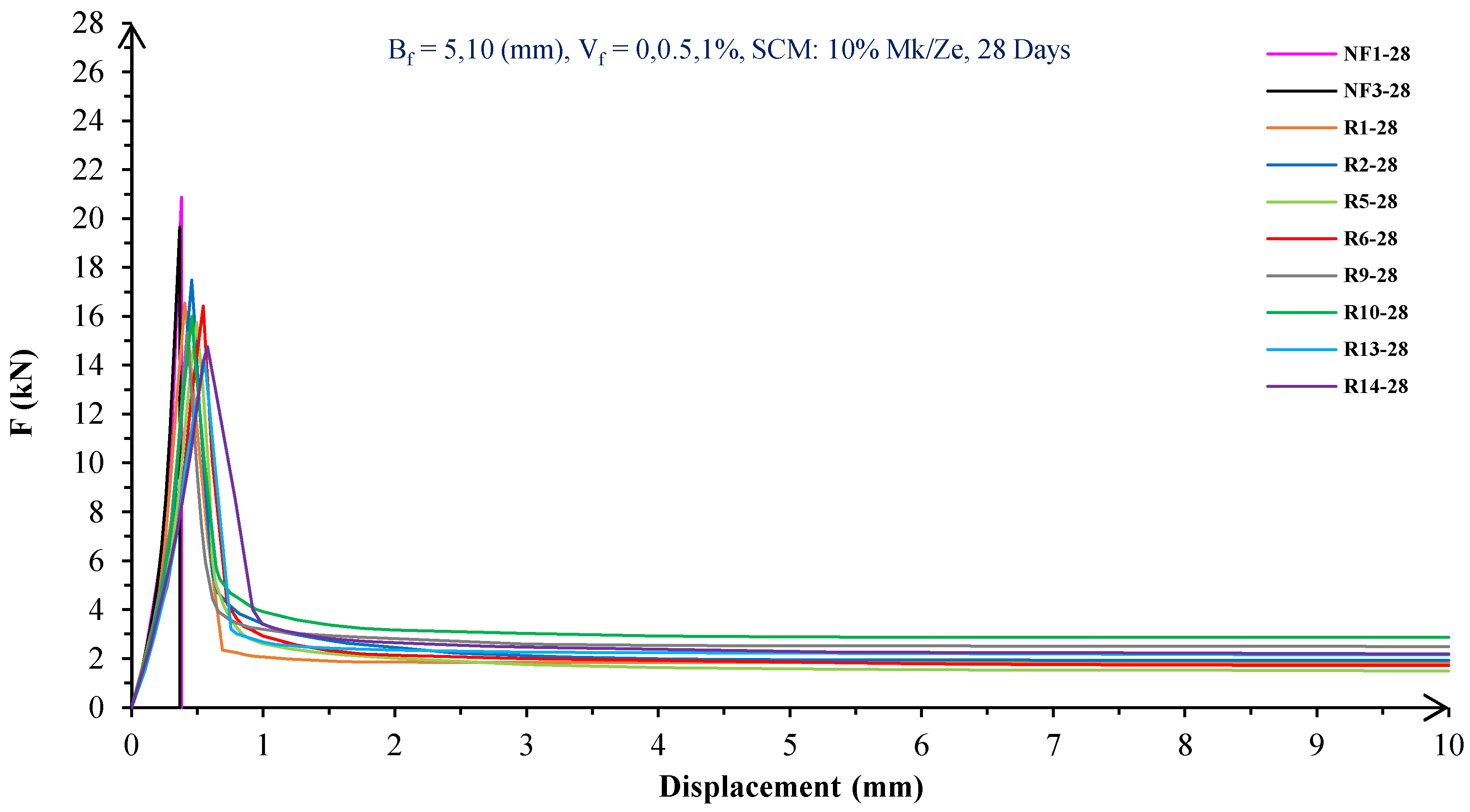

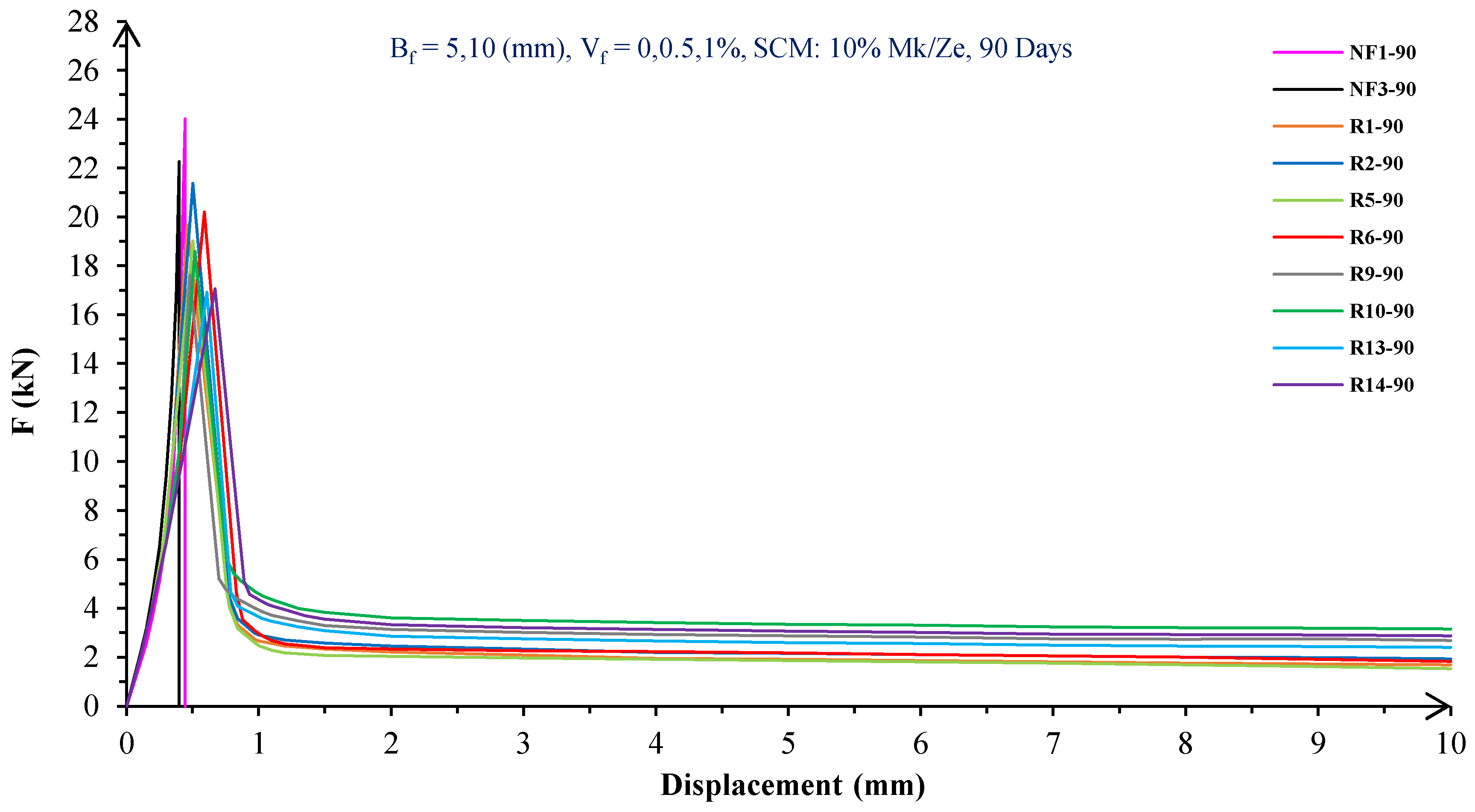

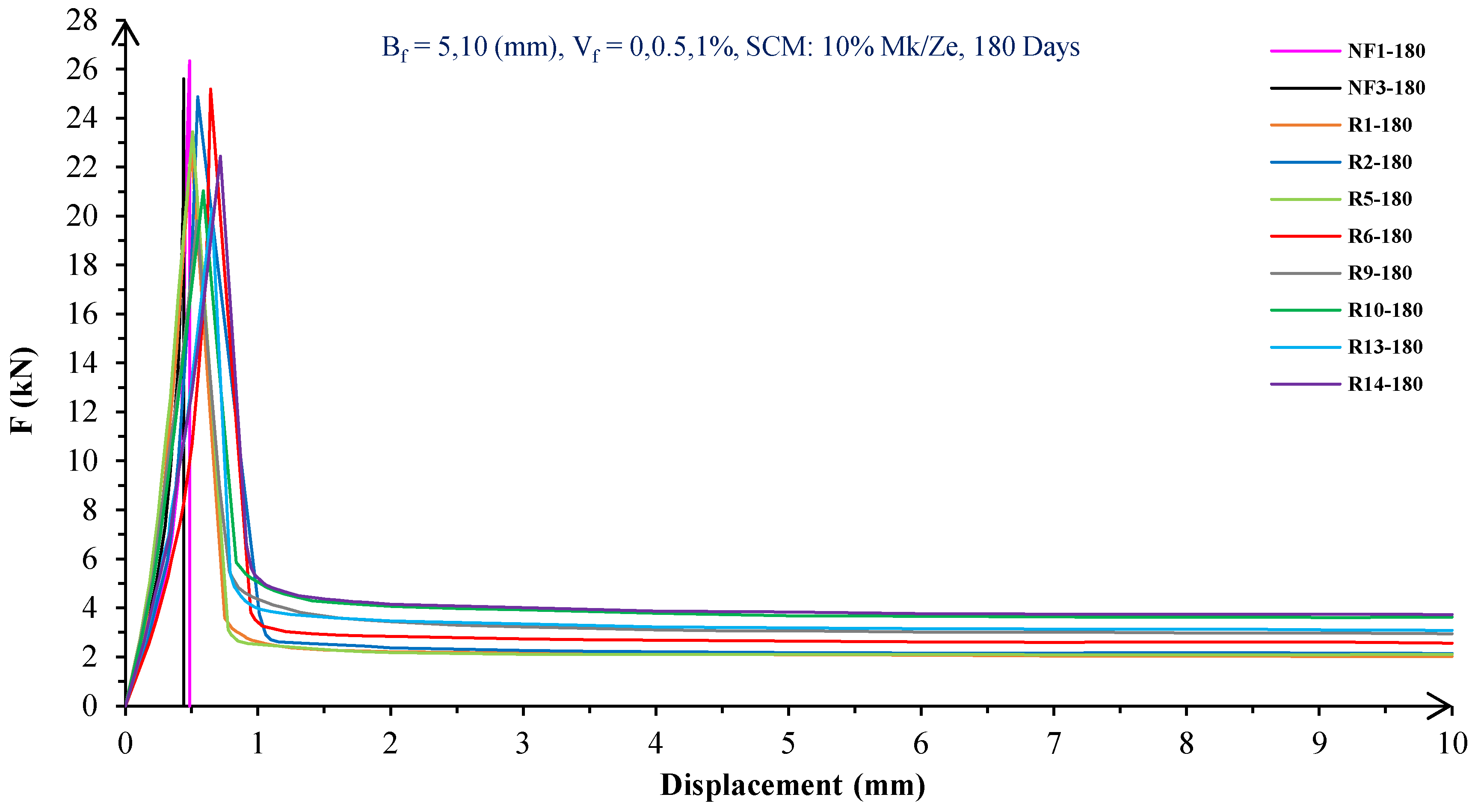

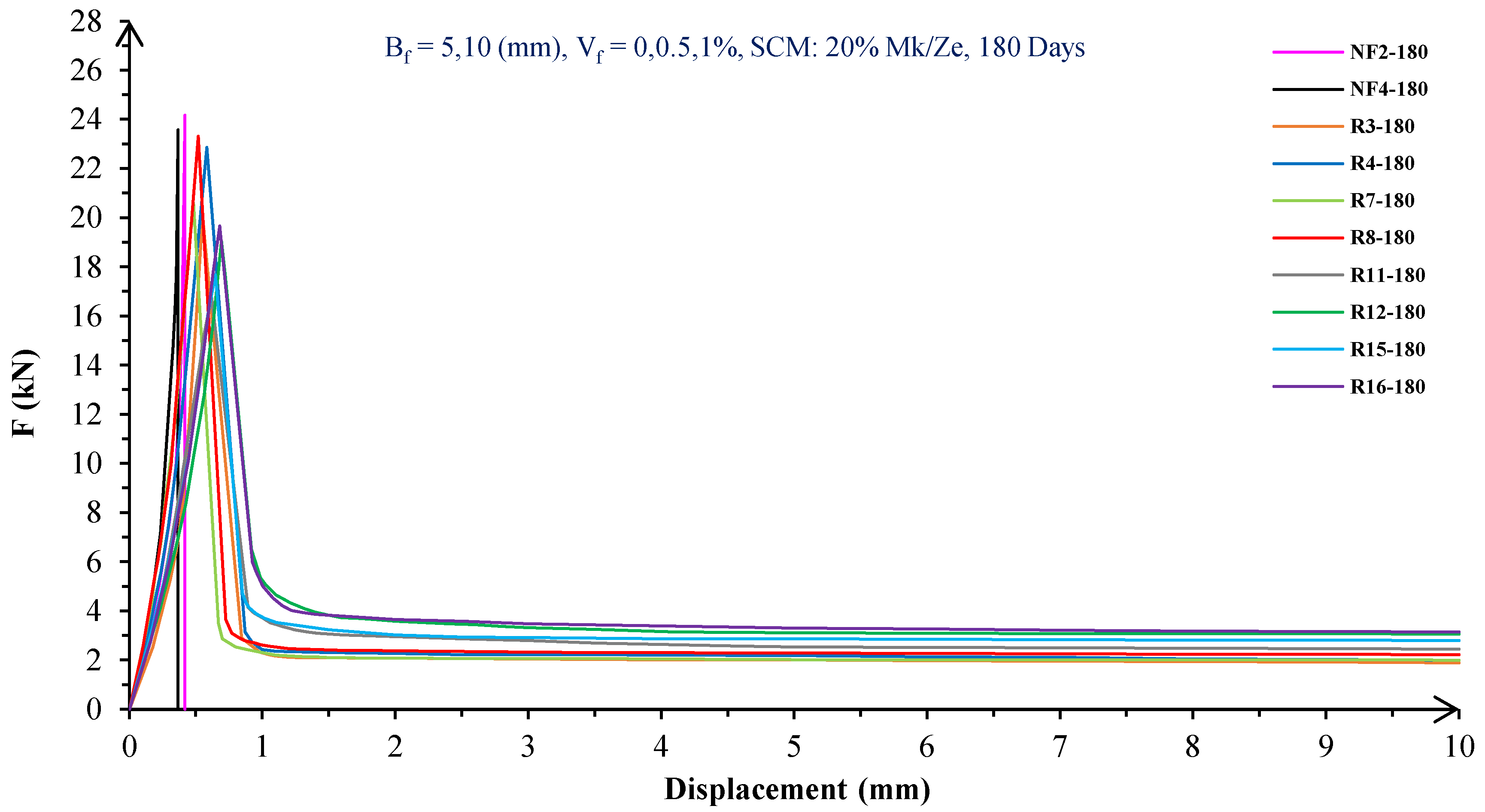

5.1.1. Flexural Behavior of RF Concrete

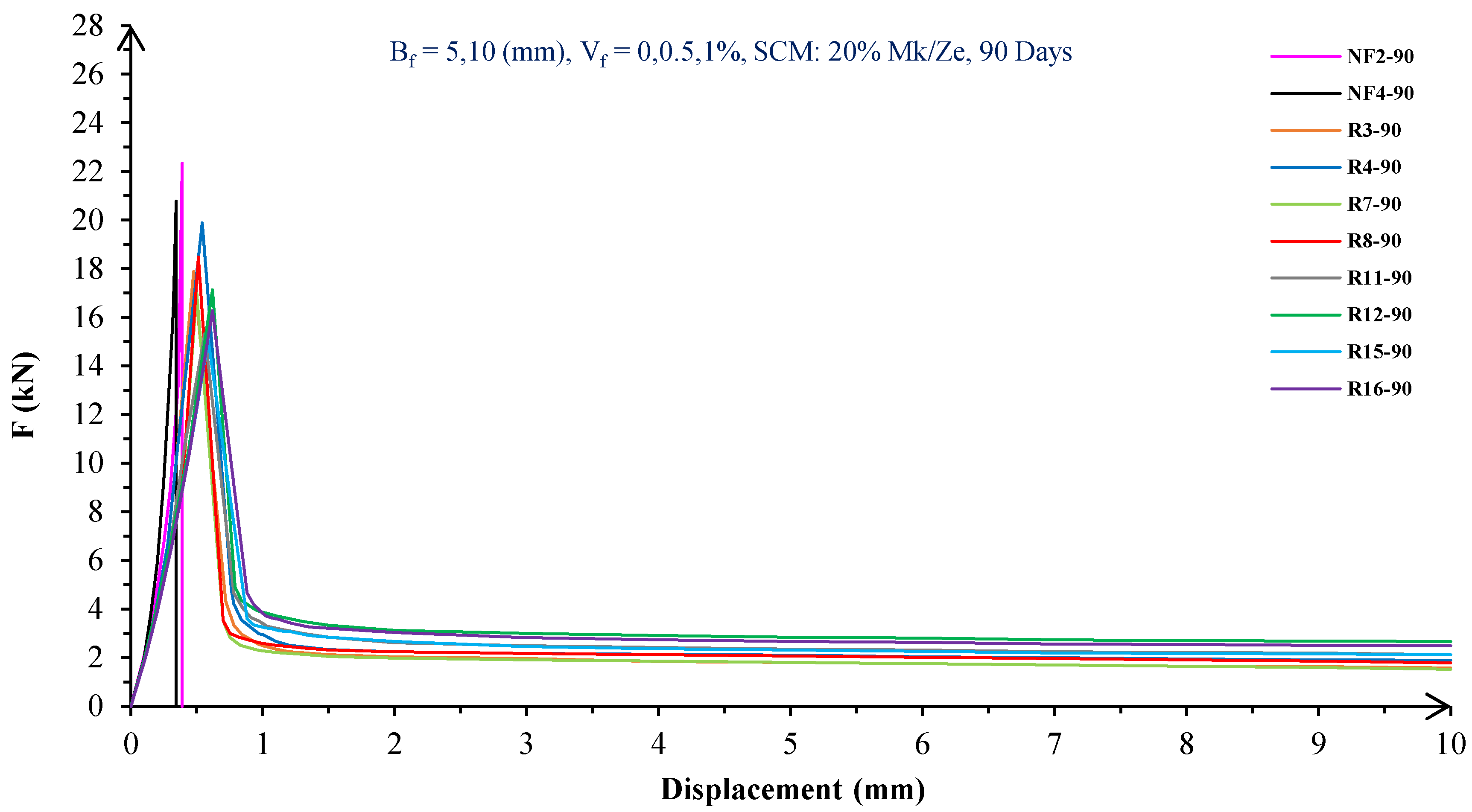

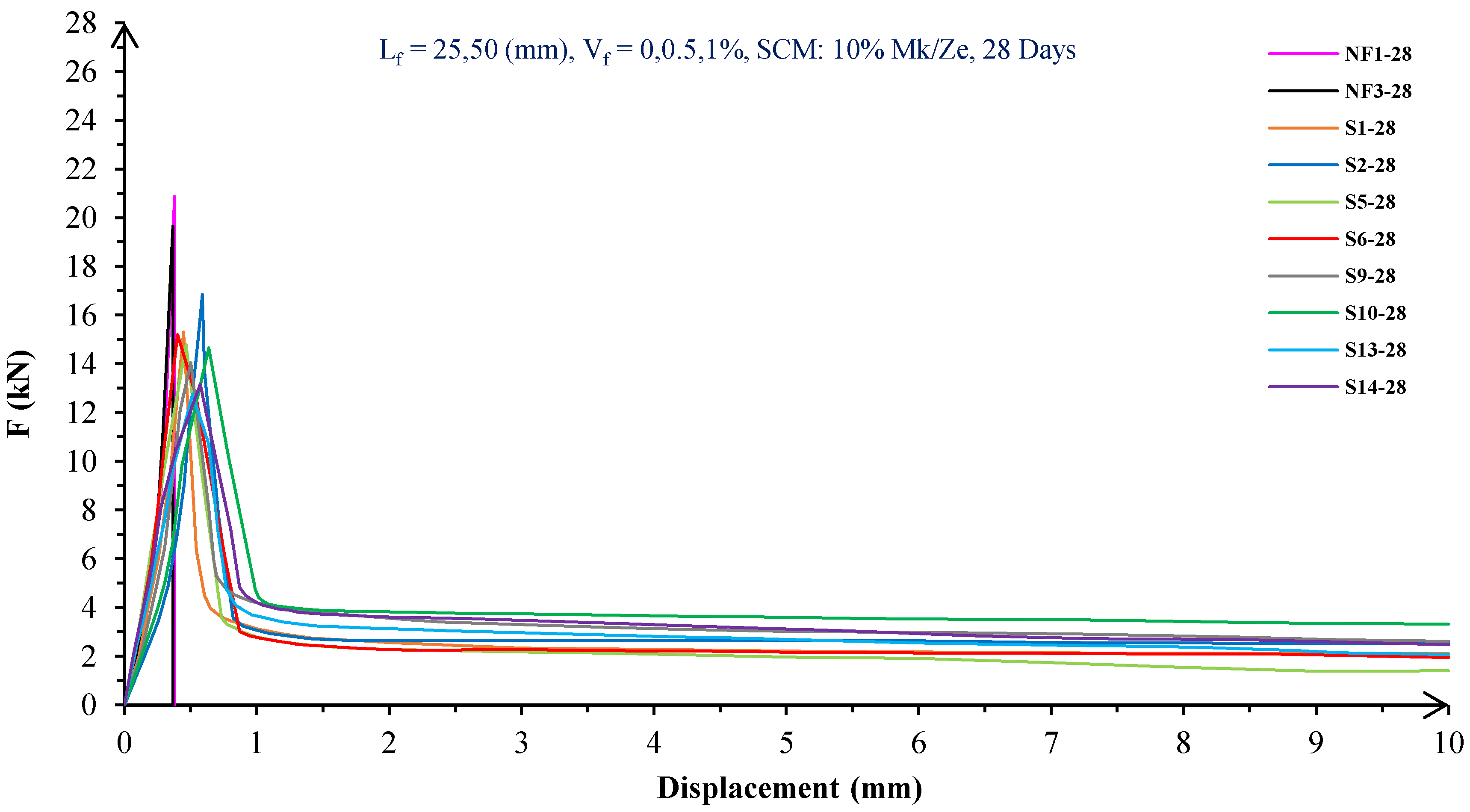

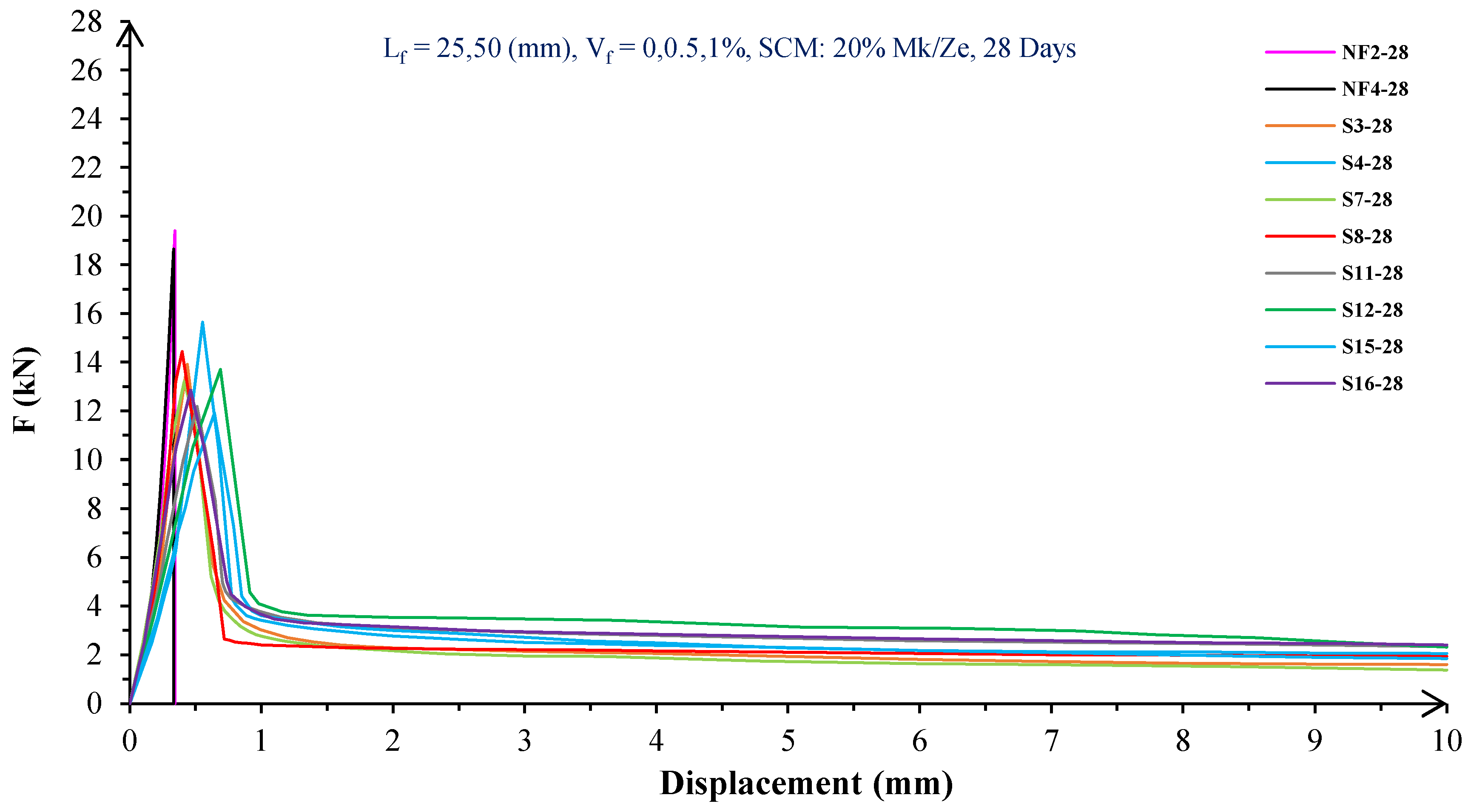

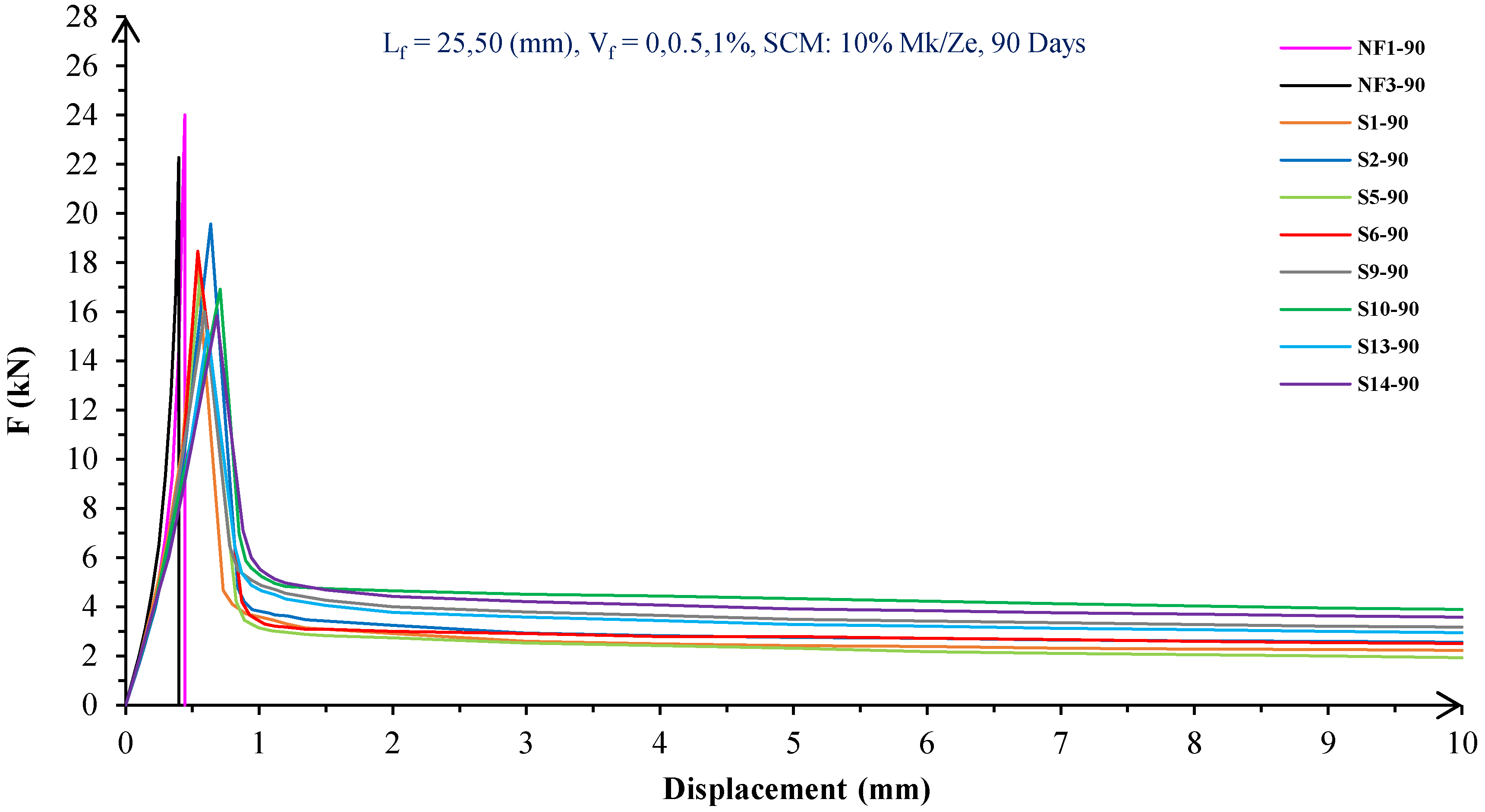

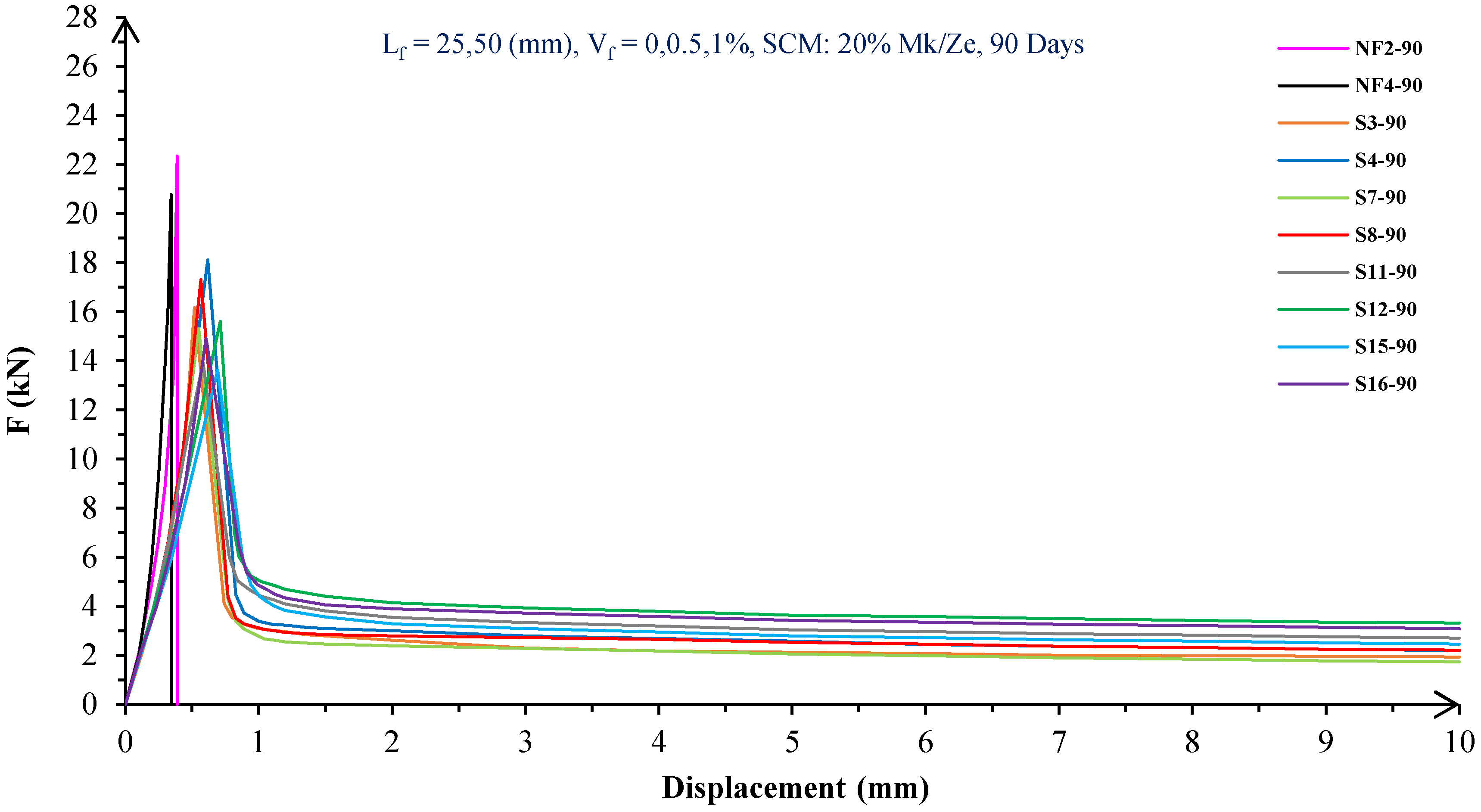

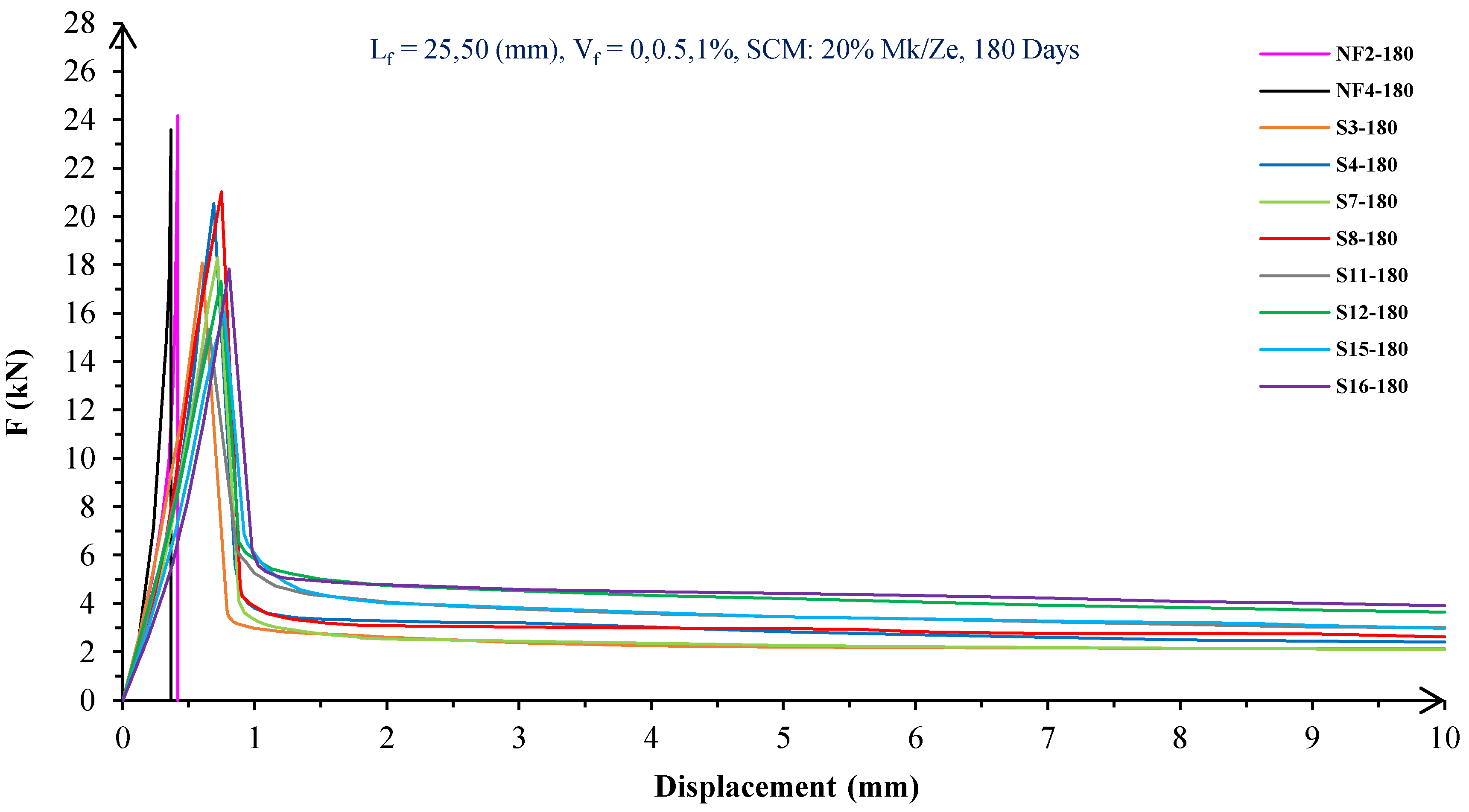

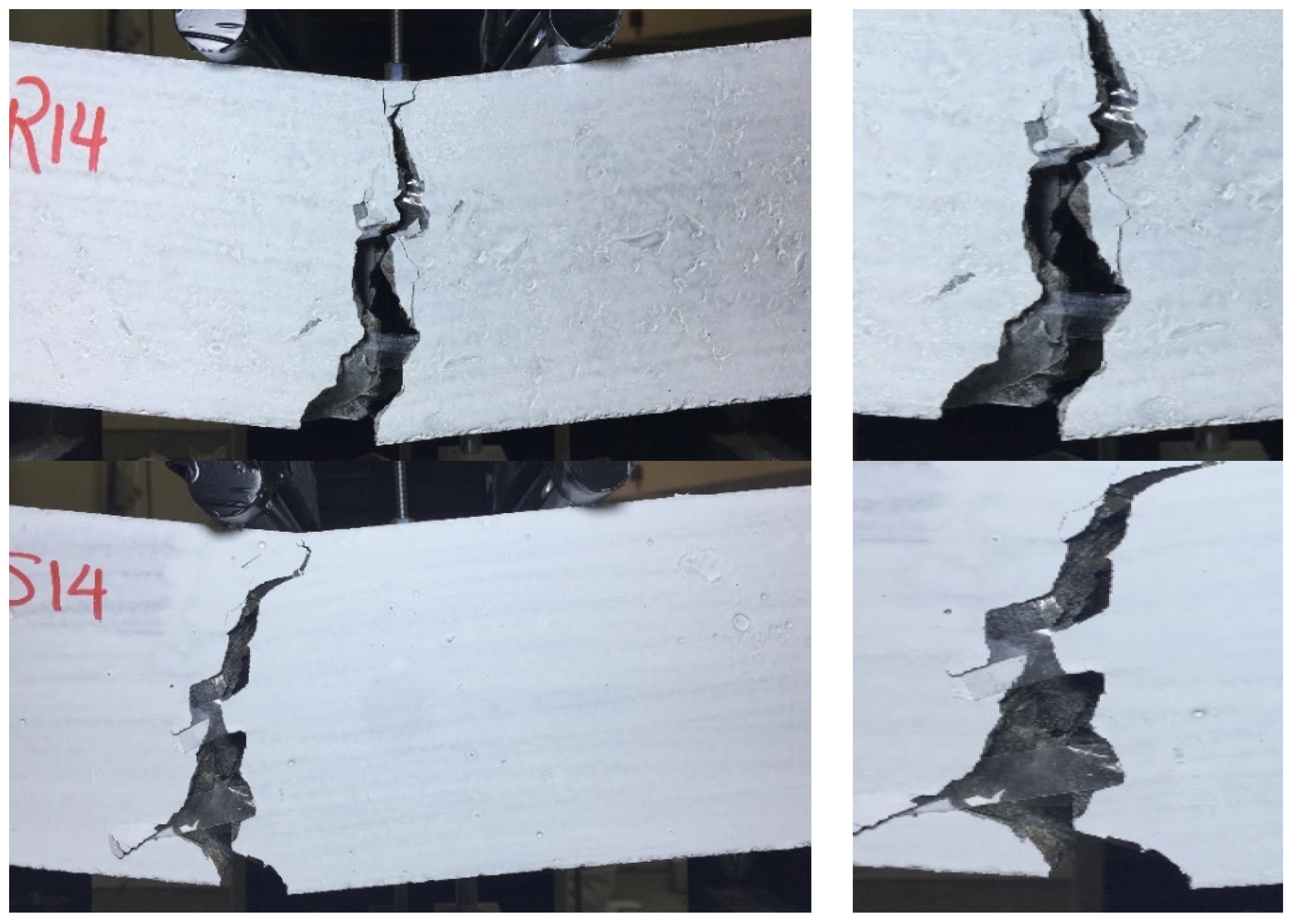

5.1.2. Flexural Behavior of SF Concrete

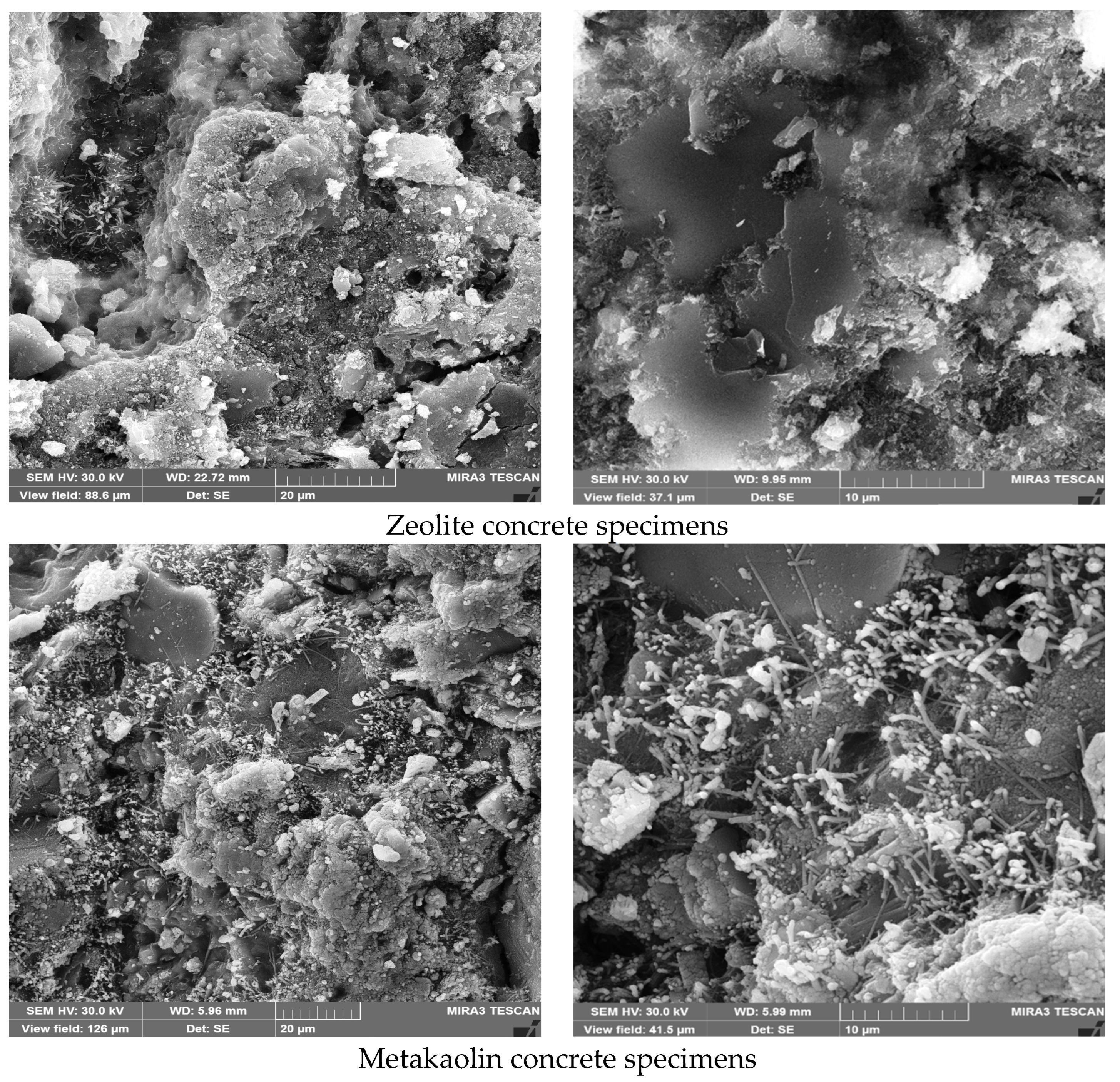

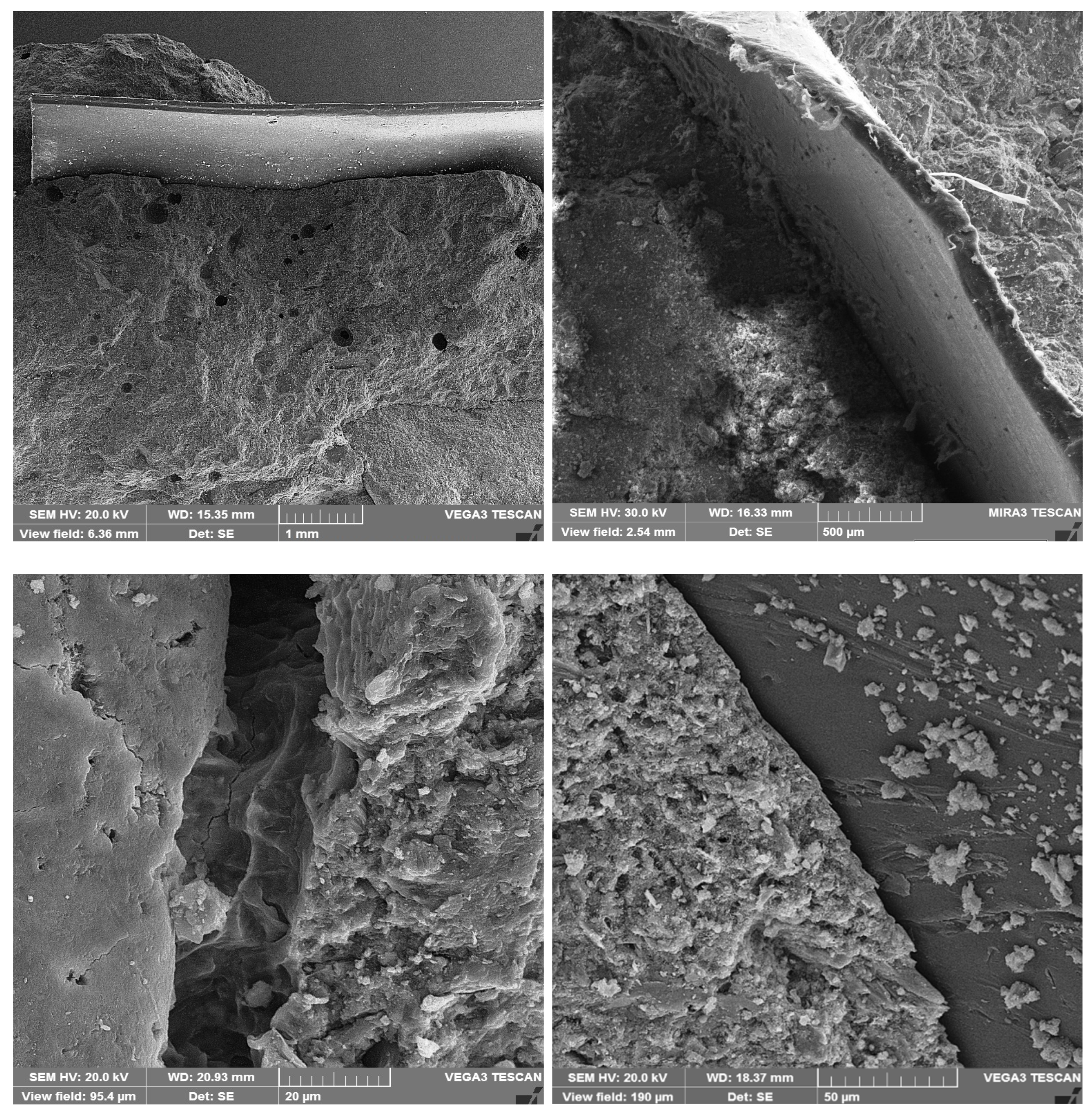

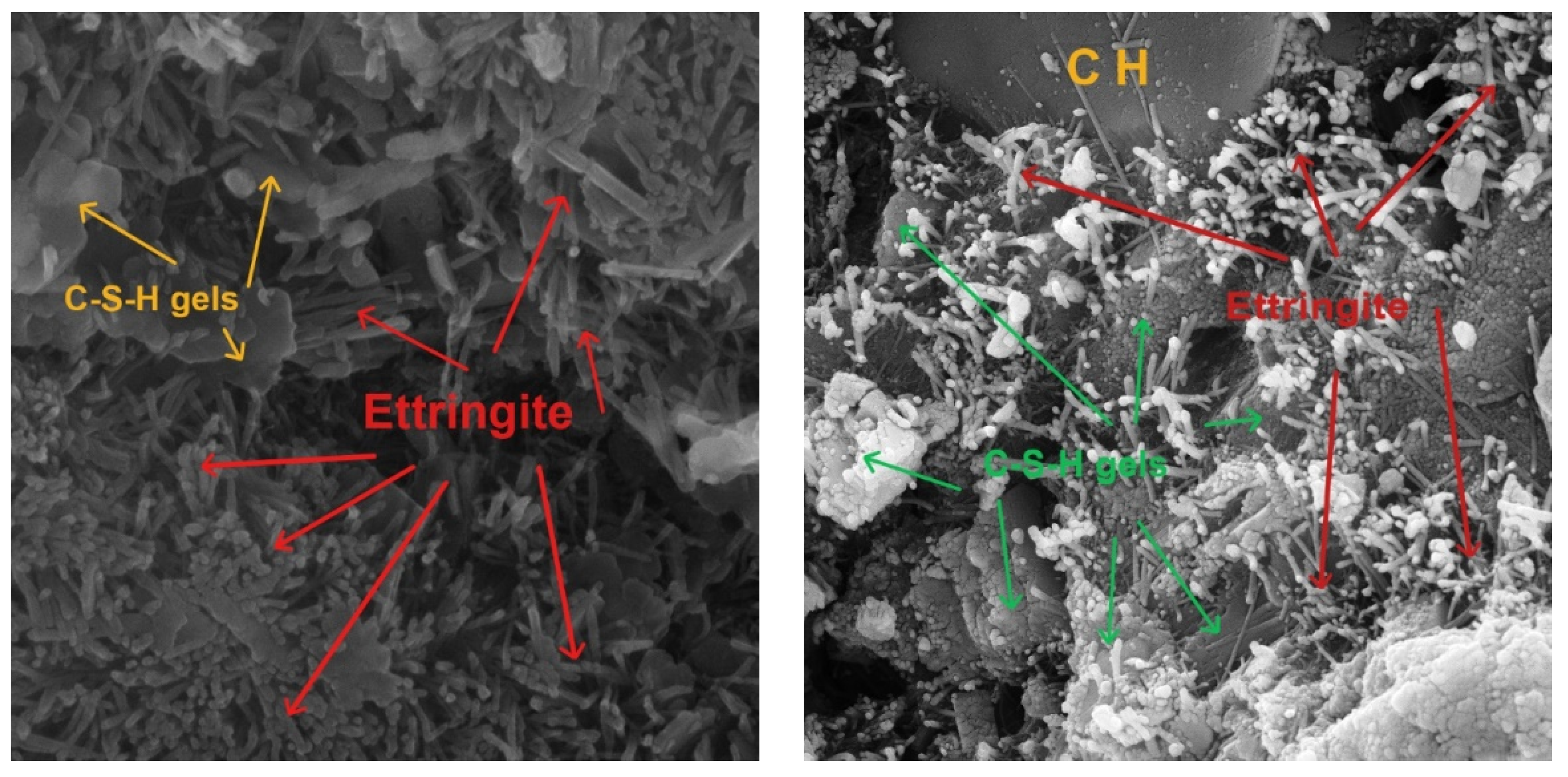

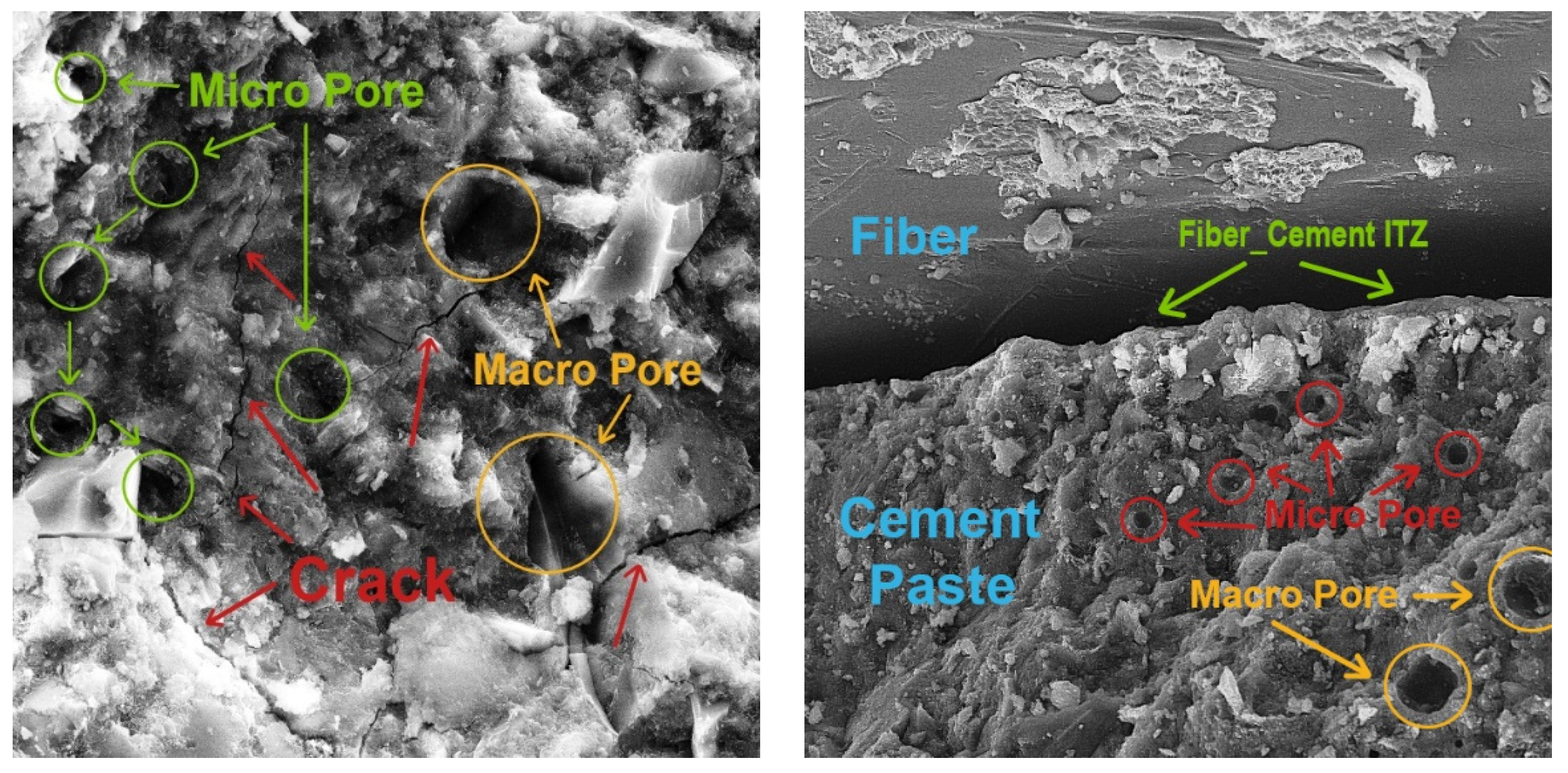

5.2. Scanning Electron Microscope (SEM)

6. Conclusions

- The maximum load capacities of green concrete beams with RF/SF were decreased up to 31 and 37% compared to control specimens, respectively. Although in the short term, the maximum load capacity for metakaolin concrete was greater than zeolite concrete, the results were reversed in the long term.

- Green concrete beams containing RF had maximum load capacity up to 13% greater than green concrete beams containing SF.

- The flexural toughness values of green concrete with 0.5 and 1% RF were increased up to 11 and 16 times more than the control specimens, respectively.

- The flexural toughness values of 0.5 and 1% SF-reinforced concrete containing metakaolin and zeolite were increased up to 14 and 20 times more than the control specimens, respectively.

- The flexural toughness of green concrete beams with SF was 24% greater than green concrete beams containing RF.

- In the short term, the flexural toughness of beams containing metakaolin increased by up to 13% than zeolite concrete beams. But, for long periods, beams with zeolite exhibited 8% greater flexural toughness than those with metakaolin.

- The evaluation of the SEM showed that although the use of microplastic fibers increased the porosity of concrete, adding SCMs (metakaolin/zeolite) to concrete mixes greatly reduced the porosity and its negative effects. Also, the fiber–SCM coupling performance was better than those of the separate elements.

- By using SCMs (metakaolin/zeolite) and recycled disposable glass fibers in concrete mixtures, air and marine pollution decrease, ductility increases, and cracks are limited; thus, the durability and service life of marine concrete structures are enhanced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Valipour, M.; Yekkalar, M.; Shekarchi, M. Panahi, Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Najimi, M.; Sobhani, J.; Ahmadi, B.; Shekarchi, M. An experimental study on durability properties of concrete containing zeolite as a highly reactive natural pozzolan. Constr. Build. Mater. 2012, 35, 1023–1033. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Valipour, M.; Shekarchi, M.; Arezoumandi, M. Chlorine diffusion resistivity of sustainable green concrete in harsh marine environments. J. Clean. Prod. 2017, 142, 4092–4100. [Google Scholar] [CrossRef]

- Tran, Y.T.; Lee, J.; Kumar, P.; Kim, K.-H.; Lee, S.S. Natural zeolite and its application in concrete composite production. Compos. Part B Eng. 2019, 165, 354–364. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Shahrabadi, H.; Sayareh, S.; Sarkardeh, H. Effect of Natural Zeolite-Pozzolan on Compressive Strength of Oil-Polluted Concrete Marine Structures. Civ. Eng. J. 2018, 2, 623. [Google Scholar] [CrossRef]

- Shahrabadi, H.; Sayareh, S.; Sarkardeh, H. Effect of silica fume on compressive strength of oil-polluted concrete in different marine environments. China Ocean Eng. 2017, 31, 716–723. [Google Scholar] [CrossRef]

- Kavitha, O.R.; Shanthi, V.M.; Arulraj, G.P.; Sivakumar, P. Fresh, micro- and macrolevel studies of metakaolin blended self-compacting concrete. Appl. Clay Sci. 2015, 114, 370–374. [Google Scholar] [CrossRef]

- Ahmadi, B.; Shekarchi, M. Use of natural zeolite as a supplementary cementitious material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Iswarya, G.; Beulah, M. Use of zeolite and industrial waste materials in high strength concrete—A review. Mater. Today Proc. 2021, 46, 116–123. [Google Scholar] [CrossRef]

- Qian, X.; Li, Z. The relationships between stress and strain for high-performance concrete with metakaolin. Cem. Concr. Res. 2001, 31, 1607–1611. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z. Enhancement of mechanical properties in polypropylene– and nylon–fibre reinforced oil palm shell concrete. Mater. Des. 2013, 49, 1034–1041. [Google Scholar] [CrossRef]

- Alyousef, R.; Mohammadhosseini, H.; Tahir, M.M.; Alabduljabbar, H. Green concrete composites production comprising metalized plastic waste fibers and palm oil fuel ash. Mater. Today Proc. 2021, 39, 911–916. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- Gautam, L.; Jain, J.K.; Kalla, P.; Choudhary, S. Materials Today: Proceedings a review on the utilization of ceramic waste in sustainable construction products. Mater. Today Proc. 2021, 43, 1884–1891. [Google Scholar] [CrossRef]

- Alani, A.H.; Johari, M.A.M.; Noaman, A.T.; Bunnori, N.M.; Majid, T.A. Effect of the incorporation of PET fiber and ternary blended binder on the flexural and tensile behaviour of ultra-high performance green concrete. Constr. Build. Mater. 2022, 331, 127306. [Google Scholar] [CrossRef]

- Al-Darzi, S.Y. The effect of using shredded plastic on the behavior of reinforced concrete slab. Case Stud. Constr. Mater. 2022, 17, e01681. [Google Scholar] [CrossRef]

- Dong, C.; Zhang, Q.; Chen, C.; Jiang, T.; Guo, Z.; Liu, Y.; Lin, S. Fresh and hardened properties of recycled plastic fiber reinforced self-compacting concrete made with recycled concrete aggregate and fly ash, slag, silica fume. J. Build. Eng. 2022, 62, 105384. [Google Scholar] [CrossRef]

- Gautam, L.; Kumar, J.; Jain, A.; Kalla, P. Valorization of bone-China ceramic powder waste along with granite waste in self-compacting concrete. Constr. Build. Mater. 2022, 315, 125730. [Google Scholar] [CrossRef]

- De Oliveira, L.A.P.; Castro-Gomes, J.P. Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Constr. Build. Mater. 2011, 25, 1712–1717. [Google Scholar] [CrossRef]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Khalid, F.S.; Irwan, J.M.; Ibrahim, M.H.W.; Othman, N.; Shahidan, S. Performance of plastic wastes in fiber-reinforced concrete beams. Constr. Build. Mater. 2018, 183, 451–464. [Google Scholar] [CrossRef]

- Shayanfar, M.; Shahrabadi, H. Flexural behavior of green RC beams with disposable glasses fibers in a marine environment. Case Stud. Constr. Mater. 2023, 18, e01972. [Google Scholar] [CrossRef]

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. ASTM: West Conshohocken, PA, USA, 2003; Volume 95, pp. 1–2.

- ASTM C204; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability. ASTM: West Conshohocken, PA, USA, 2009.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2001. [CrossRef]

- Meza, A.; Siddique, S. Effect of aspect ratio and dosage on the flexural response of FRC with recycled fiber. Constr. Build. Mater. 2019, 213, 286–291. [Google Scholar] [CrossRef]

- ASTM C78-08; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2008. [CrossRef]

- ASTM C1609/C1609M-12; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Martínez-López, M.; Martínez-Barrera, G.; Barrera-Díaz, C.; Ureña-Núñez, F.; Brostow, W. Waste Materials from Tetra Pak Packages as Reinforcement of Polymer Concrete. Int. J. Polym. Sci. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Wei, Y.; Qin, Y.; Chai, J.; Xu, C.; Zhang, Y.; Zhang, X. Experimental Study on Compressive and Flexural Performances of Polypropylene Fiber-Reinforced Concrete. Geofluids 2022, 2022, 1–24. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Awoyera, P.O.; Rondon, C.; Echeverría, A.M.; Kolawole, J.T. A Review of the Engineering Properties of Metakaolin Based Concrete: Towards Combatting Chloride Attack in Coastal/Marine Structures. Adv. Civ. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Gowram, I.; Sudhir, M.R.; Mohan, M.K.; Jain, D. Efficacy of Natural Zeolite and Metakaolin as Partial Alternatives to Cement in Fresh and Hardened High Strength Concrete. Adv. Mater. Sci. Eng. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Jain, A.; Sharma, N.; Choudhary, R.; Gupta, R.; Chaudhary, S. Utilization of non-metalized plastic bag fibers along with fly ash in concrete. Constr. Build. Mater. 2021, 291, 123329. [Google Scholar] [CrossRef]

- Ouldkhaoua, Y.; Benabed, B.; Abousnina, R.; Kadri, E.-H.; Khatib, J. Effect of using metakaolin as supplementary cementitious material and recycled CRT funnel glass as fine aggregate on the durability of green self-compacting concrete. Constr. Build. Mater. 2020, 235, 117802. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, C.; Chen, Z.; Ke, L. Study on Mechanical Properties and Optimum Fiber Content for Basalt/Polyacrylonitrile Hybrid Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 1–11. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Ghiasvand, E.; Nickseresht, I.; Mahdikhani, M.; Moodi, F. Influence of various amounts of limestone powder on performance of Portland limestone cement concretes. Cem. Concr. Compos. 2009, 31, 715–720. [Google Scholar] [CrossRef]

- Khan, S.U.; Nuruddin, M.F.; Shafiq, N. Strength Development of Concrete Incorporating Metakaolin and PVA Fibres. Appl. Mech. Mater. 2014, 567, 505–510. [Google Scholar] [CrossRef]

- Foti, D. Recycled waste PET for sustainable fiber-reinforced concrete. In Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 387–410. [Google Scholar] [CrossRef]

- Khan, S.U.; Ayub, T. Flexure and shear behaviour of self-compacting reinforced concrete beams with polyethylene terephthalate fibres and strips. Structures 2020, 25, 200–211. [Google Scholar] [CrossRef]

- Ahdal, A.Q.; Amrani, M.A.; Ghaleb, A.A.A.; Abadel, A.A.; Alghamdi, H.; Alamri, M.; Wasim, M.; Shameeri, M. Mechanical performance and feasibility analysis of green concrete prepared with local natural zeolite and waste PET plastic fibers as cement replacements. Case Stud. Constr. Mater. 2022, 17, e01256. [Google Scholar] [CrossRef]

- Kumaresan, M.; Nachiar, S.S.; Anandh, S. Implementation of waste recycled fibers in concrete: A review. Mater. Today Proc. 2022, 68, 1988–1994. [Google Scholar] [CrossRef]

| Composition (%) | Cement | Metakaolin | Zeolite |

|---|---|---|---|

| CaO | ≈63 | ≈1 | ≈8 |

| SiO2 | ≈21 | ≈81 | ≈58 |

| Al2O3 | ≈5 | ≈11 | ≈8 |

| Fe2O3 | ≈4 | ≈1 | ≈2 |

| MgO | ≈2 | ≈1 | ≈4 |

| K2O | 0 | ≈1 | ≈1 |

| Na2O | 0 | ≈1 | ≈1 |

| TiO2 | 0 | ≈0 | ≈0 |

| MnO | 0 | ≈0 | ≈0 |

| L.O.I | ≈4 | ≈3 | ≈19 |

| Specific gravity (ASTM C188) [27] | 3.15 | 2.45 | 2.18 |

| Specific surface area (m2/kg) (Blain: ASTM C204) [28] | 310 | 1200 | 320 |

| Aggregate | Water Absorption (%) | Specific Gravity |

|---|---|---|

| Fine | ≈2.9 | 2.64 |

| Coarse | ≈1.8 | 2.42 |

| Fiber Type | No | Width (cm) | Thickness (µm) | Diameter/ Length (cm) | Aspect Ratio | Density (kg/m3) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| Ring (R) | Ri1 | 0.5 | 30 | ≈6–6.5 | - | ≈680 | ≈570 |

| Ri2 | 1 | ||||||

| Strip (S) | St1 | 1 | 30 | 2.5 | ≈40 | ||

| St2 | 5 | ≈80 |

| Mix | Sand (kg/m3) | Gravel (kg/m3) | Water (kg/m3) | Binders (kg/m3) | Fibers (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement (C) | Metakaolin (Mk) | Zeolite (Ze) | Ring (R) | Strip (S) | ||||||||

| Ri1 | Ri2 | St1 | St2 | |||||||||

| NF1 | 664 | 1054 | 205 | 369 | 41 | - | - | - | ||||

| NF2 | 664 | 1054 | 205 | 328 | 82 | - | - | - | ||||

| NF3 | 664 | 1054 | 205 | 369 | - | 41 | - | - | ||||

| NF4 | 664 | 1054 | 205 | 328 | - | 82 | - | - | ||||

| R1 | 664 | 1054 | 205 | 369 | 41 | - | 3.4 | - | - | |||

| R2 | 664 | 1054 | 205 | 369 | 41 | - | - | 3.4 | - | |||

| R3 | 664 | 1054 | 205 | 328 | 82 | - | 3.4 | - | - | |||

| R4 | 664 | 1054 | 205 | 328 | 82 | - | - | 3.4 | - | |||

| R5 | 664 | 1054 | 205 | 369 | - | 41 | 3.4 | - | - | |||

| R6 | 664 | 1054 | 205 | 369 | - | 41 | - | 3.4 | - | |||

| R7 | 664 | 1054 | 205 | 328 | - | 82 | 3.4 | - | - | |||

| R8 | 664 | 1054 | 205 | 328 | - | 82 | - | 3.4 | - | |||

| R9 | 664 | 1054 | 205 | 369 | 41 | - | 6.8 | - | - | |||

| R10 | 664 | 1054 | 205 | 369 | 41 | - | - | 6.8 | - | |||

| R11 | 664 | 1054 | 205 | 328 | 82 | - | 6.8 | - | - | |||

| R12 | 664 | 1054 | 205 | 328 | 82 | - | - | 6.8 | - | |||

| R13 | 664 | 1054 | 205 | 369 | - | 41 | 6.8 | - | - | |||

| R14 | 664 | 1054 | 205 | 369 | - | 41 | - | 6.8 | - | |||

| R15 | 664 | 1054 | 205 | 328 | - | 82 | 6.8 | - | - | |||

| R16 | 664 | 1054 | 205 | 328 | - | 82 | - | 6.8 | - | |||

| S1 | 664 | 1054 | 205 | 369 | 41 | - | - | 3.4 | - | |||

| S2 | 664 | 1054 | 205 | 369 | 41 | - | - | - | 3.4 | |||

| S3 | 664 | 1054 | 205 | 328 | 82 | - | - | 3.4 | - | |||

| S4 | 664 | 1054 | 205 | 328 | 82 | - | - | - | 3.4 | |||

| S5 | 664 | 1054 | 205 | 369 | - | 41 | - | 3.4 | - | |||

| S6 | 664 | 1054 | 205 | 369 | - | 41 | - | - | 3.4 | |||

| S7 | 664 | 1054 | 205 | 328 | - | 82 | - | 3.4 | - | |||

| S8 | 664 | 1054 | 205 | 328 | - | 82 | - | - | 3.4 | |||

| S9 | 664 | 1054 | 205 | 369 | 41 | - | - | 6.8 | - | |||

| S10 | 664 | 1054 | 205 | 369 | 41 | - | - | - | 6.8 | |||

| S11 | 664 | 1054 | 205 | 328 | 82 | - | - | 6.8 | - | |||

| S12 | 664 | 1054 | 205 | 328 | 82 | - | - | - | 6.8 | |||

| S13 | 664 | 1054 | 205 | 369 | - | 41 | - | 6.8 | - | |||

| S14 | 664 | 1054 | 205 | 369 | - | 41 | - | - | 6.8 | |||

| S15 | 664 | 1054 | 205 | 328 | - | 82 | - | 6.8 | - | |||

| S16 | 664 | 1054 | 205 | 328 | - | 82 | - | - | 6.8 | |||

| Chemical | PH | Hardness | Alkalinity | SO4 2− | NO2− | NO3− | Cl− | Ca | Mg | NH3 | Zn | Al | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lab water | ≈6.7 | 45 | 20 | 100 | 0.01 | 2.82 | 5 | 4 | ≈0 | ≈0 | ≈0 | 0.3 | 0.02 | ≈0 |

| Sea water | ≈8 | 225 | 120 | ≈0 | ≈0 | 0.22 | 5 | 68 | 95 | 1.3 | 0.2 | 0.3 | 0.02 | 0.04 |

| Chemical | March | April | May | June | July | August | September | October | November |

|---|---|---|---|---|---|---|---|---|---|

| Min temperature (°C) | 27–21 | 31–27 | 31–29 | 30–27 | 30–27 | 28–27 | 28–24 | 24–20 | 21–17 |

| Max temperature (°C) | 31–26 | 35–30 | 37–32 | 33–30 | 34–31 | 33–31 | 33–29 | 31–28 | 30–24 |

| Air humidity (%) | 75–70 | 85–80 | 90–85 | 85–80 | 70–65 | 80–75 | 75–70 | 65–60 | 55–50 |

| Mix | Pmax (kN) | Mix | Pmax (kN) | ||||

|---|---|---|---|---|---|---|---|

| 28 | 90 | 180 | 28 | 90 | 180 | ||

| N1 | 20.88 | 24.01 | 26.35 | R15 | 13.08 | 15.07 | 17.68 |

| N2 | 19.42 | 22.35 | 24.17 | R16 | 13.73 | 16.27 | 19.67 |

| N3 | 19.65 | 22.27 | 25.60 | S1 | 15.31 | 17.97 | 20.33 |

| N4 | 18.65 | 20.78 | 23.59 | S2 | 16.87 | 19.57 | 21.95 |

| R1 | 16.54 | 19.68 | 22.75 | S3 | 13.92 | 16.17 | 18.09 |

| R2 | 17.49 | 21.39 | 24.88 | S4 | 15.66 | 18.12 | 20.54 |

| R3 | 15.34 | 17.89 | 20.08 | S5 | 14.79 | 17.52 | 20.98 |

| R4 | 16.71 | 19.89 | 22.86 | S6 | 15.21 | 18.46 | 22.66 |

| R5 | 15.75 | 19.03 | 23.45 | S7 | 13.23 | 15.30 | 18.30 |

| R6 | 16.43 | 20.21 | 25.18 | S8 | 14.45 | 17.30 | 21.03 |

| R7 | 14.55 | 17.01 | 20.59 | S9 | 14.05 | 15.98 | 17.91 |

| R8 | 15.14 | 18.49 | 23.32 | S10 | 14.67 | 16.92 | 18.86 |

| R9 | 15.34 | 17.63 | 19.81 | S11 | 12.20 | 13.94 | 15.35 |

| R10 | 15.98 | 18.60 | 21.03 | S12 | 13.71 | 15.60 | 17.32 |

| R11 | 13.73 | 15.32 | 16.78 | S13 | 12.76 | 15.23 | 18.44 |

| R12 | 14.79 | 17.13 | 19.06 | S14 | 13.17 | 15.83 | 19.59 |

| R13 | 14.19 | 16.93 | 20.29 | S15 | 11.91 | 13.63 | 16.06 |

| R14 | 14.76 | 17.07 | 22.46 | S16 | 12.86 | 14.92 | 17.83 |

| Mix | T (kN.m) | Mix | T (kN.m) | ||||

|---|---|---|---|---|---|---|---|

| 28 | 90 | 180 | 28 | 90 | 180 | ||

| N1 | 2.40 | 2.64 | 2.84 | R15 | 23.97 | 28.21 | 33.90 |

| N2 | 2.13 | 2.30 | 2.46 | R16 | 26.88 | 32.14 | 39.37 |

| N3 | 2.28 | 2.46 | 2.67 | S1 | 25.92 | 29.17 | 32.33 |

| N4 | 2.06 | 2.17 | 2.35 | S2 | 29.47 | 33.37 | 37.40 |

| R1 | 22.24 | 24.93 | 27.20 | S3 | 23.28 | 25.76 | 28.00 |

| R2 | 24.77 | 27.73 | 30.58 | S4 | 27.44 | 30.71 | 33.93 |

| R3 | 20.40 | 23.03 | 25.11 | S5 | 23.79 | 27.96 | 33.49 |

| R4 | 23.71 | 26.58 | 28.69 | S6 | 27.16 | 32.51 | 39.50 |

| R5 | 20.77 | 23.91 | 28.09 | S7 | 21.87 | 24.89 | 28.79 |

| R6 | 23.22 | 27.42 | 33.05 | S8 | 24.76 | 29.43 | 35.41 |

| R7 | 19.35 | 22.02 | 25.39 | S9 | 34.06 | 39.39 | 44.72 |

| R8 | 21.58 | 24.70 | 29.02 | S10 | 39.86 | 46.65 | 53.77 |

| R9 | 28.70 | 32.85 | 36.80 | S11 | 30.35 | 34.73 | 39.09 |

| R10 | 33.08 | 38.16 | 43.55 | S12 | 35.33 | 40.78 | 46.25 |

| R11 | 24.97 | 28.34 | 31.60 | S13 | 30.66 | 37.26 | 45.66 |

| R12 | 28.46 | 33.33 | 37.75 | S14 | 35.36 | 43.70 | 55.44 |

| R13 | 25.94 | 30.91 | 37.18 | S15 | 27.43 | 32.63 | 39.75 |

| R14 | 29.55 | 36.14 | 44.94 | S16 | 31.34 | 38.50 | 47.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shayanfar, M.A.; Shahrabadi, H. Investigating the Effects of Recycled Plastic as Fibers on Bending Behavior of Green Concrete Beams Exposed to Marine Environment. Materials 2023, 16, 5912. https://doi.org/10.3390/ma16175912

Shayanfar MA, Shahrabadi H. Investigating the Effects of Recycled Plastic as Fibers on Bending Behavior of Green Concrete Beams Exposed to Marine Environment. Materials. 2023; 16(17):5912. https://doi.org/10.3390/ma16175912

Chicago/Turabian StyleShayanfar, Mohsen Ali, and Hamid Shahrabadi. 2023. "Investigating the Effects of Recycled Plastic as Fibers on Bending Behavior of Green Concrete Beams Exposed to Marine Environment" Materials 16, no. 17: 5912. https://doi.org/10.3390/ma16175912

APA StyleShayanfar, M. A., & Shahrabadi, H. (2023). Investigating the Effects of Recycled Plastic as Fibers on Bending Behavior of Green Concrete Beams Exposed to Marine Environment. Materials, 16(17), 5912. https://doi.org/10.3390/ma16175912