A Novel Nickel-Plated Carbon Fiber Insert in Aluminum Joints with Thermoplastic ABS Polymer or Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

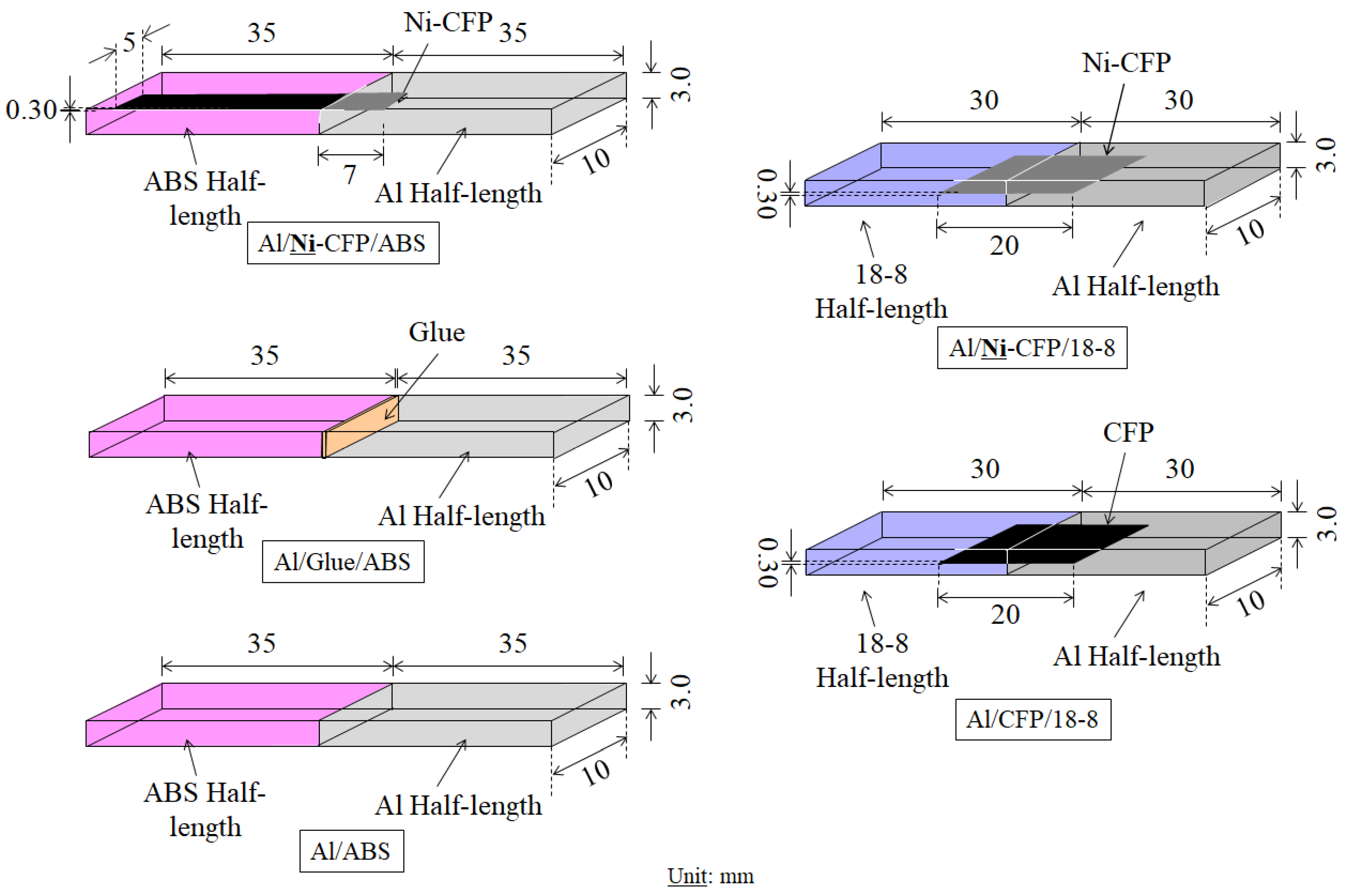

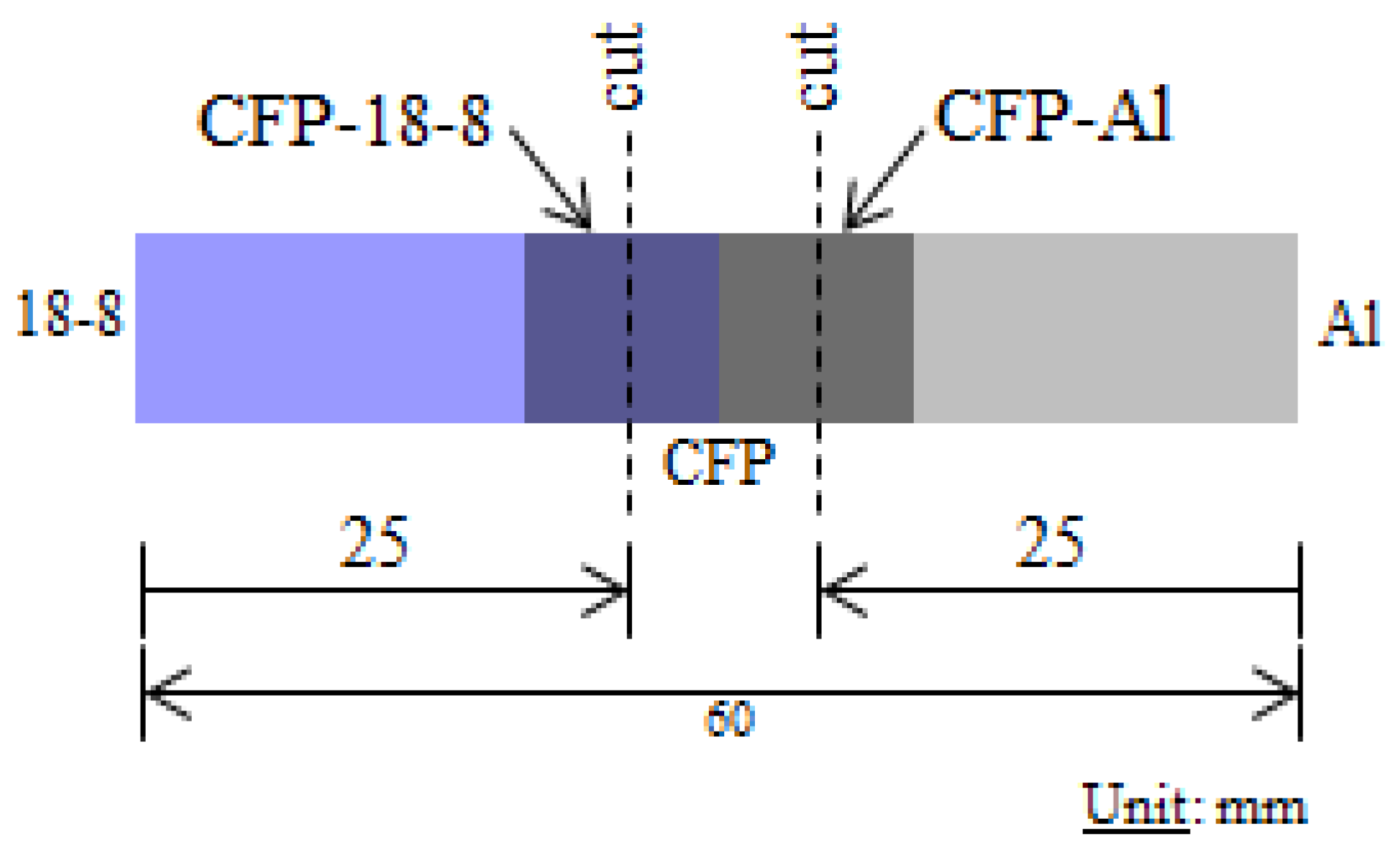

2.1. Sample Preparation

2.2. Ni Coating Process (STEP 1)

2.3. Al/Ni-CFP/ABS Joint (STEPS 2 and 3)

2.4. Al/Ni-CFP/18-8 Joint (STEPS 2 and 3)

2.5. Tensile Testing and Characterization

3. Results and Discussion

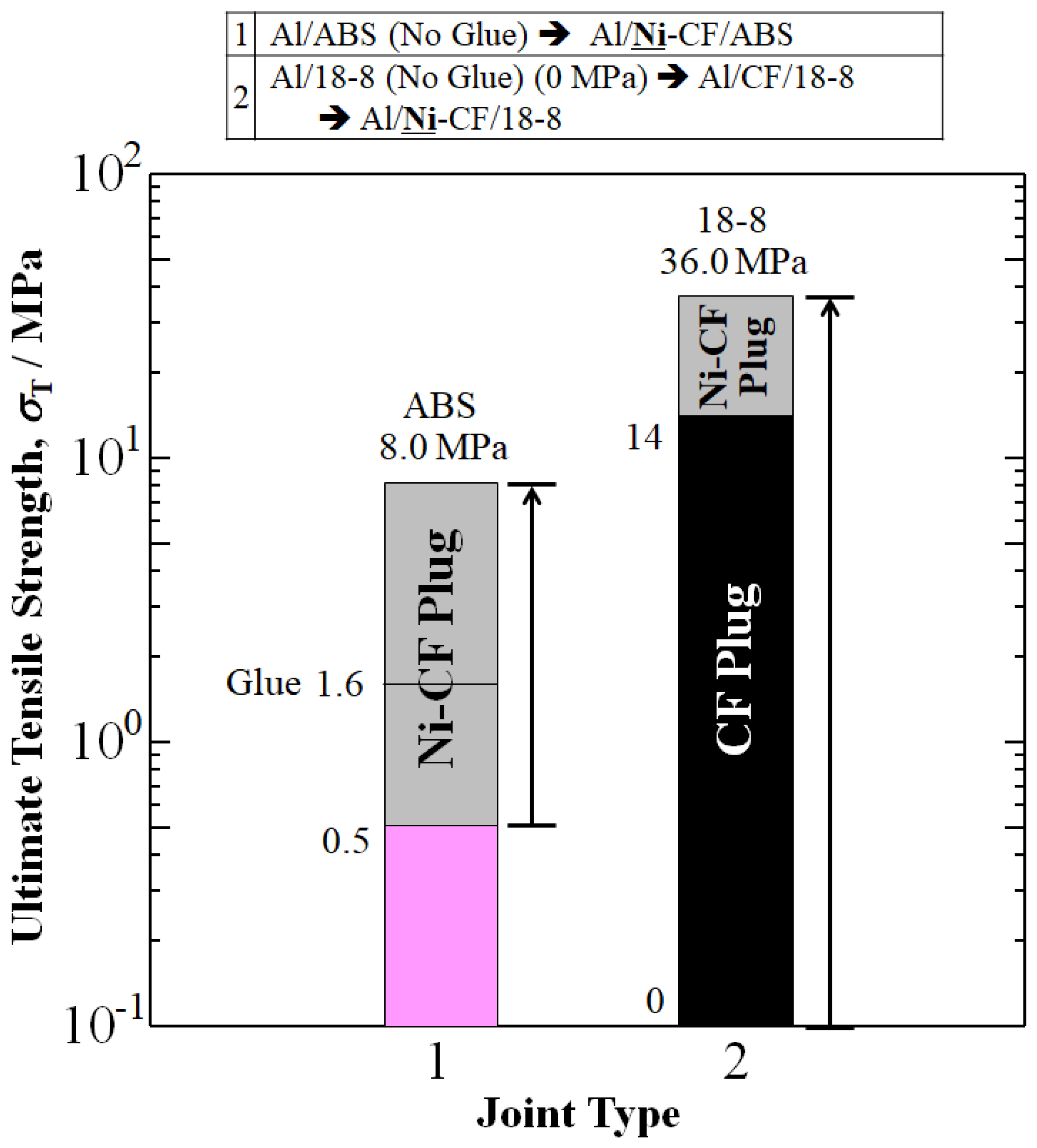

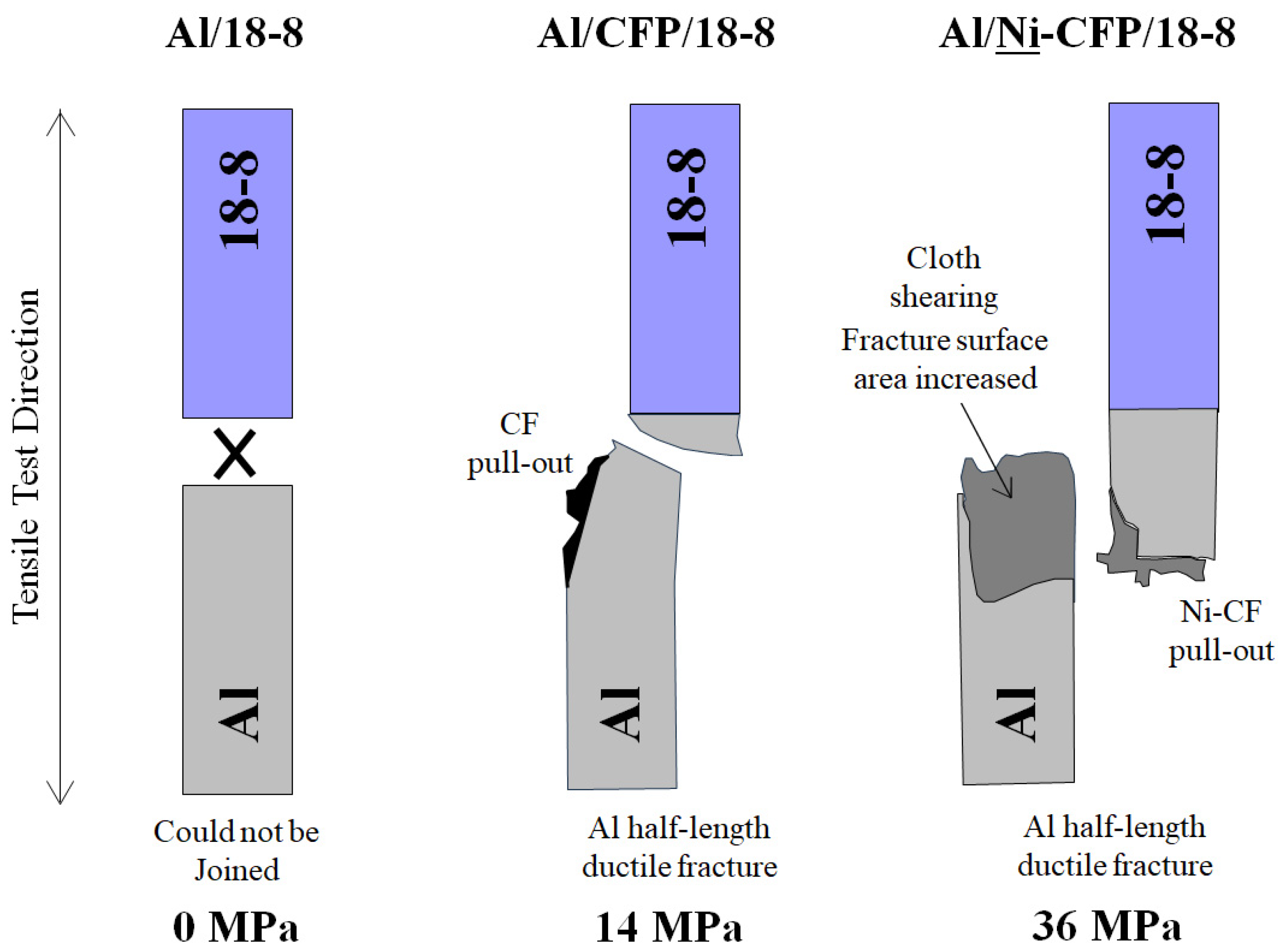

3.1. Increase in UTS by Ni-CFP Plug

Al/Ni-CFP/ABS (16 times), and no adhesion of Al/18-8 to Al/Ni-CFP/18-8.

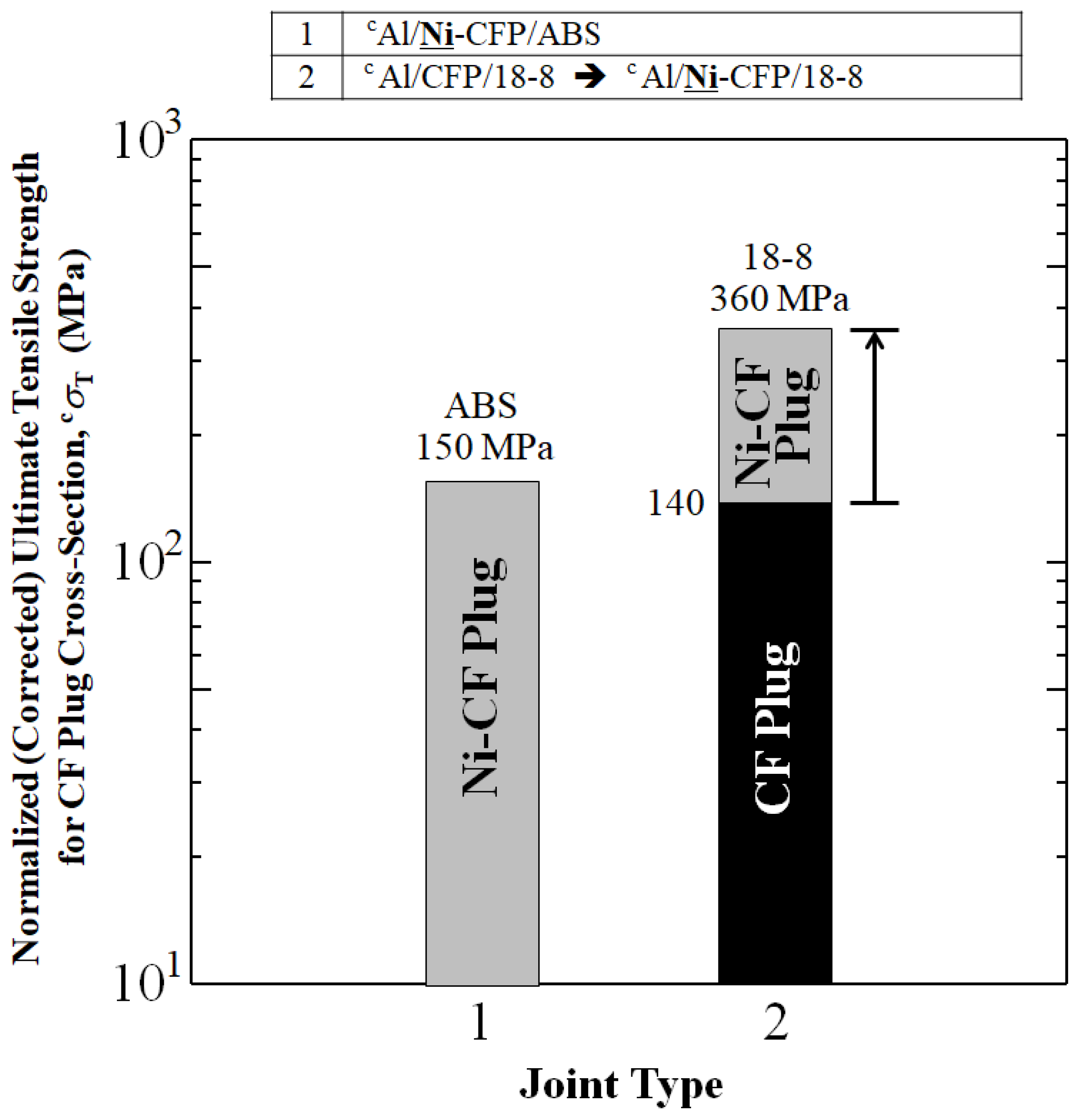

Al/Ni-CFP/ABS (16 times), and no adhesion of Al/18-8 to Al/Ni-CFP/18-8.3.2. Rule of Mixtures Calculation for Corrected (Normalized) cσT (cUTS) for CFRP Fractional Cross-Sectional Area

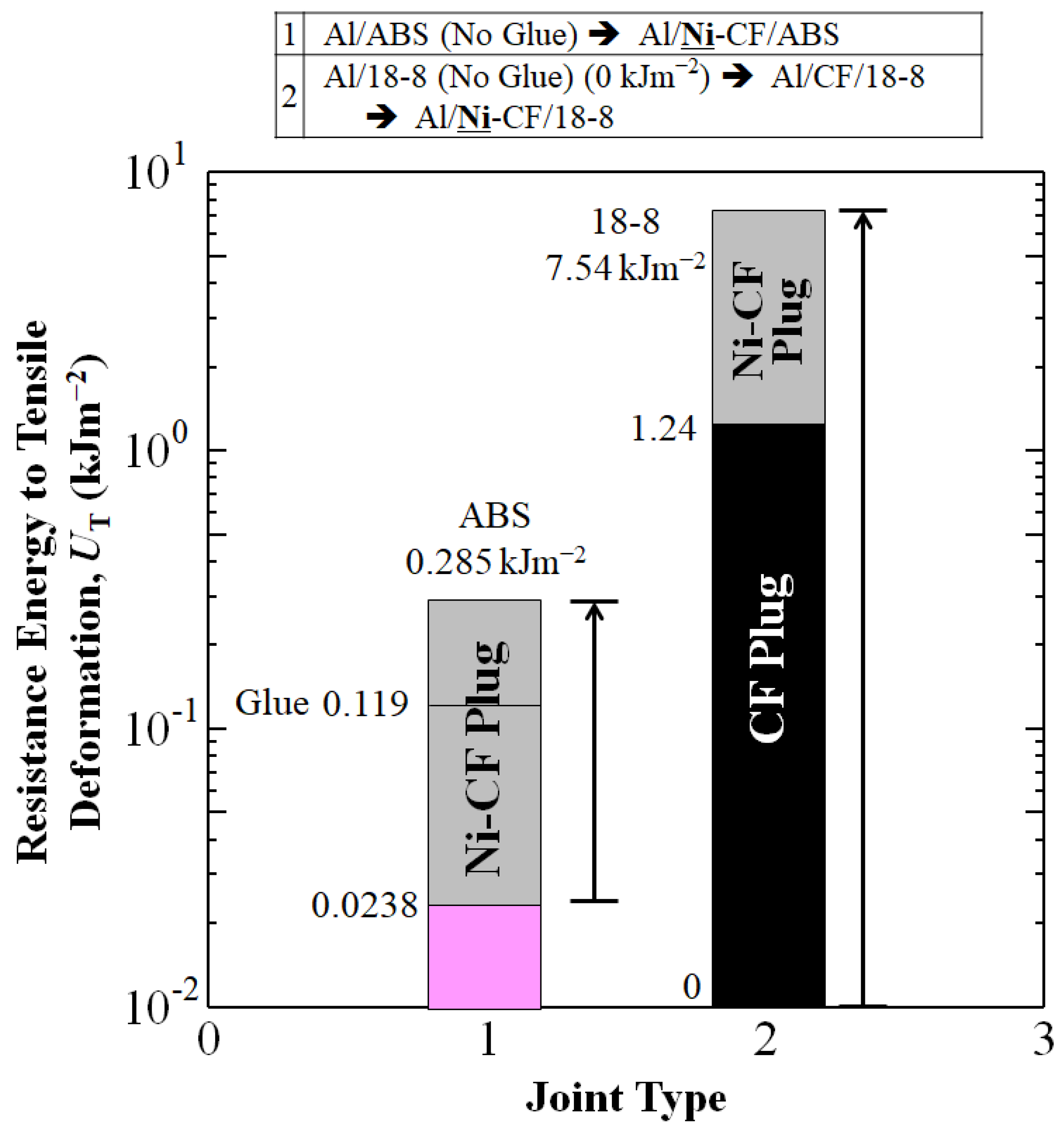

3.3. Resistance Energy to Tensile Deformation, UT

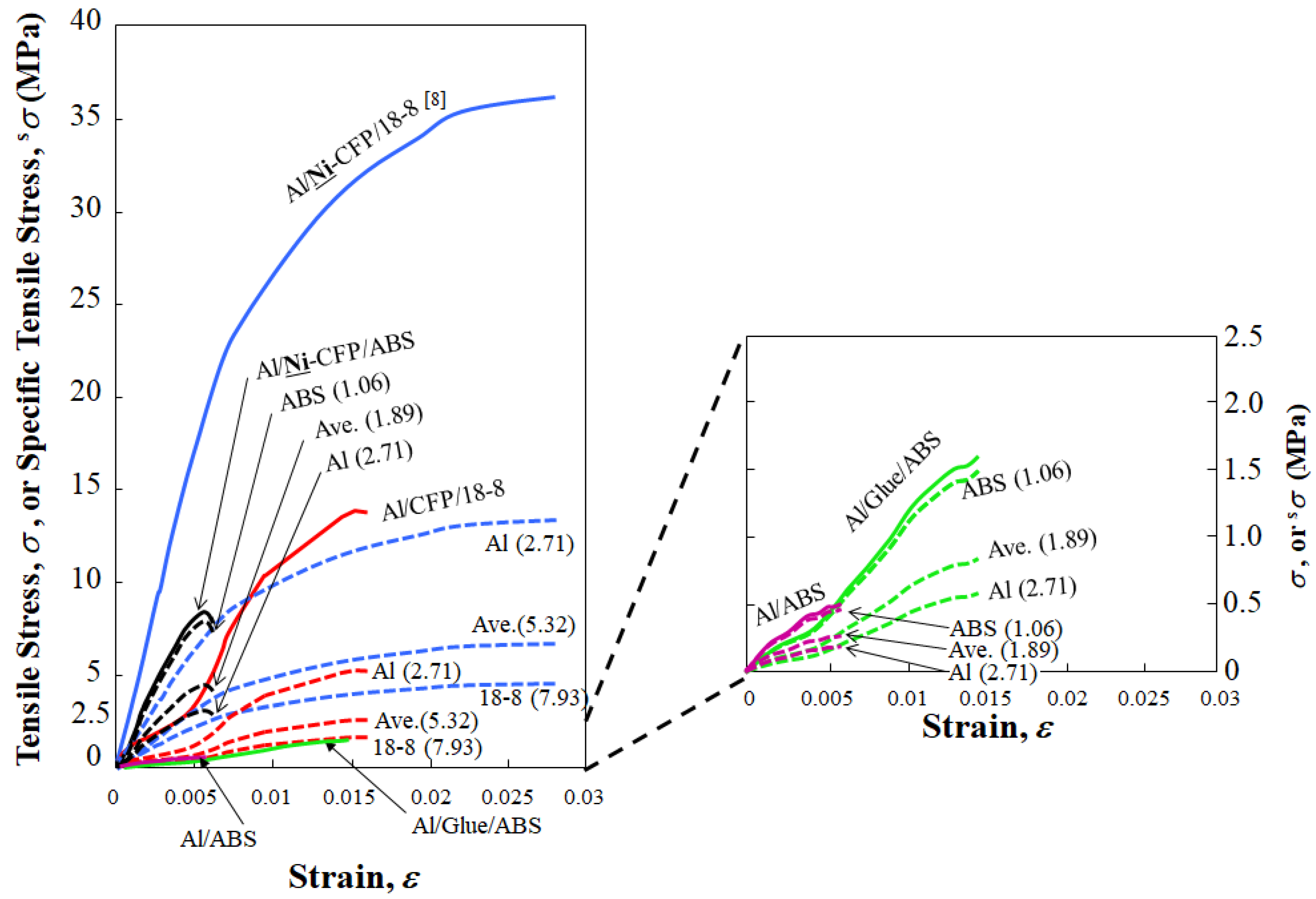

3.4. Stress-Strain Curves and Specific Tensile Strength, ssT

Al/CFP/18-8

Al/CFP/18-8  Al/Ni-CFP/ABS

Al/Ni-CFP/ABS  Al/Glue/ABS

Al/Glue/ABS  Al/ABS.

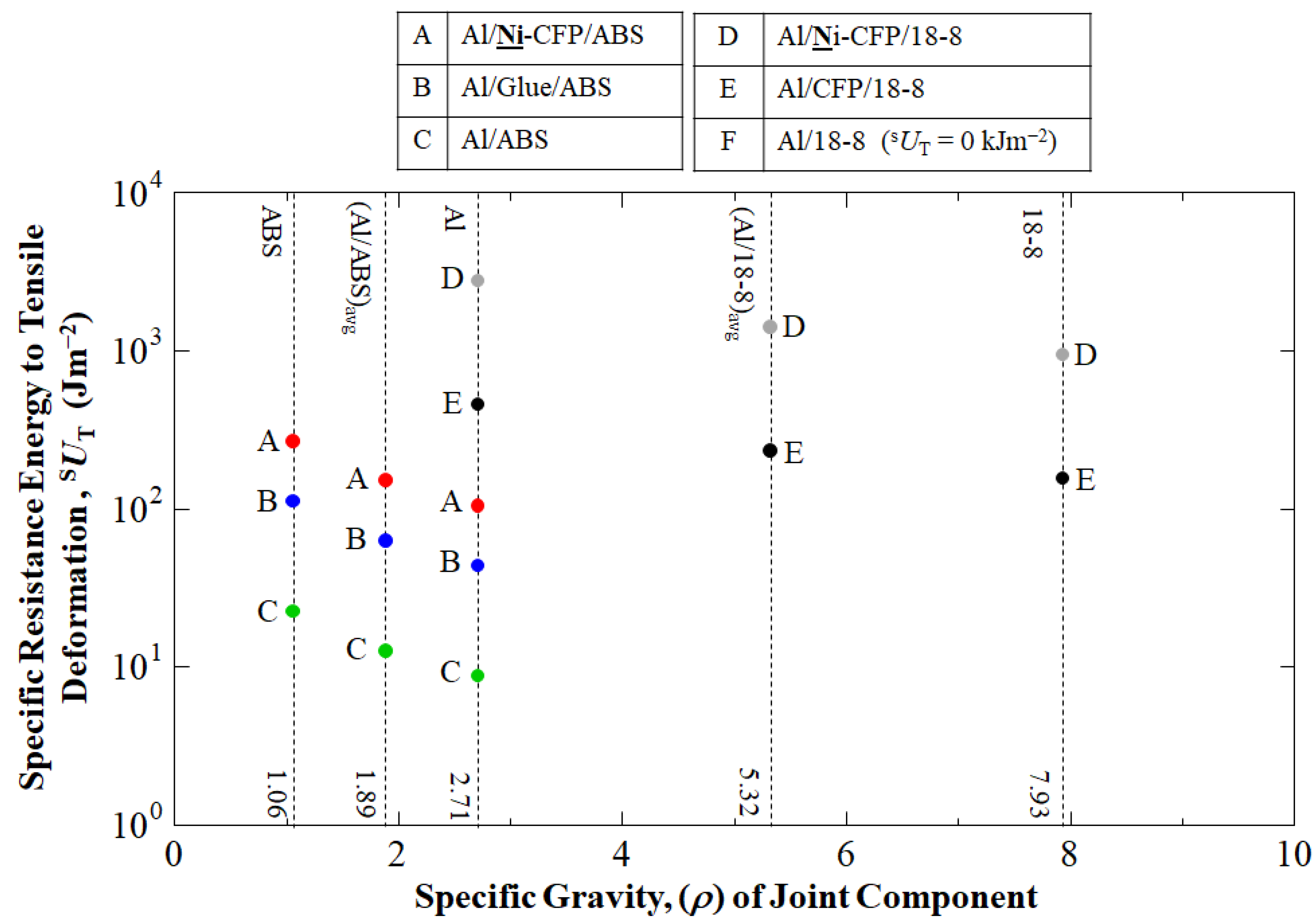

Al/ABS.3.5. Specific Resistance Energy to Tensile Deformation

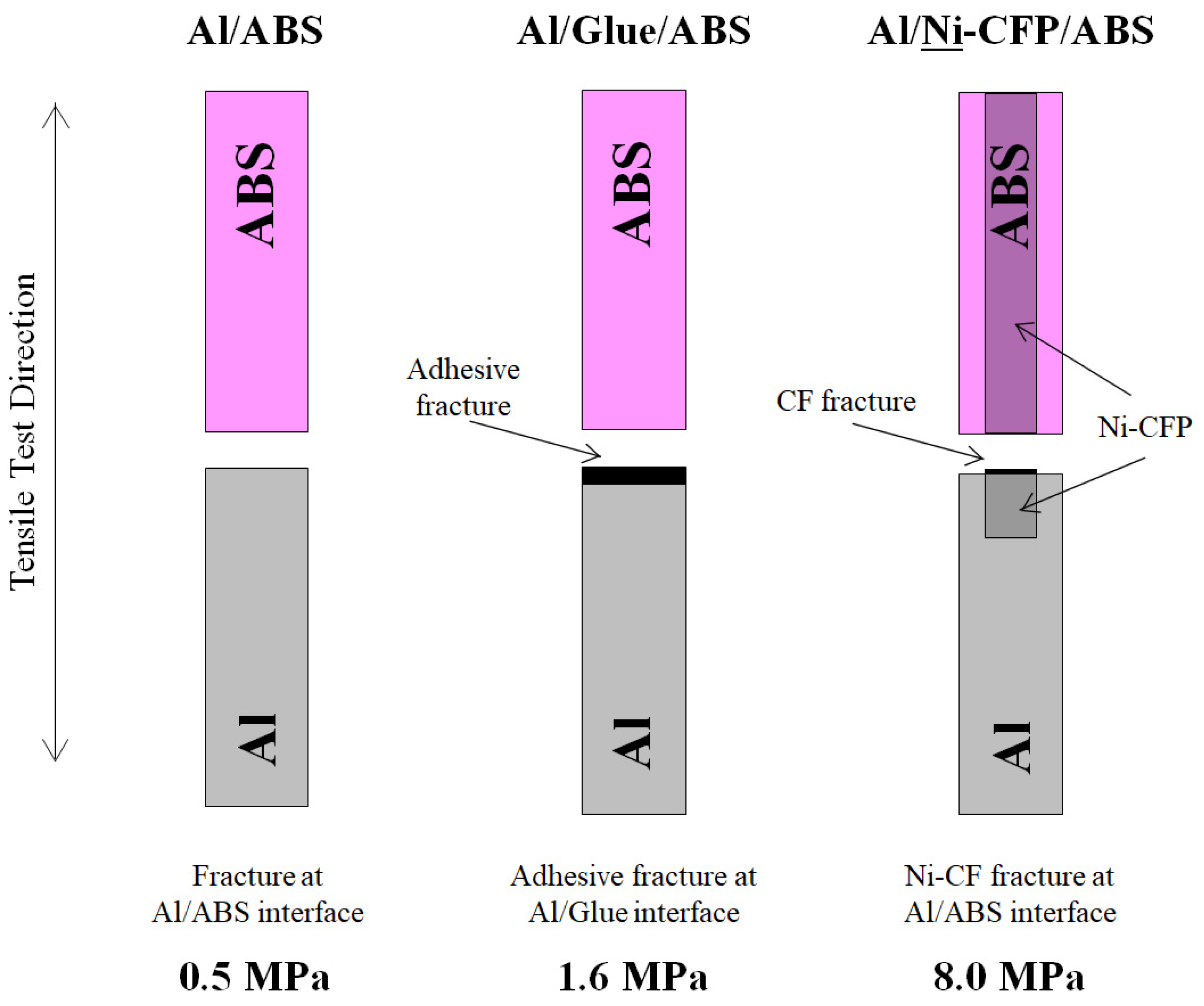

3.6. Fracture Mechanisms of Al-ABS Joints

3.7. Fracture Mechanisms of Al-18-8 Joints

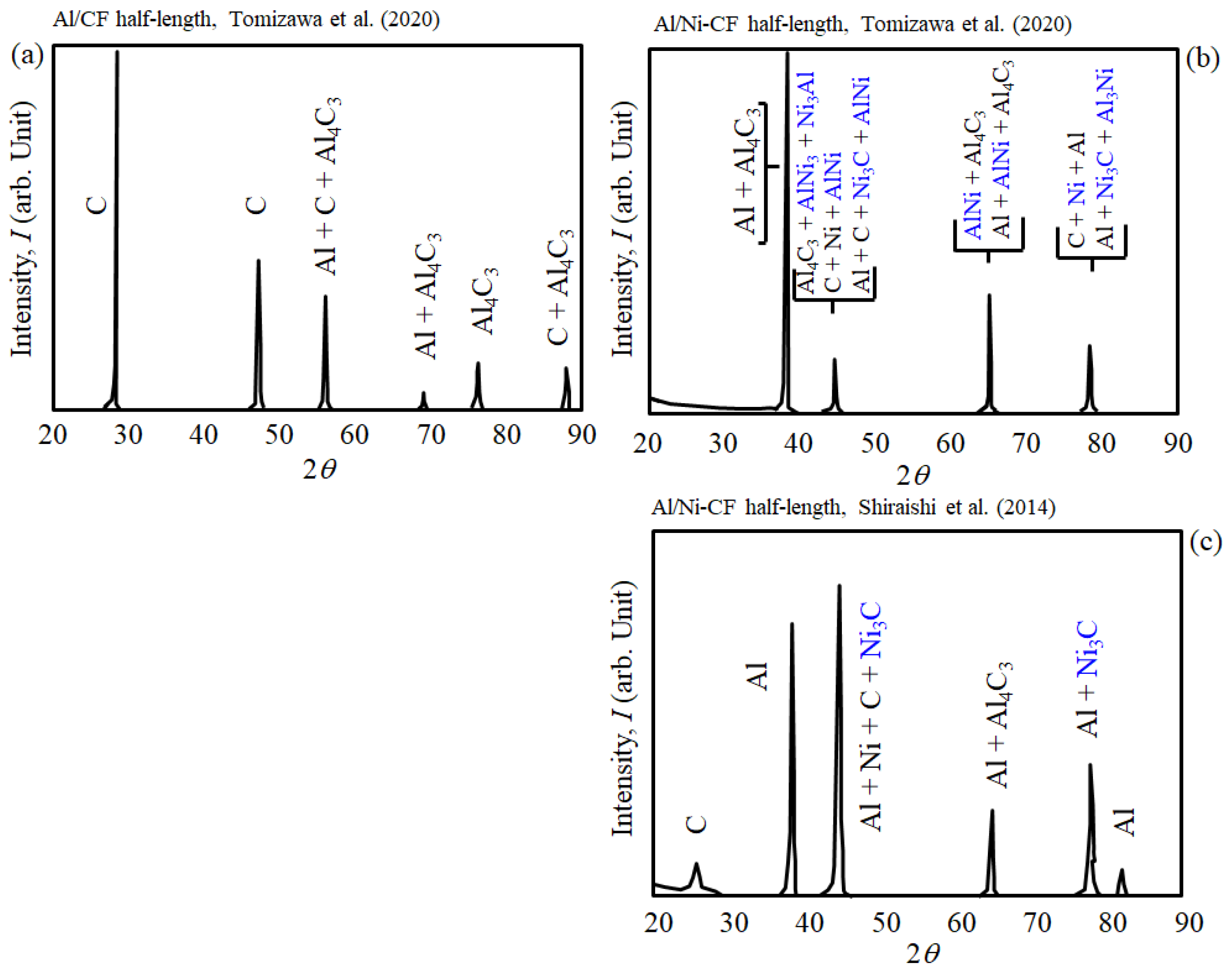

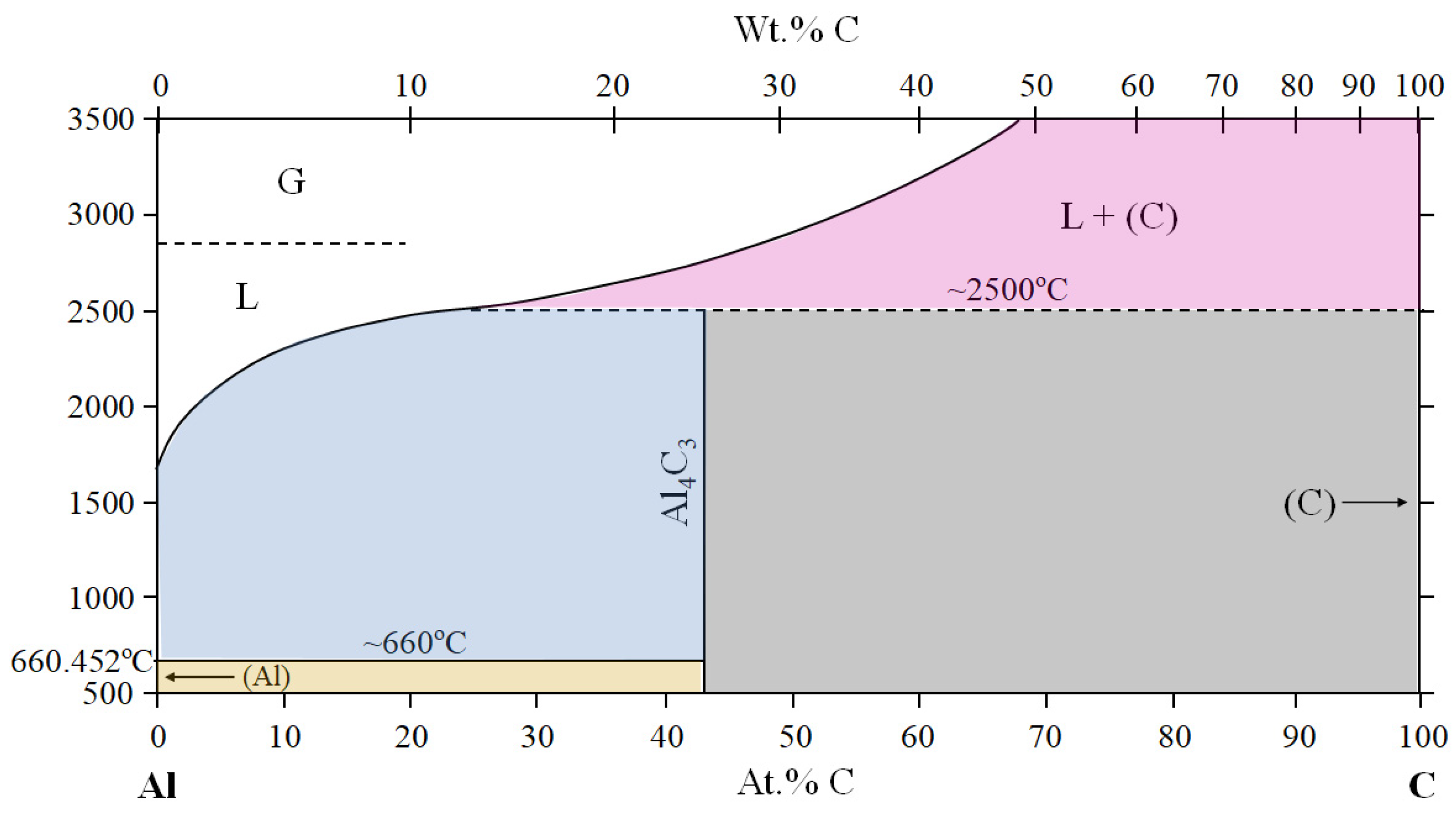

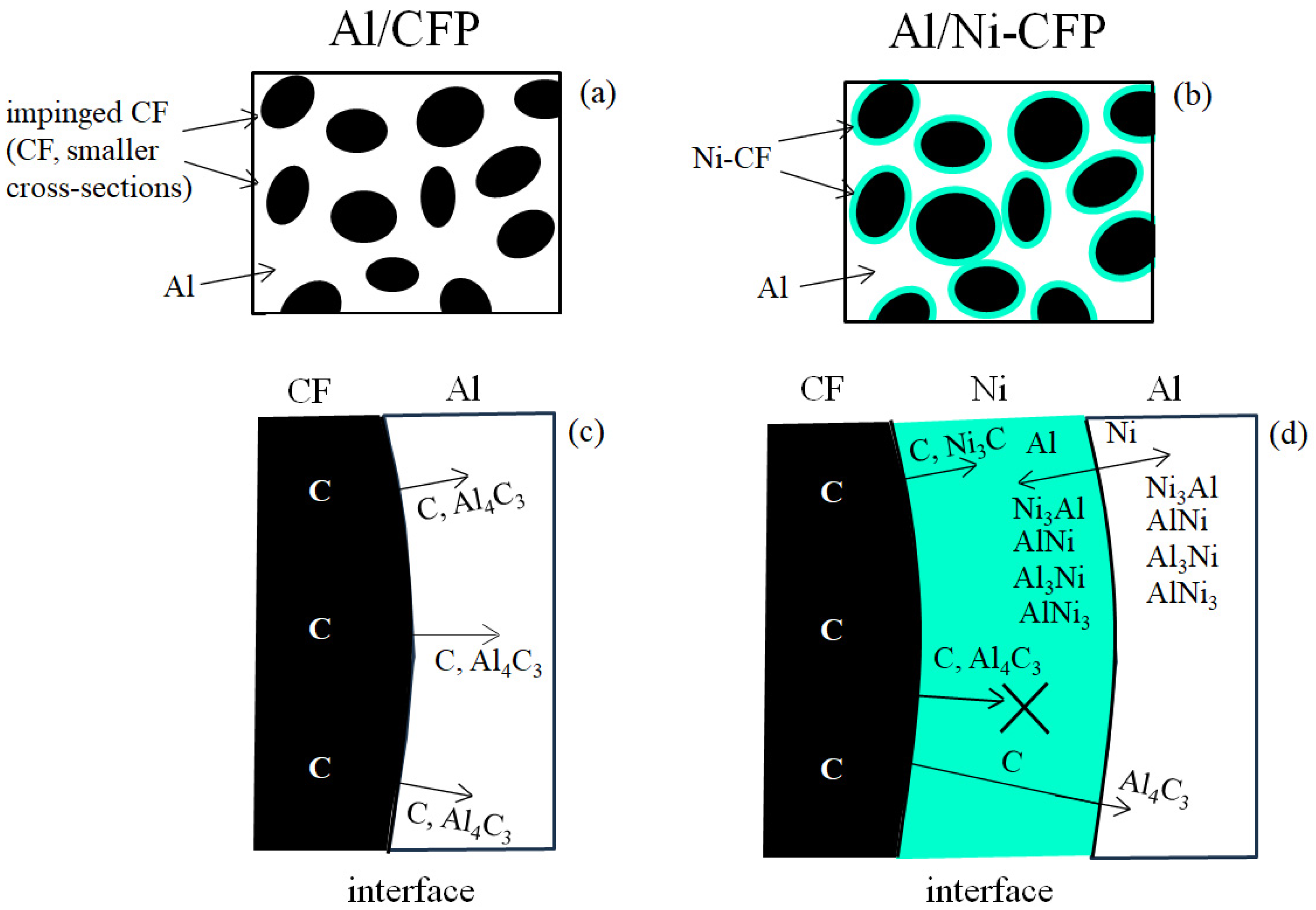

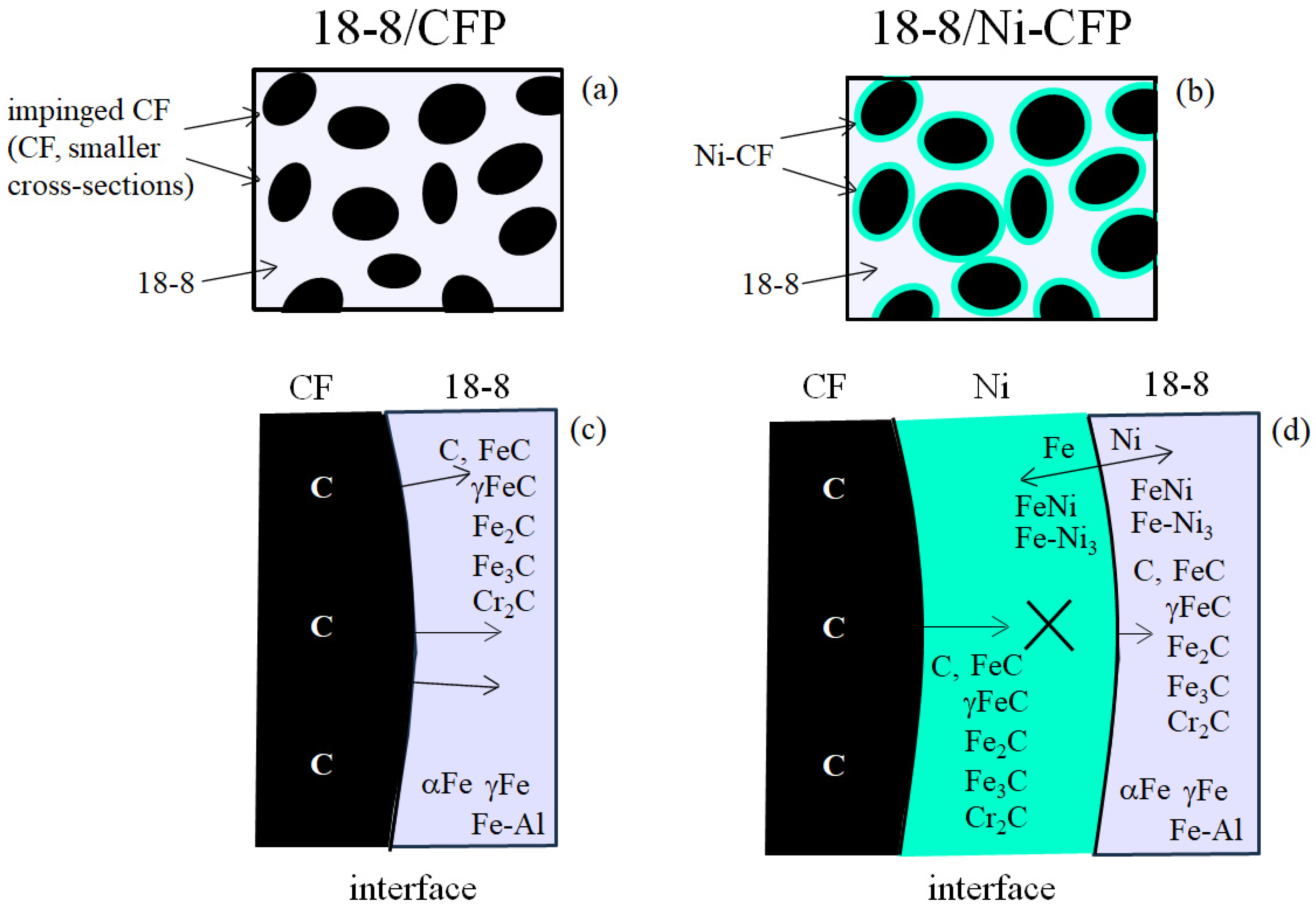

3.8. Metallographic Processes of Al Half-Length: XRD and EPMA Data

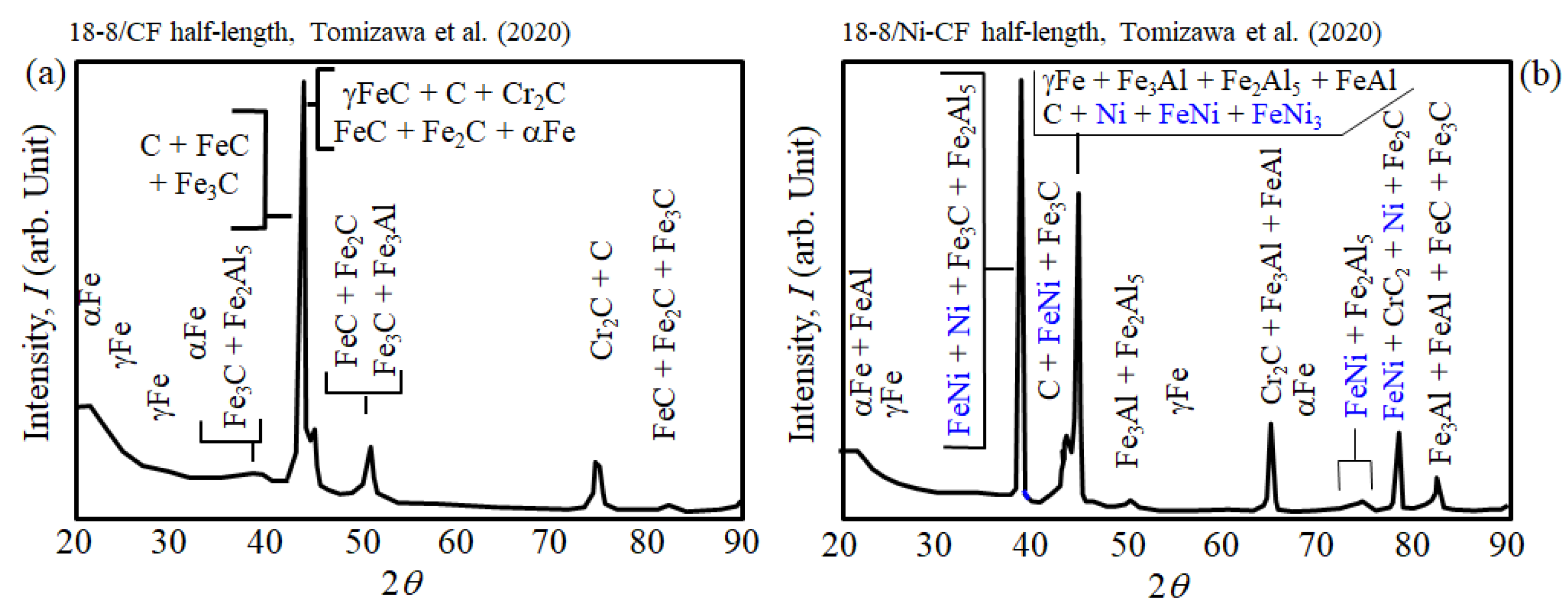

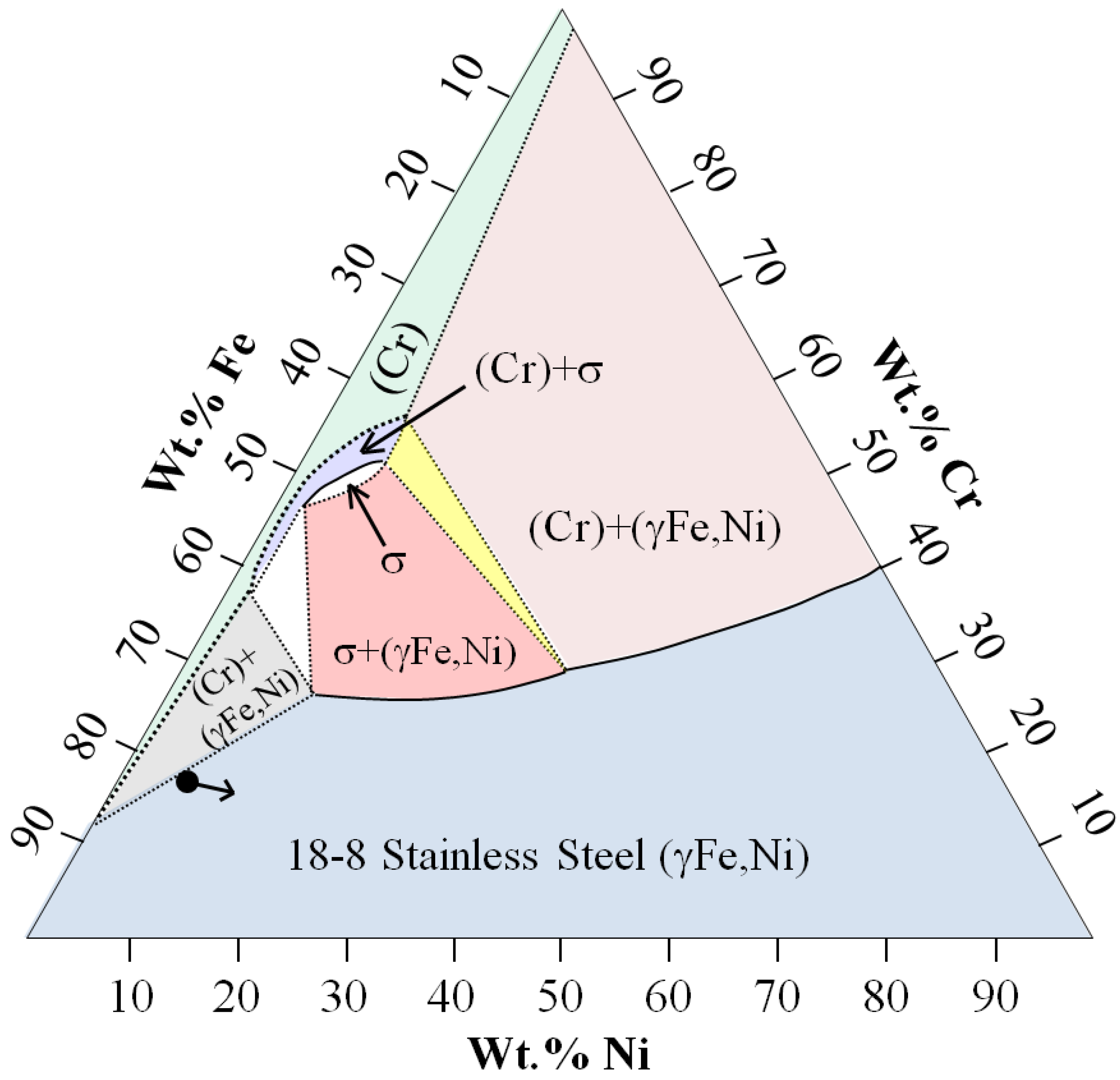

3.9. Metallographic Processes of 18-8 Half-Length: XRD and EPMA Data

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Drozdov, A. Aluminium: The Thirteenth Element; RUSAL Library: Moscow, Russia, 2007; ISBN 978-5-91523-002-5. [Google Scholar]

- Nishi, Y.; Inoue, K.; Salvia, M. Improvement of Charpy impact of carbon fiber reinforced polymer by low energy sheet electron beam irradiation. Mater. Trans. 2006, 47, 2846–2851. [Google Scholar] [CrossRef]

- Nishi, Y.; Takei, H.; Iwata, K.; Salvia, M.; Vautrin, A. Effects of electron beam irradiation on impact value of carbon fiber reinforced thermoplastic polyetheretherketone. Mater. Trans. 2009, 50, 2826–2832. [Google Scholar] [CrossRef]

- Takei, H.; Iwata, K.; Salvia, M.; Vautrin, A.; Nishi, Y. Effects of electron beam irradiation on impact value of novolak-type phenol CFRTP. Mater. Trans. 2010, 51, 2259–2265. [Google Scholar] [CrossRef]

- Yang, Q.; Mironov, S.; Sato, Y.S.; Okamoto, K. Material flow during friction stir spot welding. Mater. Sci. Eng. A 2010, 527, 4389–4398. [Google Scholar] [CrossRef]

- Daily Metal Prices. Available online: https://www.dailymetalprice.com/metalprices.php (accessed on 23 February 2023).

- Shiraishi, K.; Inui, S.; Ishii, S.; Matsumura, Y.; Nishi, Y. Tensile Strength of Al/ABS-CFRP Joint Reinforced by Nickel Coated Carbon Fiber Cloth. Mater. Trans. 2014, 55, 1564–1567. [Google Scholar] [CrossRef]

- Tomizawa, M.; Faudree, M.C.; Kitahara, D.; Takase, S.; Matsumura, Y.; Jimbo, I.; Salvia, M.; Nishi, Y. A Novel Joint of 18-8 Stainless Steel and Aluminum by Partial Welding Process to Ni-Plated Carbon Fiber Junction. Mater. Trans. 2020, 61, 2292–2301. [Google Scholar] [CrossRef]

- Shackelford, J.F. Introduction to Materials Science for Engineers, 5th ed.; Prentice Hall International: London, UK, 2000; pp. 136, 137, 194, 412. [Google Scholar]

- Handbook of Stainless Steel; Outokumpu: Outokumpu Oyj, Finland, 2013; p. 22.

- Lu, T.; Chen, W.-T. Material recycling of Acrylonitrile Butadiene Styrene (ABS) from toy waste using density separation and safer solvents. Resour. Conserv. Recycl. 2023, 197, 107090. [Google Scholar] [CrossRef]

- Dul, S.; Gutierrez, B.J.A.; Pegoretti, A.; Alvarez-Quintana, J.; Fambri, L. 3D printing of ABS Nanocomposites. Comparison of processing and effects of multi-wall and single-wall carbon nanotubes on thermal, mechanical and electrical properties. J. Mater. Sci. Technol. 2022, 121, 52–66. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, S. Improvement in toughness of poly(l-lactide) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): Morphology and properties. Eur. Polym. J. 2009, 45, 738–746. [Google Scholar] [CrossRef]

- Hasegawa, H.; Faudree, M.C.; Matsumuara, Y.; Jimbo, I.; Nishi, Y. Tensile Strength of a Ti/Thermoplastic ABS Matrix CFRTP Joint Connected by Surface Activated Carbon Fiber Cross-Weave Irradiated by Electron Beam. Mater. Trans. 2016, 57, 1202–1208. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, J. Compatibilization of acrylonitrile- butadiene- styrene terpolymer/poly(ethylene glycol-co-1,4-cyclohexanedimethanol terephthalate) blend: Effect on morphology, interface, mechanical properties and hydrophilicity. Appl. Surf. Sci. 2018, 437, 62–69. [Google Scholar] [CrossRef]

- Tang, L.; Wang, L.; Chen, P.; Fu, J.; Xiao, P.; Ye, N.; Zhang, M. Toughness of ABS/PBT blends: The relationship between composition, morphology, and fracture behavior. J. Appl. Polym. Sci. 2018, 135, 46051–46059. [Google Scholar] [CrossRef]

- Shirai, H.; Mochizuki, M.; Toyota, M. Development of Joining Process between Aluminum Alloy and Stainless Steel by Using Plastic Flow in Automotive Parts. J. Light Met. Weld. 2010, 48, 286–292. (In Japanese) [Google Scholar]

- Šesták, P.; Friák, M.; Holec, D.; Všianská, M.; Šob, M. Strength and Brittleness of Interfaces in Fe-Al Superalloy Nanocomposites under Multiaxial Loading: An ab initio and Atomistic Study. Nanomaterials 2018, 8, 873. [Google Scholar] [CrossRef]

- Yılmaz, M.; Çöl, M.; Acet, M. Interface properties of aluminum/steel friction welded components. Mater. Charact. 2002, 49, 421–429. [Google Scholar] [CrossRef]

- Yamamoto, N.; Takahashi, M.; Ikeuchi, K.; Aritoshi, M. Interfacial Layer in Friction-Bonded Joint of Low Carbon Steel to Al-Mg Alloy (AA5083) and its Influence on Bond Strength. Mater. Trans. 2004, 45, 296–299. [Google Scholar] [CrossRef]

- Hamada, K.; Isaka, K.; Doi, D.; Yonemitsu, Y.; Iwasaki, S. Application of the Direct Resistance Heating for Stainless Steel/Aluminum Clad Manufacturing Process. Tetsu–Hagané 2002, 88, 66–72. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Okui, T.; Yonemitsu, Y.; Yoshida, K. Development of Metal Clad Sheets and Strips; Technical Report No. 396; Nippon Steel & Sumikin Engineering Co., Ltd.: Delhi, India, 2013; pp. 106–110. (In Japanese) [Google Scholar]

- Nishi, Y.; Tanaka, K. Strength of Carbon Fiber Reinforced Cu-25 at%Al Alloy Junction Device. Mater. Trans. 2006, 47, 1821–1825. [Google Scholar] [CrossRef]

- Harigae, N.; Nishi, Y. Fracture behavior of Ti/Al joint reinforced by Ni coated carbon fiber. J. Jpn. Inst. Met. 2011, 75, 235–242. (In Japanese) [Google Scholar] [CrossRef]

- Nishi, Y.; Tanaka, K. Advanced CFRM Joint Device for Mover Engineering. In Solid State Phenomena; Trans Tech Publishings, Ltd.: Stafa-Zurich, Switzerland, 2006; Volume 127, pp. 185–188. ISSN 1012-0394. Available online: http://www.scientic.net (accessed on 20 May 2023).

- Ozaki, H.; Kutsuna, M. Laser Roll Welding of Dissimilar Metal Joint of Low Carbon Steel to Aluminum Alloy Using 2kW Fiber Laser. Q. J. Jpn. Weld. Soc. 2007, 25, 473–479. (In Japanese) [Google Scholar] [CrossRef]

- Mizutani, A.; Uchida, N.; Oguri, K.; Nishi, Y. Tensile Fracture Load of Carbon Fiber Joined to Pure Iron by Percission Welding. J. Jpn. Inst. Met. 2004, 68, 158–161. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Harada, Y.; Yamada, Y.; Kumai, S. Interfacial microstructure and thermal history of SS400 steel stud/5052 aluminum alloy plate joints fabricated by solid-state stud welding. J. Inst. Light Met. 2016, 66, 489–496. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Park, H.J.; Rhee, S.; Kang, M.J.; Kim, D.C. Joining of Steel to Aluminum Alloy by AC Pulse MIG Welding. Mater. Trans. 2009, 50, 2314–2317. [Google Scholar] [CrossRef]

- Shim, J.-Y.; Kim, I.-S.; Kang, M.-J.; Kim, I.-J.; Lee, K.-J.; Kang, B.-Y. Joining of Aluminum to Steel Pipe by Magnetic Pulse Welding. Mater. Trans. 2011, 52, 999–1002. [Google Scholar] [CrossRef]

- Muralidhara, B.; Kumaresh Babu, S.P.; Suresha, B. The effect of fiber architecture on the mechanical properties of carbon/epoxy composites. Mater. Today Proc. 2020, 22, 1755–1764. [Google Scholar] [CrossRef]

- Wan, Y.; Xiao, J.; Li, C.; Xiong, G.; Guo, R.; Li, L.; Han, M.; Luo, H. Microwave absorption properties of FeCo-coated carbon fibers with varying morphologies. J. Magn. Magn. Mater. 2016, 399, 252–259. [Google Scholar] [CrossRef]

- Calderon, N.R.; Voytovych, R.; Narciso, J.; Eustathopoulos, N. Wetting dynamics versus interfacial reactivity of AlSi alloys on carbon. J. Mater. Sci. 2010, 45, 2150–2156. [Google Scholar] [CrossRef]

- Li, S.-H.; Chao, C.-G. Effects of carbon fiber/Al interface on mechanical properties of carbon-fiber-reinforced aluminum-matrix composites. Metall. Mater. Trans. 2004, 35, 2153–2160. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Wang, W.; Yang, X.; Liu, S.; Zhang, J.; Guo, Z.; Wang, T.; Li, T. Interfacial enhancement and mechanical properties of CF/Al composites with improved interfacial structure induced by Al-Ni-Mg ternary reaction. Mater. Sci. Eng. A 2022, 831, 142040. [Google Scholar] [CrossRef]

- Lancin, M.; Marhic, C. TEM study of carbon fibre reinforced aluminium matrix composites: Influence of brittle phases and interface on mechanical properties. J. Eur. Ceram. Soc. 2000, 20, 1493–1503. [Google Scholar] [CrossRef]

- Baumli, P.; Sychev, J.; Budai, I.; Szabo, J.T.; Kaptay, G. Fabrication of carbon fiber reinforced aluminum matrix composites via a titanium-ion containing flux. Compos. Part A 2013, 44, 47–50. [Google Scholar] [CrossRef]

- Zhao, X.W.; Zang, C.G.; Ma, Q.K.; Wen, Y.Q.; Jiao, Q.J. Thermal and electrical properties of composites based on (3-mercaptopropyl) trimethoxysilane- and Cu-coated carbon fiber and silicone rubber. J. Mater. Sci. 2016, 51, 4088–4095. [Google Scholar] [CrossRef]

- Cao, X.G.; Liang, C.L.; Xia, S.M. Preparation and Conductivity of Carbon Fiber Coated with Silver. Mater. Sci. Forum 2016, 847, 137–142. [Google Scholar] [CrossRef]

- Guo, Z.; Sang, L.; Wang, Z.; Chen, Q.; Yang, L.; Liu, Z. Deposition of copper thin films by plasma enhanced pulsed chemical vapor deposition for metallization of carbon fiber reinforced plastics. Surf. Coat. Tech. 2016, 307, 1059–1064. [Google Scholar] [CrossRef]

- Garlow, J.A.; Barrett, L.K.; Wu, L.; Kisslinger, K.; Zhu, Y.; Pulecio, J.F. Large-Area Growth of Turbostratic Graphene on Ni(111) via Physical Vapor Deposition. Sci. Rep. 2016, 6, 19804. [Google Scholar] [CrossRef]

- Sun, C.; Chen, S.; Li, Z. Controllable synthesis of Fe2O3-carbon fiber composites via a facile sol-gel route as anode materials for lithium ion batteries. Appl. Surf. Sci. Part A 2018, 427, 476–484. [Google Scholar] [CrossRef]

- Feng, Y.; Mcguire, G.E.; Shenderova, O.A.; Ke, H.; Burkett, S.L. Fabrication of copper/carbon nanotube composite thin films by periodic pulse reverse electroplating using nanodiamond as a dispersing agent. Thin Solid Film. 2016, 615, 116–121. [Google Scholar] [CrossRef]

- Abbasipour, B.; Monirvaghefi, S.M.; Niroumand, B. Electroless Ni-P-CNT composite coating on aluminum powder. Met. Mater. Int. 2012, 18, 1015–1021. [Google Scholar] [CrossRef]

- Ip, S.; Sridhar, R.; Toguri, J.; Stephenson, T.; Warner, A. Wettability of nickel coated graphite by aluminum. Mater. Sci. Eng. 1998, 244, 31–38. [Google Scholar] [CrossRef]

- Zeng, W.Q.; Zeng, W.M.; Gao, Z.Z.; Ma, Y.L. Electroless nickel-plating on carbon fiber in wire mesh catalyzing method. Surf. Technol. 2017, 46, 276–281. [Google Scholar]

- Li, Y.; Nie, J.H.; Li, N.; Liu, X.Q.; Jia, C.C. The preparation and properties of nickel-coated carbon fiber by MOCVD process. J. Funct. Mater. 2012, 43, 1688–1691. [Google Scholar] [CrossRef]

- Xue, Y.; Chen, W.; Zhao, Q.; Fu, Y.-Q. Electroless carbon fibers: A new route for improving mechanical property and wettability of composites. Surf. Coat. Technol. 2019, 358, 409–415. [Google Scholar] [CrossRef]

- Lv, X.X.; Lv, C.X.; Yang, Y.; An, F.; Ji, Y.L.; He, F. Study on nickel plating on carbon fiber. New Chem. Mater. 2011, 39, 89–91. [Google Scholar]

- Nishi, Y.; Ishii, S.; Inui, S.; Kasai, A.; Faudree, M.C. Impact Value of CFRP/Ti Joint Reinforced by Nickel Coated Carbon Fiber. Mater.Trans. 2014, 55, 323–326. [Google Scholar] [CrossRef]

- Faudree, M.C.; Uchida, H.T.; Kimura, H.; Kaneko, S.; Salvia, M.; Nishi, Y. Advances in Titanium/Polymer Hybrid Joints by Carbon Fiber Plug Insert: Current Status and Review. Materials 2022, 15, 3220. [Google Scholar] [CrossRef] [PubMed]

- Nishi, Y.; Kunikyo, N.; Kanda, M.; Lebrun, L.; Guyomar, D. Impact Value of High Electric Conductive ABS Composites with Copper Powder Dispersion Prepared by Solution-Cast Method. Mater. Trans. 2010, 51, 165–170. [Google Scholar] [CrossRef]

- Henkel Japan Company Website. Available online: https://www.askul.co.jp/p/WP21498/ (accessed on 20 July 2023).

- JIS G 4304; Hot-rolled stainless steel plate, sheet and strip. Japanese Industrial Standards (JIS): Tokyo, Japan, 2012.

- Trautha, A.; Kirchenbauer, K.; Weidenmanna, K.A. Dynamic-mechanical-thermal analysis of hybrid continuous–discontinuous sheet molding compounds. Compos. C Open Access 2021, 5, 100148. [Google Scholar] [CrossRef]

- James, A.; Lord, M. Macmillan’s Chemical and Physical Data; The Macmillan Press, Ltd.: London/Basingstoke, UK, 1992; p. 285. ISBN 0-333-51167-0. [Google Scholar]

- Kobayashi, H.; Nishi, Y. Critical Implant Length of Carbon Fiber in Transparent Adhesive Polymer for Tensile Fracture Test. J. Jpn. Inst. Met. 2005, 69, 1021–1025. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Dabouz, R.; Bendoumia, M.; Belaid, L.; Azzaz, M. Dissolution of Al 6%wt C Mixture Using Mechanical Alloying. Defect Diffus. Forum Online 2019, 391, 82–87. [Google Scholar] [CrossRef]

- Nam, S.; Kim, C.; Kim, Y.-M. Hot Cracking of Ni-Cr-Fe Alloys: Test Methods and Metallurgical Effect. J. Weld. Join. 2017, 35, 7–15. [Google Scholar] [CrossRef][Green Version]

| Parameter | Value |

|---|---|

| Leak rate (Pa·m3·s−1) | 8 × 10−6 to 1 × 10−4 |

| Residual gas pressure (Pa) | below 1.5 × 10−3 |

| Ar gas sputtering pressure (Pa) | 5.0 ×10−1 |

| Sputtering potential (V) | 300 |

| Sputtering current (A) | 0.7 |

| Deposition rate (µm·h−1) | 30 |

| Parameter | Value |

|---|---|

| Current (A) | 1.5 |

| Voltage (V) | 7.0 |

| Electro-plating time (min) | 30 |

| Temperature (K) | 298 |

| Water solution: 400 mL with 12 g boric acid; 100 g nickel sulfate; 18 g nickel chloride | |

| JOINT (Units in mm) | l | w | t | CFP l | CFP w | CFP th | CFP in Al | CFP in ABS | CFP in 18-8 |

|---|---|---|---|---|---|---|---|---|---|

| Al/Ni-CFP/ABS-CFRTP | 70 | 10 | 3 | 42 | 5 | 0.3 | 7 | 35 | - |

| Al/Ni-CFP/18-8 | 60 | 10 | 3 | 20 | 10 | 0.3 | 10 | - | 10 |

| Al/ABS | 70 | 10 | 3 | - | - | - | |||

| Al/Glue/ABS | 70 | 10 | 3 | - | - | - |

| Joint | UT (kJm−2) | σT (MPa) | εT |

|---|---|---|---|

| [Al/Ni-CFP/ABS] | 0.285 | 8 | 0.006 |

| [Al/Glue/ABS] | 0.119 | 1.6 | 0.015 |

| [Al/ABS] | 0.0238 | 0.5 | 0.006 |

| [Al/Ni-CFP/18-8] | 7.54 | 36 | 0.028 |

| [Al/CFP/18-8] | 1.24 | 14 | 0.016 |

| [Al/18-8] | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishi, Y.; Sagawa, K.; Faudree, M.C.; Uchida, H.T.; Kanda, M.; Kaneko, S.; Salvia, M.; Matsumura, Y.; Kimura, H. A Novel Nickel-Plated Carbon Fiber Insert in Aluminum Joints with Thermoplastic ABS Polymer or Stainless Steel. Materials 2023, 16, 5777. https://doi.org/10.3390/ma16175777

Nishi Y, Sagawa K, Faudree MC, Uchida HT, Kanda M, Kaneko S, Salvia M, Matsumura Y, Kimura H. A Novel Nickel-Plated Carbon Fiber Insert in Aluminum Joints with Thermoplastic ABS Polymer or Stainless Steel. Materials. 2023; 16(17):5777. https://doi.org/10.3390/ma16175777

Chicago/Turabian StyleNishi, Yoshitake, Kouhei Sagawa, Michael C. Faudree, Helmut Takahiro Uchida, Masae Kanda, Satoru Kaneko, Michelle Salvia, Yoshihito Matsumura, and Hideki Kimura. 2023. "A Novel Nickel-Plated Carbon Fiber Insert in Aluminum Joints with Thermoplastic ABS Polymer or Stainless Steel" Materials 16, no. 17: 5777. https://doi.org/10.3390/ma16175777

APA StyleNishi, Y., Sagawa, K., Faudree, M. C., Uchida, H. T., Kanda, M., Kaneko, S., Salvia, M., Matsumura, Y., & Kimura, H. (2023). A Novel Nickel-Plated Carbon Fiber Insert in Aluminum Joints with Thermoplastic ABS Polymer or Stainless Steel. Materials, 16(17), 5777. https://doi.org/10.3390/ma16175777