Prediction of Grain Size in a High Cobalt Nickel-Based Superalloy

Abstract

1. Introduction

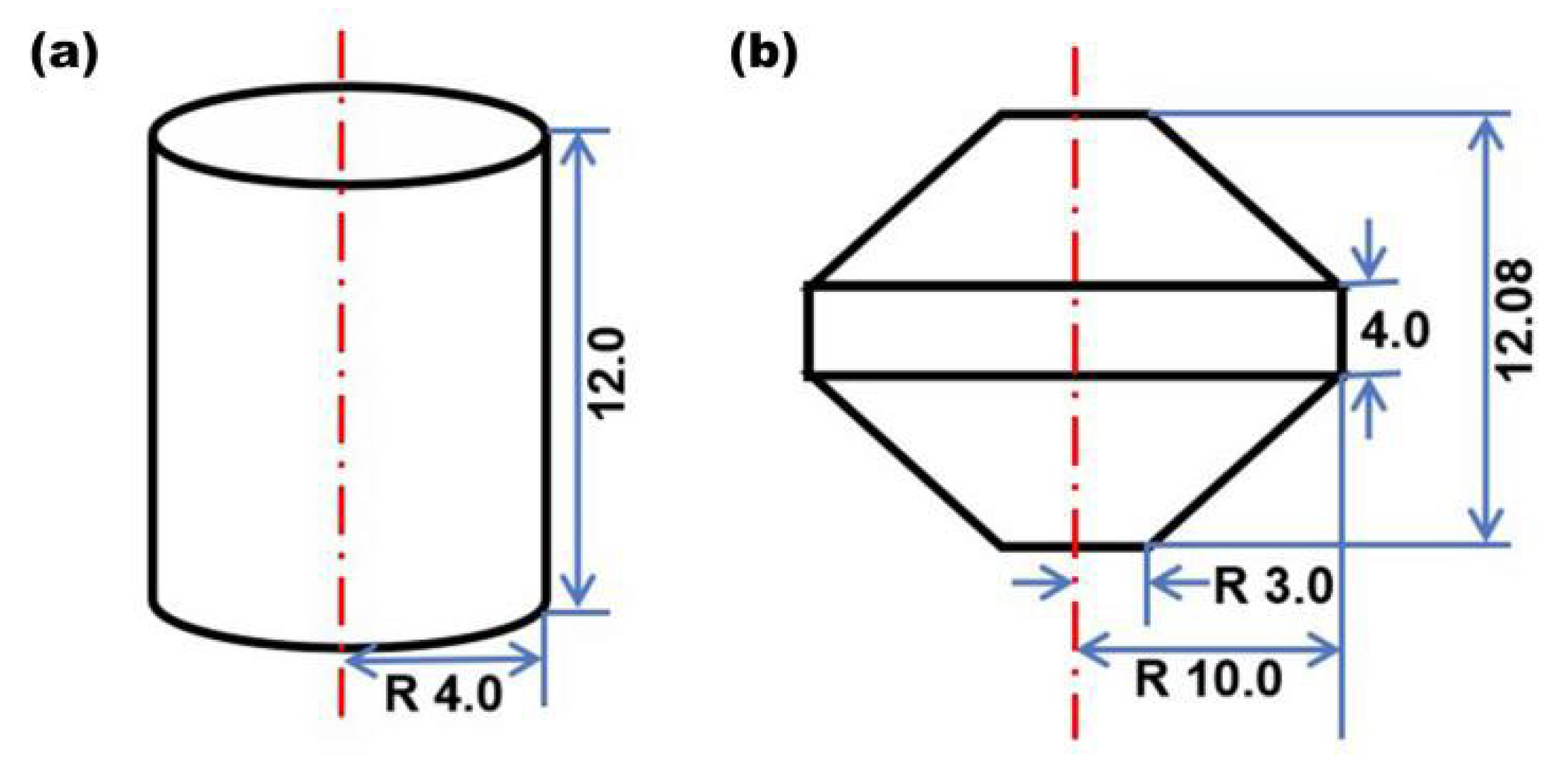

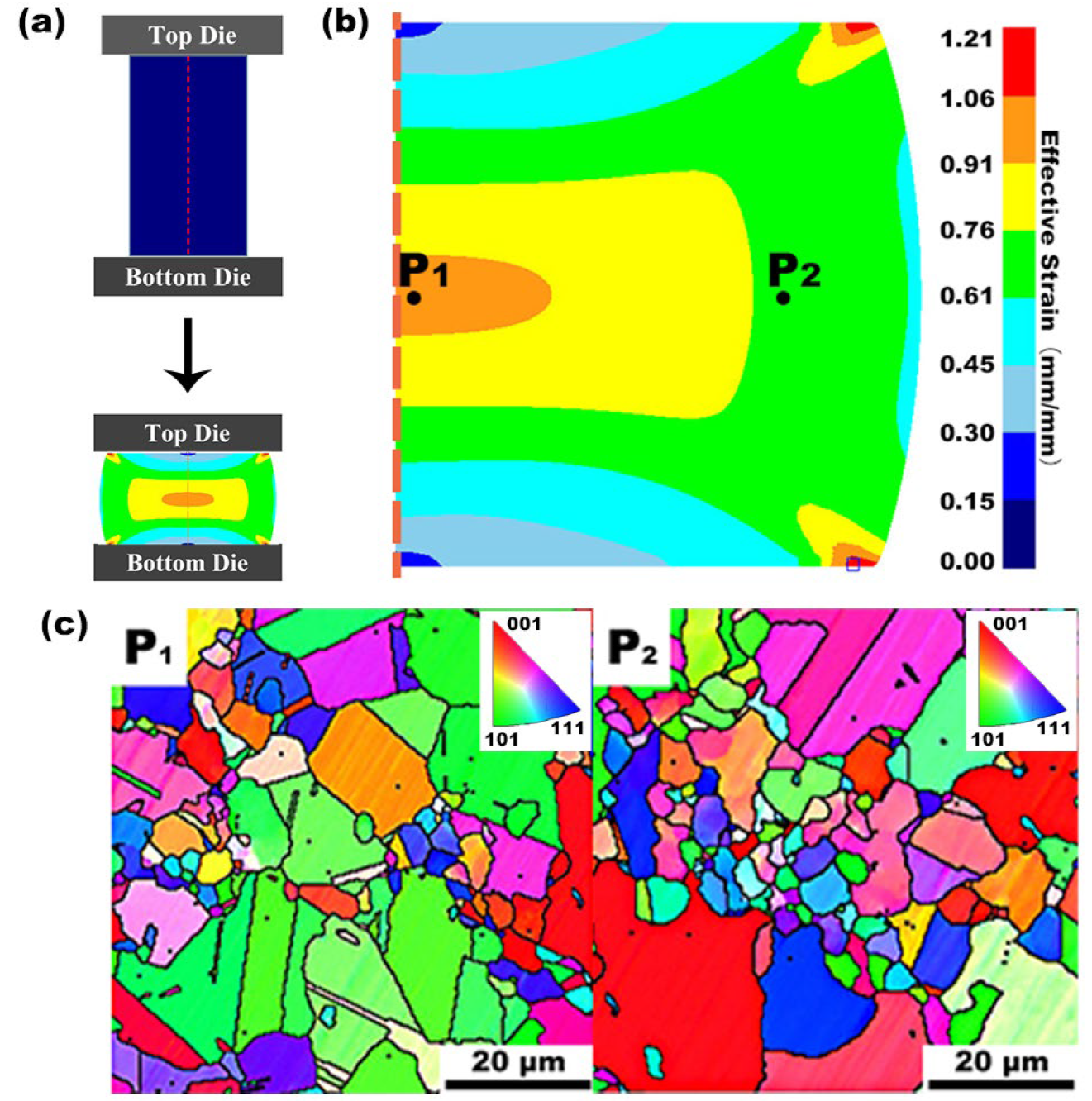

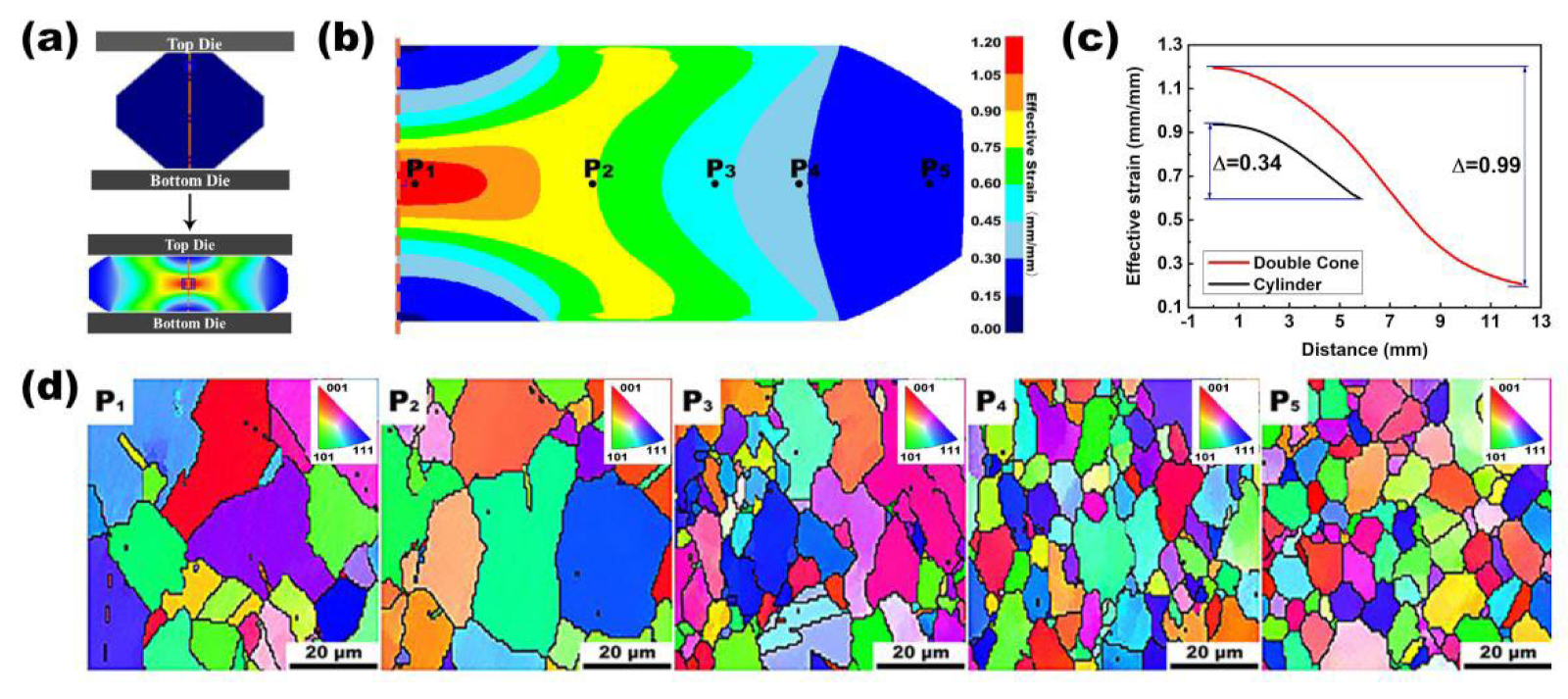

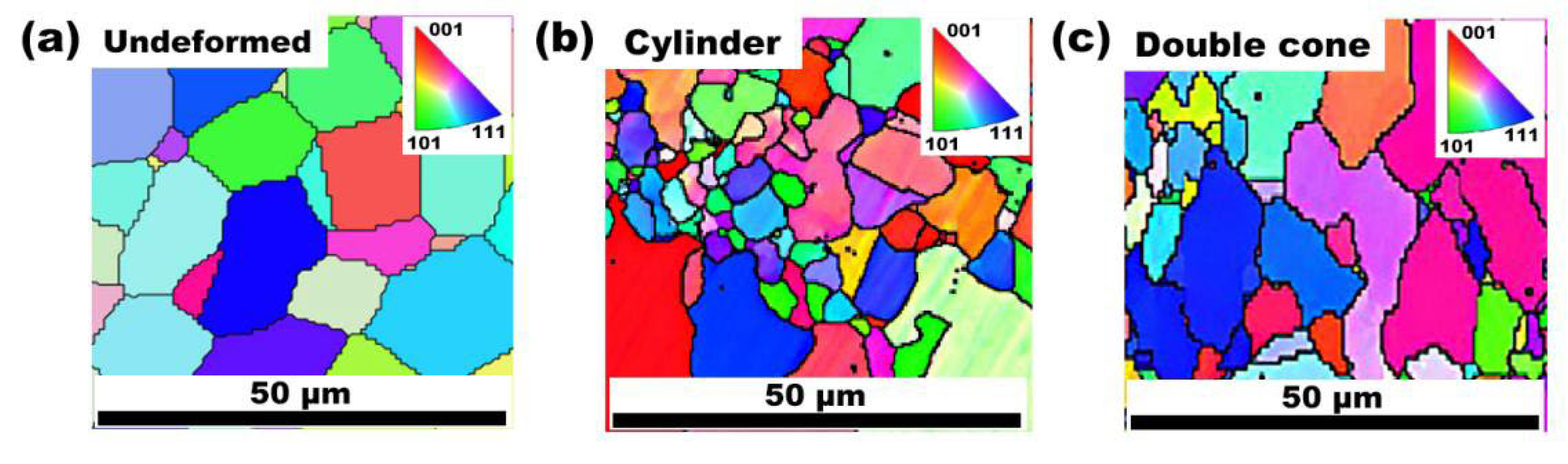

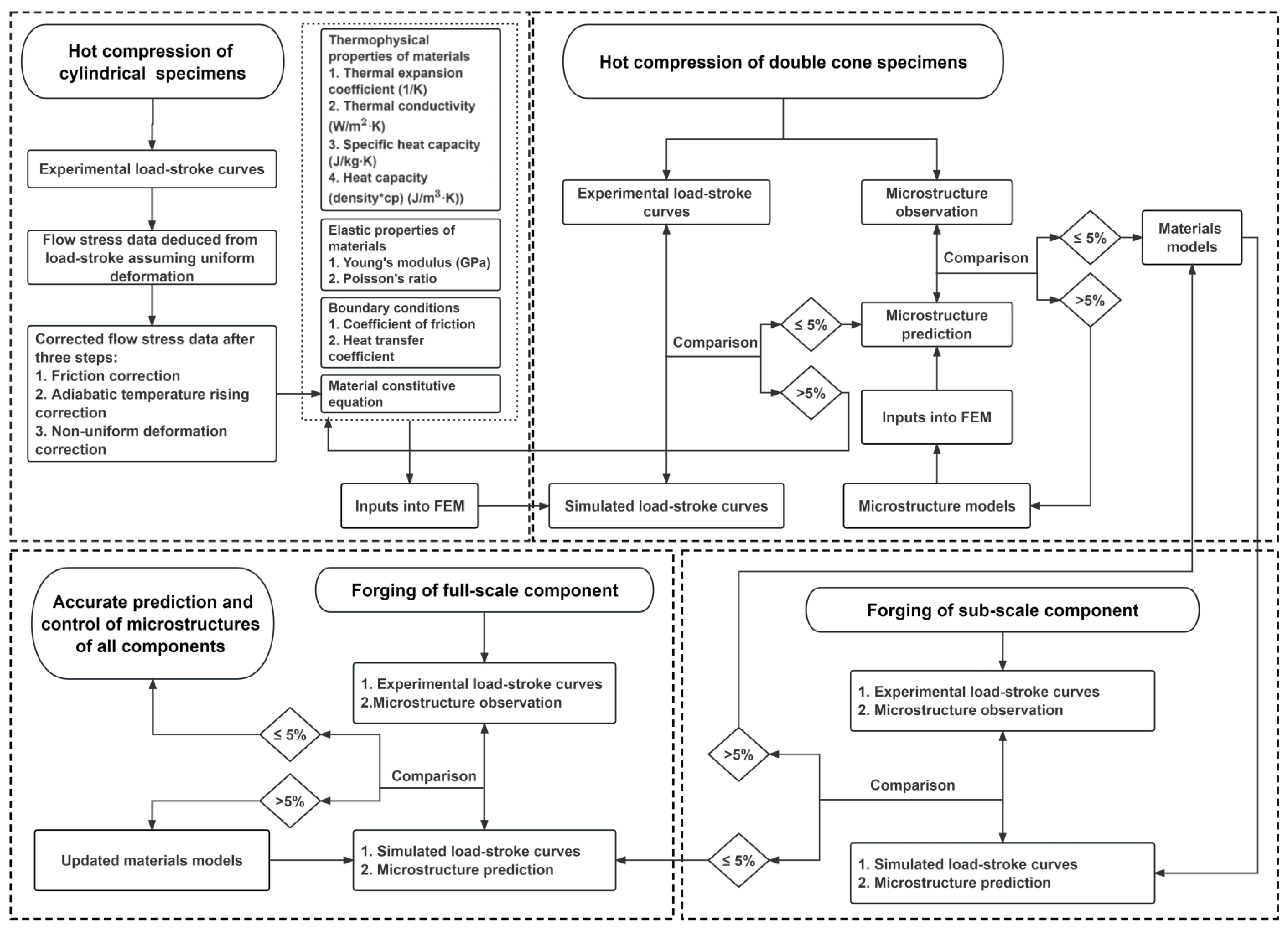

2. Materials and Methods

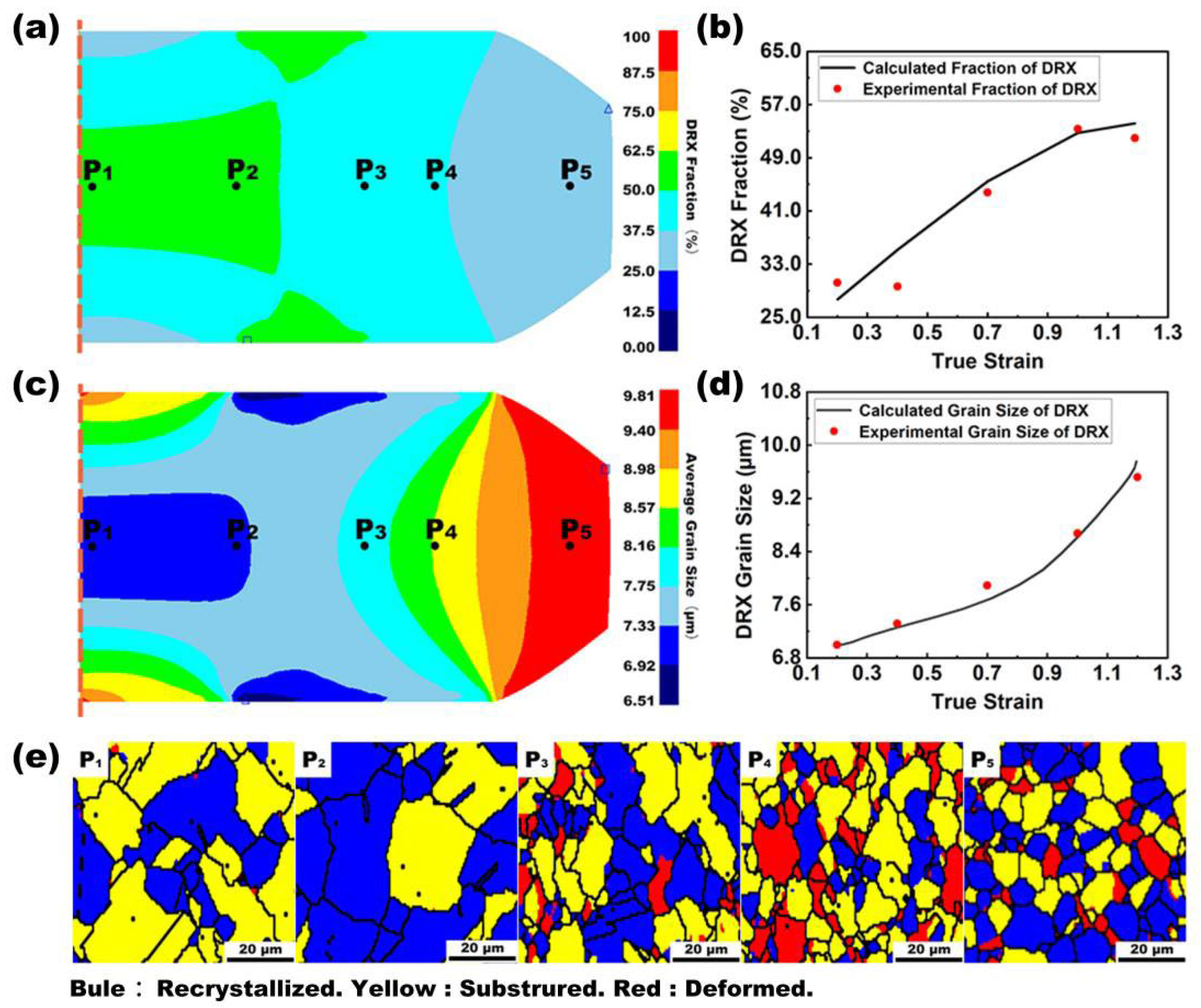

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Williams, J.C. Business Directions and Materials Challenges for the Aircraft Engine Industry. Acta Metall. Sin. 1996, 9, 407. [Google Scholar]

- Sah, J.P.; Richardson, G.J.; Sellars, C.M. Grain-Size Effects during Dynamic Recrystallization of Nickel Metal Science. Met. Sci. 1974, 8, 325–331. [Google Scholar] [CrossRef]

- Collins, D.M.; Conduit, B.D.; Stone, H.J.; Hardy, M.C.; Conduit, G.J.; Mitchell, R.J. Grain growth behaviour during near-γ′ solvus thermal exposures in a polycrystalline nickel-base superalloy. Acta Mater. 2013, 61, 3378–3391. [Google Scholar] [CrossRef]

- Semiatin, S.L.; McClary, K.E.; Rollett, A.D.; Roberts, C.G.; Payton, E.J.; Zhang, F.; Gabb, T.P. Microstructure evolution during supersolvus heat treatment of a powder metallurgy nickel-base superalloy. Metall. Mater. Trans. A 2012, 43, 1649–1661. [Google Scholar] [CrossRef]

- Mandal, S.; Jayalakshmi, M.; Bhaduri, A.K.; Subramanya Sarma, V. Effect of Strain Rate on the Dynamic Recrystallization Behavior in a Nitrogen-Enhanced 316L(N). Metall. Mater. Trans. A 2014, 45, 5645–5656. [Google Scholar] [CrossRef]

- Matsui, T.; Takizawa, H.; Kikuchi, H.; Wakita, S. The Microstructure Prediction of Alloy720LI for Turbine Disk Applications. In Proceedings of the Superalloys 2000, 9th International Symposium on Superalloys, Seven Springs, PA, USA, 17–21 September 2000; pp. 127–133. [Google Scholar] [CrossRef]

- Na, Y.S.; Yeom, J.T.; Park, N.K.; Lee, J.Y. Simulation of microstructures for Alloy 718 blade forging using 3D FEM simulator. J. Mater. Process. Technol. 2003, 141, 337–342. [Google Scholar] [CrossRef]

- Ryan, N.D.; McQueen, H.J. Flow stress, dynamic restoration, strain hardening and ductility in hot working of 316 steel. J. Mater. Process. Technol. 1990, 21, 177–199. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Z.; Cai, B.; Zhou, N.; Magdysyuk, O.; Gao, Y.; Srivatsa, S.; Tan, L.; Jiang, L. Formation mechanism of abnormally large grains in a polycrystalline nickel-based superalloy during heat treatment processing. Acta Mater. 2019, 168, 287–298. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Najafizadeh, A. A new method for evaluation of friction in bulk metal forming. J. Mater. Process. Technol. 2004, 152, 136–143. [Google Scholar] [CrossRef]

- Mandal, S.; Sivaprasad, P.V.; Dube, R.K. Kinetics, mechanism and modelling of microstructural evolution during thermomechanical processing of a 15Cr–15Ni–2.2Mo–Ti modified austenitic stainless steel. J. Mater. Sci. 2007, 42, 2724–2734. [Google Scholar] [CrossRef]

- Yeom, J.T.; Lee, C.S.; Kim, J.H.; Park, N.K. Finite-element analysis of microstructure evolution in the cogging of an Alloy 718 ingot. Mater. Sci. Eng. A 2007, 449–451, 722–726. [Google Scholar] [CrossRef]

- Sakui, S.; Sakai, T.; Takeishi, K. Hot Deformation of Austenite in a Plain Carbon Steel. Trans. Iron Steel Inst. Jpn. 1977, 17, 718–725. [Google Scholar] [CrossRef]

- Shakib, M.; Perkins, K.M.; Bray, S.E.; Siviour, C.R. Development of a high temperature flow stress model for AerMet 100 covering several orders of magnitude of strain rate. Mater. Sci. Eng. A 2016, 657, 26–32. [Google Scholar] [CrossRef]

- Solhjoo, S. A note on “Barrel Compression Test”: A method for evaluation of friction. Comput. Mater. Sci. 2010, 49, 435–438. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kobayashi, S.; Oh, S.I.; Altan, T. Metal Forming and the Finite-Element Method; Oxford University Press: New York, NY, USA, 1989. [Google Scholar] [CrossRef][Green Version]

- Poliak, E.I.; Jonas, J.J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 1996, 44, 127–136. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Weaver, D.S.; Goetz, R.L.; Thomas, J.P.; Turner, T.J. Deformation and Recrystallization during Thermomechanical Processing of a Nickel-Base Superalloy Ingot Material. Mater. Sci. Forum 2007, 550, 129–140. [Google Scholar] [CrossRef]

- Eriksson, E.; Hanning, F.; Andersson, J.; Colliander, M.H. The Effect of Grain Boundary Carbides on Dynamic Recrystallization During Hot Compression of Ni-Based Superalloy Haynes 282TM. Metall. Mater. Trans. A 2022, 53, 29–38. [Google Scholar] [CrossRef]

- Tan, L.; Huang, Z.; Liu, F.; He, G.; Wang, X.; Huang, L.; Zhang, Y.; Jiang, L. Effects of strain amount and strain rate on grain structure of a novel high Co nickel-based polycrystalline superalloy. Mater. Des. 2017, 131, 60–68. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Huang, L.; Srivatsa, S.; Zhou, K.; Huang, Z.; Jiang, L. Correction of flow stress data due to non-homogeneous deformation and thermal conditions during hot compression testing of a polycrystalline nickel-base superalloy. J. Mater. Sci. 2021, 56, 7727–7739. [Google Scholar] [CrossRef]

- Mejía, I.; Bedolla-Jacuinde, A.; Maldonado, C.; Cabrera, J.M. Determination of the critical conditions for the initiation of dynamic recrystallization in boron microalloyed steels. Mater. Sci. Eng. A 2011, 528, 4133–4140. [Google Scholar] [CrossRef]

- Roberts, W.; Ahlblom, B. A nucleation criterion for dynamic recrystallization during hot working. Acta Metall. 1978, 26, 801–813. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Ravichandran, N. Application of Dynamic Recrystallization Model for the Prediction of Microstructure During Hot Working. J. Mater. Eng. Perform. 2003, 12, 653–655. [Google Scholar] [CrossRef]

- Jonas, J.J. Dynamic Recrystallization–Scientific Curiosity of Industrial Tool? Mater. Sci. Eng. A 1994, 184, 155–165. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Subramanya Sarma, V. Role of Twinning on Dynamic Recrystallization and Microstructure During Moderate to High Strain Rate Hot Deformation of a Ti-Modified Austenitic Stainless Steel. Metall. Mater. Trans. A 2012, 43, 2056–2068. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, S.; Jiang, L.; Srivatsa, S.; Huang, Z. Prediction of Grain Size in a High Cobalt Nickel-Based Superalloy. Materials 2023, 16, 5776. https://doi.org/10.3390/ma16175776

Wang J, Zhang S, Jiang L, Srivatsa S, Huang Z. Prediction of Grain Size in a High Cobalt Nickel-Based Superalloy. Materials. 2023; 16(17):5776. https://doi.org/10.3390/ma16175776

Chicago/Turabian StyleWang, Jingzhe, Siyu Zhang, Liang Jiang, Shesh Srivatsa, and Zaiwang Huang. 2023. "Prediction of Grain Size in a High Cobalt Nickel-Based Superalloy" Materials 16, no. 17: 5776. https://doi.org/10.3390/ma16175776

APA StyleWang, J., Zhang, S., Jiang, L., Srivatsa, S., & Huang, Z. (2023). Prediction of Grain Size in a High Cobalt Nickel-Based Superalloy. Materials, 16(17), 5776. https://doi.org/10.3390/ma16175776