Theoretical and Experimental Analyses on the Sound Absorption Coefficient of Rice and Buckwheat Husks Based on Micro-CT Scan Data

Abstract

:1. Introduction

2. Experimental Measurements

2.1. Sound Absorption

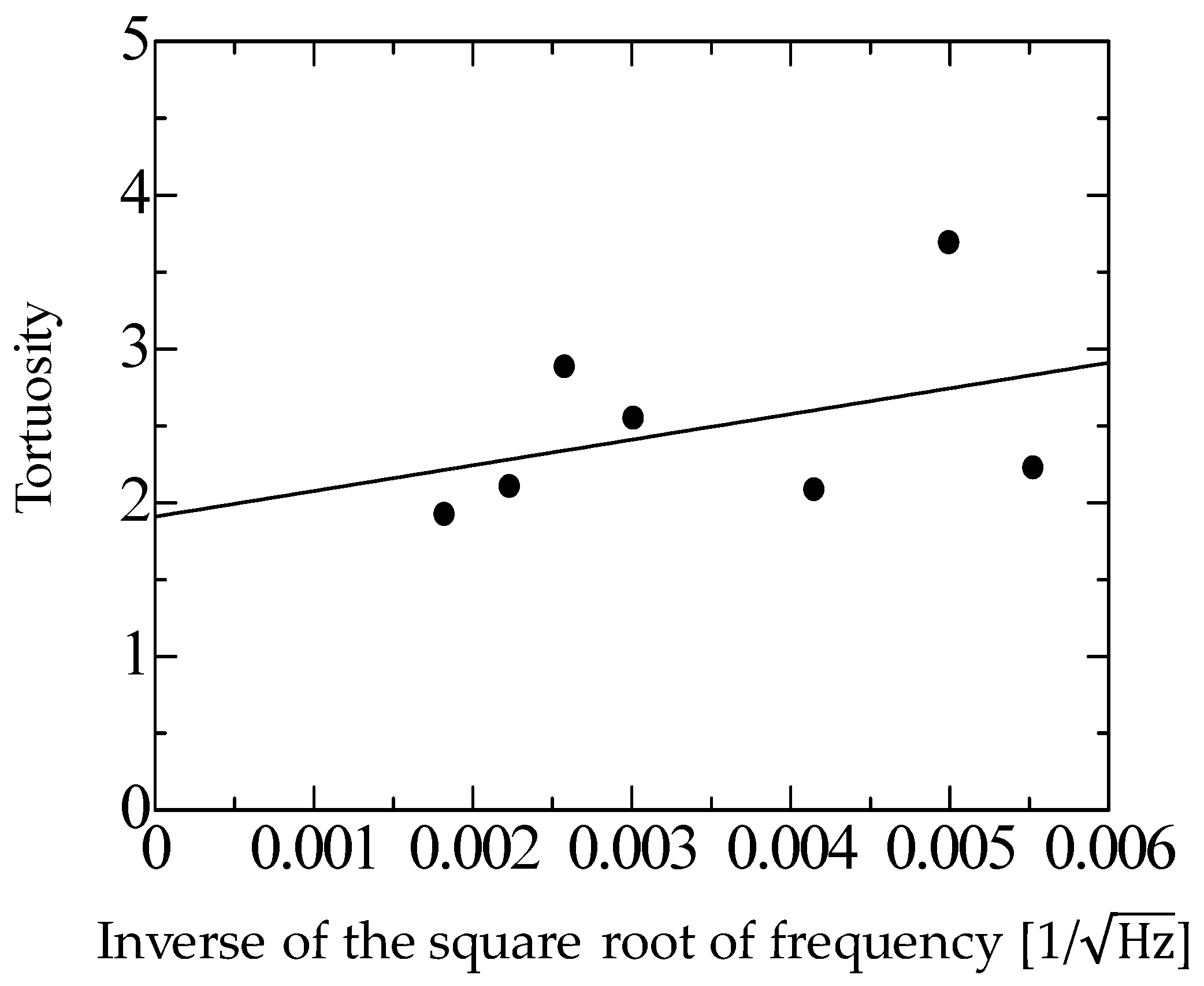

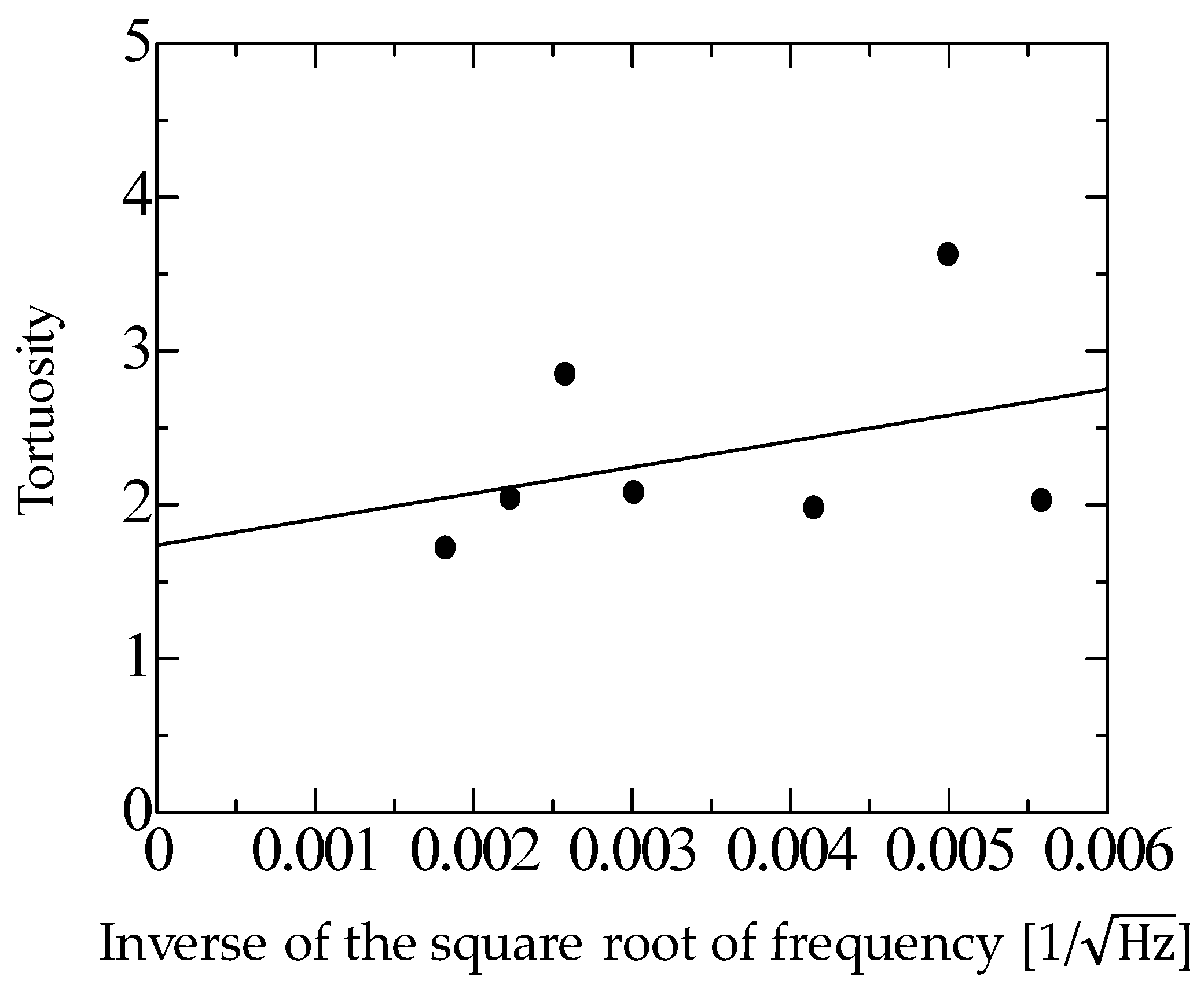

2.2. Tortuosity

3. Theoretical Analysis

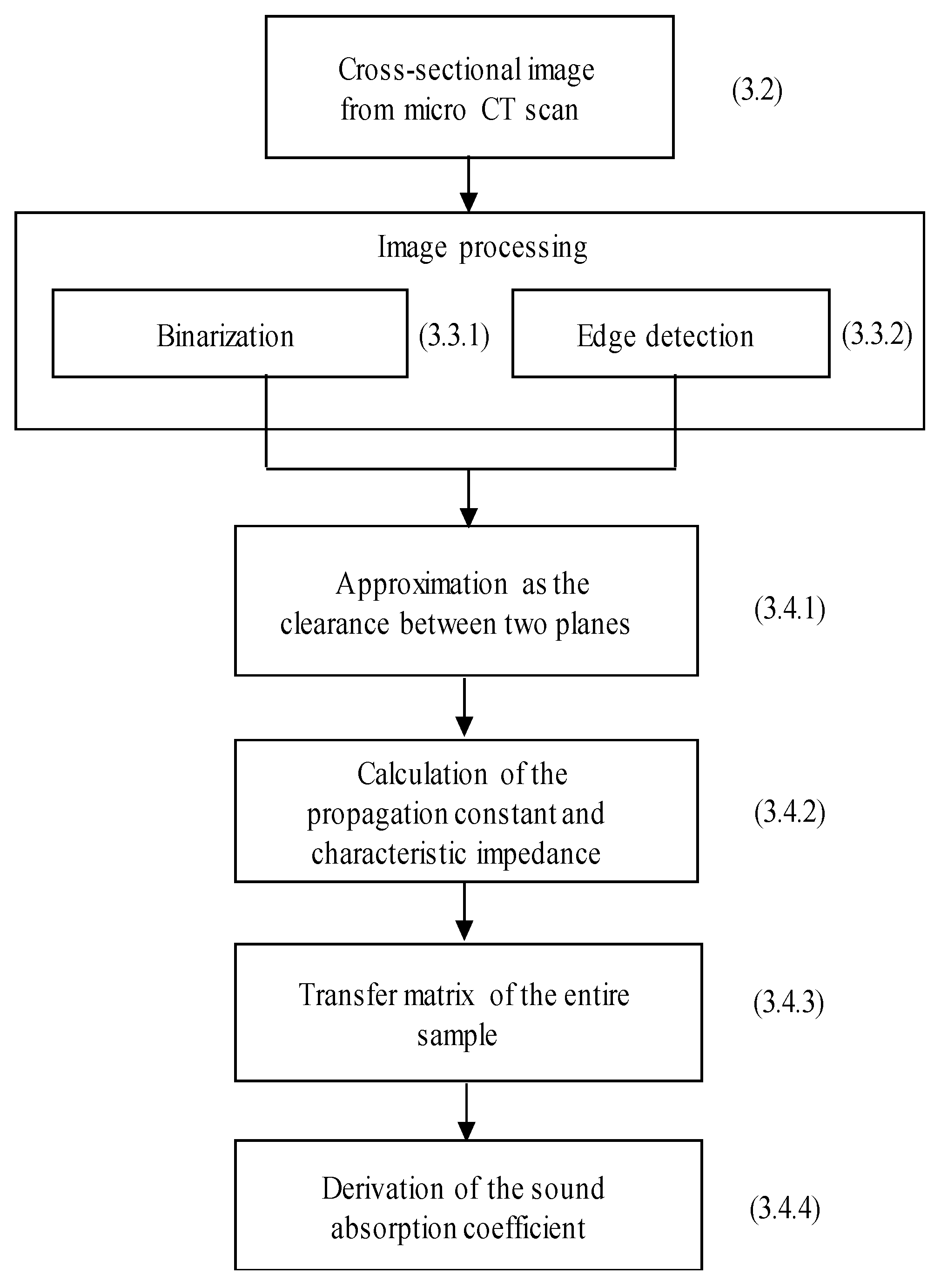

3.1. Overview

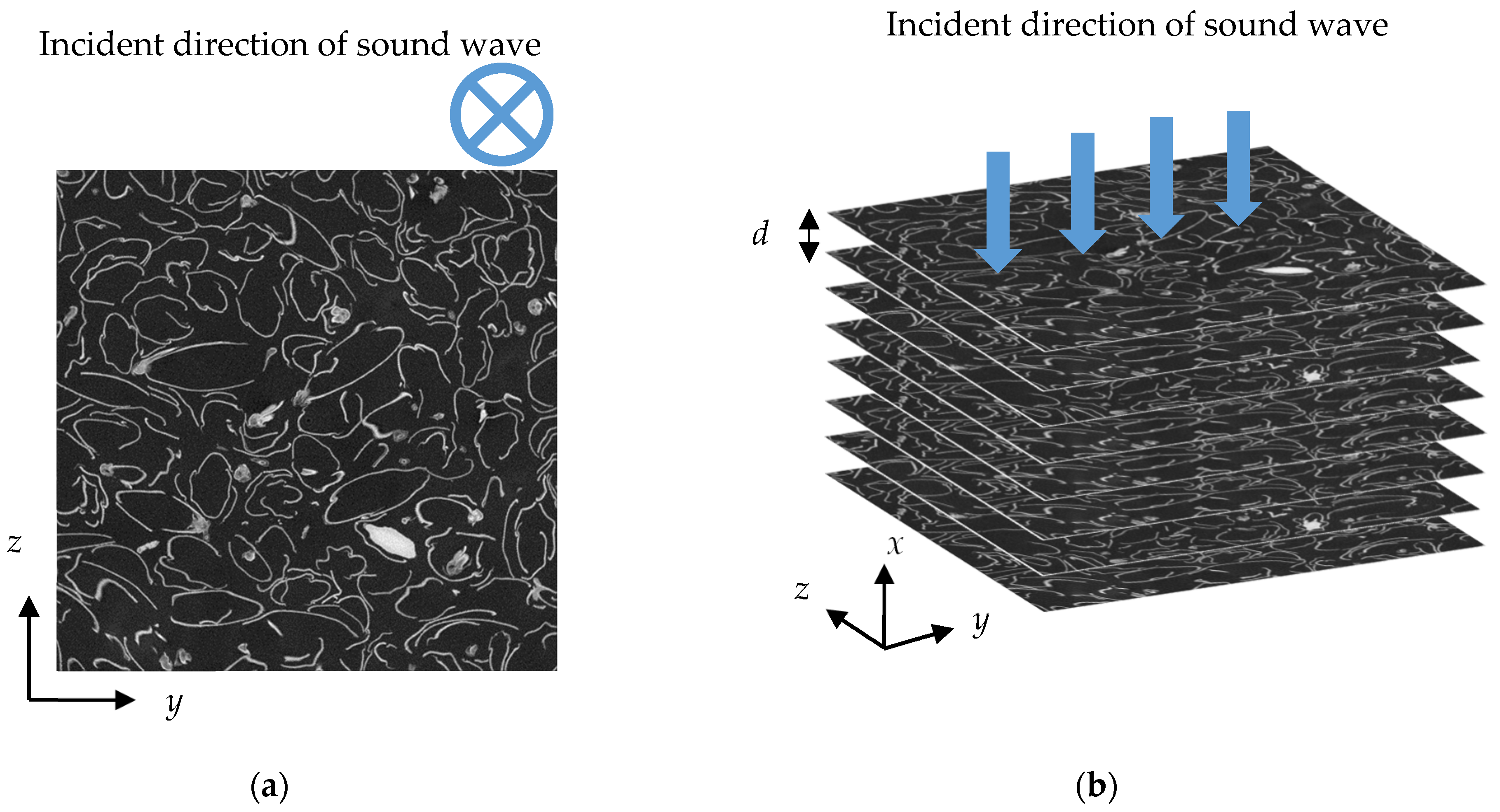

3.2. Image Acquisition

3.3. Image Processing

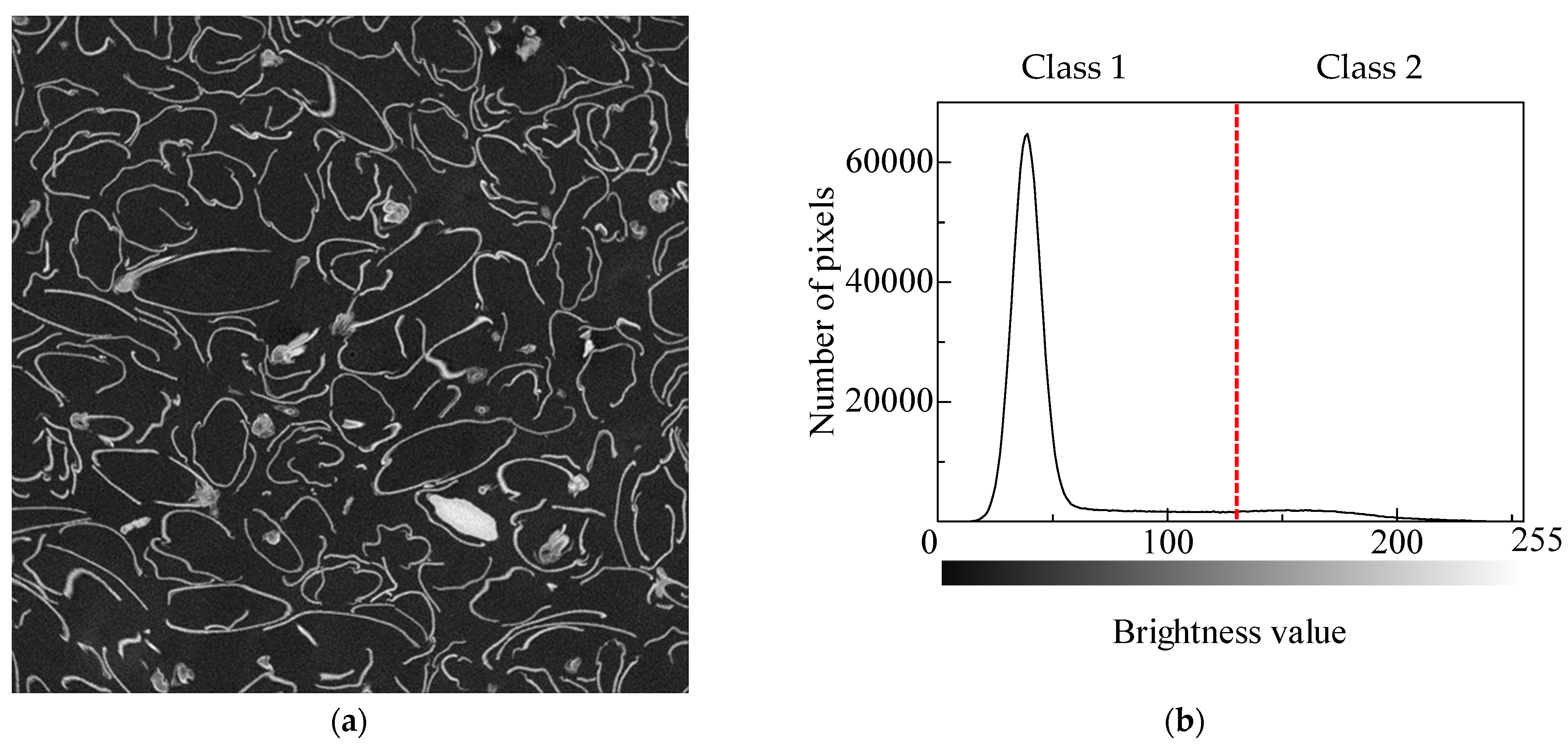

3.3.1. Binarization

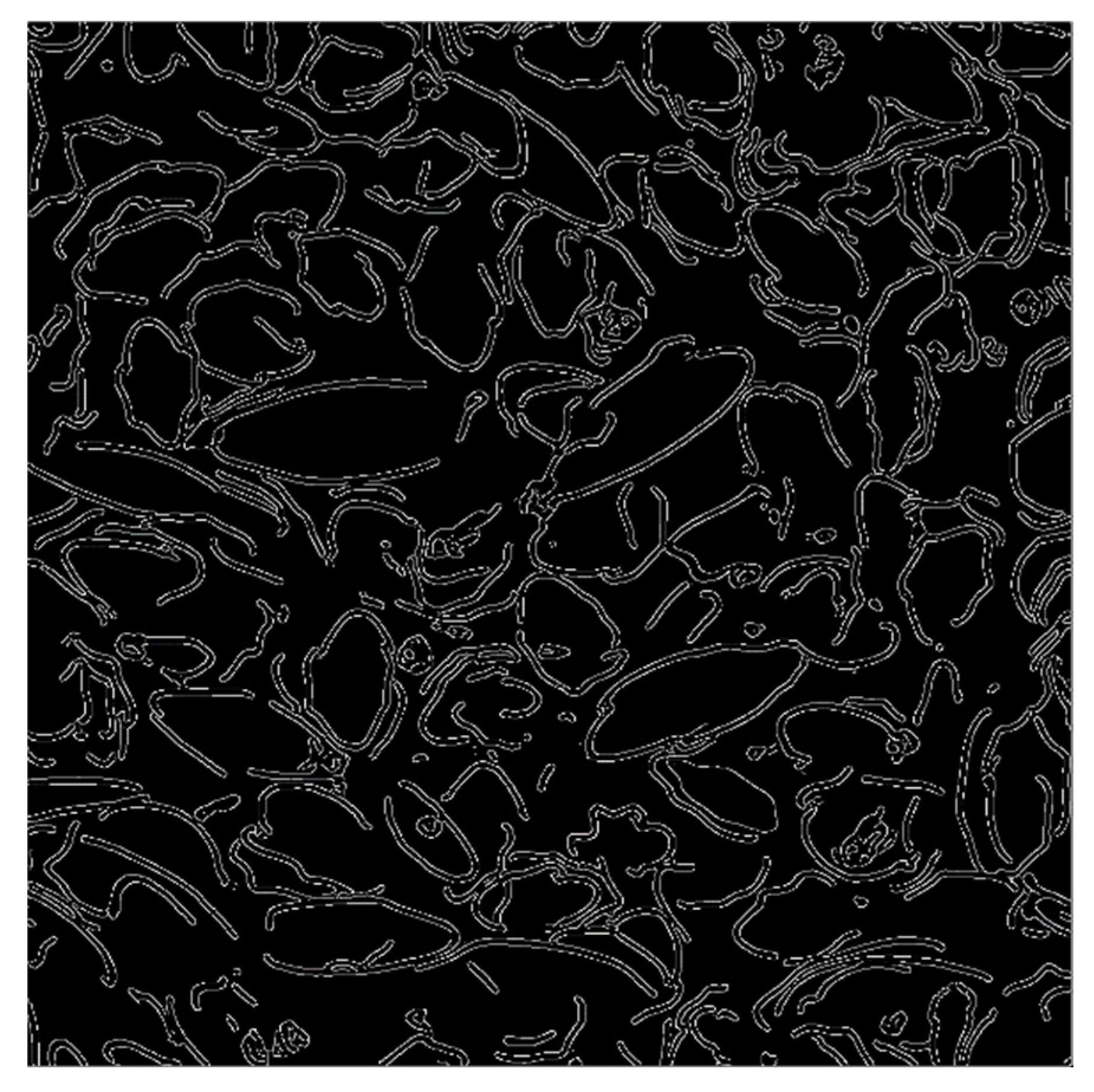

3.3.2. Edge Extraction

3.4. Derivation of the Sound Absorption Coefficient

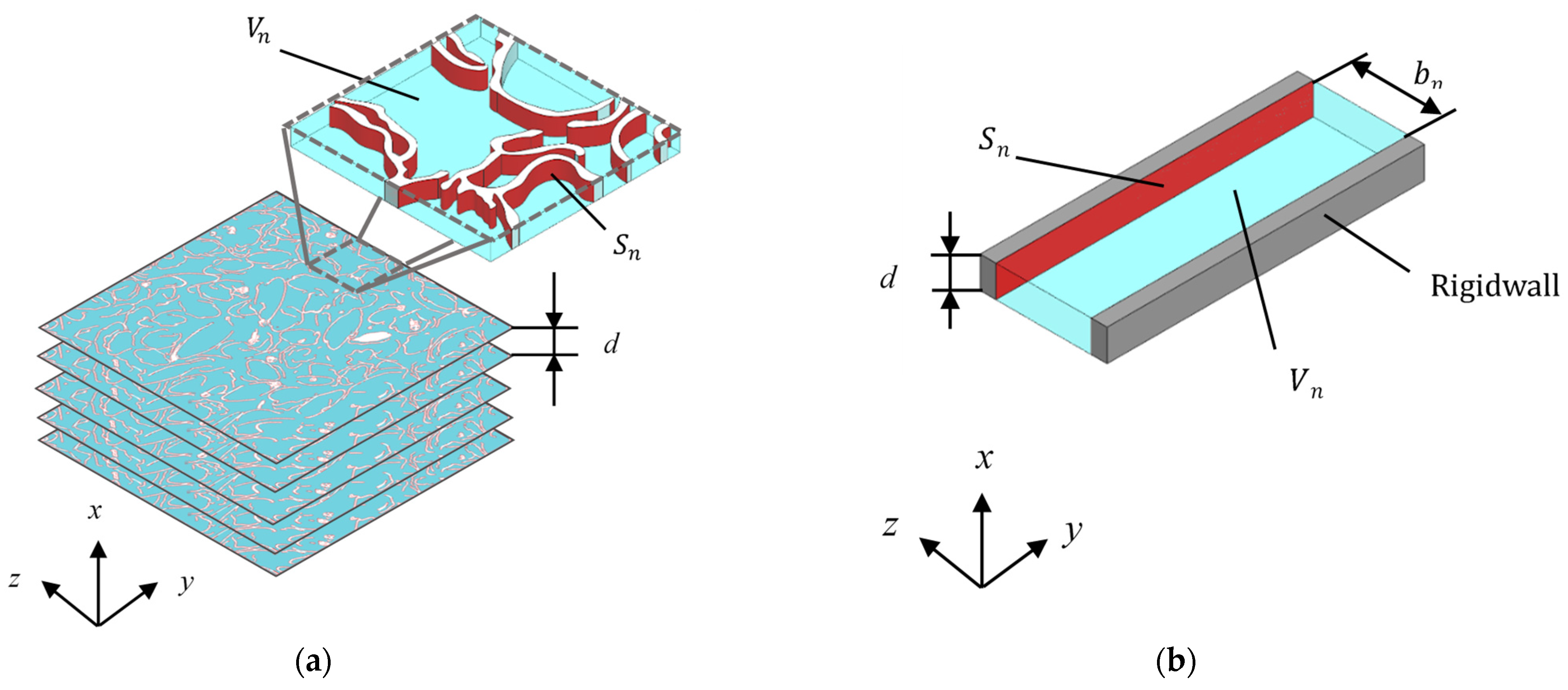

3.4.1. Approximation to Clearance between Two Planes

3.4.2. Propagation Constants and Characteristic Impedance

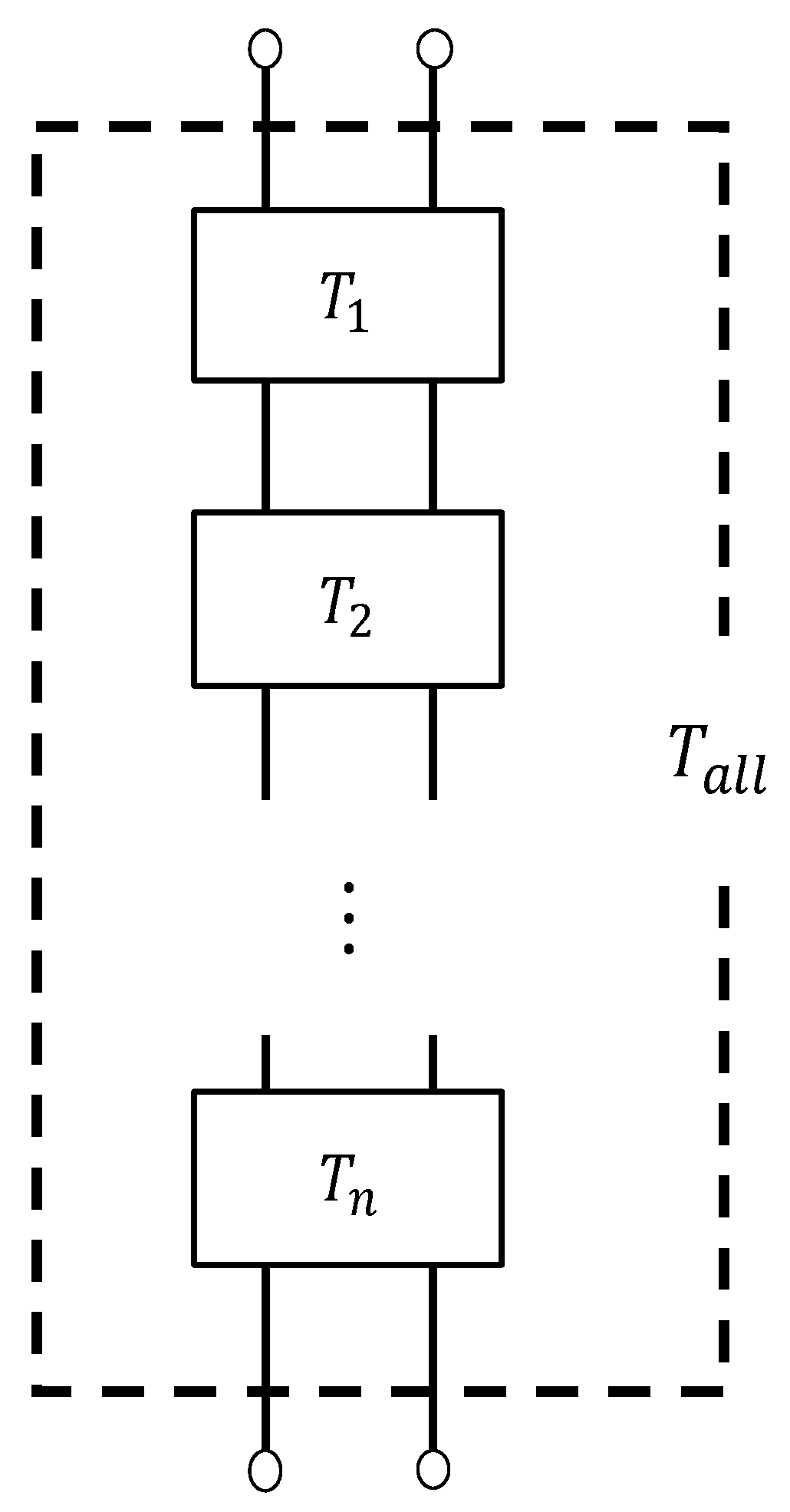

3.4.3. Transfer Matrix

3.4.4. Normal Incident Sound Absorption Coefficient

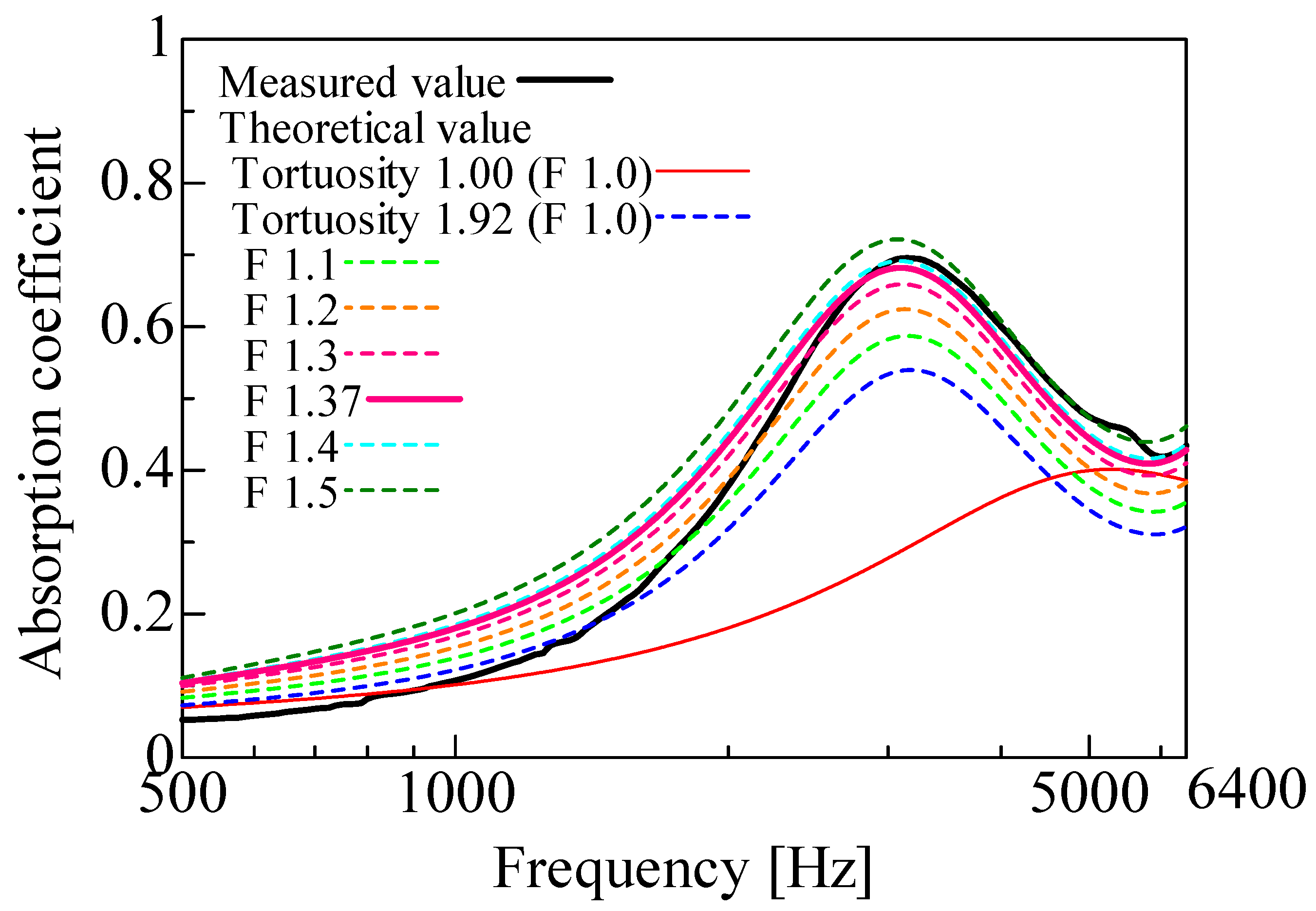

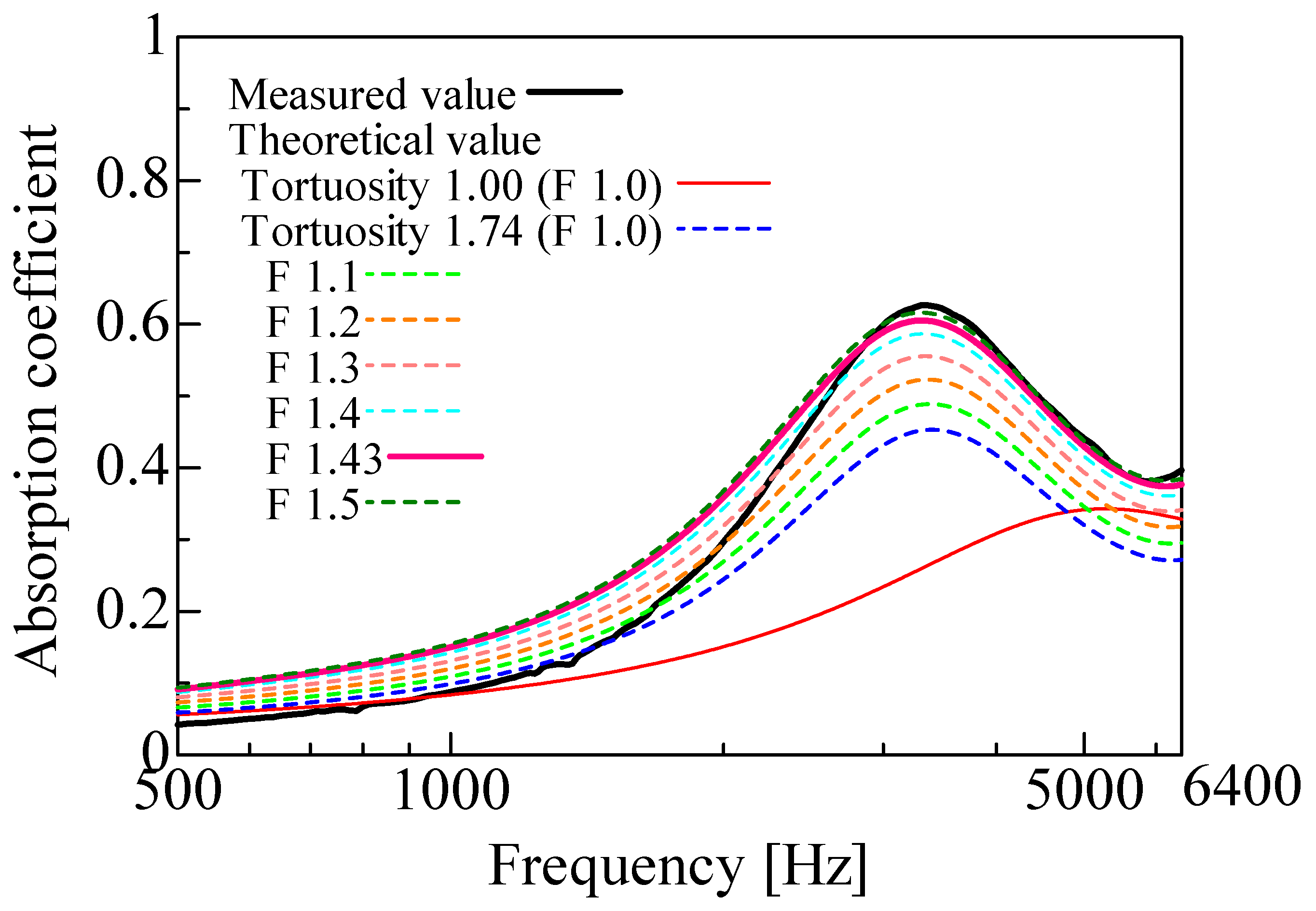

4. Results and Discussion

5. Conclusions

- The structures filled with rice and buckwheat husks were not periodic, which made constructing a geometric model difficult. Therefore, the sound absorption coefficient was estimated theoretically by first processing CT images.

- The tortuosity increased the theoretical value of the peak sound absorption and lowered the frequency, which decreased the difference with the measured values. Therefore, the measured tortuosity was considered reasonable.

- We used a correction factor to bring the surface area of the granular material closer to the actual surface area and observed that the tortuosity obtained theoretical values that matched the trend of the measured values. These results indicate that using CT images to estimate the sound absorption coefficient is a viable approach.

- Mass production application studies based on this research are under consideration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sakamoto, S.; Takauchi, Y.; Yanagimoto, K.; Watanabe, S. Study for Sound Absorbing Materials of Biomass Tubule etc (Measured Result for Rice Straw, Rice Husks, and Buckwheat Husks). J. Environ. Eng. 2011, 6, 352–364. [Google Scholar] [CrossRef]

- Sakamoto, S.; Tsurumaki, T.; Fujisawa, K.; Yamamiya, K. Study for sound-absorbing materials of biomass tubule (Oblique incident sound-absorption coefficient of oblique arrangement of rice straws). Trans. JSME 2016, 15, 16–00344. (In Japanese) [Google Scholar] [CrossRef]

- Sakamoto, S.; Tanikawa, H.; Maruyama, Y.; Yamaguchi, K.; Ii, K. Estimation and experiment for sound absorption coefficient of three clearance types using a bundle of nested tubes. J. Acoust. Soc. Am. 2018, 144, 2281–2293. [Google Scholar] [CrossRef]

- Bastos, L.P.; Melo, G.d.S.V.d.; Soeiro, N.S. Panels Manufactured from Vegetable Fibers: An Alternative Approach for Controlling Noises in Indoor Environments. Adv. Acoust. Vib. 2012, 2012, 698737. [Google Scholar] [CrossRef]

- Buot, P.G.C.; Cueto, R.M.; Esguerra, A.A.; Pascua, R.I.C.; Magon, E.S.S.; Gumasing, M.J.J. Design and Development of Sound Absorbing Panels using Biomass Materials. In Proceedings of the 2nd African International Conference on Industrial Engineering and Operations Management Harare, Harare, Zimbabwe, 7–10 December 2020. [Google Scholar]

- Or, K.H.; Putra, A.; Selamat, M.Z. Oil palm empty fruit bunch fibres as sustainable acoustic absorber. Appl. Acoust. 2017, 119, 9–16. [Google Scholar] [CrossRef]

- Ersoy, S.; Küçük, H. Investigation of industrial tea-leaf-fibre waste material for its sound absorption properties. Appl. Acoust. 2009, 70, 215–220. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Morillas, J.M.B.; Escobar, V.G. Acoustical performance of loose cork granulates. Eur. J. Wood Wood Prod. 2014, 72, 321–330. [Google Scholar] [CrossRef]

- Koizumi, T.; Tsujiuchi, N.; Adachi, A. The development of sound absorbing materials using natural bamboo fibers. High Perform. Struct. Mater. 2002, 4, 157–166. [Google Scholar] [CrossRef]

- McGinnes, C.; Kleiner, M.; Xiang, N. An environmental and economical solution to sound absorption using straw. J. Acoust. Soc. Am. 2005, 118, 1869. [Google Scholar] [CrossRef]

- Putra, A.; Abdullah, Y.; Efendy, H.; Farid, W.M.; Ayob, R.M.; Py, M.S. Utilizing sugarcane wasted fibers as a sustainable acoustic absorber. Procedia Eng. 2013, 53, 632–638. [Google Scholar] [CrossRef]

- Tsuchiya, Y.; Kobayashi, M. Examination of practical sound absorption coefficient by material and the composition. Toda Tech. Res. Rep. 2005, 31, 6. (In Japanese) [Google Scholar]

- Sakamoto, S.; Suzuki, K.; Toda, K.; Seino, S. Mathematical Models and Experiments on the Acoustic Properties of Granular Packing Structures (Measurement of tortuosity in hexagonal close-packed and face-centered cubic lattices). Materials 2022, 15, 7393. [Google Scholar] [CrossRef]

- Sakamoto, S.; Suzuki, K.; Toda, K.; Seino, S. Estimation of the Acoustic Properties of the Random Packing Structures of Granular Materials: Estimation of the Sound Ab-sorption Coefficient Based on Micro-CT Scan Data. Materials 2023, 16, 337. [Google Scholar] [CrossRef] [PubMed]

- Furubayashi, T. O-13 Analysis of Rice Husk Energy Utilization System Considering Monthly Generation Amount. In Proceedings of the Conference on Biomass Science, Online, 20–21 January 2021. (In Japanese). [Google Scholar] [CrossRef]

- Kojima, Y. Studies on Utilization of Husks from Buckwheat. In Proceedings of the Annual Conference of the Japan Institute of Energy, Hokkaido, Japan, 30–31 July 2003; pp. 3–41. (In Japanese). [Google Scholar] [CrossRef]

- Sakamoto, S.; Shintani, T.; Hasegawa, T. Simplified Limp Frame Model for Application to Nanofiber Nonwovens (Selection of Dominant Biot Parameters). Nanomaterials 2022, 12, 3050. [Google Scholar] [CrossRef]

- Maeda, E.; Miyake, H. A non-destructive tracing with an X-ray micro CT scanner of vascular bundles in the ear axes at the base of the lower level rachis-branches in Japonica type rice (oryza sativa). Jpn. J. Crop Sci. 2009, 78, 382–386. [Google Scholar] [CrossRef]

- Sakamoto, S.; Takakura, R.; Suzuki, R.; Katayama, I.; Saito, R.; Suzuki, K. Theoretical and Experimental Analyses of Acoustic Characteristics of Fine-grain Powder Considering Longitudinal Vibration and Boundary Layer Viscosity. J. Acoust. Soc. Am. 2021, 149, 1030–1040. [Google Scholar] [CrossRef] [PubMed]

- ISO 10534-2; Acoustics–Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes–Part 2: Transfer-Function Method. International Organization for Standardization: Geneva, Switzerland, 2002.

- Allard, J.F.; Castagnede, B.; Henry, M.; Lauriks, W. Evaluation of tortuosity in acoustic porous materials saturated by air. Rev. Sci. Instrum. 1994, 65, 754–755. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Canny, J. A Computational Approach to Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 8, 679–698. [Google Scholar] [CrossRef]

- Tijdeman, H. On the propagation of sound waves in cylindrical tubes. J. Sound Vib. 1975, 39, 1–33. [Google Scholar] [CrossRef]

- Stinson, M.R. The propagation of plane sound waves in narrow and wide circular tubes and generalization to uniform tubes of arbitrary cross-sectional shape. J. Acoust. Soc. Am. 1991, 89, 550–558. [Google Scholar] [CrossRef]

- Stinson, M.R.; Champoux, Y. Propagation of sound and the assignment of shape factors in model porous materials having simple pore geometries. J. Acoust. Soc. Am. 1992, 91, 685–695. [Google Scholar] [CrossRef]

- Beltman, W.; van der Hoogt, P.; Spiering, R.; Tijdeman, H. Implementation and experimental validation of a new viscothermal acoustic finite element for acousto-elastic problems. J. Sound Vib. 1998, 216, 159–185. [Google Scholar] [CrossRef]

- Allard, J.-F.; Daigle, G. Propagation of sound in Porous Media Modeling Sound Absorbing Materials. J. Acoust. Soc. Am. 1994, 95, 2785. [Google Scholar] [CrossRef]

- Sakamoto, S.; Shin, J.; Abe, S.; Toda, K. Addition of Two Substantial Side-Branch Silencers to the Interference Silencer by Incorporating a Zero-Mass Metamaterial. Materials 2022, 15, 5140. [Google Scholar] [CrossRef]

- Taban, E.; Khavanin, A.; Jafari, A.J.; Faridan, M.; Tabrizi, A.K. Experimental and mathematical survey of sound absorption performance of date palm fibers. Heliyon 2019, 5, e01977. [Google Scholar] [CrossRef]

- Cuiyun, D.; Guang, C.; Xinbang, X.; Peisheng, L. Sound absorption characteristics of a high-temperature sintering porous ceramic material. Appl. Acoust. 2012, 73, 865–871. [Google Scholar] [CrossRef]

- Sakamoto, S.; Tsutsumi, Y.; Yanagimoto, K.; Watanabe, S. Study for Acoustic Characteristics Variation of Granular Material by Water Content. Trans. Jpn. Soc. Mech. Eng. (Part C) 2009, 75, 2515–2520. [Google Scholar] [CrossRef]

- Sakamoto, S.; Higuchi, K.; Saito, K.; Koseki, S. Theoretical analysis for sound-absorbing materials using layered narrow clearances between two planes. J. Adv. Mech. Des. Syst. Manuf. 2014, 8, JAMDSM0036. [Google Scholar] [CrossRef]

| Material | Average Grain Size (mm) | Mass per Grain (mg) | Bulk Density (kg/m3) | Measured Tortuosity |

|---|---|---|---|---|

| Rice husk | 7.3 × 3.6 | 2.15 | 105.36 | 1.92 |

| Buckwheat husk | 5.7 × 4.1 | 4.54 | 110.66 | 1.74 |

| Surface Area Calculated from CT Images (mm2) | Surface Area in the 3D Model (mm2) | Correction Factor F | |

|---|---|---|---|

| Rice husk | 49,383 | 67,481 | 1.37 |

| Buckwheat husk | 41,461 | 59,403 | 1.43 |

| Peak Frequency (Hz) | Absorption Coefficient at Peak | Tortuosity | Correction Factor F | |

|---|---|---|---|---|

| Measured value | 3150 | 0.696 | - | - |

| Theoretical value | 5288 | 0.401 | 1.00 | 1.00 |

| Theoretical value (Considering tortuosity) | 3175 | 0.540 | 1.92 | 1.00 |

| Theoretical value (Considering surface correction) | 3100 | 0.682 | 1.92 | 1.37 |

| Peak Frequency (Hz) | Absorption Coefficient at Peak | Tortuosity | Correction Factor F | |

|---|---|---|---|---|

| Measured value | 3325 | 0.627 | - | - |

| Theoretical value | 5275 | 0.343 | 1.00 | 1.00 |

| Theoretical value (Considering tortuosity) | 3400 | 0.453 | 1.74 | 1.00 |

| Theoretical value (Considering surface correction) | 3313 | 0.605 | 1.74 | 1.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakamoto, S.; Toda, K.; Seino, S.; Hoshiyama, K.; Satoh, T. Theoretical and Experimental Analyses on the Sound Absorption Coefficient of Rice and Buckwheat Husks Based on Micro-CT Scan Data. Materials 2023, 16, 5671. https://doi.org/10.3390/ma16165671

Sakamoto S, Toda K, Seino S, Hoshiyama K, Satoh T. Theoretical and Experimental Analyses on the Sound Absorption Coefficient of Rice and Buckwheat Husks Based on Micro-CT Scan Data. Materials. 2023; 16(16):5671. https://doi.org/10.3390/ma16165671

Chicago/Turabian StyleSakamoto, Shuichi, Kentaro Toda, Shotaro Seino, Kohta Hoshiyama, and Takamasa Satoh. 2023. "Theoretical and Experimental Analyses on the Sound Absorption Coefficient of Rice and Buckwheat Husks Based on Micro-CT Scan Data" Materials 16, no. 16: 5671. https://doi.org/10.3390/ma16165671

APA StyleSakamoto, S., Toda, K., Seino, S., Hoshiyama, K., & Satoh, T. (2023). Theoretical and Experimental Analyses on the Sound Absorption Coefficient of Rice and Buckwheat Husks Based on Micro-CT Scan Data. Materials, 16(16), 5671. https://doi.org/10.3390/ma16165671