Effect of Mo2C Addition on the Tribological Behavior of Ti(C,N)-Based Cermets

Abstract

:1. Introduction

2. Materials and Methods

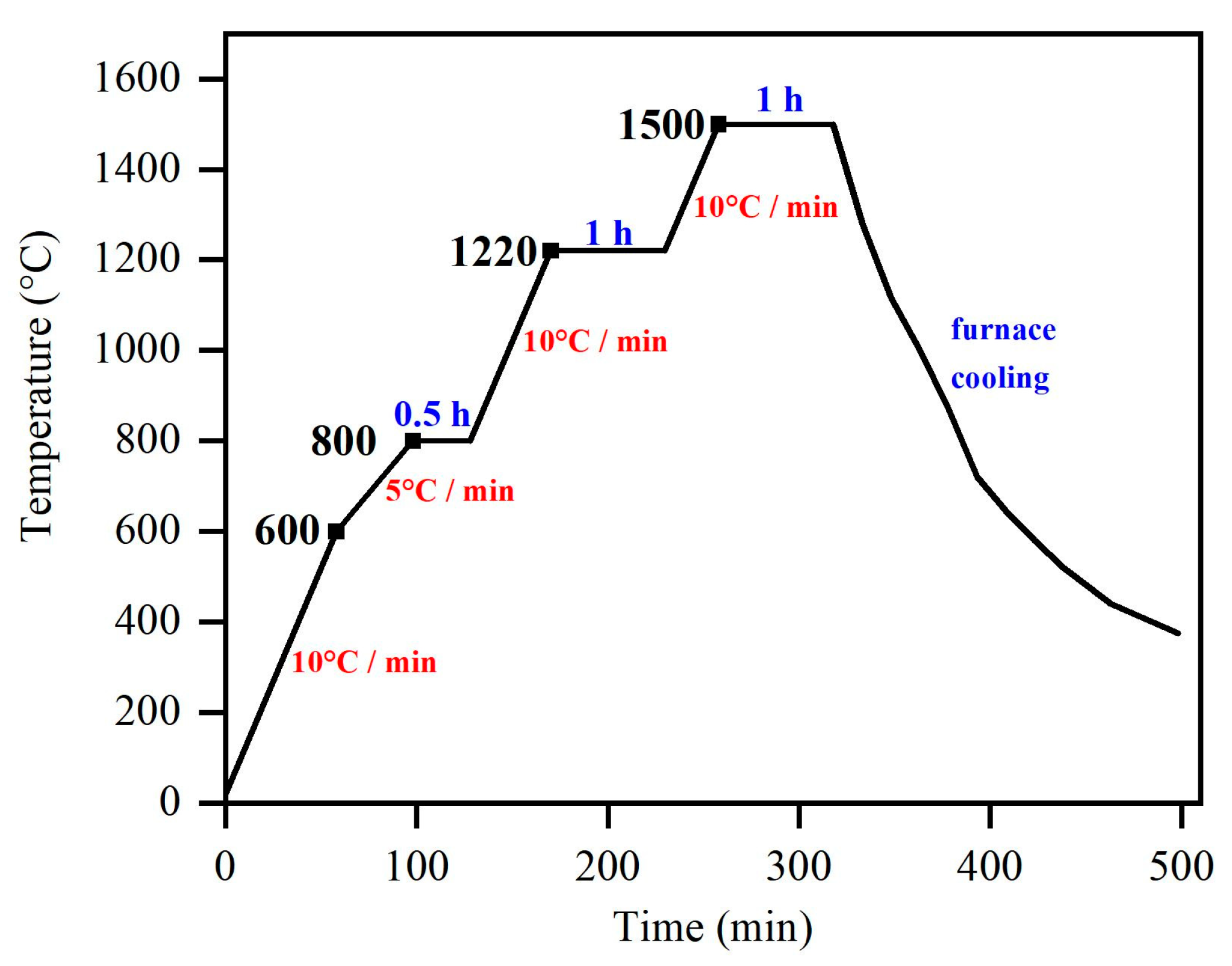

2.1. Preparation of Cermets

2.2. Characterization

2.3. Fretting Wear Test

3. Results and Discussion

3.1. Phase Analysis of TiCN-Based Cermets

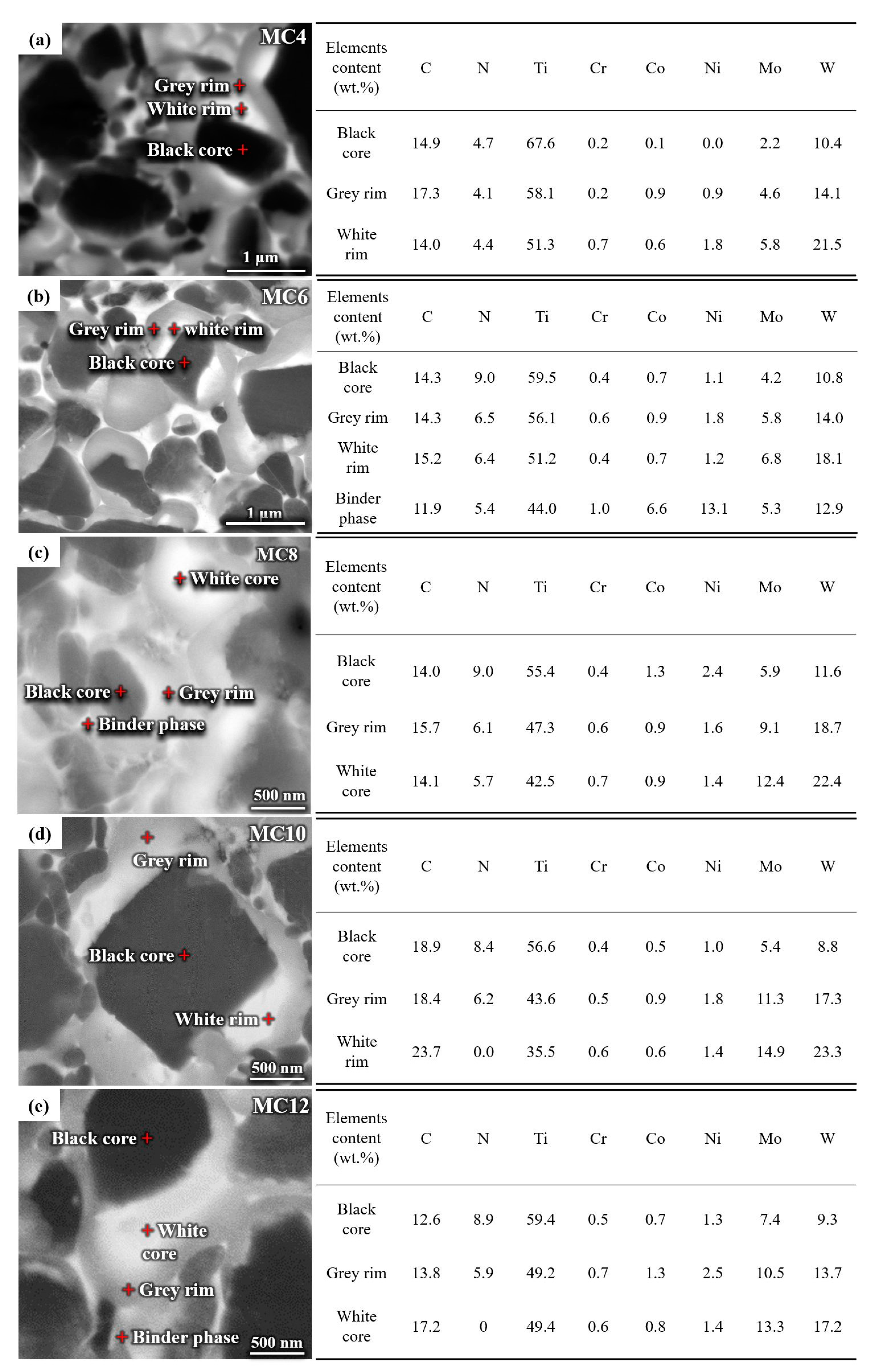

3.2. Core–Rim Morphology of Sintered TiCN-Based Cermet

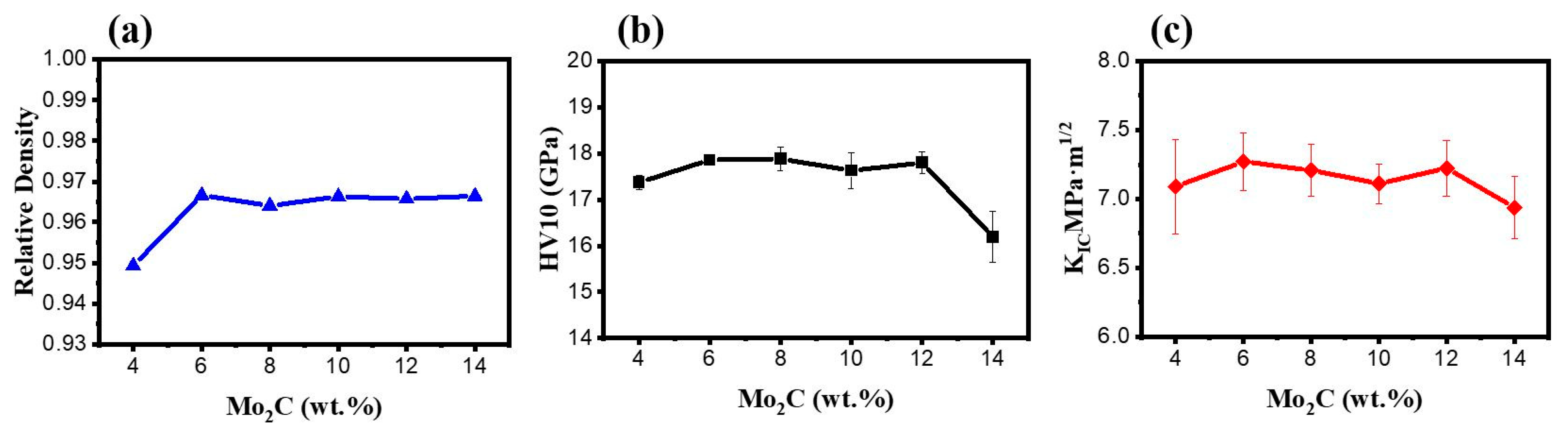

3.3. Mechanical Properties of Sintered TiCN-Based Cermet

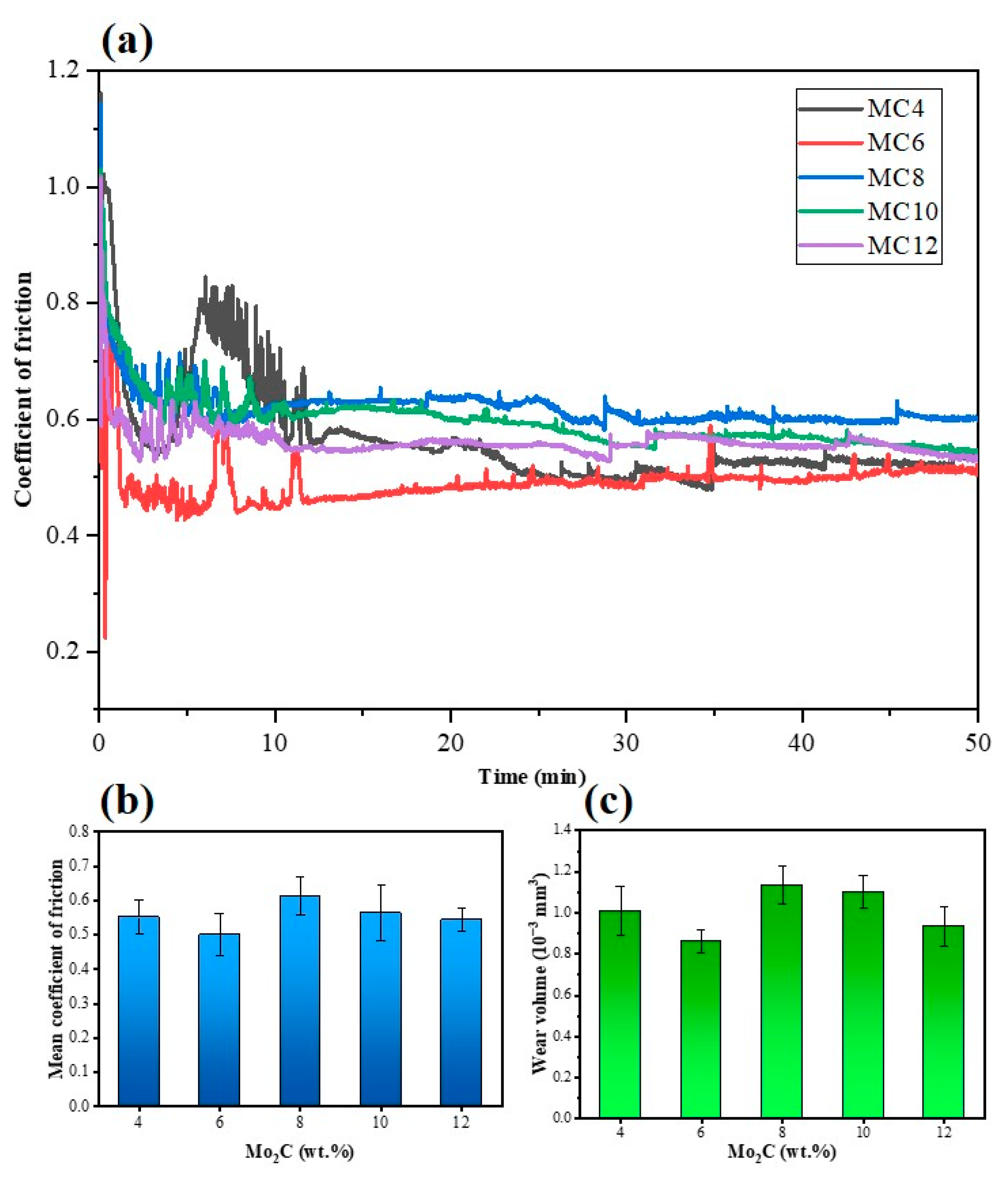

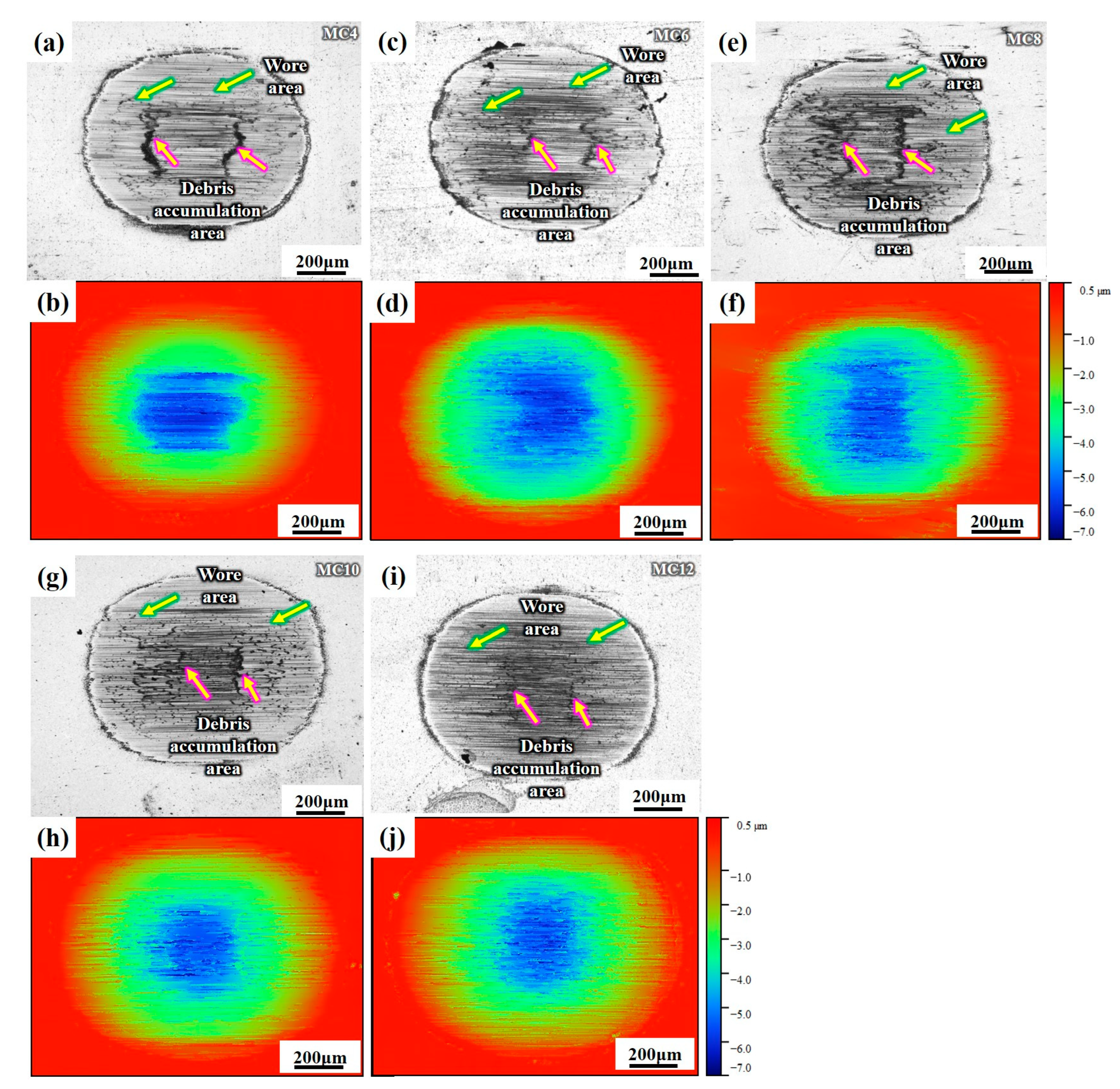

3.4. Frictional Behavior and Wear Results

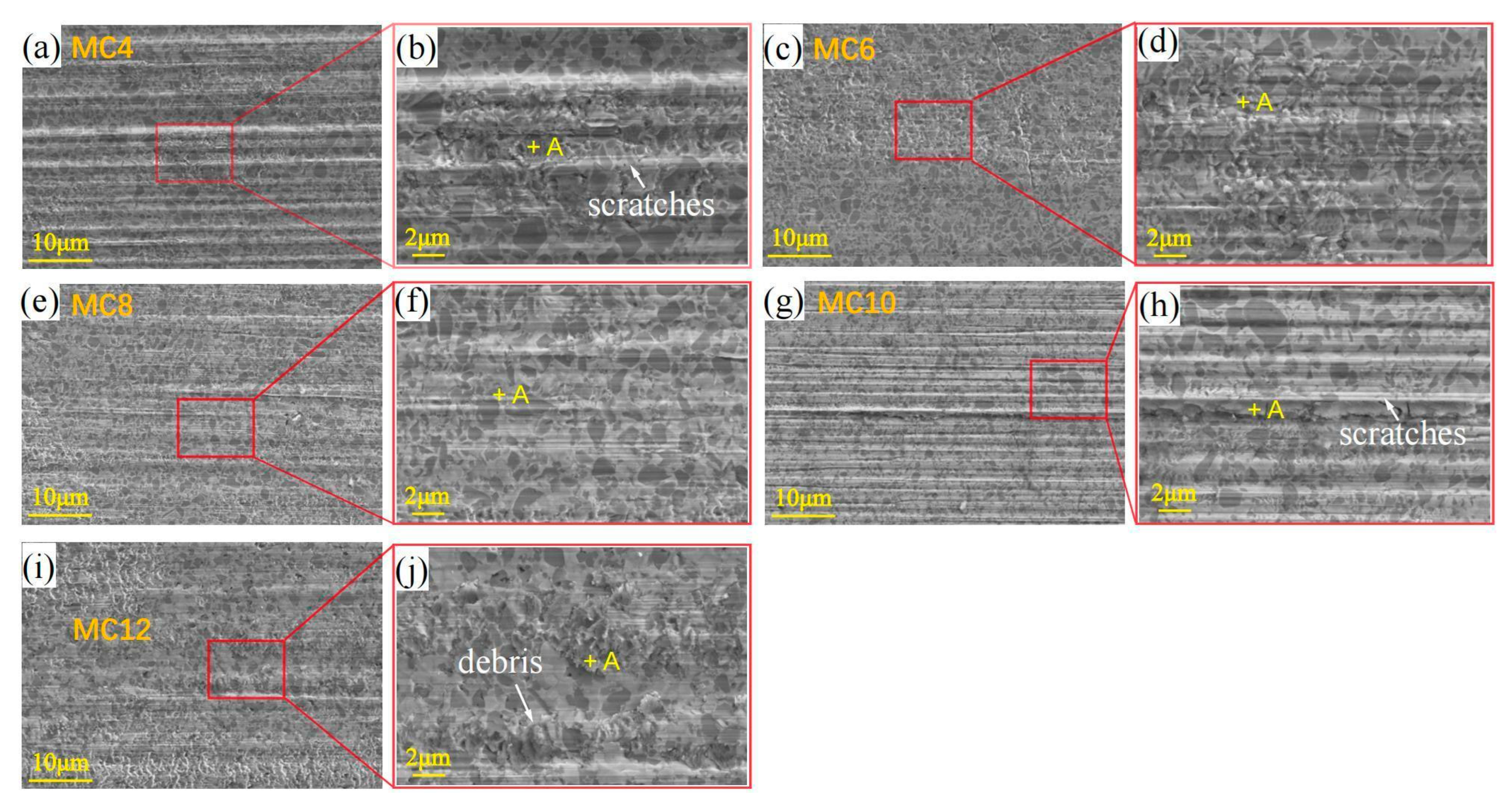

3.5. SEM and EDS Analysis of Worn Surfaces

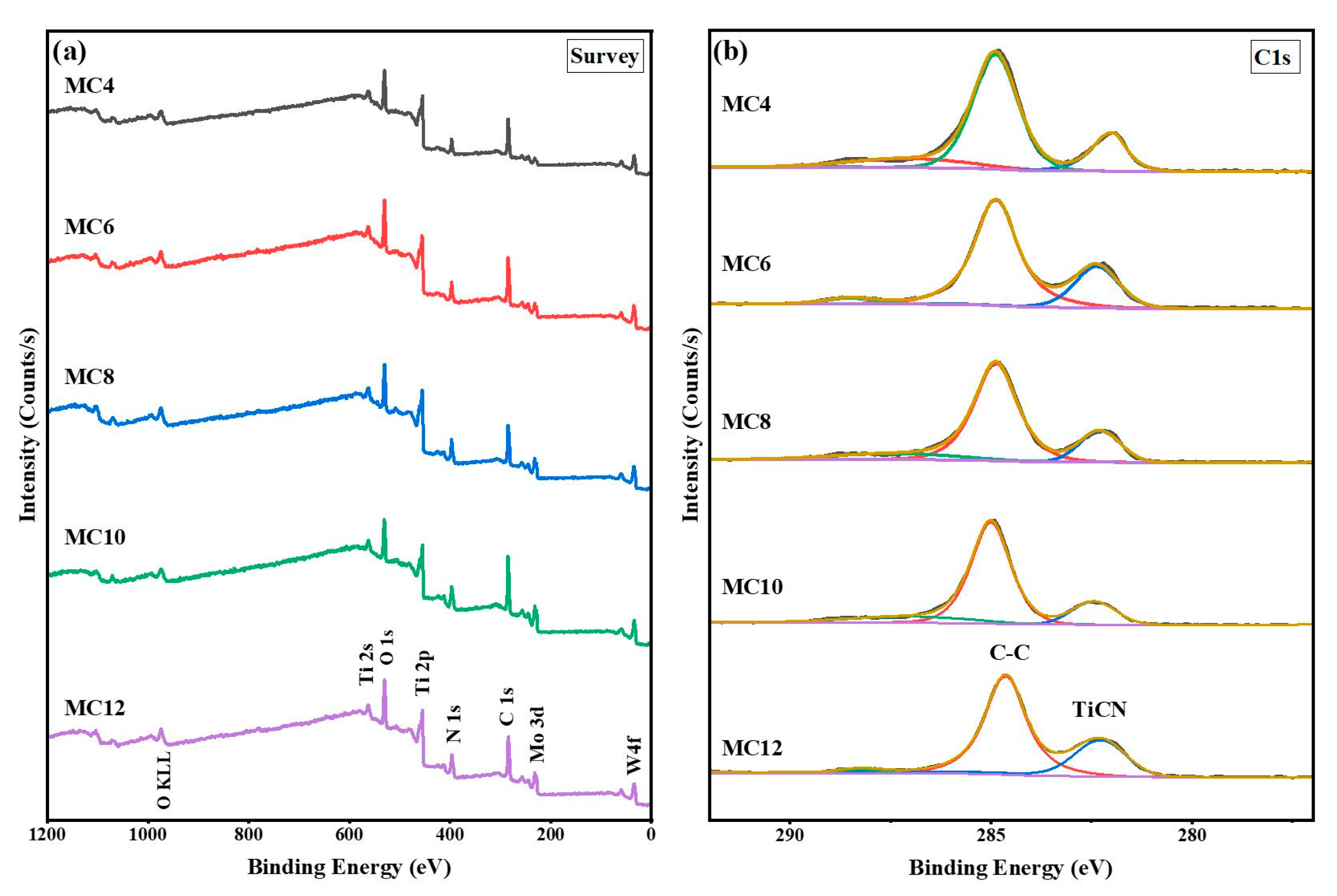

3.6. XPS Analysis of Worn Surfaces

4. Conclusions

- The addition of Mo2C could induce the formation of a “core–rim” structure, which exhibited significant strengthening effects on the mechanical properties, including hardness and fracture toughness. The core phase is mainly composed of Ti(C,N), while the rim phase is mainly composed of (W,Mo,Ti)(C,N). When the content of Mo2C is 6 wt.%, the cermets have optimal mechanical properties.

- Due to the Mo2C addition and “core–rim” structure, the wear mechanisms of cermets are mainly abrasive wear, adhesive wear, and oxidation wear. As the content of Mo2C increases from 4 wt.% to 12 wt.%, the friction coefficient and wear volume have a variation law of first decreasing, then increasing, and then decreasing, and reach minimum values at 6 wt.% and 12 wt.%, which is the result of the comprehensive effect of the Mo2C strengthening and the oxide film.

- The tribological behavior of Ti(C,N)-based cermets was determined according to the hardness, toughness and formation of an oxide film. On the one hand, the addition of Mo2C helped to increase the hardness and to form an oxide film, which plays a role in protecting the surface. On the other hand, the excessive carbide reduced the toughness and increased the risk of crushing. Combining these findings with practical engineering applications, and considering the mechanical properties, tribological properties, and cost factors, cermets with a Mo2C content of 6 wt.% are feasible.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lengauer, W.; Scagnetto, F. Ti(C,N)-Based Cermets: Critical Review of Achievements and Recent Developments. Solid State Phenom. 2018, 274, 53–100. [Google Scholar] [CrossRef]

- Peng, Y.; Miao, H.; Peng, Z. Development of TiCN-Based Cermets: Mechanical Properties and Wear Mechanism. Int. J. Refract. Met. Hard Mater. 2013, 39, 78–89. [Google Scholar] [CrossRef]

- Ettmayer, P.; Kolaska, H.; Lengauer, W.; Dreyer, K. Ti(C,N) Cermets—Metallurgy and Properties. Int. J. Refract. Met. Hard Mater. 1995, 13, 343–351. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Syarif, J.; Daud, A.R. Development and Application of Tool Wear: A Review of the Characterization of TiC-Based Cermets with Different Binders. Chem. Eng. J. 2014, 255, 445–452. [Google Scholar] [CrossRef]

- Heydari, L.; Lietor, P.F.; Corpas-Iglesias, F.A.; Laguna, O.H. Ti(C,N) and WC-Based Cermets: A Review of Synthesis, Properties and Applications in Additive Manufacturing. Materials 2021, 14, 6786. [Google Scholar] [CrossRef]

- Zhuang, Q.; Lin, N.; He, Y.; Kang, X. Influence of Temperature on Sintering Behavior and Properties of TiC-Fe-Co-Ni-Cr-Mo Cermets. Ceram. Int. 2017, 43, 15992–15998. [Google Scholar] [CrossRef]

- Hadi, M.; Rafiaei, S.M.; Fernandes, F. The Effect of Mo2C Additions on the Oxidation Resistance of (Ti,W)CN Cermets as Base Material for the Production of Cutting Tools. Ceram. Int. 2023, 49, 21538–21545. [Google Scholar] [CrossRef]

- Verma, V.; Kumar, B.V.M. Sliding Wear Behavior of SPS Processed TaC-Containing Ti(CN)-WC-Ni/Co Cermets against Silicon Carbide. Wear 2017, 376–377, 1570–1579. [Google Scholar] [CrossRef]

- Kwon, W.T.; Park, J.S.; Kim, S.W.; Kang, S.; Tae, W.; Seuk, J.; Kim, S.W.; Kang, S.; Kwon, W.T.; Park, J.S.; et al. Effect of WC and Group IV Carbides on the Cutting Performance of Ti(C,N) Cermet Tools. Int. J. Mach. Tools Manuf. 2004, 44, 341–346. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Kang, S. Formation of Core/Rim Structures in Ti(C,N)-WC-Ni Cermets via a Dissolution and Precipitation Process. J. Am. Ceram. Soc. 2000, 83, 1489–1494. [Google Scholar] [CrossRef]

- Binder, S.; Lengauer, W.; Ettmayer, P.; Bauer, J.; Debuigne, J.; Bohn, M. Phase Equilibria in the Systems TiCN, ZrCN and HfCN. J. Alloys Compd. 1995, 217, 128–136. [Google Scholar] [CrossRef]

- Hu, H.; Cheng, Y.; Yin, Z.; Zhang, Y.; Lu, T. Mechanical Properties and Microstructure of Ti(C, N) Based Cermet Cutting Tool Materials Fabricated by Microwave Sintering. Ceram. Int. 2015, 41, 15017–15023. [Google Scholar] [CrossRef]

- Rodriguez, N.; Sanchez, J.M.; Aristizabal, M. Consolidation of (Ti,Mo)(C,N)–Ni Cermets by Glass Encapsulated Hot Isostatic Pressing. Mater. Sci. Eng. A 2011, 528, 4453–4461. [Google Scholar] [CrossRef]

- Lemboub, S.; Boudebane, S.; Gotor, F.J.J.; Haouli, S.; Mezrag, S.; Bouhedja, S.; Hesser, G.; Chadli, H.; Chouchane, T. Core-Rim Structure Formation in TiC-Ni Based Cermets Fabricated by a Combined Thermal Explosion/Hot-Pressing Process. Int. J. Refract. Met. Hard Mater. 2018, 70, 84–92. [Google Scholar] [CrossRef]

- Chicardi, E.; Gotor, F.J.; Medri, V.; Guicciardi, S.; Lascano, S.; Córdoba, J.M. Hot-Pressing of (Ti,Mt)(C,N)-Co-Mo2C (Mt = Ta,Nb) Powdered Cermets Synthesized by a Mechanically Induced Self-Sustaining Reaction. Chem. Eng. J. 2016, 292, 51–61. [Google Scholar] [CrossRef]

- Monteverde, F.; Medri, V.; Bellosi, A. Microstructure of Hot-Pressed Ti(C,N)-Based Cermets. J. Eur. Ceram. Soc. 2002, 22, 2587–2593. [Google Scholar] [CrossRef]

- Sparling, W.A.; Plucknett, K.P. The Effects of Mo2C Additions on the Sintering Response of TiC0.3N0.7–Ni3Al Cermets. Int. J. Refract. Met. Hard Mater. 2016, 61, 98–106. [Google Scholar] [CrossRef]

- Xu, Q.; Zhao, J.; Ai, X.; Qin, W.; Wang, D.; Huang, W. Effect of Mo2C/(Mo2C+WC) Weight Ratio on the Microstructure and Mechanical Properties of Ti(C,N)-Based Cermet Tool Materials. J. Alloys Compd. 2015, 649, 885–890. [Google Scholar] [CrossRef]

- Lin, Z.; Xiong, J.; Guo, Z.; Zhou, W.; Wan, W.; Yang, L. Effect of Mo2C Addition on the Microstructure and Fracture Behavior of (W,Ti)C-Based Cemented Carbides. Ceram. Int. 2014, 40, 16421–16428. [Google Scholar] [CrossRef]

- Lindahl, P.; Rolander, U.; Andrén, H.O. Atom-Probe Analysis of the Binder Phase in TiC-TiN-Mo2C-(Ni, Co) Cermets. Int. J. Refract. Met. Hard Mater. 1993, 12, 115–119. [Google Scholar] [CrossRef]

- Rafiaei, S.M.; Bahrami, A.; Shokouhimehr, M. Influence of Ni/Co Binders and Mo2C on the Microstructure Evolution and Mechanical Properties of (Ti0.93W0.07)C–Based Cermets. Ceram. Int. 2018, 44, 17655–17659. [Google Scholar] [CrossRef]

- Engqvist, H.; Högberg, H.; Botton, G.; Ederyd, S.; Axén, N. Tribofilm Formation on Cemented Carbides in Dry Sliding Conformal Contact. Wear 2000, 239, 219–228. [Google Scholar] [CrossRef]

- Espinosa-Fernandez, L.; Borrell, A.; Salvador, M.D.; Gutierrez-Gonzalez, C.F. Sliding Wear Behavior of WC-Co-Cr3C2-VC Composites Fabricated by Conventional and Non-Conventional Techniques. Wear 2013, 307, 60–67. [Google Scholar] [CrossRef]

- Manoj Kumar, B.V.; Basu, B.; Kalin, M.; Vizintin, J. Load-Dependent Transition in Sliding Wear Properties of TiCN–WC–Ni Cermets. J. Am. Ceram. Soc. 2007, 90, 1534–1540. [Google Scholar] [CrossRef]

- Verma, V.; Manoj Kumar, B. V Tribological Characteristics of Conventionally Sintered TiCN-WC-Ni/Co Cermets against Cemented Carbide. Ceram. Int. 2017, 43, 368–375. [Google Scholar] [CrossRef]

- Qiu, H.; Li, X.; Pan, C.; Fan, J.; Qu, S. Effect of Mo2C Addition on the Formation of Core-Rim Structure and Mechanical Properties of Ti(C,N)-WC-Mo2C-(Ni,Co) Cermet. J. Mater. Res. Technol. 2023, 25, 750–762. [Google Scholar] [CrossRef]

- Liu, C.; Lin, N.; He, Y.H. Influence of Mo2C and TaC Additions on the Microstructure and Mechanical Properties of Ti(C,N)-Based Cermets. Ceram. Int. 2016, 42, 3569–3574. [Google Scholar] [CrossRef]

- Lóh, N.J.; Simão, L.; Faller, C.A.; De Noni, A.; Montedo, O.R.K. A Review of Two-Step Sintering for Ceramics. Ceram. Int. 2016, 42, 12556–12572. [Google Scholar] [CrossRef]

- Yang, Q.; Xiong, W.; Zhang, M.; Huang, B.; Chen, S. Microstructure and Mechanical Properties of Mo-Free Ti(C,N)-Based Cermets with Ni–XCr Binders. J. Alloys Compd. 2015, 636, 270–274. [Google Scholar] [CrossRef]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation Fracture of WC-Co Cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Cardinal, S.; Malchère, A.; Garnier, V.; Fantozzi, G. Microstructure and Mechanical Properties of TiC-TiN Based Cermets for Tools Application. Int. J. Refract. Met. Hard Mater. 2009, 27, 521–527. [Google Scholar] [CrossRef]

- Xu, L.W.; Lin, N.; Zhao, L.B.; Ma, C.; Wang, Z.Y.; He, Y.H. Improvement in Wear and Corrosion Resistance of Ti(C,N)-Based Cermets via Aluminum Nitride Additions. Vacuum 2019, 168, 108849. [Google Scholar] [CrossRef]

- Ye, J.; Xiong, J.; Guo, Z.; Yang, T.; Zhou, L.; Liu, J.; Li, S.; Li, T. Preparation of Self-Lubricating Ti(C,N)-Based Cermets by Solid Carburization and Wear Behavior. Int. J. Refract. Met. Hard Mater. 2017, 67, 68–73. [Google Scholar] [CrossRef]

- Akhtar, F.; Guo, S.J. Microstructure, Mechanical and Fretting Wear Properties of TiC-Stainless Steel Composites. Mater. Charact. 2008, 59, 84–90. [Google Scholar] [CrossRef]

- Lindahl, P.; Gustafson, P.; Rolander, U.; Stals, L.; Andrén, H.O. Microstructure of Model Cermets with High Mo or W Content. Int. J. Refract. Met. Hard Mater. 1999, 17, 411–421. [Google Scholar] [CrossRef]

- Demoly, A.; Lengauer, W.; Veitsch, C.; Rabitsch, K. Effect of Submicron Ti(C,N) on the Microstructure and the Mechanical Properties of Ti(C,N)-Based Cermets. Int. J. Refract. Met. Hard Mater. 2011, 29, 716–723. [Google Scholar] [CrossRef]

- Xiong, H.; Wen, Y.; Gan, X.; Li, Z.; Chai, L. Influence of Coarse TiCN Content on the Morphology and Mechanical Properties of Ultrafine TiCN-Based Cermets. Mater. Sci. Eng. A 2017, 682, 648–655. [Google Scholar] [CrossRef]

- García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Aramian, A.; Sadeghian, Z.; Narimani, M.; Razavi, N.; Berto, F. A Review on the Microstructure and Properties of TiC and Ti(C,N) Based Cermets. Int. J. Refract. Met. Hard Mater. 2023, 115, 106320. [Google Scholar] [CrossRef]

- Walbrühl, M.; Linder, D.; Ågren, J.; Borgenstam, A. Diffusion Modeling in Cemented Carbides: Solubility Assessment for Co, Fe and Ni Binder Systems. Int. J. Refract. Met. Hard Mater. 2017, 68, 41–48. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, S.; You, M.; Tan, H.; Xiong, W. Fabrication of Nanocomposite Ti(C,N)-Based Cermet by Spark Plasma Sintering. Mater. Chem. Phys. 2005, 92, 64–70. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Luo, D.M. Corrosion Behavior of Ti-Mo Alloys Cold Rolled and Heat Treated. J. Alloys Compd. 2011, 509, 6267–6272. [Google Scholar] [CrossRef]

- Oshikawa, K.; Nagai, M.; Omi, S. Characterization of Molybdenum Carbides for Methane Reforming by TPR, XRD, and XPS. J. Phys. Chem. B 2001, 105, 9124–9131. [Google Scholar] [CrossRef]

- Gengenbach, T.R.; Major, G.H.; Linford, M.R.; Easton, C.D. Practical Guides for X-ray Photoelectron Spectroscopy (XPS): Interpreting the Carbon 1s Spectrum. J. Vac. Sci. Technol. A 2021, 39, 13204. [Google Scholar] [CrossRef]

- Meng, J.; Lu, J.; Wang, J.; Yang, S. Tribological Behavior of TiCN-Based Cermets at Elevated Temperatures. Mater. Sci. Eng. A 2006, 418, 68–76. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Z.; Zheng, H.; Zhang, S.; Chen, Z.; Wang, S.; Zhao, X. Effects of the Addition of Multi-Walled Carbon Nanotubes on the Microstructure and Properties of Ti(C,N)-Based Cermets Prepared by Spark Plasma Sintering. Mater. Charact. 2022, 193, 112289. [Google Scholar] [CrossRef]

- Ren, B.; Li, D.; Jin, Q.; Cui, H.; Wang, C. A Self-Supported Porous WN Nanowire Array: An Efficient 3D Electrocatalyst for the Hydrogen Evolution Reaction. J. Mater. Chem. A 2017, 5, 19072–19078. [Google Scholar] [CrossRef]

- Qiao, X.-Q.; Wang, Z.; Li, C.; Zhang, H.; Hou, D.; Lan, Y.-Q.; Li, D.-S. A New, Efficient and Durable MoO2/Mo2C-C Cocatalyst with the Optimized Composition and Electronic Structure Via In-Situ Carburization for Photocatalytic H2 Evolution. SSRN Electron. J. 2022, 455, 140791. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.; Li, Z. Effect of MoO3 on the Microstructure and Tribological Properties of Laser-Clad Ni60/NanoCu/h-BN/MoO3 Composite Coatings over Wide Temperature Range. Surf. Coat. Technol. 2020, 387, 125477. [Google Scholar] [CrossRef]

- Yi, M.; Wang, J.; Li, C.; Bai, X.; Wei, G.; Zhang, J.; Xiao, G.; Chen, Z.; Zhou, T.; Wang, L.; et al. Friction and Wear Behavior of Ti(C,N) Self-Lubricating Cermet Materials with Multilayer Core-Shell Microstructure. Int. J. Refract. Met. Hard Mater. 2021, 100, 105629. [Google Scholar] [CrossRef]

| Powder | TiCN | WC | Mo2C | Cr3C2 | Ni | Co |

|---|---|---|---|---|---|---|

| Particle size (μm) | <1 | <0.8 | 2–5 | <0.8 | <5 | <5 |

| purity | 99.9% | 99.9% | 99.9% | 99.9% | 99.8% | 99.8% |

| Specimen | Composition (wt.%) | |||||

|---|---|---|---|---|---|---|

| TiCN | Co | Ni | Mo2C | WC | Cr3C2 | |

| MC4 | Bal. | 5 | 10 | 4 | 10 | 1 |

| MC6 | Bal. | 5 | 10 | 6 | 10 | 1 |

| MC8 | Bal. | 5 | 10 | 8 | 10 | 1 |

| MC10 | Bal. | 5 | 10 | 10 | 10 | 1 |

| MC12 | Bal. | 5 | 10 | 12 | 10 | 1 |

| MC14 | Bal. | 5 | 10 | 14 | 10 | 1 |

| Parameter | Set Value |

|---|---|

| Stroke (μm) | 200 |

| Frequency (Hz) | 20 |

| Preloading Time (min) | 5 |

| Preloading Force (N) | 5 |

| Normal Force (N) | 50 |

| Loading Time (min) | 50 |

| Samples | Mo2C (wt.%) | Black Core/Grey Rim | White Core/Grey Rim | Binder |

|---|---|---|---|---|

| MC4 | 4 | 4.287 | - | 3.557 |

| MC6 | 6 | 4.296 | 4.286 | 3.568 |

| MC8 | 8 | 4.302 | 4.290 | 3.572 |

| MC10 | 10 | 4.302 | 4.289 | 3.573 |

| MC12 | 12 | 4.308 | 4.290 | 3.577 |

| Samples | C | N | O | Ti | Si | Cr | Co | Ni | Mo | W |

|---|---|---|---|---|---|---|---|---|---|---|

| MC4 | 10.03 | 9.87 | 1.36 | 66.73 | - | 0.53 | 2.68 | 8.79 | ||

| MC6 | 9.05 | 9.66 | 3.83 | 61.4 | - | 1.12 | 2.15 | 3.79 | 9.01 | |

| MC8 | 8.02 | 16.63 | 50.24 | - | 0.45 | 0.7 | 1.19 | 9.75 | 13.01 | |

| MC10 | 4.23 | 0 | 15.92 | 49.7 | 1.19 | 0.52 | 0.38 | 0.7 | 12.17 | 15.2 |

| MC12 | 5.24 | 1.26 | 14.76 | 52.82 | - | 0.5 | 2.19 | 4.45 | 9.01 | 9.79 |

| Elements and Compounds | Binding Energy (eV) | at. % | Elements and Compounds | Binding Energy (eV) | at. % | |

|---|---|---|---|---|---|---|

| MC4 | Ti 2p3/2 | 455.16 | 7.51 | Mo2C 3d5/2 | 228.56 | 11.69 |

| Ti 2p1/2 | 461.16 | 8.31 | Mo2C 3d3/2 | 231.86 | 11.66 | |

| Ti 2p3/2 sat. | 458.35 | 36.57 | MoO2 3d5/2 | 228.61 | 17.93 | |

| Ti 2p1/2 sat. | 462.93 | 13.37 | MoO2 3d3/2 | 231.61 | 17.74 | |

| Ti others | 455.84 | 34.25 | Mo2O5 3d5/2 | 230.17 | 7.01 | |

| WC 4f7/2 | 32.40 | 4.33 | Mo2O5 3d3/2 | 233.17 | 7.02 | |

| WC 4f5/2 | 34.47 | 4.33 | MoO3 3d5/2 | 232.47 | 13.47 | |

| WO2 4f7/2 | 33.46 | 1.14 | MoO3 3d3/2 | 235.47 | 13.48 | |

| WO2 4f5/2 | 35.61 | 1.15 | ||||

| W 4f others | 34.50 | 61.98 | ||||

| W 4f others | 36.99 | 27.06 | ||||

| MC6 | Ti 2p3/2 | 455.16 | 5.31 | Mo2C 3d5/2 | 228.64 | 7.91 |

| Ti 2p1/2 | 461.16 | 5.91 | Mo2C 3d3/2 | 231.64 | 7.92 | |

| Ti 2p3/2 sat. | 458.26 | 35.15 | MoO2 3d5/2 | 228.93 | 22.16 | |

| Ti 2p1/2 sat. | 462.77 | 18.50 | MoO2 3d3/2 | 231.93 | 21.90 | |

| Ti others | 455.92 | 35.13 | Mo2O5 3d5/2 | 230.17 | 8.03 | |

| WC 4f7/2 | 32.40 | 6.70 | Mo2O5 3d3/2 | 233.17 | 8.04 | |

| WC 4f5/2 | 34.47 | 10.99 | MoO3 3d5/2 | 235.58 | 12.03 | |

| WO2 4f7/2 | 33.46 | 2.96 | MoO3 3d3/2 | 232.58 | 12.02 | |

| WO2 4f5/2 | 35.53 | 7.89 | ||||

| W 4f others | 35.09 | 45.03 | ||||

| W 4f others | 37.35 | 26.44 | ||||

| MC8 | Ti 2p3/2 | 455.16 | 6.70 | Mo2C 3d5/2 | 228.64 | 11.44 |

| Ti 2p1/2 | 461.16 | 7.45 | Mo2C 3d3/2 | 231.85 | 11.45 | |

| Ti 2p3/2 sat. | 458.36 | 3.58 | MoO2 3d5/2 | 228.93 | 5.91 | |

| Ti 2p1/2 sat. | 462.35 | 7.93 | MoO2 3d3/2 | 234.85 | 7.92 | |

| Ti others | 456.04 | 74.34 | Mo2O5 3d5/2 | 230.17 | 21.97 | |

| WC 4f7/2 | 32.40 | 3.97 | Mo2O5 3d3/2 | 233.17 | 22.00 | |

| WC 4f5/2 | 34.47 | 3.97 | MoO3 3d5/2 | 232.47 | 9.65 | |

| WO2 4f7/2 | 33.46 | 1.15 | MoO3 3d3/2 | 235.77 | 9.66 | |

| WO2 4f5/2 | 35.53 | 1.16 | ||||

| W 4f others | 34.65 | 47.66 | ||||

| W 4f others | 37.01 | 42.09 | ||||

| MC10 | Ti 2p3/2 | 455.16 | 9.30 | Mo2C 3d5/2 | 228.64 | 21.04 |

| Ti 2p1/2 | 460.96 | 10.15 | Mo2C 3d3/2 | 231.80 | 21.06 | |

| Ti 2p3/2 sat. | 457.81 | 12.06 | MoO2 3d5/2 | 228.93 | 13.24 | |

| Ti 2p1/2 sat. | 462.34 | 13.39 | MoO2 3d3/2 | 231.93 | 13.25 | |

| Ti others | 455.58 | 55.09 | Mo2O5 3d5/2 | 230.17 | 7.73 | |

| WC 4f7/2 | 32.23 | 4.76 | Mo2O5 3d3/2 | 233.17 | 7.69 | |

| WC 4f5/2 | 34.36 | 4.76 | MoO3 3d5/2 | 232.47 | 7.99 | |

| WO2 4f7/2 | 33.46 | 2.81 | MoO3 3d3/2 | 235.47 | 8.00 | |

| WO2 4f5/2 | 35.46 | 2.81 | ||||

| W 4f others | 34.96 | 43.09 | ||||

| W 4f others | 37.29 | 41.77 | ||||

| MC12 | Ti 2p3/2 | 455.16 | 8.98 | Mo2C 3d5/2 | 228.64 | 17.07 |

| Ti 2p1/2 | 460.96 | 9.85 | Mo2C 3d3/2 | 231.78 | 11.29 | |

| Ti 2p3/2 sat. | 458.10 | 21.60 | MoO2 3d5/2 | 228.93 | 11.69 | |

| Ti 2p1/2 sat. | 462.47 | 17.93 | MoO2 3d3/2 | 232.22 | 7.73 | |

| Ti others | 456.04 | 32.52 | Mo2O5 3d5/2 | 230.17 | 19.10 | |

| WC 4f7/2 | 32.40 | 17.18 | Mo2O5 3d3/2 | 233.25 | 12.63 | |

| WC 4f5/2 | 34.50 | 13.33 | MoO3 3d5/2 | 232.47 | 12.34 | |

| WO2 4f7/2 | 33.46 | 3.57 | MoO3 3d3/2 | 235.55 | 8.16 | |

| WO2 4f5/2 | 35.13 | 2.82 | ||||

| W 4f others | 35.21 | 41.74 | ||||

| W 4f others | 37.61 | 21.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, H.; Li, X.; Pan, C.; Fan, J. Effect of Mo2C Addition on the Tribological Behavior of Ti(C,N)-Based Cermets. Materials 2023, 16, 5645. https://doi.org/10.3390/ma16165645

Qiu H, Li X, Pan C, Fan J. Effect of Mo2C Addition on the Tribological Behavior of Ti(C,N)-Based Cermets. Materials. 2023; 16(16):5645. https://doi.org/10.3390/ma16165645

Chicago/Turabian StyleQiu, Hao, Xiaoqiang Li, Cunliang Pan, and Jiafeng Fan. 2023. "Effect of Mo2C Addition on the Tribological Behavior of Ti(C,N)-Based Cermets" Materials 16, no. 16: 5645. https://doi.org/10.3390/ma16165645

APA StyleQiu, H., Li, X., Pan, C., & Fan, J. (2023). Effect of Mo2C Addition on the Tribological Behavior of Ti(C,N)-Based Cermets. Materials, 16(16), 5645. https://doi.org/10.3390/ma16165645