Study on the Modification of Silty Soil Sites Using Nanosilica and Methylsilicate

Abstract

:1. Introduction

2. Experiment Scheme

2.1. Experimental Materials

2.2. Experimental Method

3. Results and Discussion

3.1. Modification Experiment of Single Doping by Nanosilica

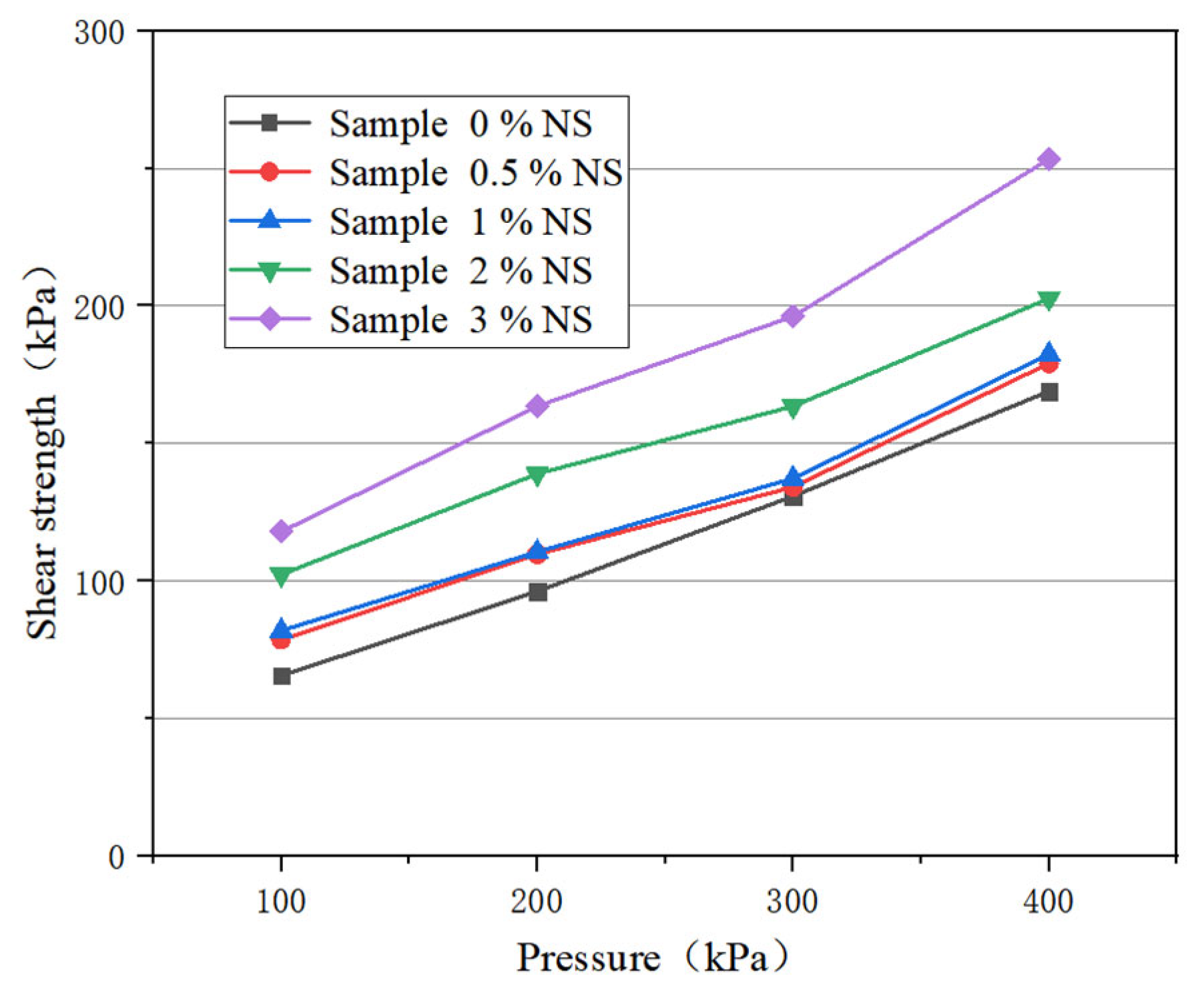

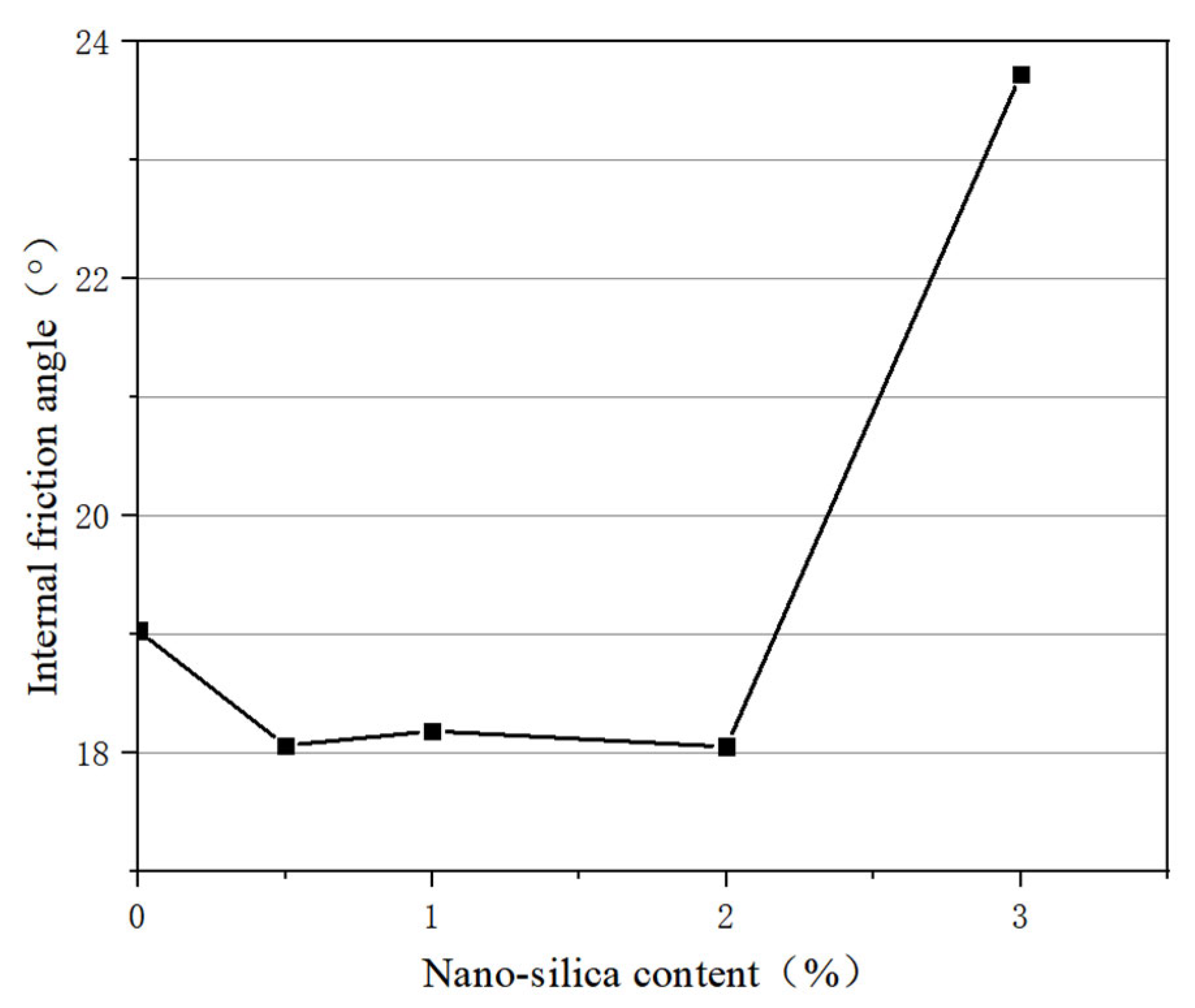

3.1.1. Direct Shear Testing

3.1.2. Capillary Water Rise Testing

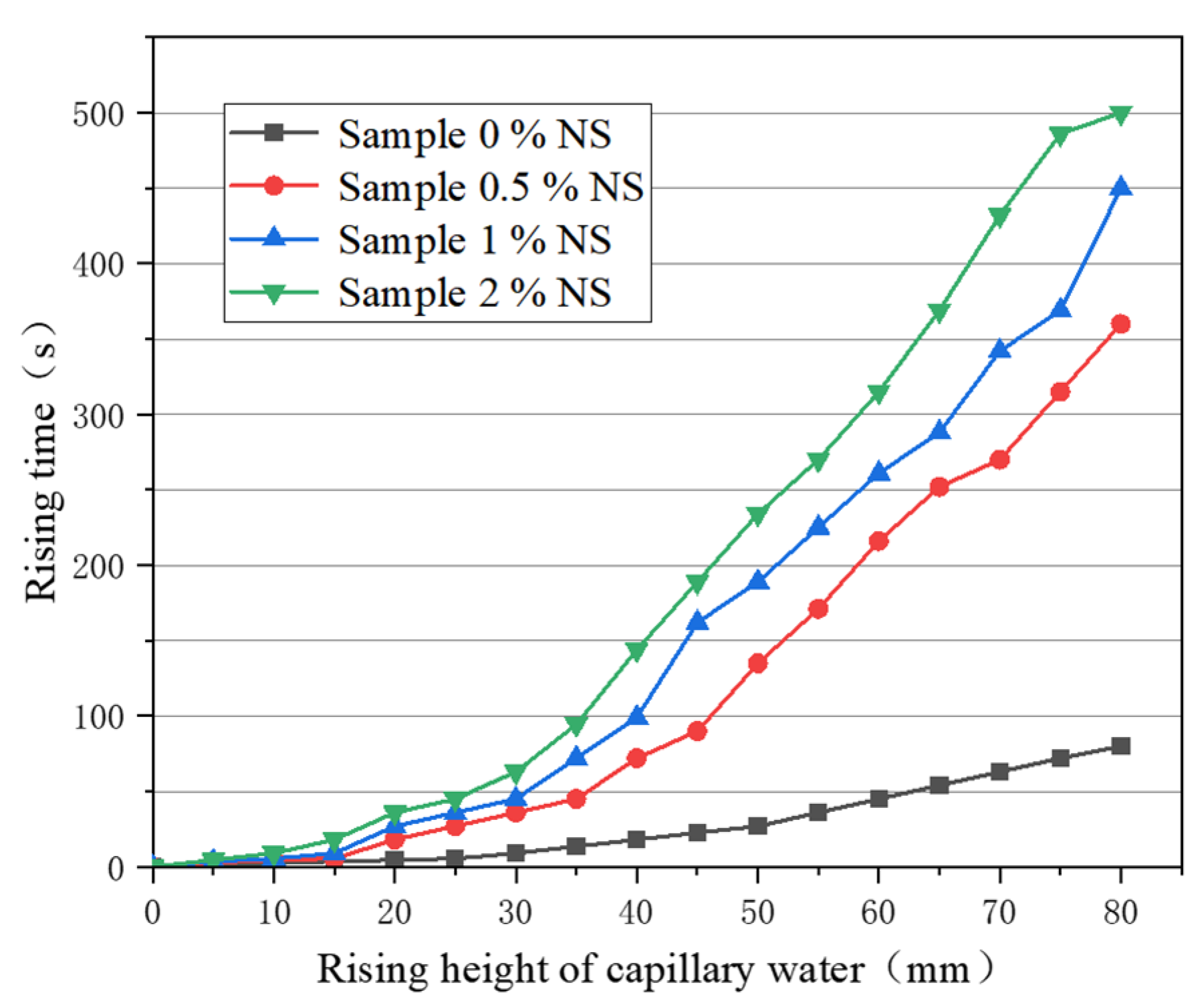

3.2. Experimental Study on Combined Modification with Nanosilica and Potassium Methylsilicate

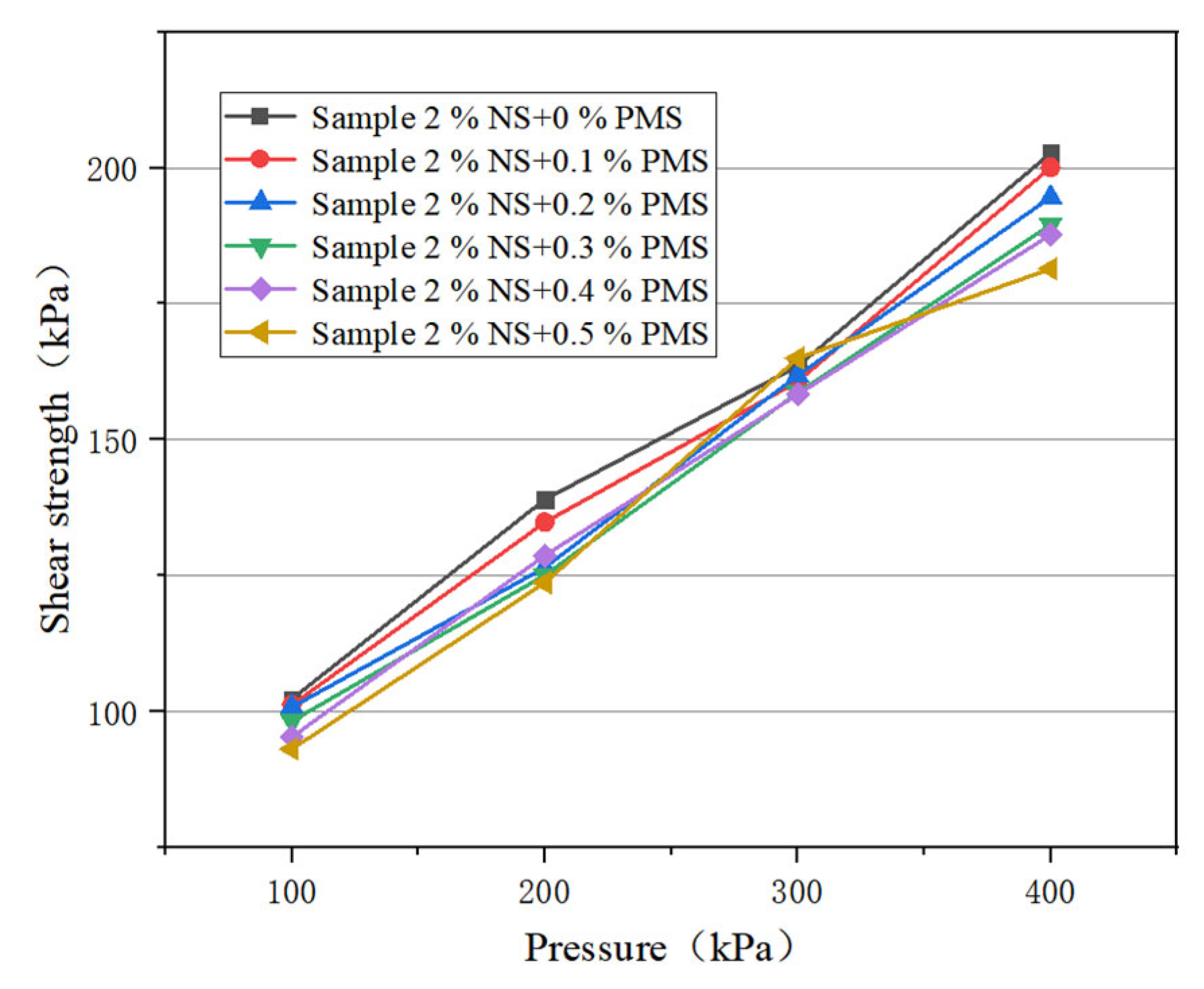

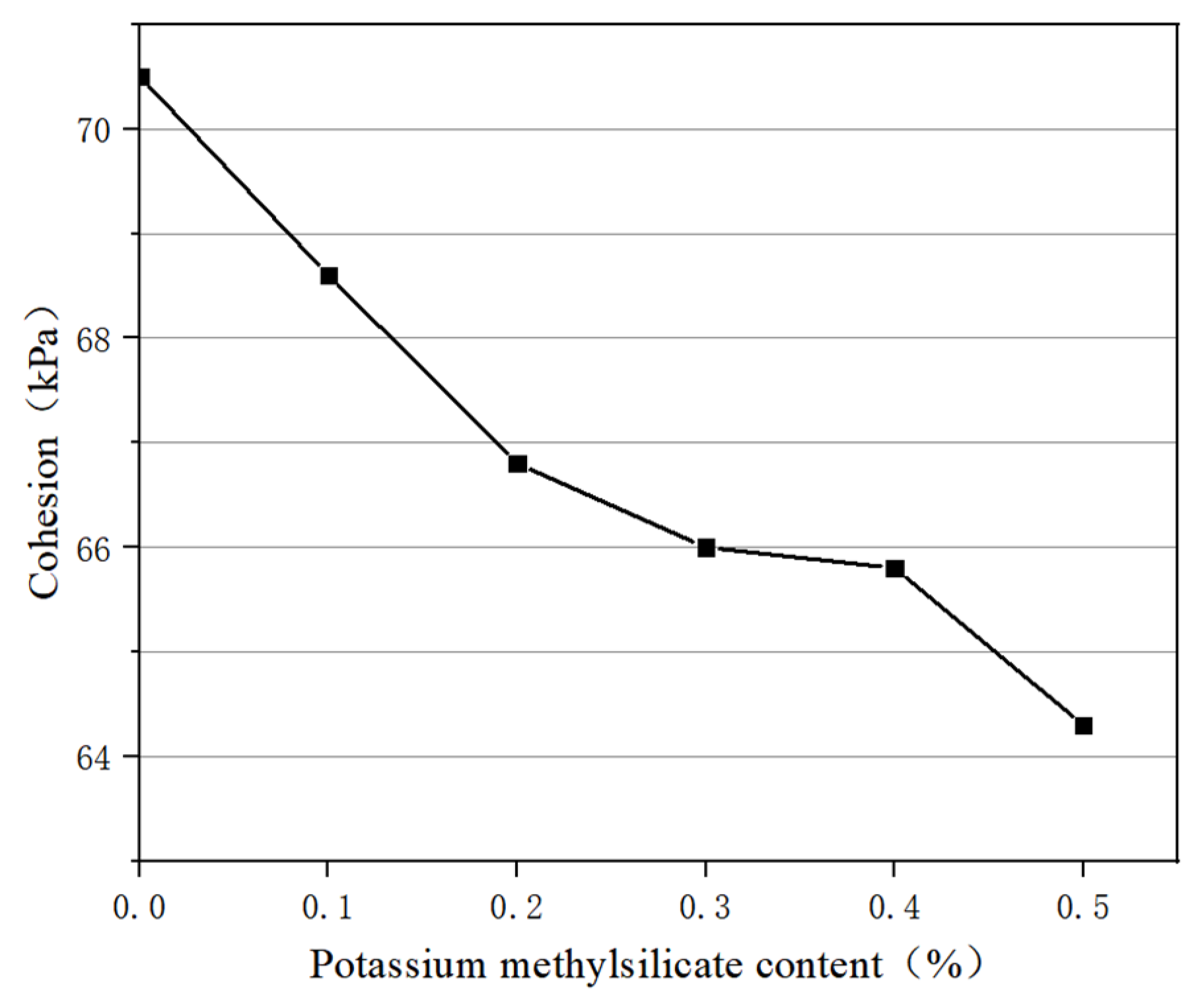

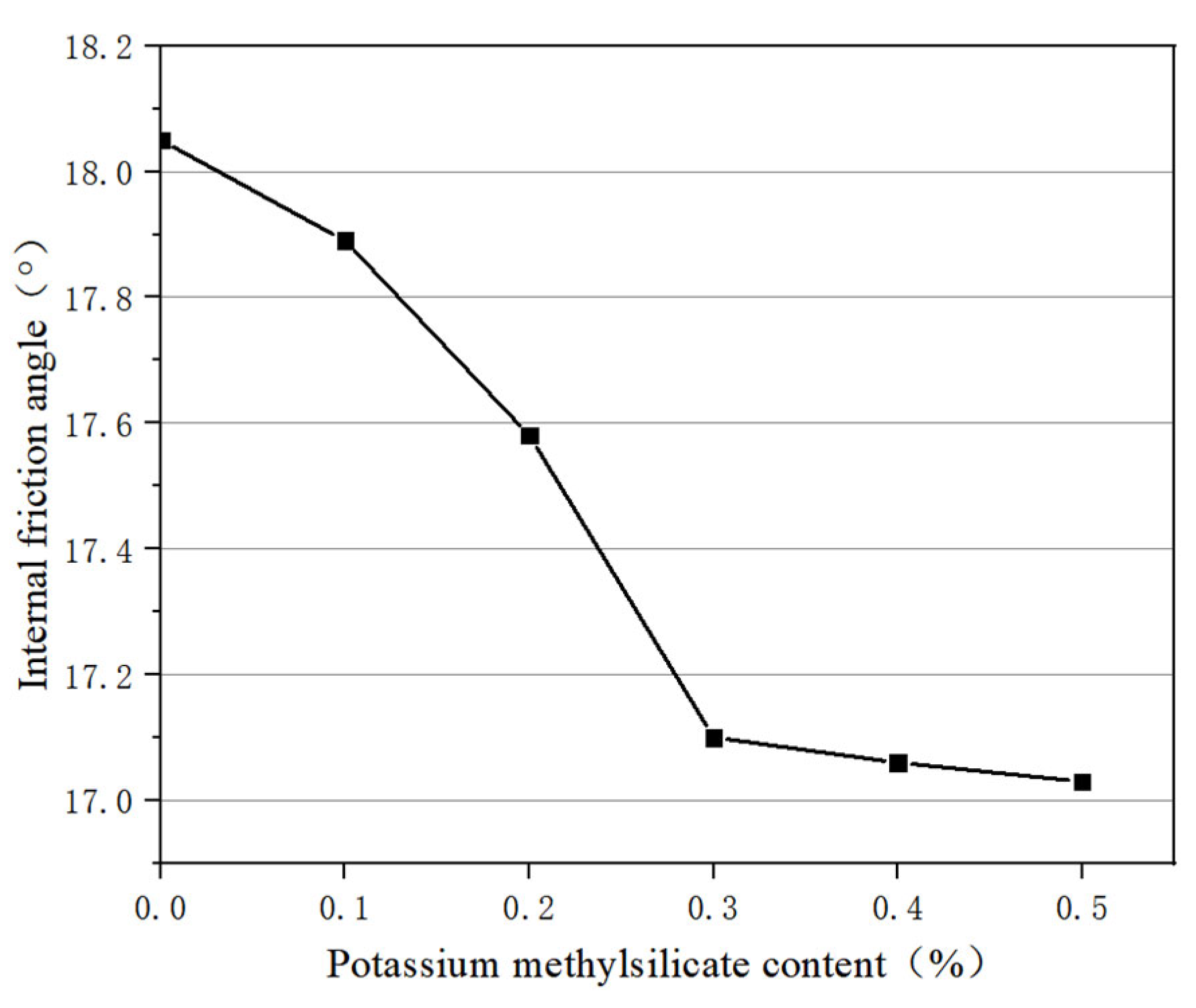

3.2.1. Direct Shear Testing

3.2.2. Capillary Water Rise Testing

3.3. Micro-Mechanism of the Composite Modified Soil

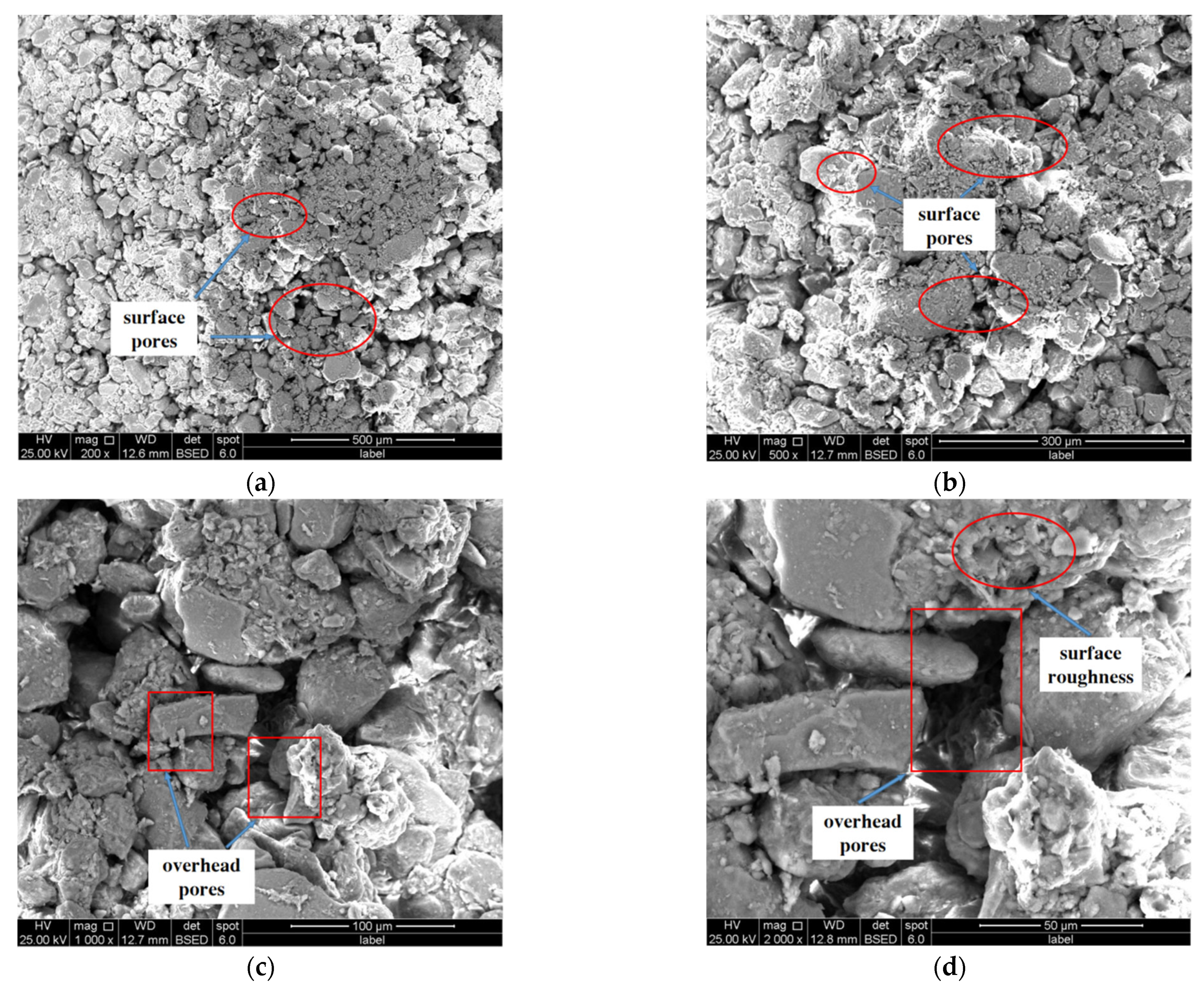

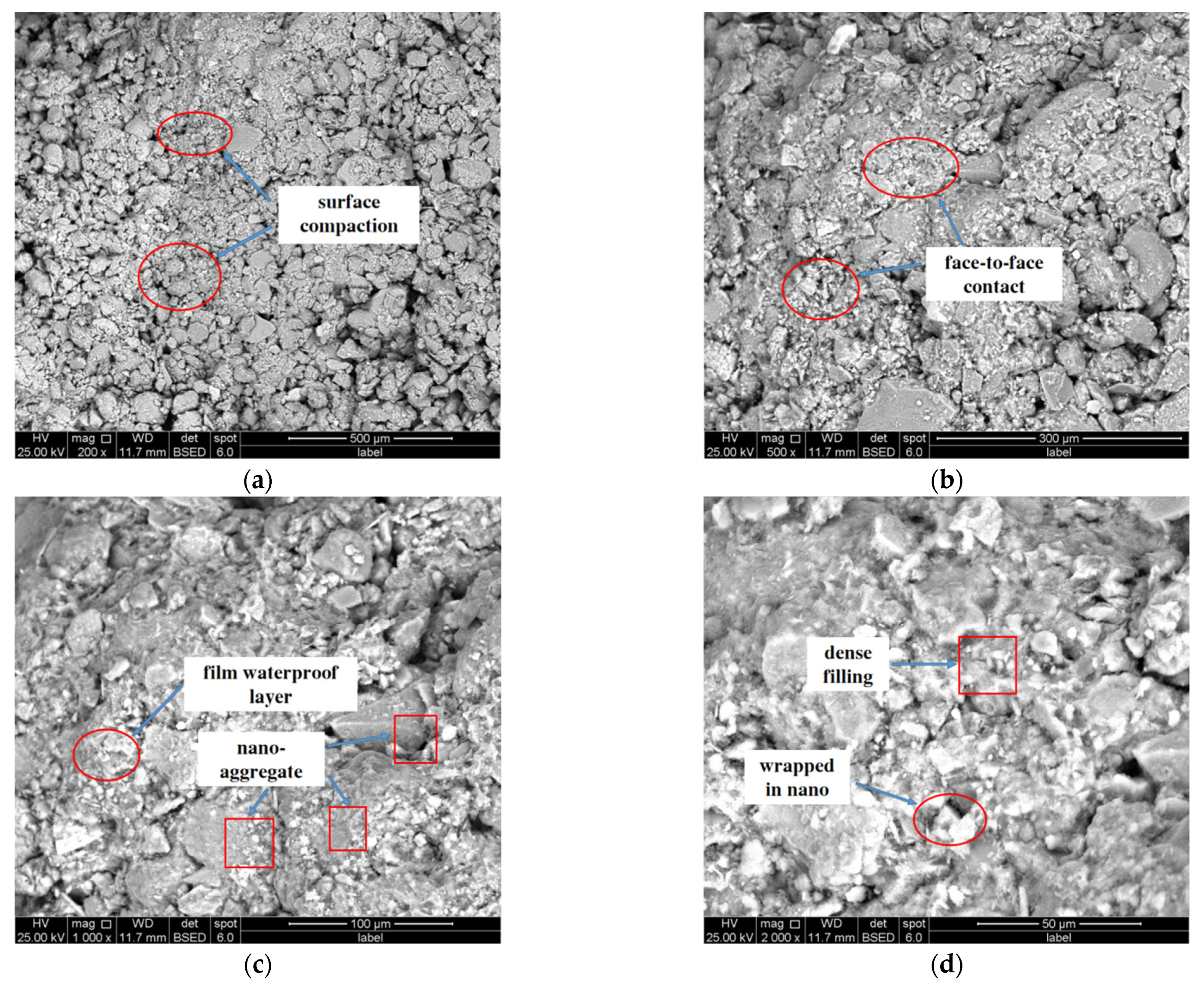

3.3.1. SEM Testing Results and Analysis

3.3.2. XRD Testing Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, Y. Research on the Application of Photoscan Multi-Angle 3D Reconstruction Technology in the Protection of Earth Sites. Master’s Thesis, Northwest University, Xi’an, China, 2017. [Google Scholar]

- Sun, M. Present situation and progress of research on the protection of earthen sites. Sci. Conserv. Archaeol. 2007, 19, 64–70. [Google Scholar]

- Lv, J.; Liu, X.; Du, Q. Research progress and engineering application of repairing materials for earthen sites. Relics Museol. 2015, 7, 104–107. [Google Scholar]

- Li, Z.; Zhang, H.; Wang, X. Study on the Reinforcement of Ancient Earth Architecture Sites. Dunhuang Res. 1995, 3, 1–17. [Google Scholar]

- Li, Z.; Wang, X. New progress in research on protection and reinforcement of ancient earthen architecture sites. Dunhuang Res. 1997, 4, 169–174. [Google Scholar]

- Wang, X.; Zhang, L.; Li, Z.; Wang, C.; Li, W. Study on the present situation, protection and reinforcement of No.3 Mausoleum in Xixia, Yinchuan. Dunhuang Res. 2002, 4, 64–72+112–116. [Google Scholar]

- Zhou, H.; Zhang, B.; Chen, G.; Zhao, H.; Zeng, Y.; Guo, Q.; Li, Z.; Wang, X. Study on in-situ protection and reinforcement of ancient earth sites in humid environment. Rock Soil Mech. 2008, 29, 954–962. [Google Scholar]

- Zhao, H.; Li, Z.; Han, W.; Wang, N. Experimental study on strengthening earthen sites in arid areas of northwest China with PS materials. J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.) 2008, 23, 45–49. [Google Scholar]

- Bahmani, S.H.; Huat, B.B.; Asadi, A.; Farzadnia, N. Stabilization of residual soil using SiO2 nanoparticles and cement. Constr. Build. Mater. 2014, 64, 350–359. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Strength properties of soft clay treated with mixture of nano silica and recycled polyester fiber. J. Rock Mech. Geotech. Eng. 2015, 7, 367–378. [Google Scholar] [CrossRef]

- Ren, X. Experimental Study on Mechanical Properties of Frozen (Melted) Soil Improved by Nano Silica. Ph.D. Thesis, Lanzhou University, Lanzhou, China, 2016. [Google Scholar]

- Ghasabkolaei, N.; Janalizadeh, A.; Jahanshahi, M.; Roshan, N.; Ghasemi, S.E. Physical and geotechnical properties of cement-treated clayey soil using silica nanoparticles: An experimental study. Eur. Phys. J. Plus 2016, 131, 134. [Google Scholar] [CrossRef]

- Qu, J.; Hu, C.; Zhao, C. Experimental study on shear strength of Shanghai clay reinforced by basalt fiber and nano silica. J. Water Resour. Water Eng. 2017, 28, 186–192. [Google Scholar]

- Shang, Y.; Fu, Y. Experimental study of the mechanical properties of expansive soil with added nanomaterials. Arab. J. Geosci. 2018, 11, 180. [Google Scholar] [CrossRef]

- Lv, Q.; Chang, C.; Zhao, B.; Ma, B. Loess soil stabilization by means of SiO2 nanoparticles. Soil Mech. Found. Eng. 2018, 54, 409–413. [Google Scholar] [CrossRef]

- Tomar, A.; Sharma, T.; Singh, S. Strength properties and durability of clay soil treated with mixture of nano silica and polypropylene fiber. Mater. Today Proc. 2020, 23, 3449–3457. [Google Scholar] [CrossRef]

- Tian, Z.; Lv, X.; Qin, Y.; He, Y.; Cui, X. Preparation of PMS modified silica sol and its application in inorganic coatings. Mod. Chem. Ind. 2021, 41, 111–116+121. [Google Scholar]

- Lv, X.; Qin, Y.; Liang, H.; Liang, H.; Han, Y.-C. Potassium methyl silicate (CH5SiO3Na) assisted activation and modification of alkali-activated-slag-based drying powder coating for protecting cement concrete. Constr. Build. Mater. 2022, 326. [Google Scholar] [CrossRef]

- ASTM D4318-10; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2010.

- GB/T 50123-2019; Geotechnical Test Method Standard. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Ahmed, A. Recycled bassanite for enhancing the stability of poor subgrades clay soil in road construction projects. Constr. Build. Mater. 2013, 48, 151–159. [Google Scholar] [CrossRef]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Ju, Z. Study on Shear Strength and Disintegration Characteristics of Loess Improved by Different Materials. Master’s Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Kong, R. Study on Mechanical Properties and Structural Characteristics of Loess Solidified by Nano Silica. Ph.D. Thesis, Lanzhou University, Lanzhou, China, 2019. [Google Scholar]

- Jin, Z. Experimental Study on Mechanical Properties of Soil Strengthened with Carbon Fiber and Nano Silica. Master’s Thesis, Shenzhen University, Shenzhen, China, 2019. [Google Scholar]

- Muñoz, P.; Letelier, V.; Muñoz, L.; Gencel, O.; Sutcu, M.; Vasic, M. Assessing technological properties and environmental impact of fired bricks made by partially adding bottom ash from an industrial approach. Constr. Build. Mater. 2023, 396, 132338. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Sand (0.074~2 mm) | 17.78% |

| Silt (0.002~0.074 mm) | 82.11% |

| Clay (<0.002 mm) | 0.11% |

| Liquid limit | 25.1% |

| Plastic limit | 16.3% |

| Plasticity index | 8.7% |

| Maximum dry density | 1.711 g·cm−3 |

| Optimum moisture content | 12.41% |

| Test Method | Particle Size Interval Group/mm | Less than a Particle Size Mass Fraction/% |

|---|---|---|

| Sieving method | >99.8 | 100 |

| 2.0–1.0 | 99.15 | |

| 1.0–0.5 | 98.75 | |

| 0.5–0.25 | 98.55 | |

| 0.25–0.15 | 97.25 | |

| 0.15–0.075 | 90.30 | |

| Densimeter method | 0.075–0.005 | 82.88 |

| 0.005–0.002 | 5.05 | |

| <0.002 | 0.13 |

| Average Grain Diameter/nm | Pureness/% | Proportion/(m2/g) | Bulk Density/(g/cm3) | Colour | Form |

|---|---|---|---|---|---|

| 20 | ≥99.8 | 200 | 0.05 | White | Spherical granular powder |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, P.; Ma, Q.; Zha, M.; Zhang, J.; Huo, Z. Study on the Modification of Silty Soil Sites Using Nanosilica and Methylsilicate. Materials 2023, 16, 5646. https://doi.org/10.3390/ma16165646

Cao P, Ma Q, Zha M, Zhang J, Huo Z. Study on the Modification of Silty Soil Sites Using Nanosilica and Methylsilicate. Materials. 2023; 16(16):5646. https://doi.org/10.3390/ma16165646

Chicago/Turabian StyleCao, Pengke, Qingwen Ma, Mingming Zha, Jian Zhang, and Zijian Huo. 2023. "Study on the Modification of Silty Soil Sites Using Nanosilica and Methylsilicate" Materials 16, no. 16: 5646. https://doi.org/10.3390/ma16165646

APA StyleCao, P., Ma, Q., Zha, M., Zhang, J., & Huo, Z. (2023). Study on the Modification of Silty Soil Sites Using Nanosilica and Methylsilicate. Materials, 16(16), 5646. https://doi.org/10.3390/ma16165646