Topology of WC/Co Interfaces in Cemented Carbides

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

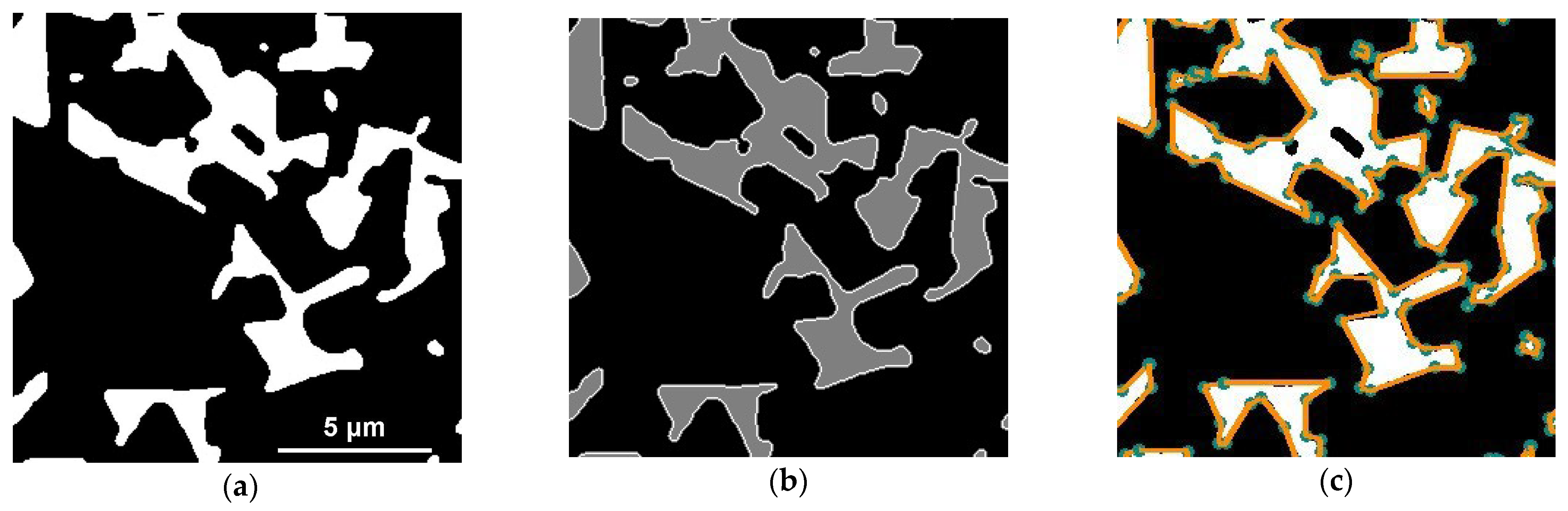

3.1. Image Processing

3.2. Angle Distribution

3.3. The Length Distribution for Ellipse Semiaxes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schröter, K. DRP 420.689: Sintered Hardmetal Alloy And Procedure For Its fabrication. 1923. Available online: https://patents.google.com/patent/DE420689C/en (accessed on 1 August 2023).

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Haynes, W.M. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Swab, J.J.; Wright, J.C. Application of ASTM C1421 to WC-Co fracture toughness measurement. Int. J. Refract. Met. Hard Mater. 2016, 58, 8–13. [Google Scholar] [CrossRef]

- Konyashin, I.; Straumal, B.B.; Ries, B.; Bulatov, M.F.; Kolesnikova, K.I. Contact angles of WC/WC grain boundaries with binder in cemented carbides with various carbon content. Mater. Lett. 2017, 196, 1–3. [Google Scholar] [CrossRef]

- Konyashin, I.; Ries, B.; Hlawatschek, D.; Zhuk, Y.; Mazilkin, A.; Straumal, B.; Dorn, F.; Park, D. Wear-resistance and hardness: Are they directly related for nanostructured hard materials? Int. J. Refract. Met. Hard Mater. 2015, 49, 203–211. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Mohanty, A.; Gangopadhyay, S.; Vipindas, K. An insight into microstructure and machining performance of deep cryogenically treated cemented carbide inserts. J. Manuf. Process. 2020, 58, 819–831. [Google Scholar] [CrossRef]

- Gille, G.; Bredthauer, J.; Gries, B.; Mende, B.; Heinrich, W. Advanced and new grades of WC and binder powder—Their properties and application. Int. J. Refract. Met. Hard Mater. 2000, 18, 87–102. [Google Scholar] [CrossRef]

- Chang, S.H.; Chang, M.H.; Huang, K.T. Study on the sintered characteristics and properties of nanostructured WC-15 wt.% (Fe-Ni-Co) and WC-15 wt.% Co hard metal alloys. J. Alloys Compd. 2015, 649, 89–95. [Google Scholar] [CrossRef]

- Bounhoure, V.; Lay, S.; Coindeau, S.; Norgren, S.; Pauty, E.; Missiaen, J.M. Effect of Cr addition on solid state sintering of WC-Co alloys. Int. J. Refract. Met. Hard Mater. 2015, 52, 21–28. [Google Scholar] [CrossRef]

- Huang, Z.; Ren, X.R.; Liu, M.X.; Xu, C.; Zhang, X.H.; Guo, S.D.; Chen, H. Effect of Cu on the microstructures and properties of WC-6Co cemented carbides fabricated by SPS. Int. J. Refract. Met. Hard Mater. 2017, 62, 155–160. [Google Scholar] [CrossRef]

- Lin, N.; Jiang, Y.; Zhang, D.F.; Wu, C.H.; He, Y.H.; Xiao, D.H. Effect of Cu, Ni on the property and microstructure of ultrafine WC-10Co alloys by sinter-hipping. Int. J. Refract. Met. Hard Mater. 2011, 29, 509–515. [Google Scholar] [CrossRef]

- Puga, J.B.; Fernandes, C.M.; Vieira, M.T.; Senos, A.M.R. Morphological characterization by scanning electron microscopy of WC powder particles coated with Cu. Microsc. Microanal. 2013, 19, 145–146. [Google Scholar] [CrossRef][Green Version]

- Chen, C.S.; Yang, C.C.; Chai, H.Y.; Yeh, J.W.; Chau, J.L.H. Novel cermet material of WC/multi-element alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 200–204. [Google Scholar] [CrossRef]

- Shon, I.J. Effect of Al on sintering and mechanical properties of WC-Al composites. Ceram. Int. 2016, 42, 17884–17891. [Google Scholar] [CrossRef]

- Wittmann, B.; Schubert, W.D.; Lux, B. WC grain growth and grain growth inhibition in nickel and iron binder hardmetals. Int. J. Refract. Met. Hard Mater. 2002, 20, 51–60. [Google Scholar] [CrossRef]

- Norgren, S.; Garcia, J.; Blomqvist, A.; Yin, L. Trends in the P/M hard metal industry. Int. J. Refract. Met. Hard Mater. 2015, 48, 31–45. [Google Scholar] [CrossRef]

- Ahmadian, M.; Wexler, D.; Calka, A.; Chandra, T. Liquid phase sintering of WC-FeAl and WC-Ni3Al composites with and without boron. Mater. Sci. Forum 2003, 426–432, 1951–1956. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R.; Vieira, M.T.; Antunes, J.M. Mechanical characterization of composites prepared from WC powders coated with Ni rich binders. Int. J. Refract. Met. Hard Mater. 2008, 26, 491–498. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R. Cemented carbide phase diagrams: A review. Int. J. Refract. Met. Hard Mater. 2011, 29, 405–418. [Google Scholar] [CrossRef]

- Gonzalez, R.; Echeberria, J.; Sanchez, J.M.; Castro, F. WC-(Fe,Ni,C) hardmetals with improved toughness through isothermal heat-treatments. J. Mater. Sci. 1995, 30, 3435–3439. [Google Scholar] [CrossRef]

- Schubert, W.D.; Fugger, M.; Wittmann, B.; Useldinger, R. Aspects of sintering of cemented carbides with Fe-based binders. Int. J. Refract. Met. Hard Mater. 2015, 49, 110–123. [Google Scholar] [CrossRef]

- Garcia, J. Investigations on kinetics of formation of fcc-free surface layers on cemented carbides with Fe-Ni-Co binders. Int. J. Refract. Met. Hard Mater. 2011, 29, 306–311. [Google Scholar] [CrossRef]

- Habibi Rad, M.; Ahmadian, M.; Golozar, M.A. Investigation of the corrosion behavior of WC–FeAl–B composites in aqueous media. Int. J. Refract. Met. Hard Mater. 2012, 35, 62–69. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R.; Vieira, M.T. Versatility of the sputtering technique in the processing of WC-Fe-Ni-Cr composites. Surf. Coat. Tech. 2012, 206, 4915–4921. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Liu, J.W.; Tang, H.G.; Ma, X.F.; Zhao, W. Investigation on the mechanical properties of WC-Fe-Cu hard alloys. J. Alloys Compd. 2015, 632, 729–734. [Google Scholar] [CrossRef]

- Razavi, M.; Rahimipour, M.R.; Yazdani-Rad, R. Synthesis of Fe-WC nanocomposite from industrial ferrotungsten via mechanical alloying method. Adv. Appl. Ceram. 2011, 110, 367–374. [Google Scholar] [CrossRef]

- Shon, I.J. Rapid consolidation of nanostructured WC-FeAl hard composites by high-frequency induction heating and its mechanical properties. Int. J. Refract. Met. Hard Mater. 2016, 61, 185–191. [Google Scholar] [CrossRef]

- Hanyaloglu, C.; Aksakal, B.; Bolton, J.D. Production and indentation analysis of WC/Fe-Mn as an alternative to cobalt-bonded hardmetals. Mater. Charact. 2001, 47, 315–322. [Google Scholar] [CrossRef]

- Maccio, M.R.; Berns, H. Sintered hardmetals with iron-manganese binder. Powder Metall. 2012, 55, 101–109. [Google Scholar] [CrossRef]

- Pittari III, J.J.; Murdoch, H.A.; Kilczewski, S.M.; Hornbuckle, B.C.; Swab, J.J.; Darling, K.A.; Wright, J.C. Sintering of tungsten carbide cermets with an iron-based ternary alloy binder: Processing and thermodynamic considerations. Int. J. Refract. Met. Hard Mater. 2018, 76, 1–11. [Google Scholar] [CrossRef]

- Machado, I.F.; Girardini, L.; Lonardelli, I.; Molinari, A. The study of ternary carbides formation during SPS consolidation process in the WC-Co-steel system. Int. J. Refract. Met. Hard Mater. 2009, 27, 883–891. [Google Scholar] [CrossRef]

- Oliveira, A.B.; Bastos, A.C.; Fernandes, C.M.; Pinho, C.M.S.; Senos, A.M.R.; Soares, E.; Sacramento, J.; Zheludkevich, M.L.; Ferreira, M.G.S. Corrosion behaviour of WC-10% AISI 304 cemented carbides. Corros. Sci. 2015, 100, 322–331. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R.; Vieira, M.T. Sintering of tungsten carbide particles sputter-deposited with stainless steel. Int. J. Refract. Met. Hard Mater. 2003, 21, 147–154. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Vilhena, L.M.; Pinho, C.M.S.; Oliveira, F.J.; Soares, E.; Sacramento, J.; Senos, A.M.R. Mechanical characterization of WC-10 wt.% AISI 304 cemented carbides. Mater. Sci. Eng. A 2014, 618, 629–636. [Google Scholar] [CrossRef]

- Wang, J.; Han, Y.; Zhao, Y.; Li, X.; Yi, D.; Guo, Z.; Cao, Y.; Liu, B.; Tang, H.P. Microstructure and properties of WC-12Co cemented carbide fabricated via selective electron beam melting. Int. J. Refr. Met. Hard Mater. 2022, 106, 105847. [Google Scholar] [CrossRef]

- Akerman, J.; Ericson, T. Cemented Carbide Body with Improved High Temperatures and Thermomechanical Properties. U.S. Patent 6,126,709, 1997. [Google Scholar]

- Zhang, L.; Hu, C.; Yang, Y.; Misra, R.D.K.; Kondoh, K.; Lu, Y. Laser powder bed fusion of cemented carbides by developing a new type of Co coated WC composite powder. Add. Manufact. 2022, 55, 102820. [Google Scholar] [CrossRef]

- Rabouhi, H.; Eyidi, D.; Khelfaoui, Y.; Khireddine, A. Microstructural and mechanical characterisation of WC–Co alloys elaborated by liquid phase sintering and hot isostatic pressing: Study of WC crystallites size evolution. Can. Metal. Quart. 2022, 61, 66240. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Z.; Wang, B.; Yuan, J.; Huang, L.; Yin, Z. Microstructure and properties of WC-8Co cemented carbides prepared by multiple spark plasma sintering. Int. J. Appl. Ceram. Technol. 2021, 18, 2010–2019. [Google Scholar] [CrossRef]

- Fries, S.; Burkamp, K.; Broeckmann, C.; Richter, S.; Westermann, H.; Süess, B. Influence of carbon content on fatigue strength of cemented carbides. Int. J. Refr. Met. Hard Mater. 2022, 105, 105823. [Google Scholar] [CrossRef]

- Shi, K.-H.; Zhou, K.-C.; Li, Z.-Y.; Zan, X.-Q.; Dong, K.-L.; Jiang, Q. Microstructure and properties of ultrafine WC–Co–VC cemented carbides with different Co contents. Rare Met. 2022, 41, 1955–1960. [Google Scholar] [CrossRef]

- Edtmaier, C.; Wolf, M.; de Oro Calderon, R.; Schubert, W.-D. Effect of nickel on the formation of γ/γ′ microstructures in WC/Co–Ni–Al–W. Int. J. Refr. Met. Hard Mater. 2021, 100, 105652. [Google Scholar] [CrossRef]

- Zeng, H.; Liu, W.; Han, F.; Wie, C. Microstructures and properties of WC–10Co tuned by Ru integration and ball-milling. Mater. Sci. Technol. 2022, 21, 07169. [Google Scholar] [CrossRef]

- Zeng, H.; Liu, W.; Wei, C. Influence of Ru on the microstructure and performance of WC–Co cemented carbides. Mater. Sci. Technol. 2022, 38, 940–946. [Google Scholar] [CrossRef]

- Ye, X.; Xiang, C.; Nie, H.; Lei, H.; Du, Y.; Xing, W.; Luo, J.; Yu, Z. Facet-dependent interfacial segregation behavior of V-doped WC-Co cemented carbides. Ceram. Intern. 2022, 48, 11251–11256. [Google Scholar] [CrossRef]

- Agte, C. Entwicklung der Hartmetalltechnik waehrend der letzten Jahre in der Deutschen Demokratischen Republik. Neue Huette 1957, 9, 537–544. [Google Scholar]

- Jing, K.; Guo, Z.; Hua, T.; Xiong, J.; Liao, J.; Liang, L.; Yang, S.; Yi, J.; Zhang, H. Strengthening mechanism of cemented carbide containing Re. Mater. Sci. Eng. A 2022, 838, 142803. [Google Scholar] [CrossRef]

- Hu, H.; Liu, X.; Chen, J.; Lu, H.; Liu, C.; Wang, H.; Luan, J.; Jiao, Z.; Liu, Y.X. Song, X. High-temperature mechanical behavior of ultra-coarse cemented carbide with grain strengthening. J. Mater. Sci. Technol. 2022, 104, 8–18. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Z.; Deng, X.; Lu, Z.; Liu, J.; Qu, Z.; Jin, F. Microstructure and mechanical behavior of cemented carbide with Al alloy binder fabricated by selective laser melting. Int. J. Refr. Met. Hard Mater. 2022, 108, 105916. [Google Scholar] [CrossRef]

- Mueller-Grunz, A.; Alveen, P.; Rassbach, S.; Useldinger, R.; Moseley, S. The manufacture and characterization of WC-(Al)CoCrCuFeNi cemented carbides with nominally high entropy alloy binders. Int. J. Refr. Met. Hard Mater. 2019, 84, 105032. [Google Scholar] [CrossRef]

- Brownrigg, D.R.K. The weighted median filter. Commun. ACM 1984, 27, 807. [Google Scholar] [CrossRef]

- Nobuyuki, O. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cyber. 1979, 9, 62. [Google Scholar] [CrossRef]

- Farid, H.; Simoncell, E.P. Optimally rotation-equivariant directional derivative kernels. In Proceedings 7th International Conference on Computer Analysis of Images and Patterns; Number 1296 in Series Lecture Notes in Computer Science; Sommer, G., Daniilidis, K., Pauli, J., Eds.; Springer: Berlin/Heidelberg, Germany, 1997; pp. 207–214. [Google Scholar] [CrossRef]

- Rong, W.; Li, Z.; Zhang, W.; Sun, L. An improved CANNY edge detection algorithm. Proc. IEEE Int. Conf. Mechatron. Automat. 2014, 2, 577–582. [Google Scholar] [CrossRef]

- Suzuki, S.; Abe, K. Topological structural analysis of digitized binary images by border following. Comp. Vis. Graph. Image Proc. 1985, 30, 32–46. [Google Scholar] [CrossRef]

- John, H.; Jack, S. Speeding up the Douglas-Peucker Line-Simplification Algorithm. (CiteSeerX, Vancouver, 1992). Available online: https://tildesites.bowdoin.edu/~ltoma/teaching/cs350/spring04/Handouts/hershberger92speeding.pdf (accessed on 1 August 2023).

- Rabkin, E.I.; Shvindlerman, L.S.; Straumal, B.B. Grain boundaries: Phase transitions and critical phenomena. Int. J. Mod. Phys. B 1991, 5, 2989–3028. [Google Scholar] [CrossRef]

- Noskovich, O.I.; Rabkin, E.I.; Semenov, V.N.; Straumal, B.B.; Shvindlerman, L.S. Wetting and premelting phase transitions in 38°[100] tilt grain boundaries in (Fe–12at.%Si) Zn alloy in the vicinity of the A2–B2 bulk ordering in Fe–12at.%Si alloy. Acta Met. Mater. 1991, 39, 3091–3098. [Google Scholar] [CrossRef]

- Konstantinova, E.P.; Shchur, L.N. Algorithm for density of angle distribution in random sections of polyhedron. Powder Metall. 2023. submitted. [Google Scholar]

- Saltykov, S.A. Stereometric Metallography; Publishing House Metallurgy: Moscow, Russia, 1976; 270p. (In Russian) [Google Scholar]

- Götschel, M.; Lovász, L.; Schrijver, A. The ellipsoid method. In Geometric Algorithms and Combinatorial Optimization. Algorithms and Combinatorics; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Straumal, B.; Konyashin, I. WC-Based cemented carbides with high entropy alloyed binders: A review. Metals 2023, 13, 171. [Google Scholar] [CrossRef]

- Sundin, S.; Haglund, S. A comparison between magnetic properties and grain size for WC/Co hard materials containing additives of Cr and V. Int. J. Refr. Met. Hard Mater. 2000, 18, 297–300. [Google Scholar] [CrossRef]

| WC Grain Size in the Sample | Left Peak | Right Peak |

|---|---|---|

| Coarse WC grains, 8 ± 0.2 µm, green color | 112° ± 6° | 227° ± 3° |

| Medium WC grains, 5 ± 0.1 µm, orange color | 111° ± 2° | 224° ± 2° |

| Fine WC grains, 2 ± 0.05 µm, blue color | 109° ± 3° | 241° ± 2° |

| WC Grain Size and Cobalt Content | Number of Studied Areas | Long Semiaxis, µm | Short Semiaxis, µm |

|---|---|---|---|

| Coarse grains, 6 wt.% Co, green color | 17026 | 1.48 | 0.75 |

| Medium grains, 11 wt.% Co, orange color | 31243 | 1.07 | 0.57 |

| Fine grains, 26 wt.% Co, blue color | 87934 | 0.84 | 0.47 |

| Co Content, wt.% | WC Grain Size, µm | Density, kg/m3 | Vickers Hardness, HV | Coercive Force, Oe |

|---|---|---|---|---|

| 6 | 8 ± 0.2 | 14,900 ± 5 | 1090 ± 2 | 70 ± 0.3 |

| 11 | 5 ± 0.1 | 14,520 ± 5 | 1030 ± 2 | 62 ± 0.3 |

| 26 | 2 ± 0.05 | 13,480 ± 5 | 1060 ± 2 | 91 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Straumal, B.B.; Shchur, L.N.; Kagramanyan, D.G.; Konstantinova, E.P.; Druzhinin, A.V.; Nekrasov, A.N. Topology of WC/Co Interfaces in Cemented Carbides. Materials 2023, 16, 5560. https://doi.org/10.3390/ma16165560

Straumal BB, Shchur LN, Kagramanyan DG, Konstantinova EP, Druzhinin AV, Nekrasov AN. Topology of WC/Co Interfaces in Cemented Carbides. Materials. 2023; 16(16):5560. https://doi.org/10.3390/ma16165560

Chicago/Turabian StyleStraumal, Boris B., Lev N. Shchur, David G. Kagramanyan, Elizaveta P. Konstantinova, Alexander V. Druzhinin, and Alexei N. Nekrasov. 2023. "Topology of WC/Co Interfaces in Cemented Carbides" Materials 16, no. 16: 5560. https://doi.org/10.3390/ma16165560

APA StyleStraumal, B. B., Shchur, L. N., Kagramanyan, D. G., Konstantinova, E. P., Druzhinin, A. V., & Nekrasov, A. N. (2023). Topology of WC/Co Interfaces in Cemented Carbides. Materials, 16(16), 5560. https://doi.org/10.3390/ma16165560