Using the LCA Method to Develop the Production of Pigment for Processing Plastics

Abstract

:1. Introduction

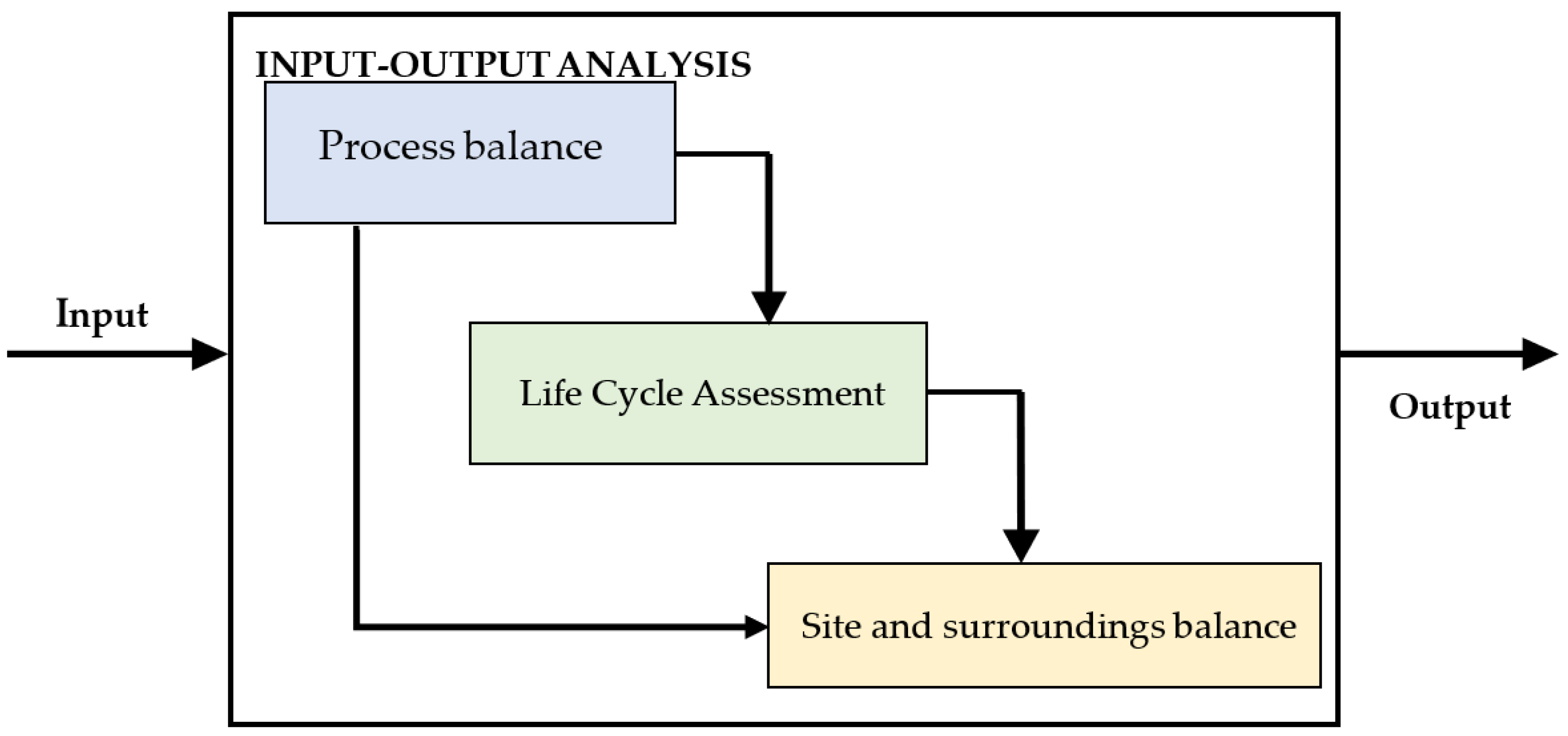

2. Models, Materials and Methods

2.1. Energy Consumption in Production and Consumption of Materials

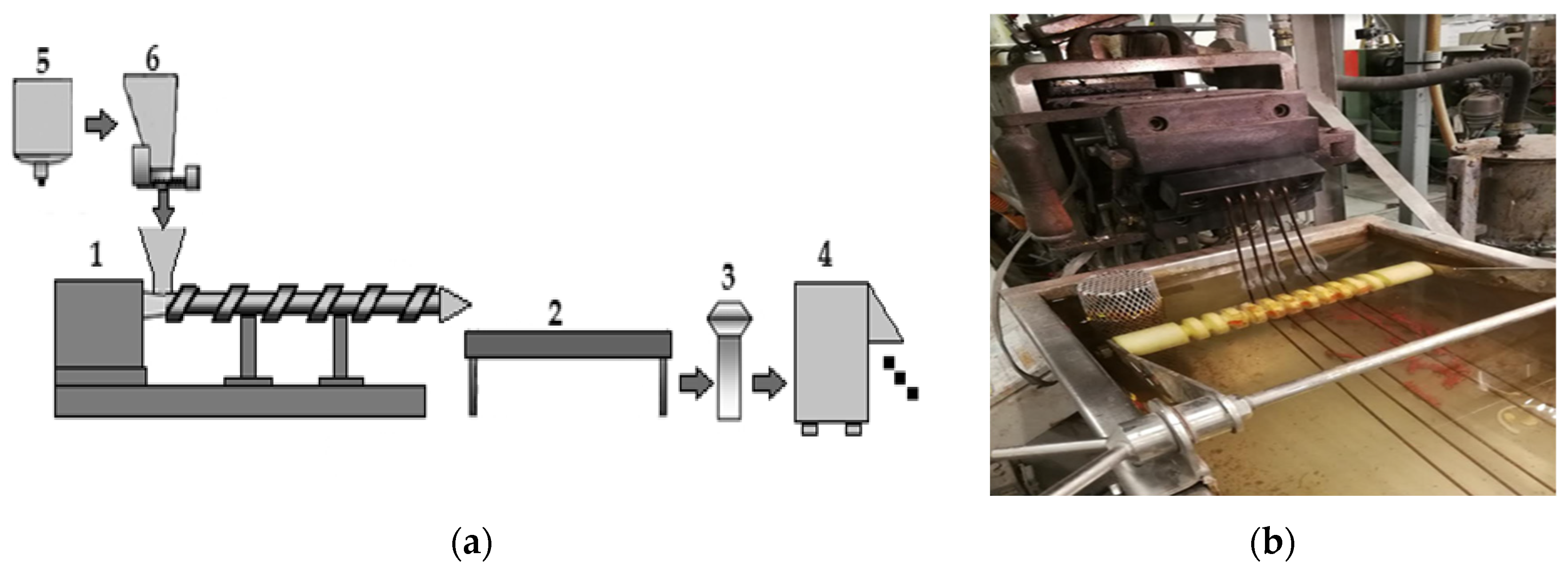

2.2. Description of the Research Object

2.3. Life Cycle Impact Assessment (LCIA)

2.4. ReCiPe 2016 Method

- −

- Human health: impacts of global warming, stratospheric ozone depletion, ionizing radiation, ozone formation, fine particulate matter formation, human carcinogenic toxicity, human non-carcinogenic toxicity, and water consumption. The unit of these interactions is DALY. The disability-adjusted DALY parameter was developed by Murray at Harvard University in collaboration with the World Health Organization (WHO) to quantify the burden of disease and injury on humans. It is a time-based measure, which combines the time lost due to premature death (indicating years of life lost, YLL) and the duration of disability caused by disease (years of life lived with a disability, YLD) in survivors. One DALY corresponds to one year of healthy life lost, which is equivalent to only 90% full capacity and life for 10 years.

- −

- Impact on the quality of ecosystems: Impacts related to global warming, ozone formation, terrestrial acidification, freshwater eutrophication, marine eutrophication, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, land use, and water consumption. The unit of quality of these impacts on ecosystems is the loss of local species integrated in time (year of survival of a given species) species per yr.

- −

- USD 2013: Resource scarcity damage refers to the additional dollar cost (USD 2013) of future resource extraction. In this way, a wide variety of environmental effects are considered. As in the case of introducing economic factors, some environmental parameters depend on regional specificities, such as the country’s energy mix. These results can be found in some studies on environmental parameters. Four emission areas for individual chemical compounds were also specified, including air, water, soil, and raw [5,17,18,19].

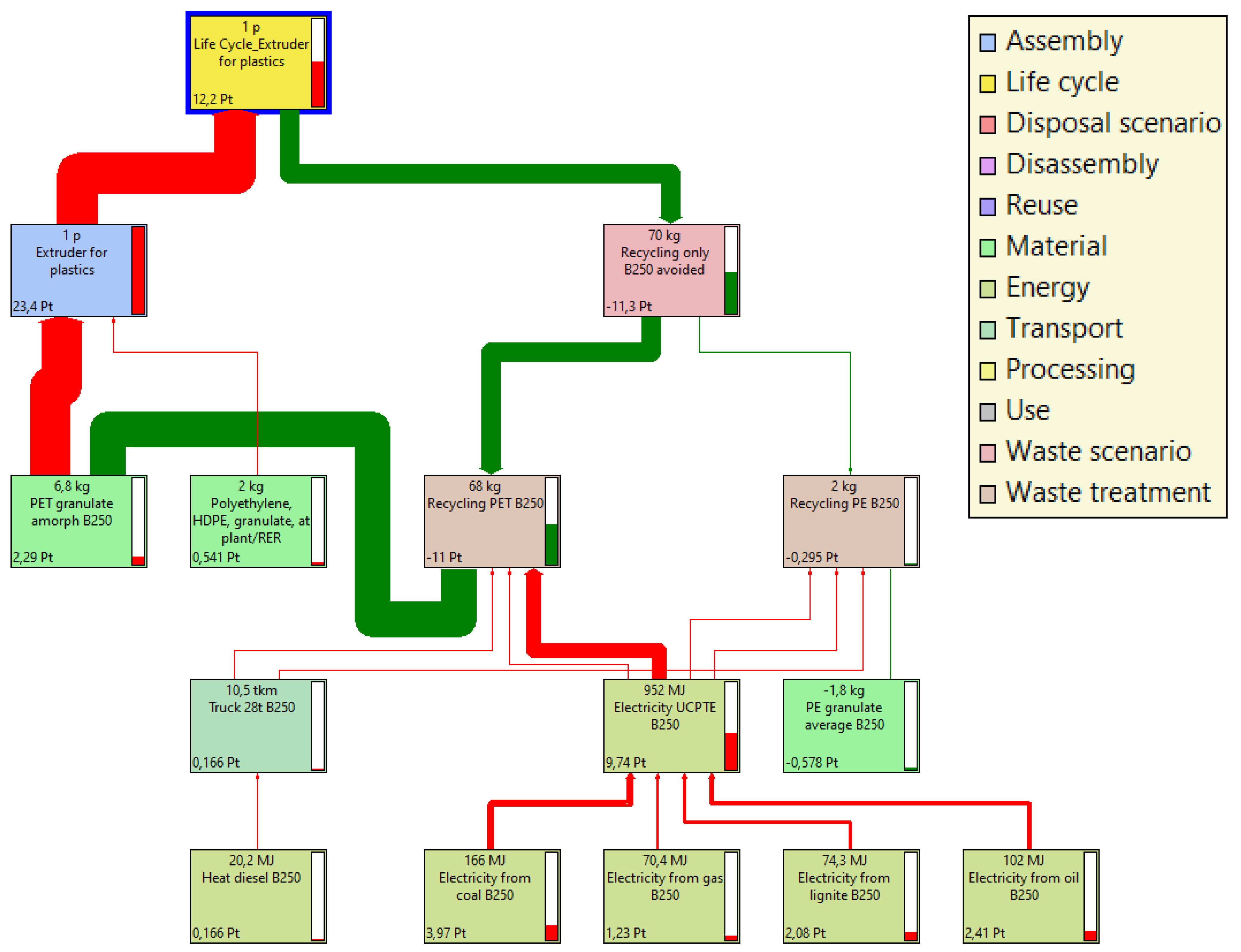

3. Results

3.1. ReCiPe 2016 Method

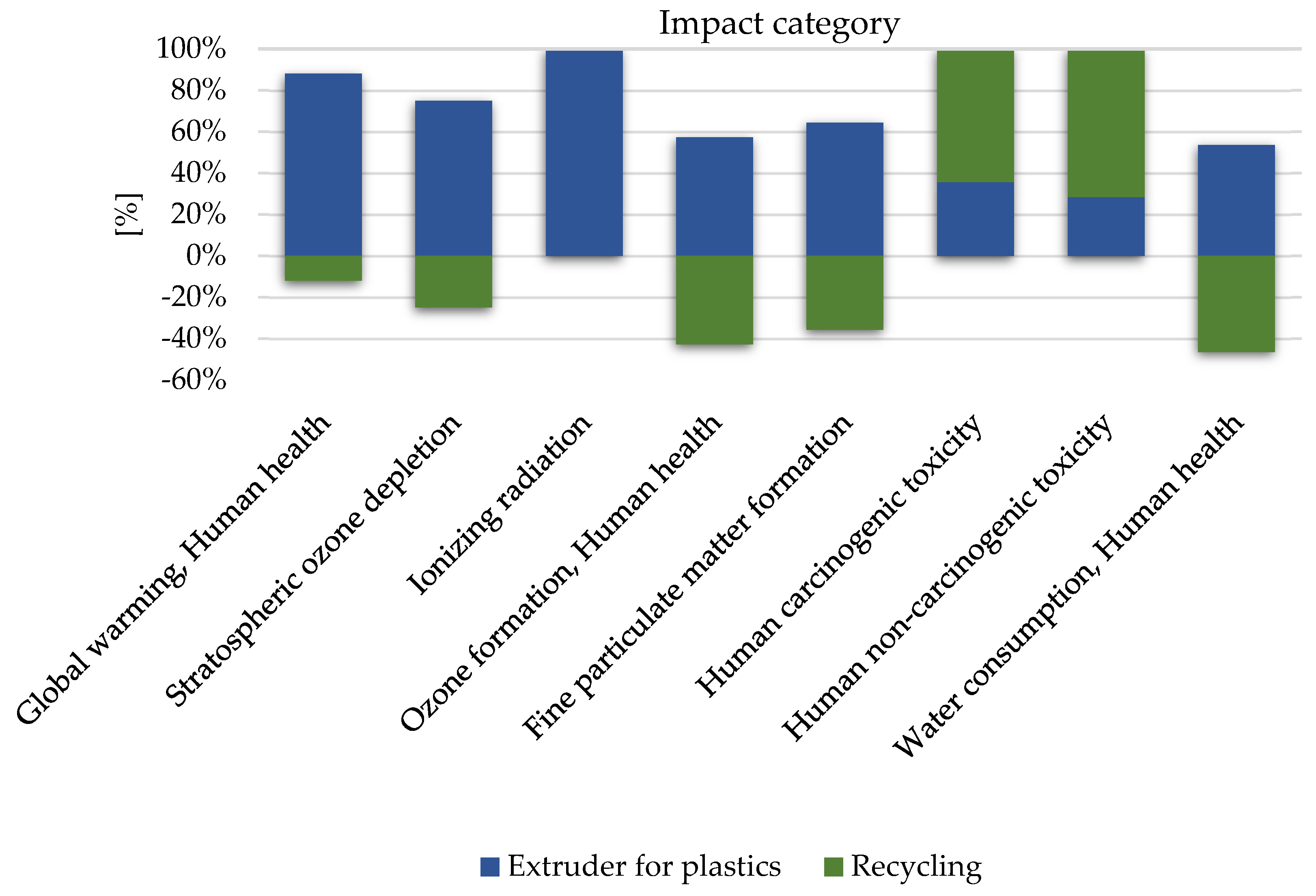

3.2. Results of the Characterization

3.3. Results of Grouping and Weighing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pepliński, K. Influence of the technology of obtaining cavities in injection molds on the efficiency of plastics processing. Polimery 2008, 63, 633–639. [Google Scholar]

- Sobański, R. Human Rights in an Ecological State; Wyd. Akademii Teologii Katolickiej: Warsaw, Poland, 1998. [Google Scholar]

- Report of the World Commission on Environment and Development. General Assembly Resolution; United Nations: New York, NY, USA, 1987.

- Singh, R.; Kumar, S. Green Technologies and Environmental Sustainability; Springer: Cham, Switzerland, 2017; pp. 1–43. [Google Scholar]

- Guineé, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311–313. [Google Scholar]

- Graczyk, T.; Wandelt, P. Explosive defibering of lignocellulosic materials. Prospects for practical application in the chemical and bio-chemical processing of plant materials. Przegl. Papierń. 1991, 47, 5. [Google Scholar]

- Korzeń, Z. Ecology; Instytut Logistyki i Magazynowania: Poznań, Poland, 2001. [Google Scholar]

- Available online: www.tworzywa.com.pl/Poradnik/ (accessed on 8 May 2022).

- Available online: www.tworzywa.pwr.wroc.pl/pl (accessed on 8 May 2022).

- Available online: https://www.oni.de/en/ (accessed on 8 May 2022).

- Doerffer, K.; Baldowska-Witos, P.; Pysz, M.; Doerffer, P.; Tomporowski, A. Manufacturing and Recycling Impact on Environmental Life Cycle Assessment of Innovative Wind Power Plant Part ½. Materials 2021, 14, 220. [Google Scholar] [CrossRef] [PubMed]

- Baldowska-Witos, P.; Kruszelnicka, W.; Tomporowski, A. Life cycle assessment of beverage bottles. J. Phys. Conf. Ser. 2020, 1426, 012038. [Google Scholar] [CrossRef]

- Kłos, Z. Ecobalancial assessment of chosen packaging processes in food industry. Int. J. Life Cycle Assess. 2002, 7, 309. [Google Scholar] [CrossRef]

- Curran, M.A. Goal and Scope Definition in Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2017; pp. 1–167. [Google Scholar]

- Guinée, J.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Rydberg, T. Life Cycle Assessment: Past, present, and future. Environ. Sci. Technol. 2011, 1, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Garrett, P.; Rendc, K. Life cycle assessment of wind power: Comprehensive results from a state-of-the-art approach. Int. J. Life Cycle Assess 2013, 18, 37–48. [Google Scholar] [CrossRef]

- Droste-Franke, B.; Paal, B.; Rehtanz, C.; Sauer, D.U.; Schneider, J.P.; Schreurs, M.; Ziesemer, T. Balancing Renewable Electricity. In Energy Storage, Demand Side Management and Network Extension from an Interdisciplinary Perspective; Springer: Berlin, Germany, 2012; pp. 9–142. [Google Scholar]

- Ulgiati, S.; Raugei, M.; Bargigli, S. Overcoming the in adequacy of single-criterion approaches to Life Cycle Assessment. Ecol. Modell. 2006, 3, 432–442. [Google Scholar] [CrossRef]

- Frankl, P.; Rubik, F. Life Cycle Assessment in Industry and Business; Springer: Berlin, Germany, 2000; pp. 9–101. [Google Scholar]

- Piotrowska, K.; Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Rudnicki, J.; Tomporowski, A.; Flizikowski, J.; Opielak, M. Assessment of the Environmental Impact of a Car Tire throughout Its Life Cycle Using the LCA Method. Materials 2019, 12, 4177–4202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klinglmair, M.; Sala, S.; Brandão, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess 2014, 19, 580–592. [Google Scholar] [CrossRef]

- Tol, R. Environmental Crises; Springer: Berlin/Heidelberg, Germany, 2008; pp. 5–15. [Google Scholar]

- Basosi, R.; Cellura, M.; Longo, S.; Parisi, M.L. Life Cycle Assessment of Energy Systems and Sustainable Energy Technologies; Springer: Basel, Switzerland, 2019; pp. 3–15. [Google Scholar]

- Toke, D. Ecological Modernization and Renewable Energy; Palgrave Macmillan: New York, NY, USA, 2011; pp. 167–179. [Google Scholar]

- Tomporowski, A.; Piasecka, I.; Flizikowski, J.; Kasner, R.; Kruszelnicka, W.; Mroziński, A.; Bieliński, K. Comparison analysis of blade life cycles of land-based and offshore wind power plants. Pol. Marit. Res. 2018, 25, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Laws, E.A. Environmental Toxicology; Springer: New York, NY, USA, 2013; pp. 1–69. [Google Scholar]

- Mannheim, V. Empirical and scale-up modeling in stirred ball mills. Chem. Eng. Res. Des. 2011, 89, 405–409. [Google Scholar] [CrossRef]

- Baldowska-Witos, P.; Piotrowska, K.; Kruszelnicka, W.; Blaszczak, M.; Tomporowski, A.; Opielak, M.; Kasner, R.; Flizikowski, J. Managing the Uncertainty and Accuracy of Life Cycle Assessment Results for the Process of Beverage Bottle Moulding. Polymers 2020, 12, 1320. [Google Scholar] [CrossRef] [PubMed]

- Wałęsa, K.; Malujada, I.; Talaska, K. Butt welding of round drive belts. Acta Mech. Autom. 2018, 12, 115–126. [Google Scholar] [CrossRef] [Green Version]

- Bembenek, M.; Wdaniec, P. Influence of the type of crusher and its operating parameters on dry granulation of powders. Przem. Chem. 2019, 98, 310–313. [Google Scholar]

| Inputs | Outputs |

|---|---|

| MATERIALS | PRODUCTS |

|

|

| ENERGY | MATERIAL EMISSIONS |

|

|

| ENERGY EMISSIONS | |

|

| Material | Amount |

|---|---|

| PET | 76 kg/h |

| Pigment granules 0.4% in HDPE | 28 kg |

| 0.07% X + 1% TiO2 on HDPE support | |

| Cooling water quantity | 1015 l |

| The amount of water in a closed circuit | 1.29 l |

| Electricity consumption for the extrusion process | 13.93 kWh |

| Electricity consumption for the cooling process | 1.57 kWh |

| Electricity consumption for the operation of the water pump | 0.5 kWh |

| Electricity consumption for other processes | 0.3 kWh |

| Material | Amount |

|---|---|

| The amount of PET waste before starting the process | 5 kg |

| Completion of the process, removal of raw material residues from the machine | 3 kg |

| Water losses | 300 L/week |

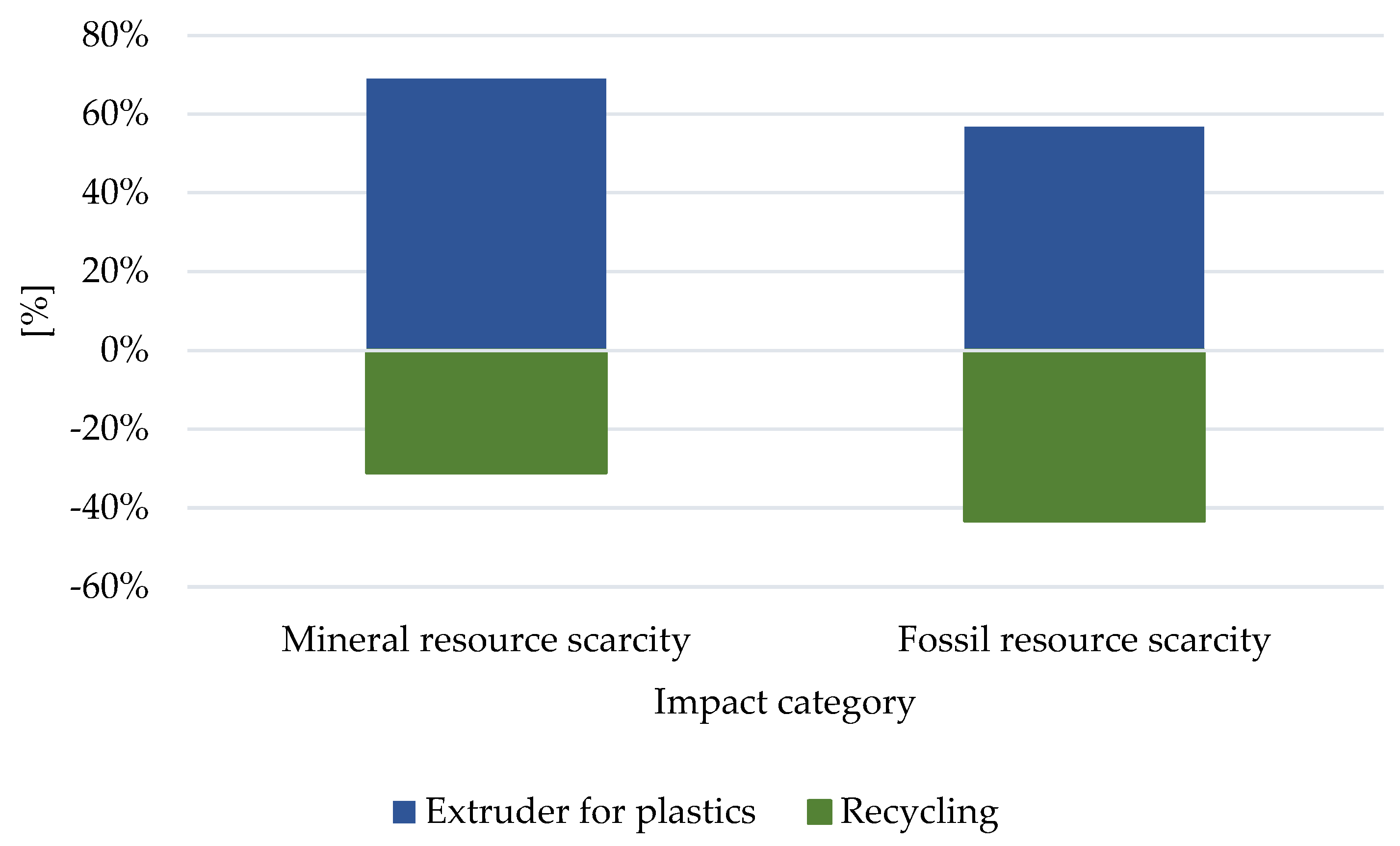

| Impact Category | Unit | Total | Extruder for Plastics | Recycling |

|---|---|---|---|---|

| Global warming, human health | DALY | 0.00013 | 0.00015 | −2.1 × 10−5 |

| Global warming, terrestrial ecosystems | species.yr | 3.91 × 10−7 | 4.53 × 10−7 | −6.2 × 10−8 |

| Global warming, freshwater ecosystems | species.yr | 1.07 × 10−11 | 1.24 × 10−11 | −1.7 × 10−12 |

| Stratospheric ozone depletion | DALY | 2.54 × 10−8 | 3.81 × 10−8 | −1.3 × 10−8 |

| Ionizing radiation | DALY | 5.75 × 10−10 | 5.75 × 10−10 | 0 |

| Ozone formation, human health | DALY | 4.01 × 10−7 | 1.58 × 10−6 | −1.2 × 10−6 |

| Fine particulate matter formation | DALY | 0.000162 | 0.000363 | −0.0002 |

| Ozone formation, terrestrial ecosystems | species.yr | 6.11 × 10−8 | 2.57 × 10−7 | −2 × 10−7 |

| Terrestrial acidification | species.yr | 1.87 × 10−7 | 4.17 × 10−7 | −2.3 × 10−7 |

| Freshwater eutrophication | species.yr | 7.11 × 10−7 | 2.19 × 10−10 | 4.92 × 10−10 |

| Marine eutrophication | species.yr | 6.63 × 10−13 | 9.73 × 10−13 | −3.1 × 10−13 |

| Terrestrial ecotoxicity | species.yr | 4.9 × 10−10 | 1.99 × 10−10 | 2.91 × 10−10 |

| Freshwater ecotoxicity | species.yr | 1.25 × 10−10 | 3.73 × 10−11 | 8.77 × 10−11 |

| Marine ecotoxicity | species.yr | 2.8 × 10−11 | 8.62 × 10−12 | 1.93 × 10−11 |

| Human carcinogenic toxicity | DALY | 3.69 × 10−7 | 1.32 × 10−7 | 2.38 × 10−7 |

| Human non-carcinogenic toxicity | DALY | 3.41 × 10−6 | 9.7 × 10−7 | 2.44 × 10−6 |

| Land use | species.yr | 1.76 × 10−10 | 1.76 × 10−10 | 0 |

| Mineral resource scarcity | USD2013 | 0.000265 | 0.000483 | −0.00022 |

| Fossil resource scarcity | USD2013 | 11.54808 | 48.9723 | −37.4242 |

| Water consumption, human health | DALY | 3.63 × 10−7 | 2.74 × 10−6 | −2.4 × 10−6 |

| Water consumption, terrestrial ecosystem | species.yr | 2.21 × 10−9 | 1.67 × 10−8 | −1.4 × 10−8 |

| Water consumption, aquatic ecosystems | species.yr | 9.88 × 10−14 | 7.47 × 10−13 | −6.5 × 10−13 |

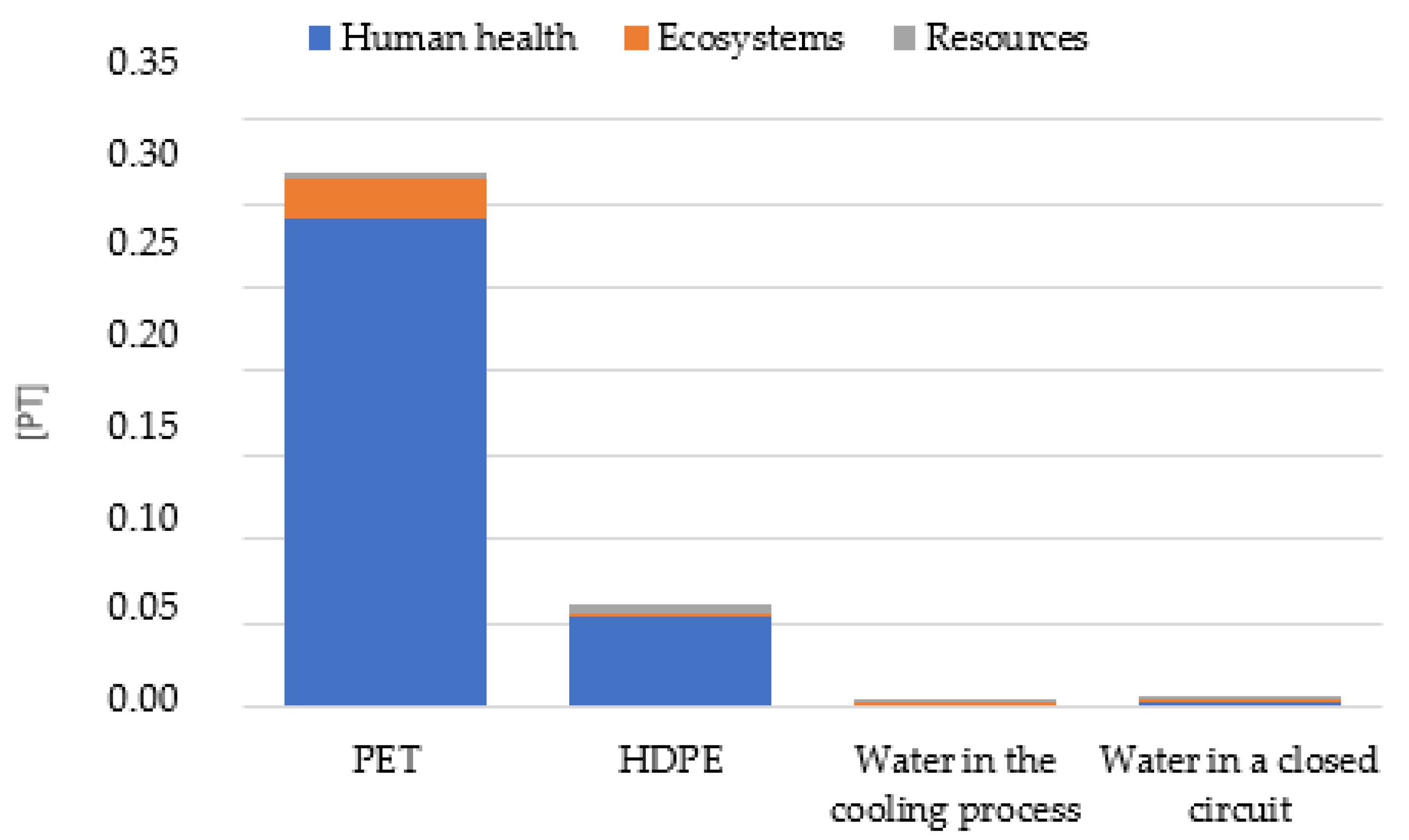

| Damage Category | Unit | PET | Pigment | Water in the Cooling Process | Water in a Closed Circuit |

|---|---|---|---|---|---|

| Human health | Pt | 2.91 × 10−1 | 5.42 × 10−2 | 1.86 × 10−3 | 7.14 × 10−3 |

| Ecosystems | Pt | 2.35 × 10−2 | 2.18 × 10−3 | 1.42 × 10−4 | 2.47 × 10−3 |

| Resources | Pt | 4.23 × 10−3 | 4.56 × 10−3 | 2.49 × 10−5 | 2.11 × 10−3 |

| Total | Pt | 3.19 × 10−1 | 6.10 × 10−2 | 2.02 × 10−3 | 2.56 × 10−3 |

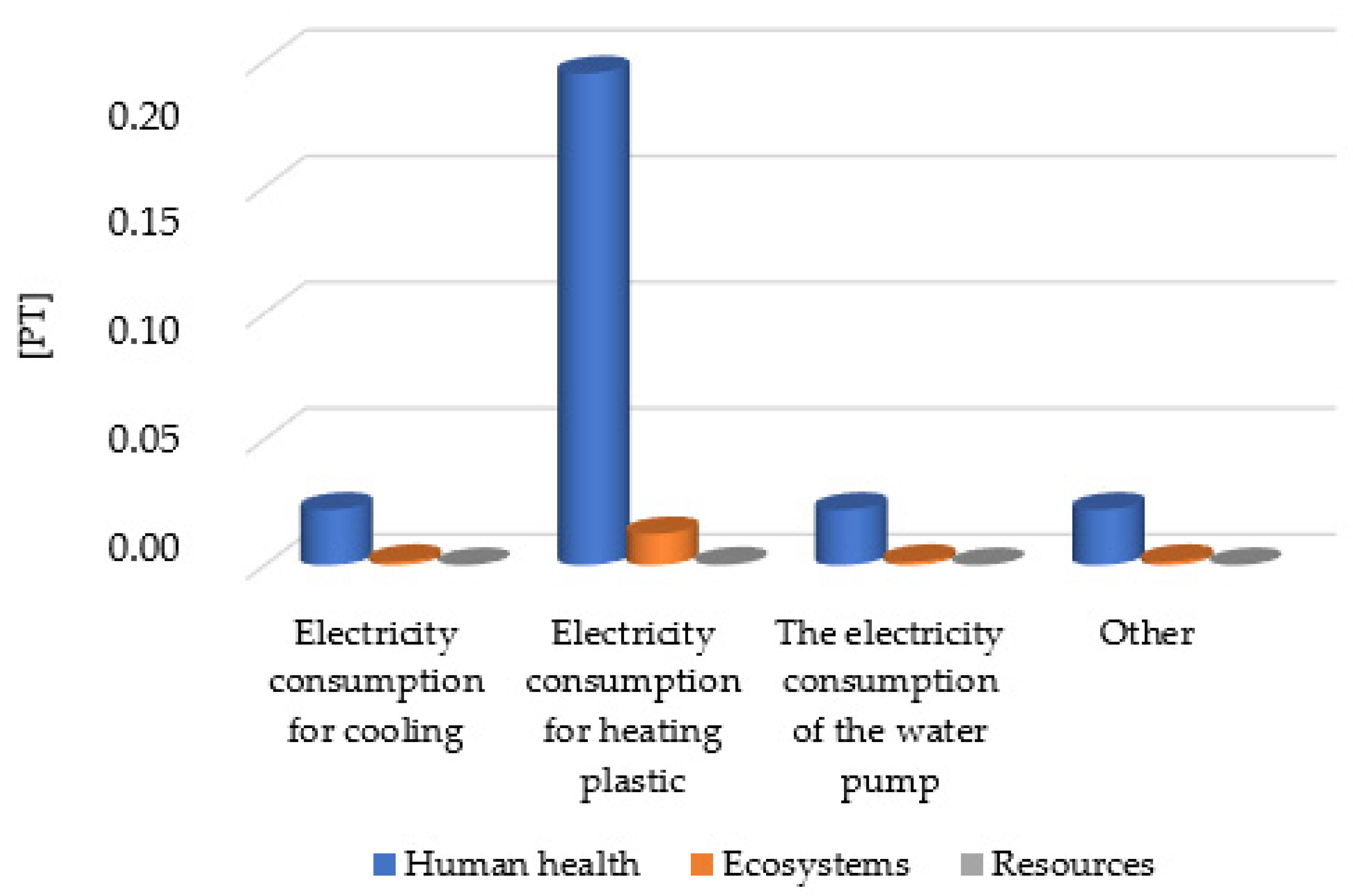

| Damage Category | Unit | Electricity Consumption for Cooling | Electricity Consumption for Heating Plastic | The Electricity Consumption of the Water Pump | Other |

|---|---|---|---|---|---|

| Human health | Pt | 2.20 × 10−2 | 1.95 × 10−1 | 2.20 × 10−2 | 2.20 × 10−2 |

| Ecosystems | Pt | 1.40 × 10−3 | 1.24 × 10−2 | 1.40 × 10−3 | 1.40 × 10−3 |

| Resources | Pt | 4.13 × 10−5 | 3.66 × 10−4 | 4.13 × 10−5 | 4.13 × 10−5 |

| Total | Pt | 2.34 × 10−2 | 2.08 × 10−1 | 2.34 × 10−2 | 2.34 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bałdowska-Witos, P.; Tomporowski, A.; Bieliński, M. Using the LCA Method to Develop the Production of Pigment for Processing Plastics. Materials 2023, 16, 5524. https://doi.org/10.3390/ma16165524

Bałdowska-Witos P, Tomporowski A, Bieliński M. Using the LCA Method to Develop the Production of Pigment for Processing Plastics. Materials. 2023; 16(16):5524. https://doi.org/10.3390/ma16165524

Chicago/Turabian StyleBałdowska-Witos, Patrycja, Andrzej Tomporowski, and Marek Bieliński. 2023. "Using the LCA Method to Develop the Production of Pigment for Processing Plastics" Materials 16, no. 16: 5524. https://doi.org/10.3390/ma16165524

APA StyleBałdowska-Witos, P., Tomporowski, A., & Bieliński, M. (2023). Using the LCA Method to Develop the Production of Pigment for Processing Plastics. Materials, 16(16), 5524. https://doi.org/10.3390/ma16165524